battery NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2530 of 3171

PG-1

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONPG

A

B

PG

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Wiring Diagrams and Trouble Diagnosis .................. 3

POWER SUPPLY ROUTING CIRCUIT ...................... 4

Schematic ................................................................ 4

Wiring Diagram — POWER — ................................. 5

BATTERY POWER SUPPLY — IGNITION SW.

IN ANY POSITION ................................................ 5

ACCESSORY POWER SUPPLY — IGNITION

SW. IN ACC OR ON ............................................ 10

IGNITION POWER SUPPLY — IGNITION SW.

IN ON ................................................................... 11

IGNITION POWER SUPPLY — IGNITION SW.

IN ON AND/OR START ....................................... 12

IPDM E/R (INTELLIGENT POWER DISTRIBUTION

MODULE ENGINE ROOM) ...................................... 14

System Description ................................................ 14

SYSTEMS CONTROLLED BY IPDM E/R ........... 14

CAN COMMUNICATION LINE CONTROL ......... 14

IPDM E/R STATUS CONTROL ........................... 15

CAN Communication System Description .............. 15

Function of Detecting Ignition Relay Malfunction ... 15

CONSULT-II Function (IPDM E/R) ......................... 16

CONSULT-II BASIC OPERATION ...................... 16

SELF-DIAGNOSTIC RESULTS .......................... 17

DATA MONITOR ................................................. 17

CAN DIAG SUPPORT MNTR ............................. 18

ACTIVE TEST ..................................................... 18

Auto Active Test ..................................................... 19

DESCRIPTION .................................................... 19

OPERATION PROCEDURE ............................... 19

INSPECTION IN AUTO ACTIVE TEST MODE... 20

Schematic .............................................................. 22

IPDM E/R Terminal Arrangement ........................... 23

Check IPDM E/R Power Supply and Ground Circuit... 24Inspection with CONSULT-II (Self-Diagnosis) ........ 25

Removal and Installation of IPDM E/R ................... 26

REMOVAL ........................................................... 26

INSTALLATION ................................................... 26

GROUND CIRCUIT ................................................... 27

Ground Distribution ................................................. 27

MAIN HARNESS ................................................. 27

ENGINE ROOM HARNESS ................................ 30

ENGINE CONTROL HARNESS .......................... 34

BODY HARNESS (LH SIDE) .............................. 35

BODY HARNESS (RH SIDE) .............................. 36

DEFOGGER CABLE ........................................... 37

HARNESS ................................................................. 38

Harness Layout ...................................................... 38

HOW TO READ HARNESS LAYOUT ................. 38

OUTLINE/DOUBLE CAB MODELS .................... 39

OUTLINE/KING CAB MODELS .......................... 40

MAIN HARNESS/LHD MODELS ......................... 41

MAIN HARNESS/RHD MODELS ........................ 44

ENGINE ROOM HARNESS/LHD MODELS ........ 47

ENGINE ROOM HARNESS/RHD MODELS ....... 49

ENGINE CONTROL HARNESS .......................... 51

CHASSIS HARNESS .......................................... 53

BODY HARNESS (LH SIDE)/DOUBLE CAB

MODELS ............................................................. 54

BODY HARNESS (RH SIDE)/DOUBLE CAB

MODELS ............................................................. 56

BODY HARNESS (LH SIDE)/KING CAB MOD-

ELS ...................................................................... 58

BODY HARNESS (RH SIDE)/KING CAB MOD-

ELS ...................................................................... 60

ROOM LAMP HARNESS .................................... 62

FRONT DOOR LH HARNESS/LHD MODELS .... 63

FRONT DOOR RH HARNESS/LHD MODELS ... 63

FRONT DOOR LH HARNESS/RHD MODELS ... 64

FRONT DOOR RH HARNESS/RHD MODELS ... 64

REAR DOOR LH HARNESS/DOUBLE CAB

MODELS ............................................................. 65

REAR DOOR RH HARNESS/DOUBLE CAB

MODELS ............................................................. 65

Page 2534 of 3171

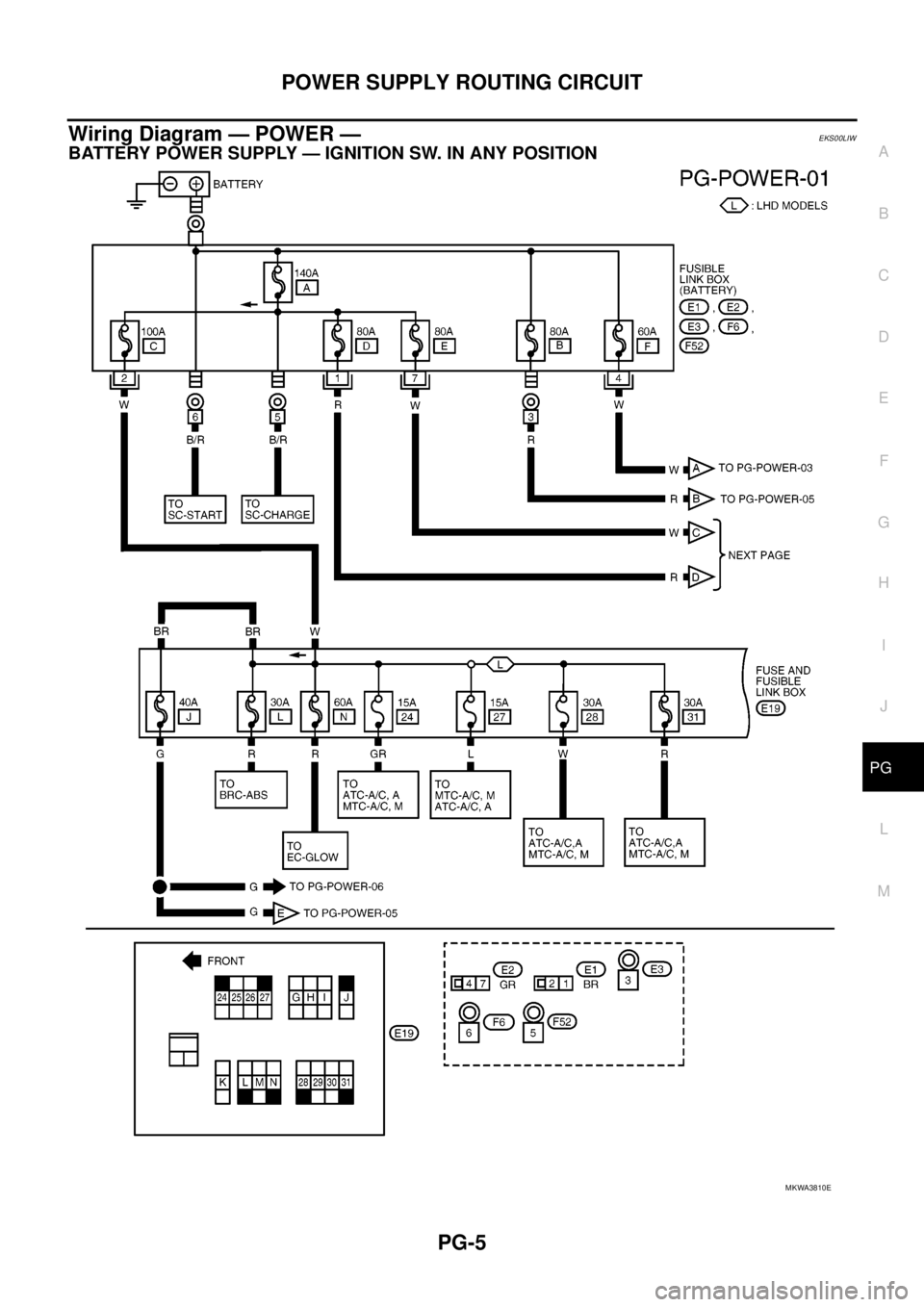

POWER SUPPLY ROUTING CIRCUIT

PG-5

C

D

E

F

G

H

I

J

L

MA

B

PG

Wiring Diagram — POWER —EKS00LIW

BATTERY POWER SUPPLY — IGNITION SW. IN ANY POSITION

MKWA3810E

Page 2553 of 3171

PG-24

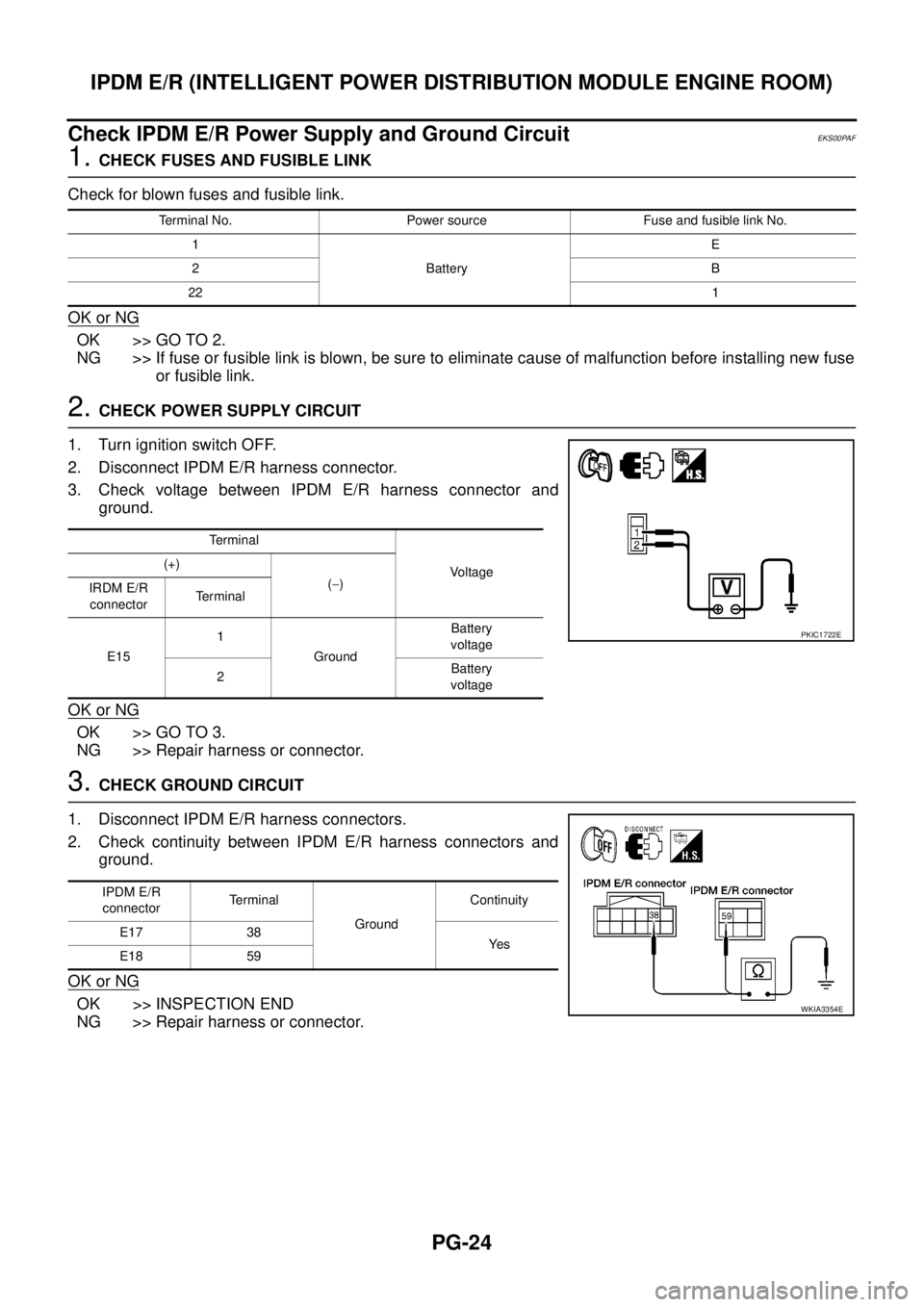

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Check IPDM E/R Power Supply and Ground Circuit

EKS00PAF

1.CHECK FUSES AND FUSIBLE LINK

Check for blown fuses and fusible link.

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector.

3. Check voltage between IPDM E/R harness connector and

ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

1. Disconnect IPDM E/R harness connectors.

2. Check continuity between IPDM E/R harness connectors and

ground.

OK or NG

OK >> INSPECTION END

NG >> Repair harness or connector.

Terminal No. Power source Fuse and fusible link No.

1

BatteryE

2B

221

Te r m i n a l

Vo l ta g e (+)

(-)

IRDM E/R

connectorTerminal

E151

GroundBattery

voltage

2Battery

voltage

PKIC1722E

IPDM E/R

connectorTerminal

GroundContinuity

E17 38

Ye s

E18 59

WKIA3354E

Page 2555 of 3171

PG-26

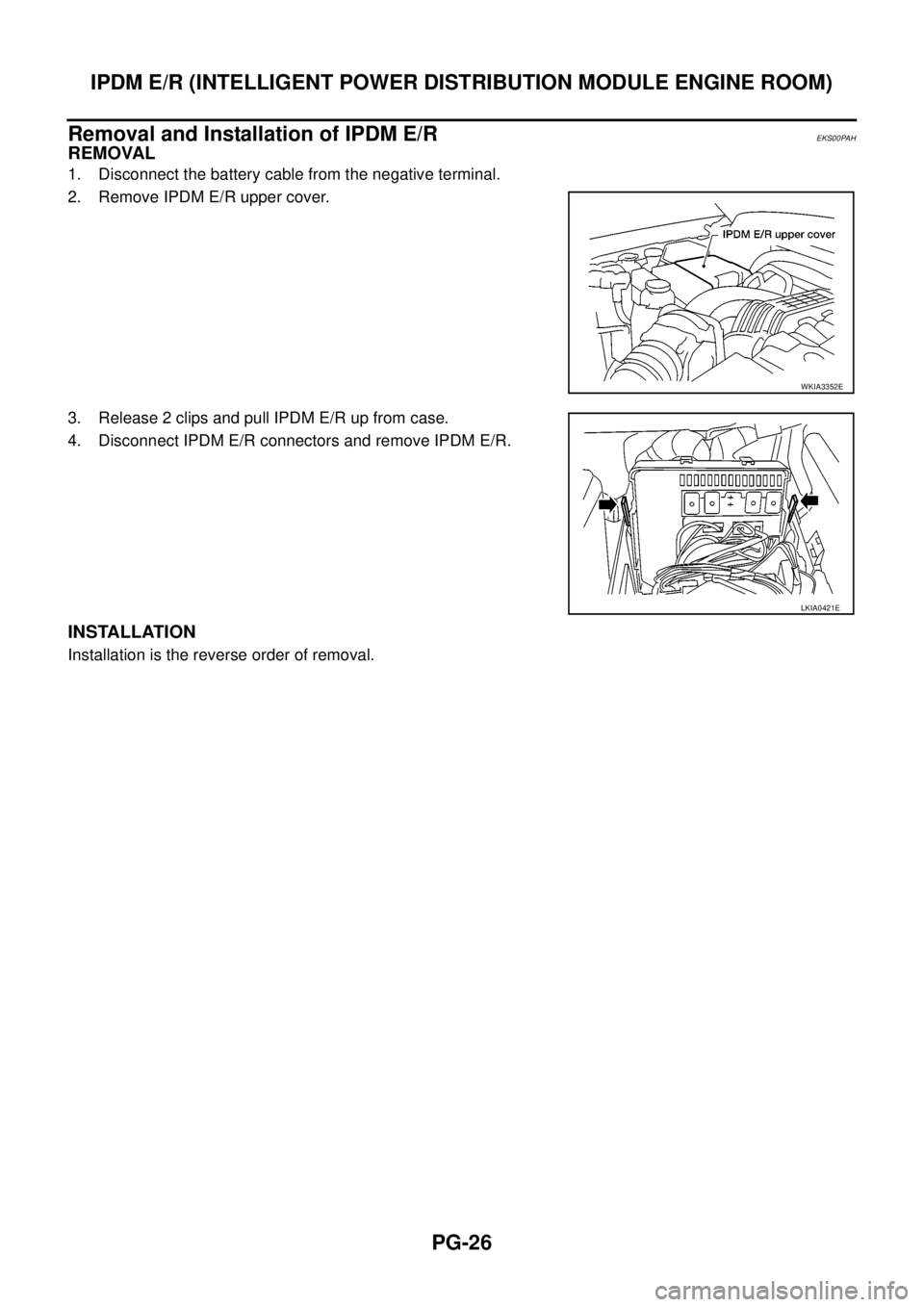

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Removal and Installation of IPDM E/R

EKS00PAH

REMOVAL

1. Disconnect the battery cable from the negative terminal.

2. Remove IPDM E/R upper cover.

3. Release 2 clips and pull IPDM E/R up from case.

4. Disconnect IPDM E/R connectors and remove IPDM E/R.

INSTALLATION

Installation is the reverse order of removal.

WKIA3352E

LKIA0421E

Page 2679 of 3171

RF-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EIS00CE9

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

PrecautionsEIS00B92

lDisconnect both battery cables in advance.

lNever tamper with or force air bag lid open, as this may adversely affect air bag performance.

lBe careful not to scratch pad and other parts.

lWhen removing or disassembling any part, be careful not to damage or deform it. Protect parts which may

get in the way with cloth.

lWhen removing parts with a screwdriver or other tool, protect parts by wrapping them with vinyl or tape.

lKeep removed parts protected with cloth.

lIf a clip is deformed or damaged, replace it.

lIf an unreusable part is removed, replace it with a new one.

lTighten bolts and nuts firmly to the specified torque.

lAfter re-assembly has been completed, make sure each part functions correctly.

lRemove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tightly. After wiping the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain

with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely.

Thenwipetheareawithasoftdrycloth.

lDo not use any organic solvent, such as thinner or benzine.

Page 2689 of 3171

RF-12

SUNROOF

MEMORY RESET PROCEDURE

1. Please observe the following instructions while confirming the sunroof operation.

NOTE:

Do not disconnect the electronic power while the sunroof is operating or within 5 seconds after the sunroof

stops. (to wipe-out the memory of lid position and operating friction.)

2. Initialization of system should be conducted after the following conditions.

lWhen the battery is out or connector is disconnected while sunroof is operating or within 5 seconds

after sunroof stops.

lWhen the sunroof motor is changed.

lWhen an emergency handle is used.

lWhen the sunroof does not operate normally. (Incomplete initialization conditions)

INITIALIZATION PROCEDURE

If sunroof does not close or open normally, use following procedure to return sunroof operation to normal.

1. Close sunroof if it is not in close position. It may be necessary to repeatedly push TILT UP/SLIDE CLOSE

switch to close sunroof.

2. Tilt up sunroof, and release TILT UP/SLIDE CLOSE switch once.

3. Keep pushing TILT UP/SLIDE CLOSE switch. After 10seconds, glass lid will back up a few millimeters.

then will be stopped at normal tilt up position.

(Keep pushing TILT UP/SLIDE CLOSE switch during this operation.)

4. Within first 10 seconds of releasing TILT UP/SLIDE CLOSE switch, keep pushing TILT UP/SLIDE CLOSE

switch again. After 4 seconds, glass lid will be automatically TILT DOWN®SLIDE OPEN®SLIDE

CLOSE.

(Keep pushing TILT UP/SLIDE CLOSE switch during this operation.)

5. After glass lid stops, release TILT UP/SLIDE CLOSE switch later 0.5 seconds.

6. Initializing procedure is completed. Confirm proper operation of sunroof (slide open, slide close, tilt up, tilt

down).

Page 2692 of 3171

SUNROOF

RF-15

C

D

E

F

G

H

J

K

L

MA

B

RF

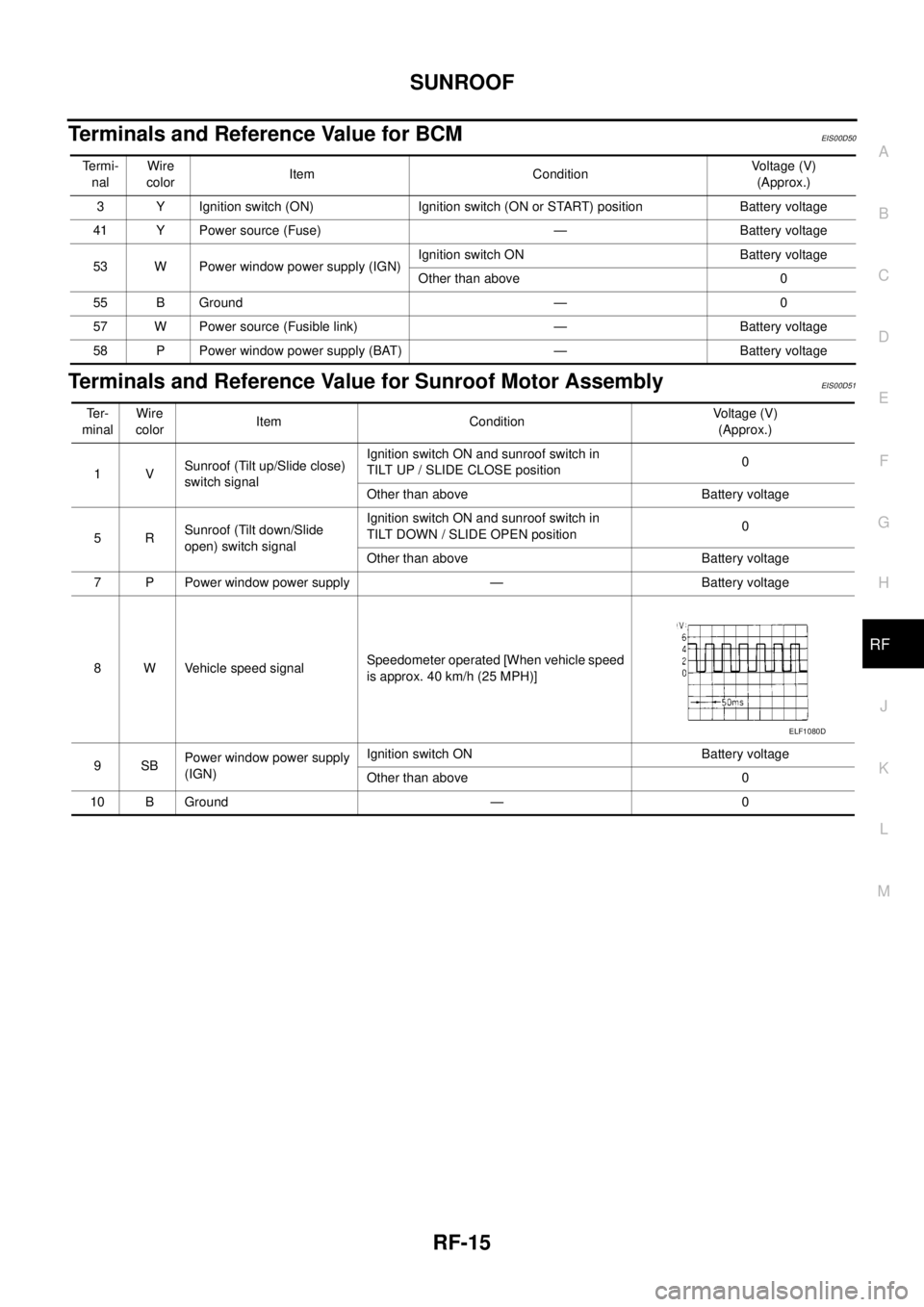

Terminals and Reference Value for BCMEIS00D50

Terminals and Reference Value for Sunroof Motor AssemblyEIS00D51

Te r m i -

nalWire

colorItem ConditionVo l ta g e (V )

(Approx.)

3 Y Ignition switch (ON) Ignition switch (ON or START) position Battery voltage

41 Y Power source (Fuse) — Battery voltage

53 W Power window power supply (IGN)Ignition switch ON Battery voltage

Other than above 0

55 B Ground — 0

57 W Power source (Fusible link) — Battery voltage

58 P Power window power supply (BAT) — Battery voltage

Te r -

minalWire

colorItem ConditionVoltage (V)

(Approx.)

1VSunroof (Tilt up/Slide close)

switch signalIgnition switch ON and sunroof switch in

TILT UP / SLIDE CLOSE position0

Other than above Battery voltage

5RSunroof (Tilt down/Slide

open) switch signalIgnition switch ON and sunroof switch in

TILT DOWN / SLIDE OPEN position0

Other than above Battery voltage

7 P Power window power supply — Battery voltage

8 W Vehicle speed signalSpeedometer operated [When vehicle speed

is approx. 40 km/h (25 MPH)]

9SBPower window power supply

(IGN)Ignition switch ON Battery voltage

Other than above 0

10 B Ground — 0

ELF1080D

Page 2693 of 3171

RF-16

SUNROOF

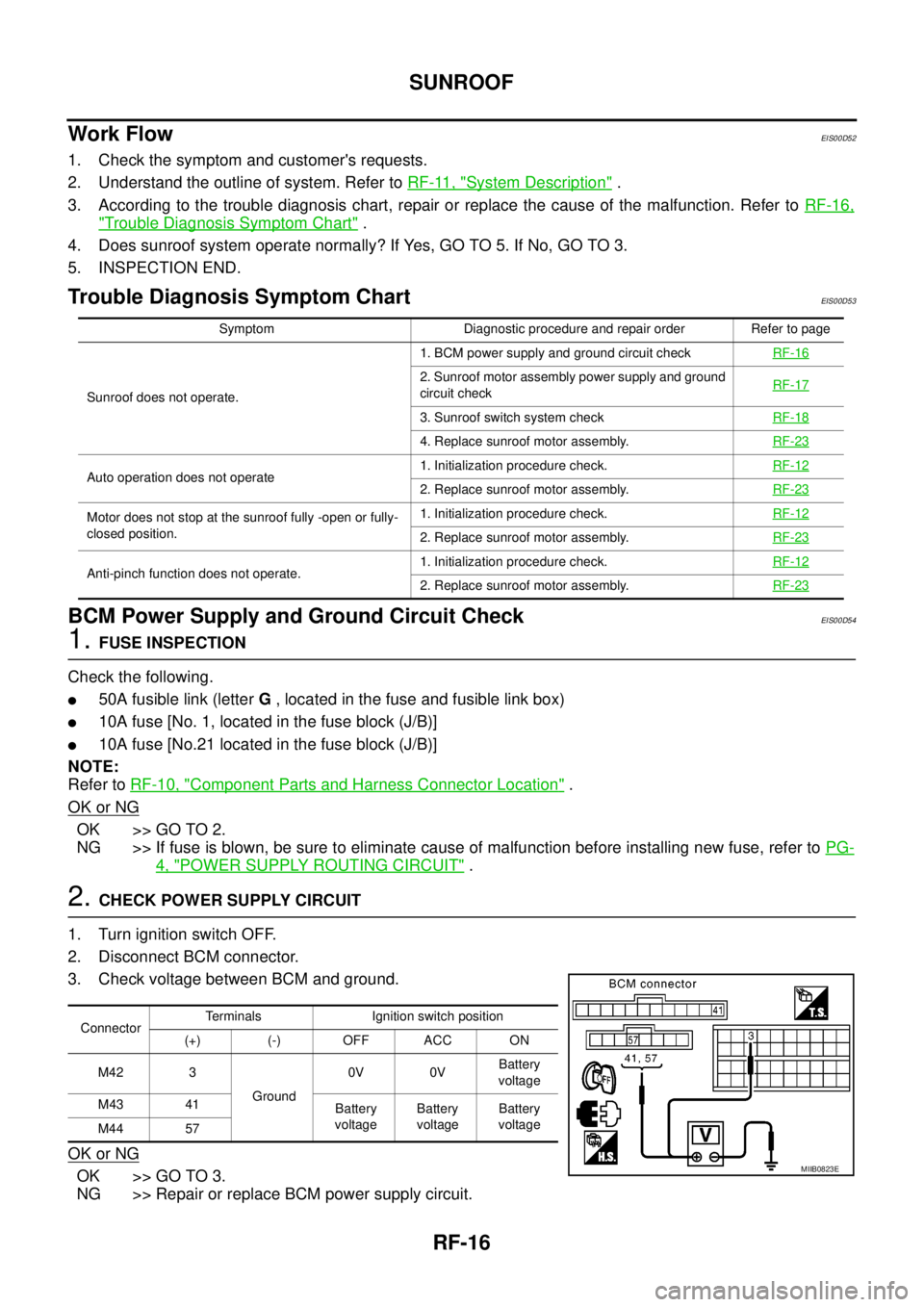

Work Flow

EIS00D52

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer toRF-11, "

System Description".

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer toRF-16,

"Trouble Diagnosis Symptom Chart".

4. Does sunroof system operate normally? If Yes, GO TO 5. If No, GO TO 3.

5. INSPECTION END.

Trouble Diagnosis Symptom ChartEIS00D53

BCM Power Supply and Ground Circuit CheckEIS00D54

1.FUSE INSPECTION

Check the following.

l50A fusible link (letterG, located in the fuse and fusible link box)

l10A fuse [No. 1, located in the fuse block (J/B)]

l10A fuse [No.21 located in the fuse block (J/B)]

NOTE:

Refer toRF-10, "

Component Parts and Harness Connector Location".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse, refer toPG-

4, "POWER SUPPLY ROUTING CIRCUIT".

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace BCM power supply circuit.

Symptom Diagnostic procedure and repair order Refer to page

Sunroof does not operate.1. BCM power supply and ground circuit checkRF-16

2. Sunroof motor assembly power supply and ground

circuit checkRF-17

3. Sunroof switch system checkRF-18

4. Replace sunroof motor assembly.RF-23

Auto operation does not operate1. Initialization procedure check.RF-122. Replace sunroof motor assembly.RF-23

Motor does not stop at the sunroof fully -open or fully-

closed position.1. Initialization procedure check.RF-12

2. Replace sunroof motor assembly.RF-23

Anti-pinch function does not operate.1. Initialization procedure check.RF-122. Replace sunroof motor assembly.RF-23

ConnectorTerminals Ignition switch position

(+) (-) OFF ACC ON

M42 3

Ground0V 0VBattery

voltage

M43 41

Battery

voltageBattery

voltageBattery

voltage

M44 57

MIIB0823E

Page 2694 of 3171

SUNROOF

RF-17

C

D

E

F

G

H

J

K

L

MA

B

RF

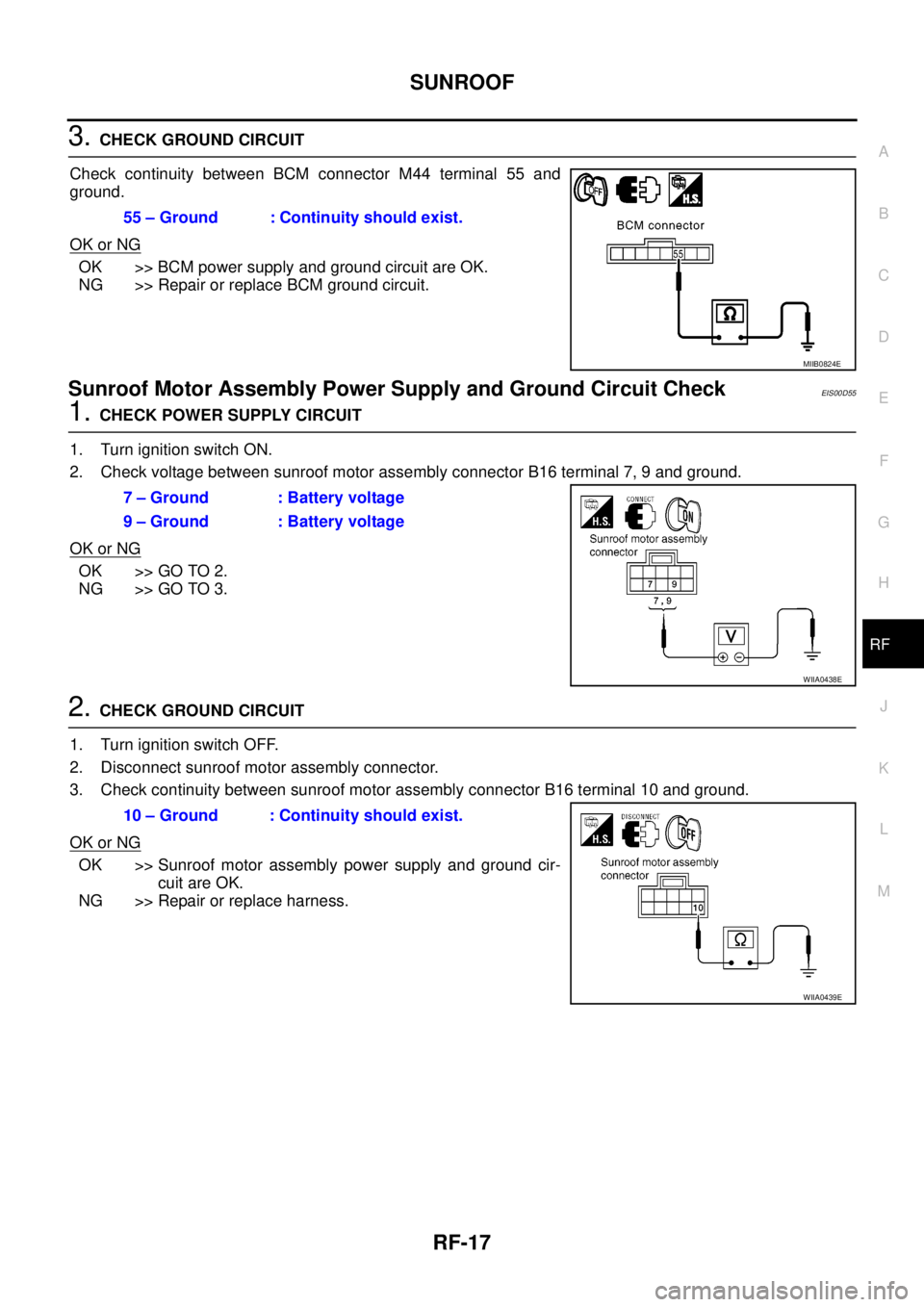

3.CHECK GROUND CIRCUIT

Check continuity between BCM connector M44 terminal 55 and

ground.

OK or NG

OK >> BCM power supply and ground circuit are OK.

NG >> Repair or replace BCM ground circuit.

Sunroof Motor Assembly Power Supply and Ground Circuit CheckEIS00D55

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between sunroof motor assembly connector B16 terminal 7, 9 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect sunroof motor assembly connector.

3. Check continuity between sunroof motor assembly connector B16 terminal 10 and ground.

OK or NG

OK >> Sunroof motor assembly power supply and ground cir-

cuit are OK.

NG >> Repair or replace harness.55 – Ground : Continuity should exist.

MIIB0824E

7 – Ground : Battery voltage

9 – Ground : Battery voltage

WIIA0438E

10 – Ground : Continuity should exist.

WIIA0439E

Page 2695 of 3171

RF-18

SUNROOF

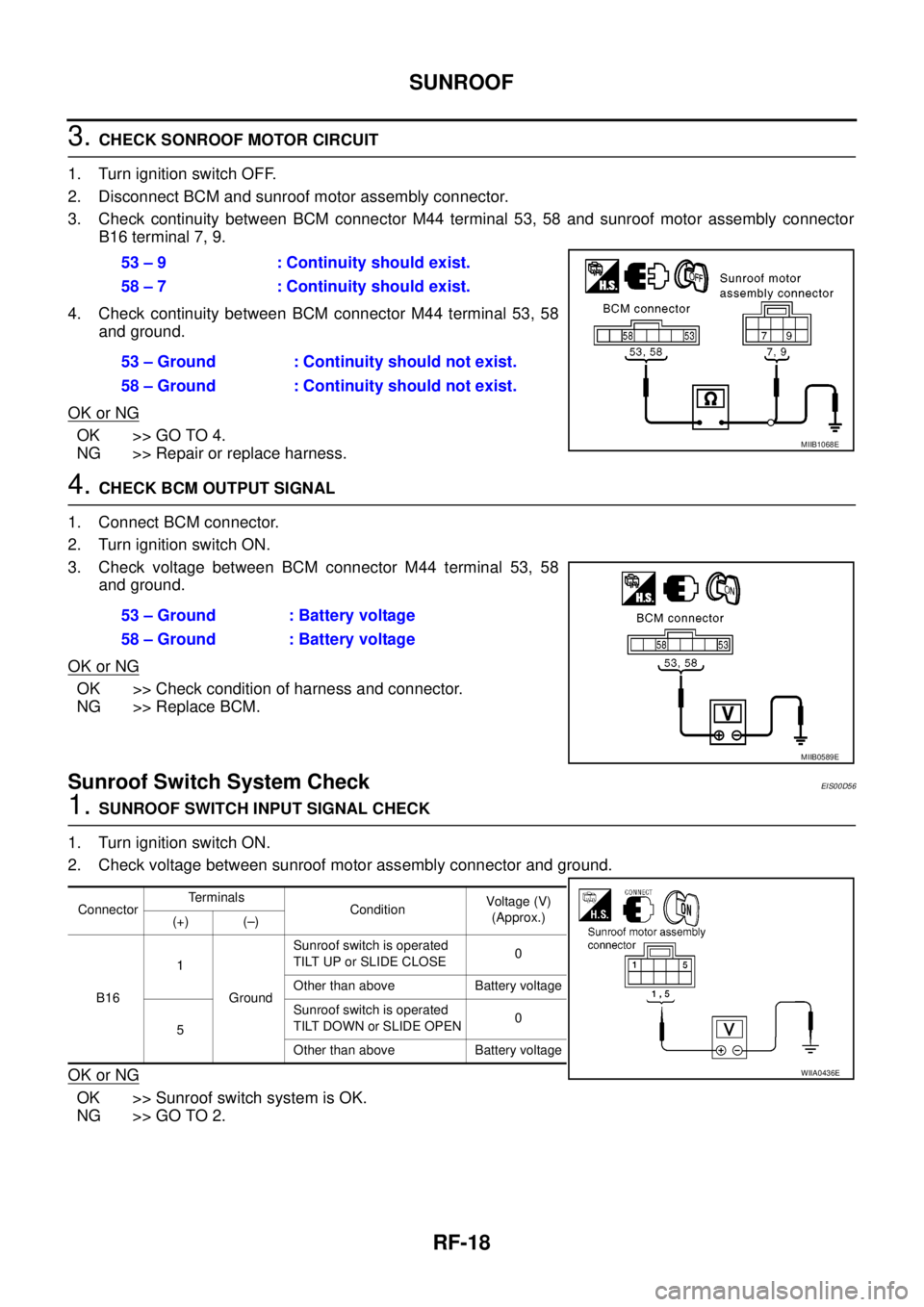

3.CHECK SONROOF MOTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM and sunroof motor assembly connector.

3. Check continuity between BCM connector M44 terminal 53, 58 and sunroof motor assembly connector

B16 terminal 7, 9.

4. Check continuity between BCM connector M44 terminal 53, 58

and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

2. Turn ignition switch ON.

3. Check voltage between BCM connector M44 terminal 53, 58

and ground.

OK or NG

OK >> Check condition of harness and connector.

NG >> Replace BCM.

Sunroof Switch System CheckEIS00D56

1.SUNROOF SWITCH INPUT SIGNAL CHECK

1. Turn ignition switch ON.

2. Check voltage between sunroof motor assembly connector and ground.

OK or NG

OK >> Sunroof switch system is OK.

NG >> GO TO 2.53 – 9 : Continuity should exist.

58 – 7 : Continuity should exist.

53 – Ground : Continuity should not exist.

58 – Ground : Continuity should not exist.

MIIB1068E

53 – Ground : Battery voltage

58 – Ground : Battery voltage

MIIB0589E

ConnectorTerminals

ConditionVoltag e (V)

(Approx.)

(+) (–)

B161

GroundSunroof switch is operated

TILT UP or SLIDE CLOSE0

Other than above Battery voltage

5Sunroof switch is operated

TILT DOWN or SLIDE OPEN0

Other than above Battery voltage

WIIA0436E