battery NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2081 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual LAN-304

[CAN]

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between data link connector M45 terminals 6, 14

and ground.

OK or NG

OK >> GO TO 4.

NG >>

lRepair harness. NISSAN NAVARA 2005 Repair Workshop Manual LAN-304

[CAN]

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between data link connector M45 terminals 6, 14

and ground.

OK or NG

OK >> GO TO 4.

NG >>

lRepair harness.](/img/5/57362/w960_57362-2080.png)

LAN-304

[CAN]

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between data link connector M45 terminals 6, 14

and ground.

OK or NG

OK >> GO TO 4.

NG >>

lRepair harness.

lChange harness if shielded lines are used for the har-

ness.

4.ECM AND IPDM E/R INTERNAL CIRCUIT INSPECTION

1. Remove ECM and IPDM E/R from vehicle.

2. Check resistance between ECM terminals.

3. Check resistance between IPDM E/R terminals.

OK or NG

OK >> GO TO 5.

NG >> Replace ECM and/or IPDM E/R.

5.CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Connect all connectors, and then make sure that the symptom is reproduced.

OK or NG

OK >> GO TO 6.

NG >> Refer toLAN-13, "

Example of Filling in Check Sheet When Initial Conditions Are Not Reproduced"

.

6.UNIT REPRODUCIBILITY INSPECTION

Perform the following procedure for each unit on the CAN network, and then perform reproducibility test.

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect the unit connector.

4. Connect the battery cable to the negative terminal.

5. Make sure that the symptom filled in the “Symptom” of the check sheet is reproduced. (Do not confuse it

with the symptom related to removed unit.)

6. Make sure that the same symptom is reproduced.

Inspection results

Reproduced>>Install removed unit, and then check the other unit.

Not reproduced>>Replace removed unit.

IPDM E/R Ignition Relay Circuit InspectionEKS00O5C

Check the following. If no malfunction is found, replace the IPDM E/R.

lIPDM E/R power supply circuit. Refer toPG-24, "Check IPDM E/R Power Supply and Ground Circuit". 6 – Ground : Continuity should not exist.

14 – Ground : Continuity should not exist.

PKIA9872E

Terminal Resistance (Approx.)

95 87 108 – 132W

Terminal Resistance (Approx.)

39 40 108 – 132W

LKIA0037E

Page 2086 of 3171

LT-3

C

D

E

F

G

H

I

J

L

MA

B

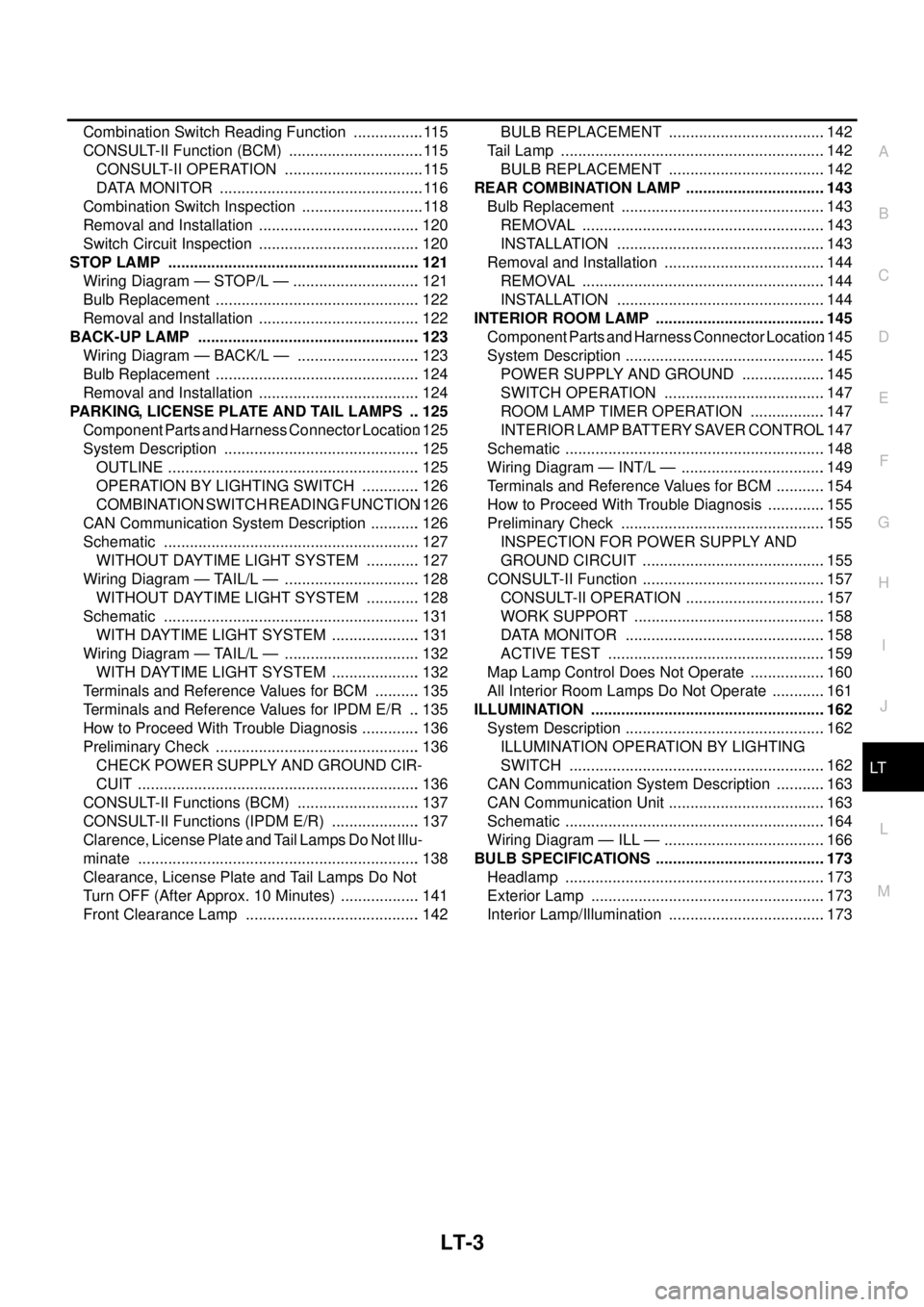

LT Combination Switch Reading Function ................. 115

CONSULT-II Function (BCM) ................................ 115

CONSULT-II OPERATION ................................. 115

DATA MONITOR ................................................ 116

Combination Switch Inspection ............................. 118

Removal and Installation ...................................... 120

Switch Circuit Inspection ...................................... 120

STOP LAMP ........................................................... 121

Wiring Diagram — STOP/L — .............................. 121

Bulb Replacement ................................................ 122

Removal and Installation ...................................... 122

BACK-UP LAMP .................................................... 123

Wiring Diagram — BACK/L — ............................. 123

Bulb Replacement ................................................ 124

Removal and Installation ...................................... 124

PARKING, LICENSE PLATE AND TAIL LAMPS ... 125

Component Parts and Harness Connector Location. 125

System Description .............................................. 125

OUTLINE ........................................................... 125

OPERATION BY LIGHTING SWITCH .............. 126

COMBINATION SWITCH READING FUNCTION. 126

CAN Communication System Description ............ 126

Schematic ............................................................ 127

WITHOUT DAYTIME LIGHT SYSTEM ............. 127

Wiring Diagram — TAIL/L — ................................ 128

WITHOUT DAYTIME LIGHT SYSTEM ............. 128

Schematic ............................................................ 131

WITH DAYTIME LIGHT SYSTEM ..................... 131

Wiring Diagram — TAIL/L — ................................ 132

WITH DAYTIME LIGHT SYSTEM ..................... 132

Terminals and Reference Values for BCM ........... 135

Terminals and Reference Values for IPDM E/R ... 135

How to Proceed With Trouble Diagnosis .............. 136

Preliminary Check ................................................ 136

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................. 136

CONSULT-II Functions (BCM) ............................. 137

CONSULT-II Functions (IPDM E/R) ..................... 137

Clarence, License Plate and Tail Lamps Do Not Illu-

minate .................................................................. 138

Clearance, License Plate and Tail Lamps Do Not

Turn OFF (After Approx. 10 Minutes) ................... 141

Front Clearance Lamp ......................................... 142BULB REPLACEMENT .....................................142

Tail Lamp ..............................................................142

BULB REPLACEMENT .....................................142

REAR COMBINATION LAMP .................................143

Bulb Replacement ................................................143

REMOVAL .........................................................143

INSTALLATION .................................................143

Removal and Installation ......................................144

REMOVAL .........................................................144

INSTALLATION .................................................144

INTERIOR ROOM LAMP ........................................145

Component Parts and Harness Connector Location.145

System Description ...............................................145

POWER SUPPLY AND GROUND ....................145

SWITCH OPERATION ......................................147

ROOM LAMP TIMER OPERATION ..................147

INTERIOR LAMP BATTERY SAVER CONTROL.147

Schematic .............................................................148

Wiring Diagram — INT/L — ..................................149

Terminals and Reference Values for BCM ............154

How to Proceed With Trouble Diagnosis ..............155

Preliminary Check ................................................155

INSPECTION FOR POWER SUPPLY AND

GROUND CIRCUIT ...........................................155

CONSULT-II Function ...........................................157

CONSULT-II OPERATION .................................157

WORK SUPPORT .............................................158

DATA MONITOR ...............................................158

ACTIVE TEST ...................................................159

Map Lamp Control Does Not Operate ..................160

All Interior Room Lamps Do Not Operate .............161

ILLUMINATION .......................................................162

System Description ...............................................162

ILLUMINATION OPERATION BY LIGHTING

SWITCH ............................................................162

CAN Communication System Description ............163

CAN Communication Unit .....................................163

Schematic .............................................................164

Wiring Diagram — ILL — ......................................166

BULB SPECIFICATIONS ........................................173

Headlamp .............................................................173

Exterior Lamp .......................................................173

Interior Lamp/Illumination .....................................173

Page 2088 of 3171

HEADLAMP -CONVENTIONAL TYPE-

LT-5

C

D

E

F

G

H

I

J

L

MA

B

LT

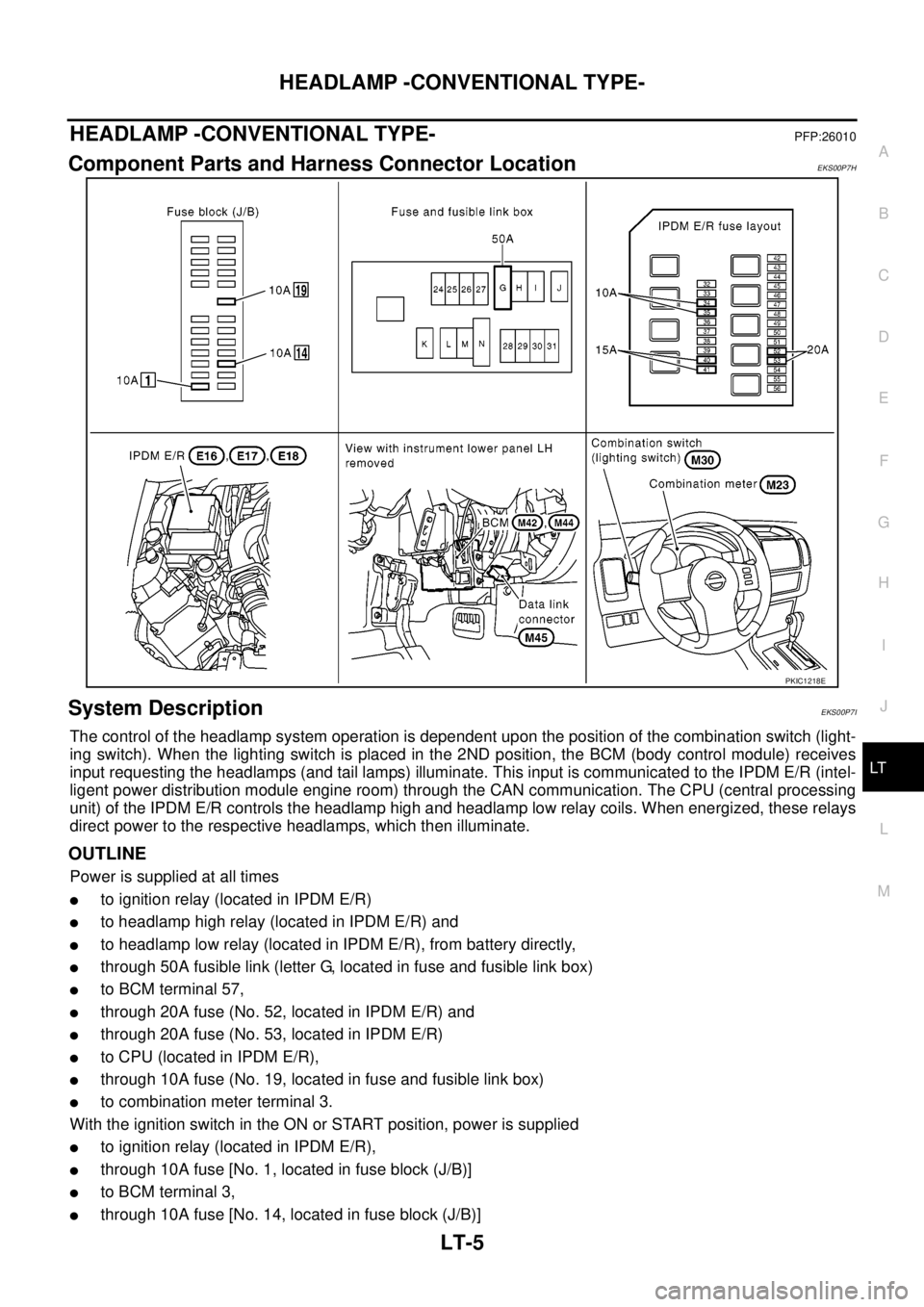

HEADLAMP -CONVENTIONAL TYPE-PFP:26010

Component Parts and Harness Connector LocationEKS00P7H

System DescriptionEKS00P7I

The control of the headlamp system operation is dependent upon the position of the combination switch (light-

ing switch). When the lighting switch is placed in the 2ND position, the BCM (body control module) receives

input requesting the headlamps (and tail lamps) illuminate. This input is communicated to the IPDM E/R (intel-

ligent power distribution module engine room) through the CAN communication. The CPU (central processing

unit) of the IPDM E/R controls the headlamp high and headlamp low relay coils. When energized, these relays

direct power to the respective headlamps, which then illuminate.

OUTLINE

Power is supplied at all times

lto ignition relay (located in IPDM E/R)

lto headlamp high relay (located in IPDM E/R) and

lto headlamp low relay (located in IPDM E/R), from battery directly,

lthrough 50A fusible link (letter G, located in fuse and fusible link box)

lto BCM terminal 57,

lthrough 20A fuse (No. 52, located in IPDM E/R) and

lthrough 20A fuse (No. 53, located in IPDM E/R)

lto CPU (located in IPDM E/R),

lthrough 10A fuse (No. 19, located in fuse and fusible link box)

lto combination meter terminal 3.

With the ignition switch in the ON or START position, power is supplied

lto ignition relay (located in IPDM E/R),

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3,

lthrough 10A fuse [No. 14, located in fuse block (J/B)]

PKIC1218E

Page 2095 of 3171

LT-12

HEADLAMP -CONVENTIONAL TYPE-

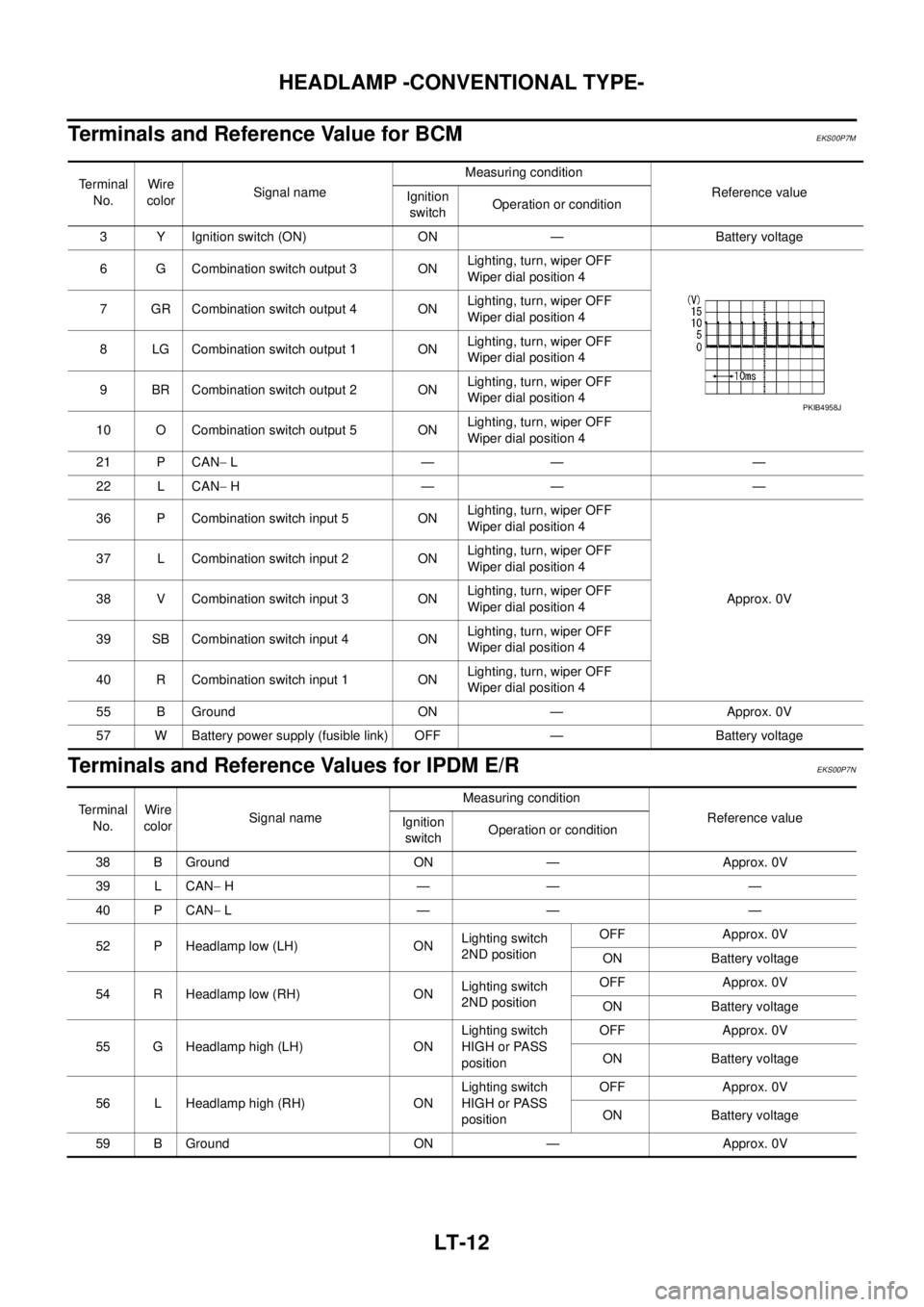

Terminals and Reference Value for BCM

EKS00P7M

Terminals and Reference Values for IPDM E/REKS00P7N

Terminal

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

3 Y Ignition switch (ON) ON — Battery voltage

6 G Combination switch output 3 ONLighting, turn, wiper OFF

Wiper dial position 4

7 GR Combination switch output 4 ONLighting, turn, wiper OFF

Wiper dial position 4

8 LG Combination switch output 1 ONLighting, turn, wiper OFF

Wiper dial position 4

9 BR Combination switch output 2 ONLighting, turn, wiper OFF

Wiper dial position 4

10 O Combination switch output 5 ONLighting, turn, wiper OFF

Wiper dial position 4

21 P CAN-L—— —

22 L CAN-H—— —

36 P Combination switch input 5 ONLighting, turn, wiper OFF

Wiper dial position 4

Approx. 0V 37 L Combination switch input 2 ONLighting, turn, wiper OFF

Wiper dial position 4

38 V Combination switch input 3 ONLighting, turn, wiper OFF

Wiper dial position 4

39 SB Combination switch input 4 ONLighting, turn, wiper OFF

Wiper dial position 4

40 R Combination switch input 1 ONLighting, turn, wiper OFF

Wiper dial position 4

55 B Ground ON — Approx. 0V

57 W Battery power supply (fusible link) OFF — Battery voltage

PKIB4958J

Te r m i n a l

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

38 B Ground ON — Approx. 0V

39 L CAN-H—— —

40 P CAN-L—— —

52 P Headlamp low (LH) ONLighting switch

2ND positionOFF Approx. 0V

ON Battery voltage

54 R Headlamp low (RH) ONLighting switch

2ND positionOFF Approx. 0V

ON Battery voltage

55 G Headlamp high (LH) ONLighting switch

HIGH or PASS

positionOFF Approx. 0V

ON Battery voltage

56 L Headlamp high (RH) ONLighting switch

HIGH or PASS

positionOFF Approx. 0V

ON Battery voltage

59 B Ground ON — Approx. 0V

Page 2096 of 3171

HEADLAMP -CONVENTIONAL TYPE-

LT-13

C

D

E

F

G

H

I

J

L

MA

B

LT

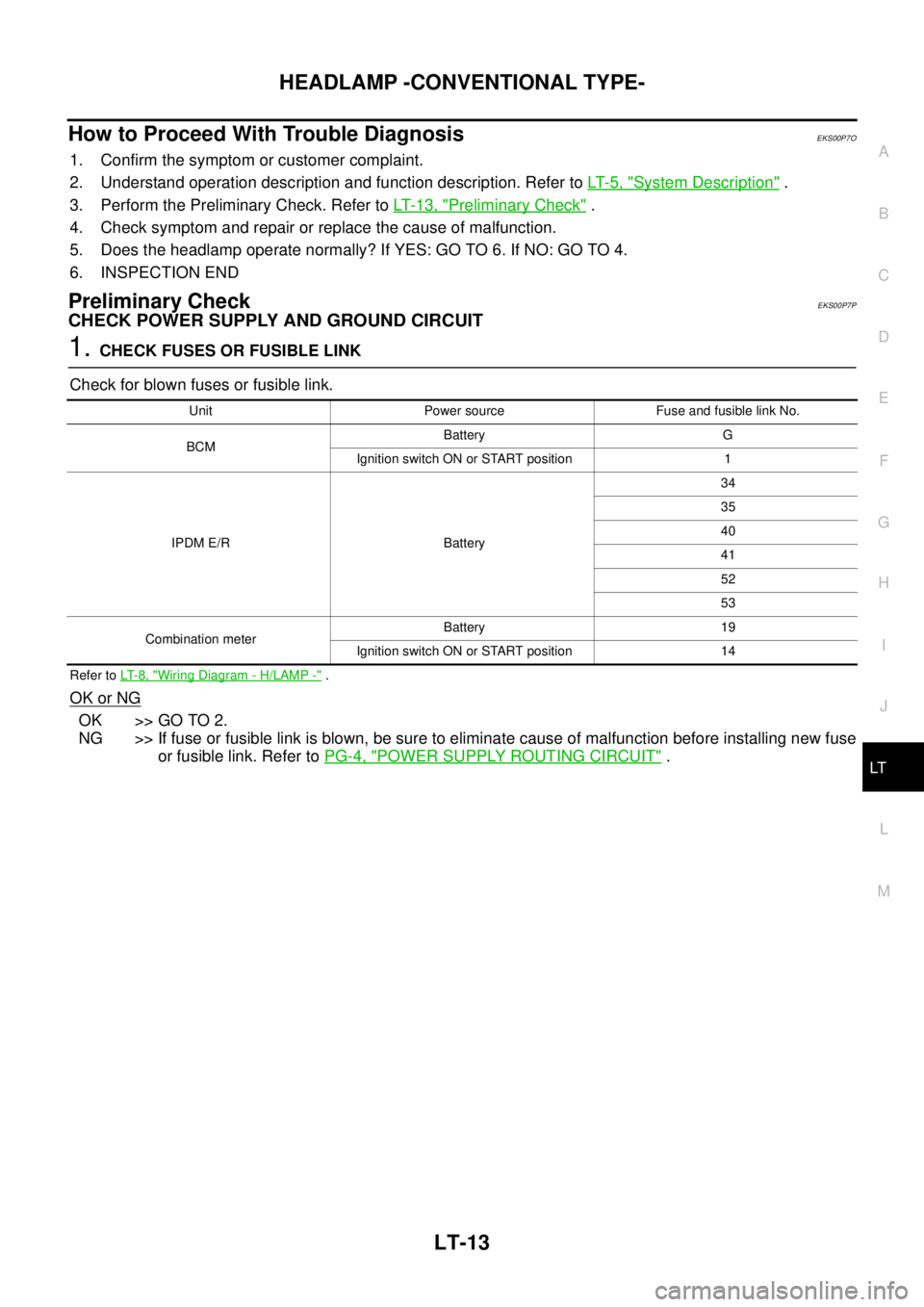

How to Proceed With Trouble DiagnosisEKS00P7O

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer toLT- 5 , "

System Description".

3. Perform the Preliminary Check. Refer toLT-13, "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction.

5. Does the headlamp operate normally? If YES: GO TO 6. If NO: GO TO 4.

6. INSPECTION END

Preliminary CheckEKS00P7P

CHECK POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSES OR FUSIBLE LINK

Check for blown fuses or fusible link.

Refer toLT- 8 , "Wiring Diagram - H/LAMP -".

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link. Refer toPG-4, "

POWER SUPPLY ROUTING CIRCUIT".

Unit Power source Fuse and fusible link No.

BCMBattery G

Ignition switch ON or START position 1

IPDM E/R Battery34

35

40

41

52

53

Combination meterBattery 19

Ignition switch ON or START position 14

Page 2097 of 3171

LT-14

HEADLAMP -CONVENTIONAL TYPE-

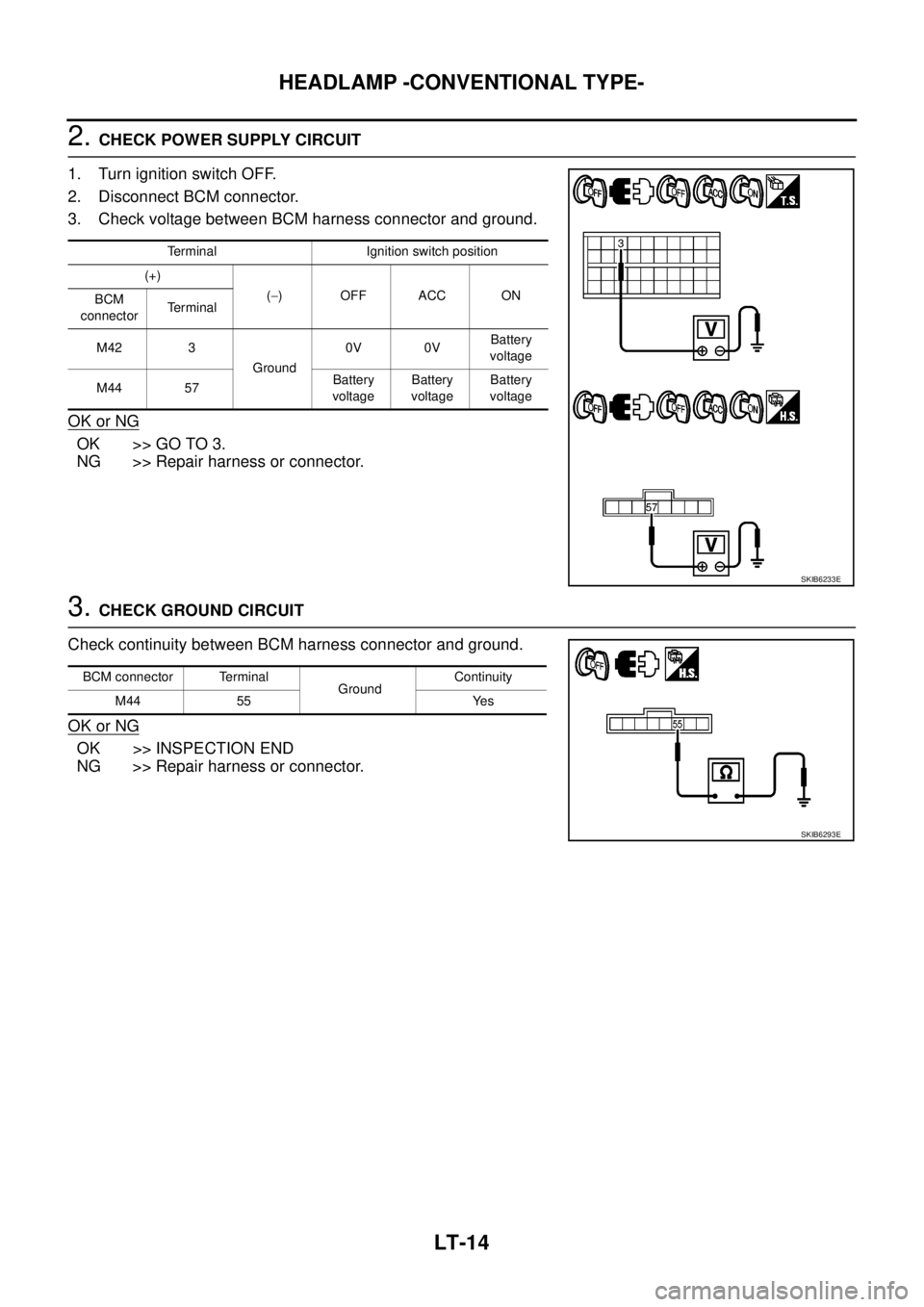

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM harness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

OK or NG

OK >> INSPECTION END

NG >> Repair harness or connector.

Terminal Ignition switch position

(+)

(-)OFFACCON

BCM

connectorTerminal

M42 3

Ground0V 0VBattery

voltage

M44 57Battery

voltageBattery

voltageBattery

voltage

SKIB6233E

BCM connector Terminal

GroundContinuity

M44 55 Yes

SKIB6293E

Page 2104 of 3171

HEADLAMP -CONVENTIONAL TYPE-

LT-21

C

D

E

F

G

H

I

J

L

MA

B

LT

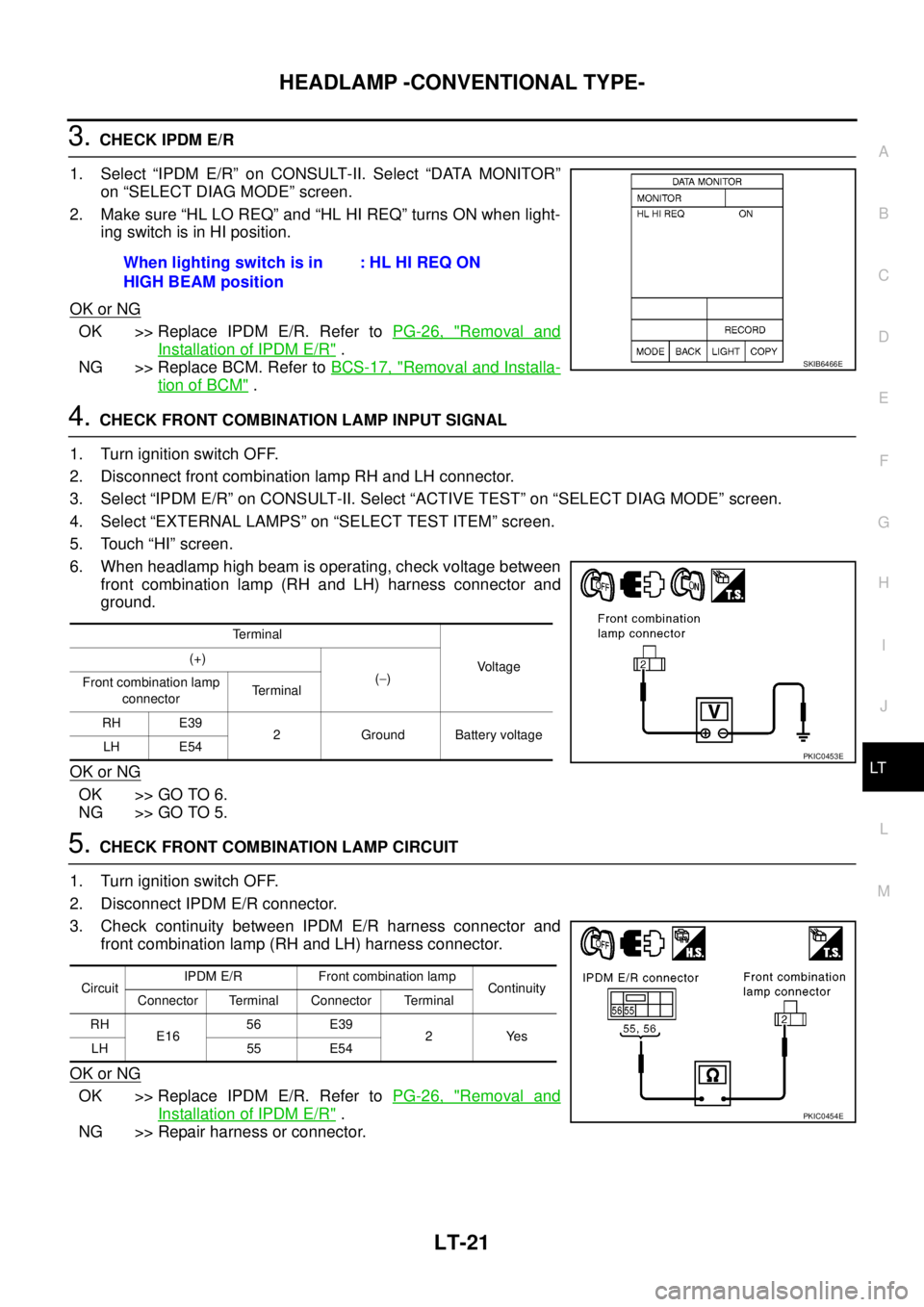

3.CHECK IPDM E/R

1. Select “IPDM E/R” on CONSULT-II. Select “DATA MONITOR”

on “SELECT DIAG MODE” screen.

2. Make sure “HL LO REQ” and “HL HI REQ” turns ON when light-

ingswitchisinHIposition.

OK or NG

OK >> Replace IPDM E/R. Refer toPG-26, "Removal and

Installation of IPDM E/R".

NG >> Replace BCM. Refer toBCS-17, "

Removal and Installa-

tion of BCM".

4.CHECK FRONT COMBINATION LAMP INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH and LH connector.

3. Select “IPDM E/R” on CONSULT-II. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

4. Select “EXTERNAL LAMPS” on “SELECT TEST ITEM” screen.

5. Touch “HI” screen.

6. When headlamp high beam is operating, check voltage between

front combination lamp (RH and LH) harness connector and

ground.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.CHECK FRONT COMBINATION LAMP CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and

front combination lamp (RH and LH) harness connector.

OK or NG

OK >> Replace IPDM E/R. Refer toPG-26, "Removal and

Installation of IPDM E/R".

NG >> Repair harness or connector.When lighting switch is in

HIGH BEAM position:HLHIREQON

SKIB6466E

Terminal

Voltage (+)

(-)

Front combination lamp

connectorTerminal

RH E39

2 Ground Battery voltage

LH E54

PKIC0453E

CircuitIPDM E/R Front combination lamp

Continuity

Connector Terminal Connector Terminal

RH

E1656 E39

2Yes

LH 55 E54

PKIC0454E

Page 2105 of 3171

LT-22

HEADLAMP -CONVENTIONAL TYPE-

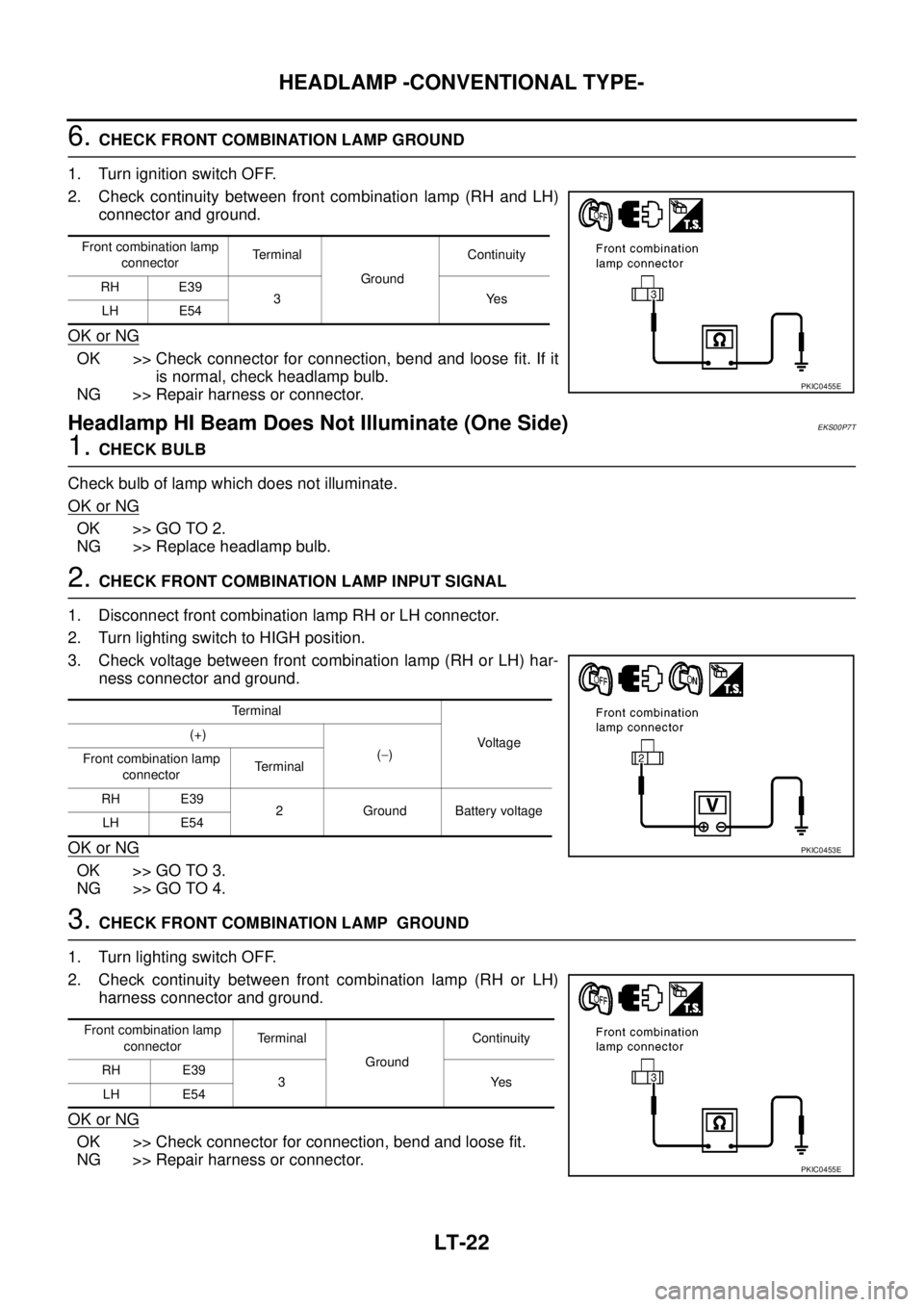

6.CHECK FRONT COMBINATION LAMP GROUND

1. Turn ignition switch OFF.

2. Check continuity between front combination lamp (RH and LH)

connector and ground.

OK or NG

OK >> Check connector for connection, bend and loose fit. If it

is normal, check headlamp bulb.

NG >> Repair harness or connector.

Headlamp HI Beam Does Not Illuminate (One Side)EKS00P7T

1.CHECK BULB

Check bulb of lamp which does not illuminate.

OK or NG

OK >> GO TO 2.

NG >> Replace headlamp bulb.

2.CHECK FRONT COMBINATION LAMP INPUT SIGNAL

1. Disconnect front combination lamp RH or LH connector.

2. Turn lighting switch to HIGH position.

3. Check voltage between front combination lamp (RH or LH) har-

ness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

3.CHECK FRONT COMBINATION LAMP GROUND

1. Turn lighting switch OFF.

2. Check continuity between front combination lamp (RH or LH)

harness connector and ground.

OK or NG

OK >> Check connector for connection, bend and loose fit.

NG >> Repair harness or connector.

Front combination lamp

connectorTerminal

GroundContinuity

RH E39

3Yes

LH E54

PKIC0455E

Terminal

Voltag e (+)

(-)

Front combination lamp

connectorTerminal

RH E39

2 Ground Battery voltage

LH E54

PKIC0453E

Front combination lamp

connectorTe r m i n a l

GroundContinuity

RH E39

3Yes

LH E54

PKIC0455E

Page 2107 of 3171

LT-24

HEADLAMP -CONVENTIONAL TYPE-

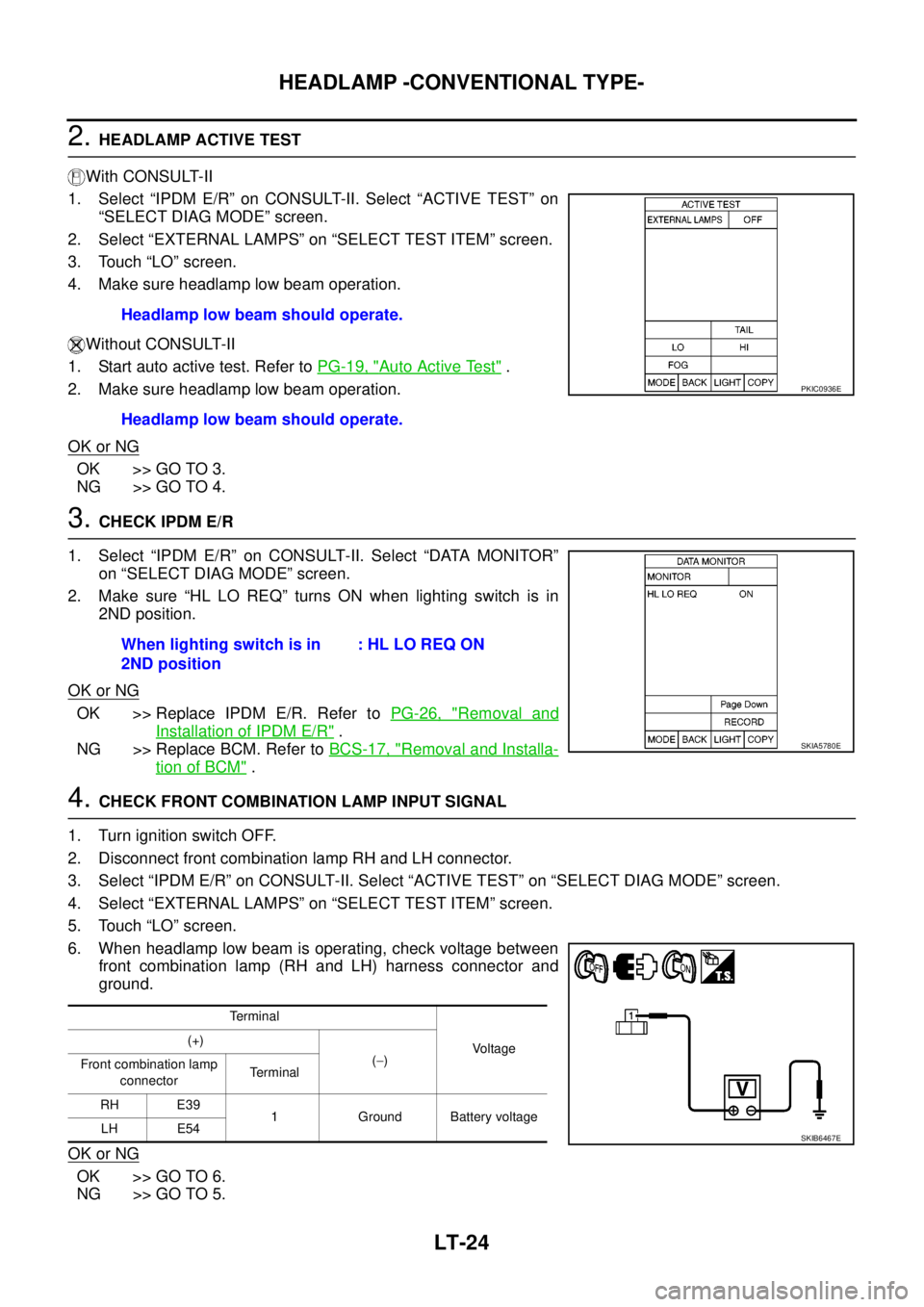

2.HEADLAMP ACTIVE TEST

With CONSULT-II

1. Select “IPDM E/R” on CONSULT-II. Select “ACTIVE TEST” on

“SELECT DIAG MODE” screen.

2. Select “EXTERNAL LAMPS” on “SELECT TEST ITEM” screen.

3. Touch “LO” screen.

4. Make sure headlamp low beam operation.

Without CONSULT-II

1. Start auto active test. Refer toPG-19, "

Auto Active Test".

2. Make sure headlamp low beam operation.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

3.CHECK IPDM E/R

1. Select “IPDM E/R” on CONSULT-II. Select “DATA MONITOR”

on “SELECT DIAG MODE” screen.

2. Make sure “HL LO REQ” turns ON when lighting switch is in

2ND position.

OK or NG

OK >> Replace IPDM E/R. Refer toPG-26, "Removal and

Installation of IPDM E/R".

NG >> Replace BCM. Refer toBCS-17, "

Removal and Installa-

tion of BCM".

4.CHECK FRONT COMBINATION LAMP INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH and LH connector.

3. Select “IPDM E/R” on CONSULT-II. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

4. Select “EXTERNAL LAMPS” on “SELECT TEST ITEM” screen.

5. Touch “LO” screen.

6. When headlamp low beam is operating, check voltage between

front combination lamp (RH and LH) harness connector and

ground.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.Headlamp low beam should operate.

Headlamp low beam should operate.

PKIC0936E

When lighting switch is in

2ND position:HLLOREQON

SKIA5780E

Te r m i n a l

Voltage (+)

(-)

Front combination lamp

connectorTerminal

RH E39

1 Ground Battery voltage

LH E54

SKIB6467E

Page 2108 of 3171

HEADLAMP -CONVENTIONAL TYPE-

LT-25

C

D

E

F

G

H

I

J

L

MA

B

LT

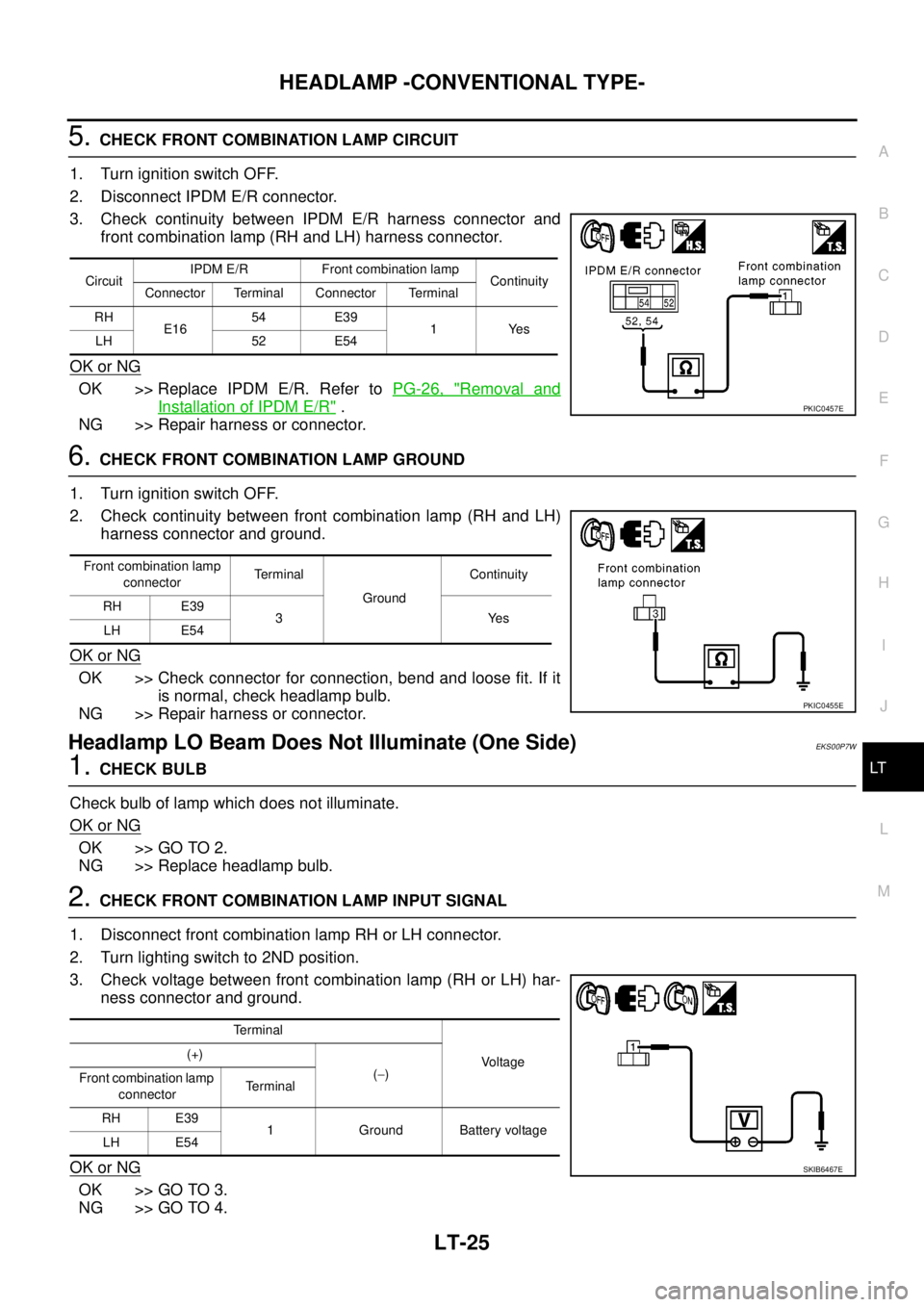

5.CHECK FRONT COMBINATION LAMP CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and

front combination lamp (RH and LH) harness connector.

OK or NG

OK >> Replace IPDM E/R. Refer toPG-26, "Removal and

Installation of IPDM E/R".

NG >> Repair harness or connector.

6.CHECK FRONT COMBINATION LAMP GROUND

1. Turn ignition switch OFF.

2. Check continuity between front combination lamp (RH and LH)

harness connector and ground.

OK or NG

OK >> Check connector for connection, bend and loose fit. If it

is normal, check headlamp bulb.

NG >> Repair harness or connector.

Headlamp LO Beam Does Not Illuminate (One Side)EKS00P7W

1.CHECK BULB

Check bulb of lamp which does not illuminate.

OK or NG

OK >> GO TO 2.

NG >> Replace headlamp bulb.

2.CHECK FRONT COMBINATION LAMP INPUT SIGNAL

1. Disconnect front combination lamp RH or LH connector.

2. Turn lighting switch to 2ND position.

3. Check voltage between front combination lamp (RH or LH) har-

ness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

CircuitIPDM E/R Front combination lamp

Continuity

Connector Terminal Connector Terminal

RH

E1654 E39

1Yes

LH 52 E54

PKIC0457E

Front combination lamp

connectorTerminal

GroundContinuity

RH E39

3Yes

LH E54

PKIC0455E

Terminal

Voltage (+)

(-)

Front combination lamp

connectorTerminal

RH E39

1 Ground Battery voltage

LH E54

SKIB6467E