transmission NISSAN NAVARA 2005 Repair Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 204 of 3171

AT-196

TROUBLE DIAGNOSIS FOR SYMPTOMS

A/T Does Not Perform Lock-up

ECS00G2N

SYMPTOM:

A/T does not perform lock-up at the specified speed.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Is any malfunction detected by self-diagnostic results?

YES >> Check malfunctioning system. Refer toAT-80, "SELF-DIAGNOSTIC RESULT MODE",AT- 9 0 ,

"Judgement Self-diagnosis Code".

NO >> GO TO 2.

2.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer toAT-12, "

Checking A/T Fluid".

OK or NG

OK >> GO TO 3.

NG >> Refill ATF.

3.CHECK LINE PRESSURE

Check line pressure at the engine stall point. Refer toAT-44, "

LINE PRESSURE TEST".

OK or NG

OK >> GO TO 6.

NG - 1 >> Line pressure high. GO TO 4.

NG - 2 >> Line pressure low. GO TO 5.

4.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer toAT- 2 1 8 , "

Control Valve With TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer toAT- 2 6 3 , "

DISASSEMBLY".

3. Check the following.

–Oil pump assembly. Refer toAT- 2 8 1 , "Oil Pump".

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

5.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer toAT- 2 1 8 , "

Control Valve With TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer toAT- 2 6 3 , "

DISASSEMBLY".

3. Check the following.

–Oil pump assembly. Refer toAT- 2 8 1 , "Oil Pump".

–Power train system. Refer toAT- 2 6 3 , "DISASSEMBLY".

–Transmission case. Refer toAT- 2 6 3 , "DISASSEMBLY".

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

Page 229 of 3171

ON-VEHICLE SERVICE

AT-221

D

E

F

G

H

I

J

K

L

MA

B

AT

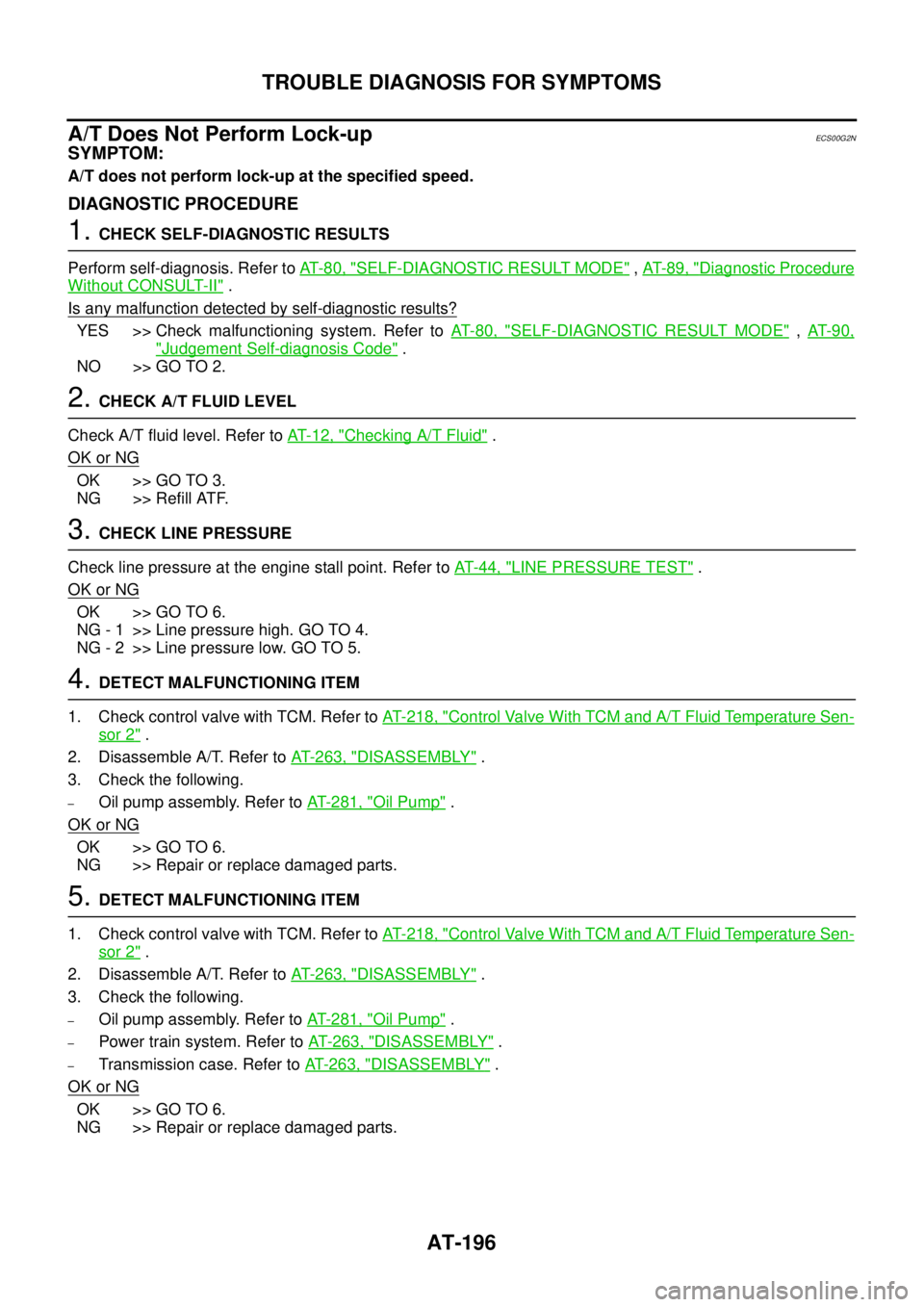

15. Remove bolts A, B and C from control valve with TCM.

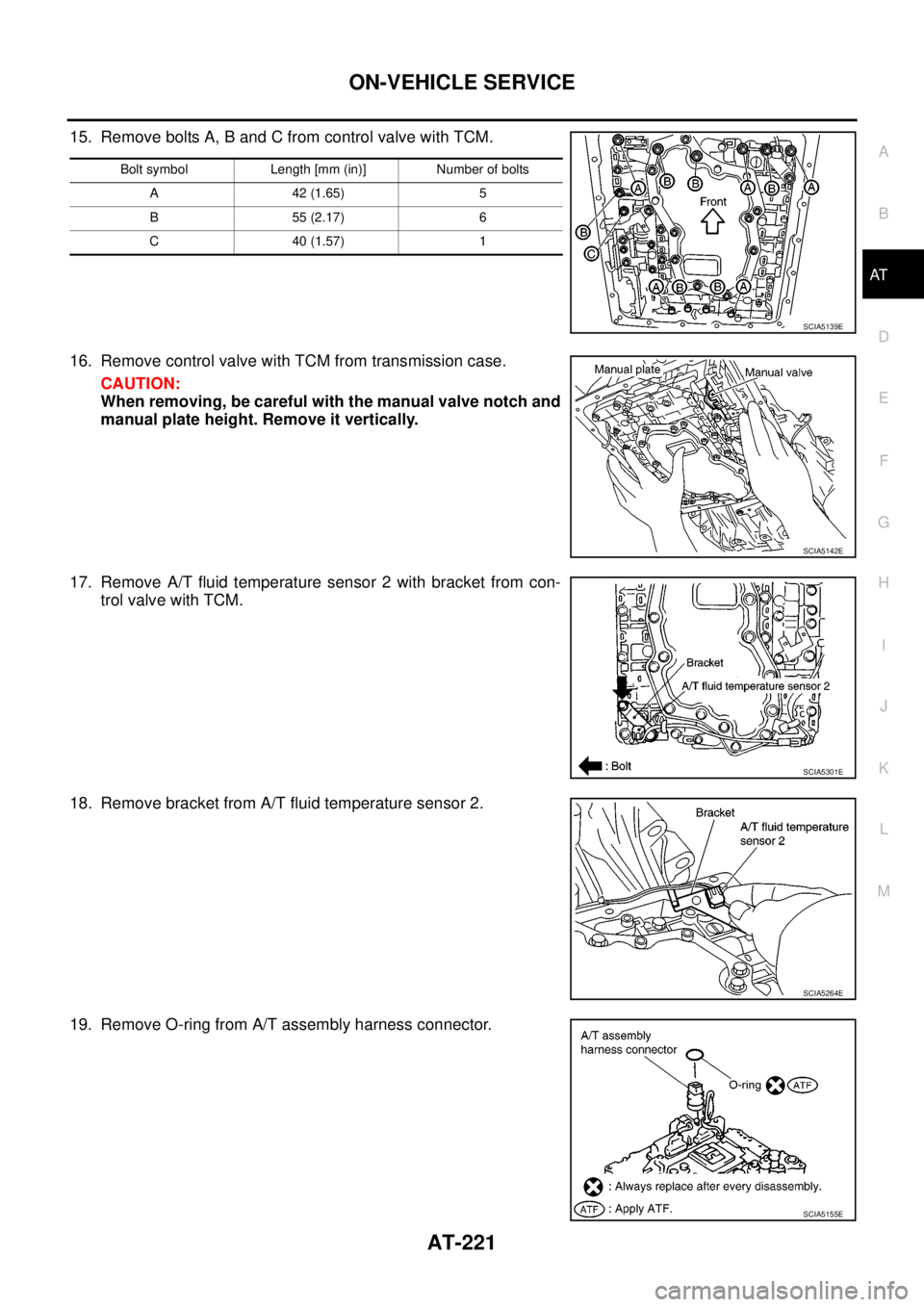

16. Remove control valve with TCM from transmission case.

CAUTION:

When removing, be careful with the manual valve notch and

manual plate height. Remove it vertically.

17. Remove A/T fluid temperature sensor 2 with bracket from con-

trol valve with TCM.

18. Remove bracket from A/T fluid temperature sensor 2.

19. Remove O-ring from A/T assembly harness connector.

Bolt symbol Length [mm (in)] Number of bolts

A42(1.65) 5

B55(2.17) 6

C40(1.57) 1

SCIA5139E

SCIA5142E

SCIA5301E

SCIA5264E

SCIA5155E

Page 232 of 3171

AT-224

ON-VEHICLE SERVICE

7. Install control valve with TCM in transmission case.

CAUTION:

lMake sure that turbine revolution sensor securely installs

turbine revolution sensor hole.

lHang down revolution sensor harness toward outside so

as not to disturb installation of control valve with TCM.

lAdjust A/T assembly harness connector of control valve

with TCM to terminal hole of transmission case.

lAssemble it so that manual valve cutout is engaged with

manual plate projection.

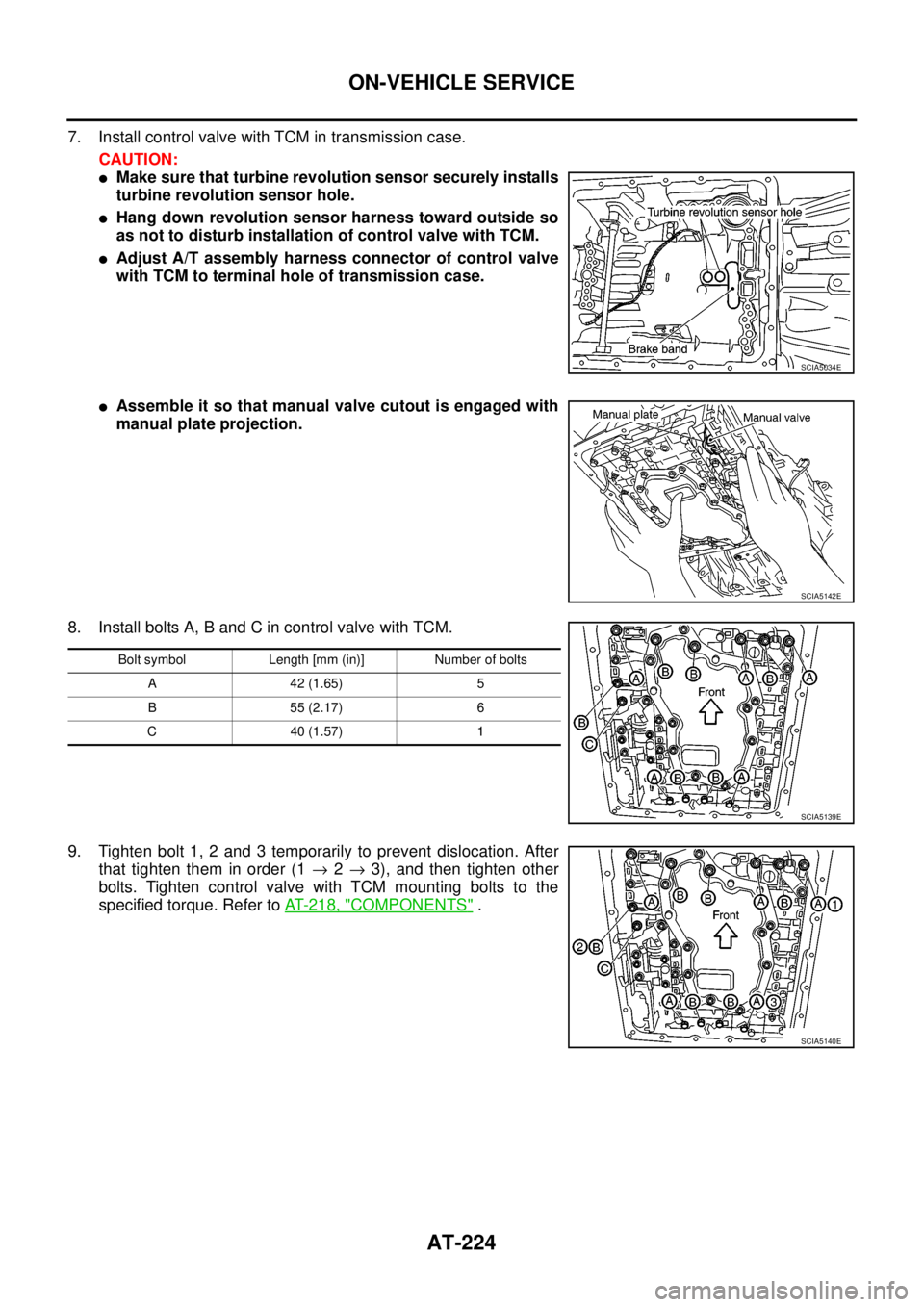

8. Install bolts A, B and C in control valve with TCM.

9. Tighten bolt 1, 2 and 3 temporarily to prevent dislocation. After

that tighten them in order (1®2®3), and then tighten other

bolts. Tighten control valve with TCM mounting bolts to the

specified torque. Refer toAT- 2 1 8 , "

COMPONENTS".

SCIA5034E

SCIA5142E

Bolt symbol Length [mm (in)] Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA5139E

SCIA5140E

Page 234 of 3171

AT-226

ON-VEHICLE SERVICE

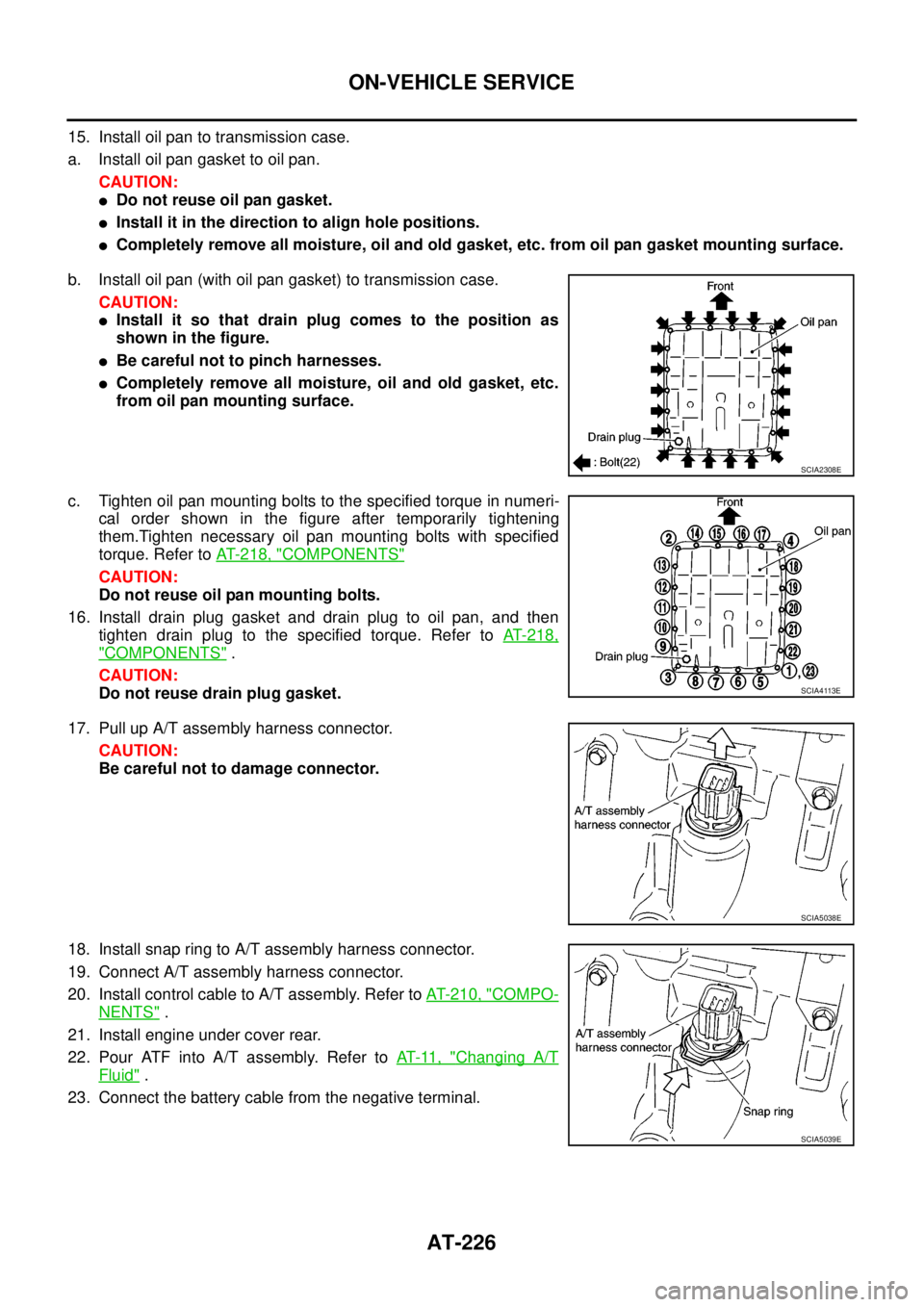

15. Install oil pan to transmission case.

a. Install oil pan gasket to oil pan.

CAUTION:

lDo not reuse oil pan gasket.

lInstall it in the direction to align hole positions.

lCompletely remove all moisture, oil and old gasket, etc. from oil pan gasket mounting surface.

b. Install oil pan (with oil pan gasket) to transmission case.

CAUTION:

lInstall it so that drain plug comes to the position as

shown in the figure.

lBe careful not to pinch harnesses.

lCompletely remove all moisture, oil and old gasket, etc.

from oil pan mounting surface.

c. Tighten oil pan mounting bolts to the specified torque in numeri-

cal order shown in the figure after temporarily tightening

them.Tighten necessary oil pan mounting bolts with specified

torque. Refer toAT- 2 1 8 , "

COMPONENTS"

CAUTION:

Do not reuse oil pan mounting bolts.

16. Install drain plug gasket and drain plug to oil pan, and then

tighten drain plug to the specified torque. Refer toAT-218,

"COMPONENTS".

CAUTION:

Do not reuse drain plug gasket.

17. Pull up A/T assembly harness connector.

CAUTION:

Be careful not to damage connector.

18. Install snap ring to A/T assembly harness connector.

19. Connect A/T assembly harness connector.

20. Install control cable to A/T assembly. Refer toAT- 2 1 0 , "

COMPO-

NENTS".

21. Install engine under cover rear.

22. Pour ATF into A/T assembly. Refer toAT-11, "

Changing A/T

Fluid".

23. Connect the battery cable from the negative terminal.

SCIA2308E

SCIA4113E

SCIA5038E

SCIA5039E

Page 237 of 3171

ON-VEHICLE SERVICE

AT-229

D

E

F

G

H

I

J

K

L

MA

B

AT

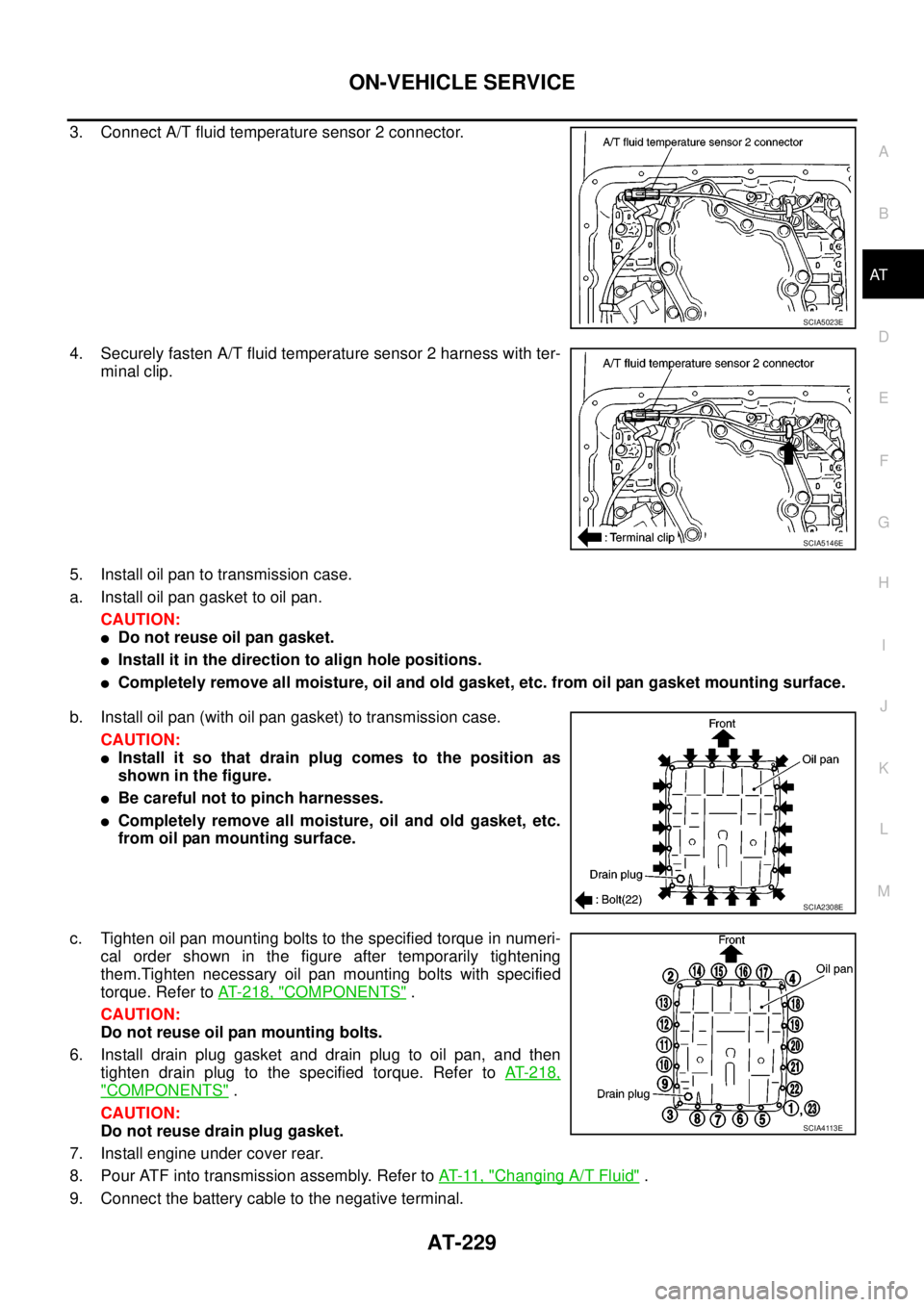

3. Connect A/T fluid temperature sensor 2 connector.

4. Securely fasten A/T fluid temperature sensor 2 harness with ter-

minal clip.

5. Install oil pan to transmission case.

a. Install oil pan gasket to oil pan.

CAUTION:

lDo not reuse oil pan gasket.

lInstall it in the direction to align hole positions.

lCompletely remove all moisture, oil and old gasket, etc. from oil pan gasket mounting surface.

b. Install oil pan (with oil pan gasket) to transmission case.

CAUTION:

lInstall it so that drain plug comes to the position as

shown in the figure.

lBe careful not to pinch harnesses.

lCompletely remove all moisture, oil and old gasket, etc.

from oil pan mounting surface.

c. Tighten oil pan mounting bolts to the specified torque in numeri-

cal order shown in the figure after temporarily tightening

them.Tighten necessary oil pan mounting bolts with specified

torque. Refer toAT- 2 1 8 , "

COMPONENTS".

CAUTION:

Do not reuse oil pan mounting bolts.

6. Install drain plug gasket and drain plug to oil pan, and then

tighten drain plug to the specified torque. Refer toAT-218,

"COMPONENTS".

CAUTION:

Do not reuse drain plug gasket.

7. Install engine under cover rear.

8. Pour ATF into transmission assembly. Refer toAT-11, "

Changing A/T Fluid".

9. Connect the battery cable to the negative terminal.

SCIA5023E

SCIA5146E

SCIA2308E

SCIA4113E

Page 238 of 3171

AT-230

ON-VEHICLE SERVICE

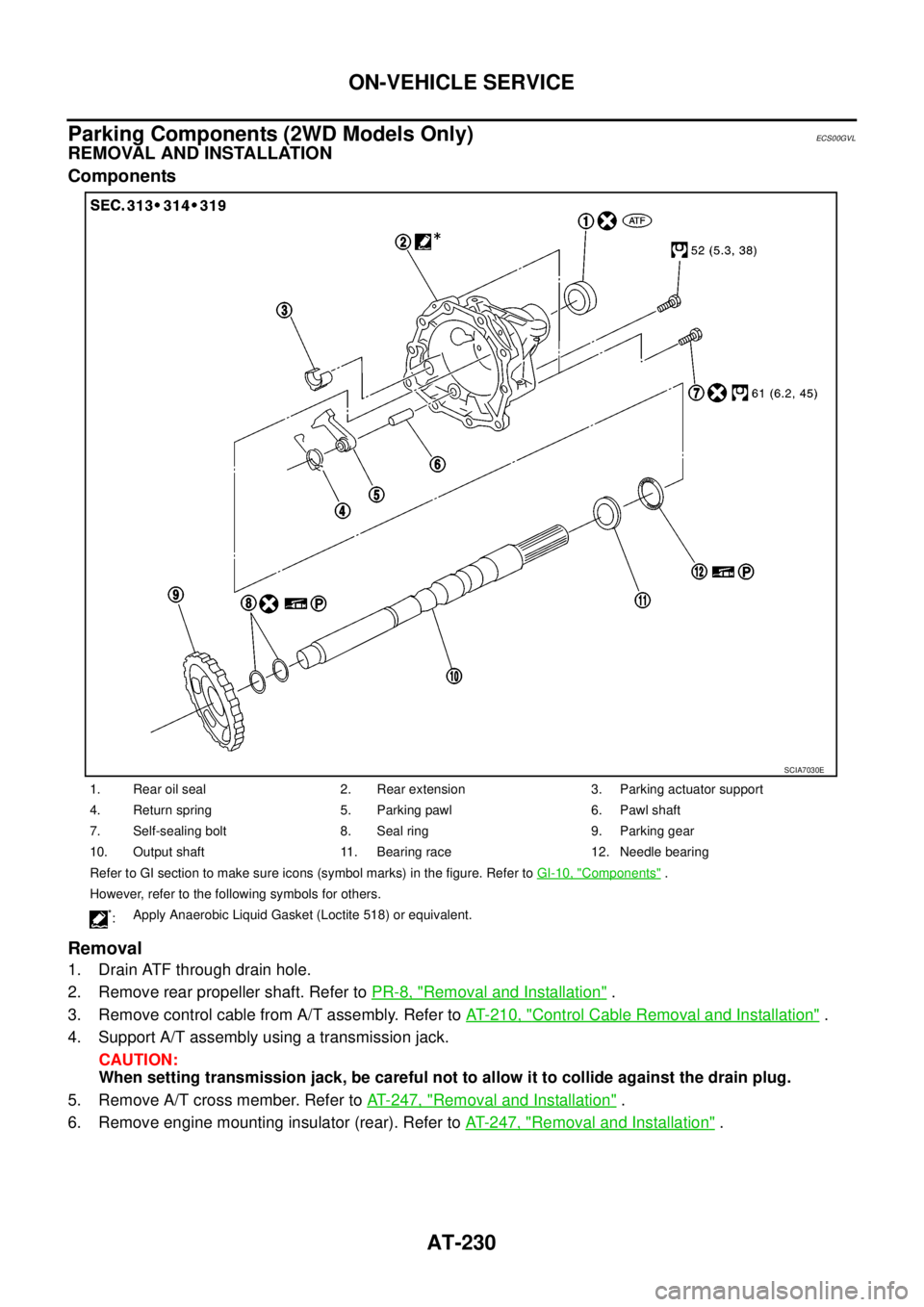

Parking Components (2WD Models Only)

ECS00GVL

REMOVAL AND INSTALLATION

Components

Removal

1. Drain ATF through drain hole.

2. Remove rear propeller shaft. Refer toPR-8, "

Removal and Installation".

3. Remove control cable from A/T assembly. Refer toAT- 2 1 0 , "

Control Cable Removal and Installation".

4. Support A/T assembly using a transmission jack.

CAUTION:

When setting transmission jack, be careful not to allow it to collide against the drain plug.

5. Remove A/T cross member. Refer toAT- 2 4 7 , "

Removal and Installation".

6. Remove engine mounting insulator (rear). Refer toAT- 2 4 7 , "

Removal and Installation".

1. Rear oil seal 2. Rear extension 3. Parking actuator support

4. Return spring 5. Parking pawl 6. Pawl shaft

7. Self-sealing bolt 8. Seal ring 9. Parking gear

10. Output shaft 11. Bearing race 12. Needle bearing

Refer to GI section to make sure icons (symbol marks) in the figure. Refer toGI-10, "

Components".

However, refer to the following symbols for others.

*:Apply Anaerobic Liquid Gasket (Loctite 518) or equivalent.

SCIA7030E

Page 239 of 3171

ON-VEHICLE SERVICE

AT-231

D

E

F

G

H

I

J

K

L

MA

B

AT

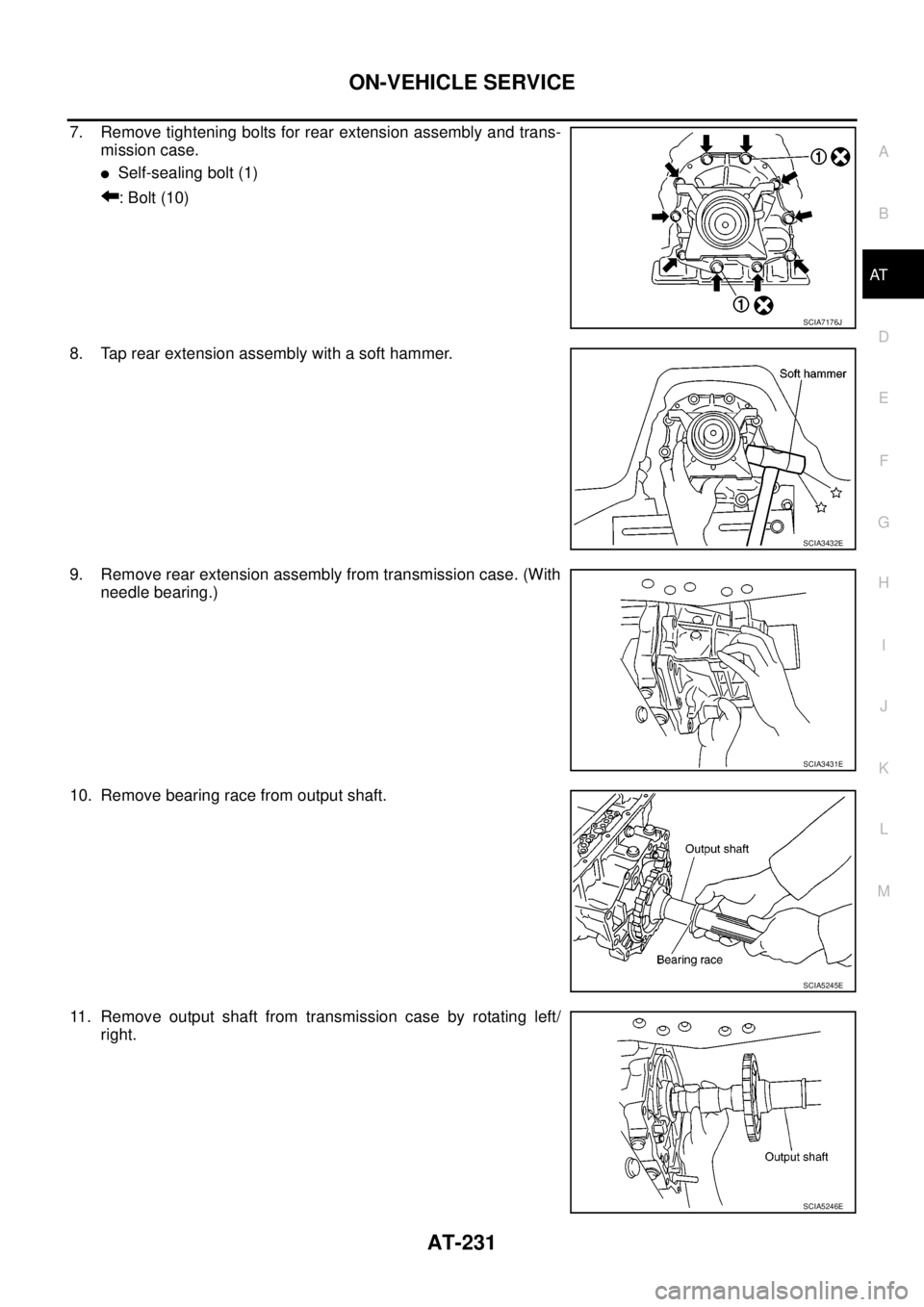

7. Remove tightening bolts for rear extension assembly and trans-

mission case.

lSelf-sealing bolt (1)

: Bolt (10)

8. Tap rear extension assembly with a soft hammer.

9. Remove rear extension assembly from transmission case. (With

needle bearing.)

10. Remove bearing race from output shaft.

11. Remove output shaft from transmission case by rotating left/

right.

SCIA7176J

SCIA3432E

SCIA3431E

SCIA5245E

SCIA5246E

Page 243 of 3171

ON-VEHICLE SERVICE

AT-235

D

E

F

G

H

I

J

K

L

MA

B

AT

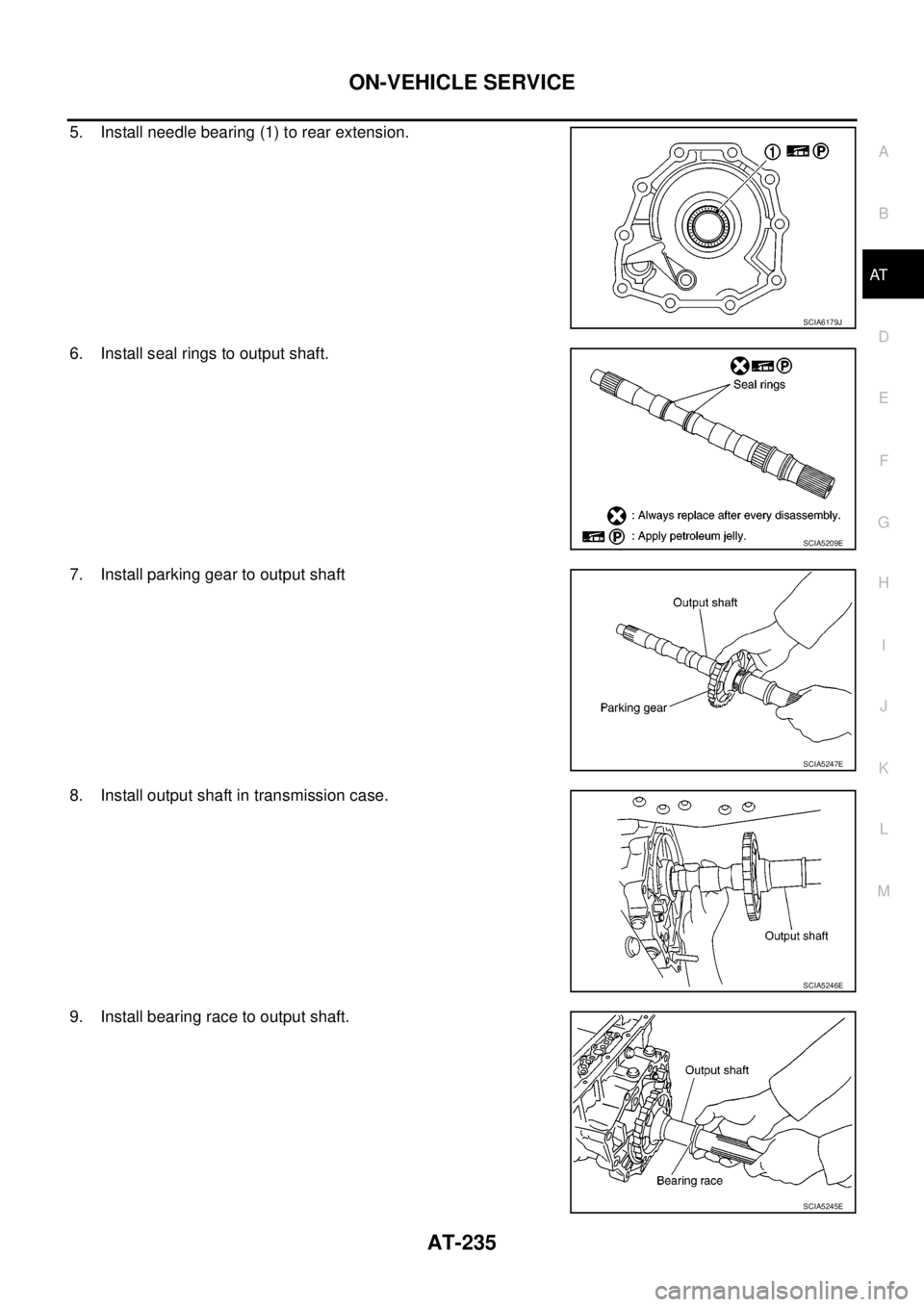

5. Install needle bearing (1) to rear extension.

6. Install seal rings to output shaft.

7. Install parking gear to output shaft

8. Install output shaft in transmission case.

9. Install bearing race to output shaft.

SCIA6179J

SCIA5209E

SCIA5247E

SCIA5246E

SCIA5245E

Page 244 of 3171

AT-236

ON-VEHICLE SERVICE

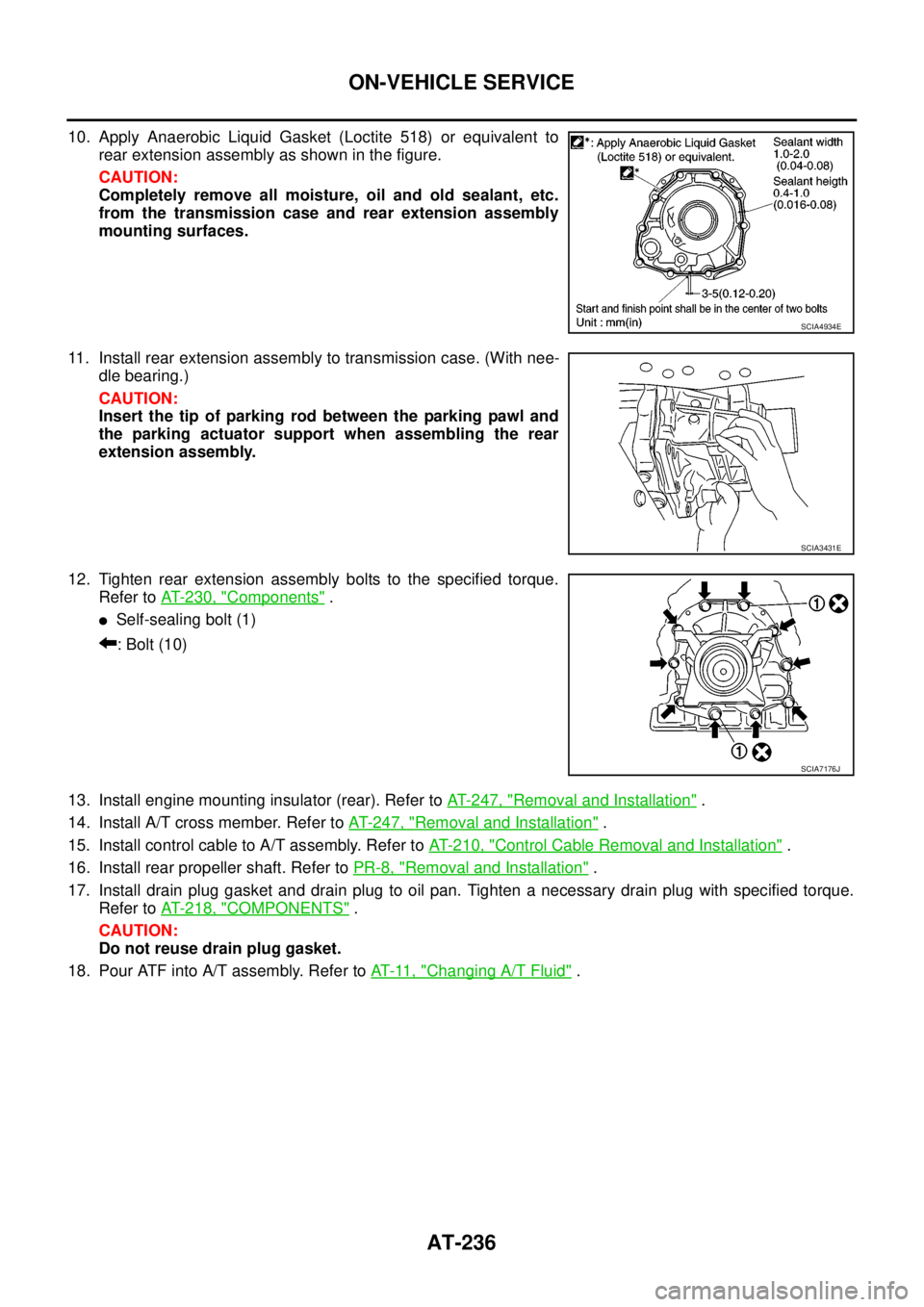

10. Apply Anaerobic Liquid Gasket (Loctite 518) or equivalent to

rear extension assembly as shown in the figure.

CAUTION:

Completely remove all moisture, oil and old sealant, etc.

from the transmission case and rear extension assembly

mounting surfaces.

11. Install rear extension assembly to transmission case. (With nee-

dle bearing.)

CAUTION:

Insert the tip of parking rod between the parking pawl and

the parking actuator support when assembling the rear

extension assembly.

12. Tighten rear extension assembly bolts to the specified torque.

Refer toAT- 2 3 0 , "

Components".

lSelf-sealing bolt (1)

:Bolt(10)

13. Install engine mounting insulator (rear). Refer toAT- 2 4 7 , "

Removal and Installation".

14. Install A/T cross member. Refer toAT- 2 4 7 , "

Removal and Installation".

15. Install control cable to A/T assembly. Refer toAT- 2 1 0 , "

Control Cable Removal and Installation".

16. Install rear propeller shaft. Refer toPR-8, "

Removal and Installation".

17. Install drain plug gasket and drain plug to oil pan. Tighten a necessary drain plug with specified torque.

Refer toAT- 2 1 8 , "

COMPONENTS".

CAUTION:

Do not reuse drain plug gasket.

18. Pour ATF into A/T assembly. Refer toAT-11, "

Changing A/T Fluid".

SCIA4934E

SCIA3431E

SCIA7176J

Page 247 of 3171

ON-VEHICLE SERVICE

AT-239

D

E

F

G

H

I

J

K

L

MA

B

AT

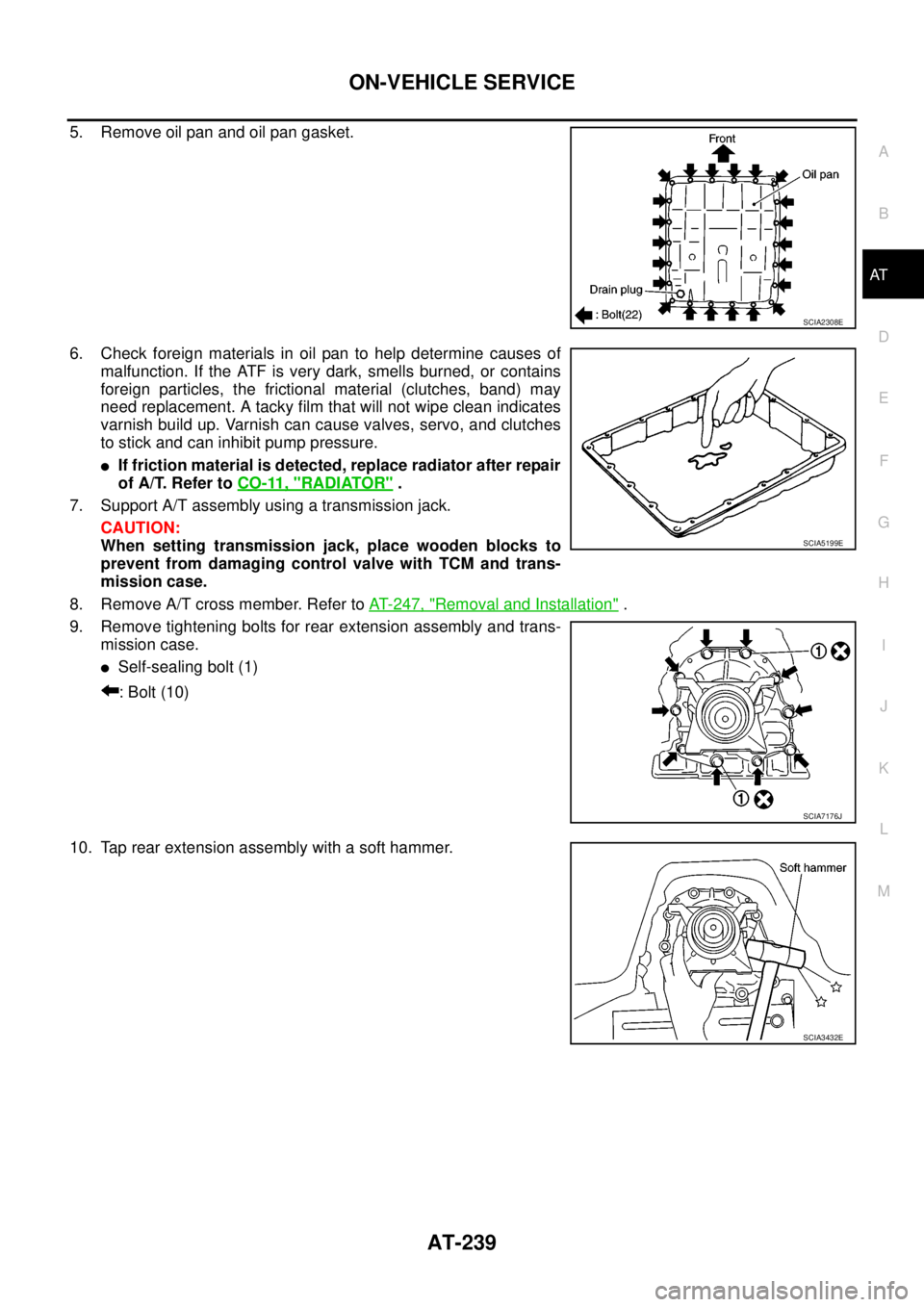

5. Remove oil pan and oil pan gasket.

6. Check foreign materials in oil pan to help determine causes of

malfunction. If the ATF is very dark, smells burned, or contains

foreign particles, the frictional material (clutches, band) may

need replacement. A tacky film that will not wipe clean indicates

varnish build up. Varnish can cause valves, servo, and clutches

to stick and can inhibit pump pressure.

lIf friction material is detected, replace radiator after repair

of A/T. Refer toCO-11, "

RADIATOR".

7. Support A/T assembly using a transmission jack.

CAUTION:

When setting transmission jack, place wooden blocks to

prevent from damaging control valve with TCM and trans-

mission case.

8. Remove A/T cross member. Refer toAT- 2 4 7 , "

Removal and Installation".

9. Remove tightening bolts for rear extension assembly and trans-

mission case.

lSelf-sealing bolt (1)

: Bolt (10)

10. Tap rear extension assembly with a soft hammer.

SCIA2308E

SCIA5199E

SCIA7176J

SCIA3432E