oil change NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 39 of 3171

A/T CONTROL SYSTEM

AT-31

D

E

F

G

H

I

J

K

L

MA

B

AT

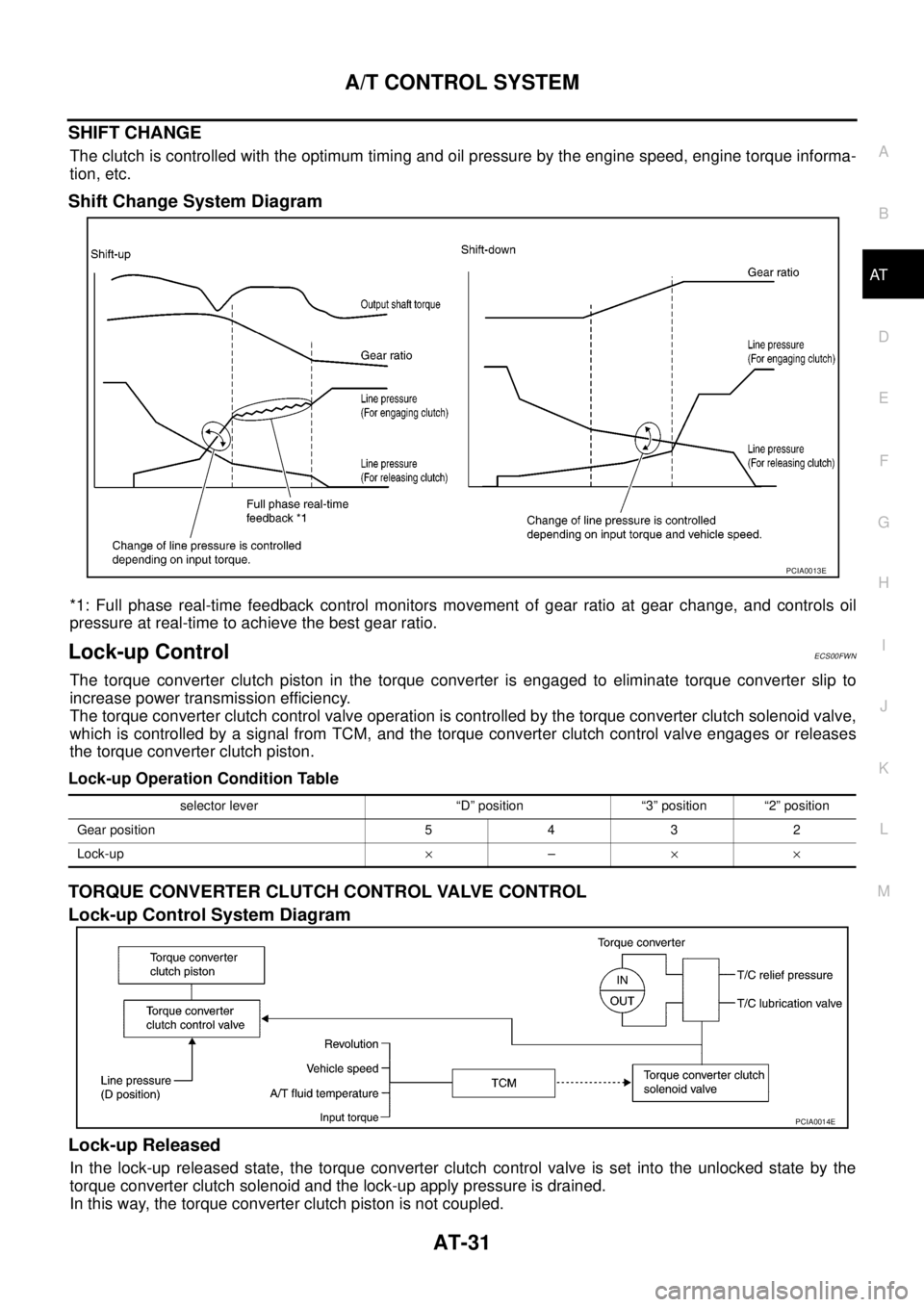

SHIFT CHANGE

The clutch is controlled with the optimum timing and oil pressure by the engine speed, engine torque informa-

tion, etc.

Shift Change System Diagram

*1: Full phase real-time feedback control monitors movement of gear ratio at gear change, and controls oil

pressure at real-time to achieve the best gear ratio.

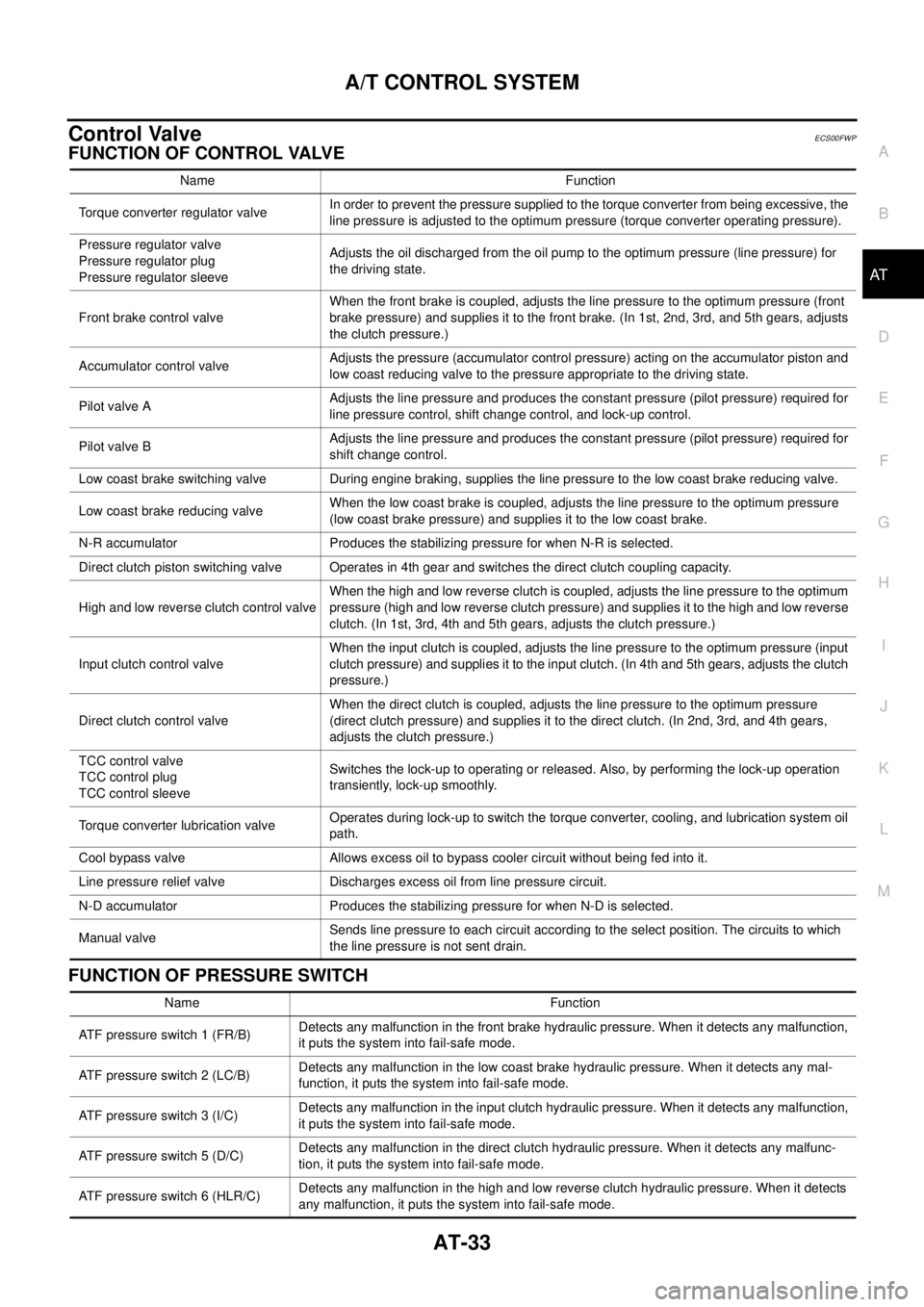

Lock-up ControlECS00FWN

The torque converter clutch piston in the torque converter is engaged to eliminate torque converter slip to

increase power transmission efficiency.

The torque converter clutch control valve operation is controlled by the torque converter clutch solenoid valve,

which is controlled by a signal from TCM, and the torque converter clutch control valve engages or releases

the torque converter clutch piston.

Lock-up Operation Condition Table

TORQUE CONVERTER CLUTCH CONTROL VALVE CONTROL

Lock-up Control System Diagram

Lock-up Released

In the lock-up released state, the torque converter clutch control valve is set into the unlocked state by the

torque converter clutch solenoid and the lock-up apply pressure is drained.

In this way, the torque converter clutch piston is not coupled.

PCIA0013E

selector lever “D” position “3” position “2” position

Gear position 5 4 3 2

Lock-up´–´´

PCIA0014E

Page 41 of 3171

A/T CONTROL SYSTEM

AT-33

D

E

F

G

H

I

J

K

L

MA

B

AT

Control ValveECS00FWP

FUNCTION OF CONTROL VALVE

FUNCTION OF PRESSURE SWITCH

Name Function

Torque converter regulator valveIn order to prevent the pressure supplied to the torque converter from being excessive, the

line pressure is adjusted to the optimum pressure (torque converter operating pressure).

Pressure regulator valve

Pressure regulator plug

Pressure regulator sleeveAdjusts the oil discharged from the oil pump to the optimum pressure (line pressure) for

the driving state.

Front brake control valveWhen the front brake is coupled, adjusts the line pressure to the optimum pressure (front

brake pressure) and supplies it to the front brake. (In 1st, 2nd, 3rd, and 5th gears, adjusts

theclutchpressure.)

Accumulator control valveAdjusts the pressure (accumulator control pressure) acting on the accumulator piston and

low coast reducing valve to the pressure appropriate to the driving state.

Pilot valve AAdjusts the line pressure and produces the constant pressure (pilot pressure) required for

line pressure control, shift change control, and lock-up control.

Pilot valve BAdjusts the line pressure and produces the constant pressure (pilot pressure) required for

shift change control.

Low coast brake switching valve During engine braking, supplies the line pressure to the low coast brake reducing valve.

Low coast brake reducing valveWhen the low coast brake is coupled, adjusts the line pressure to the optimum pressure

(low coast brake pressure) and supplies it to the low coast brake.

N-R accumulator Produces the stabilizing pressure for when N-R is selected.

Direct clutch piston switching valve Operates in 4th gear and switches the direct clutch coupling capacity.

High and low reverse clutch control valveWhen the high and low reverse clutch is coupled, adjusts the line pressure to the optimum

pressure (high and low reverse clutch pressure) and supplies it to the high and low reverse

clutch. (In 1st, 3rd, 4th and 5th gears, adjusts the clutch pressure.)

Input clutch control valveWhen the input clutch is coupled, adjusts the line pressure to the optimum pressure (input

clutch pressure) and supplies it to the input clutch. (In 4th and 5th gears, adjusts the clutch

pressure.)

Direct clutch control valveWhen the direct clutch is coupled, adjusts the line pressure to the optimum pressure

(direct clutch pressure) and supplies it to the direct clutch. (In 2nd, 3rd, and 4th gears,

adjusts the clutch pressure.)

TCC control valve

TCC control plug

TCC control sleeveSwitches the lock-up to operating or released. Also, by performing the lock-up operation

transiently, lock-up smoothly.

Torque converter lubrication valveOperates during lock-up to switch the torque converter, cooling, and lubrication system oil

path.

Cool bypass valve Allows excess oil to bypass cooler circuit without being fed into it.

Line pressure relief valve Discharges excess oil from line pressure circuit.

N-D accumulator Produces the stabilizing pressure for when N-D is selected.

Manual valveSends line pressure to each circuit according to the select position. The circuits to which

the line pressure is not sent drain.

Name Function

ATFpressureswitch1(FR/B)Detects any malfunction in the front brake hydraulic pressure. When it detects any malfunction,

it puts the system into fail-safe mode.

ATFpressureswitch2(LC/B)Detects any malfunction in the low coast brake hydraulic pressure. When it detects any mal-

function, it puts the system into fail-safe mode.

ATFpressureswitch3(I/C)Detects any malfunction in the input clutch hydraulic pressure. When it detects any malfunction,

it puts the system into fail-safe mode.

ATF pressure switch 5 (D/C)Detects any malfunction in the direct clutch hydraulic pressure. When it detects any malfunc-

tion, it puts the system into fail-safe mode.

ATF pressure switch 6 (HLR/C)Detects any malfunction in the high and low reverse clutch hydraulic pressure. When it detects

any malfunction, it puts the system into fail-safe mode.

Page 69 of 3171

TROUBLE DIAGNOSIS

AT-61

D

E

F

G

H

I

J

K

L

MA

B

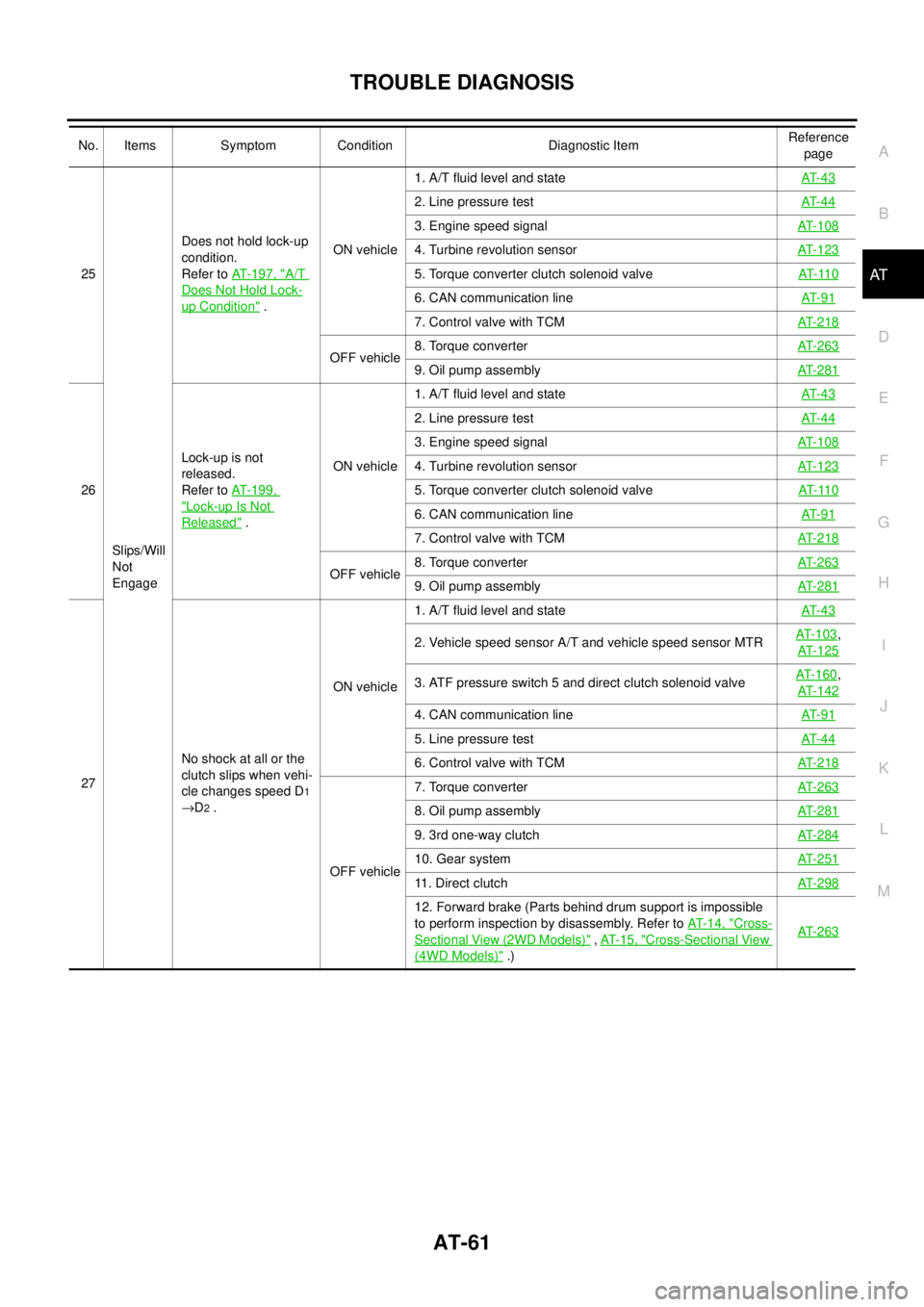

AT25

Slips/Will

Not

EngageDoes not hold lock-up

condition.

Refer toAT-197, "A/T

Does Not Hold Lock-

up Condition".ON vehicle1. A/T fluid level and stateAT- 4 3

2. Line pressure testAT- 4 4

3. Engine speed signalAT-108

4. Turbine revolution sensorAT-123

5. Torque converter clutch solenoid valveAT- 11 0

6. CAN communication lineAT- 9 1

7. Control valve with TCMAT-218

OFF vehicle8. Torque converterAT-2639. Oil pump assemblyAT-281

26Lock-up is not

released.

Refer toAT-199,

"Lock-up Is Not

Released".ON vehicle1. A/T fluid level and stateAT- 4 3

2. Line pressure testAT- 4 4

3. Engine speed signalAT-108

4. Turbine revolution sensorAT-123

5. Torque converter clutch solenoid valveAT- 11 0

6. CAN communication lineAT- 9 1

7. Control valve with TCMAT-218

OFF vehicle8. Torque converterAT-2639. Oil pump assemblyAT-281

27No shock at all or the

clutch slips when vehi-

cle changes speed D1

®D2.ON vehicle1. A/T fluid level and stateAT- 4 3

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT-103,

AT-125

3. ATF pressure switch 5 and direct clutch solenoid valveAT-160,

AT-142

4. CAN communication lineAT- 9 1

5. Line pressure testAT- 4 4

6. Control valve with TCMAT-218

OFF vehicle7. Torque converterAT-263

8. Oil pump assemblyAT-281

9. 3rd one-way clutchAT-284

10. Gear systemAT-251

11 . D i r e c t c l u t c hAT-298

12. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer toAT- 1 4 , "

Cross-

Sectional View (2WD Models)",AT- 1 5 , "Cross-Sectional View

(4WD Models)".)AT-263

No. Items Symptom Condition Diagnostic ItemReference

page

Page 70 of 3171

AT-62

TROUBLE DIAGNOSIS

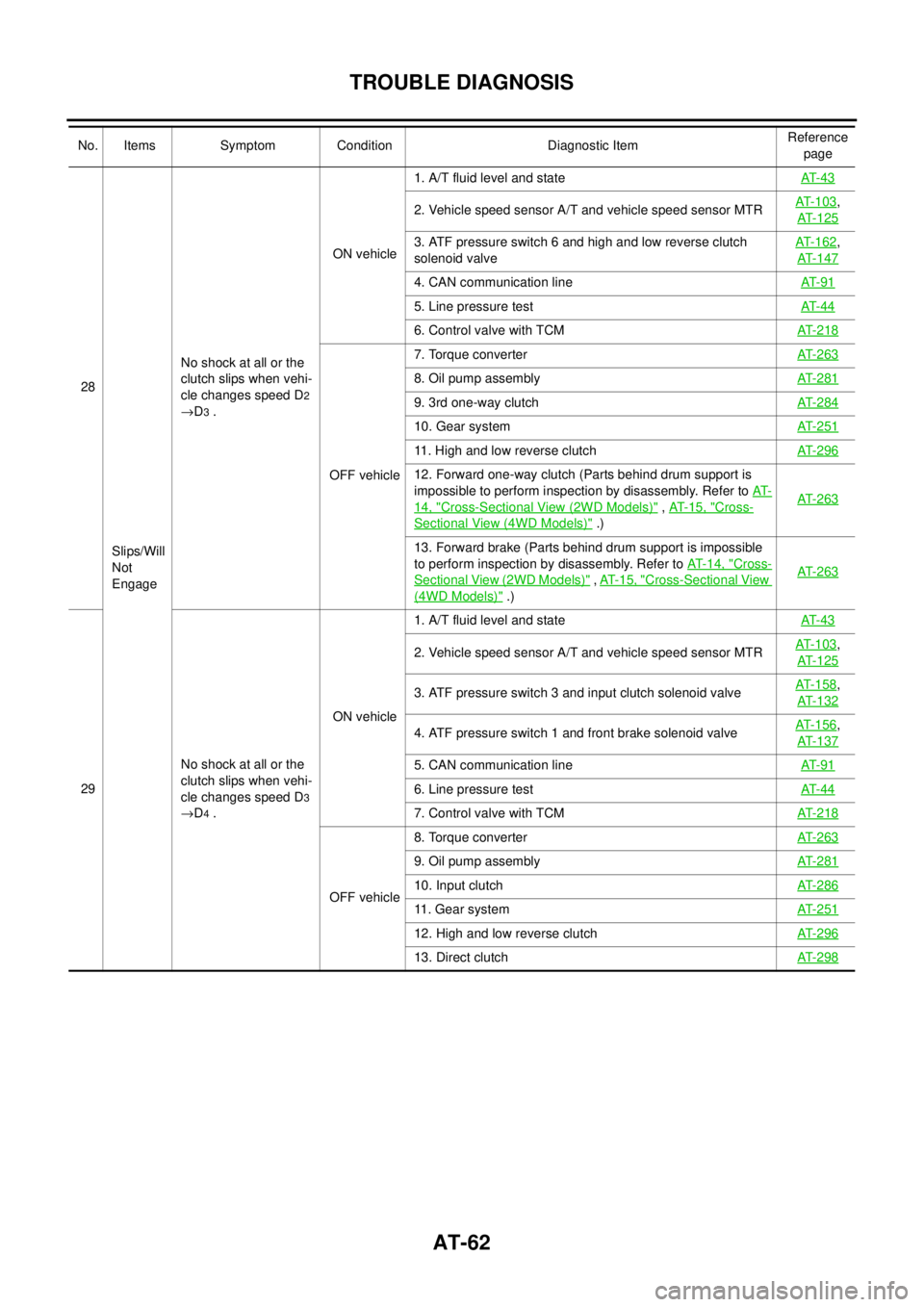

28

Slips/Will

Not

EngageNo shock at all or the

clutch slips when vehi-

cle changes speed D2

®D3.ON vehicle1. A/T fluid level and stateAT- 4 3

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 3,

AT- 1 2 5

3. ATF pressure switch 6 and high and low reverse clutch

solenoid valveAT- 1 6 2,

AT- 1 4 7

4. CAN communication lineAT- 9 1

5. Line pressure testAT- 4 4

6. Control valve with TCMAT- 2 1 8

OFF vehicle7. Torque converterAT- 2 6 3

8. Oil pump assemblyAT- 2 8 1

9. 3rd one-way clutchAT- 2 8 4

10. Gear systemAT- 2 5 1

11. High and low reverse clutchAT- 2 9 6

12. Forward one-way clutch (Parts behind drum support is

impossible to perform inspection by disassembly. Refer toAT-

14, "Cross-Sectional View (2WD Models)",AT- 1 5 , "Cross-

Sectional View (4WD Models)".)AT- 2 6 3

13. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer toAT-14, "

Cross-

Sectional View (2WD Models)",AT-15, "Cross-Sectional View

(4WD Models)".)AT- 2 6 3

29No shock at all or the

clutch slips when vehi-

cle changes speed D3

®D4.ON vehicle1. A/T fluid level and stateAT- 4 3

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 3,

AT- 1 2 5

3. ATF pressure switch 3 and input clutch solenoid valveAT- 1 5 8,

AT- 1 3 2

4. ATF pressure switch 1 and front brake solenoid valveAT- 1 5 6,

AT- 1 3 7

5. CAN communication lineAT- 9 1

6. Line pressure testAT- 4 4

7. Control valve with TCMAT- 2 1 8

OFF vehicle8. Torque converterAT- 2 6 3

9. Oil pump assemblyAT- 2 8 1

10. Input clutchAT- 2 8 6

11. Gear systemAT- 2 5 1

12. High and low reverse clutchAT- 2 9 6

13. Direct clutchAT- 2 9 8

No. Items Symptom Condition Diagnostic ItemReference

page

Page 71 of 3171

TROUBLE DIAGNOSIS

AT-63

D

E

F

G

H

I

J

K

L

MA

B

AT

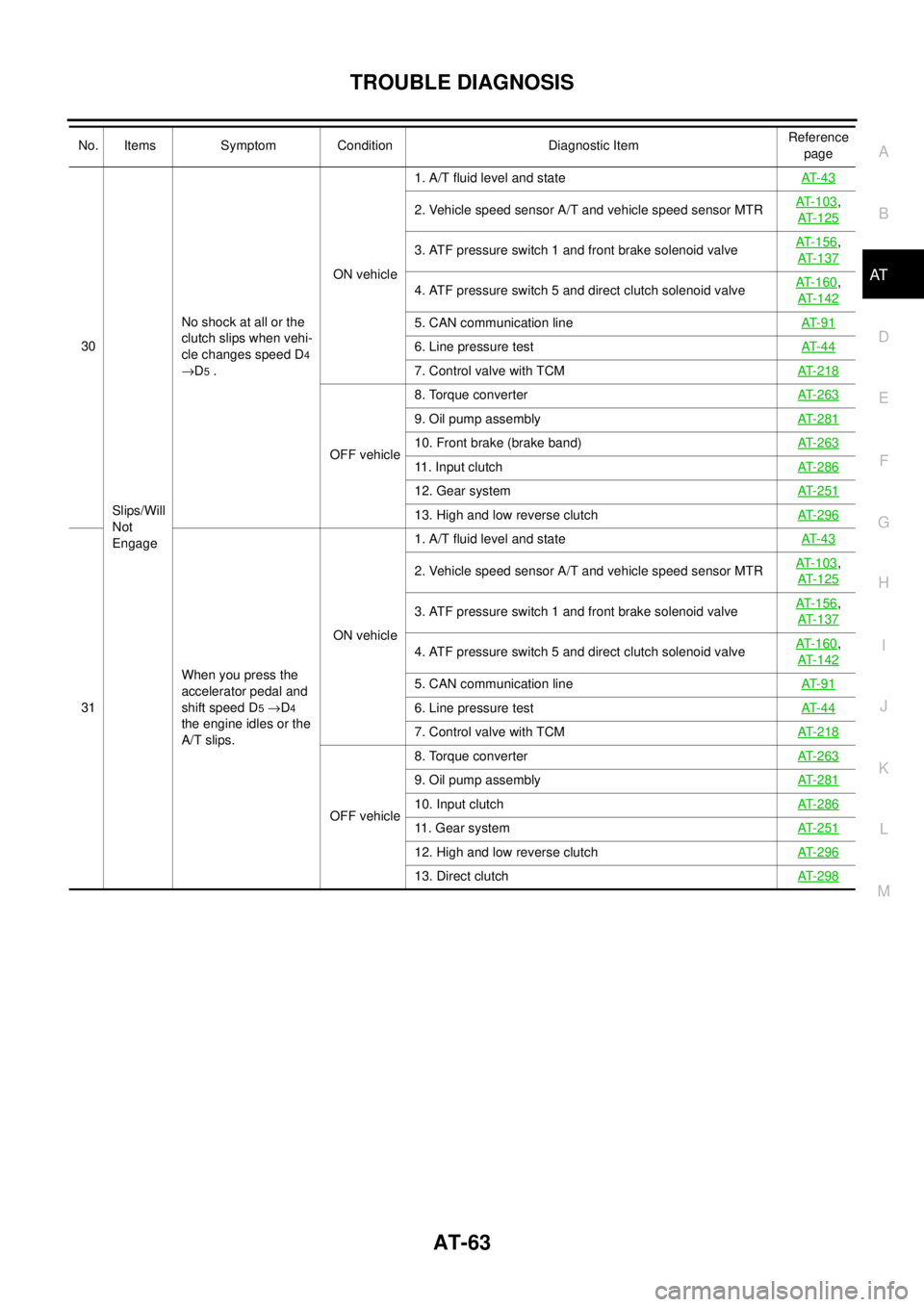

30

Slips/Will

Not

EngageNo shock at all or the

clutch slips when vehi-

cle changes speed D4

®D5.ON vehicle1. A/T fluid level and stateAT- 4 3

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT-103,

AT-125

3. ATF pressure switch 1 and front brake solenoid valveAT-156,

AT-137

4. ATF pressure switch 5 and direct clutch solenoid valveAT-160,

AT-142

5. CAN communication lineAT- 9 1

6. Line pressure testAT- 4 4

7. Control valve with TCMAT-218

OFF vehicle8. Torque converterAT-263

9. Oil pump assemblyAT-281

10. Front brake (brake band)AT-263

11. Input clutchAT-286

12. Gear systemAT-251

13. High and low reverse clutchAT-296

31When you press the

accelerator pedal and

shift speed D5®D4

the engine idles or the

A/T slips.ON vehicle1. A/T fluid level and stateAT- 4 3

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT-103,

AT-125

3. ATF pressure switch 1 and front brake solenoid valveAT-156,

AT-137

4. ATF pressure switch 5 and direct clutch solenoid valveAT-160,

AT-142

5. CAN communication lineAT- 9 1

6. Line pressure testAT- 4 4

7. Control valve with TCMAT-218

OFF vehicle8. Torque converterAT-263

9. Oil pump assemblyAT-281

10. Input clutchAT-286

11. Gear systemAT-251

12. High and low reverse clutchAT-296

13. Direct clutchAT-298

No. Items Symptom Condition Diagnostic ItemReference

page

Page 350 of 3171

ATC-16

PREPARATION

PREPARATION

PFP:00002

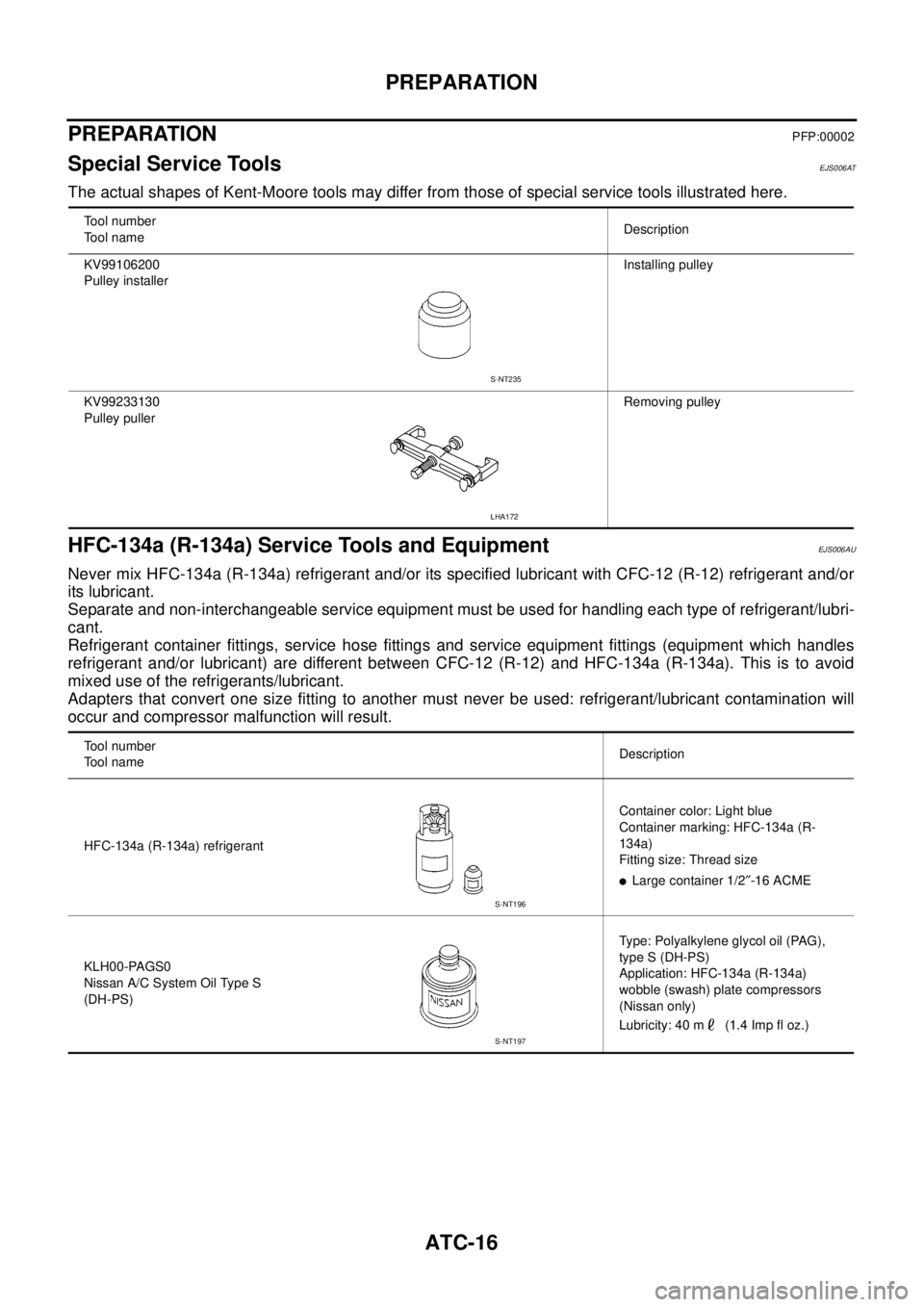

Special Service ToolsEJS006AT

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

HFC-134a (R-134a) Service Tools and EquipmentEJS006AU

Never mix HFC-134a (R-134a) refrigerant and/or its specified lubricant with CFC-12 (R-12) refrigerant and/or

its lubricant.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/lubri-

cant.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or lubricant) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid

mixed use of the refrigerants/lubricant.

Adapters that convert one size fitting to another must never be used: refrigerant/lubricant contamination will

occur and compressor malfunction will result.

Tool number

Tool nameDescription

KV99106200

Pulley installerInstalling pulley

KV99233130

Pulley pullerRemoving pulley

S-NT235

LHA172

Tool number

Tool nameDescription

HFC-134a (R-134a) refrigerantContainer color: Light blue

Container marking: HFC-134a (R-

134a)

Fitting size: Thread size

lLarge container 1/2²-16 ACME

KLH00-PAGS0

Nissan A/C System Oil Type S

(DH-PS)Type: Polyalkylene glycol oil (PAG),

type S (DH-PS)

Application: HFC-134a (R-134a)

wobble (swash) plate compressors

(Nissan only)

Lubricity: 40 m (1.4 Imp fl oz.)

S-NT196

S-NT197

Page 1105 of 3171

DTC P0201 - P0204 FUEL INJECTOR

EC-125

C

D

E

F

G

H

I

J

K

L

MA

EC

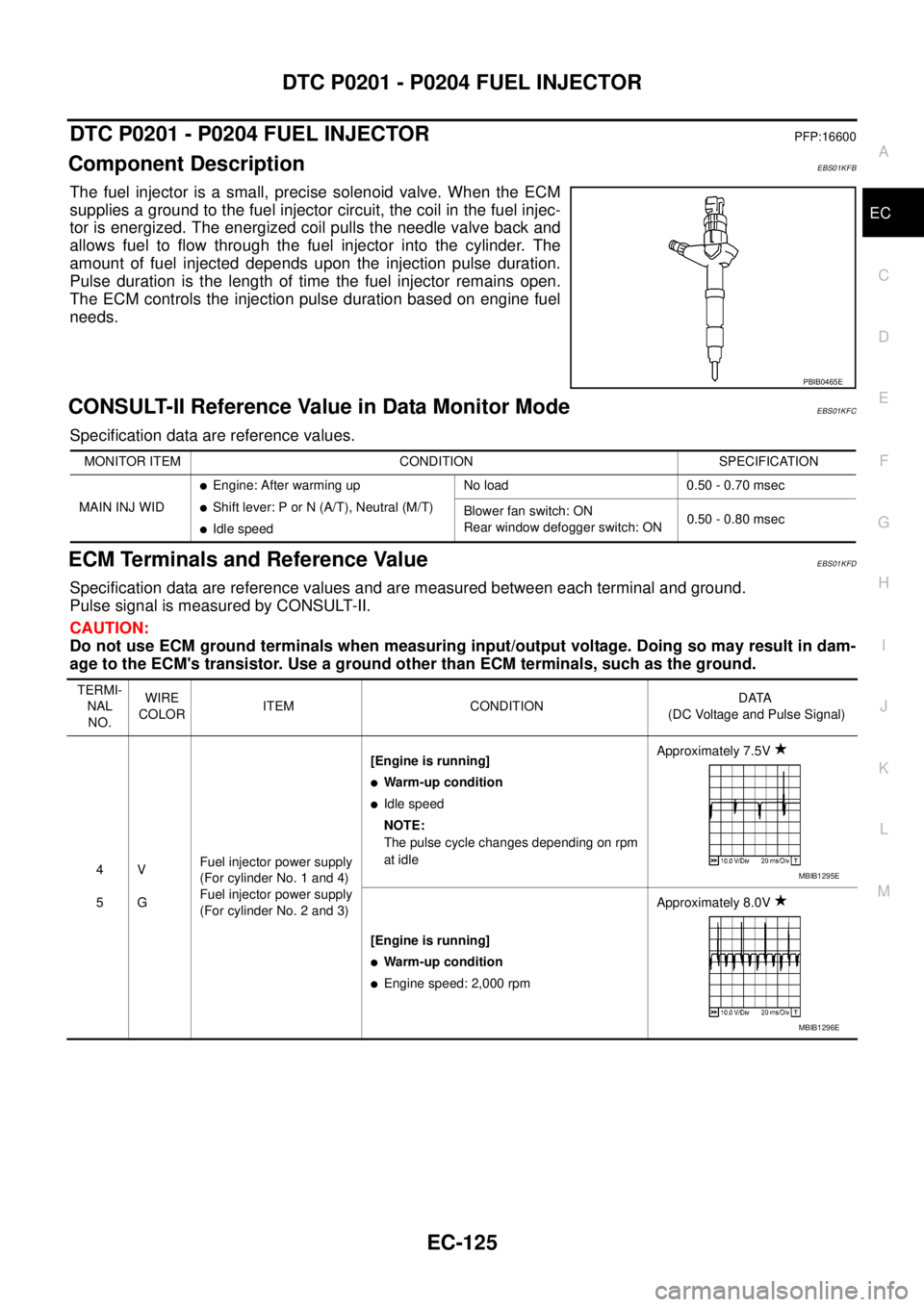

DTC P0201 - P0204 FUEL INJECTORPFP:16600

Component DescriptionEBS01KFB

The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the fuel injector circuit, the coil in the fuel injec-

tor is energized. The energized coil pulls the needle valve back and

allows fuel to flow through the fuel injector into the cylinder. The

amount of fuel injected depends upon the injection pulse duration.

Pulse duration is the length of time the fuel injector remains open.

The ECM controls the injection pulse duration based on engine fuel

needs.

CONSULT-II Reference Value in Data Monitor ModeEBS01KFC

Specification data are reference values.

ECM Terminals and Reference ValueEBS01KFD

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

PBIB0465E

MONITOR ITEM CONDITION SPECIFICATION

MAIN INJ WID

lEngine: After warming up

lShift lever: P or N (A/T), Neutral (M/T)

lIdle speedNo load 0.50 - 0.70 msec

Blower fan switch: ON

Rear window defogger switch: ON0.50 - 0.80 msec

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

4

5V

GFuel injector power supply

(For cylinder No. 1 and 4)

Fuel injector power supply

(For cylinder No. 2 and 3)[Engine is running]

lWarm-up condition

lIdle speed

NOTE:

The pulse cycle changes depending on rpm

at idleApproximately 7.5V

[Engine is running]

lWarm-up condition

lEngine speed: 2,000 rpmApproximately 8.0V

MBIB1295E

MBIB1296E

Page 1217 of 3171

DTC P1268 - P1271 FUEL INJECTOR

EC-237

C

D

E

F

G

H

I

J

K

L

MA

EC

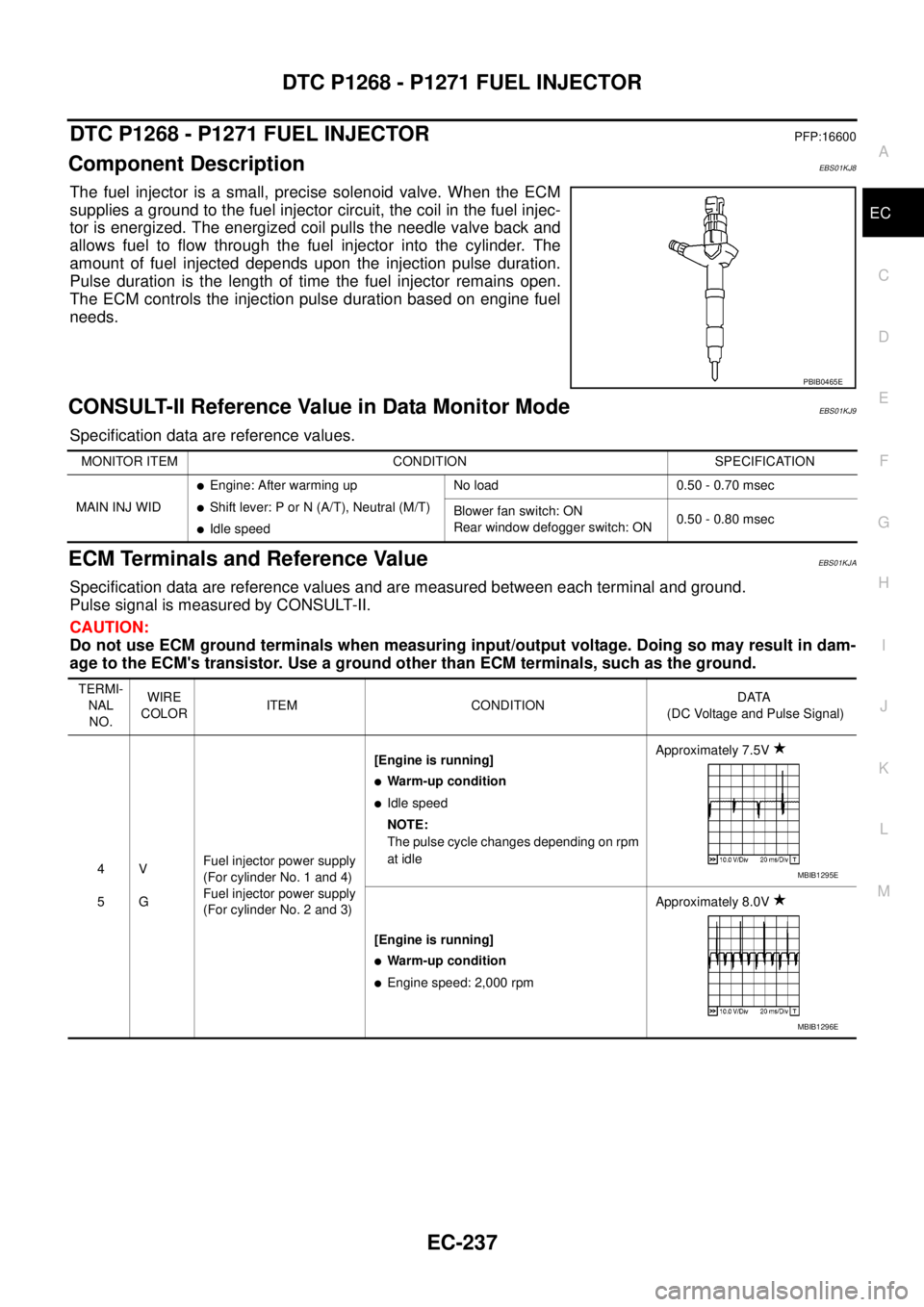

DTC P1268 - P1271 FUEL INJECTORPFP:16600

Component DescriptionEBS01KJ8

The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the fuel injector circuit, the coil in the fuel injec-

tor is energized. The energized coil pulls the needle valve back and

allows fuel to flow through the fuel injector into the cylinder. The

amount of fuel injected depends upon the injection pulse duration.

Pulse duration is the length of time the fuel injector remains open.

The ECM controls the injection pulse duration based on engine fuel

needs.

CONSULT-II Reference Value in Data Monitor ModeEBS01KJ9

Specification data are reference values.

ECM Terminals and Reference ValueEBS01KJA

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

PBIB0465E

MONITOR ITEM CONDITION SPECIFICATION

MAIN INJ WID

lEngine: After warming up

lShift lever: P or N (A/T), Neutral (M/T)

lIdle speedNo load 0.50 - 0.70 msec

Blower fan switch: ON

Rear window defogger switch: ON0.50 - 0.80 msec

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

4

5V

GFuel injector power supply

(For cylinder No. 1 and 4)

Fuel injector power supply

(For cylinder No. 2 and 3)[Engine is running]

lWarm-up condition

lIdle speed

NOTE:

The pulse cycle changes depending on rpm

at idleApproximately 7.5V

[Engine is running]

lWarm-up condition

lEngine speed: 2,000 rpmApproximately 8.0V

MBIB1295E

MBIB1296E

Page 1261 of 3171

DTC P2146, P2149 FUEL INJECTOR POWER SUPPLY

EC-281

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P2146, P2149 FUEL INJECTOR POWER SUPPLYPFP:16600

Component DescriptionEBS01KL2

The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the fuel injector circuit, the coil in the fuel injec-

tor is energized. The energized coil pulls the needle valve back and

allows fuel to flow through the fuel injector into the cylinder. The

amount of fuel injected depends upon the injection pulse duration.

Pulse duration is the length of time the fuel injector remains open.

The ECM controls the injection pulse duration based on engine fuel

needs.

CONSULT-II Reference Value in Data Monitor ModeEBS01KL3

Specification data are reference values.

ECM Terminals and Reference ValueEBS01KL4

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

PBIB0465E

MONITOR ITEM CONDITION SPECIFICATION

MAIN INJ WID

lEngine: After warming up

lShift lever: P or N (A/T), Neutral (M/T)

lIdle speedNo load 0.50 - 0.70 msec

Blower fan switch: ON

Rear window defogger switch: ON0.50 - 0.80 msec

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

4

5V

GFuel injector power supply

(For cylinder No. 1 and 4)

Fuel injector power supply

(For cylinder No. 2 and 3)[Engine is running]

lWarm-up condition

lIdle speed

NOTE:

The pulse cycle changes depending on rpm

at idleApproximately 7.5V

[Engine is running]

lWarm-up condition

lEngine speed: 2,000 rpmApproximately 8.0V

MBIB1295E

MBIB1296E

Page 1266 of 3171

EC-286

DTC P2147, P2148 FUEL INJECTOR CIRCUIT

DTC P2147, P2148 FUEL INJECTOR CIRCUIT

PFP:16600

Component DescriptionEBS01KL9

The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the fuel injector circuit, the coil in the fuel injec-

tor is energized. The energized coil pulls the needle valve back and

allows fuel to flow through the fuel injector into the cylinder. The

amount of fuel injected depends upon the injection pulse duration.

Pulse duration is the length of time the fuel injector remains open.

The ECM controls the injection pulse duration based on engine fuel

needs.

CONSULT-II Reference Value in Data Monitor ModeEBS01KLA

Specification data are reference values.

ECM Terminals and Reference ValueEBS01KLB

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

PBIB0465E

MONITOR ITEM CONDITION SPECIFICATION

MAIN INJ WID

lEngine: After warming up

lShift lever: P or N (A/T), Neutral (M/T)

lIdle speedNo load 0.50 - 0.70 msec

Blower fan switch: ON

Rear window defogger switch: ON0.50 - 0.80 msec

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

4

5V

GFuel injector power supply

(For cylinder No. 1 and 4)

Fuel injector power supply

(For cylinder No. 2 and 3)[Engine is running]

lWarm-up condition

lIdle speed

NOTE:

The pulse cycle changes depending on rpm

at idleApproximately 7.5V

[Engine is running]

lWarm-up condition

lEngine speed: 2,000 rpmApproximately 8.0V

21

22

23

24G

P

W

WFuel injector No. 2

Fuel injector No. 2

Fuel injector No. 3

Fuel injector No. 3[Engine is running]

lWarm-up condition

lIdle speed

NOTE:

The pulse cycle changes depending on rpm

at idleApproximately 7.5V

MBIB1295E

MBIB1296E

MBIB1297E