transmission NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 322 of 3171

AT-314

ASSEMBLY

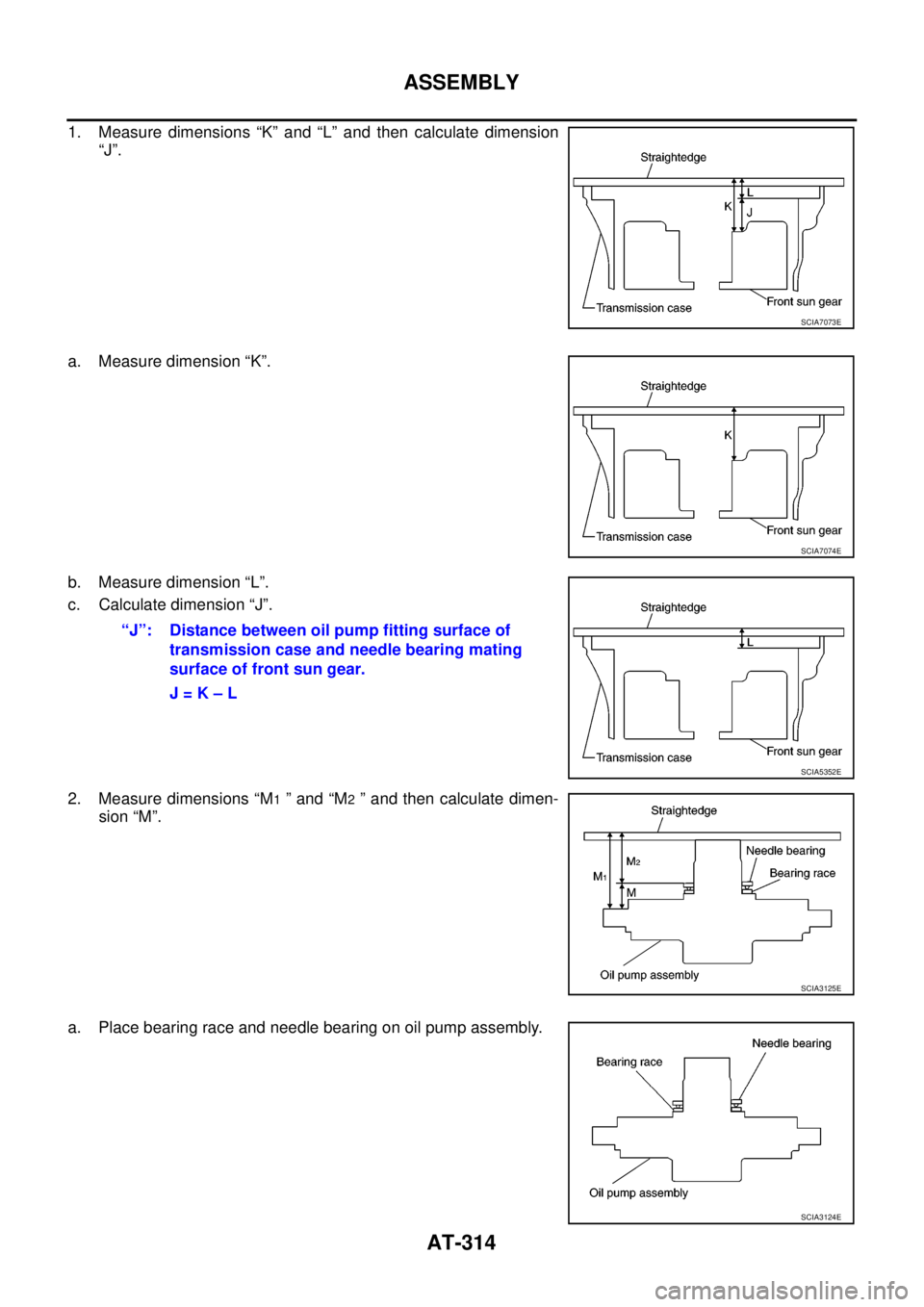

1. Measure dimensions “K” and “L” and then calculate dimension

“J”.

a. Measure dimension “K”.

b. Measure dimension “L”.

c. Calculate dimension “J”.

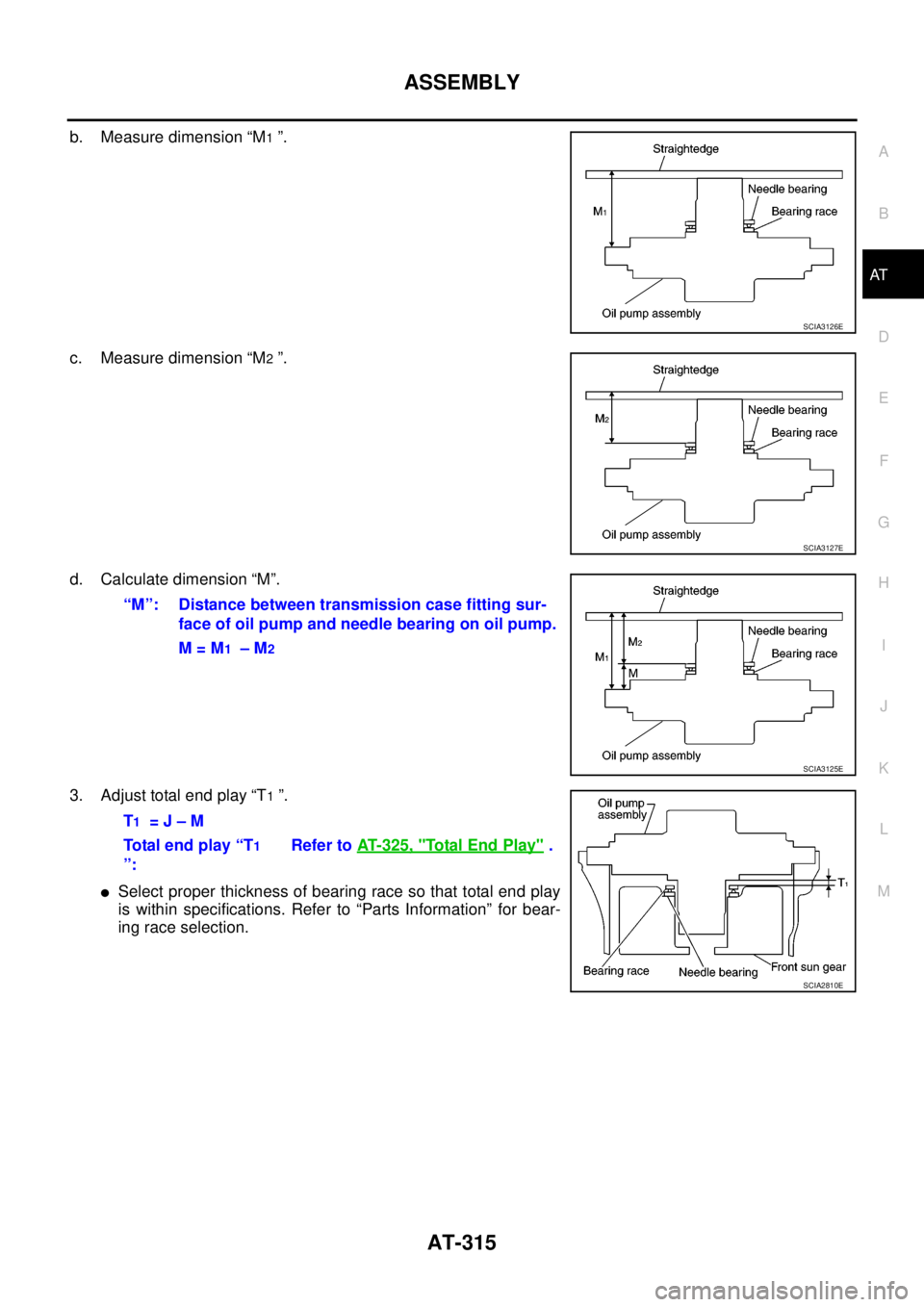

2. Measure dimensions “M

1”and“M2” and then calculate dimen-

sion “M”.

a. Place bearing race and needle bearing on oil pump assembly.

SCIA7073E

SCIA7074E

“J”: Distance between oil pump fitting surface of

transmission case and needle bearing mating

surface of front sun gear.

J=K–L

SCIA5352E

SCIA3125E

SCIA3124E

Page 323 of 3171

ASSEMBLY

AT-315

D

E

F

G

H

I

J

K

L

MA

B

AT

b. Measure dimension “M1”.

c. Measure dimension “M

2”.

d. Calculate dimension “M”.

3. Adjust total end play “T

1”.

lSelect proper thickness of bearing race so that total end play

is within specifications. Refer to “Parts Information” for bear-

ing race selection.

SCIA3126E

SCIA3127E

“M”: Distance between transmission case fitting sur-

face of oil pump and needle bearing on oil pump.

M=M

1–M2

SCIA3125E

T1=J–M

Total end play “T

1

”:Refer toAT- 3 2 5 , "

To ta l E n d P l a y".

SCIA2810E

Page 324 of 3171

AT-316

ASSEMBLY

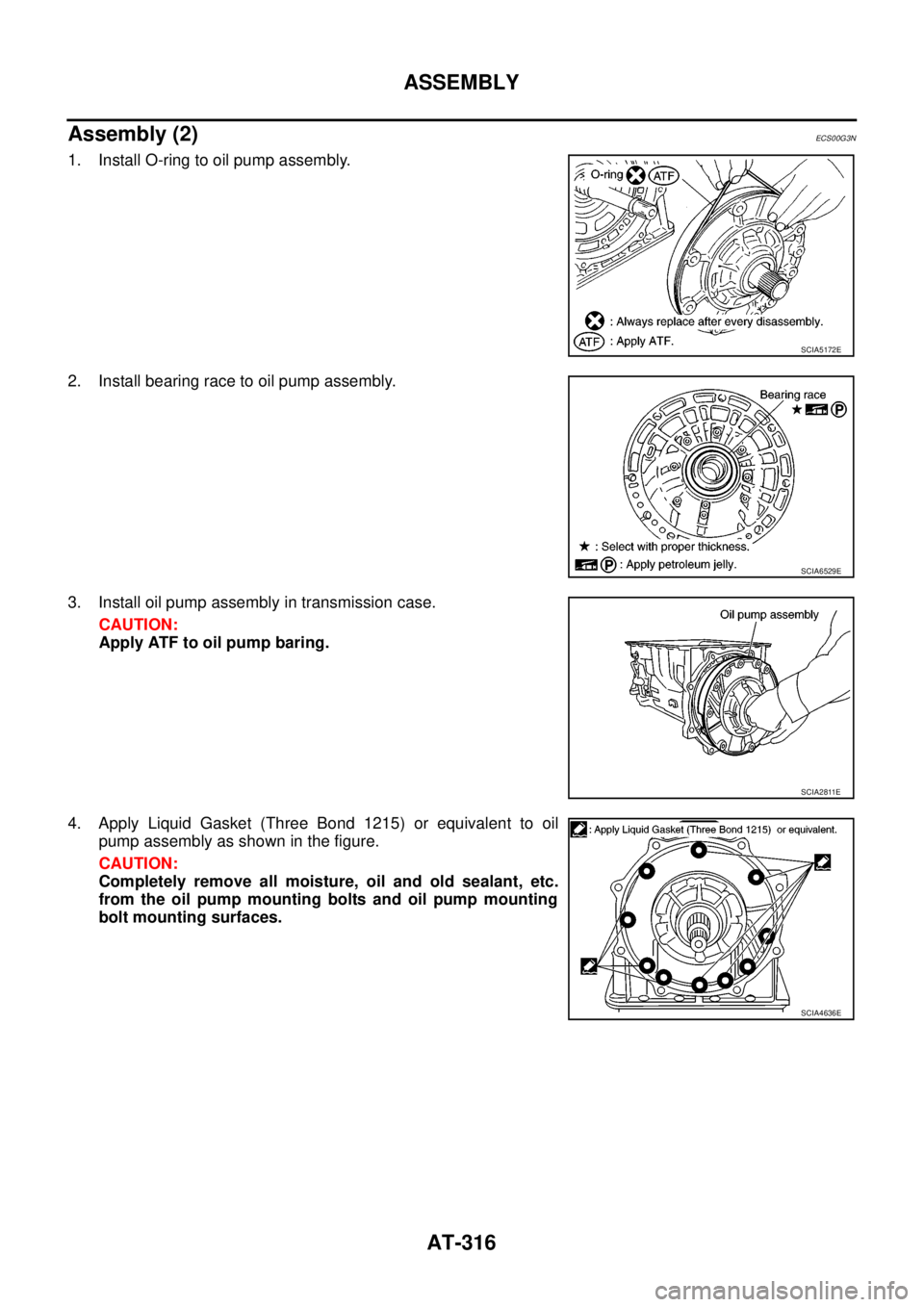

Assembly (2)

ECS00G3N

1. Install O-ring to oil pump assembly.

2. Install bearing race to oil pump assembly.

3. Install oil pump assembly in transmission case.

CAUTION:

Apply ATF to oil pump baring.

4. Apply Liquid Gasket (Three Bond 1215) or equivalent to oil

pump assembly as shown in the figure.

CAUTION:

Completely remove all moisture, oil and old sealant, etc.

from the oil pump mounting bolts and oil pump mounting

bolt mounting surfaces.

SCIA5172E

SCIA6529E

SCIA2811E

SCIA4636E

Page 325 of 3171

ASSEMBLY

AT-317

D

E

F

G

H

I

J

K

L

MA

B

AT

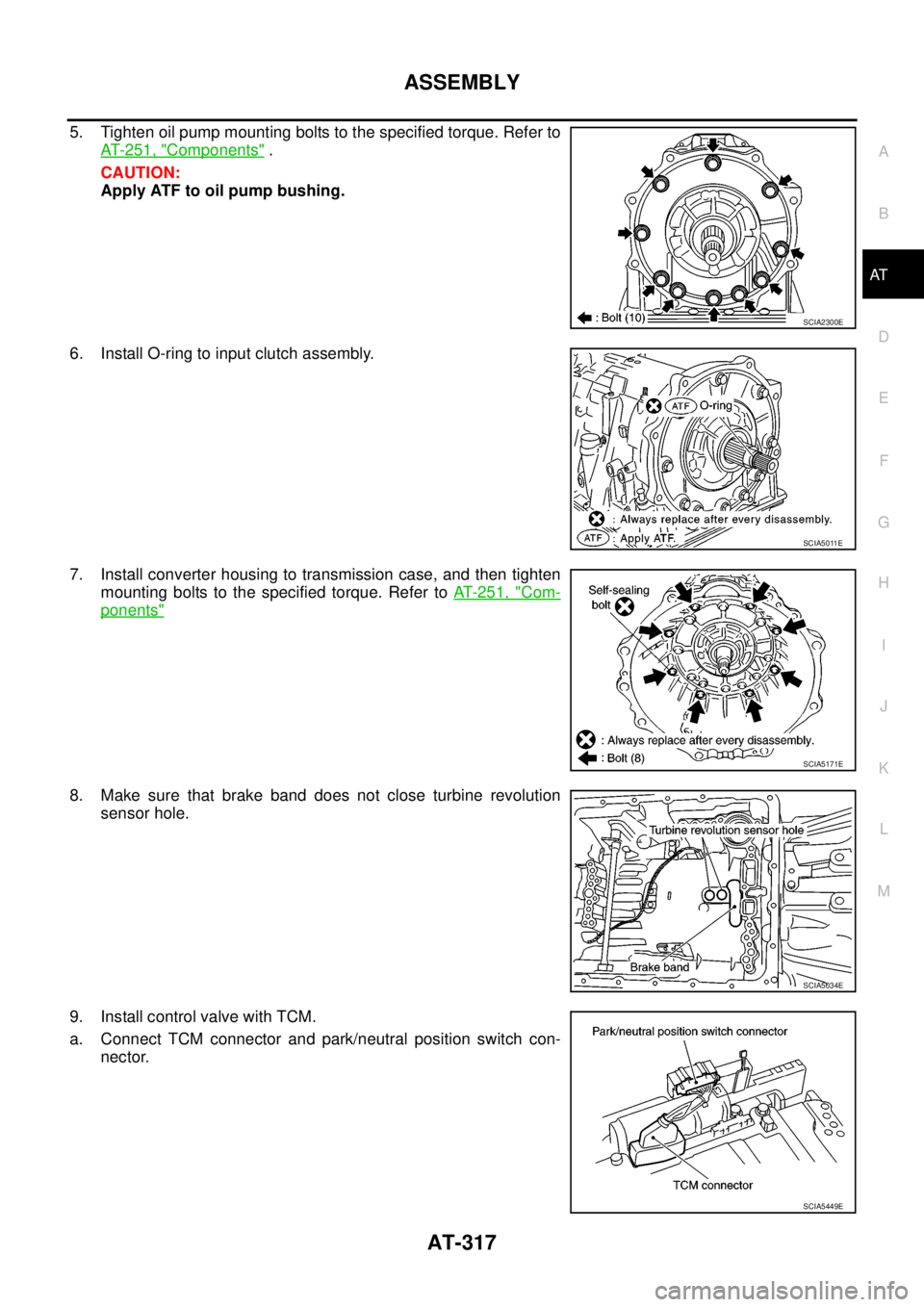

5. Tighten oil pump mounting bolts to the specified torque. Refer to

AT- 2 5 1 , "

Components".

CAUTION:

Apply ATF to oil pump bushing.

6. Install O-ring to input clutch assembly.

7. Install converter housing to transmission case, and then tighten

mounting bolts to the specified torque. Refer toAT- 2 5 1 , "

Com-

ponents"

8. Make sure that brake band does not close turbine revolution

sensor hole.

9. Install control valve with TCM.

a. Connect TCM connector and park/neutral position switch con-

nector.

SCIA2300E

SCIA5011E

SCIA5171E

SCIA5034E

SCIA5449E

Page 327 of 3171

ASSEMBLY

AT-319

D

E

F

G

H

I

J

K

L

MA

B

AT

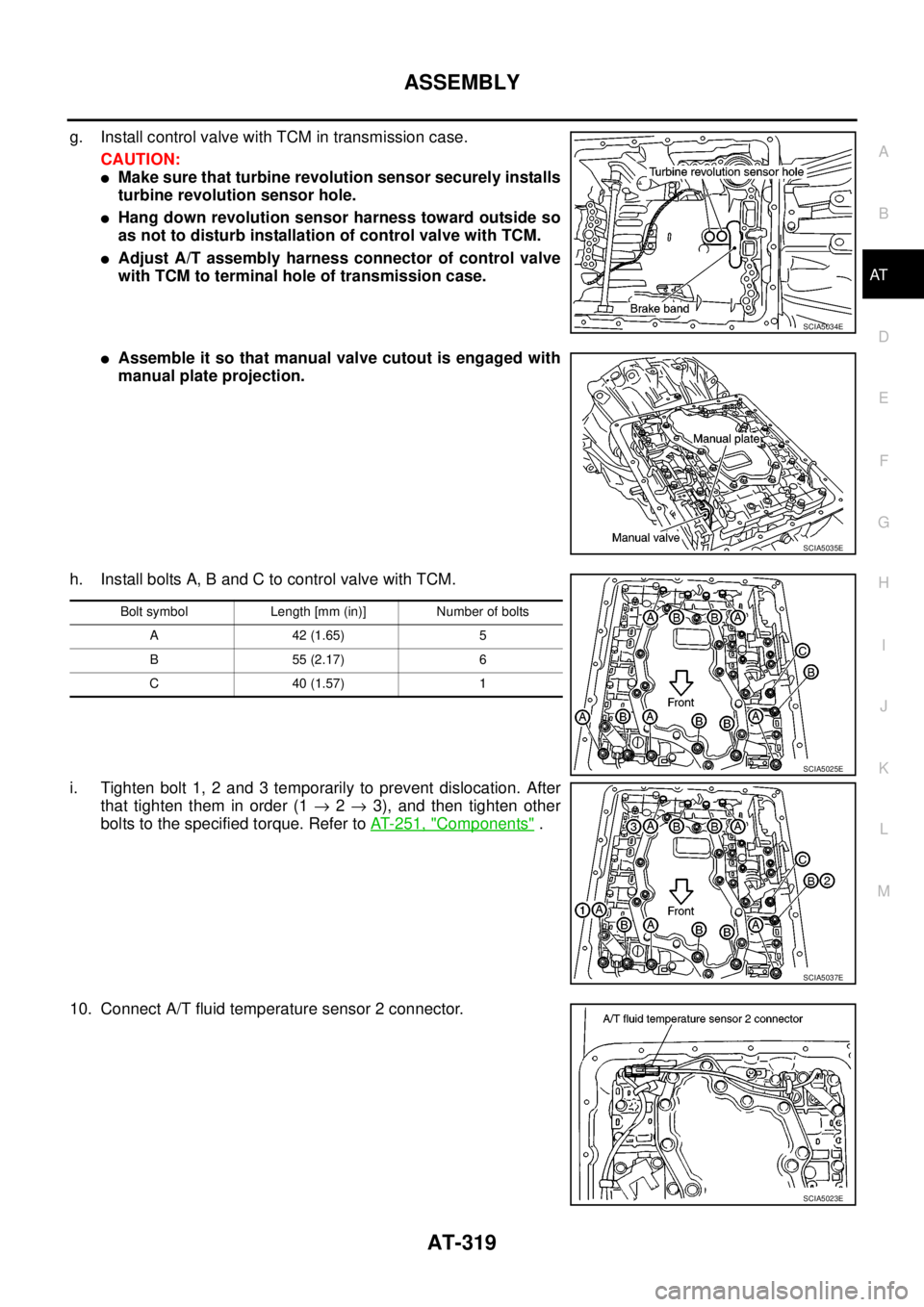

g. Install control valve with TCM in transmission case.

CAUTION:

lMake sure that turbine revolution sensor securely installs

turbine revolution sensor hole.

lHang down revolution sensor harness toward outside so

as not to disturb installation of control valve with TCM.

lAdjust A/T assembly harness connector of control valve

with TCM to terminal hole of transmission case.

lAssemble it so that manual valve cutout is engaged with

manual plate projection.

h. Install bolts A, B and C to control valve with TCM.

i. Tighten bolt 1, 2 and 3 temporarily to prevent dislocation. After

that tighten them in order (1®2®3), and then tighten other

bolts to the specified torque. Refer toAT- 2 5 1 , "

Components".

10. Connect A/T fluid temperature sensor 2 connector.

SCIA5034E

SCIA5035E

Bolt symbol Length [mm (in)] Number of bolts

A42(1.65) 5

B55(2.17) 6

C40(1.57) 1

SCIA5025E

SCIA5037E

SCIA5023E

Page 329 of 3171

ASSEMBLY

AT-321

D

E

F

G

H

I

J

K

L

MA

B

AT

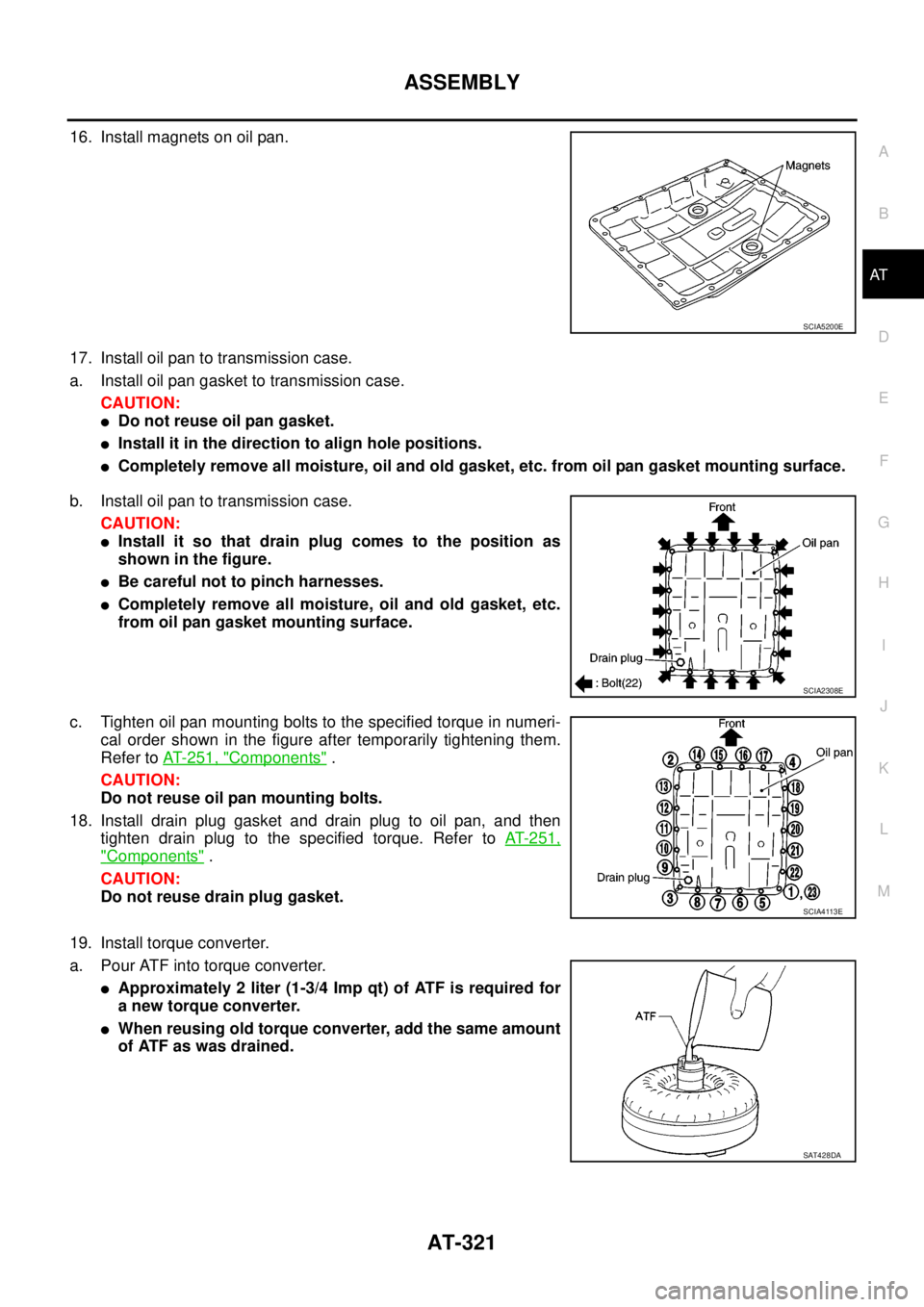

16. Install magnets on oil pan.

17. Install oil pan to transmission case.

a. Install oil pan gasket to transmission case.

CAUTION:

lDo not reuse oil pan gasket.

lInstall it in the direction to align hole positions.

lCompletely remove all moisture, oil and old gasket, etc. from oil pan gasket mounting surface.

b. Install oil pan to transmission case.

CAUTION:

lInstall it so that drain plug comes to the position as

shown in the figure.

lBe careful not to pinch harnesses.

lCompletely remove all moisture, oil and old gasket, etc.

from oil pan gasket mounting surface.

c. Tighten oil pan mounting bolts to the specified torque in numeri-

cal order shown in the figure after temporarily tightening them.

Refer toAT- 2 5 1 , "

Components".

CAUTION:

Do not reuse oil pan mounting bolts.

18. Install drain plug gasket and drain plug to oil pan, and then

tighten drain plug to the specified torque. Refer toAT-251,

"Components".

CAUTION:

Do not reuse drain plug gasket.

19. Install torque converter.

a. Pour ATF into torque converter.

lApproximately 2 liter (1-3/4 Imp qt) of ATF is required for

a new torque converter.

lWhen reusing old torque converter, add the same amount

of ATF as was drained.

SCIA5200E

SCIA2308E

SCIA4113E

SAT428DA

Page 331 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

AT-323

D

E

F

G

H

I

J

K

L

MA

B

AT

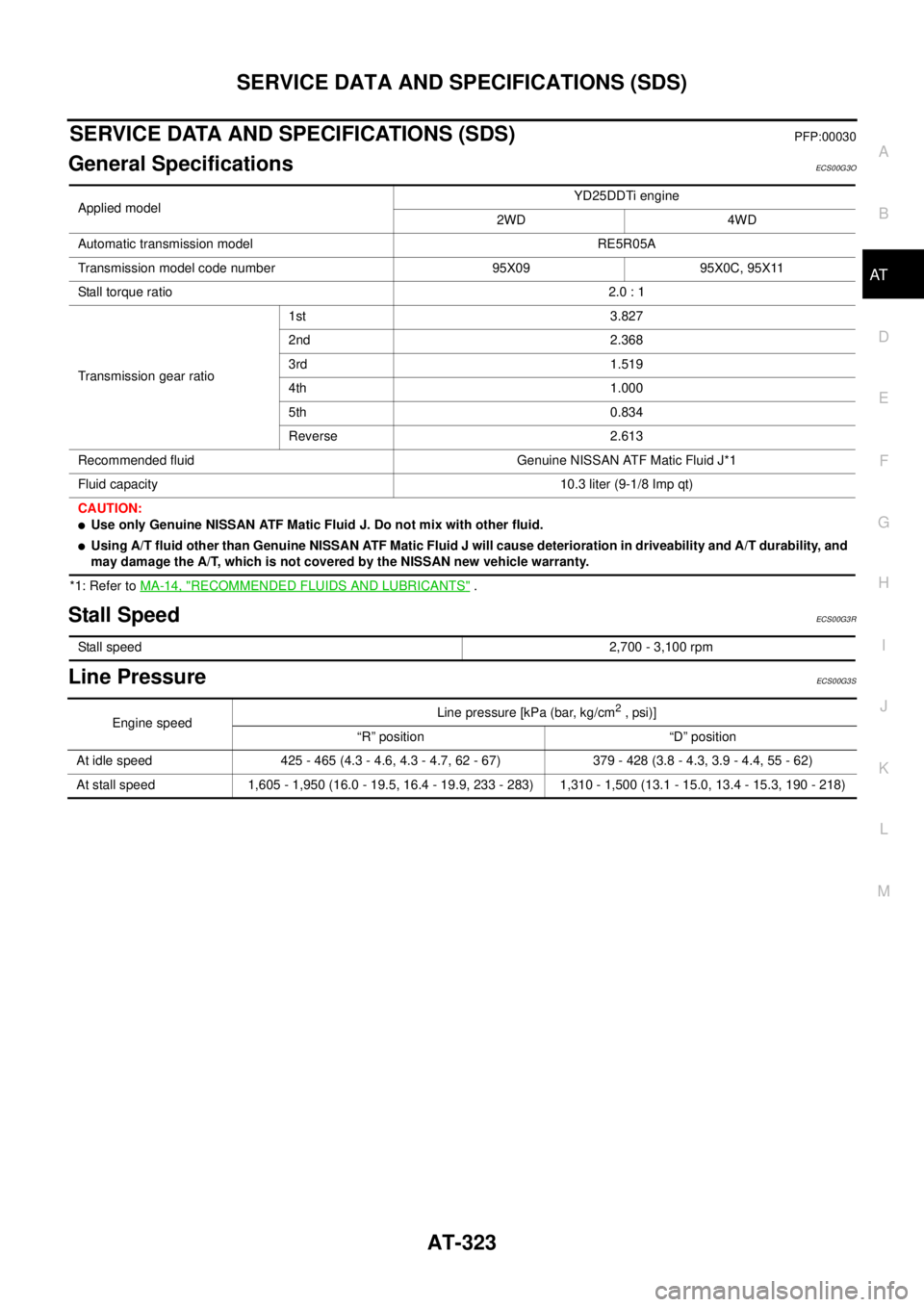

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsECS00G3O

*1: Refer toMA-14, "RECOMMENDED FLUIDS AND LUBRICANTS".

Stall SpeedECS00G3R

Line PressureECS00G3S

Applied modelYD25DDTi engine

2WD 4WD

Automatic transmission model RE5R05A

Transmission model code number 95X09 95X0C, 95X11

Stall torque ratio2.0 : 1

Transmission gear ratio1st 3.827

2nd 2.368

3rd 1.519

4th 1.000

5th 0.834

Reverse 2.613

Recommended fluid Genuine NISSAN ATF Matic Fluid J*1

Fluid capacity 10.3 liter (9-1/8 Imp qt)

CAUTION:

lUse only Genuine NISSAN ATF Matic Fluid J. Do not mix with other fluid.

lUsing A/T fluid other than Genuine NISSAN ATF Matic Fluid J will cause deterioration in driveability and A/T durability, and

may damage the A/T, which is not covered by the NISSAN new vehicle warranty.

Stall speed2,700 - 3,100 rpm

Engine speedLine pressure [kPa (bar, kg/cm2,psi)]

“R” position “D” position

At idle speed 425 - 465 (4.3 - 4.6, 4.3 - 4.7, 62 - 67) 379 - 428 (3.8 - 4.3, 3.9 - 4.4, 55 - 62)

At stall speed 1,605 - 1,950 (16.0 - 19.5, 16.4 - 19.9, 233 - 283) 1,310 - 1,500 (13.1 - 15.0, 13.4 - 15.3, 190 - 218)

Page 521 of 3171

SYSTEM DESCRIPTION

AV-33

C

D

E

F

G

H

I

J

L

MA

B

AV

CAN CommunicationEKS00Q6A

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. Refer toLAN-30, "

CAN

Communication Unit".

Page 609 of 3171

POWERDOORLOCKSYSTEM

BL-25

C

D

E

F

G

H

J

K

L

MA

B

BL

Door lock indicator timer

Door lock indicator timer is designed to reacts and shut down the indicator. The default timer values are 1

minute and 30 minutes.

lWhen the lock operation is activated by keyfob or auto door lock (for further details, refer toBL-92, "Auto

Re-lock Function"), then the illuminate time is set to 1 minute.

lWhen the lock operation is activated by door lock/unlock switch, then the timer is set to 30 minutes.

NOTE:

When the 30 minutes timer is active and ignition switch is turned ON, the indicator illuminate for perma-

nently, unless ignition switch is turned OFF then timer will be reset back to 30 minutes.

CAN Communication System DescriptionEIS00D7T

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitEIS00D7U

Refer toLAN-23, "CAN COMMUNICATION".

Page 643 of 3171

POWER DOOR LOCK — SUPER LOCK —

BL-59

C

D

E

F

G

H

J

K

L

MA

B

BL

Door Lock Warning Function

Under following conditions lock actuators will not response and buzzer warning will beeps while pressing door

lock/unlock switch in LOCK direction.

lIgnition switch is turned OFF

lMechanical key is out of ignition key cylinder

lAny door is opened (except driver side door)

Key Reminder Function

Under following conditions lock actuators will lock the door once, but then immediately unlock all doors and

buzzer warning will beeps while pressing door lock/unlock switch in LOCK direction.

lIgnition switch is turned OFF

lMechanical key is inserted in ignition key cylinder

lDriver side door is opened

Door Lock/Unlock Switch Indicator

The Door lock/unlock switch indicates door lock status. The indicator will illuminate when a lock operation is

accomplish, during this state, if any door is open, the indicator will turn OFF.

Door Lock Indicator Timer

Door lock indicator timer is designed to reacts and shut down the indicator. The default timer values are 1

minute and 30 minutes.

lWhen the lock operation is activated by keyfob or auto door lock (for further details refer toBL-92, "Auto

Re-lock Function"), then the illuminate time is set to 1 minute.

lWhen the lock operation is activated by door lock/unlock switch, then the timer is set to 30 minutes.

NOTE:

When the 30 minutes timer is active and ignition switch is turned ON, then the indicator illuminate for per-

manently unless ignition switch is turned OFF then timer will be reset back to 30 minutes.

CAN Communication System DescriptionEIS00DX1

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitEIS00DX2

Refer toLAN-23, "CAN COMMUNICATION".