transmission fluid NISSAN NAVARA 2005 Repair Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 256 of 3171

AT-248

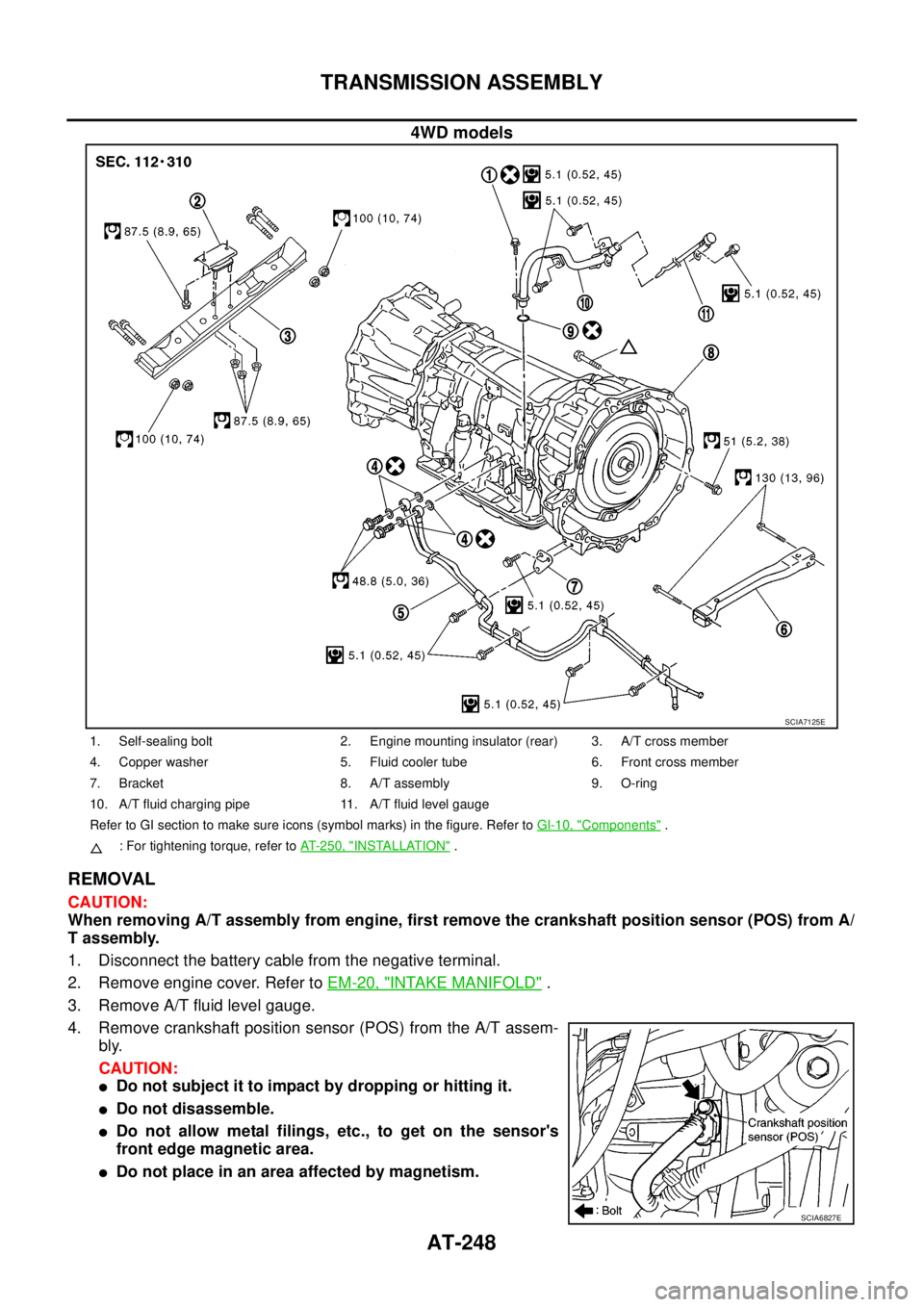

TRANSMISSION ASSEMBLY

4WD models

REMOVAL

CAUTION:

When removing A/T assembly from engine, first remove the crankshaft position sensor (POS) from A/

T assembly.

1. Disconnect the battery cable from the negative terminal.

2. Remove engine cover. Refer toEM-20, "

INTAKE MANIFOLD".

3. Remove A/T fluid level gauge.

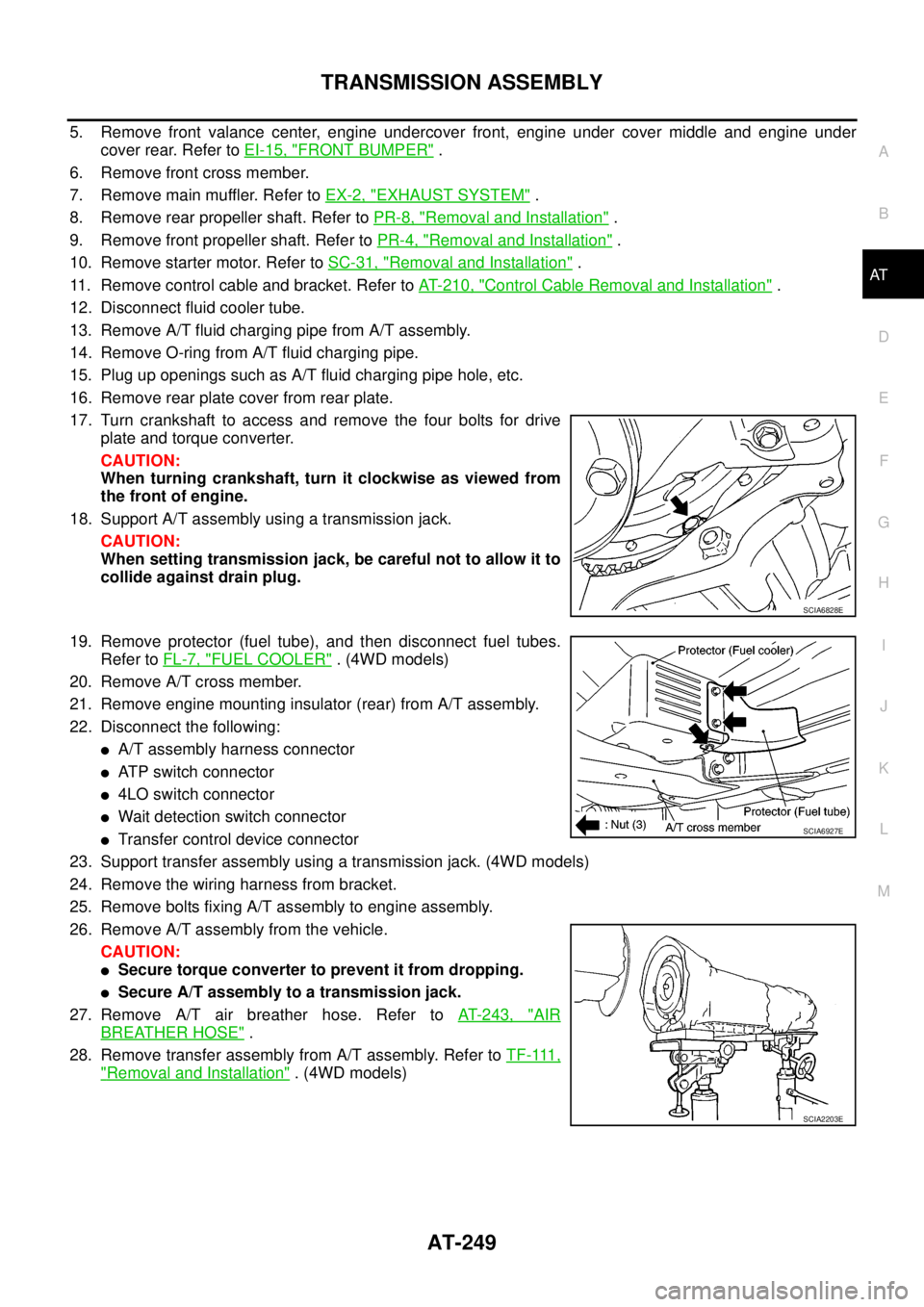

4. Remove crankshaft position sensor (POS) from the A/T assem-

bly.

CAUTION:

lDo not subject it to impact by dropping or hitting it.

lDo not disassemble.

lDo not allow metal filings, etc., to get on the sensor's

front edge magnetic area.

lDo not place in an area affected by magnetism.

SCIA7125E

1. Self-sealing bolt 2. Engine mounting insulator (rear) 3. A/T cross member

4. Copper washer 5. Fluid cooler tube 6. Front cross member

7. Bracket 8. A/T assembly 9. O-ring

10. A/T fluid charging pipe 11. A/T fluid level gauge

Refer to GI section to make sure icons (symbol marks) in the figure. Refer toGI-10, "

Components".

: For tightening torque, refer toAT-250, "

INSTALLATION".

SCIA6827E

Page 257 of 3171

TRANSMISSION ASSEMBLY

AT-249

D

E

F

G

H

I

J

K

L

MA

B

AT

5. Remove front valance center, engine undercover front, engine under cover middle and engine under

coverrear.RefertoEI-15, "

FRONT BUMPER".

6. Remove front cross member.

7. Remove main muffler. Refer toEX-2, "

EXHAUST SYSTEM".

8. Remove rear propeller shaft. Refer toPR-8, "

Removal and Installation".

9. Remove front propeller shaft. Refer toPR-4, "

Removal and Installation".

10. Remove starter motor. Refer toSC-31, "

Removal and Installation".

11. Remove control cable and bracket. Refer toAT- 2 1 0 , "

Control Cable Removal and Installation".

12. Disconnect fluid cooler tube.

13. Remove A/T fluid charging pipe from A/T assembly.

14. Remove O-ring from A/T fluid charging pipe.

15. Plug up openings such as A/T fluid charging pipe hole, etc.

16. Remove rear plate cover from rear plate.

17. Turn crankshaft to access and remove the four bolts for drive

plate and torque converter.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of engine.

18. Support A/T assembly using a transmission jack.

CAUTION:

When setting transmission jack, be careful not to allow it to

collide against drain plug.

19. Remove protector (fuel tube), and then disconnect fuel tubes.

Refer toFL-7, "

FUEL COOLER". (4WD models)

20. Remove A/T cross member.

21. Remove engine mounting insulator (rear) from A/T assembly.

22. Disconnect the following:

lA/T assembly harness connector

lATP switch connector

l4LO switch connector

lWait detection switch connector

lTransfer control device connector

23. Support transfer assembly using a transmission jack. (4WD models)

24. Remove the wiring harness from bracket.

25. Remove bolts fixing A/T assembly to engine assembly.

26. Remove A/T assembly from the vehicle.

CAUTION:

lSecure torque converter to prevent it from dropping.

lSecure A/T assembly to a transmission jack.

27. Remove A/T air breather hose. Refer toAT- 2 4 3 , "

AIR

BREATHER HOSE".

28. Remove transfer assembly from A/T assembly. Refer toT F - 111 ,

"Removal and Installation". (4WD models)

SCIA6828E

SCIA6927E

SCIA2203E

Page 258 of 3171

AT-250

TRANSMISSION ASSEMBLY

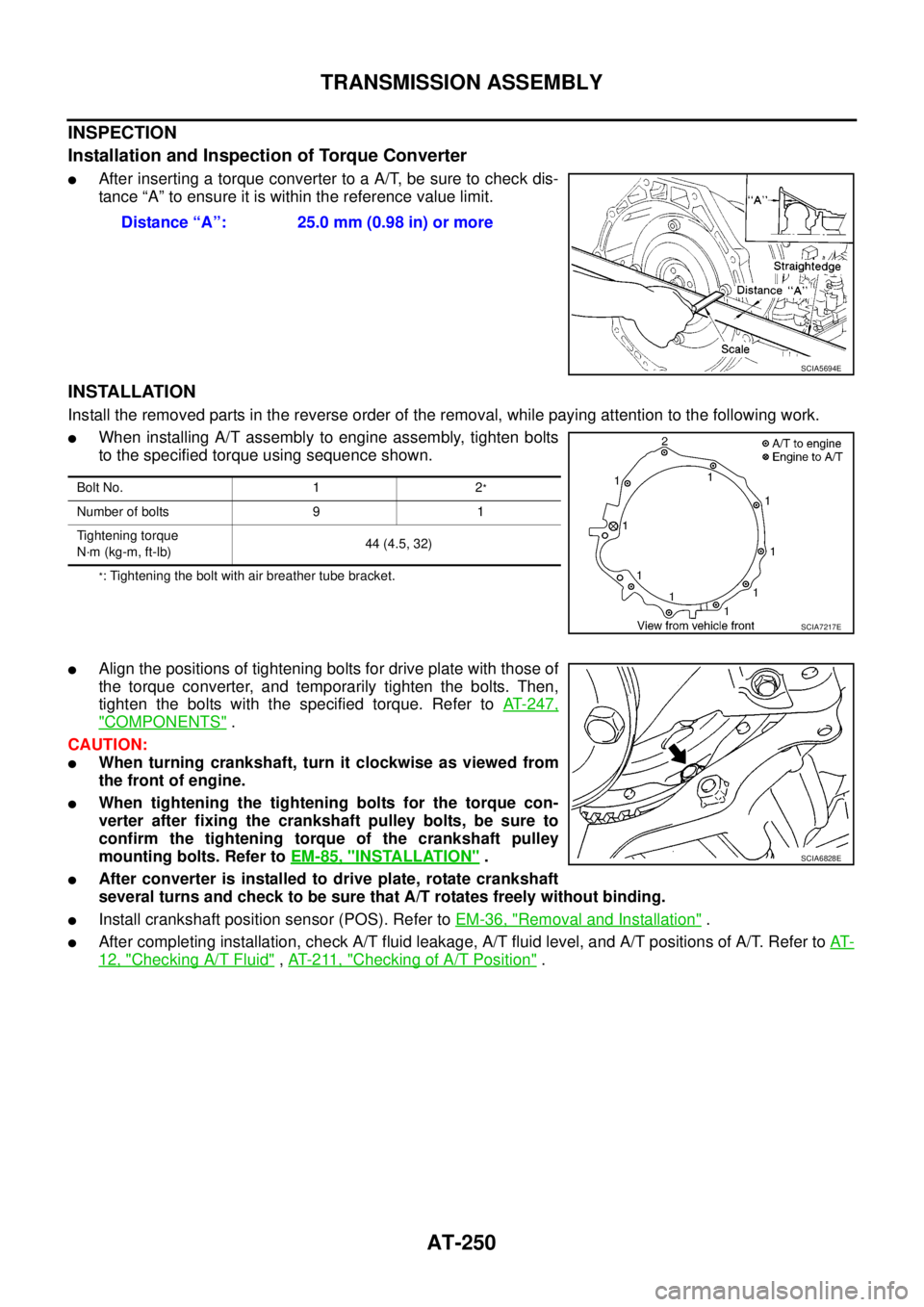

INSPECTION

Installation and Inspection of Torque Converter

lAfter inserting a torque converter to a A/T, be sure to check dis-

tance “A” to ensure it is within the reference value limit.

INSTALLATION

Install the removed parts in the reverse order of the removal, while paying attention to the following work.

lWhen installing A/T assembly to engine assembly, tighten bolts

to the specified torque using sequence shown.

*: Tightening the bolt with air breather tube bracket.

lAlign the positions of tightening bolts for drive plate with those of

the torque converter, and temporarily tighten the bolts. Then,

tighten the bolts with the specified torque. Refer toAT-247,

"COMPONENTS".

CAUTION:

lWhen turning crankshaft, turn it clockwise as viewed from

the front of engine.

lWhen tightening the tightening bolts for the torque con-

verter after fixing the crankshaft pulley bolts, be sure to

confirm the tightening torque of the crankshaft pulley

mounting bolts. Refer toEM-85, "

INSTALLATION".

lAfter converter is installed to drive plate, rotate crankshaft

several turns and check to be sure that A/T rotates freely without binding.

lInstall crankshaft position sensor (POS). Refer toEM-36, "Removal and Installation".

lAfter completing installation, check A/T fluid leakage, A/T fluid level, and A/T positions of A/T. Refer toAT-

12, "Checking A/T Fluid",AT- 2 11 , "Checking of A/T Position". Distance “A”: 25.0 mm (0.98 in) or more

SCIA5694E

Bolt No. 1 2*

Number of bolts 9 1

Tightening torque

N·m (kg-m, ft-lb)44 (4.5, 32)

SCIA7217E

SCIA6828E

Page 264 of 3171

AT-256

OVERHAUL

7. Pawl shaft 8. Seal ring 9. Needle bearing

10. Revolution sensor 11. Parking gear 12. Output shaft

13. Bearing race 14. Needle bearing 15. Manual plate

16. Parking rod 17. Manual shaft oil seal 18. Manual shaft

19. O-ring 20. Band servo anchor end pin 21. Detent spring

22. Spacer 23. Seal ring 24. Snap ring

25. Return spring 26. O-ring 27. Servo assembly

28. Snap ring 29. Sub-harness 30. Control valve with TCM

31. Bracket 32. A/T fluid temperature sensor 2 33. Oil pan

34. Magnet 35. Drain plug 36. Drain plug gasket

37. Oil pan mounting bolt 38. Oil pan gasket 39. Terminal cord assembly

40. O-ring 41. Retaining pin 42. Transmission case

Refer to GI section to make sure icons (symbol marks) in the figure. Refer toGI-10, "

Components".

However, refer to the following symbols for others.

*:Apply Anaerobic Liquid Gasket (Loctite 518) or equivalent.

Page 266 of 3171

AT-258

OVERHAUL

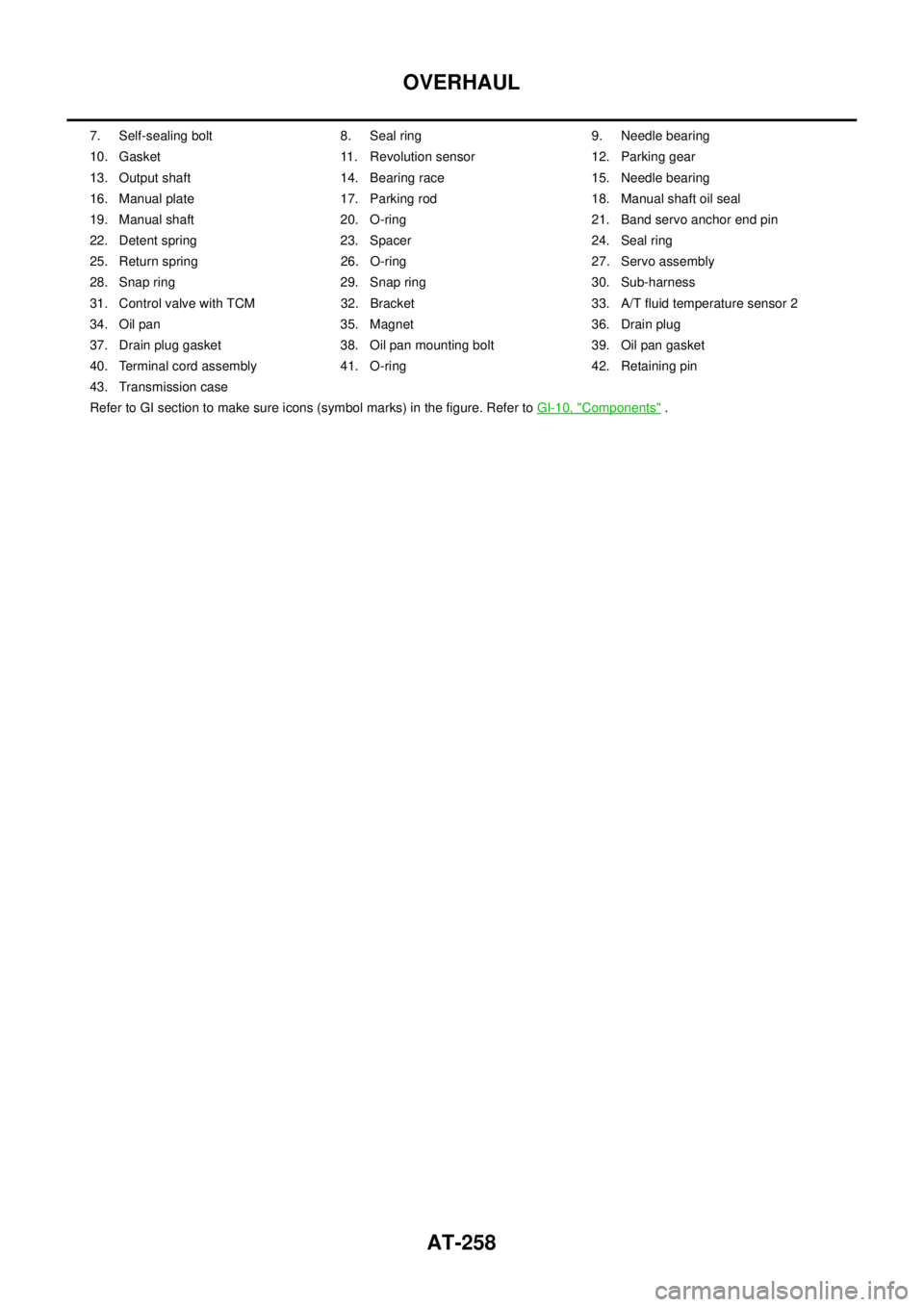

7. Self-sealing bolt 8. Seal ring 9. Needle bearing

10. Gasket 11. Revolution sensor 12. Parking gear

13. Output shaft 14. Bearing race 15. Needle bearing

16. Manual plate 17. Parking rod 18. Manual shaft oil seal

19. Manual shaft 20. O-ring 21. Band servo anchor end pin

22. Detent spring 23. Spacer 24. Seal ring

25. Return spring 26. O-ring 27. Servo assembly

28. Snap ring 29. Snap ring 30. Sub-harness

31. Control valve with TCM 32. Bracket 33. A/T fluid temperature sensor 2

34. Oil pan 35. Magnet 36. Drain plug

37. Drain plug gasket 38. Oil pan mounting bolt 39. Oil pan gasket

40. Terminal cord assembly 41. O-ring 42. Retaining pin

43. Transmission case

Refer to GI section to make sure icons (symbol marks) in the figure. Refer toGI-10, "

Components".

Page 278 of 3171

AT-270

DISASSEMBLY

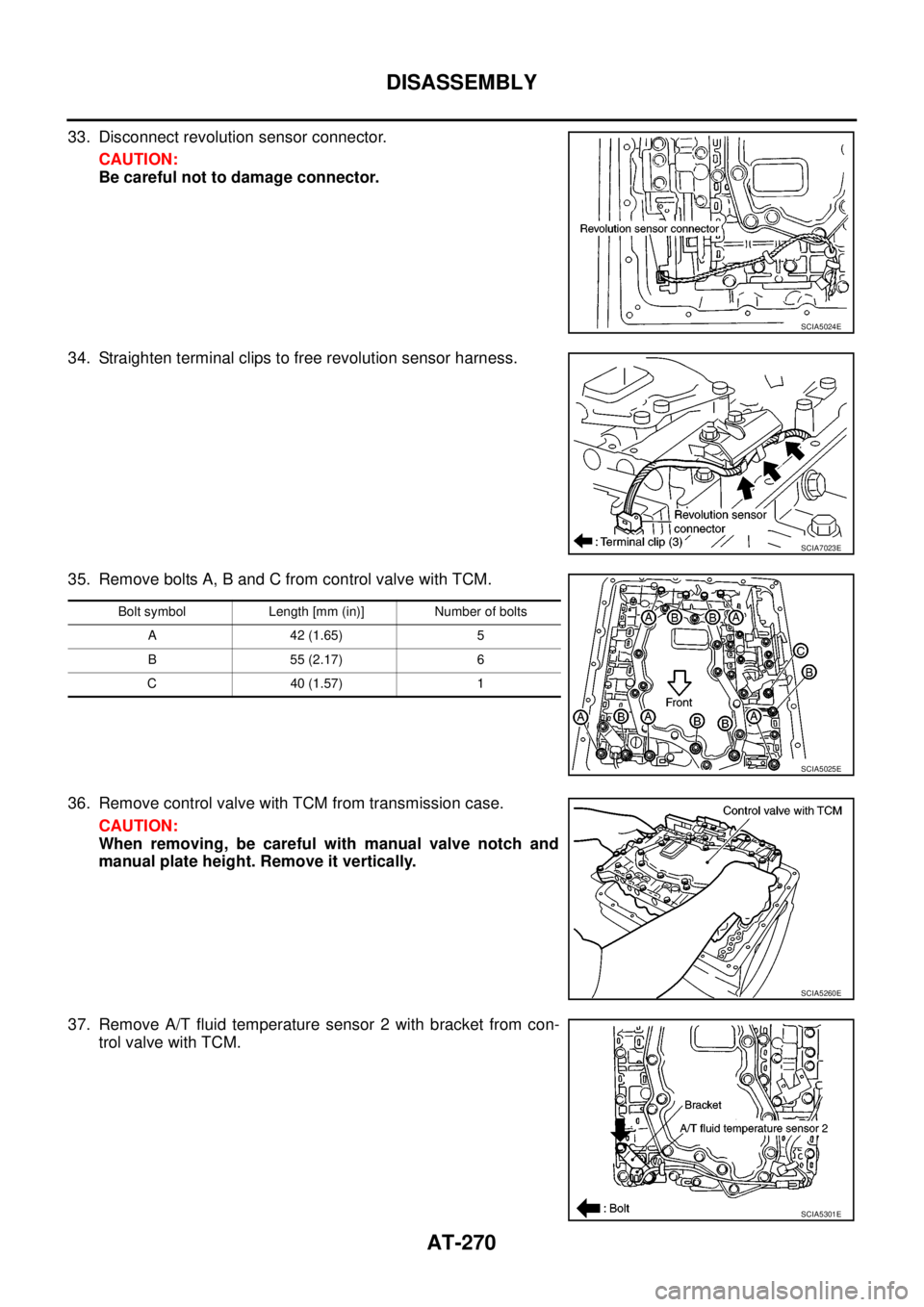

33. Disconnect revolution sensor connector.

CAUTION:

Be careful not to damage connector.

34. Straighten terminal clips to free revolution sensor harness.

35. Remove bolts A, B and C from control valve with TCM.

36. Remove control valve with TCM from transmission case.

CAUTION:

When removing, be careful with manual valve notch and

manual plate height. Remove it vertically.

37. Remove A/T fluid temperature sensor 2 with bracket from con-

trol valve with TCM.

SCIA5024E

SCIA7023E

Bolt symbol Length [mm (in)] Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA5025E

SCIA5260E

SCIA5301E

Page 327 of 3171

ASSEMBLY

AT-319

D

E

F

G

H

I

J

K

L

MA

B

AT

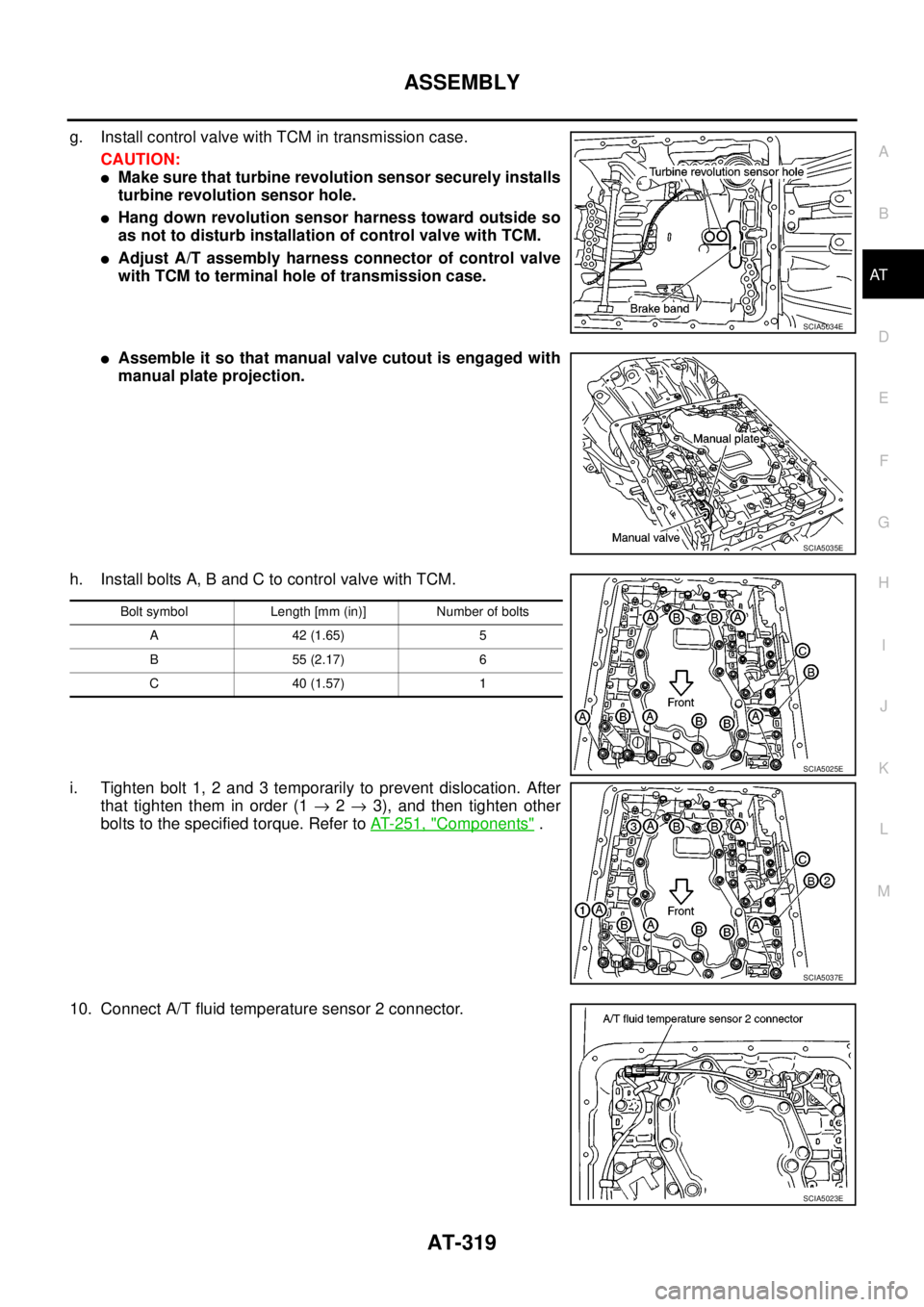

g. Install control valve with TCM in transmission case.

CAUTION:

lMake sure that turbine revolution sensor securely installs

turbine revolution sensor hole.

lHang down revolution sensor harness toward outside so

as not to disturb installation of control valve with TCM.

lAdjust A/T assembly harness connector of control valve

with TCM to terminal hole of transmission case.

lAssemble it so that manual valve cutout is engaged with

manual plate projection.

h. Install bolts A, B and C to control valve with TCM.

i. Tighten bolt 1, 2 and 3 temporarily to prevent dislocation. After

that tighten them in order (1®2®3), and then tighten other

bolts to the specified torque. Refer toAT- 2 5 1 , "

Components".

10. Connect A/T fluid temperature sensor 2 connector.

SCIA5034E

SCIA5035E

Bolt symbol Length [mm (in)] Number of bolts

A42(1.65) 5

B55(2.17) 6

C40(1.57) 1

SCIA5025E

SCIA5037E

SCIA5023E

Page 331 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

AT-323

D

E

F

G

H

I

J

K

L

MA

B

AT

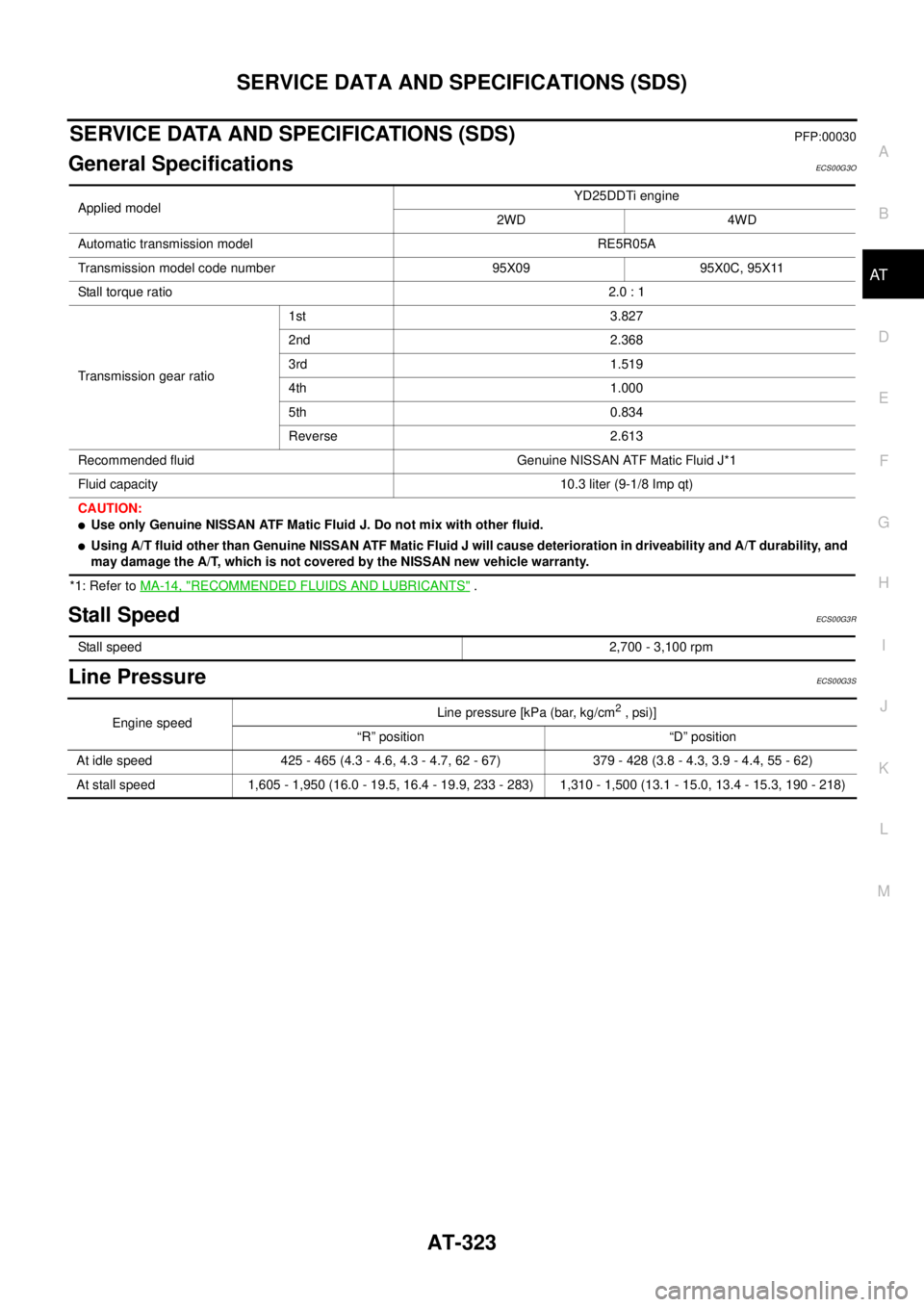

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsECS00G3O

*1: Refer toMA-14, "RECOMMENDED FLUIDS AND LUBRICANTS".

Stall SpeedECS00G3R

Line PressureECS00G3S

Applied modelYD25DDTi engine

2WD 4WD

Automatic transmission model RE5R05A

Transmission model code number 95X09 95X0C, 95X11

Stall torque ratio2.0 : 1

Transmission gear ratio1st 3.827

2nd 2.368

3rd 1.519

4th 1.000

5th 0.834

Reverse 2.613

Recommended fluid Genuine NISSAN ATF Matic Fluid J*1

Fluid capacity 10.3 liter (9-1/8 Imp qt)

CAUTION:

lUse only Genuine NISSAN ATF Matic Fluid J. Do not mix with other fluid.

lUsing A/T fluid other than Genuine NISSAN ATF Matic Fluid J will cause deterioration in driveability and A/T durability, and

may damage the A/T, which is not covered by the NISSAN new vehicle warranty.

Stall speed2,700 - 3,100 rpm

Engine speedLine pressure [kPa (bar, kg/cm2,psi)]

“R” position “D” position

At idle speed 425 - 465 (4.3 - 4.6, 4.3 - 4.7, 62 - 67) 379 - 428 (3.8 - 4.3, 3.9 - 4.4, 55 - 62)

At stall speed 1,605 - 1,950 (16.0 - 19.5, 16.4 - 19.9, 233 - 283) 1,310 - 1,500 (13.1 - 15.0, 13.4 - 15.3, 190 - 218)

Page 865 of 3171

CL-1

CLUTCH

C TRANSMISSION/TRANSAXLE

CONTENTS

D

E

F

G

H

I

J

K

L

M

SECTIONCL

A

B

CL

CLUTCH

PRECAUTIONS .......................................................... 2

Service Notice or Precautions .................................. 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 3

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 5

NVH Troubleshooting Chart ..................................... 5

CLUTCH PEDAL ........................................................ 6

On-Vehicle Inspection and Adjustment .................... 6

Removal and Installation .......................................... 7

COMPONENTS .................................................... 7

REMOVAL ............................................................. 7

INSPECTION AFTER REMOVAL ......................... 7

INSTALLATION ..................................................... 7

CLUTCH FLUID .......................................................... 8

Air Bleeding Procedure ............................................ 8

CLUTCH MASTER CYLINDER .................................. 9

Components ............................................................. 9

Removal and Installation .......................................... 9

REMOVAL ............................................................. 9

INSTALLATION ..................................................... 9

Disassembly and Assembly ................................... 10

DISASSEMBLY ................................................... 10

INSPECTION AFTER DISASSEMBLY ............... 10

ASSEMBLY ......................................................... 10

OPERATING CYLINDER ...........................................11

Components ............................................................ 11

Removal and Installation ......................................... 11REMOVAL ........................................................... 11

INSTALLATION ................................................... 12

Disassembly and Assembly .................................... 12

DISASSEMBLY ................................................... 12

INSPECTION AFTER DISASSEMBLY ................ 12

ASSEMBLY ......................................................... 12

CLUTCH PIPING ....................................................... 13

Removal and Installation ........................................ 13

CLUTCH RELEASE MECHANISM ........................... 14

Removal and Installation ........................................ 14

COMPONENTS ................................................... 14

REMOVAL ........................................................... 14

INSPECTION AFTER REMOVAL ....................... 15

INSTALLATION ................................................... 15

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL... 17

Removal and Installation ........................................ 17

COMPONENTS ................................................... 17

REMOVAL ........................................................... 17

INSPECTION AND ADJUSTMENT AFTER

REMOVAL ........................................................... 17

INSTALLATION ................................................... 18

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 20

Clutch Control System ............................................ 20

Clutch Master Cylinder ........................................... 20

Clutch Operating Cylinder ...................................... 20

Clutch Disc ............................................................. 20

Clutch Cover ........................................................... 20

Clutch Pedal ........................................................... 20

Page 1447 of 3171

CAMSHAFT

EM-65

C

D

E

F

G

H

I

J

K

L

MA

EM

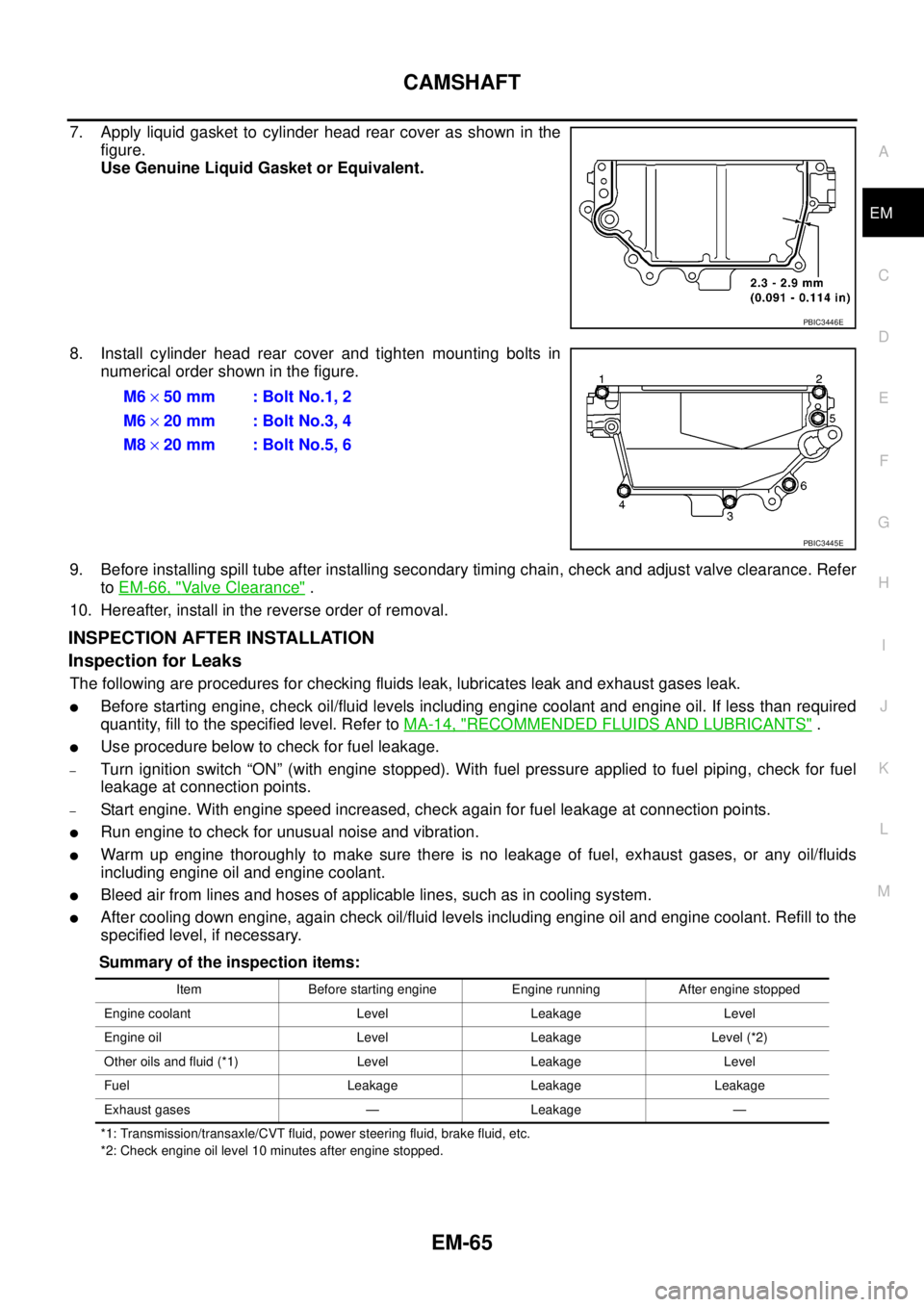

7. Apply liquid gasket to cylinder head rear cover as shown in the

figure.

Use Genuine Liquid Gasket or Equivalent.

8. Install cylinder head rear cover and tighten mounting bolts in

numerical order shown in the figure.

9. Before installing spill tube after installing secondary timing chain, check and adjust valve clearance. Refer

toEM-66, "

Valve Clearance".

10. Hereafter, install in the reverse order of removal.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

lBefore starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer toMA-14, "

RECOMMENDED FLUIDS AND LUBRICANTS".

lUse procedure below to check for fuel leakage.

–Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel

leakage at connection points.

–Start engine. With engine speed increased, check again for fuel leakage at connection points.

lRun engine to check for unusual noise and vibration.

lWarm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids

including engine oil and engine coolant.

lBleed air from lines and hoses of applicable lines, such as in cooling system.

lAfter cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*1: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

*2: Check engine oil level 10 minutes after engine stopped.

PBIC3446E

M6´50 mm : Bolt No.1, 2

M6´20 mm : Bolt No.3, 4

M8´20 mm : Bolt No.5, 6

PBIC3445E

Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level (*2)

Other oils and fluid (*1) Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —