battery NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2865 of 3171

SC-32

STARTING SYSTEM

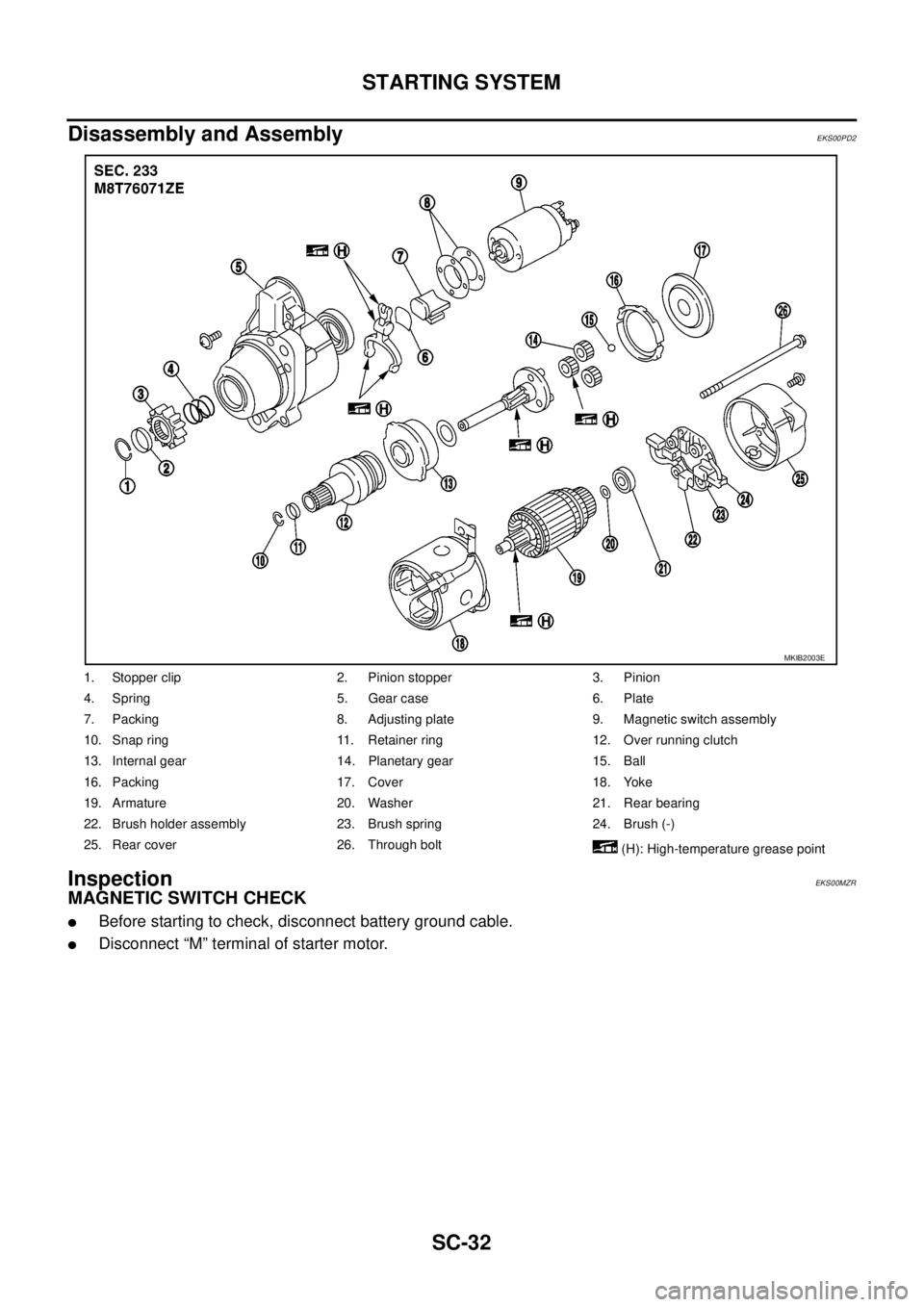

Disassembly and Assembly

EKS00PD2

InspectionEKS00MZR

MAGNETIC SWITCH CHECK

lBefore starting to check, disconnect battery ground cable.

lDisconnect “M” terminal of starter motor.

1. Stopper clip 2. Pinion stopper 3. Pinion

4. Spring 5. Gear case 6. Plate

7. Packing 8. Adjusting plate 9. Magnetic switch assembly

10. Snap ring 11. Retainer ring 12. Over running clutch

13. Internal gear 14. Planetary gear 15. Ball

16. Packing 17. Cover 18. Yoke

19. Armature 20. Washer 21. Rear bearing

22. Brush holder assembly 23. Brush spring 24. Brush (-)

25. Rear cover 26. Through bolt

(H): High-temperature grease point

MKIB2003E

Page 2870 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

SC-37

C

D

E

F

G

H

I

J

L

MA

B

SC

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

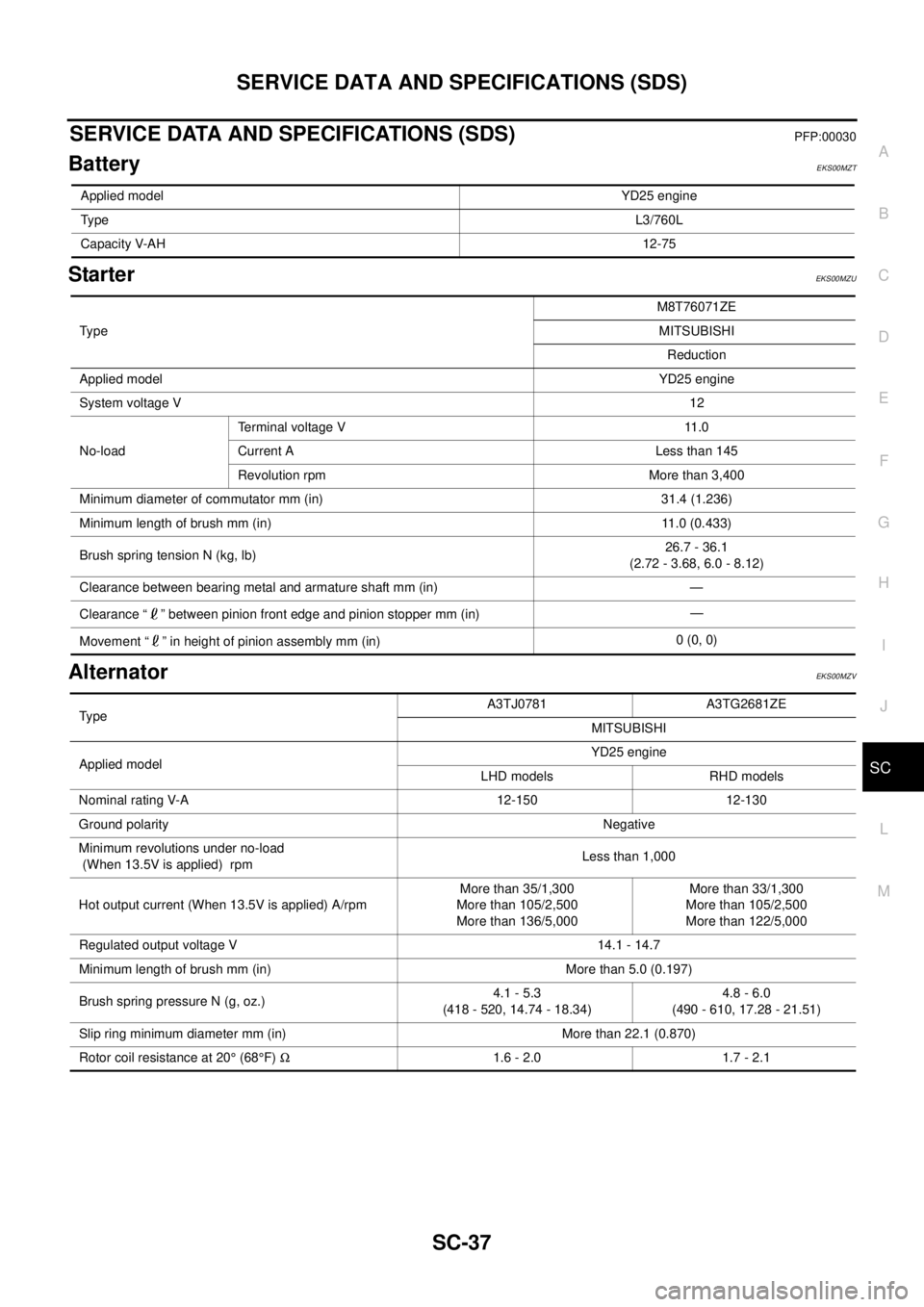

BatteryEKS00MZT

StarterEKS00MZU

AlternatorEKS00MZV

Applied modelYD25 engine

TypeL3/760L

Capacity V-AH12-75

Ty p eM8T76071ZE

MITSUBISHI

Reduction

Applied modelYD25 engine

System voltage V12

No-loadTerminal voltage V 11.0

Current A Less than 145

Revolution rpm More than 3,400

Minimum diameter of commutator mm (in) 31.4 (1.236)

Minimum length of brush mm (in) 11.0 (0.433)

Brush spring tension N (kg, lb)26.7 - 36.1

(2.72 - 3.68, 6.0 - 8.12)

Clearance between bearing metal and armature shaft mm (in) —

Clearance “ ” between pinion front edge and pinion stopper mm (in)—

Movement “ ” in height of pinion assembly mm (in)0 (0, 0)

TypeA3TJ0781 A3TG2681ZE

MITSUBISHI

Applied modelYD25 engine

LHD models RHD models

Nominal rating V-A 12-150 12-130

Ground polarityNegative

Minimum revolutions under no-load

(When 13.5V is applied) rpmLess than 1,000

Hot output current (When 13.5V is applied) A/rpmMore than 35/1,300

More than 105/2,500

More than 136/5,000More than 33/1,300

More than 105/2,500

More than 122/5,000

Regulated output voltage V 14.1 - 14.7

Minimum length of brush mm (in) More than 5.0 (0.197)

Brush spring pressure N (g, oz.)4.1 - 5.3

(418 - 520, 14.74 - 18.34)4.8 - 6.0

(490 - 610, 17.28 - 21.51)

Slip ring minimum diameter mm (in) More than 22.1 (0.870)

Rotor coil resistance at 20°(68°F)W1.6 - 2.0 1.7 - 2.1

Page 2894 of 3171

FRONT SEAT

SE-23

C

D

E

F

G

H

J

K

L

MA

B

SE

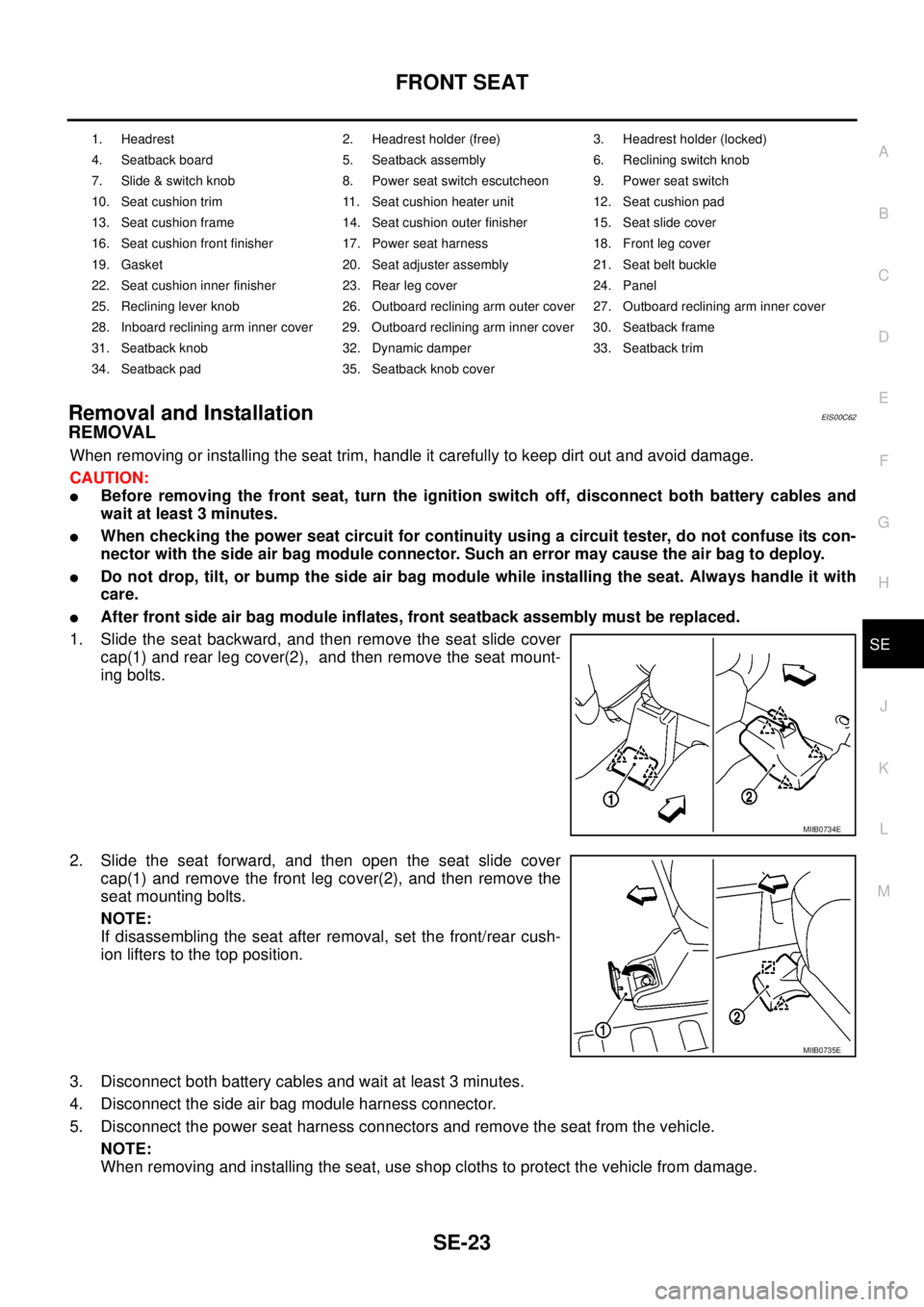

Removal and InstallationEIS00C62

REMOVAL

When removing or installing the seat trim, handle it carefully to keep dirt out and avoid damage.

CAUTION:

lBefore removing the front seat, turn the ignition switch off, disconnect both battery cables and

wait at least 3 minutes.

lWhen checking the power seat circuit for continuity using a circuit tester, do not confuse its con-

nector with the side air bag module connector. Such an error may cause the air bag to deploy.

lDo not drop, tilt, or bump the side air bag module while installing the seat. Always handle it with

care.

lAfter front side air bag module inflates, front seatback assembly must be replaced.

1. Slide the seat backward, and then remove the seat slide cover

cap(1) and rear leg cover(2), and then remove the seat mount-

ing bolts.

2. Slide the seat forward, and then open the seat slide cover

cap(1) and remove the front leg cover(2), and then remove the

seat mounting bolts.

NOTE:

If disassembling the seat after removal, set the front/rear cush-

ion lifters to the top position.

3. Disconnect both battery cables and wait at least 3 minutes.

4. Disconnect the side air bag module harness connector.

5. Disconnect the power seat harness connectors and remove the seat from the vehicle.

NOTE:

When removing and installing the seat, use shop cloths to protect the vehicle from damage.

1. Headrest 2. Headrest holder (free) 3. Headrest holder (locked)

4. Seatback board 5. Seatback assembly 6. Reclining switch knob

7. Slide & switch knob 8. Power seat switch escutcheon 9. Power seat switch

10. Seat cushion trim 11. Seat cushion heater unit 12. Seat cushion pad

13. Seat cushion frame 14. Seat cushion outer finisher 15. Seat slide cover

16. Seat cushion front finisher 17. Power seat harness 18. Front leg cover

19. Gasket 20. Seat adjuster assembly 21. Seat belt buckle

22. Seat cushion inner finisher 23. Rear leg cover 24. Panel

25. Reclining lever knob 26. Outboard reclining arm outer cover 27. Outboard reclining arm inner cover

28. Inboard reclining arm inner cover 29. Outboard reclining arm inner cover 30. Seatback frame

31. Seatback knob 32. Dynamic damper 33. Seatback trim

34. Seatback pad 35. Seatback knob cover

MIIB0734E

MIIB0735E

Page 2912 of 3171

PRECAUTIONS

SRS-3

C

D

E

F

G

I

J

K

L

MA

B

SRS

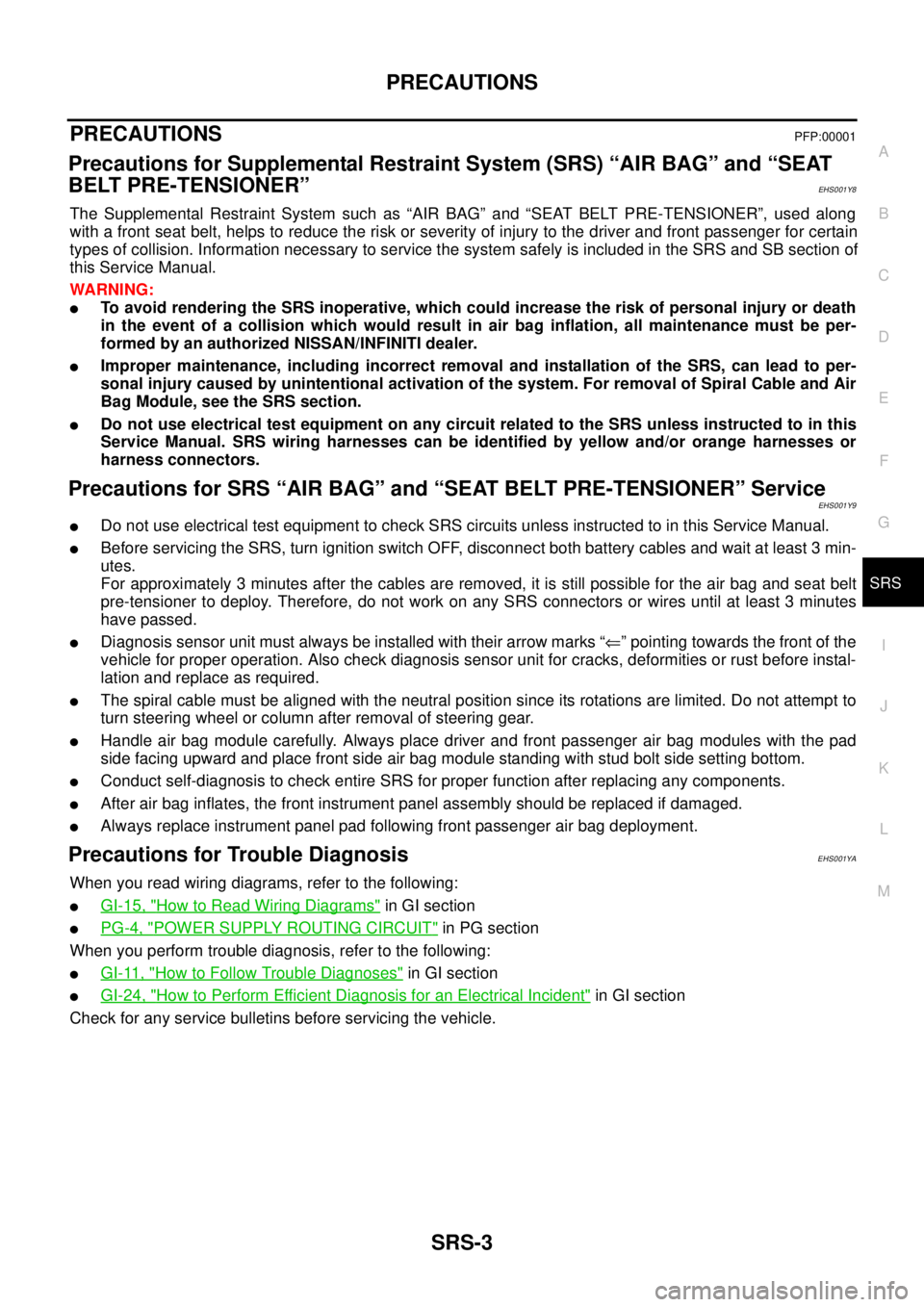

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EHS001Y8

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for SRS “AIR BAG” and “SEAT BELT PRE-TENSIONER” ServiceEHS001Y9

lDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

lBefore servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3 min-

utes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

lDiagnosis sensor unit must always be installed with their arrow marks “Ü” pointing towards the front of the

vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before instal-

lation and replace as required.

lThe spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

lHandle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and place front side air bag module standing with stud bolt side setting bottom.

lConduct self-diagnosis to check entire SRS for proper function after replacing any components.

lAfter air bag inflates, the front instrument panel assembly should be replaced if damaged.

lAlways replace instrument panel pad following front passenger air bag deployment.

Precautions for Trouble DiagnosisEHS001YA

When you read wiring diagrams, refer to the following:

lGI-15, "How to Read Wiring Diagrams"in GI section

lPG-4, "POWER SUPPLY ROUTING CIRCUIT"in PG section

When you perform trouble diagnosis, refer to the following:

lGI-11, "How to Follow Trouble Diagnoses"in GI section

lGI-24, "How to Perform Efficient Diagnosis for an Electrical Incident"in GI section

Check for any service bulletins before servicing the vehicle.

Page 2918 of 3171

TROUBLE DIAGNOSIS

SRS-9

C

D

E

F

G

I

J

K

L

MA

B

SRS

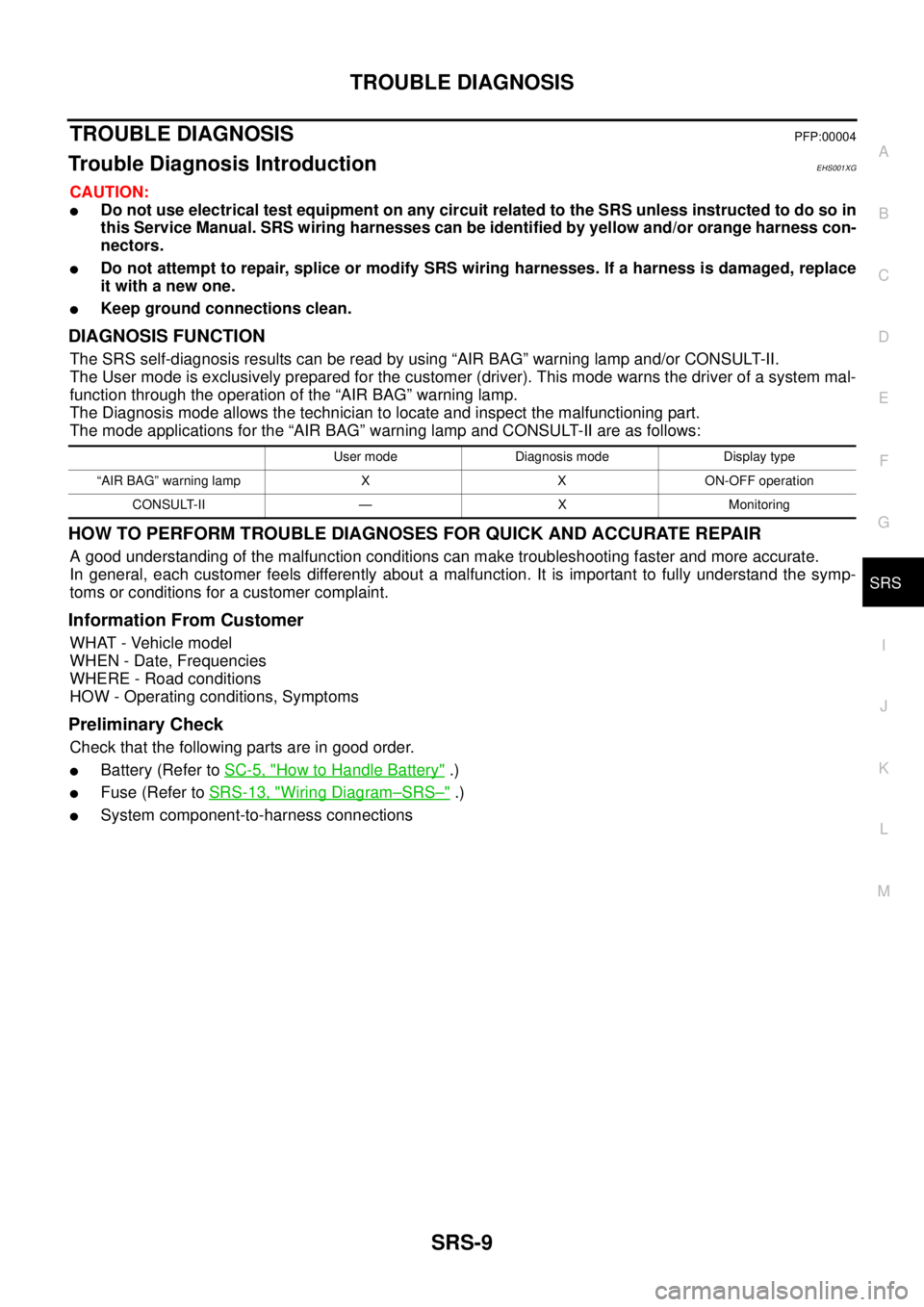

TROUBLE DIAGNOSISPFP:00004

Trouble Diagnosis IntroductionEHS001XG

CAUTION:

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to do so in

this Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harness con-

nectors.

lDo not attempt to repair, splice or modify SRS wiring harnesses. If a harness is damaged, replace

it with a new one.

lKeep ground connections clean.

DIAGNOSIS FUNCTION

The SRS self-diagnosis results can be read by using “AIR BAG” warning lamp and/or CONSULT-II.

The User mode is exclusively prepared for the customer (driver). This mode warns the driver of a system mal-

function through the operation of the “AIR BAG” warning lamp.

The Diagnosis mode allows the technician to locate and inspect the malfunctioning part.

The mode applications for the “AIR BAG” warning lamp and CONSULT-II are as follows:

HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIR

A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a malfunction. It is important to fully understand the symp-

toms or conditions for a customer complaint.

Information From Customer

WHAT - Vehicle model

WHEN - Date, Frequencies

WHERE - Road conditions

HOW - Operating conditions, Symptoms

Preliminary Check

Check that the following parts are in good order.

lBattery (Refer toSC-5, "How to Handle Battery".)

lFuse (Refer toSRS-13, "Wiring Diagram–SRS–".)

lSystem component-to-harness connections

User mode Diagnosis mode Display type

“AIR BAG” warning lamp X X ON-OFF operation

CONSULT-II — X Monitoring

Page 2930 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

SRS-21

C

D

E

F

G

I

J

K

L

MA

B

SRS

7. Diagnostic code is displayed on "SELF-DIAG [CURRENT]".

If no malfunction is detected on "SELF-DIAG [CURRENT]" even

though malfunction is detected NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

SRS-21

C

D

E

F

G

I

J

K

L

MA

B

SRS

7. Diagnostic code is displayed on "SELF-DIAG [CURRENT]".

If no malfunction is detected on "SELF-DIAG [CURRENT]" even

though malfunction is detected](/img/5/57362/w960_57362-2929.png)

TROUBLE DIAGNOSIS

SRS-21

C

D

E

F

G

I

J

K

L

MA

B

SRS

7. Diagnostic code is displayed on "SELF-DIAG [CURRENT]".

If no malfunction is detected on "SELF-DIAG [CURRENT]" even

though malfunction is detected in "SRS Operation Check", refer to

SRS-26, "

DIAGNOSTIC PROCEDURE 4 (CONTINUED FROM

DIAGNOSTIC PROCEDURE 2)", to diagnose the following cases:

lSelf-diagnostic result "SELF-DIAG [PAST]" (previously stored in

the memory) might not be erased after repair.

lThe SRS system malfunctions intermittently.

CONSULT-II Diagnostic Code Chart ("SELF-DIAG [CURRENT]")

WHIA0151E

SRS701

Diagnostic item ExplanationRepair order

Recheck SRS at each replacement

NO DTC IS DETECTEDWhen malfunction is

indicated by the “AIR

BAG” warning lamp in

User mode.

lLow battery voltage (Less than

9V)lGo toSRS-24, "DIAGNOSTIC PRO-

CEDURE 3".

lSelf-diagnostic result “SELF-DIAG

[PAST]” (previously stored in the

memory) might not be erased

after repair.

lIntermittent malfunction has been

detected in the past.

lGo toSRS-26, "DIAGNOSTIC PRO-

CEDURE 4 (CONTINUED FROM

DIAGNOSTIC PROCEDURE 2)".

lGo toSRS-26, "DIAGNOSTIC PRO-

CEDURE 5".

lNo malfunction is detected. —

DRIVER AIRBAG MODULE

[OPEN]

[B1049] or [B1054]

lDriver air bag module circuit is open (including the spiral

cable).1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace driver air bag module.

(Before disposal, it must be

deployed.)

4. Replace the spiral cable.

5. Replace the air bag diagnosis sen-

sor unit.

6. Replace the related harness. DRIVER AIRBAG MODULE

[VB-SHORT]

[B1050] or [B1055]

lDriver air bag module circuit is shorted to some power sup-

ply circuit (including the spiral cable).

DRIVER AIRBAG MODULE

[GND-SHORT]

[B1051] or [B1056]

lDriver air bag module circuit is shorted to ground (including

the spiral cable).

DRIVER AIRBAG MODULE

[SHORT]

[B1052] or [B1057]

lDriver air bag module circuits are shorted to each other.

Page 2933 of 3171

SRS-24

TROUBLE DIAGNOSIS

NOTE:

Follow the procedures in numerical order when repairing malfunctioning parts. Confirm whether malfunction is

eliminated using air bag warning lamp or CONSULT-II each time repair is finished. If malfunction is still

observed, proceed to the next step. When malfunction is eliminated, further repair work is not required.

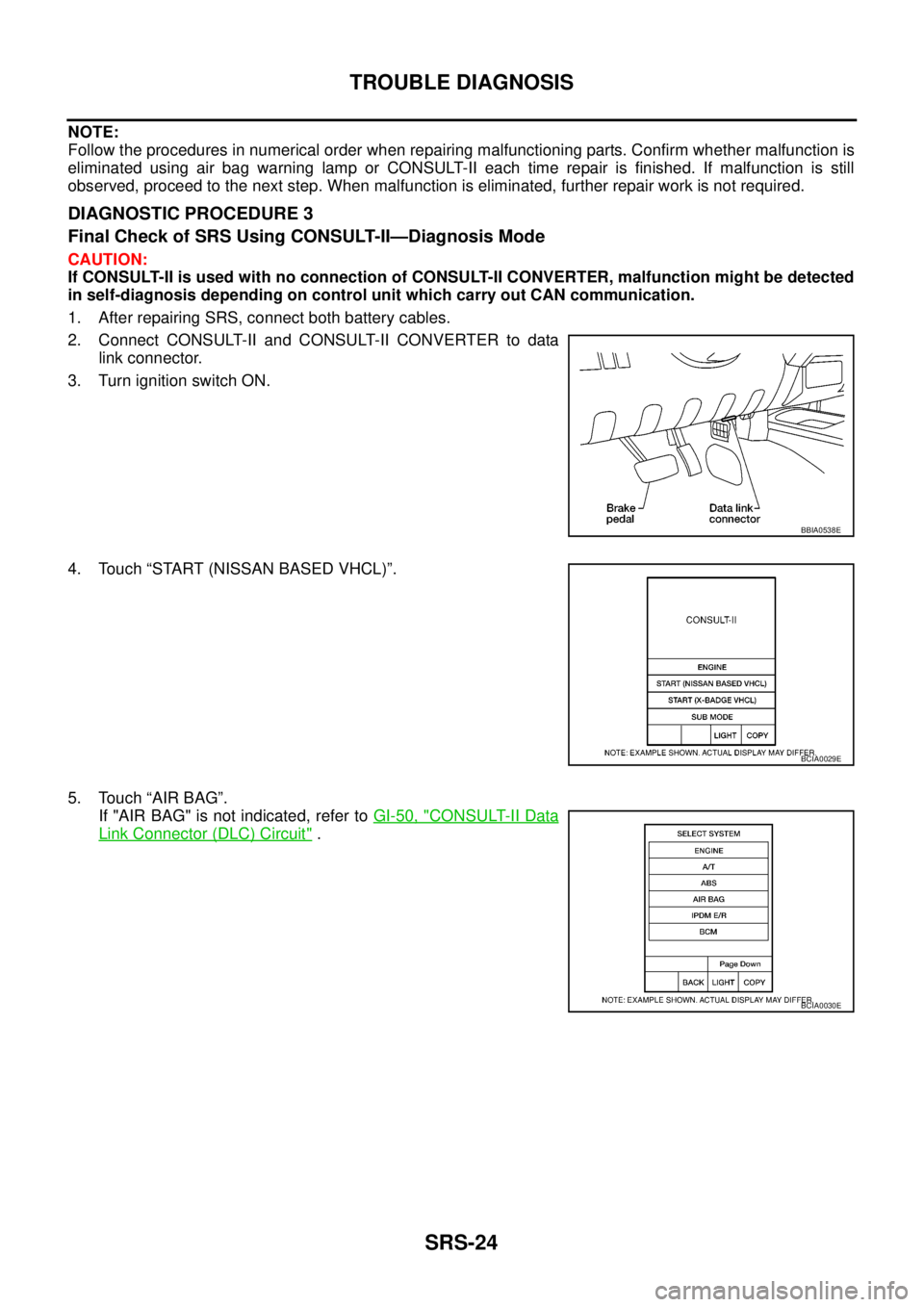

DIAGNOSTIC PROCEDURE 3

Final Check of SRS Using CONSULT-II—Diagnosis Mode

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunction might be detected

in self-diagnosis depending on control unit which carry out CAN communication.

1. After repairing SRS, connect both battery cables.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data

link connector.

3. Turn ignition switch ON.

4. Touch “START (NISSAN BASED VHCL)”.

5. Touch “AIR BAG”.

If "AIR BAG" is not indicated, refer toGI-50, "

CONSULT-II Data

Link Connector (DLC) Circuit".

BBIA0538E

BCIA0029E

BCIA0030E

Page 2936 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

SRS-27

C

D

E

F

G

I

J

K

L

MA

B

SRS

6. Touch “SELF-DIAG [PAST]”.

7. If diagnostic codes are displayed on “SELF-DIAG [PAST]”, go to

step 10.

If no malfunction is detected on “ NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

SRS-27

C

D

E

F

G

I

J

K

L

MA

B

SRS

6. Touch “SELF-DIAG [PAST]”.

7. If diagnostic codes are displayed on “SELF-DIAG [PAST]”, go to

step 10.

If no malfunction is detected on “](/img/5/57362/w960_57362-2935.png)

TROUBLE DIAGNOSIS

SRS-27

C

D

E

F

G

I

J

K

L

MA

B

SRS

6. Touch “SELF-DIAG [PAST]”.

7. If diagnostic codes are displayed on “SELF-DIAG [PAST]”, go to

step 10.

If no malfunction is detected on “SELF-DIAG [PAST]”, touch

“BACK” and go back to “SELECT DIAG MODE”.

8. Touch “TROUBLE DIAG RECORD”.

NOTE:

With “TROUBLE DIAG RECORD”, diagnosis results previ-

ously erased by a reset operation can be displayed.

9. Diagnostic code is displayed on “TROUBLE DIAG RECORD”.

10. Touch “PRINT”.

11. Compare diagnostic codes toSRS-28, "

CONSULT-II Diagnostic

Code Chart ("SELF-DIAG [PAST]" or "TROUBLE DIAG

RECORD")".

12. Touch “BACK” key of CONSULT-II until “SELECT SYSTEM”

appears.

13. Turn ignition switch OFF, and disconnect CONSULT-II, and both

battery cables.

BCIA0031E

WHIA0152E

SRS702

BCIA0031E

WHIA0153E

Page 2937 of 3171

SRS-28

TROUBLE DIAGNOSIS

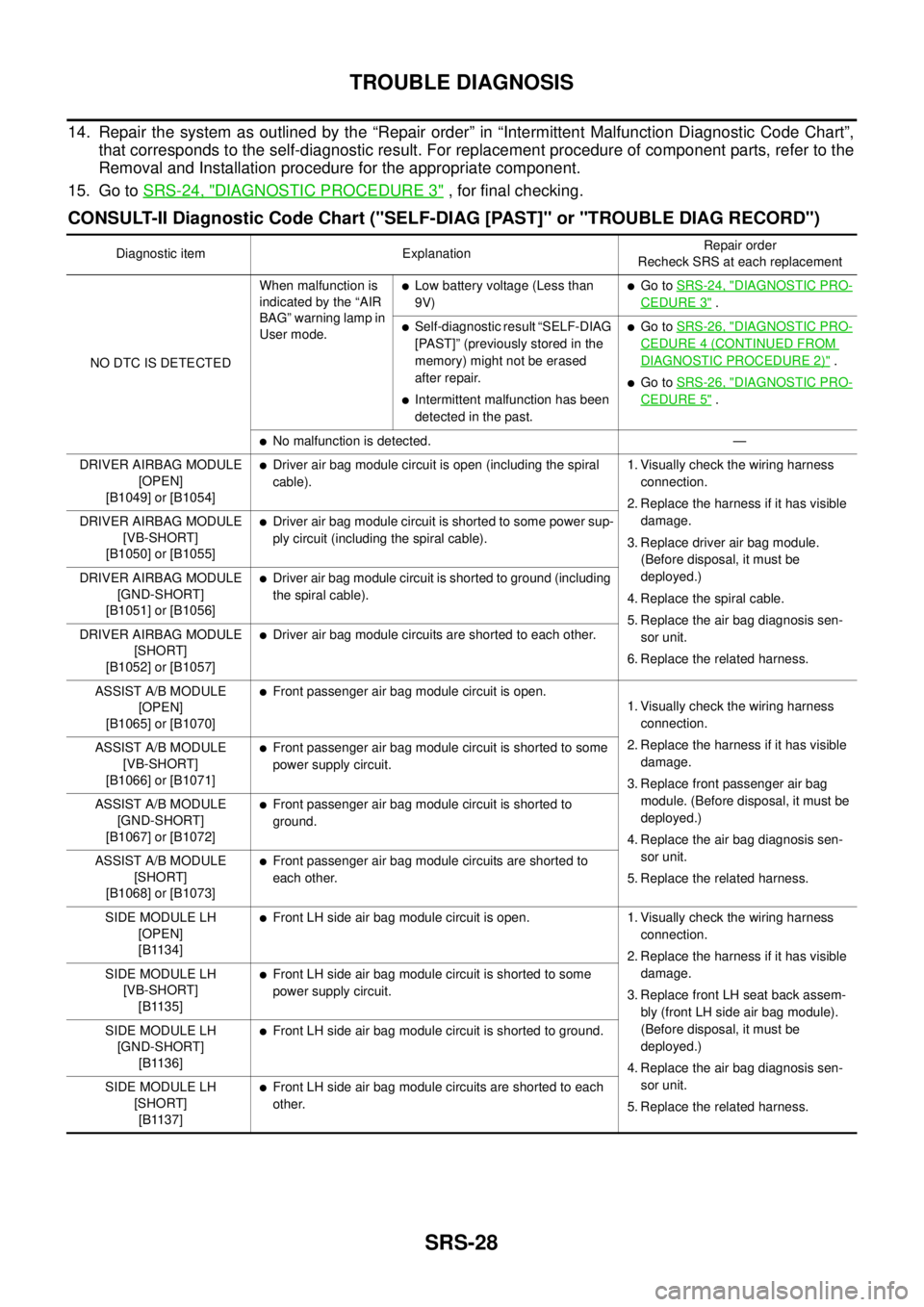

14. Repair the system as outlined by the “Repair order” in “Intermittent Malfunction Diagnostic Code Chart”,

that corresponds to the self-diagnostic result. For replacement procedure of component parts, refer to the

Removal and Installation procedure for the appropriate component.

15. Go toSRS-24, "

DIAGNOSTIC PROCEDURE 3", for final checking.

CONSULT-II Diagnostic Code Chart ("SELF-DIAG [PAST]" or "TROUBLE DIAG RECORD")

Diagnostic item ExplanationRepair order

Recheck SRS at each replacement

NO DTC IS DETECTEDWhen malfunction is

indicated by the “AIR

BAG” warning lamp in

User mode.

lLow battery voltage (Less than

9V)lGo toSRS-24, "DIAGNOSTIC PRO-

CEDURE 3".

lSelf-diagnostic result “SELF-DIAG

[PAST]” (previously stored in the

memory) might not be erased

after repair.

lIntermittent malfunction has been

detected in the past.

lGo toSRS-26, "DIAGNOSTIC PRO-

CEDURE 4 (CONTINUED FROM

DIAGNOSTIC PROCEDURE 2)".

lGo toSRS-26, "DIAGNOSTIC PRO-

CEDURE 5".

lNo malfunction is detected. —

DRIVER AIRBAG MODULE

[OPEN]

[B1049] or [B1054]

lDriver air bag module circuit is open (including the spiral

cable).1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace driver air bag module.

(Before disposal, it must be

deployed.)

4. Replace the spiral cable.

5. Replace the air bag diagnosis sen-

sor unit.

6. Replace the related harness. DRIVER AIRBAG MODULE

[VB-SHORT]

[B1050] or [B1055]

lDriver air bag module circuit is shorted to some power sup-

ply circuit (including the spiral cable).

DRIVER AIRBAG MODULE

[GND-SHORT]

[B1051] or [B1056]

lDriver air bag module circuit is shorted to ground (including

the spiral cable).

DRIVER AIRBAG MODULE

[SHORT]

[B1052] or [B1057]

lDriver air bag module circuits are shorted to each other.

ASSIST A/B MODULE

[OPEN]

[B1065] or [B1070]

lFront passenger air bag module circuit is open.

1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace front passenger air bag

module. (Before disposal, it must be

deployed.)

4. Replace the air bag diagnosis sen-

sor unit.

5. Replace the related harness. ASSIST A/B MODULE

[VB-SHORT]

[B1066] or [B1071]

lFront passenger air bag module circuit is shorted to some

power supply circuit.

ASSIST A/B MODULE

[GND-SHORT]

[B1067] or [B1072]

lFront passenger air bag module circuit is shorted to

ground.

ASSIST A/B MODULE

[SHORT]

[B1068] or [B1073]

lFront passenger air bag module circuits are shorted to

each other.

SIDE MODULE LH

[OPEN]

[B1134]

lFront LH side air bag module circuit is open. 1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace front LH seat back assem-

bly (front LH side air bag module).

(Before disposal, it must be

deployed.)

4. Replace the air bag diagnosis sen-

sor unit.

5. Replace the related harness. SIDE MODULE LH

[VB-SHORT]

[B1135]

lFront LH side air bag module circuit is shorted to some

power supply circuit.

SIDE MODULE LH

[GND-SHORT]

[B1136]

lFront LH side air bag module circuit is shorted to ground.

SIDE MODULE LH

[SHORT]

[B1137]

lFront LH side air bag module circuits are shorted to each

other.

Page 2945 of 3171

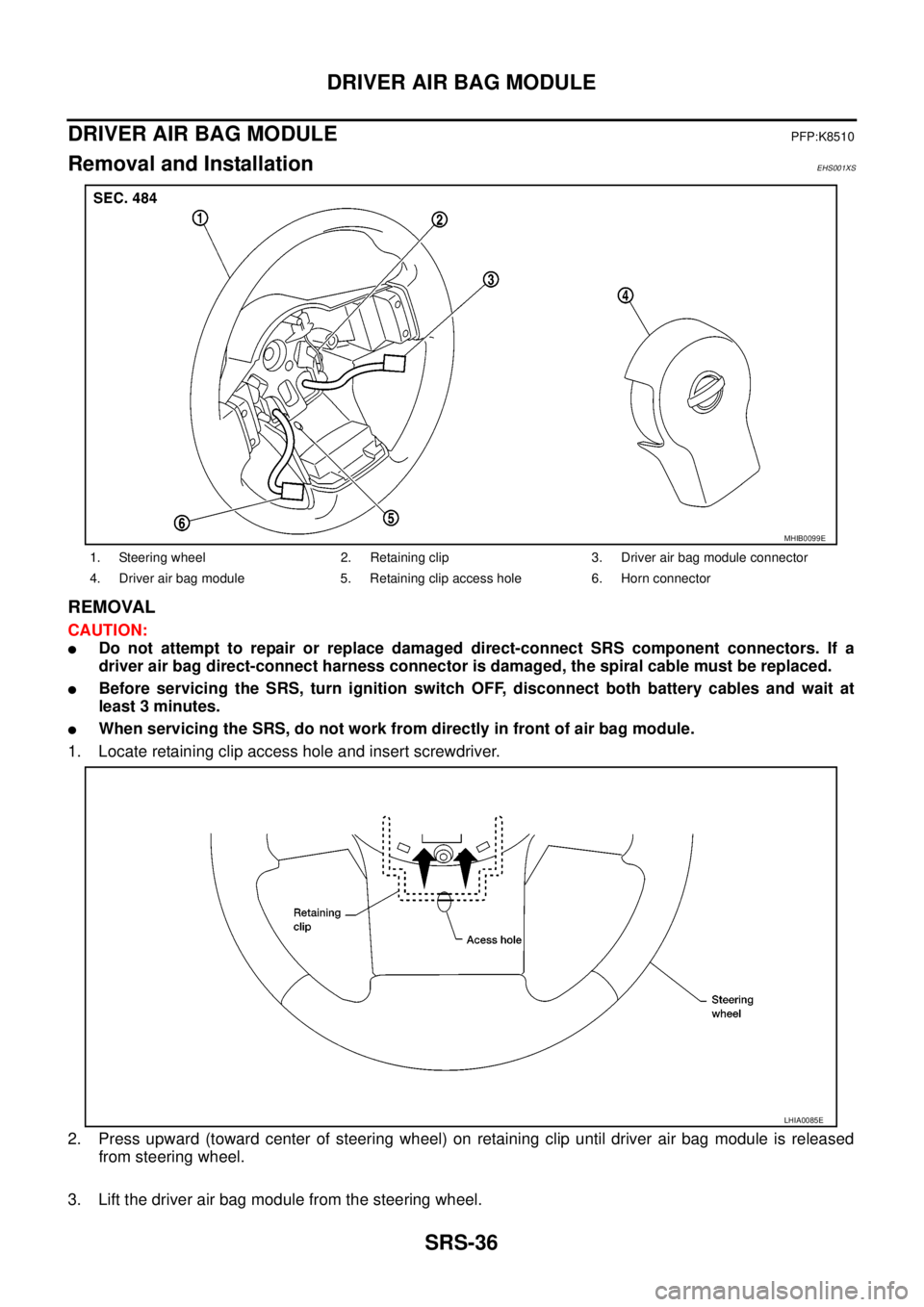

SRS-36

DRIVER AIR BAG MODULE

DRIVER AIR BAG MODULE

PFP:K8510

Removal and InstallationEHS001XS

REMOVAL

CAUTION:

lDo not attempt to repair or replace damaged direct-connect SRS component connectors. If a

driver air bag direct-connect harness connector is damaged, the spiral cable must be replaced.

lBefore servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at

least 3 minutes.

lWhen servicing the SRS, do not work from directly in front of air bag module.

1. Locate retaining clip access hole and insert screwdriver.

2. Press upward (toward center of steering wheel) on retaining clip until driver air bag module is released

from steering wheel.

3. Lift the driver air bag module from the steering wheel.

1. Steering wheel 2. Retaining clip 3. Driver air bag module connector

4. Driver air bag module 5. Retaining clip access hole 6. Horn connector

MHIB0099E

LHIA0085E