battery NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2845 of 3171

SC-12

BATTERY

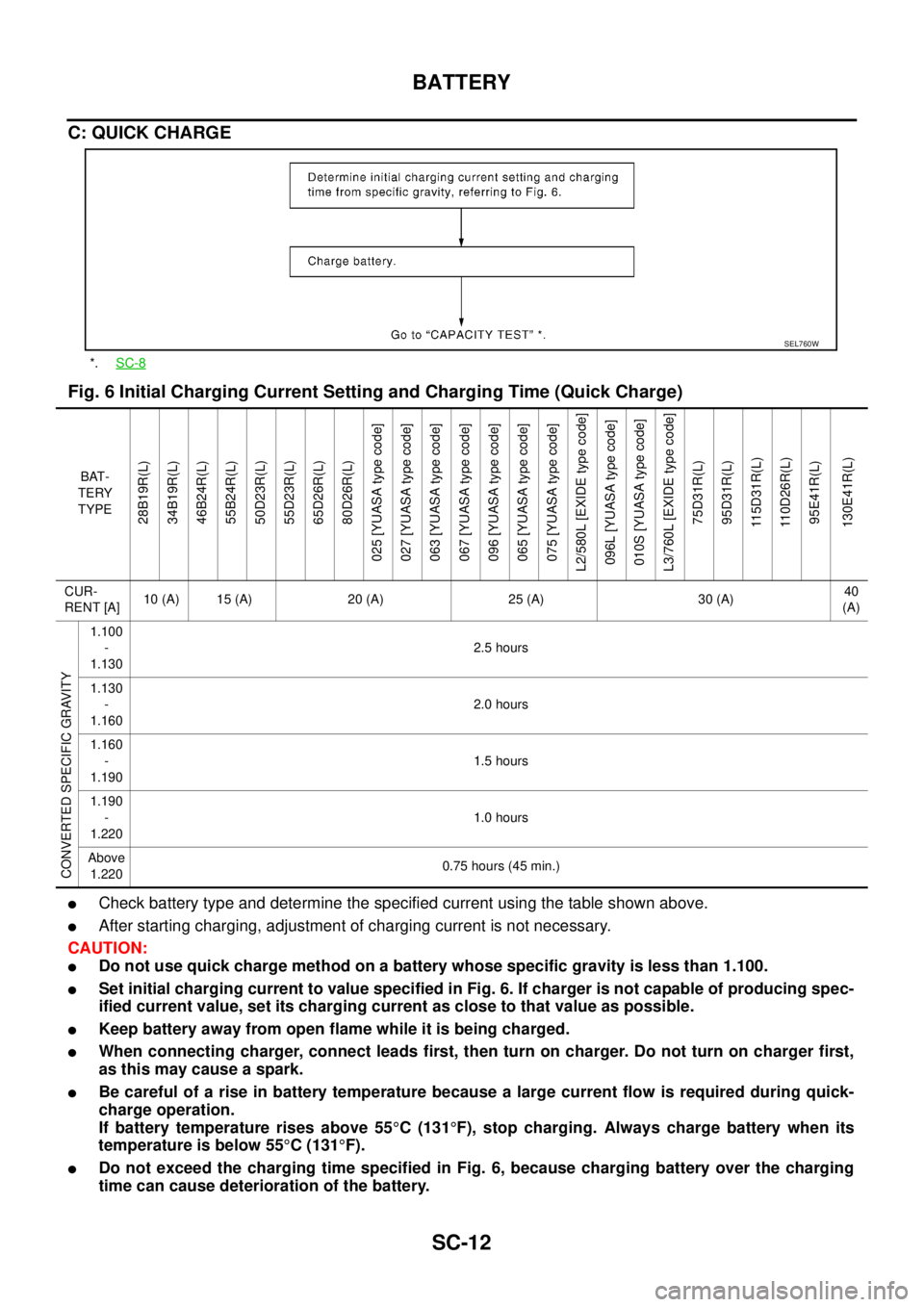

C: QUICK CHARGE

Fig. 6 Initial Charging Current Setting and Charging Time (Quick Charge)

lCheck battery type and determine the specified current using the table shown above.

lAfter starting charging, adjustment of charging current is not necessary.

CAUTION:

lDo not use quick charge method on a battery whose specific gravity is less than 1.100.

lSet initial charging current to value specified in Fig. 6. If charger is not capable of producing spec-

ified current value, set its charging current as close to that value as possible.

lKeep battery away from open flame while it is being charged.

lWhen connecting charger, connect leads first, then turn on charger. Do not turn on charger first,

as this may cause a spark.

lBe careful of a rise in battery temperature because a large current flow is required during quick-

charge operation.

If battery temperature rises above 55°C(131°F), stop charging. Always charge battery when its

temperature is below 55°C(131°F).

lDo not exceed the charging time specified in Fig. 6, because charging battery over the charging

time can cause deterioration of the battery.

*.SC-8

SEL760W

BAT-

TERY

TYPE

28B19R(L)

34B19R(L)

46B24R(L)

55B24R(L)

50D23R(L)

55D23R(L)

65D26R(L)

80D26R(L)

025 [YUASA type code]

027 [YUASA type code]

063 [YUASA type code]

067 [YUASA type code]

096 [YUASA type code]

065 [YUASA type code]

075 [YUASA type code]

L2/580L [EXIDE type code]

096L [YUASA type code]

010S [YUASA type code]

L3/760L [EXIDE type code]

75D31R(L)

95D31R(L)

115D31R(L)

110D26R(L)

95E41R(L)

130E41R(L)

CUR-

RENT [A]10 (A) 15 (A) 20 (A) 25 (A) 30 (A)40

(A)

CONVERTED SPECIFIC GRAVITY

1.100

-

1.1302.5 hours

1.130

-

1.1602.0 hours

1.160

-

1.1901.5 hours

1.190

-

1.2201.0 hours

Above

1.2200.75 hours (45 min.)

Page 2846 of 3171

BATTERY

SC-13

C

D

E

F

G

H

I

J

L

MA

B

SC

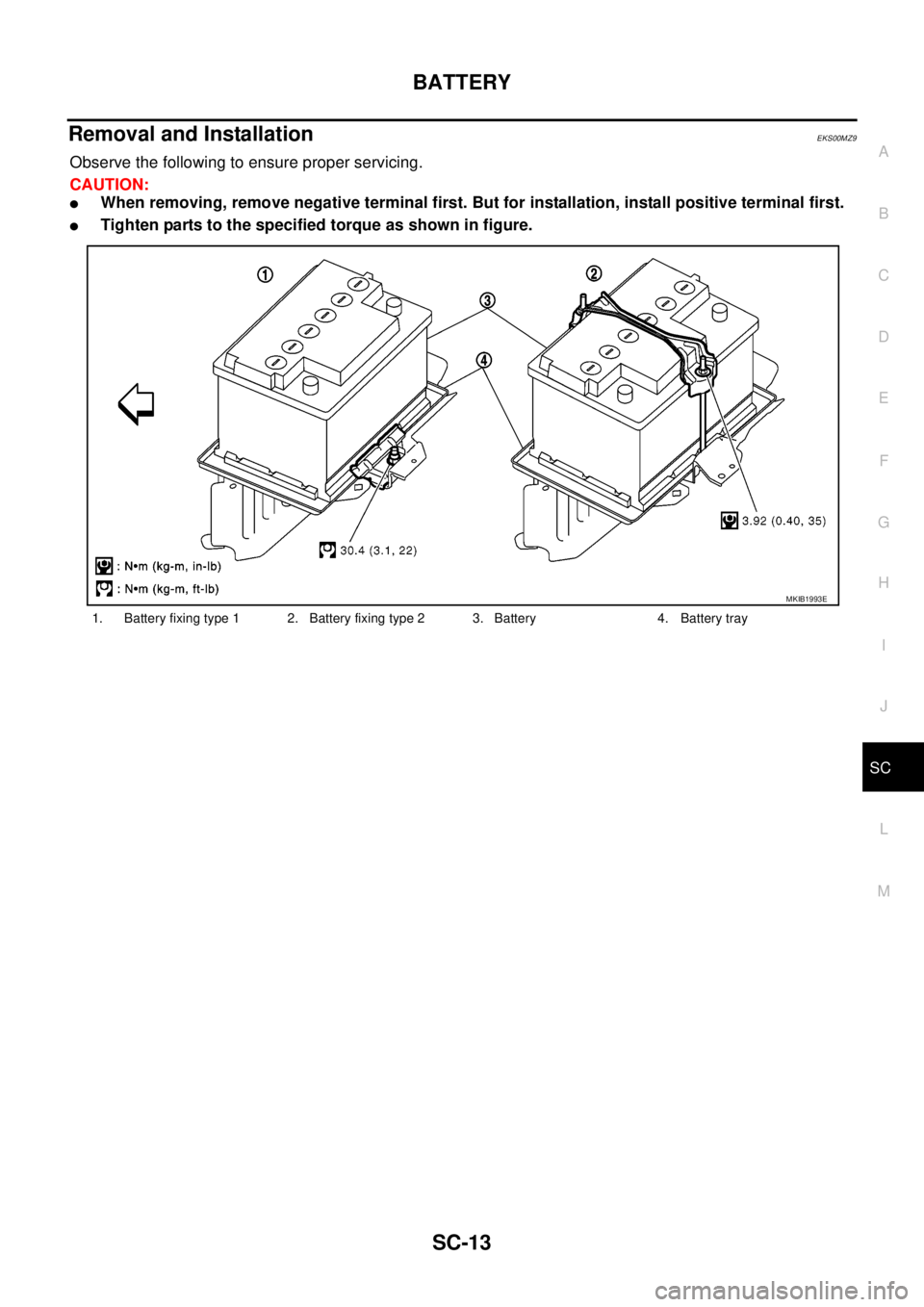

Removal and InstallationEKS00MZ9

Observethefollowingtoensureproperservicing.

CAUTION:

lWhen removing, remove negative terminal first. But for installation, install positive terminal first.

lTighten parts to the specified torque as shown in figure.

1. Battery fixing type 1 2. Battery fixing type 2 3. Battery 4. Battery tray

MKIB1993E

Page 2847 of 3171

SC-14

CHARGING SYSTEM

CHARGING SYSTEM

PFP:00011

System DescriptionEKS00MZA

The alternator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 through:

l15A fuse (No. 30, located in the fuse and fusible link box).

Terminal 1 supplies power to charge the battery and operate the vehicle's electrical system. Output voltage is

controlled by the IC regulator at terminal 4 detecting the input voltage. The charging circuit is protected by the

140A fusible link (letter "A", located in the fuse and fusible link box) .

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

l10A fuse [No. 14, located in the fuse block (J/B)]

lto combination meter terminal 16 for the charge warning lamp.

Ground is supplied With power and ground supplied

lto terminal 2 of the combination meter

lthrough terminal 3 of the alternator.

If the charge warning lamp illuminates with the engine running, a fault is indicated.

The charge warning lamp will illuminate. When the alternator is providing sufficient voltage with the engine

running, the ground is opened and the charge warning lamp will go off.

Page 2849 of 3171

SC-16

CHARGING SYSTEM

Trouble Diagnosis

EKS00MZD

DIAGNOSIS PROCEDURE

1. Check malfunction symptoms or customer's remarks.

2. Perform pre-diagnosis inspection. Refer toSC-16, "

PRE-DIAGNOSIS INSPECTION".

3. Perform trouble diagnosis for each trouble symptom. Refer toSC-16, "

DIAGNOSIS CHART BY SYMP-

TOM"

4. Repair or replace parts indicated inspection flow based on the charge warning lamp. Refer toSC-16,

"INSPECTION FLOW BY CHARGE WARNING LAMP".

5. End

PRE-DIAGNOSIS INSPECTION

1. Perform alternator belt inspection. Refer toEM-12, "DRIVE BELTS".

2. Inspect battery.

3. Check alternator terminal 1 for loose or improper connection.

4. Check alternator connector 4 and 3 terminals for loose connection, disconnection and bend.

5. Check connecting condition of harness for charging system harness (fusible link terminal and battery ter-

minal).

6. After performing 1 to 5 above, go to trouble diagnosis for symptoms. Refer toSC-16, "

DIAGNOSIS

CHART BY SYMPTOM".

DIAGNOSIS CHART BY SYMPTOM

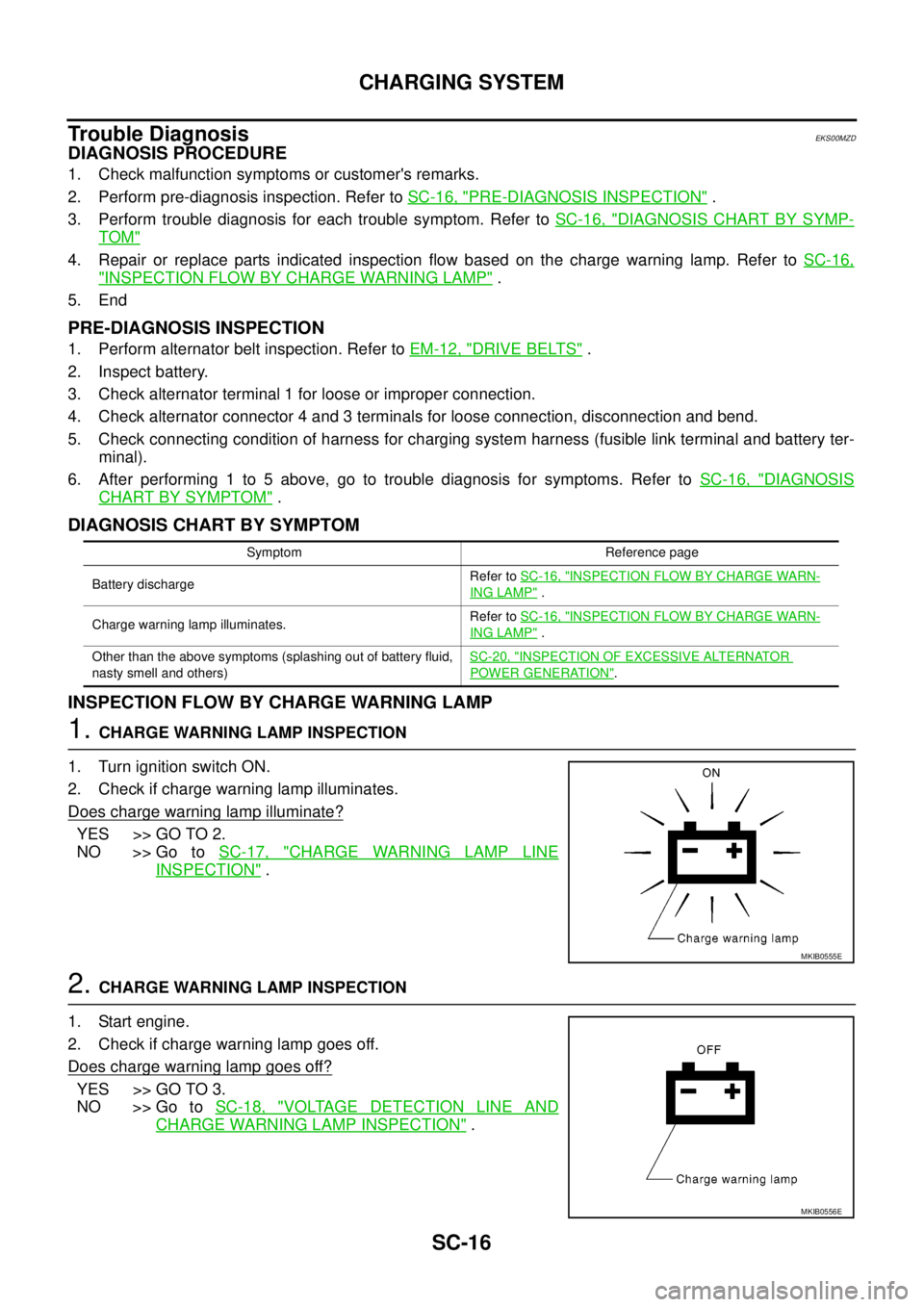

INSPECTION FLOW BY CHARGE WARNING LAMP

1.CHARGE WARNING LAMP INSPECTION

1. Turn ignition switch ON.

2. Check if charge warning lamp illuminates.

Does charge warning lamp illuminate?

YES >> GO TO 2.

NO >> Go toSC-17, "

CHARGE WARNING LAMP LINE

INSPECTION".

2.CHARGE WARNING LAMP INSPECTION

1. Start engine.

2. Check if charge warning lamp goes off.

Does charge warning lamp goes off?

YES >> GO TO 3.

NO >> Go toSC-18, "

VOLTAGE DETECTION LINE AND

CHARGE WARNING LAMP INSPECTION".

Symptom Reference page

Battery dischargeRefer toSC-16, "

INSPECTION FLOW BY CHARGE WARN-

ING LAMP".

Charge warning lamp illuminates.Refer toSC-16, "

INSPECTION FLOW BY CHARGE WARN-

ING LAMP".

Other than the above symptoms (splashing out of battery fluid,

nasty smell and others)SC-20, "

INSPECTION OF EXCESSIVE ALTERNATOR

POWER GENERATION".

MKIB0555E

MKIB0556E

Page 2853 of 3171

SC-20

CHARGING SYSTEM

INSPECTION OF INSUFFICIENT ALTERNATOR POWER GENERATION

CAUTION:

Check them using charged battery performed battery inspection.

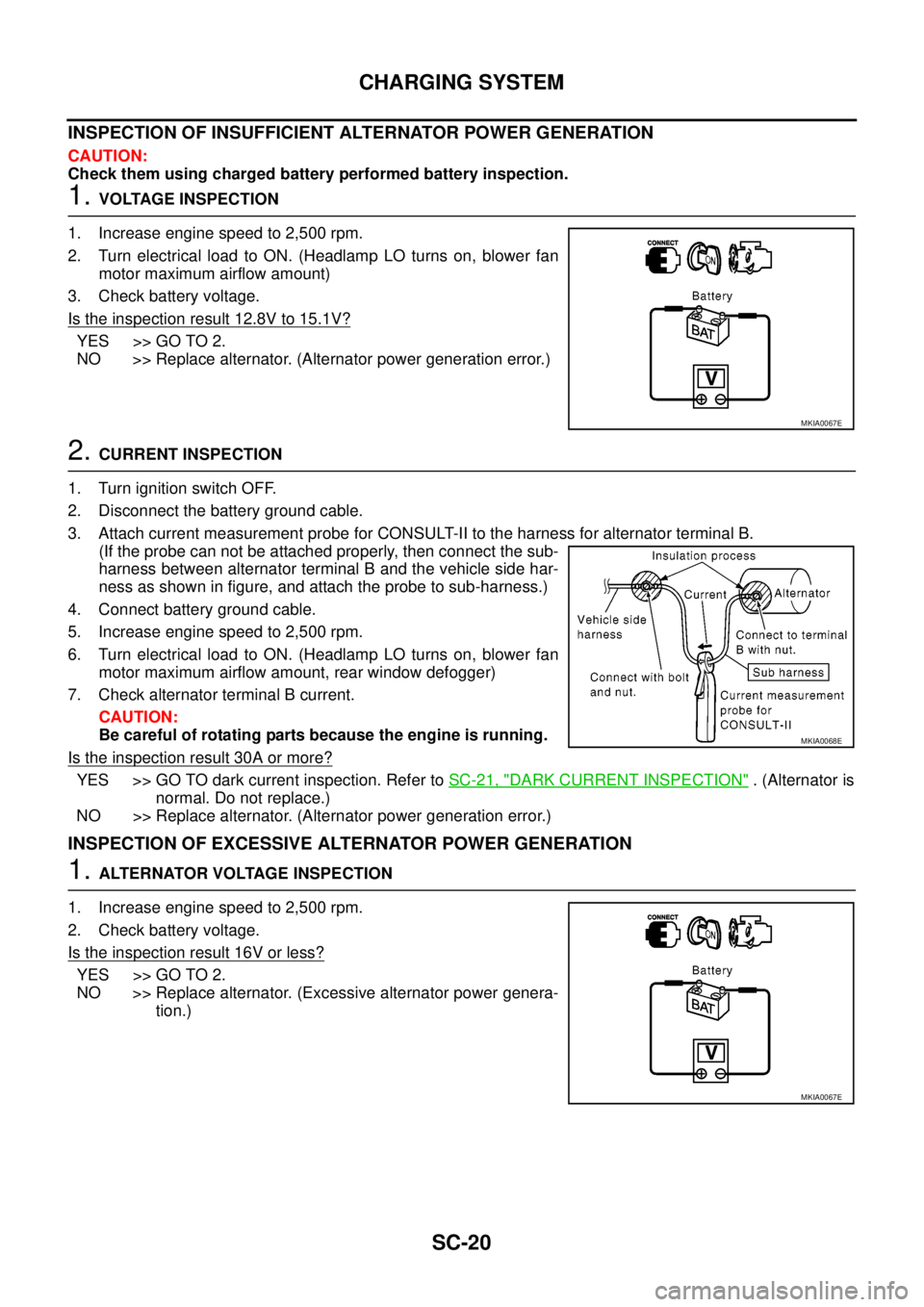

1.VOLTAGE INSPECTION

1. Increase engine speed to 2,500 rpm.

2. Turn electrical load to ON. (Headlamp LO turns on, blower fan

motor maximum airflow amount)

3. Check battery voltage.

Is the inspection result 12.8V to 15.1V?

YES >> GO TO 2.

NO >> Replace alternator. (Alternator power generation error.)

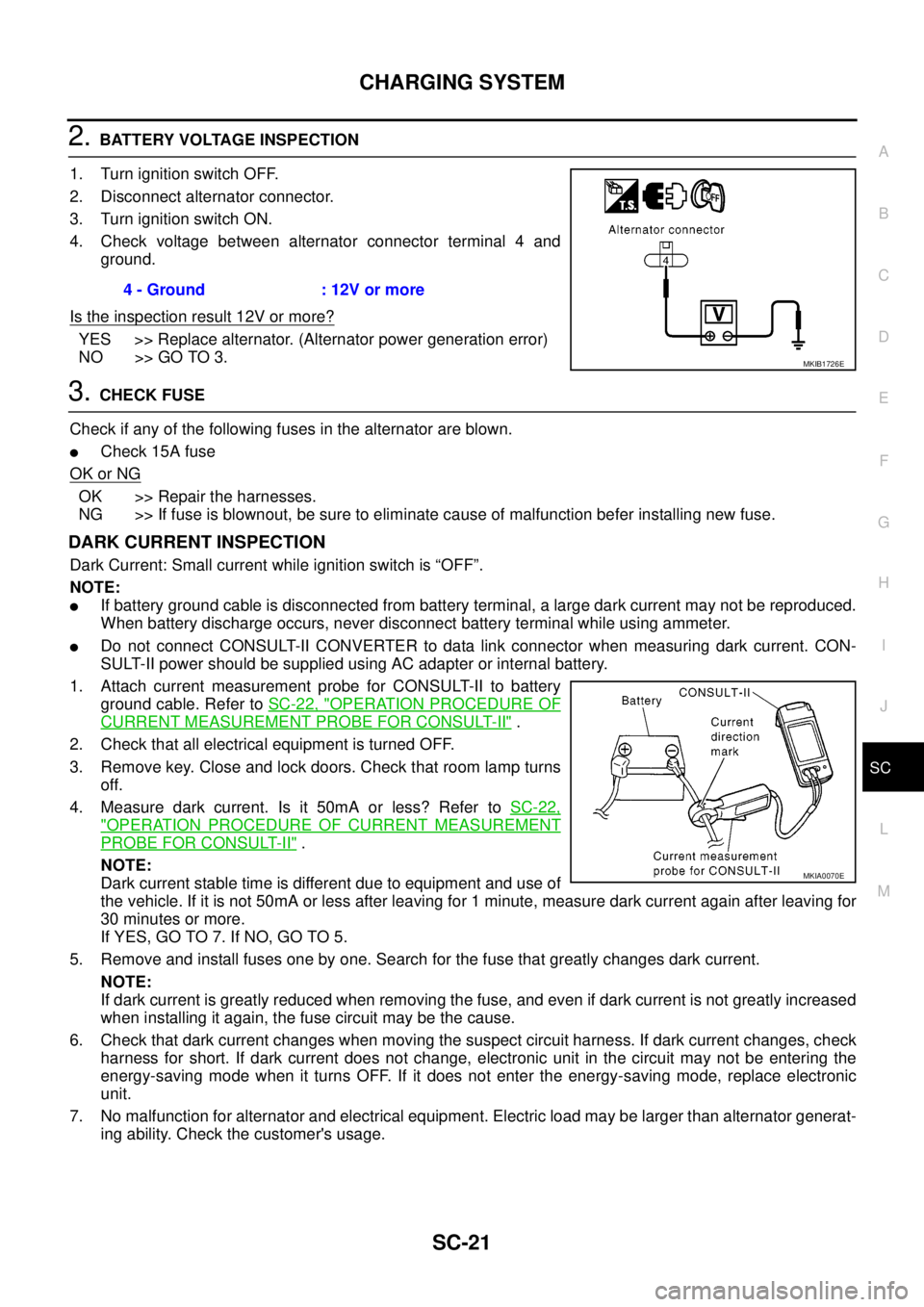

2.CURRENT INSPECTION

1. Turn ignition switch OFF.

2. Disconnect the battery ground cable.

3. Attach current measurement probe for CONSULT-II to the harness for alternator terminal B.

(If the probe can not be attached properly, then connect the sub-

harness between alternator terminal B and the vehicle side har-

ness as shown in figure, and attach the probe to sub-harness.)

4. Connect battery ground cable.

5. Increase engine speed to 2,500 rpm.

6. Turn electrical load to ON. (Headlamp LO turns on, blower fan

motor maximum airflow amount, rear window defogger)

7. Check alternator terminal B current.

CAUTION:

Be careful of rotating parts because the engine is running.

Is the inspection result 30A or more?

YES >> GO TO dark current inspection. Refer toSC-21, "DARK CURRENT INSPECTION". (Alternator is

normal. Do not replace.)

NO >> Replace alternator. (Alternator power generation error.)

INSPECTION OF EXCESSIVE ALTERNATOR POWER GENERATION

1.ALTERNATOR VOLTAGE INSPECTION

1. Increase engine speed to 2,500 rpm.

2. Check battery voltage.

Is the inspection result 16V or less?

YES >> GO TO 2.

NO >> Replace alternator. (Excessive alternator power genera-

tion.)

MKIA0067E

MKIA0068E

MKIA0067E

Page 2854 of 3171

CHARGING SYSTEM

SC-21

C

D

E

F

G

H

I

J

L

MA

B

SC

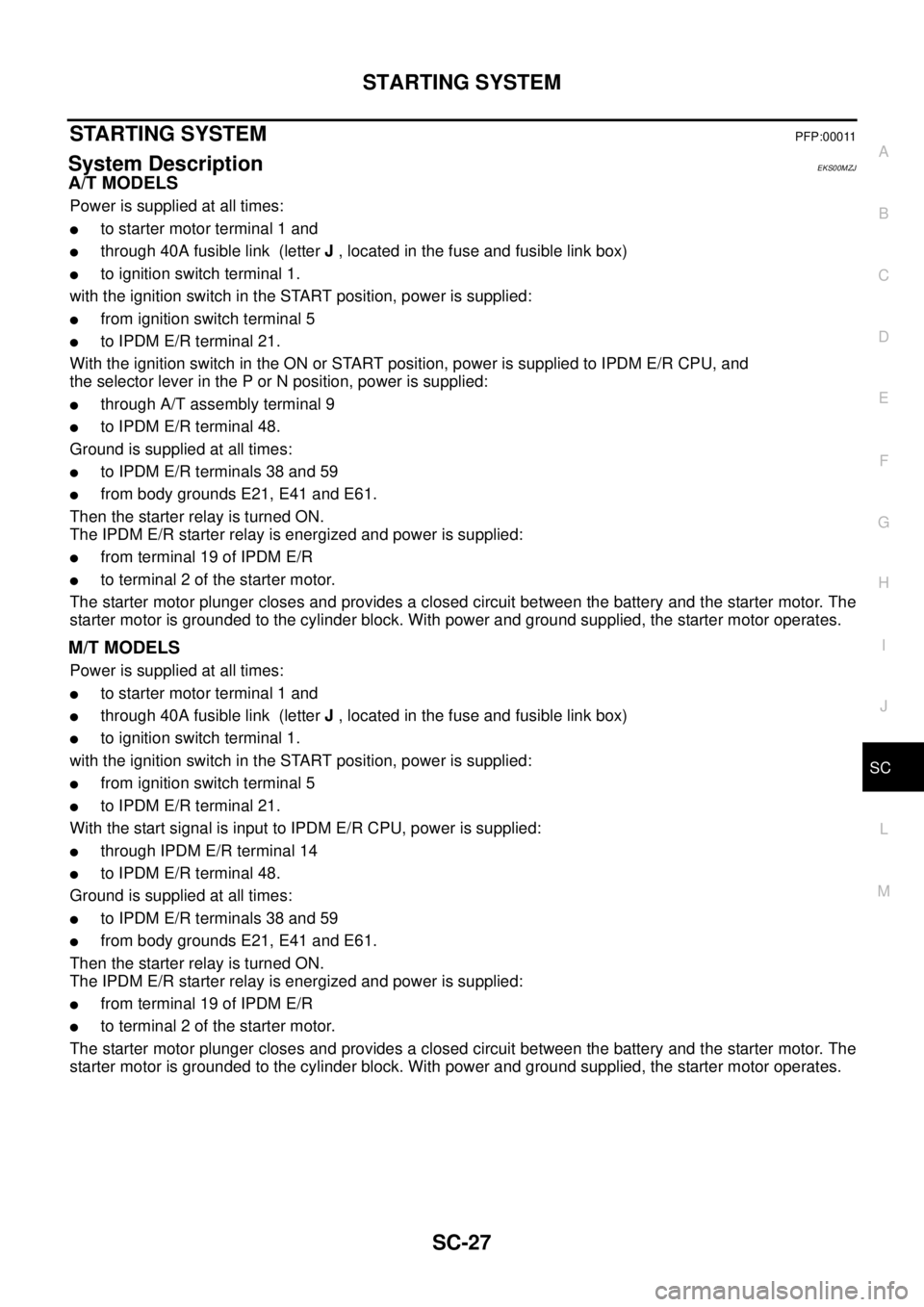

2.BATTERY VOLTAGE INSPECTION

1. Turn ignition switch OFF.

2. Disconnect alternator connector.

3. Turn ignition switch ON.

4. Check voltage between alternator connector terminal 4 and

ground.

Is the inspection result 12V or more?

YES >> Replace alternator. (Alternator power generation error)

NO >> GO TO 3.

3.CHECK FUSE

Check if any of the following fuses in the alternator are blown.

lCheck 15A fuse

OK or NG

OK >> Repair the harnesses.

NG >> If fuse is blownout, be sure to eliminate cause of malfunction befer installing new fuse.

DARK CURRENT INSPECTION

Dark Current: Small current while ignition switch is “OFF”.

NOTE:

lIf battery ground cable is disconnected from battery terminal, a large dark current may not be reproduced.

When battery discharge occurs, never disconnect battery terminal while using ammeter.

lDo not connect CONSULT-II CONVERTER to data link connector when measuring dark current. CON-

SULT-II power should be supplied using AC adapter or internal battery.

1. Attach current measurement probe for CONSULT-II to battery

ground cable. Refer toSC-22, "

OPERATION PROCEDURE OF

CURRENT MEASUREMENT PROBE FOR CONSULT-II".

2. Check that all electrical equipment is turned OFF.

3. Remove key. Close and lock doors. Check that room lamp turns

off.

4. Measure dark current. Is it 50mA or less? Refer toSC-22,

"OPERATION PROCEDURE OF CURRENT MEASUREMENT

PROBE FOR CONSULT-II".

NOTE:

Dark current stable time is different due to equipment and use of

the vehicle. If it is not 50mA or less after leaving for 1 minute, measure dark current again after leaving for

30 minutes or more.

If YES, GO TO 7. If NO, GO TO 5.

5. Remove and install fuses one by one. Search for the fuse that greatly changes dark current.

NOTE:

If dark current is greatly reduced when removing the fuse, and even if dark current is not greatly increased

when installing it again, the fuse circuit may be the cause.

6. Check that dark current changes when moving the suspect circuit harness. If dark current changes, check

harness for short. If dark current does not change, electronic unit in the circuit may not be entering the

energy-saving mode when it turns OFF. If it does not enter the energy-saving mode, replace electronic

unit.

7. No malfunction for alternator and electrical equipment. Electric load may be larger than alternator generat-

ing ability. Check the customer's usage.4 - Ground : 12V or more

MKIB1726E

MKIA0070E

Page 2856 of 3171

CHARGING SYSTEM

SC-23

C

D

E

F

G

H

I

J

L

MA

B

SC

Removal and InstallationEKS00MZE

REMOVAL

1. Disconnect negative battery cable.

2. Remove intercooler hose and duct

3. Disconnect alternator harness.

4. Remove drive belt. Refer toEM-12, "

Checking Drive Belts".

5. Remove alternator upper mounting bolt.

6. Remove alternator lower mounting nut and bolt .

7. Remove alternator.

INSTALLATION

Install in the reverse order of removal, taking care of the following point.

lInstall alternator, and check tension of drive belt. Refer toEM-13, "Deflection Adjustment".

CAUTION:

Be sure to tighten alternator terminal 1 mounting nut carefully.

Disassembly and AssemblyEKS00PD1

LHD MODELS

MKIB1992E

YD engine models - B terminal nut:

: 7.9 - 11.0 N·m (0.8 - 1.11 kg-m, 70 - 97 in-lb)

1. Rear bearing 2. Rotor 3. Retainer

4. Front bearing 5. Through bolt 6. Front cover

7. Washer 8. Pulley 9. Stator

10. IC voltage regulator assembly 11. Diode assembly 12. Rear cover

13. B terminal

MKIB2000E

Page 2860 of 3171

STARTING SYSTEM

SC-27

C

D

E

F

G

H

I

J

L

MA

B

SC

STARTING SYSTEMPFP:00011

System DescriptionEKS00MZJ

A/T MODELS

Power is supplied at all times:

lto starter motor terminal 1 and

lthrough 40A fusible link (letterJ, located in the fuse and fusible link box)

lto ignition switch terminal 1.

with the ignition switch in the START position, power is supplied:

lfrom ignition switch terminal 5

lto IPDM E/R terminal 21.

With the ignition switch in the ON or START position, power is supplied to IPDM E/R CPU, and

the selector lever in the P or N position, power is supplied:

lthrough A/T assembly terminal 9

lto IPDM E/R terminal 48.

Ground is supplied at all times:

lto IPDM E/R terminals 38 and 59

lfrom body grounds E21, E41 and E61.

Then the starter relay is turned ON.

The IPDM E/R starter relay is energized and power is supplied:

lfrom terminal 19 of IPDM E/R

lto terminal 2 of the starter motor.

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor operates.

M/T MODELS

Power is supplied at all times:

lto starter motor terminal 1 and

lthrough 40A fusible link (letterJ, located in the fuse and fusible link box)

lto ignition switch terminal 1.

with the ignition switch in the START position, power is supplied:

lfrom ignition switch terminal 5

lto IPDM E/R terminal 21.

With the start signal is input to IPDM E/R CPU, power is supplied:

lthrough IPDM E/R terminal 14

lto IPDM E/R terminal 48.

Ground is supplied at all times:

lto IPDM E/R terminals 38 and 59

lfrom body grounds E21, E41 and E61.

Then the starter relay is turned ON.

The IPDM E/R starter relay is energized and power is supplied:

lfrom terminal 19 of IPDM E/R

lto terminal 2 of the starter motor.

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor operates.

Page 2863 of 3171

SC-30

STARTING SYSTEM

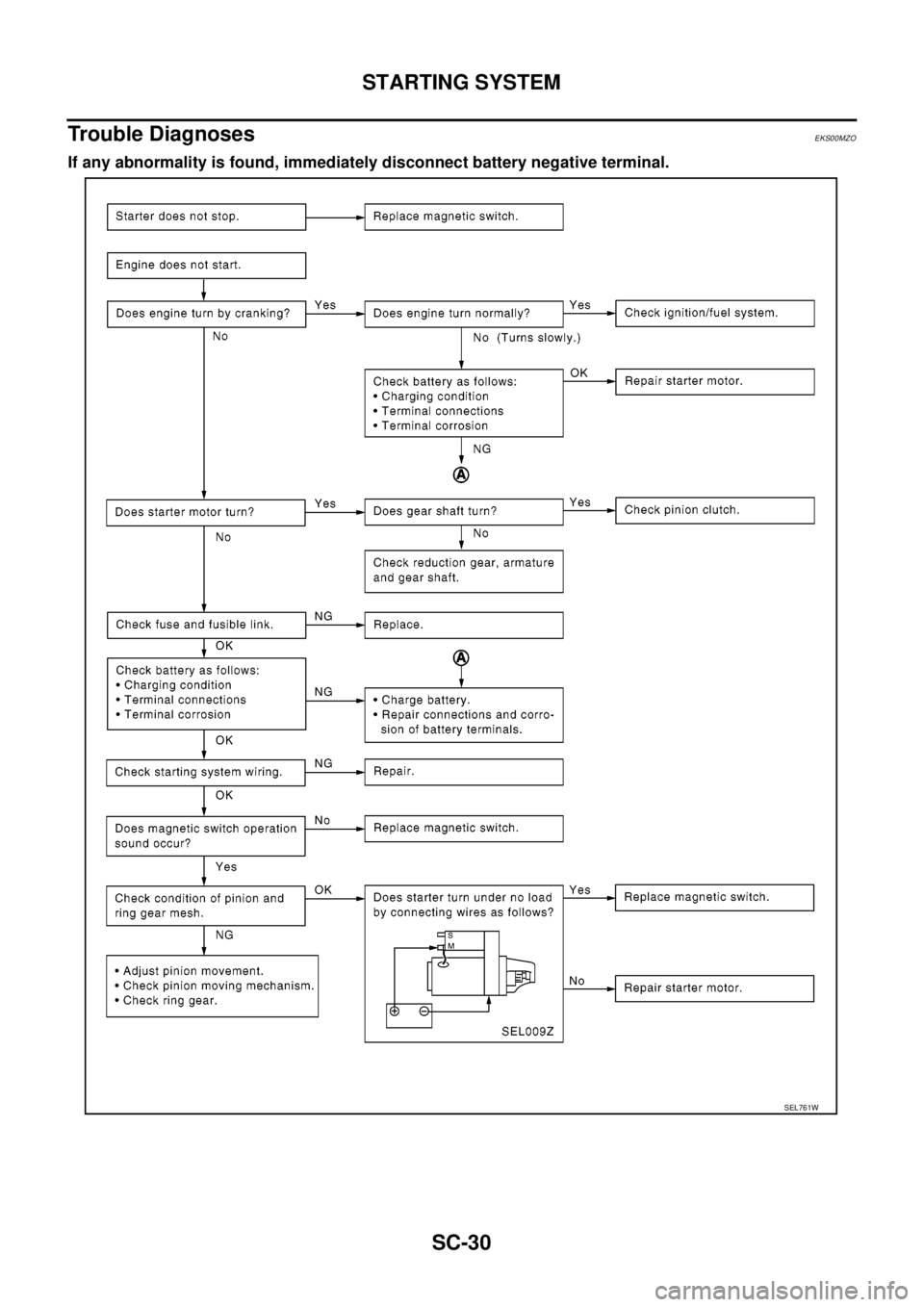

Trouble Diagnoses

EKS00MZO

If any abnormality is found, immediately disconnect battery negative terminal.

SEL761W

Page 2864 of 3171

STARTING SYSTEM

SC-31

C

D

E

F

G

H

I

J

L

MA

B

SC

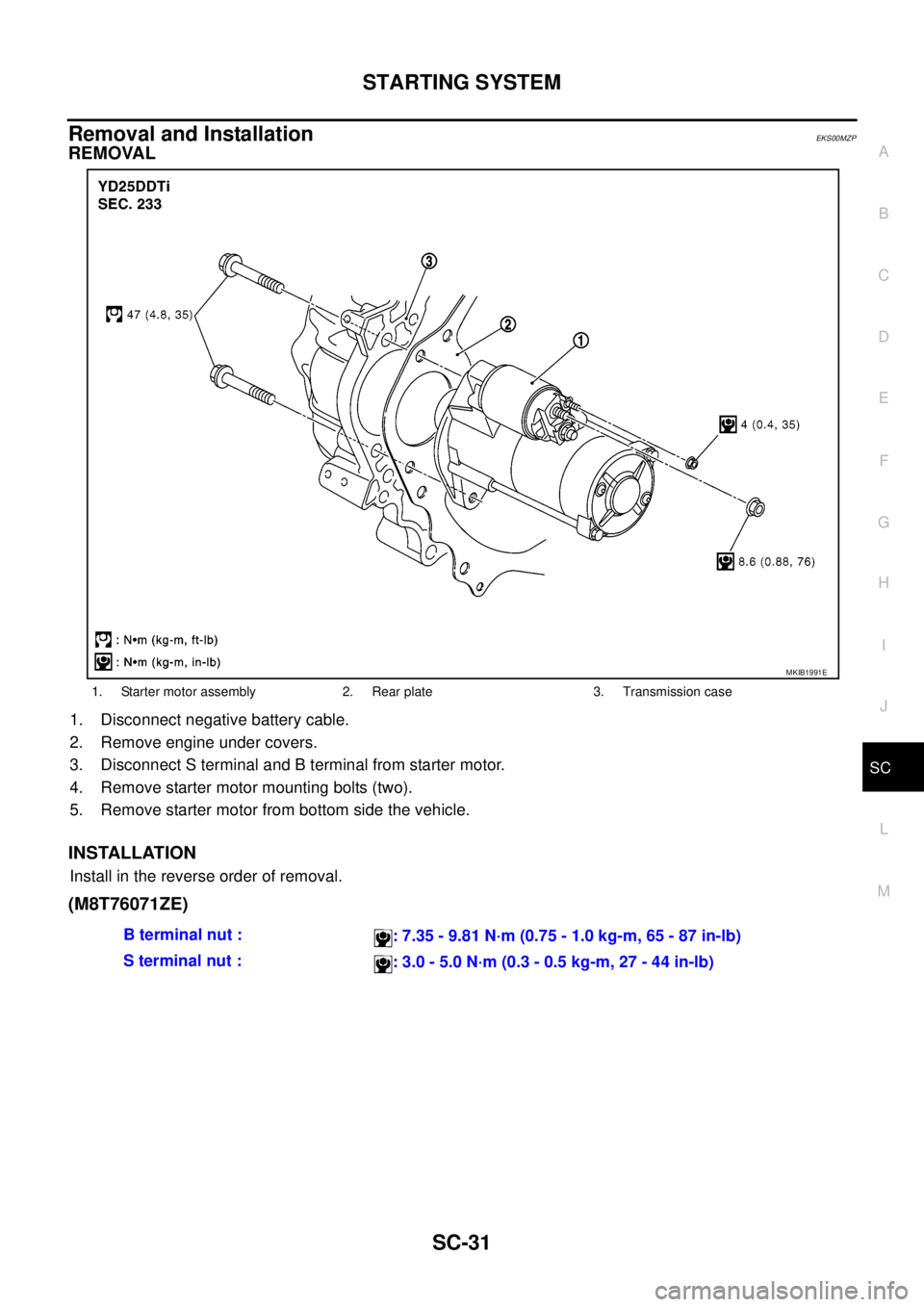

Removal and InstallationEKS00MZP

REMOVAL

1. Disconnect negative battery cable.

2. Remove engine under covers.

3. Disconnect S terminal and B terminal from starter motor.

4. Remove starter motor mounting bolts (two).

5. Remove starter motor from bottom side the vehicle.

INSTALLATION

Install in the reverse order of removal.

(M8T76071ZE)

1. Starter motor assembly 2. Rear plate 3. Transmission case

MKIB1991E

B terminal nut :

: 7.35 - 9.81 N·m (0.75 - 1.0 kg-m, 65 - 87 in-lb)

S terminal nut :

:3.0-5.0N·m(0.3-0.5kg-m,27-44in-lb)