battery NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2961 of 3171

SRS-52

DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

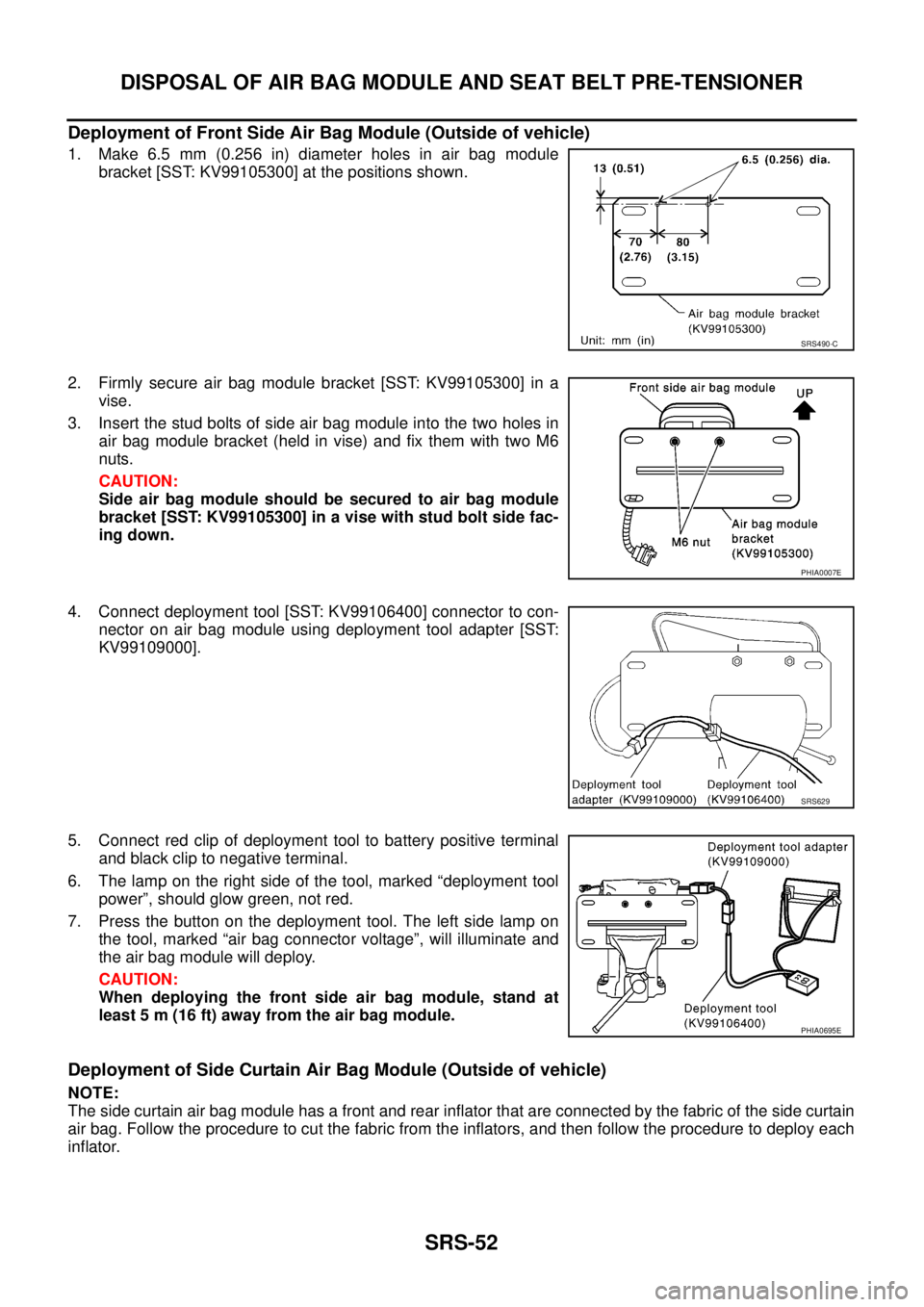

Deployment of Front Side Air Bag Module (Outside of vehicle)

1. Make 6.5 mm (0.256 in) diameter holes in air bag module

bracket [SST: KV99105300] at the positions shown.

2. Firmly secure air bag module bracket [SST: KV99105300] in a

vise.

3. Insert the stud bolts of side air bag module into the two holes in

air bag module bracket (held in vise) and fix them with two M6

nuts.

CAUTION:

Side air bag module should be secured to air bag module

bracket [SST: KV99105300] in a vise with stud bolt side fac-

ing down.

4. Connect deployment tool [SST: KV99106400] connector to con-

nector on air bag module using deployment tool adapter [SST:

KV99109000].

5. Connect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

6. The lamp on the right side of the tool, marked “deployment tool

power”, should glow green, not red.

7. Press the button on the deployment tool. The left side lamp on

the tool, marked “air bag connector voltage”, will illuminate and

the air bag module will deploy.

CAUTION:

When deploying the front side air bag module, stand at

least 5 m (16 ft) away from the air bag module.

Deployment of Side Curtain Air Bag Module (Outside of vehicle)

NOTE:

The side curtain air bag module has a front and rear inflator that are connected by the fabric of the side curtain

air bag. Follow the procedure to cut the fabric from the inflators, and then follow the procedure to deploy each

inflator.

SRS490-C

PHIA0007E

SRS629

PHIA0695E

Page 2962 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

SRS-53

C

D

E

F

G

I

J

K

L

MA

B

SRS

1. Cut the inflator from side curtain air bag module.

2. Connect deployment tool [SST: KV99106400] to the infla NISSAN NAVARA 2005 Repair Workshop Manual DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

SRS-53

C

D

E

F

G

I

J

K

L

MA

B

SRS

1. Cut the inflator from side curtain air bag module.

2. Connect deployment tool [SST: KV99106400] to the infla](/img/5/57362/w960_57362-2961.png)

DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

SRS-53

C

D

E

F

G

I

J

K

L

MA

B

SRS

1. Cut the inflator from side curtain air bag module.

2. Connect deployment tool [SST: KV99106400] to the inflator

using deployment tool adapter [SST: KV99110500].

3. Put the inflator connected with the deployment tool [SST:

KV99106400] into a tire without a wheel.

4. Put the tire with the inflator onto another tire without wheel. Add

an additional tire without a wheel and then a tire mounted on a

wheel on top.

CAUTION:

Tie all tires together with a strap in order to keep them

standing.

5. Connect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

6. The lamp on the right side of the tool, marked “deployment tool

power”, should glow green, not red.

7. Press the button on the deployment tool. The left side lamp on

the tool, marked “air bag connector voltage”, will illuminate and the air bag module will deploy.

CAUTION:

When deploying the side curtain air bag module, stand at least 5 m (16 ft) away from the side cur-

tain air bag module.

8. Repeat this procedure to deploy the second inflator.

SHIA0198E

PHIA0568E

PHIA0011E

PHIA0555E

Page 2963 of 3171

SRS-54

DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

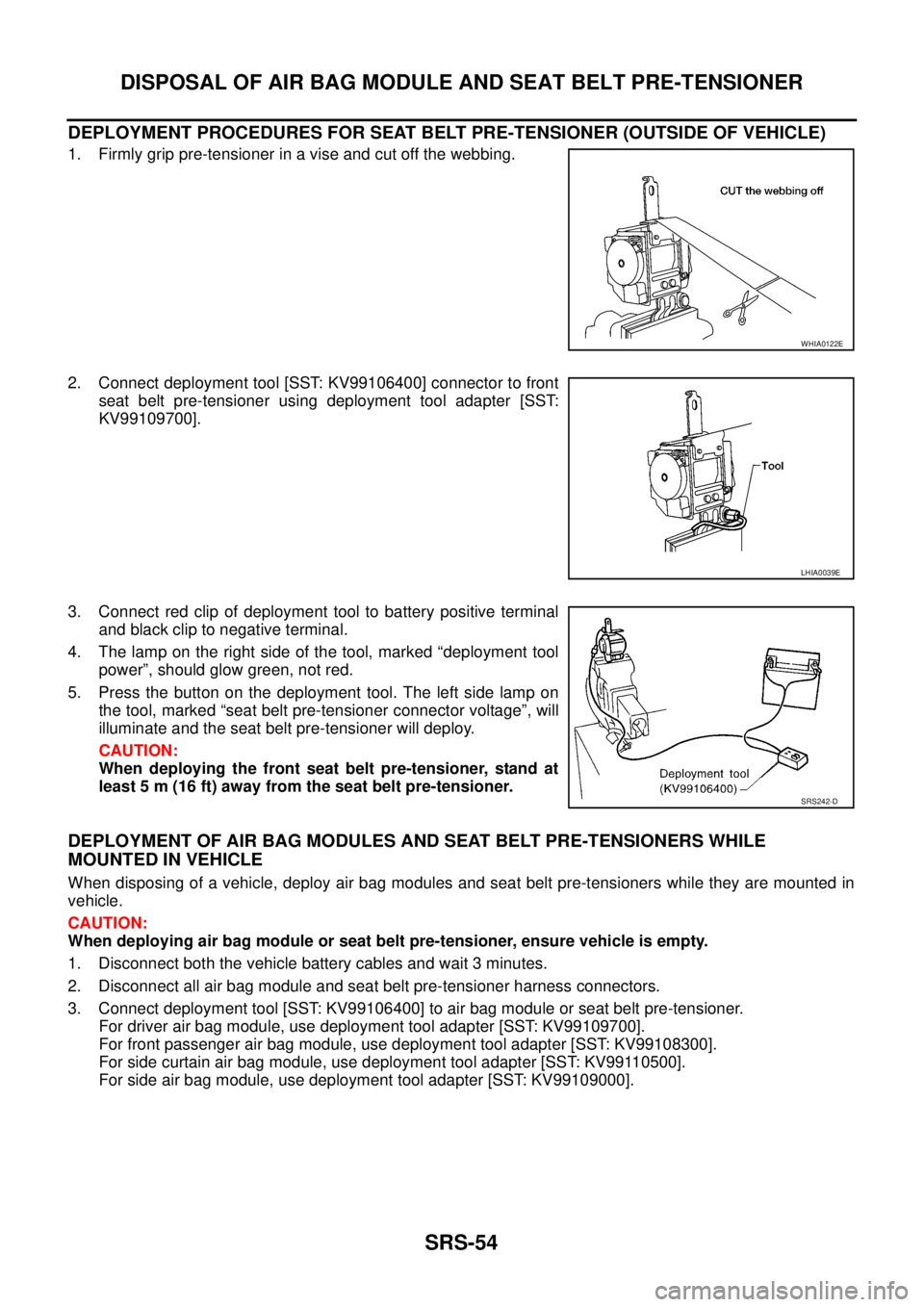

DEPLOYMENT PROCEDURES FOR SEAT BELT PRE-TENSIONER (OUTSIDE OF VEHICLE)

1. Firmly grip pre-tensioner in a vise and cut off the webbing.

2. Connect deployment tool [SST: KV99106400] connector to front

seat belt pre-tensioner using deployment tool adapter [SST:

KV99109700].

3. Connect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

4. The lamp on the right side of the tool, marked “deployment tool

power”, should glow green, not red.

5. Press the button on the deployment tool. The left side lamp on

the tool, marked “seat belt pre-tensioner connector voltage”, will

illuminate and the seat belt pre-tensioner will deploy.

CAUTION:

When deploying the front seat belt pre-tensioner, stand at

least 5 m (16 ft) away from the seat belt pre-tensioner.

DEPLOYMENT OF AIR BAG MODULES AND SEAT BELT PRE-TENSIONERS WHILE

MOUNTED IN VEHICLE

When disposing of a vehicle, deploy air bag modules and seat belt pre-tensioners while they are mounted in

vehicle.

CAUTION:

When deploying air bag module or seat belt pre-tensioner, ensure vehicle is empty.

1. Disconnect both the vehicle battery cables and wait 3 minutes.

2. Disconnect all air bag module and seat belt pre-tensioner harness connectors.

3. Connect deployment tool [SST: KV99106400] to air bag module or seat belt pre-tensioner.

For driver air bag module, use deployment tool adapter [SST: KV99109700].

For front passenger air bag module, use deployment tool adapter [SST: KV99108300].

For side curtain air bag module, use deployment tool adapter [SST: KV99110500].

For side air bag module, use deployment tool adapter [SST: KV99109000].

WHIA0122E

LHIA0039E

SRS242-D

Page 2964 of 3171

DISPOSAL OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

SRS-55

C

D

E

F

G

I

J

K

L

MA

B

SRS

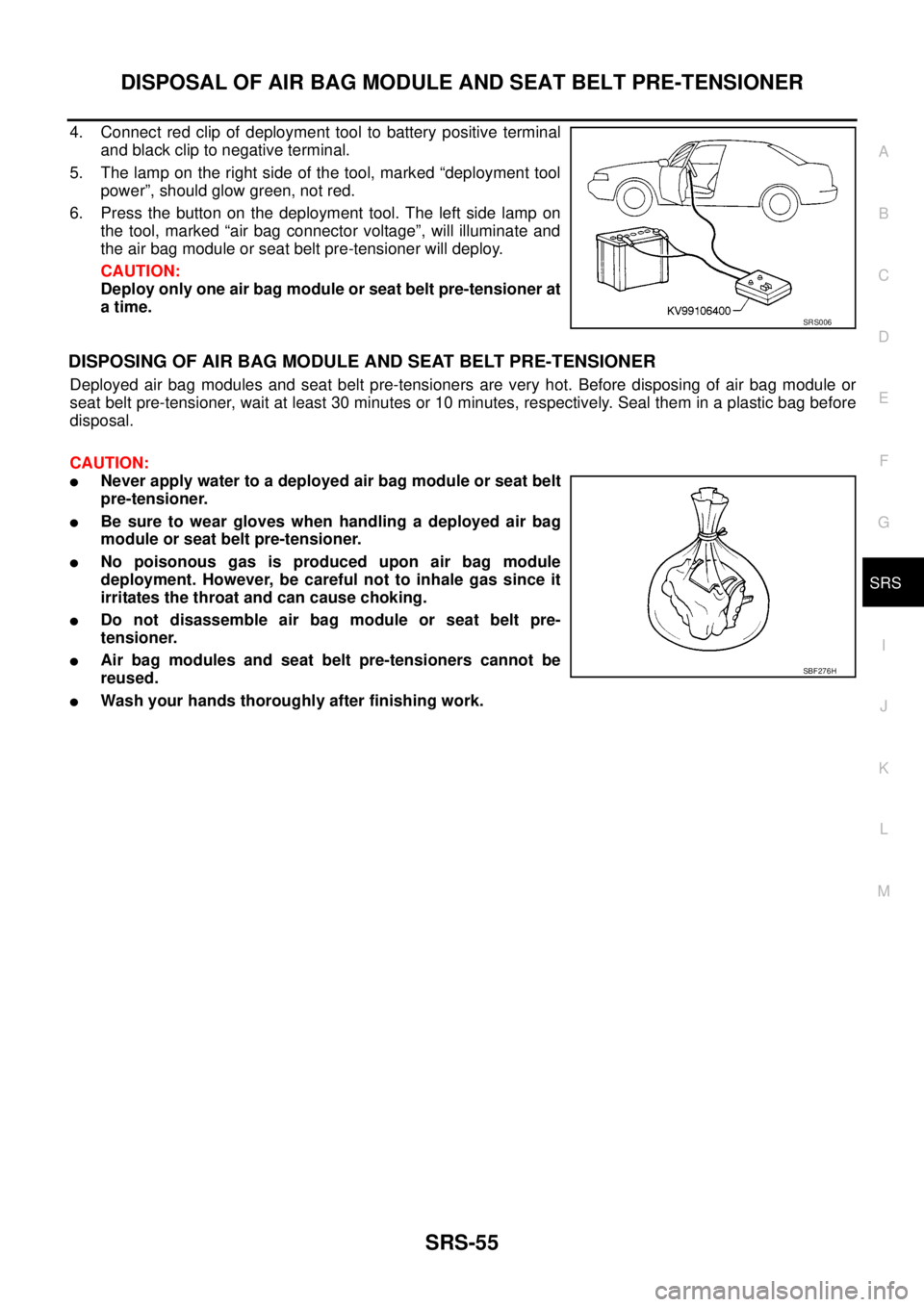

4. Connect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

5. The lamp on the right side of the tool, marked “deployment tool

power”, should glow green, not red.

6. Press the button on the deployment tool. The left side lamp on

the tool, marked “air bag connector voltage”, will illuminate and

the air bag module or seat belt pre-tensioner will deploy.

CAUTION:

Deploy only one air bag module or seat belt pre-tensioner at

atime.

DISPOSING OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

Deployed air bag modules and seat belt pre-tensioners are very hot. Before disposing of air bag module or

seat belt pre-tensioner, wait at least 30 minutes or 10 minutes, respectively. Seal them in a plastic bag before

disposal.

CAUTION:

lNever apply water to a deployed air bag module or seat belt

pre-tensioner.

lBe sure to wear gloves when handling a deployed air bag

module or seat belt pre-tensioner.

lNo poisonous gas is produced upon air bag module

deployment. However, be careful not to inhale gas since it

irritates the throat and can cause choking.

lDo not disassemble air bag module or seat belt pre-

tensioner.

lAir bag modules and seat belt pre-tensioners cannot be

reused.

lWash your hands thoroughly after finishing work.

SRS006

SBF276H

Page 2973 of 3171

TF-6

PRECAUTIONS

If 4WD shift indicator lamp and 4LO indicator lamp do not indicate proper pattern, install new transfer con-

trol unit and retry the above check.

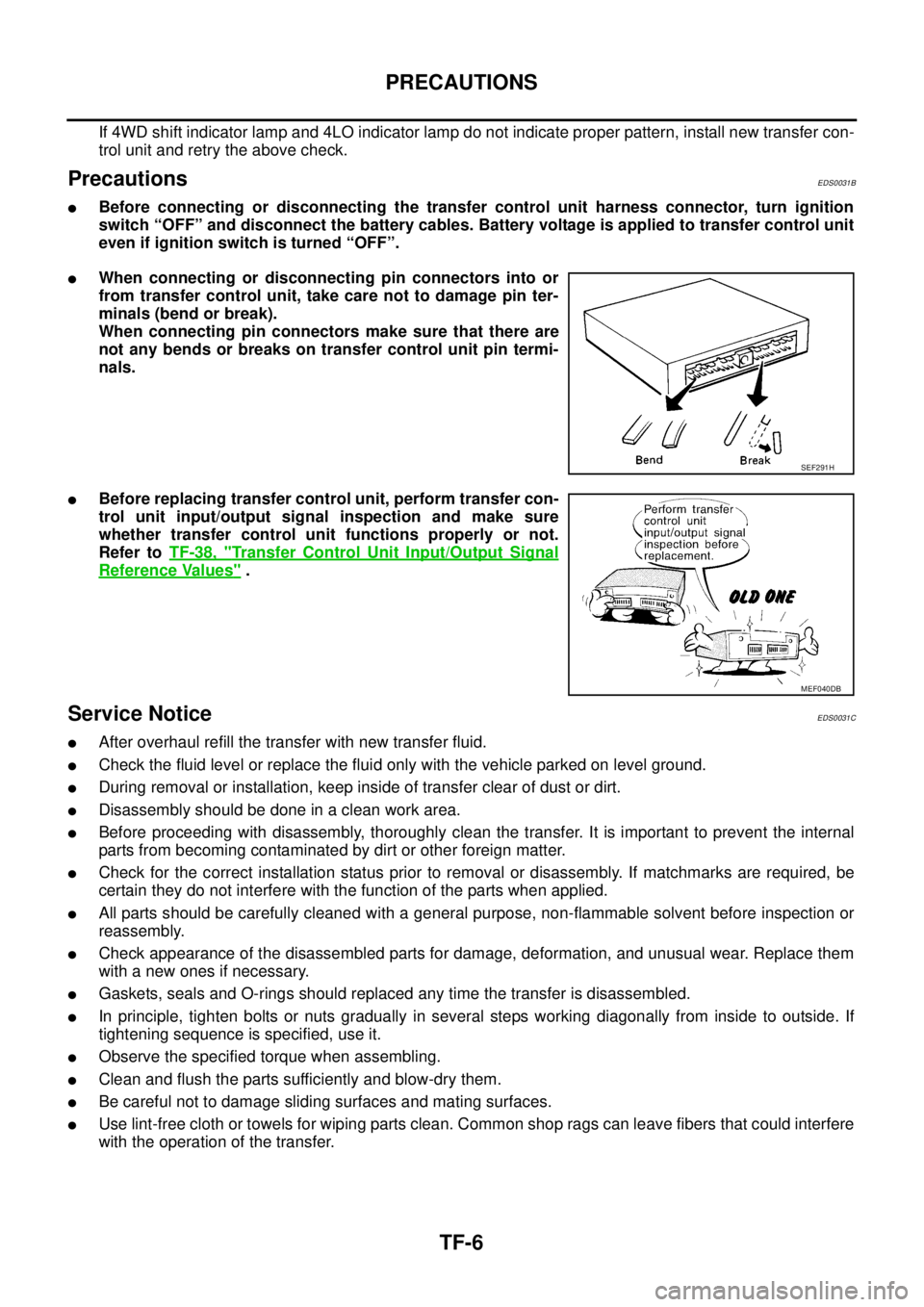

PrecautionsEDS0031B

lBefore connecting or disconnecting the transfer control unit harness connector, turn ignition

switch “OFF” and disconnect the battery cables. Battery voltage is applied to transfer control unit

even if ignition switch is turned “OFF”.

lWhen connecting or disconnecting pin connectors into or

from transfer control unit, take care not to damage pin ter-

minals (bend or break).

When connecting pin connectors make sure that there are

not any bends or breaks on transfer control unit pin termi-

nals.

lBefore replacing transfer control unit, perform transfer con-

trol unit input/output signal inspection and make sure

whether transfer control unit functions properly or not.

Refer toTF-38, "

Transfer Control Unit Input/Output Signal

Reference Values".

Service NoticeEDS0031C

lAfter overhaul refill the transfer with new transfer fluid.

lCheck the fluid level or replace the fluid only with the vehicle parked on level ground.

lDuring removal or installation, keep inside of transfer clear of dust or dirt.

lDisassemblyshouldbedoneinacleanworkarea.

lBefore proceeding with disassembly, thoroughly clean the transfer. It is important to prevent the internal

parts from becoming contaminated by dirt or other foreign matter.

lCheck for the correct installation status prior to removal or disassembly. If matchmarks are required, be

certain they do not interfere with the function of the parts when applied.

lAll parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

lCheck appearance of the disassembled parts for damage, deformation, and unusual wear. Replace them

with a new ones if necessary.

lGaskets, seals and O-rings should replaced any time the transfer is disassembled.

lIn principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If

tightening sequence is specified, use it.

lObserve the specified torque when assembling.

lClean and flush the parts sufficiently and blow-dry them.

lBe careful not to damage sliding surfaces and mating surfaces.

lUse lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could interfere

with the operation of the transfer.

SEF291H

MEF040DB

Page 3005 of 3171

TF-38

TROUBLE DIAGNOSIS

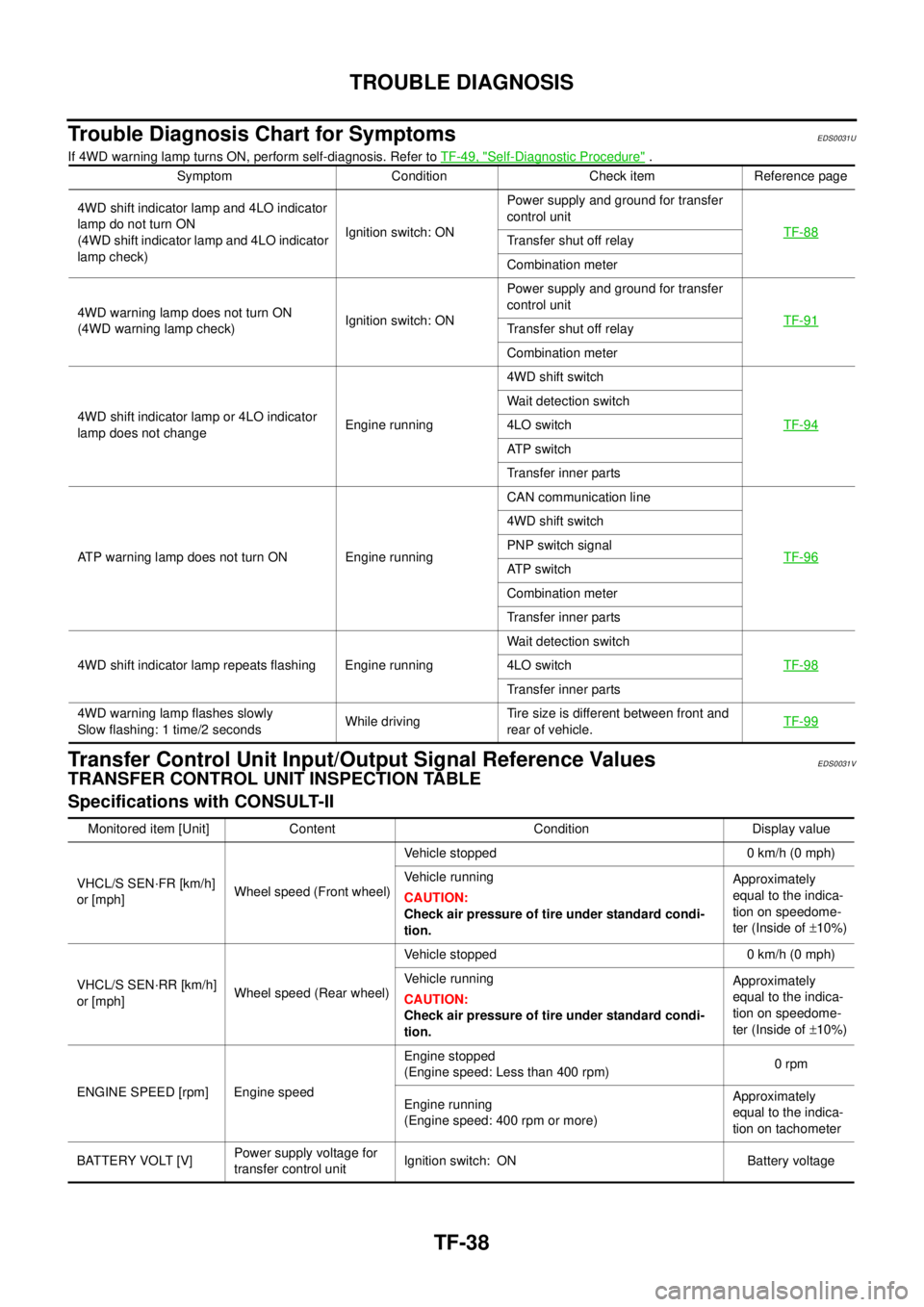

Trouble Diagnosis Chart for Symptoms

EDS0031U

If 4WD warning lamp turns ON, perform self-diagnosis. Refer toTF-49, "Self-Diagnostic Procedure".

Transfer Control Unit Input/Output Signal Reference ValuesEDS0031V

TRANSFER CONTROL UNIT INSPECTION TABLE

Specifications with CONSULT-II

Symptom Condition Check item Reference page

4WD shift indicator lamp and 4LO indicator

lamp do not turn ON

(4WD shift indicator lamp and 4LO indicator

lamp check)Ignition switch: ONPower supply and ground for transfer

control unit

TF-88

Transfer shut off relay

Combination meter

4WD warning lamp does not turn ON

(4WD warning lamp check)Ignition switch: ONPower supply and ground for transfer

control unit

TF-91

Transfer shut off relay

Combination meter

4WD shift indicator lamp or 4LO indicator

lamp does not changeEngine running4WD shift switch

TF-94

Wait detection switch

4LO switch

AT P s w i t c h

Transfer inner parts

ATP warning lamp does not turn ON Engine runningCAN communication line

TF-96

4WD shift switch

PNP switch signal

AT P s w i t c h

Combination meter

Transfer inner parts

4WD shift indicator lamp repeats flashing Engine runningWait detection switch

TF-98

4LO switch

Transfer inner parts

4WD warning lamp flashes slowly

Slow flashing: 1 time/2 secondsWhile drivingTire size is different between front and

rear of vehicle.TF-99

Monitored item [Unit] Content Condition Display value

VHCL/S SEN·FR [km/h]

or [mph]Wheel speed (Front wheel)Vehicle stopped 0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condi-

tion.Approximately

equal to the indica-

tion on speedome-

ter (Inside of±10%)

VHCL/S SEN·RR [km/h]

or [mph]Wheel speed (Rear wheel)Vehicle stopped 0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condi-

tion.Approximately

equal to the indica-

tion on speedome-

ter (Inside of±10%)

ENGINE SPEED [rpm] Engine speedEngine stopped

(Engine speed: Less than 400 rpm)0rpm

Engine running

(Engine speed: 400 rpm or more)Approximately

equal to the indica-

tion on tachometer

BATTERY VOLT [V]Power supply voltage for

transfer control unitIgnition switch: ON Battery voltage

Page 3008 of 3171

TROUBLE DIAGNOSIS

TF-41

C

E

F

G

H

I

J

K

L

MA

B

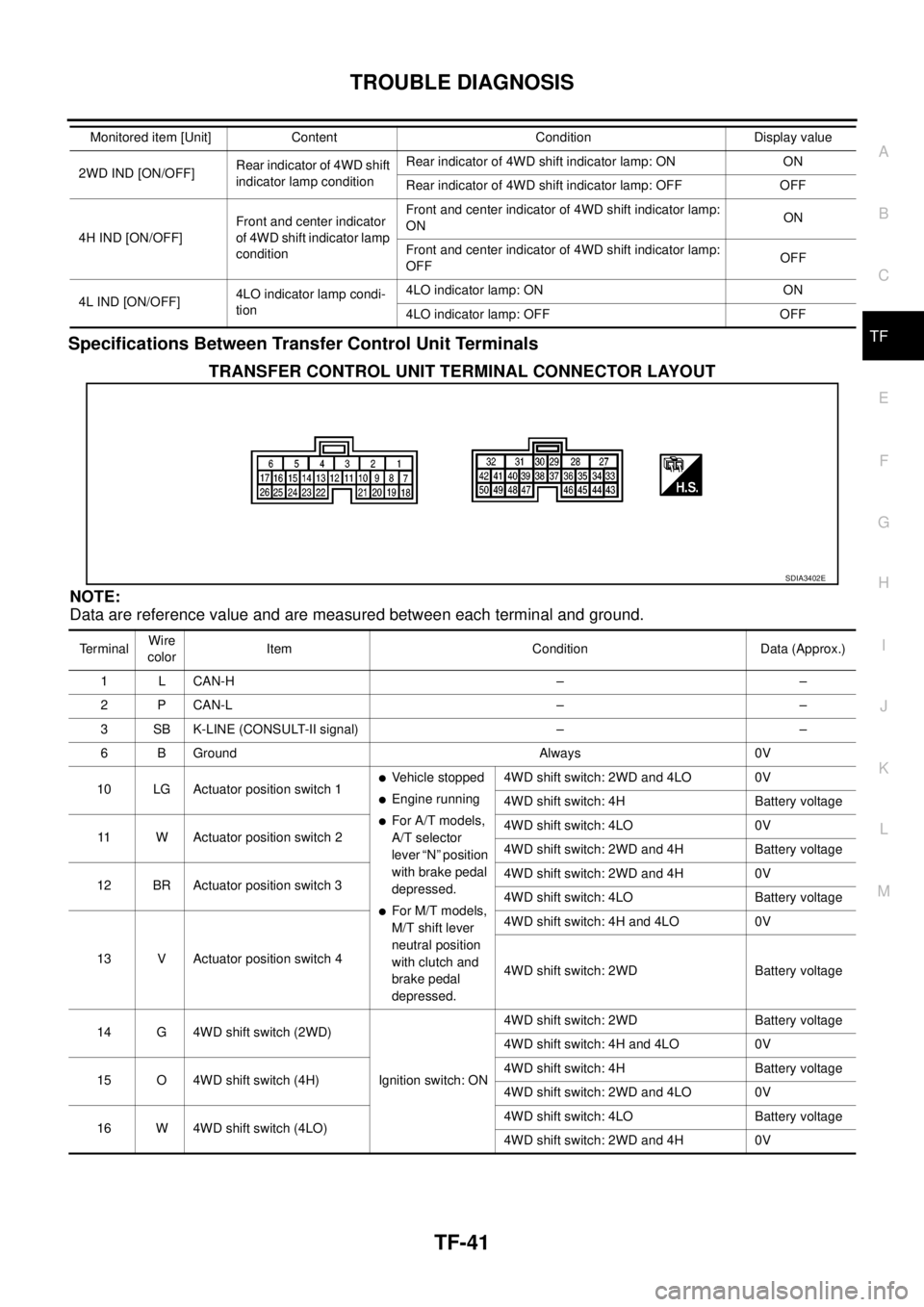

TFSpecifications Between Transfer Control Unit Terminals

TRANSFER CONTROL UNIT TERMINAL CONNECTOR LAYOUT

NOTE:

Data are reference value and are measured between each terminal and ground.

2WD IND [ON/OFF]Rear indicator of 4WD shift

indicator lamp conditionRear indicator of 4WD shift indicator lamp: ON ON

Rear indicator of 4WD shift indicator lamp: OFF OFF

4H IND [ON/OFF]Front and center indicator

of 4WD shift indicator lamp

conditionFront and center indicator of 4WD shift indicator lamp:

ONON

Front and center indicator of 4WD shift indicator lamp:

OFFOFF

4L IND [ON/OFF]4LO indicator lamp condi-

tion4LO indicator lamp: ON ON

4LO indicator lamp: OFF OFF Monitored item [Unit] Content Condition Display value

SDIA3402E

TerminalWire

colorItem Condition Data (Approx.)

1 L CAN-H – –

2 P CAN-L – –

3 SB K-LINE (CONSULT-II signal) – –

6 B Ground Always 0V

10 LG Actuator position switch 1

lVehicle stopped

lEngine running

lFor A/T models,

A/T selector

lever “N” position

with brake pedal

depressed.

lFor M/T models,

M/T shift lever

neutral position

with clutch and

brake pedal

depressed.4WD shift switch: 2WD and 4LO 0V

4WD shift switch: 4H Battery voltage

11 W Actuator position switch 24WD shift switch: 4LO 0V

4WD shift switch: 2WD and 4H Battery voltage

12 BR Actuator position switch 34WD shift switch: 2WD and 4H 0V

4WD shift switch: 4LO Battery voltage

13 V Actuator position switch 44WD shift switch: 4H and 4LO 0V

4WD shift switch: 2WD Battery voltage

14 G 4WD shift switch (2WD)

Ignition switch: ON4WD shift switch: 2WD Battery voltage

4WD shift switch: 4H and 4LO 0V

15 O 4WD shift switch (4H)4WD shift switch: 4H Battery voltage

4WD shift switch: 2WD and 4LO 0V

16 W 4WD shift switch (4LO)4WD shift switch: 4LO Battery voltage

4WD shift switch: 2WD and 4H 0V

Page 3009 of 3171

TF-42

TROUBLE DIAGNOSIS

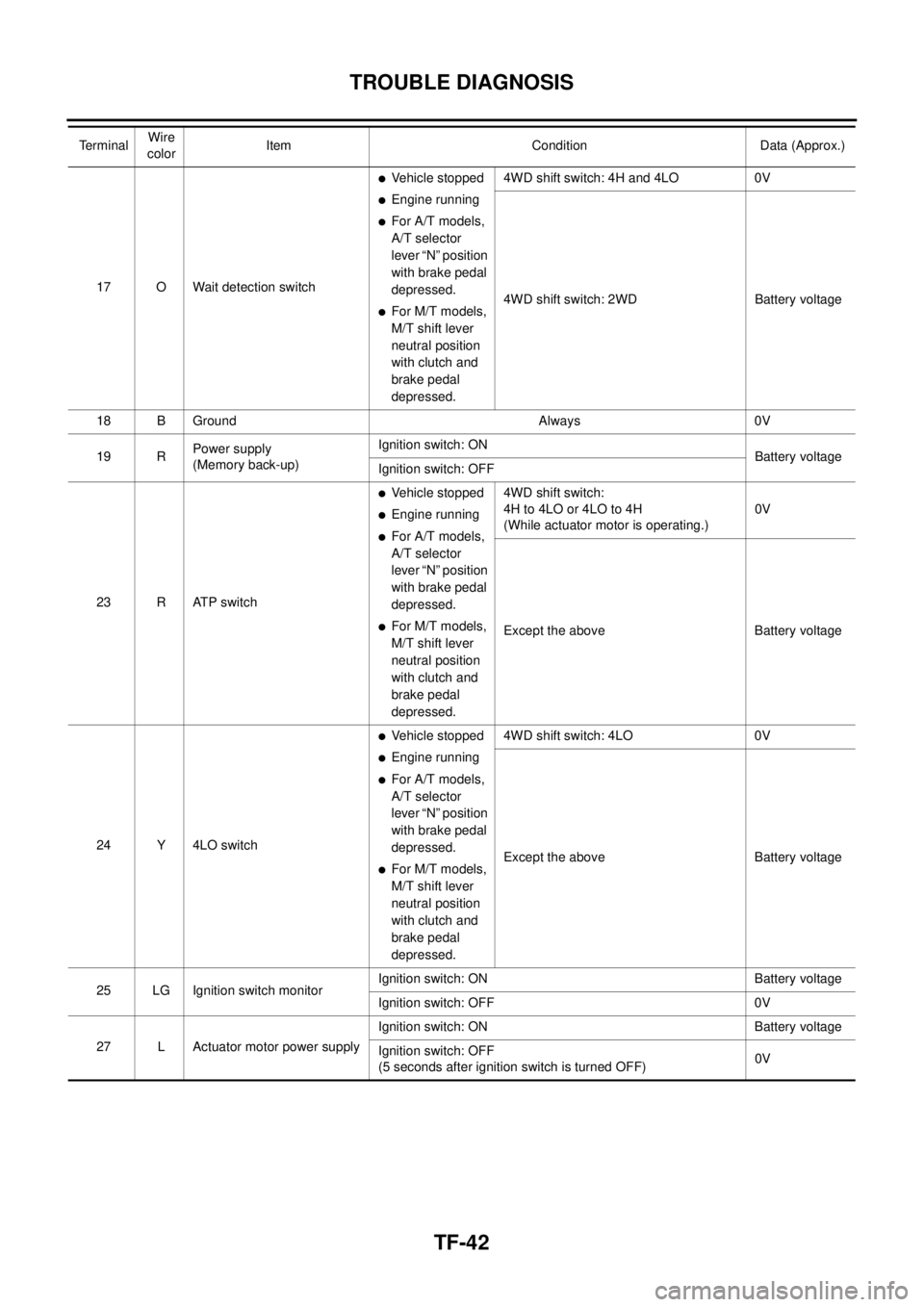

17 O Wait detection switch

lVehicle stopped

lEngine running

lFor A/T models,

A/T selector

lever “N” position

with brake pedal

depressed.

lFor M/T models,

M/T shift lever

neutral position

with clutch and

brake pedal

depressed.4WD shift switch: 4H and 4LO 0V

4WD shift switch: 2WD Battery voltage

18 B Ground Always 0V

19 RPower supply

(Memory back-up)Ignition switch: ON

Battery voltage

Ignition switch: OFF

23 R ATP switch

lVehicle stopped

lEngine running

lFor A/T models,

A/T selector

lever “N” position

with brake pedal

depressed.

lFor M/T models,

M/T shift lever

neutral position

with clutch and

brake pedal

depressed.4WD shift switch:

4H to 4LO or 4LO to 4H

(While actuator motor is operating.)0V

Except the above Battery voltage

24 Y 4LO switch

lVehicle stopped

lEngine running

lFor A/T models,

A/T selector

lever “N” position

with brake pedal

depressed.

lFor M/T models,

M/T shift lever

neutral position

with clutch and

brake pedal

depressed.4WD shift switch: 4LO 0V

Except the above Battery voltage

25 LG Ignition switch monitorIgnition switch: ON Battery voltage

Ignition switch: OFF 0V

27 L Actuator motor power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)0V Te r m i n a lWire

colorItem Condition Data (Approx.)

Page 3010 of 3171

TROUBLE DIAGNOSIS

TF-43

C

E

F

G

H

I

J

K

L

MA

B

TF

28 BR Actuator motor (+)

lVehicle stopped

lEngine running

lFor A/T models,

A/T selector

lever “N” position

with brake pedal

depressed.

lFor M/T models,

M/T shift lever

neutral position

with clutch and

brake pedal

depressed.When 4WD shift switch is operated

(while actuator motor is operating)Battery voltage

®0V

When 4WD shift switch is not operated 0V

31 G Actuator motor (-) Always 0V

32 B Ground Always 0V

33

(For M/T

models)P Park/Neutral position switch Ignition switch: ONM/T shift lever neutral position 0V

Except the above Battery voltage

35 V4WD shift indicator lamp

(Rear indicator)

Engine runningRear indicator of 4WD shift indicator

lamp: ON0V

Rear indicator of 4WD shift indicator

lamp: OFFBattery voltage

36 BR4WD shift indicator lamp

(Front and center indicator)Front and center indicator of 4WD shift

indicator lamp: ON0V

Front and center indicator of 4WD shift

indicator lamp: OFFBattery voltage

37 Y 4LO indicator lamp4LO indicator lamp: ON 0V

4LO indicator lamp: OFF Battery voltage

38 P 4WD warning lamp4WD warning lamp: ON 0V

4WD warning lamp: OFF Battery voltage

39

(For A/T

models)LG ATP warning lamp

lVehicle stopped

lEngine running

lA/T selector

lever “P” position

lBrake pedal

depressed4WD shift switch:

4H to 4LO or 4LO to 4H

(While actuator motor is operating.)Battery voltage

Except the above 0V

40 V Transfer shut off relayIgnition switch: ON 0V

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)Battery voltage

42 LG Transfer shift high relay

lVehicle stopped

lEngine running

lFor A/T models,

A/T selector

lever “N” position

with brake pedal

depressed.

lFor M/T models,

M/T shift lever

neutral position

with clutch and

brake pedal

depressed.4WD shift switch:

2WD to 4H or 4H to 4LO or 2WD to 4LO0V

Except the above Battery voltage TerminalWire

colorItem Condition Data (Approx.)

Page 3011 of 3171

TF-44

TROUBLE DIAGNOSIS

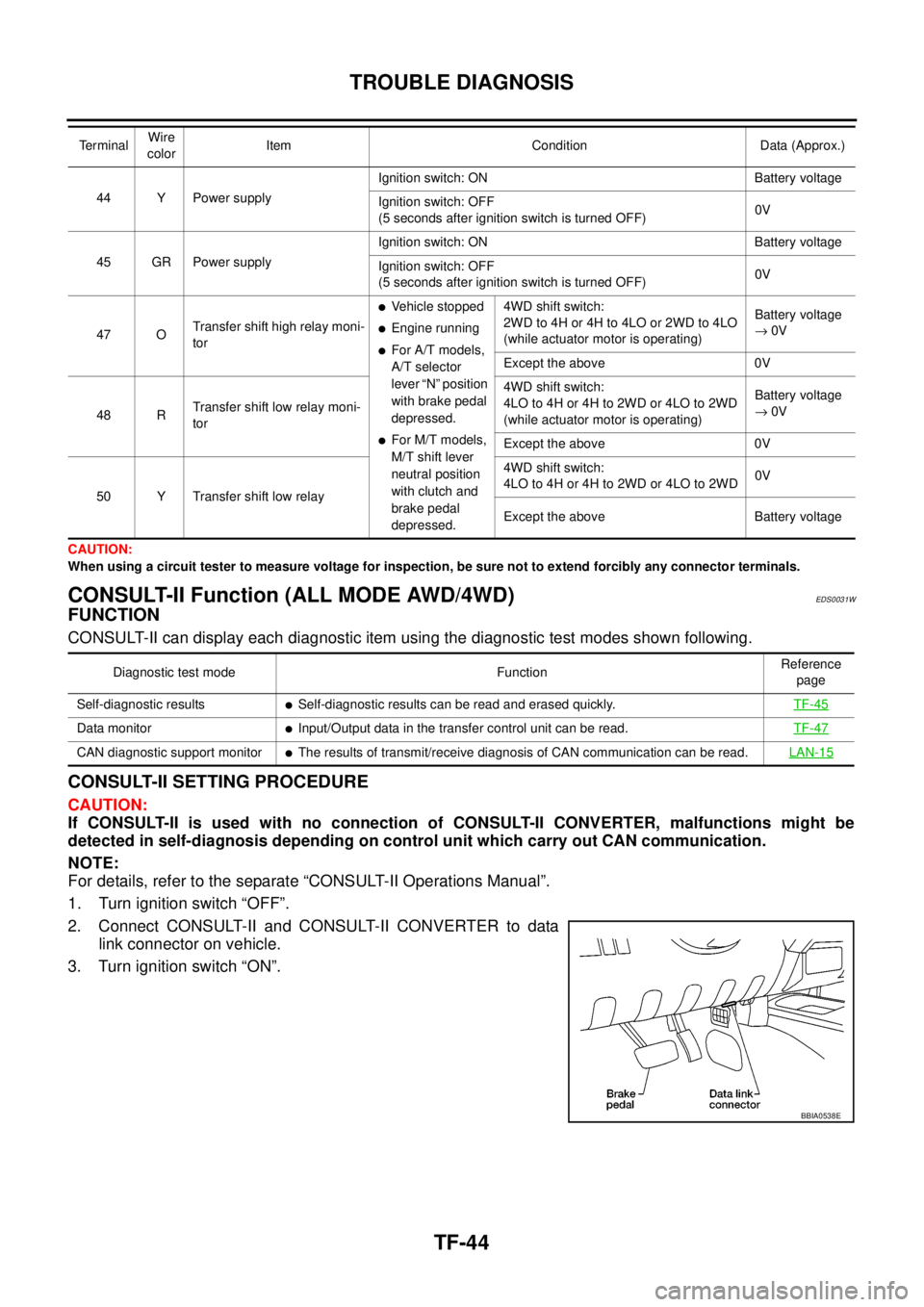

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.

CONSULT-II Function (ALL MODE AWD/4WD)EDS0031W

FUNCTION

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II SETTING PROCEDURE

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

NOTE:

For details, refer to the separate “CONSULT-II Operations Manual”.

1. Turn ignition switch “OFF”.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data

link connector on vehicle.

3. Turn ignition switch “ON”.

44 Y Power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)0V

45 GR Power supplyIgnition switch: ON Battery voltage

Ignition switch: OFF

(5 seconds after ignition switch is turned OFF)0V

47 OTransfer shift high relay moni-

tor

lVehicle stopped

lEngine running

lFor A/T models,

A/T selector

lever “N” position

with brake pedal

depressed.

lFor M/T models,

M/T shift lever

neutral position

with clutch and

brake pedal

depressed.4WD shift switch:

2WD to 4H or 4H to 4LO or 2WD to 4LO

(while actuator motor is operating)Battery voltage

®0V

Except the above 0V

48 RTransfer shift low relay moni-

tor4WD shift switch:

4LO to 4H or 4H to 2WD or 4LO to 2WD

(while actuator motor is operating)Battery voltage

®0V

Except the above 0V

50 Y Transfer shift low relay4WD shift switch:

4LO to 4H or 4H to 2WD or 4LO to 2WD0V

Except the above Battery voltage Te r m i n a lWire

colorItem Condition Data (Approx.)

Diagnostic test mode FunctionReference

page

Self-diagnostic results

lSelf-diagnostic results can be read and erased quickly.TF-45

Data monitorlInput/Output data in the transfer control unit can be read.TF-47

CAN diagnostic support monitorlThe results of transmit/receive diagnosis of CAN communication can be read.LAN-15

BBIA0538E