service NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2819 of 3171

SB-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EHS0026D

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Seat Belt ServiceEHS00265

CAUTION:

lBefore removing the seat belt pre-tensioner assembly, turn the ignition switch OFF, disconnect

both battery cables and wait at least 3 minutes.

lDo not use electrical test equipment for seat belt pre-tensioner connector.

lAfter replacing or reinstalling seat belt pre-tensioner assembly, or reconnecting seat belt pre-

tensioner assembly connector, ensure entire SRS operates properly. Refer toSRS-18, "

SRS Oper-

ation Check".

lDeploy seat belt pre-tensioner assembly before disposing. Refer toSRS-49, "DISPOSAL OF AIR

BAG MODULE AND SEAT BELT PRE-TENSIONER".

lDo not disassemble buckle or seat belt assembly.

lReplace anchor bolts if they are deformed or worn out.

lNever oil tongue and buckle.

lIf any component of seat belt assembly is questionable, do not repair. Replace the whole seat belt

assembly.

lIf webbing is cut, frayed, or damaged, replace seat belt assembly.

lWhen replacing seat belt assembly, use a genuine NISSAN seat belt assembly.

AFTER A COLLISION

WARNING:

lInspect all seat belt assemblies including retractors and attaching hardware after any collision.

lNISSAN recommends that all seat belt assemblies in use during a collision be replaced unless the

collision was minor and the belts show no damage and continue to operate properly. Failure to do

so could result in serious personal injury in an accident. Seat belt assemblies not in use during a

collision should also be replaced if either damage or improper operation is noted. Seat belt pre-

tensioner should be replaced even if the seat belts are not in use during a frontal collision in which

the air bags are deployed.

Replace any seat belt assembly (including anchor bolts) if:

lThe seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and

buckles show no damage and continue to operate properly).

lThe seat belt was damaged in an accident. (i.e., torn webbing, bent retractor or guide, etc.)

lThe seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for damage

or distortion and repair as necessary before installing a new seat belt assembly.

lAnchor bolts are deformed or worn out.

lThe seat belt pre-tensioner should be replaced even if the seat belts are not in use during the collision in

which the air bags are deployed.

Page 2832 of 3171

LATCH (LOWER ANCHORS AND TETHER FOR CHILDREN) SYSTEM

SB-15

C

D

E

F

G

I

J

K

L

MA

B

SB

LATCH (LOWER ANCHORS AND TETHER FOR CHILDREN) SYSTEMPFP:75466

Removal and Installation - Double CabEHS0026B

NOTE:

The LATCH (Lower Anchors and Tether for Children) system is not serviceable.

Page 2833 of 3171

SB-16

TOP TETHER STRAP CHILD RESTRAINT

TOP TETHER STRAP CHILD RESTRAINT

PFP:88000

Removal and Installation - Double CabEHS0026C

NOTE:

The Top Tether Strap Child Restraint system is not serviceable.

Page 2834 of 3171

SC-1

STARTING & CHARGING SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONSC

A

B

SC

STARTING & CHARGING SYSTEM

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Wiring Diagrams and Trouble Diagnosis .................. 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

BATTERY .................................................................... 5

How to Handle Battery ............................................. 5

METHODS OF PREVENTING OVER-DIS-

CHARGE ............................................................... 5

CHECKING ELECTROLYTE LEVEL .................... 5

SPECIFIC GRAVITY CHECK ............................... 6

Battery Test and Charging Chart .............................. 7

CHART I ................................................................ 7

CHART II ............................................................... 8

A: SLOW CHARGE ............................................... 9

B: STANDARD CHARGE .................................... 10

C: QUICK CHARGE ............................................ 12

Removal and Installation ........................................ 13

CHARGING SYSTEM ............................................... 14

System Description ................................................ 14

Wiring Diagram — CHARGE — ............................. 15

Trouble Diagnosis .................................................. 16

DIAGNOSIS PROCEDURE ................................ 16

PRE-DIAGNOSIS INSPECTION ......................... 16

DIAGNOSIS CHART BY SYMPTOM .................. 16

INSPECTION FLOW BY CHARGE WARNING

LAMP .................................................................. 16

CHARGE WARNING LAMP LINE INSPECTION... 17

VOLTAGE DETECTION LINE AND CHARGE

WARNING LAMP INSPECTION ......................... 18

INSPECTION OF INSUFFICIENT ALTERNA-

TOR POWER GENERATION .............................. 20

INSPECTION OF EXCESSIVE ALTERNATOR

POWER GENERATION ...................................... 20

DARK CURRENT INSPECTION ......................... 21

OPERATION PROCEDURE OF CURRENT

MEASUREMENT PROBE FOR CONSULT-II ..... 22

Removal and Installation ........................................ 23REMOVAL ........................................................... 23

INSTALLATION ................................................... 23

Disassembly and Assembly .................................... 23

LHD MODELS ..................................................... 23

RHD MODELS .................................................... 24

Disassembly ........................................................... 24

REAR COVER ..................................................... 24

REAR BEARING ................................................. 24

Inspection ............................................................... 25

ROTOR CHECK .................................................. 25

BRUSH CHECK .................................................. 25

PULLEY CHECK (WITH CLUTCH TYPE) ........... 25

STATOR CHECK ................................................. 25

Assembly ................................................................ 26

RING FITTING IN REAR BEARING .................... 26

REAR COVER INSTALLATION ........................... 26

STARTING SYSTEM ................................................. 27

System Description ................................................. 27

A/T MODELS ....................................................... 27

M/T MODELS ...................................................... 27

Wiring Diagram — START — ................................. 28

A/T MODELS ....................................................... 28

M/T MODELS ...................................................... 29

Trouble Diagnoses ................................................. 30

Removal and Installation ........................................ 31

REMOVAL ........................................................... 31

INSTALLATION ................................................... 31

Disassembly and Assembly .................................... 32

Inspection ............................................................... 32

MAGNETIC SWITCH CHECK ............................. 32

PINION/CLUTCH CHECK ................................... 33

BRUSH CHECK .................................................. 33

YOKE CHECK ..................................................... 34

ARMATURE CHECK ........................................... 35

Assembly ................................................................ 36

PINION PROTRUSION LENGTH ADJUST-

MENT .................................................................. 36

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 37

Battery .................................................................... 37

Page 2836 of 3171

PRECAUTIONS

SC-3

C

D

E

F

G

H

I

J

L

MA

B

SC

PRECAUTIONSPFP:00011

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS00MZ4

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Wiring Diagrams and Trouble DiagnosisEKS00MZ5

When you read wiring diagrams, refer to the followings:

lGI-15, "How to Read Wiring Diagrams"in GI section

lPG-4, "POWER SUPPLY ROUTING CIRCUIT"for power distribution circuit in PG section

When you perform trouble diagnosis, refer to the followings:

lGI-11, "How to Follow Trouble Diagnoses"in GI section

lGI-24, "How to Perform Efficient Diagnosis for an Electrical Incident"in GI section

Page 2837 of 3171

SC-4

PREPARATION

PREPARATION

PFP:00002

Special Service ToolsEKS00MZ6

Tool name Description

CONSULT-II unit, and

Program card

System diagnose and inspection CONSULT-II CONVERTER

Current measurement probe for

CONSULT-II

EG1187 1900

PBIA3527J

PBIA3526J

MKIA0065E

Page 2870 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

SC-37

C

D

E

F

G

H

I

J

L

MA

B

SC

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

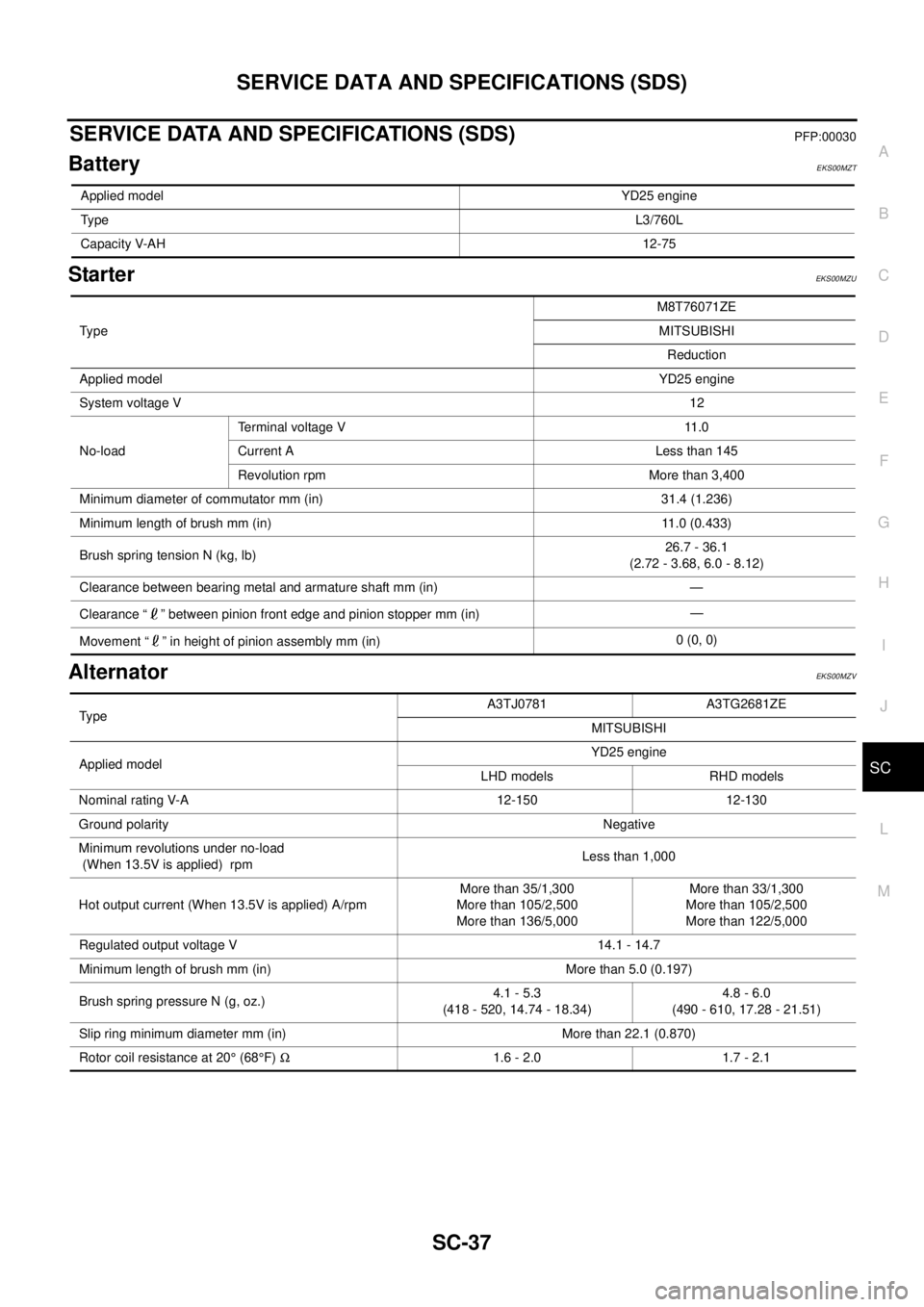

BatteryEKS00MZT

StarterEKS00MZU

AlternatorEKS00MZV

Applied modelYD25 engine

TypeL3/760L

Capacity V-AH12-75

Ty p eM8T76071ZE

MITSUBISHI

Reduction

Applied modelYD25 engine

System voltage V12

No-loadTerminal voltage V 11.0

Current A Less than 145

Revolution rpm More than 3,400

Minimum diameter of commutator mm (in) 31.4 (1.236)

Minimum length of brush mm (in) 11.0 (0.433)

Brush spring tension N (kg, lb)26.7 - 36.1

(2.72 - 3.68, 6.0 - 8.12)

Clearance between bearing metal and armature shaft mm (in) —

Clearance “ ” between pinion front edge and pinion stopper mm (in)—

Movement “ ” in height of pinion assembly mm (in)0 (0, 0)

TypeA3TJ0781 A3TG2681ZE

MITSUBISHI

Applied modelYD25 engine

LHD models RHD models

Nominal rating V-A 12-150 12-130

Ground polarityNegative

Minimum revolutions under no-load

(When 13.5V is applied) rpmLess than 1,000

Hot output current (When 13.5V is applied) A/rpmMore than 35/1,300

More than 105/2,500

More than 136/5,000More than 33/1,300

More than 105/2,500

More than 122/5,000

Regulated output voltage V 14.1 - 14.7

Minimum length of brush mm (in) More than 5.0 (0.197)

Brush spring pressure N (g, oz.)4.1 - 5.3

(418 - 520, 14.74 - 18.34)4.8 - 6.0

(490 - 610, 17.28 - 21.51)

Slip ring minimum diameter mm (in) More than 22.1 (0.870)

Rotor coil resistance at 20°(68°F)W1.6 - 2.0 1.7 - 2.1

Page 2871 of 3171

SC-38

SERVICE DATA AND SPECIFICATIONS (SDS)

Page 2872 of 3171

SE-1

SEAT

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONSE

A

B

SE

SEAT

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 2

Precautions for Work ................................................ 2

PREPARATION ........................................................... 3

Commercial Service Tool ......................................... 3

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 4

Work Flow ................................................................ 4

CUSTOMER INTERVIEW ..................................... 4

DUPLICATE THE NOISE AND TEST DRIVE ....... 5

CHECK RELATED SERVICE BULLETINS ........... 5

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 5

REPAIR THE CAUSE ........................................... 5

CONFIRM THE REPAIR ....................................... 6

Generic Squeak and Rattle Troubleshooting ........... 6

INSTRUMENT PANEL .......................................... 6

CENTER CONSOLE ............................................. 6

DOORS ................................................................. 6

TRUNK .................................................................. 7

SUNROOF/HEADLINING ..................................... 7

SEATS ................................................................... 7

UNDERHOOD ....................................................... 7

Diagnostic Worksheet .............................................. 8

POWER SEAT .......................................................... 10Wiring Diagram – SEAT – / For LHD Models ......... 10

Wiring Diagram – SEAT – / For RHD Models ......... 11

HEATED SEAT .......................................................... 12

Description .............................................................. 12

Schematic ............................................................... 13

Wiring Diagram – HSEAT – / For LHD Models ....... 14

Wiring Diagram – HSEAT – / For RHD Models ...... 17

FRONT SEAT ............................................................ 20

Components Parts Drawing .................................... 20

DRIVER SEAT ..................................................... 20

PASSENGER SEAT ............................................ 22

Removal and Installation ........................................ 23

REMOVAL ........................................................... 23

INSTALLATION ................................................... 24

Disassembly and Assembly .................................... 24

SEAT CUSHION (POWER SEAT) ....................... 24

SEAT CUSHION (MANUAL SEAT) ..................... 25

SEATBACK (POWER AND MANUAL SEAT) ...... 26

SEATBACK (FRAT FOLD SEAT) ........................ 27

REAR SEAT .............................................................. 29

Removal and Installation ........................................ 29

JUMP SEAT (KING CAB) .................................... 29

BENCH SEAT LH (DOUBLE CAB) ...................... 30

BENCH SEAT RH (DOUBLE CAB) ..................... 30

Disassembly and Assembly .................................... 32

Page 2873 of 3171

SE-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EIS00CEB

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for WorkEIS00BAR

lWhen removing or disassembling each component, be careful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

lWhen removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the compo-

nent with a shop cloth or vinyl tape to protect it.

lProtect the removed parts with a shop cloth and keep them.

lReplace a deformed or damaged clip.

lIf a part is specified as a non-reusable part, always replace it with new one.

lBe sure to tighten bolts and nuts securely to the specified torque.

lAfter re-installation is completed, be sure to check that each part works normally.

lFollow the steps below to clean components.

–Water soluble foul: Dip a soft cloth into lukewarm water, and wring the water out of the cloth to wipe the

fouled area.

Then rub with a soft and dry cloth.

–Oily foul: Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%), and wipe

the fouled area.

Then dip a cloth into fresh water, and wring the water out of the cloth to wipe the detergent off. Then rub

with a soft and dry cloth.

lDo not use organic solvent such as thinner, benzene, alcohol, or gasoline.

lFor genuine leather seats, use a genuine leather seat cleaner.