height NISSAN NAVARA 2005 Repair Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1601 of 3171

FSU-1

FRONT SUSPENSION

E SUSPENSION

CONTENTS

C

D

F

G

H

I

J

K

L

M

SECTIONFSU

A

B

FSU

FRONT SUSPENSION

PRECAUTIONS .......................................................... 2

Precautions .............................................................. 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 4

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 5

NVH Troubleshooting Chart ..................................... 5

FRONT SUSPENSION ASSEMBLY ........................... 6

Components ............................................................. 6

ON-VEHICLE SERVICE ............................................. 7

Front Suspension Parts ............................................ 7

Front Wheel Alignment ............................................. 7

PRELIMINARY INSPECTION ............................... 7

CAMBER AND CASTER ....................................... 8

TOE-IN .................................................................. 8

FRONT WHEEL TURNING ANGLE ..................... 9

COIL SPRING AND SHOCK ABSORBER ............... 10

Removal and Installation ........................................ 10

REMOVAL ........................................................... 10

INSTALLATION ................................................... 10

Disassembly and Assembly ................................... 10

DISASSEMBLY ................................................... 10

INSPECTION AFTER DISASSEMBLY ................ 11

ASSEMBLY .......................................................... 11

STABILIZER BAR ..................................................... 12

Removal and Installation ........................................ 12

REMOVAL ........................................................... 12

INSPECTION AFTER REMOVAL ....................... 12

INSTALLATION ................................................... 12UPPER LINK ............................................................. 13

Removal and Installation ........................................ 13

REMOVAL ........................................................... 13

INSPECTION AFTER REMOVAL ....................... 13

INSTALLATION ................................................... 13

LOWER LINK ............................................................ 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSPECTION AFTER REMOVAL ....................... 14

INSTALLATION ................................................... 14

UPPER BALL JOINT AND LOWER BALL JOINT ... 15

Removal and Installation ........................................ 15

Inspection ............................................................... 15

SWINGING FORCE ............................................ 15

TURNING FORCE .............................................. 15

VERTICAL END PLAY ........................................ 15

KNUCKLE ................................................................. 16

On-Vehicle Inspection and Service ......................... 16

Removal and Installation ........................................ 16

REMOVAL ........................................................... 16

INSPECTION AFTER REMOVAL ....................... 17

INSTALLATION ................................................... 18

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 19

General Specifications (Front) ................................ 19

Wheel Alignment (Unladen*

1) ................................ 19

Ball Joint ................................................................. 20

Wheelarch Height (Unladen*

1) .............................. 21

Page 1607 of 3171

ON-VEHICLE SERVICE

FSU-7

C

D

F

G

H

I

J

K

L

MA

B

FSU

ON-VEHICLE SERVICEPFP:00000

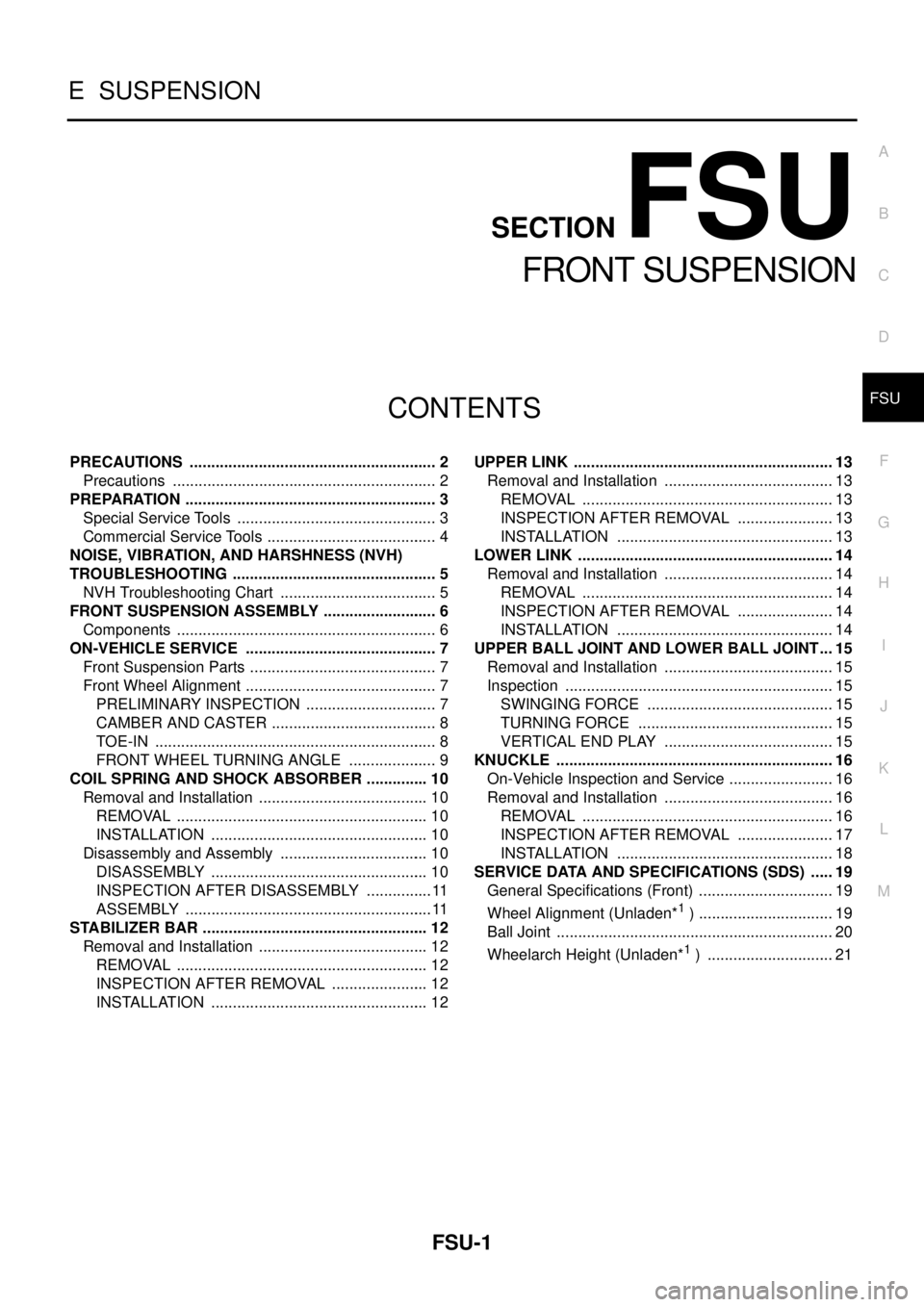

Front Suspension PartsEES002KM

Check front suspension parts for excessive play, cracks, wear and

other damage.

lShake each front wheel to check for excessive play.

If looseness is noted, inspect wheel bearing end play, then

check ball joint end play. Refer toFSU-15, "

Inspection".

lMake sure that the cotter pin is inserted in drive shaft end (4WD

models only).

lRetighten all nuts and bolts to the specified torque.

lCheck shock absorber for oil leakage and other damage.

lCheck suspension ball joint for grease leakage and ball joint

dust cover for cracks and other damage.

Front Wheel AlignmentEES002KN

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specification, inspect and replace any damaged or worn rear suspension parts before

making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer toWT-3, "

Inspection".

4. Check the wheel bearing axial end play. Refer toFA X - 5 , "

WHEEL BEARING INSPECTION".

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the rear suspension member for any damage.

8. Check the vehicle height. Refer toFSU-21, "

Wheelarch Height (Unladen*1)". Suspension component torques : Refer toFSU-6,

"Components".SMA525A

SFA392B

Page 1608 of 3171

FSU-8

ON-VEHICLE SERVICE

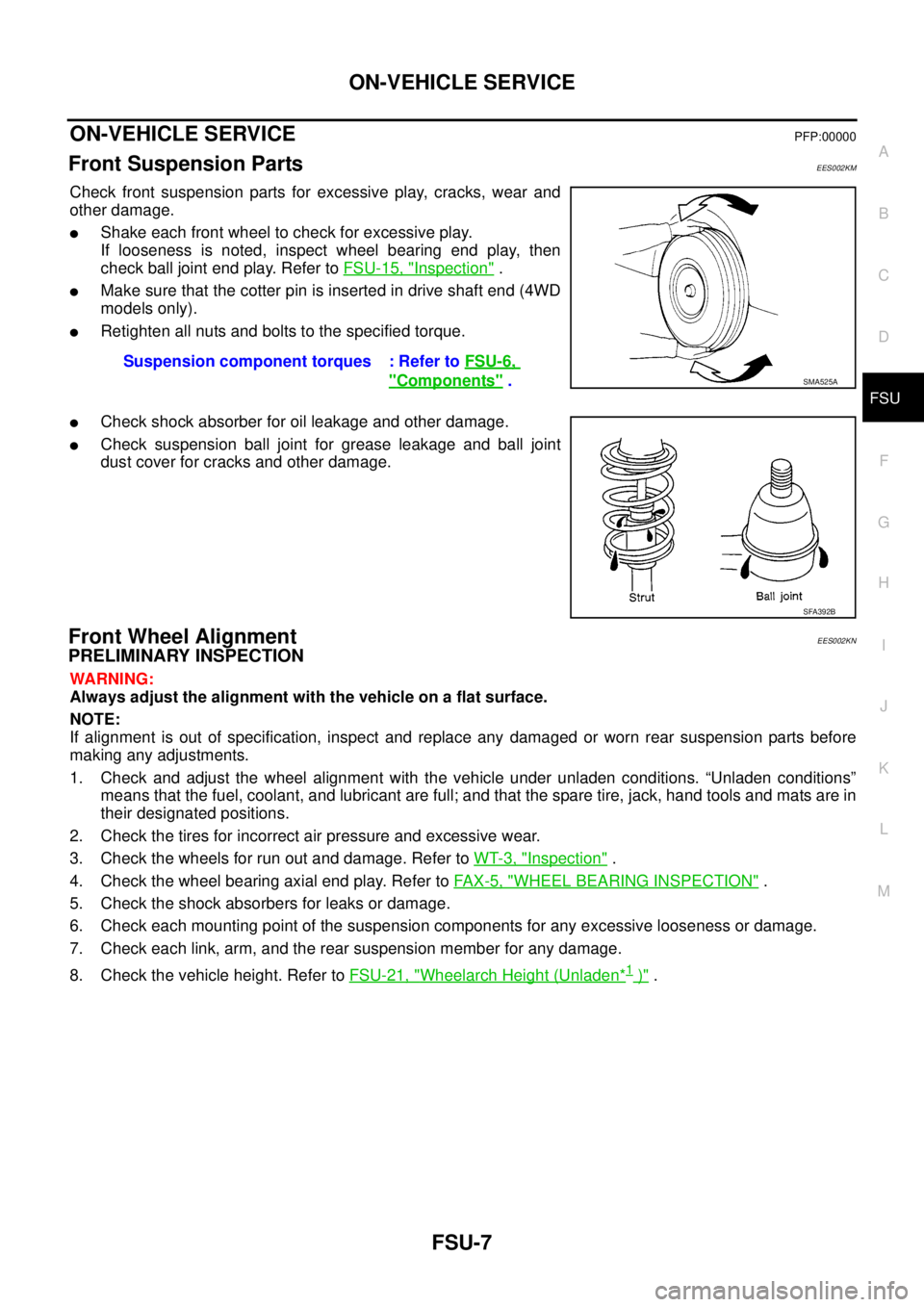

CAMBER AND CASTER

1. Install CCK gauge attachment (SST: KV991040S0) as following procedure in wheel.

a. Remove wheel nuts (2), and install a guide bolt to hub bolt.

b. Screw center plate into plate.

c. Insert plate on guide bolt. Put spring in, and then evenly screw

both guide bolt nut. When fastening guide bolt nut, do not com-

pletely compress spring.

CAUTION:

Do not use any adapter for attaching the attachment.

d. Place the dent of alignment gauge onto the projection of center

plate and tightly contact them to measure.

2. Measure camber and caster of both the right and left wheels

with a suitable alignment gauge and adjust as necessary to

specifications.

3. If outside of the specified value, adjust camber and caster using

the adjusting bolts in the front lower link.

CAUTION:

After adjusting the camber then check the toe-in.

NOTE:

Camber changes about 0°7' (0.12°), and caster changes about

0°12' (0.20°) with each graduation of one adjusting bolt. Refer to

table below for examples of lower link adjusting bolt effect on

camber and caster.

4. Tighten the adjusting bolt nuts to specification. Refer toFSU-6, "

Components".

TOE-IN

WARNING:

lAlways perform the following procedure on a flat surface.

lMake sure that no person is in front of the vehicle before pushing it.

1. Bounce the front of vehicle up and down to stabilize the vehicle height (posture).

2. Push the vehicle straight ahead about 5 m (16 ft).

MEIB9047E

Camber, caster,

kingpin inclination

angles:RefertoFSU-7, "Front Wheel

Alignment".

MEIB9048E

WEIA0115E

Rear adjusting

bolt1In 1Out 1In 1Out 0 0 1In 1Out

Front adjusting

bolt1Out 1In 1In 1Out 1In 1Out 0 0

Camber

Degree minute

(Decimal degree)0(0) 0(0)0°14'

(0.23°)-0°14'

(- 0.23°)0°7'

(0.12°)-0°7'

(- 0.12°)0°7'

(0.12°)-0°7'

(- 0.12°)

Caster

Degree minute

(Decimal degree)-0°23'

(- 0.38°)0°23'

(0.38°)0(0) 0(0)0°12'

(0.20°)-0°12'

(- 0.20°)-0°12'

(- 0.20°)0°12'

(0.20°)

Page 1609 of 3171

ON-VEHICLE SERVICE

FSU-9

C

D

F

G

H

I

J

K

L

MA

B

FSU

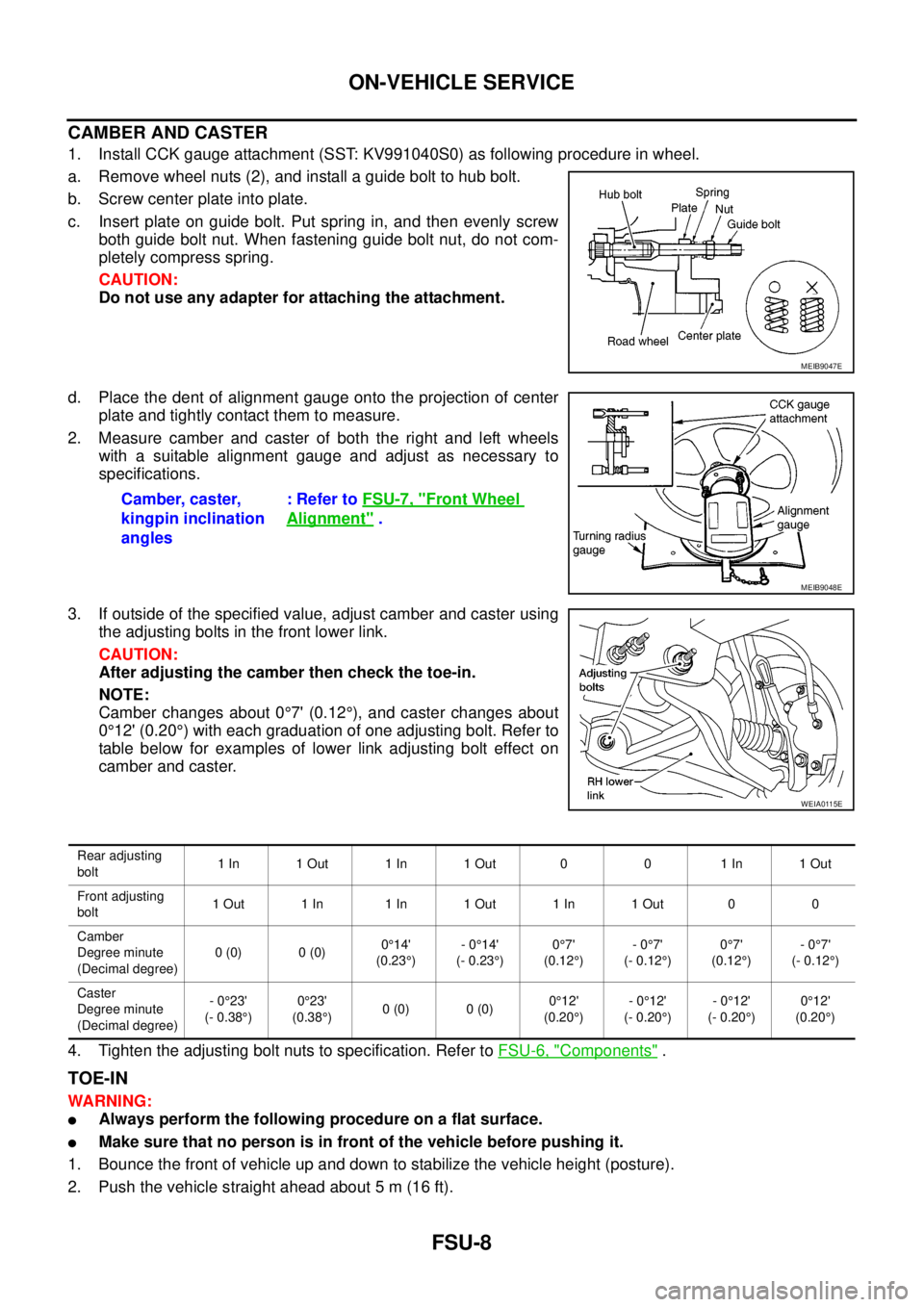

3. Put a mark on base line of the tread (rear side) of both front tires

at the same height as hub center as shown. These marks are

measuring points.

4. Measure the distance “A” on the rear side of the front tires as

shown.

5. Push the vehicle slowly ahead to rotate the wheels 180°

degrees (1/2 a turn).

CAUTION:

If the wheels have rotated more than 180°degrees (1/2

turn), start this procedure again from the beginning. Never

push the vehicle backward.

6. Measure the distance “B” on the front side of the front tires at the

same marks as shown. Total toe-in is calculated as “A” – “B”.

7. Adjust the toe-in by varying the length of the steering outer tie-

rods.

a. Loosen the outer tie-rod lock nuts.

b. Adjust the toe-in by screwing the outer tie-rods in or out.

c. Tighten the outer tie-rod lock nuts to specification.

FRONT WHEEL TURNING ANGLE

NOTE:

Check front wheel turning angle after the toe-in inspection.

1. Place front wheels on turning radius gauges in straight ahead

position and rear wheels on stands so that vehicle can be level.

Check the maximum inner and outer wheel turning angles for LH

and RH road wheels.

2. Start engine and run at idle, turn steering wheel all the way right

and left, measure the turning angle.

lAny turning angles are not adjustable. If any of steering

angles are out of the specification, check if the following parts

are worn or damaged.

–Steering gear

–Steering column

–Front suspension components

If found that they are worn or damaged, replace them with new ones.

AFA050

Total toe-in : Refer toFSU-19, "Wheel Alignment

(Unladen*1)".

SFA234AC

Standard length “L” : Refer toPS-14, "POWER

STEERING GEAR AND LINK-

AGE".

Lock nut : Refer toPS-14, "

Removal and

Installation".

SFA486A

Wheel turning angle

(full turn):RefertoFSU-19, "Wheel

Alignment (Unladen*1)".

SFA439BA

Page 1621 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

FSU-21

C

D

F

G

H

I

J

K

L

MA

B

FSU

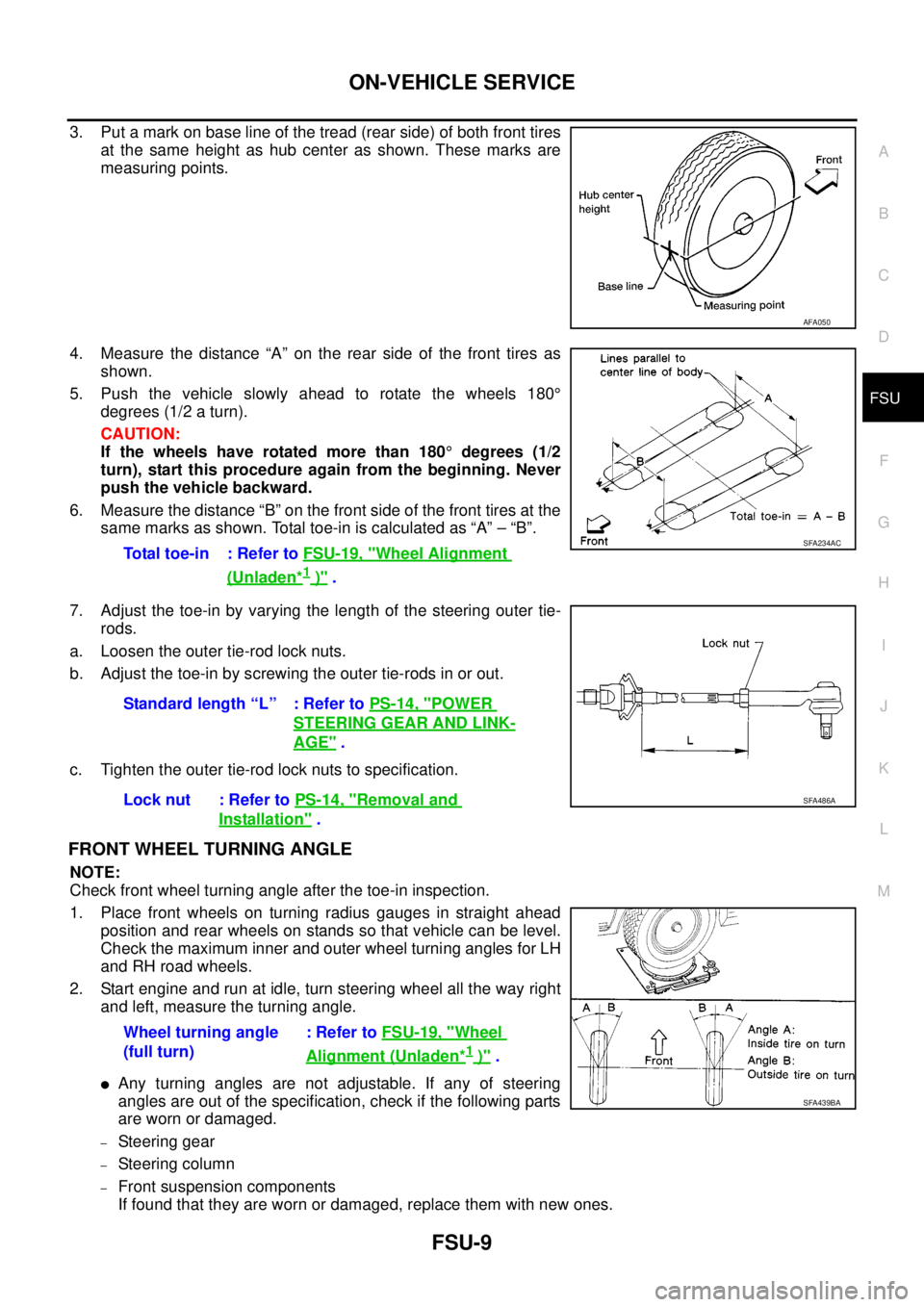

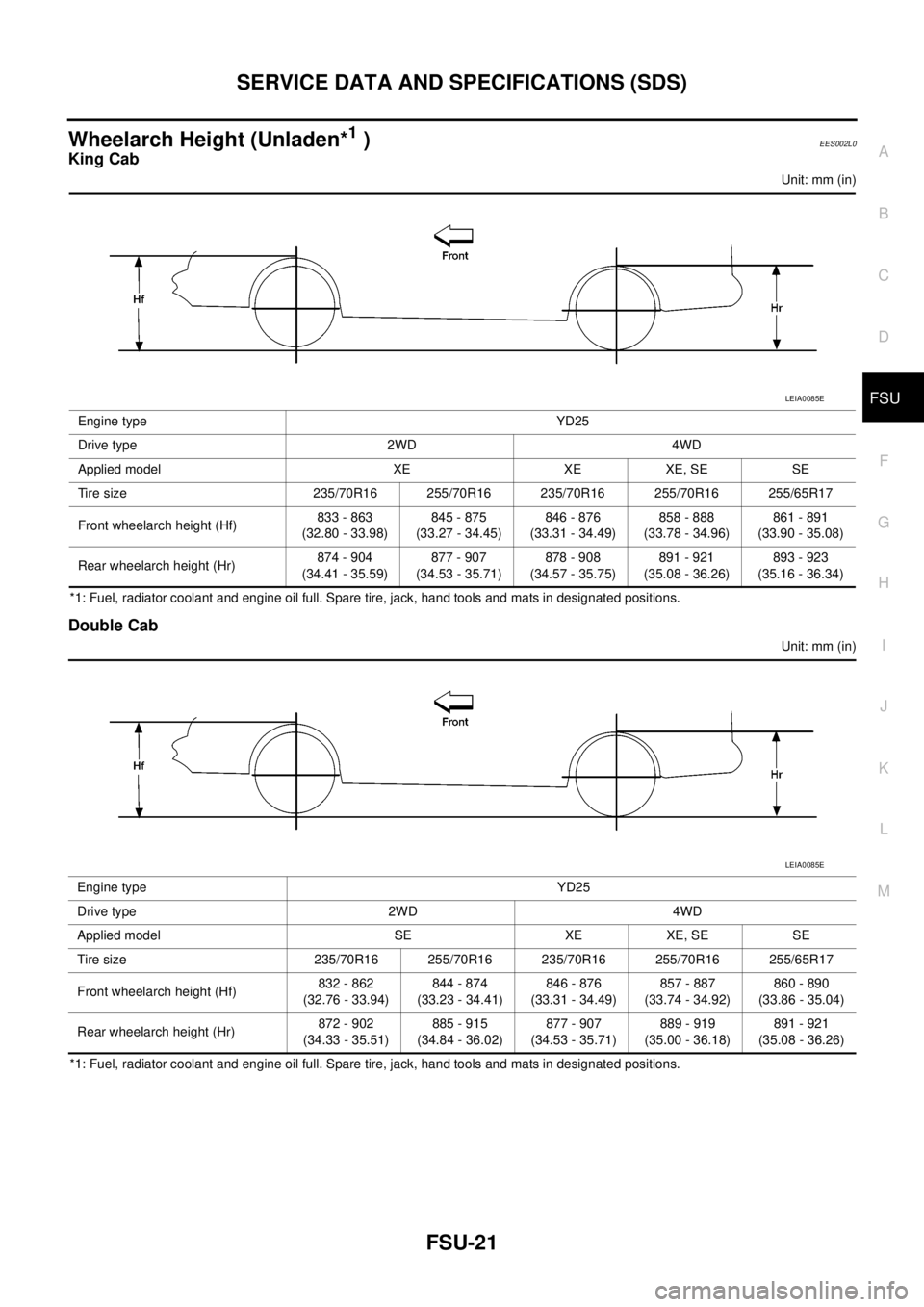

Wheelarch Height (Unladen*1)EES002L0

King Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Double Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.Engine type YD25

Drive type 2WD 4WD

Applied model XE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)833 - 863

(32.80 - 33.98)845 - 875

(33.27 - 34.45)846 - 876

(33.31 - 34.49)858 - 888

(33.78 - 34.96)861 - 891

(33.90 - 35.08)

Rear wheelarch height (Hr)874 - 904

(34.41 - 35.59)877 - 907

(34.53 - 35.71)878 - 908

(34.57 - 35.75)891 - 921

(35.08 - 36.26)893 - 923

(35.16 - 36.34)

LEIA0085E

Engine type YD25

Drive type 2WD 4WD

Applied model SE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)832 - 862

(32.76 - 33.94)844 - 874

(33.23 - 34.41)846 - 876

(33.31 - 34.49)857 - 887

(33.74 - 34.92)860 - 890

(33.86 - 35.04)

Rear wheelarch height (Hr)872 - 902

(34.33 - 35.51)885 - 915

(34.84 - 36.02)877 - 907

(34.53 - 35.71)889 - 919

(35.00 - 36.18)891 - 921

(35.08 - 36.26)

LEIA0085E

Page 1682 of 3171

GI-60

IDENTIFICATION INFORMATION

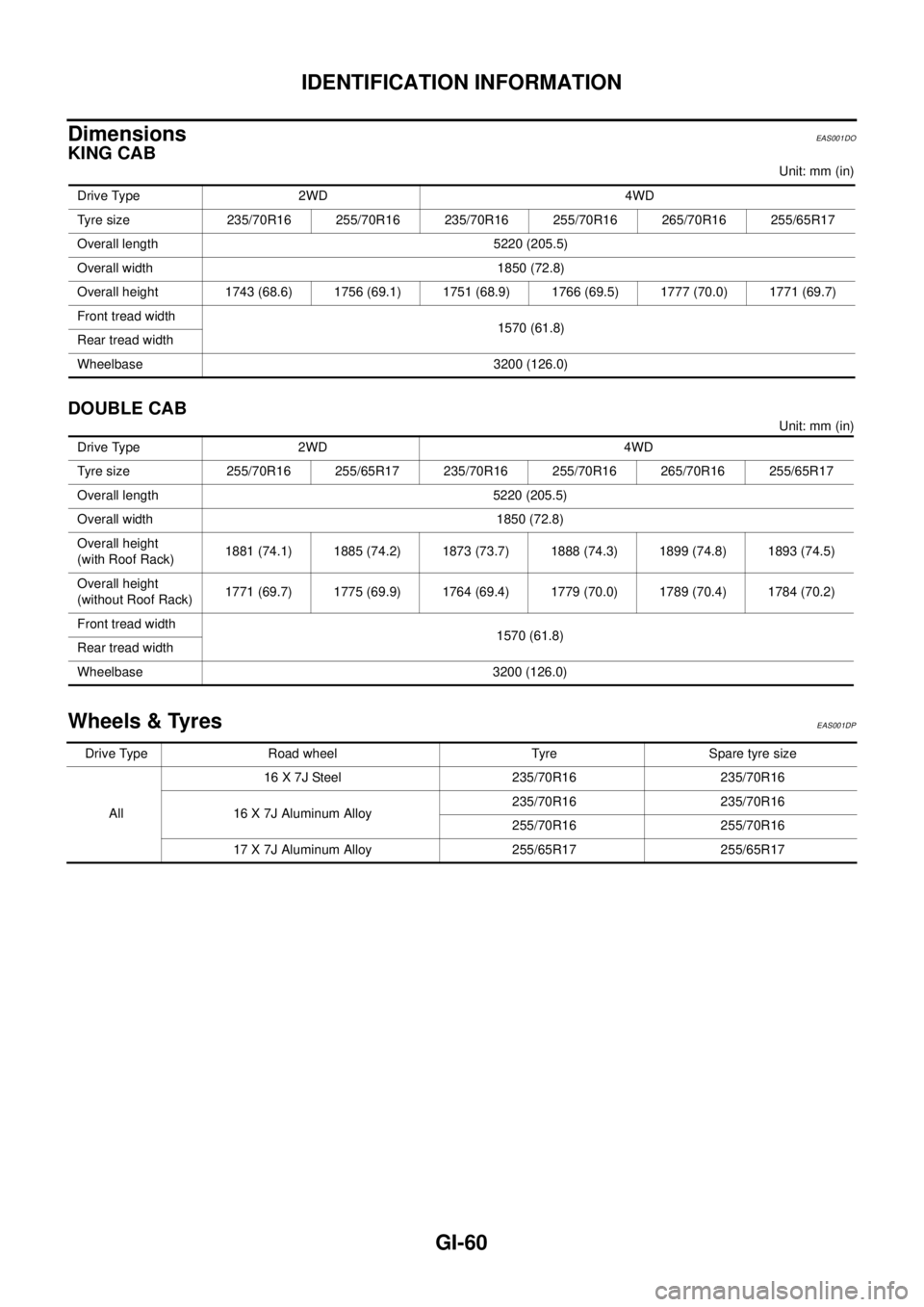

Dimensions

EAS001DO

KING CAB

Unit: mm (in)

DOUBLE CAB

Unit: mm (in)

Wheels & TyresEAS001DP

Drive Type 2WD 4WD

Tyre size 235/70R16 255/70R16 235/70R16 255/70R16 265/70R16 255/65R17

Overall length 5220 (205.5)

Overall width 1850 (72.8)

Overall height 1743 (68.6) 1756 (69.1) 1751 (68.9) 1766 (69.5) 1777 (70.0) 1771 (69.7)

Front tread width

1570 (61.8)

Rear tread width

Wheelbase 3200 (126.0)

Drive Type 2WD 4WD

Tyre size 255/70R16 255/65R17 235/70R16 255/70R16 265/70R16 255/65R17

Overall length 5220 (205.5)

Overall width 1850 (72.8)

Overall height

(with Roof Rack)1881 (74.1) 1885 (74.2) 1873 (73.7) 1888 (74.3) 1899 (74.8) 1893 (74.5)

Overall height

(without Roof Rack)1771 (69.7) 1775 (69.9) 1764 (69.4) 1779 (70.0) 1789 (70.4) 1784 (70.2)

Front tread width

1570 (61.8)

Rear tread width

Wheelbase 3200 (126.0)

Drive Type Road wheel Tyre Spare tyre size

All16 X 7J Steel 235/70R16 235/70R16

16 X 7J Aluminum Alloy235/70R16 235/70R16

255/70R16 255/70R16

17 X 7J Aluminum Alloy 255/65R17 255/65R17

Page 1756 of 3171

IDX-4

ALPHABETICAL INDEX

Engine control system diagram and chart .........EC-15

Engine coolant ....................................................CO-7

Engine coolant temperature sensor (ECTS) ....EC-103

Engine oil .............................................................LU-5

Engine oil filter replacement .............................MA-26

Engine oil precautions ..........................................GI-7

Engine removal ...............................................EM-106

Engine room cover ............................................EM-20

Engine serial number ..........................................GI-58

Evaporator ....................................ATC-149,MTC-129

Exhaust manifold ..............................................EM-34

Exhaust system ...................................................EX-2

Exhaust system inspection ..................................EX-2

Expansion valve ............................ATC-150,MTC-130

F

F/FOG - Wiring diagram .....................................LT-74

F/PUMP - Wiring diagram ..EC-248,EC-254,EC-260,

EC-266

Final drive pre-inspection .................................FFD-18

Final drive removal and installation ..RFD-14,RFD-81

Flow charts .........................................................GI-24

Fluid temperature sensor (A/T) ........................AT-118

Fluids ................................................................MA-14

Fluorescent leak detector .............ATC-150,MTC-131

Flywheel (clutch) ................................................CL-17

Flywheel runout ..............................................EM-134

Fog lamp, front ....................................................LT-71

Foot lamp ..........................................................LT-145

Fork rod (M/T) ....................................................MT-23

Freeze frame data .............................................EC-28

Front brake solenoid valve .................AT-137,AT-139

Front bumper ......................................................EI-15

Front case (Transfer) ..........................TF-114,TF-120

Front combination lamp removal and installationLT-30

Front door ................BL-118,BL-120,BL-126,GW-35

Front Door Trim ..................................................EI-30

Front drive shaft (Transfer) ...TF-114,TF-120,TF-133

Front final drive removal and installation (4WD) ...........

FFD-15

Front fog lamp .....................................................LT-71

Front passenger air bag ..................................SRS-40

Front seat ...........................................................SE-20

Front seat belt ............................................SB-3,SB-5

Front seat belt pre-tensioner ...............SRS-3,SRS-47

Front side air bag ............................................SRS-43

Front washer ......................................................WW-4

Front wiper .........................................................WW-4

FRPS - Wiring diagram ....................................EC-120

FTS - Wiring diagram .......................................EC-115

Fuel cut control (at no load high engine speed) .EC-20

Fuel filler lid ......................................................BL-136

Fuel filter ............................................................EC-23

Fuel filter replacement ..........................................FL-4

Fuel gauge ............................................................DI-4

Fuel injection control system .............................EC-18

Fuel injector ............EC-25,EC-123,EC-125,EC-237

Fuel injector and fuel tube ................................EM-44

Fuel leak ............................................................EC-88

Fuel line inspection ..............................................FL-3

Fuel pumpEC-86,EC-217,EC-245,EC-251,EC-258,

EC-263

Fuel pump(Learning Value Clearing) .................EC-24

Fuel rail pressure sensor .................................EC-118

Fuel system .........................................................FL-3

Fuel tank ..............................................................FL-9

Fuel temperature sensor ..................................EC-113

Fuse ......................................................PG-74,PG-84

Fuse and fusible link box ..................................PG-84

Fusible link ............................................PG-74,PG-84

G

Garage jack and safety stand .............................GI-52

Gauges .................................................................DI-4

Gear components (M/T) ....................................MT-21

Generator ...........................................................SC-14

Generator - See Alternator ................................SC-14

Glass ........................GW-11,GW-35,GW-38,GW-43

Glove box lamp ................................................LT-162

GLOW - Wiring diagram ..................................EC-296

Glow plug ............................................EM-41,EC-295

Glow relay ........................................................EC-295

Grease ..............................................................MA-14

Ground distribution ...........................................PG-27

H

H/AIM - Wiring diagram .....................................LT-66

Harness connector ............................................PG-75

Harness layout ..................................................PG-38

Hazard warning lamp .........................................LT-97

Headlamp aiming control ...................................LT-66

Headlamp leveler - See Headlamp aiming control ........

LT-66

Headlamp removal and installation ....................LT-30

Heat up switch .................................................EC-319

Heated seat .......................................................SE-12

Heater and cooling unit (Heater core) ..........ATC-124,

ATC-127

,MTC-103,MTC-106

Heater unit (heater core) ..............ATC-124,ATC-127,

MTC-103

,MTC-106

HEATUP - Wiring diagram ...............................EC-320

Height (Dimensions) ...........................................GI-60

HFC134a (R134a) system precaution .ATC-4,MTC-4

HFC134a (R134a) system service procedureATC-138,

MTC-118

HFC134a (R134a) system service tools ........ATC-16,

MTC-16

HFC134a system service equipment precaution ..........

ATC-12

,MTC-12

High and low reverse clutch solenoid valve ....AT-147,

AT-149

HLC - Wiring diagram ......................................WW-41

Horn .................................................................WW-59

HORN - Wiring diagram ...................................WW-59

How to erase DTC .............................................EC-27

Page 2168 of 3171

FRONT FOG LAMP

LT-85

C

D

E

F

G

H

I

J

L

MA

B

LT

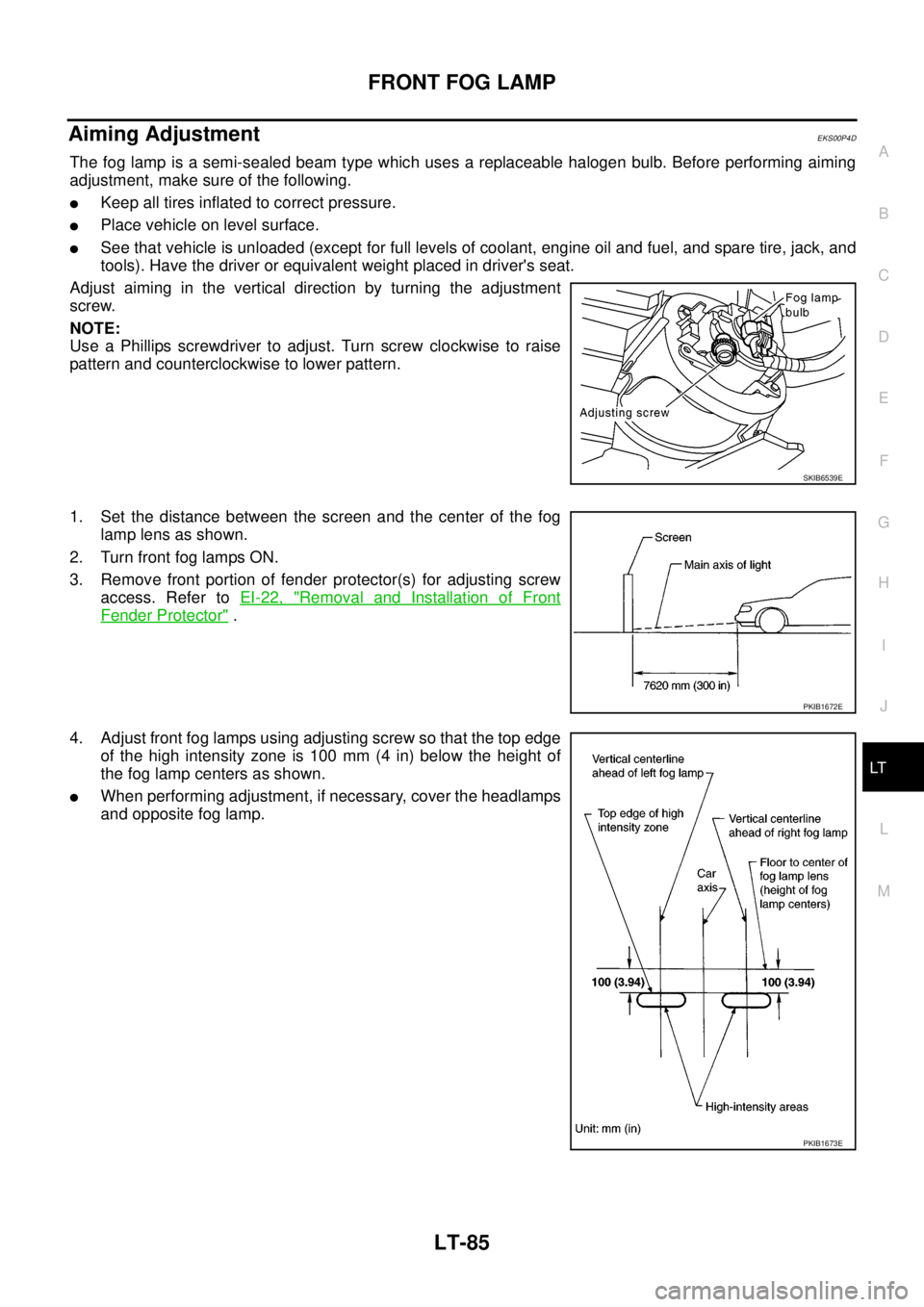

Aiming AdjustmentEKS00P4D

The fog lamp is a semi-sealed beam type which uses a replaceable halogen bulb. Before performing aiming

adjustment, make sure of the following.

lKeep all tires inflated to correct pressure.

lPlace vehicle on level surface.

lSee that vehicle is unloaded (except for full levels of coolant, engine oil and fuel, and spare tire, jack, and

tools). Have the driver or equivalent weight placed in driver's seat.

Adjust aiming in the vertical direction by turning the adjustment

screw.

NOTE:

Use a Phillips screwdriver to adjust. Turn screw clockwise to raise

pattern and counterclockwise to lower pattern.

1. Set the distance between the screen and the center of the fog

lamp lens as shown.

2. Turn front fog lamps ON.

3. Remove front portion of fender protector(s) for adjusting screw

access. Refer toEI-22, "

Removal and Installation of Front

Fender Protector".

4. Adjust front fog lamps using adjusting screw so that the top edge

of the high intensity zone is 100 mm (4 in) below the height of

the fog lamp centers as shown.

lWhen performing adjustment, if necessary, cover the headlamps

and opposite fog lamp.

SKIB6539E

PKIB1672E

PKIB1673E

Page 2644 of 3171

POWER STEERING GEAR AND LINKAGE

PS-17

C

D

E

F

H

I

J

K

L

MA

B

PS

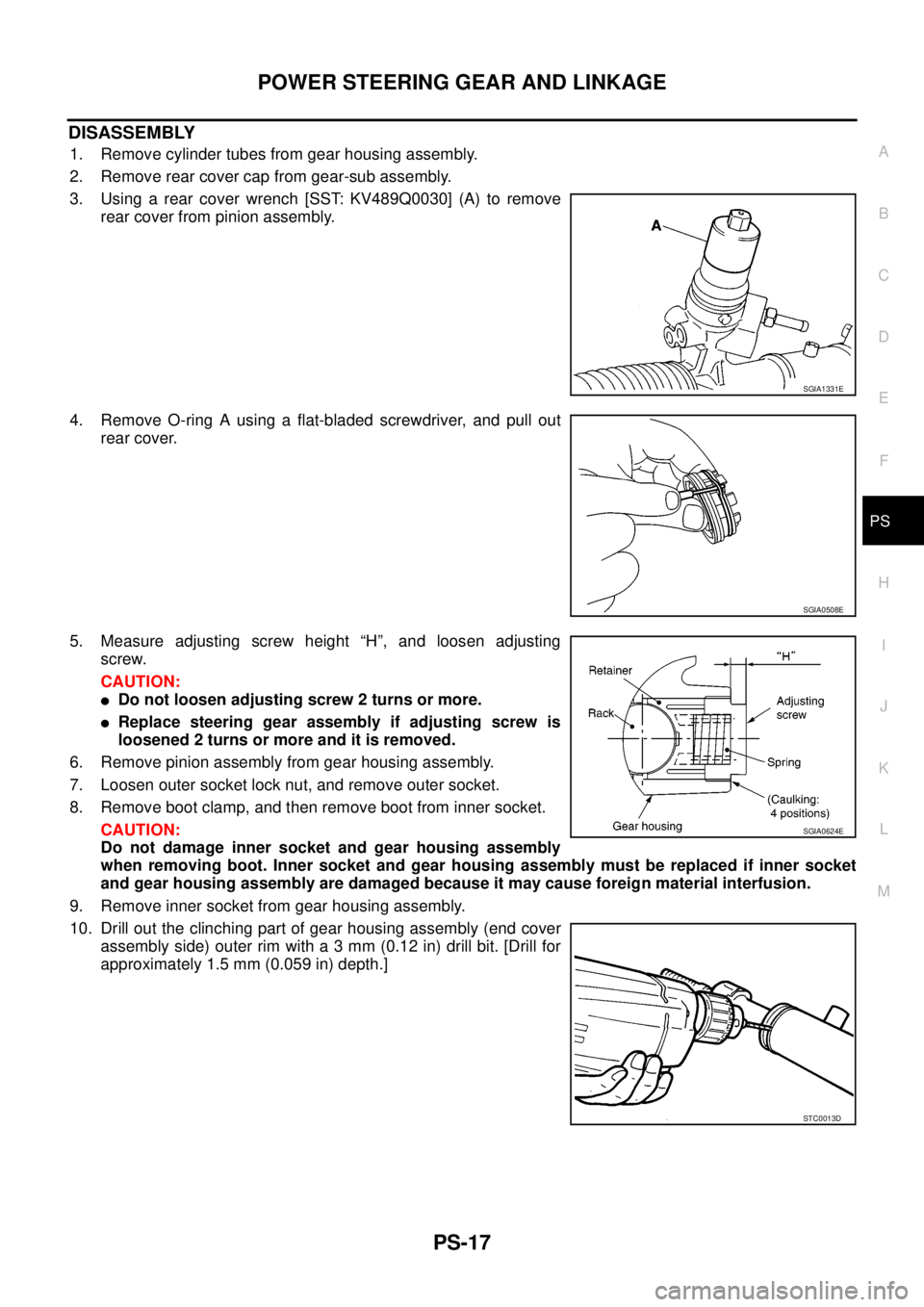

DISASSEMBLY

1. Remove cylinder tubes from gear housing assembly.

2. Remove rear cover cap from gear-sub assembly.

3. Using a rear cover wrench [SST: KV489Q0030] (A) to remove

rear cover from pinion assembly.

4. Remove O-ring A using a flat-bladed screwdriver, and pull out

rear cover.

5. Measure adjusting screw height “H”, and loosen adjusting

screw.

CAUTION:

lDo not loosen adjusting screw 2 turns or more.

lReplace steering gear assembly if adjusting screw is

loosened 2 turns or more and it is removed.

6. Remove pinion assembly from gear housing assembly.

7. Loosen outer socket lock nut, and remove outer socket.

8. Remove boot clamp, and then remove boot from inner socket.

CAUTION:

Do not damage inner socket and gear housing assembly

when removing boot. Inner socket and gear housing assembly must be replaced if inner socket

and gear housing assembly are damaged because it may cause foreign material interfusion.

9. Remove inner socket from gear housing assembly.

10. Drill out the clinching part of gear housing assembly (end cover

assemblyside)outerrimwitha3mm(0.12in)drillbit.[Drillfor

approximately 1.5 mm (0.059 in) depth.]

SGIA1331E

SGIA0508E

SGIA0624E

STC0013D

Page 2649 of 3171

PS-22

POWER STEERING GEAR AND LINKAGE

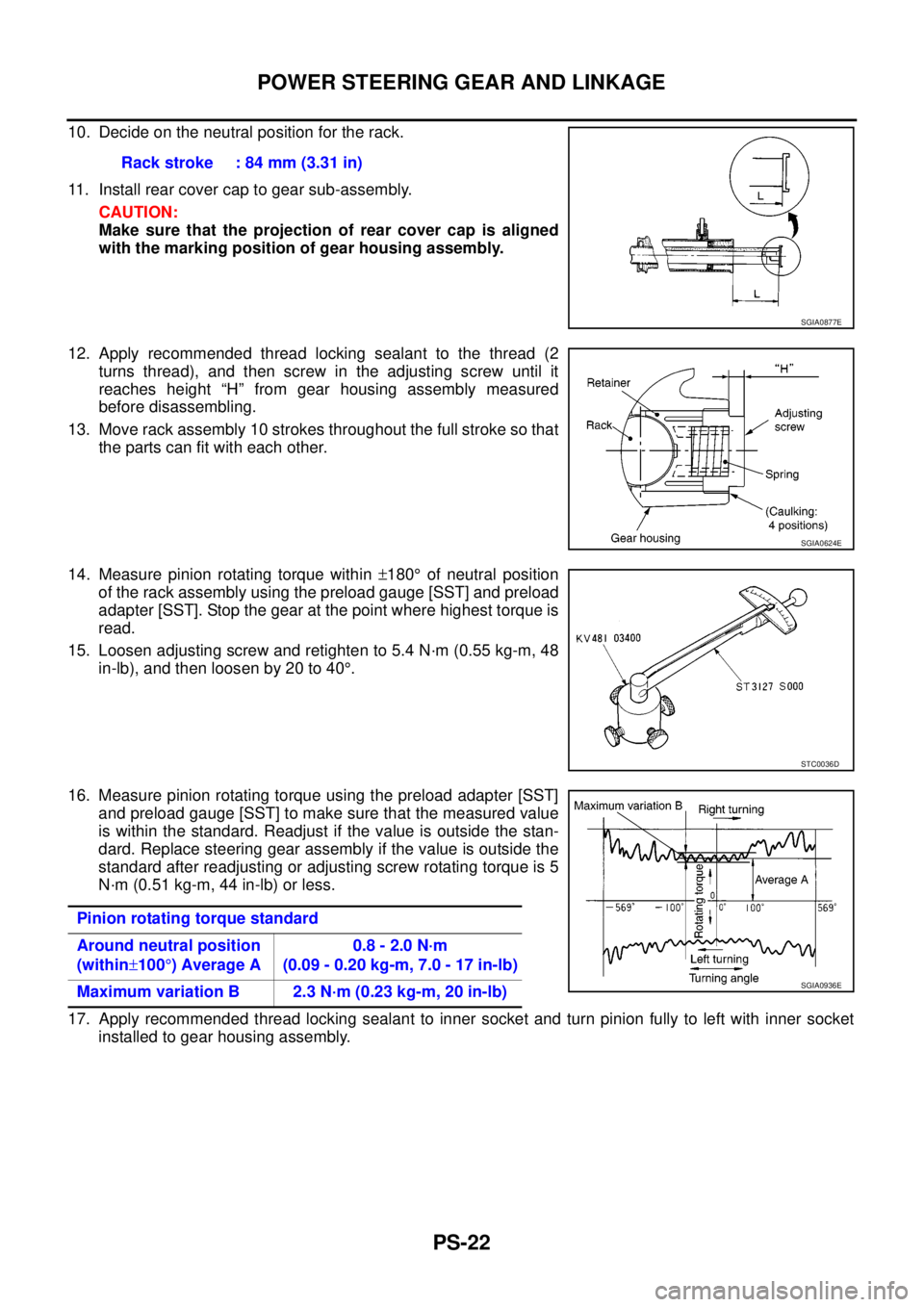

10. Decide on the neutral position for the rack.

11. Install rear cover cap to gear sub-assembly.

CAUTION:

Make sure that the projection of rear cover cap is aligned

with the marking position of gear housing assembly.

12. Apply recommended thread locking sealant to the thread (2

turns thread), and then screw in the adjusting screw until it

reaches height “H” from gear housing assembly measured

before disassembling.

13. Move rack assembly 10 strokes throughout the full stroke so that

the parts can fit with each other.

14. Measure pinion rotating torque within±180°of neutral position

of the rack assembly using the preload gauge [SST] and preload

adapter [SST]. Stop the gear at the point where highest torque is

read.

15. Loosen adjusting screw and retighten to 5.4 N·m (0.55 kg-m, 48

in-lb), and then loosen by 20 to 40°.

16. Measure pinion rotating torque using the preload adapter [SST]

and preload gauge [SST] to make sure that the measured value

is within the standard. Readjust if the value is outside the stan-

dard. Replace steering gear assembly if the value is outside the

standard after readjusting or adjusting screw rotating torque is 5

N·m (0.51 kg-m, 44 in-lb) or less.

17. Apply recommended thread locking sealant to inner socket and turn pinion fully to left with inner socket

installed to gear housing assembly.Rack stroke : 84 mm (3.31 in)

SGIA0877E

SGIA0624E

STC0036D

Pinion rotating torque standard

Around neutral position

(within±100°)AverageA0.8 - 2.0 N·m

(0.09 - 0.20 kg-m, 7.0 - 17 in-lb)

Maximum variation B 2.3 N·m (0.23 kg-m, 20 in-lb)

SGIA0936E