length NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 229 of 3171

ON-VEHICLE SERVICE

AT-221

D

E

F

G

H

I

J

K

L

MA

B

AT

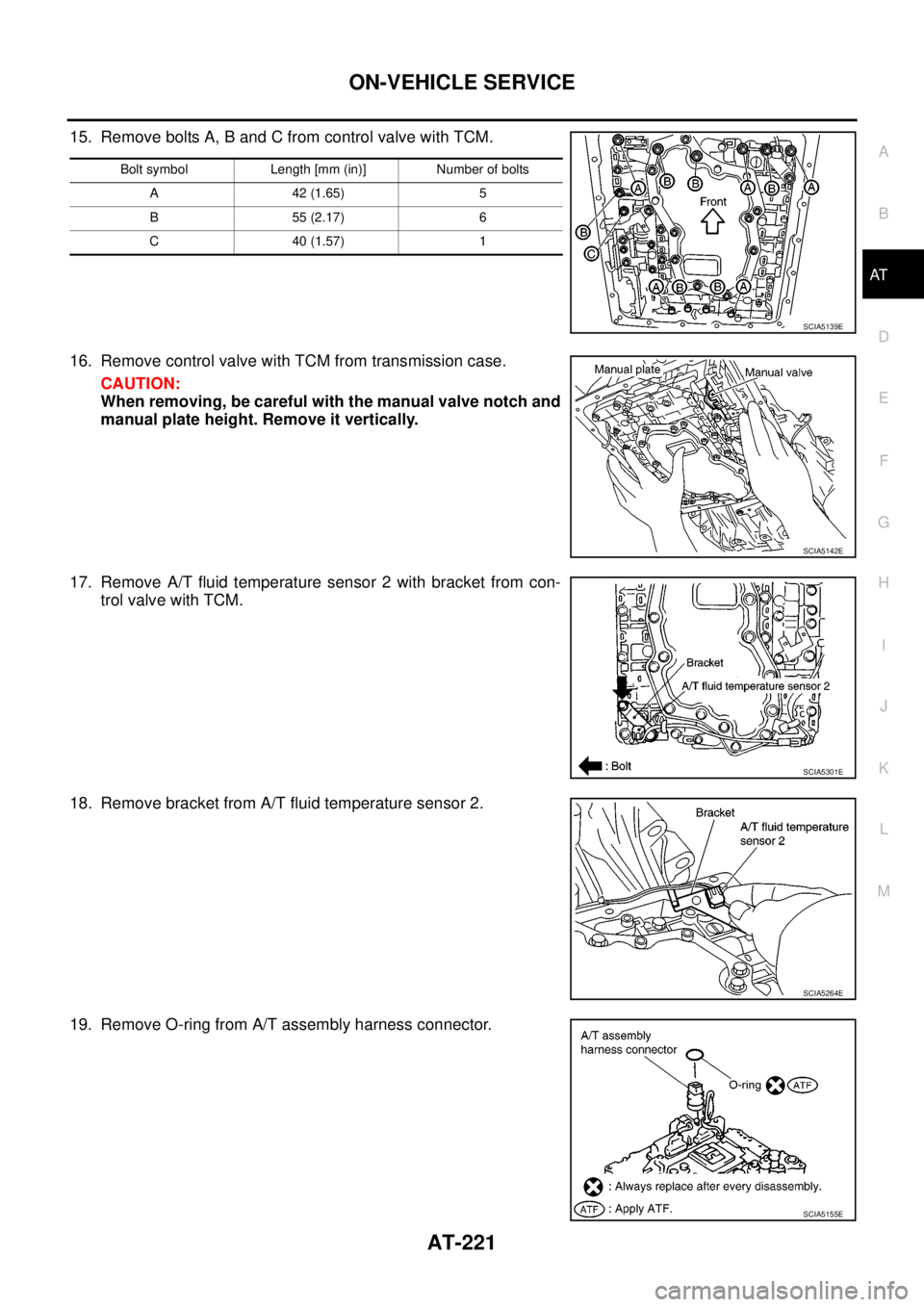

15. Remove bolts A, B and C from control valve with TCM.

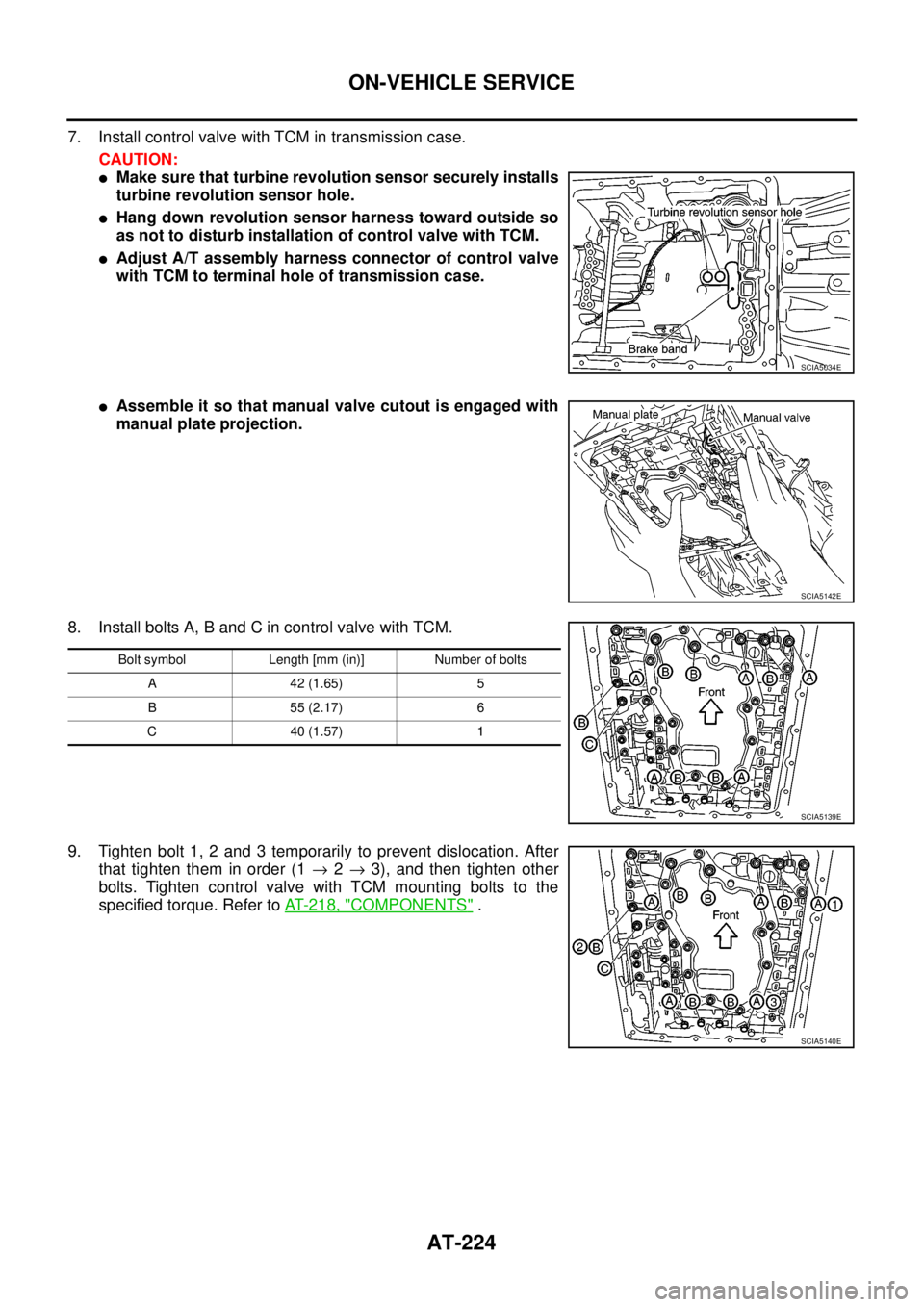

16. Remove control valve with TCM from transmission case.

CAUTION:

When removing, be careful with the manual valve notch and

manual plate height. Remove it vertically.

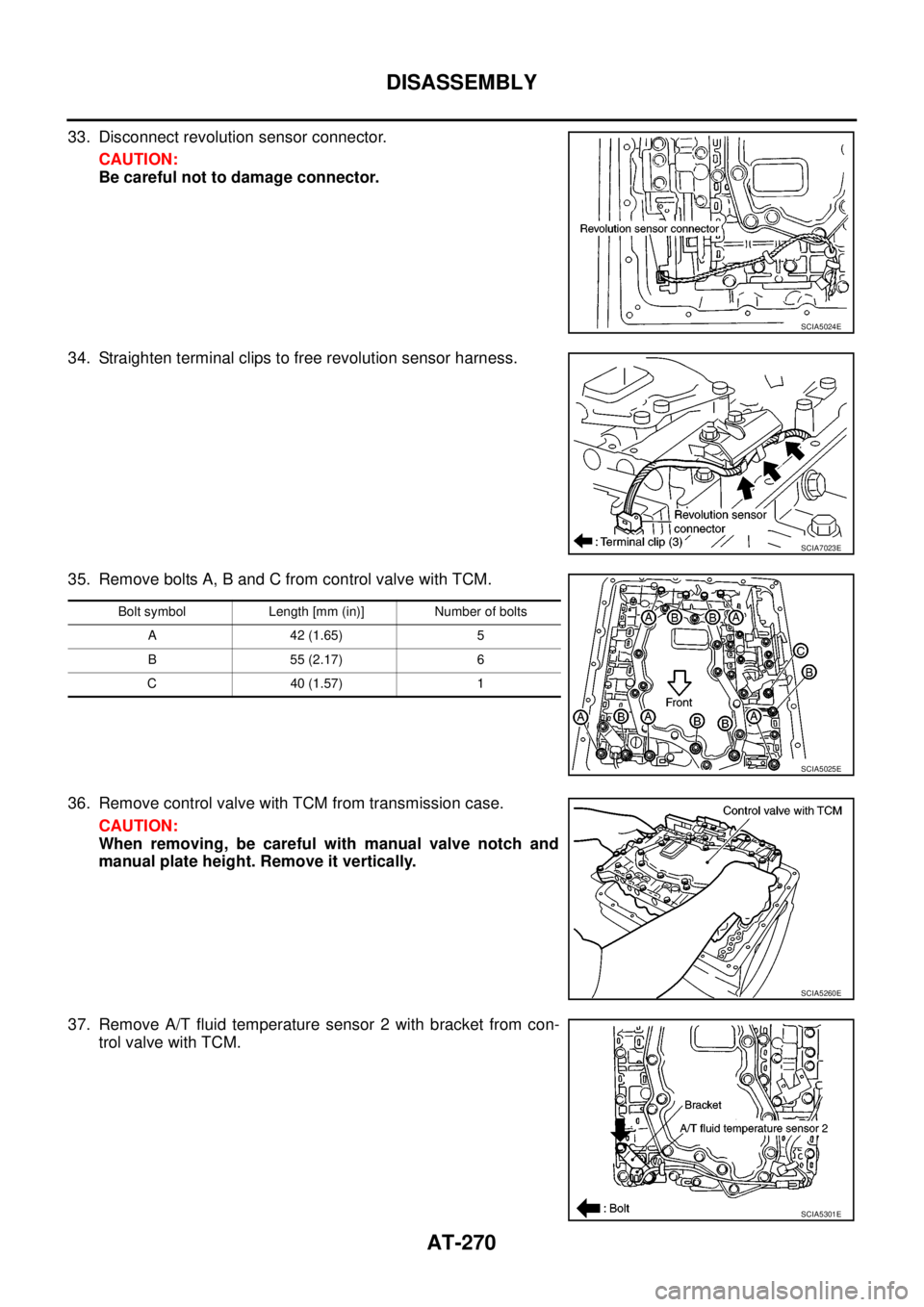

17. Remove A/T fluid temperature sensor 2 with bracket from con-

trol valve with TCM.

18. Remove bracket from A/T fluid temperature sensor 2.

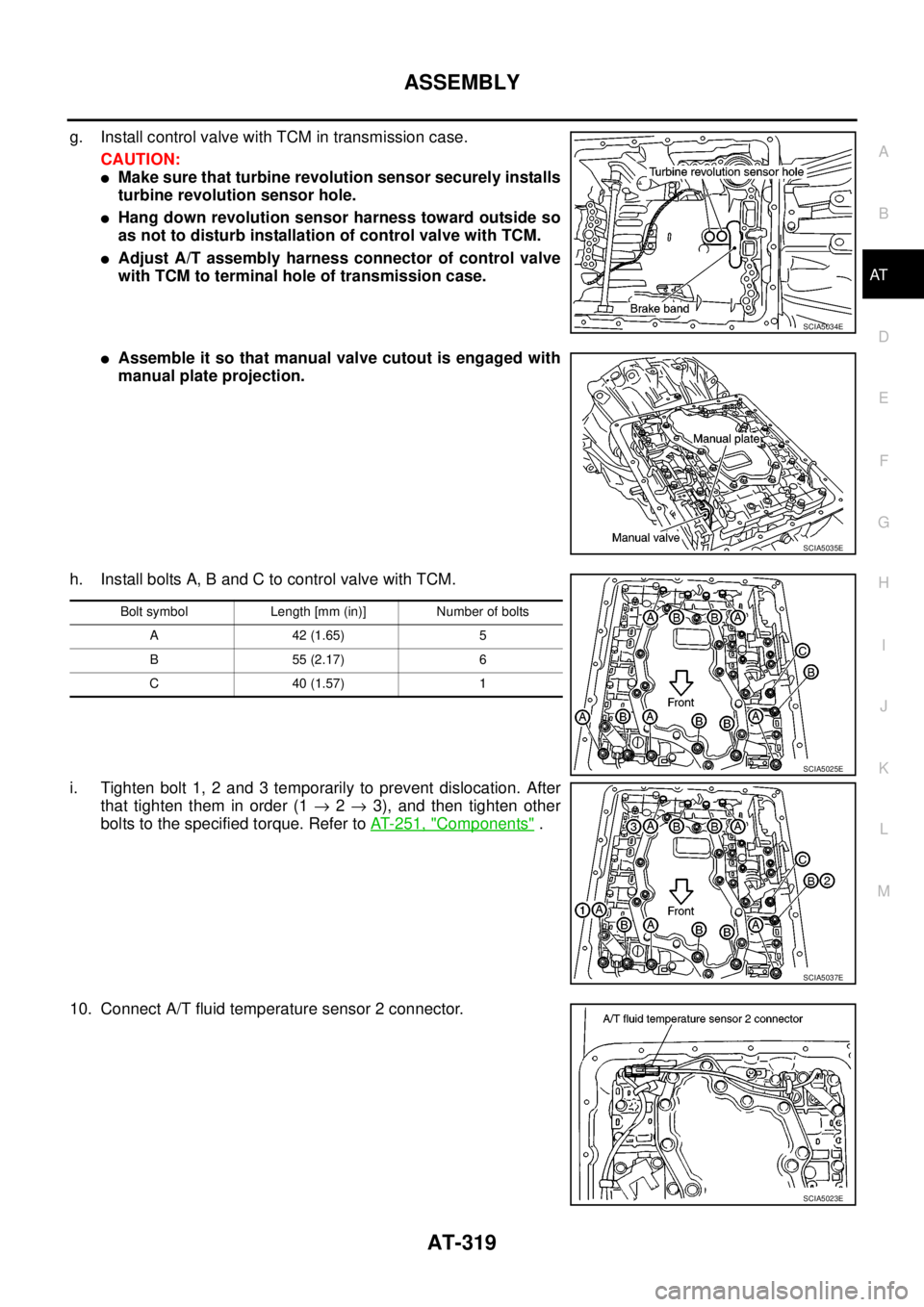

19. Remove O-ring from A/T assembly harness connector.

Bolt symbol Length [mm (in)] Number of bolts

A42(1.65) 5

B55(2.17) 6

C40(1.57) 1

SCIA5139E

SCIA5142E

SCIA5301E

SCIA5264E

SCIA5155E

Page 232 of 3171

AT-224

ON-VEHICLE SERVICE

7. Install control valve with TCM in transmission case.

CAUTION:

lMake sure that turbine revolution sensor securely installs

turbine revolution sensor hole.

lHang down revolution sensor harness toward outside so

as not to disturb installation of control valve with TCM.

lAdjust A/T assembly harness connector of control valve

with TCM to terminal hole of transmission case.

lAssemble it so that manual valve cutout is engaged with

manual plate projection.

8. Install bolts A, B and C in control valve with TCM.

9. Tighten bolt 1, 2 and 3 temporarily to prevent dislocation. After

that tighten them in order (1®2®3), and then tighten other

bolts. Tighten control valve with TCM mounting bolts to the

specified torque. Refer toAT- 2 1 8 , "

COMPONENTS".

SCIA5034E

SCIA5142E

Bolt symbol Length [mm (in)] Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA5139E

SCIA5140E

Page 278 of 3171

AT-270

DISASSEMBLY

33. Disconnect revolution sensor connector.

CAUTION:

Be careful not to damage connector.

34. Straighten terminal clips to free revolution sensor harness.

35. Remove bolts A, B and C from control valve with TCM.

36. Remove control valve with TCM from transmission case.

CAUTION:

When removing, be careful with manual valve notch and

manual plate height. Remove it vertically.

37. Remove A/T fluid temperature sensor 2 with bracket from con-

trol valve with TCM.

SCIA5024E

SCIA7023E

Bolt symbol Length [mm (in)] Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA5025E

SCIA5260E

SCIA5301E

Page 327 of 3171

ASSEMBLY

AT-319

D

E

F

G

H

I

J

K

L

MA

B

AT

g. Install control valve with TCM in transmission case.

CAUTION:

lMake sure that turbine revolution sensor securely installs

turbine revolution sensor hole.

lHang down revolution sensor harness toward outside so

as not to disturb installation of control valve with TCM.

lAdjust A/T assembly harness connector of control valve

with TCM to terminal hole of transmission case.

lAssemble it so that manual valve cutout is engaged with

manual plate projection.

h. Install bolts A, B and C to control valve with TCM.

i. Tighten bolt 1, 2 and 3 temporarily to prevent dislocation. After

that tighten them in order (1®2®3), and then tighten other

bolts to the specified torque. Refer toAT- 2 5 1 , "

Components".

10. Connect A/T fluid temperature sensor 2 connector.

SCIA5034E

SCIA5035E

Bolt symbol Length [mm (in)] Number of bolts

A42(1.65) 5

B55(2.17) 6

C40(1.57) 1

SCIA5025E

SCIA5037E

SCIA5023E

Page 775 of 3171

BODY REPAIR

BL-191

C

D

E

F

G

H

J

K

L

MA

B

BL

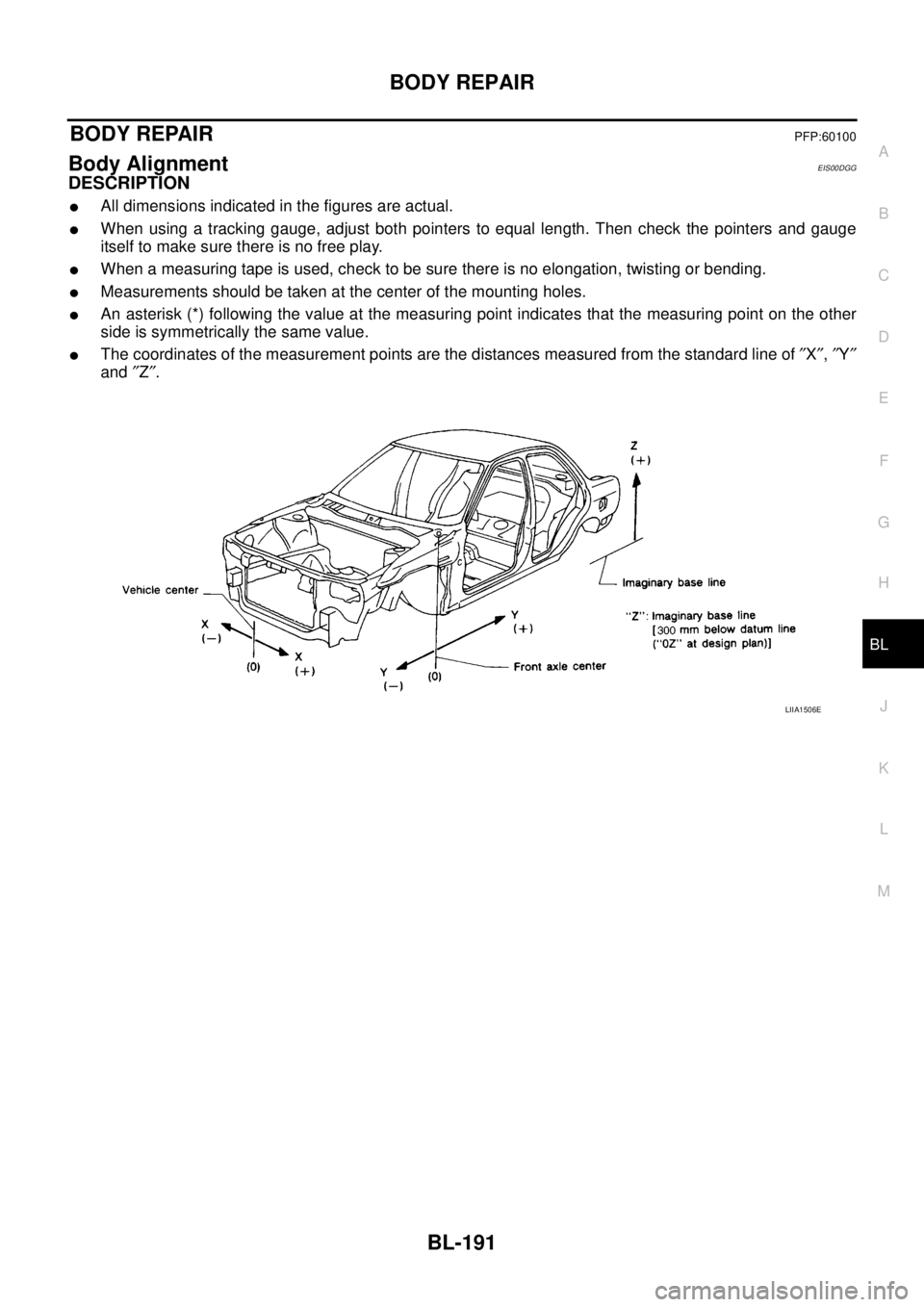

BODY REPAIRPFP:60100

Body AlignmentEIS00DGG

DESCRIPTION

lAll dimensions indicated in the figures are actual.

lWhen using a tracking gauge, adjust both pointers to equal length. Then check the pointers and gauge

itself to make sure there is no free play.

lWhen a measuring tape is used, check to be sure there is no elongation, twisting or bending.

lMeasurements should be taken at the center of the mounting holes.

lAn asterisk (*) following the value at the measuring point indicates that the measuring point on the other

side is symmetrically the same value.

lThe coordinates of the measurement points are the distances measured from the standard line of²X²,²Y²

and²Z².

LIIA1506E

Page 795 of 3171

BRAKE PEDAL

BR-9

C

D

E

G

H

I

J

K

L

MA

B

BR

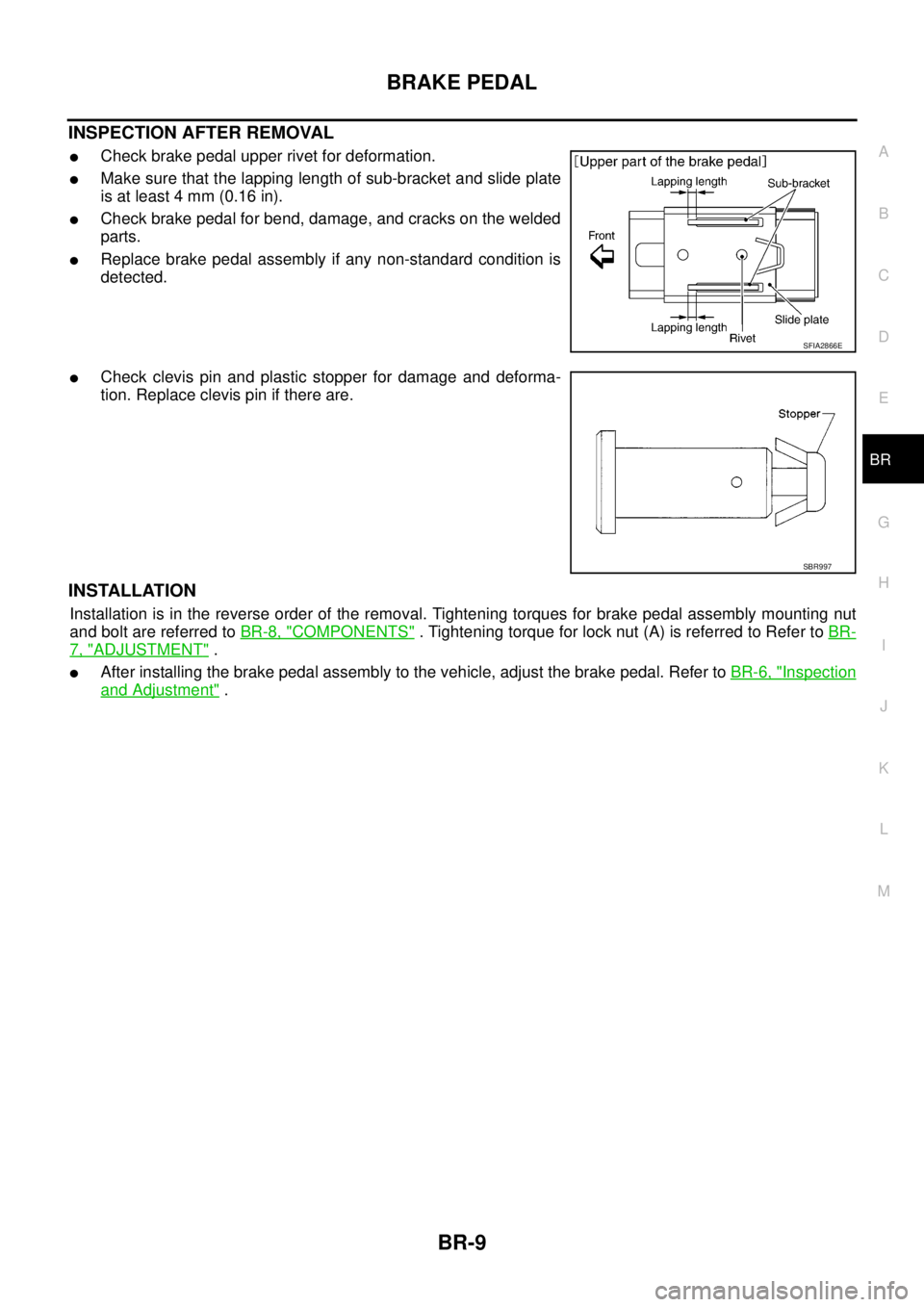

INSPECTION AFTER REMOVAL

lCheck brake pedal upper rivet for deformation.

lMake sure that the lapping length of sub-bracket and slide plate

is at least 4 mm (0.16 in).

lCheck brake pedal for bend, damage, and cracks on the welded

parts.

lReplace brake pedal assembly if any non-standard condition is

detected.

lCheck clevis pin and plastic stopper for damage and deforma-

tion. Replace clevis pin if there are.

INSTALLATION

Installation is in the reverse order of the removal. Tightening torques for brake pedal assembly mounting nut

and bolt are referred toBR-8, "

COMPONENTS". Tightening torque for lock nut (A) is referred to Refer toBR-

7, "ADJUSTMENT".

lAfter installing the brake pedal assembly to the vehicle, adjust the brake pedal. Refer toBR-6, "Inspection

and Adjustment".

SFIA2866E

SBR997

Page 801 of 3171

LOAD SENSING VALVE

BR-15

C

D

E

G

H

I

J

K

L

MA

B

BR

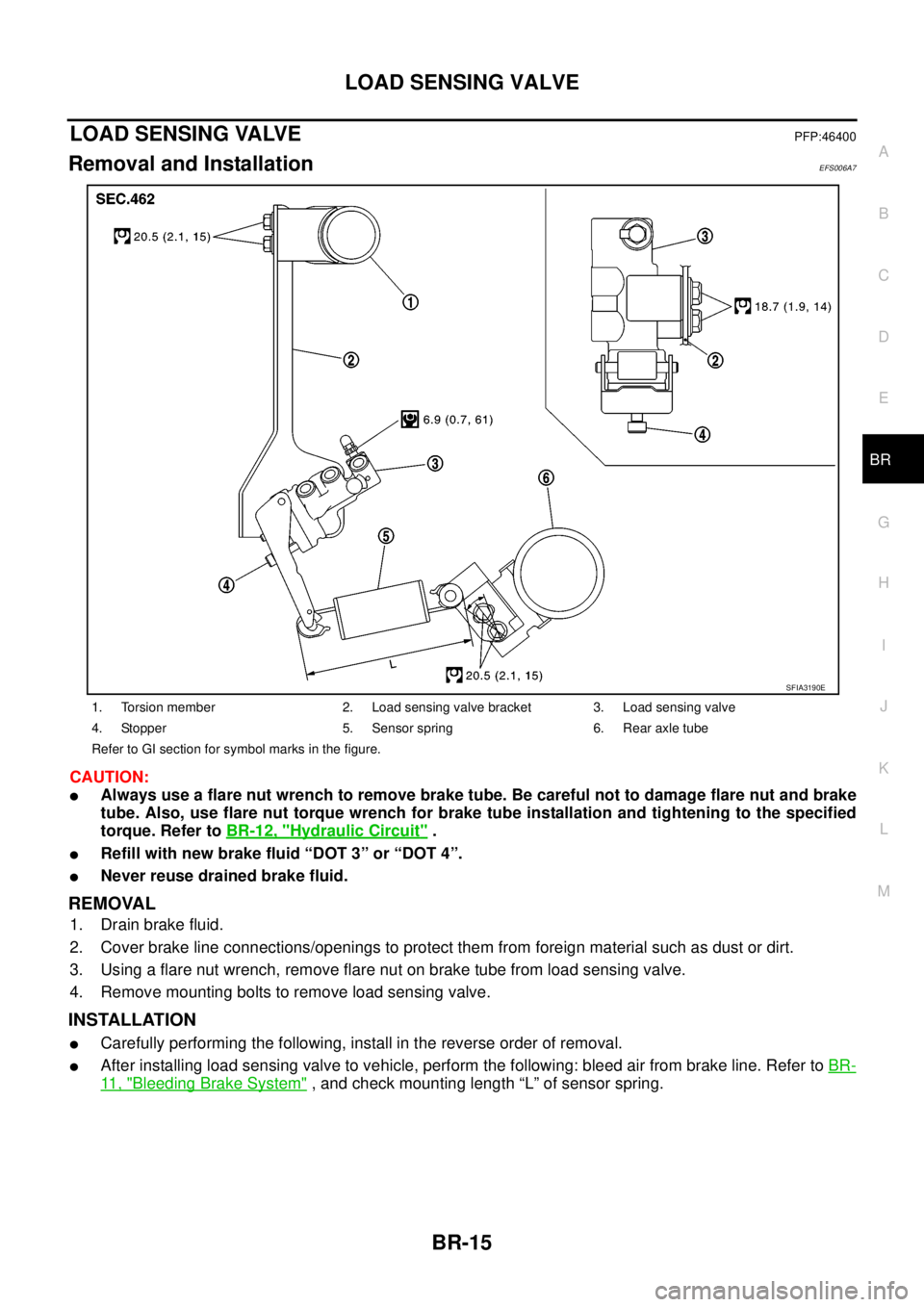

LOAD SENSING VALVEPFP:46400

Removal and InstallationEFS006A7

CAUTION:

lAlways use a flare nut wrench to remove brake tube. Be careful not to damage flare nut and brake

tube. Also, use flare nut torque wrench for brake tube installation and tightening to the specified

torque. Refer toBR-12, "

Hydraulic Circuit".

lRefill with new brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

REMOVAL

1. Drain brake fluid.

2. Cover brake line connections/openings to protect them from foreign material such as dust or dirt.

3. Using a flare nut wrench, remove flare nut on brake tube from load sensing valve.

4. Remove mounting bolts to remove load sensing valve.

INSTALLATION

lCarefully performing the following, install in the reverse order of removal.

lAfter installing load sensing valve to vehicle, perform the following: bleed air from brake line. Refer toBR-

11 , "Bleeding Brake System", and check mounting length “L” of sensor spring.

1. Torsion member 2. Load sensing valve bracket 3. Load sensing valve

4. Stopper 5. Sensor spring 6. Rear axle tube

Refer to GI section for symbol marks in the figure.

SFIA3190E

Page 802 of 3171

BR-16

LOAD SENSING VALVE

Inspection

EFS006A8

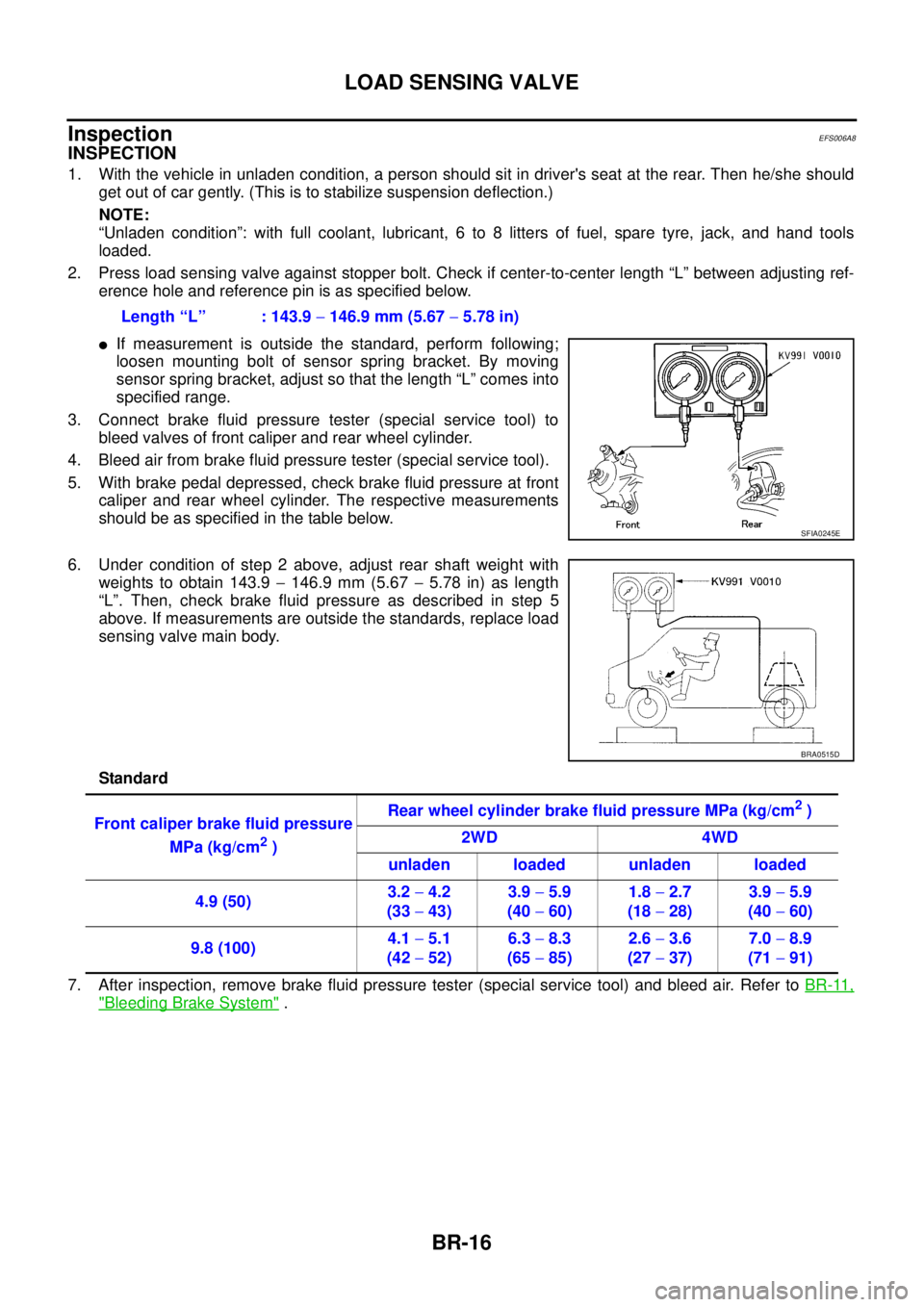

INSPECTION

1. With the vehicle in unladen condition, a person should sit in driver's seat at the rear. Then he/she should

get out of car gently. (This is to stabilize suspension deflection.)

NOTE:

“Unladen condition”: with full coolant, lubricant, 6 to 8 litters of fuel, spare tyre, jack, and hand tools

loaded.

2. Press load sensing valve against stopper bolt. Check if center-to-center length “L” between adjusting ref-

erence hole and reference pin is as specified below.

lIf measurement is outside the standard, perform following;

loosen mounting bolt of sensor spring bracket. By moving

sensor spring bracket, adjust so that the length “L” comes into

specified range.

3. Connect brake fluid pressure tester (special service tool) to

bleed valves of front caliper and rear wheel cylinder.

4. Bleed air from brake fluid pressure tester (special service tool).

5. With brake pedal depressed, check brake fluid pressure at front

caliper and rear wheel cylinder. The respective measurements

should be as specified in the table below.

6. Under condition of step 2 above, adjust rear shaft weight with

weights to obtain 143.9-146.9 mm (5.67-5.78 in) as length

“L”. Then, check brake fluid pressure as described in step 5

above. If measurements are outside the standards, replace load

sensing valve main body.

Standard

7. After inspection, remove brake fluid pressure tester (special service tool) and bleed air. Refer toBR-11,

"Bleeding Brake System". Length “L” : 143.9-146.9 mm (5.67-5.78 in)

SFIA0245E

BRA0515D

Front caliper brake fluid pressure

MPa (kg/cm

2)Rear wheel cylinder brake fluid pressure MPa (kg/cm

2)

2WD 4WD

unladen loaded unladen loaded

4.9 (50)3.2-4.2

(33-43)3.9-5.9

(40-60)1.8-2.7

(18-28)3.9-5.9

(40-60)

9.8 (100)4.1-5.1

(42-52)6.3-8.3

(65-85)2.6-3.6

(27-37)7.0-8.9

(71-91)

Page 806 of 3171

BR-20

BRAKE BOOSTER

Removal and Installation

EFS005SU

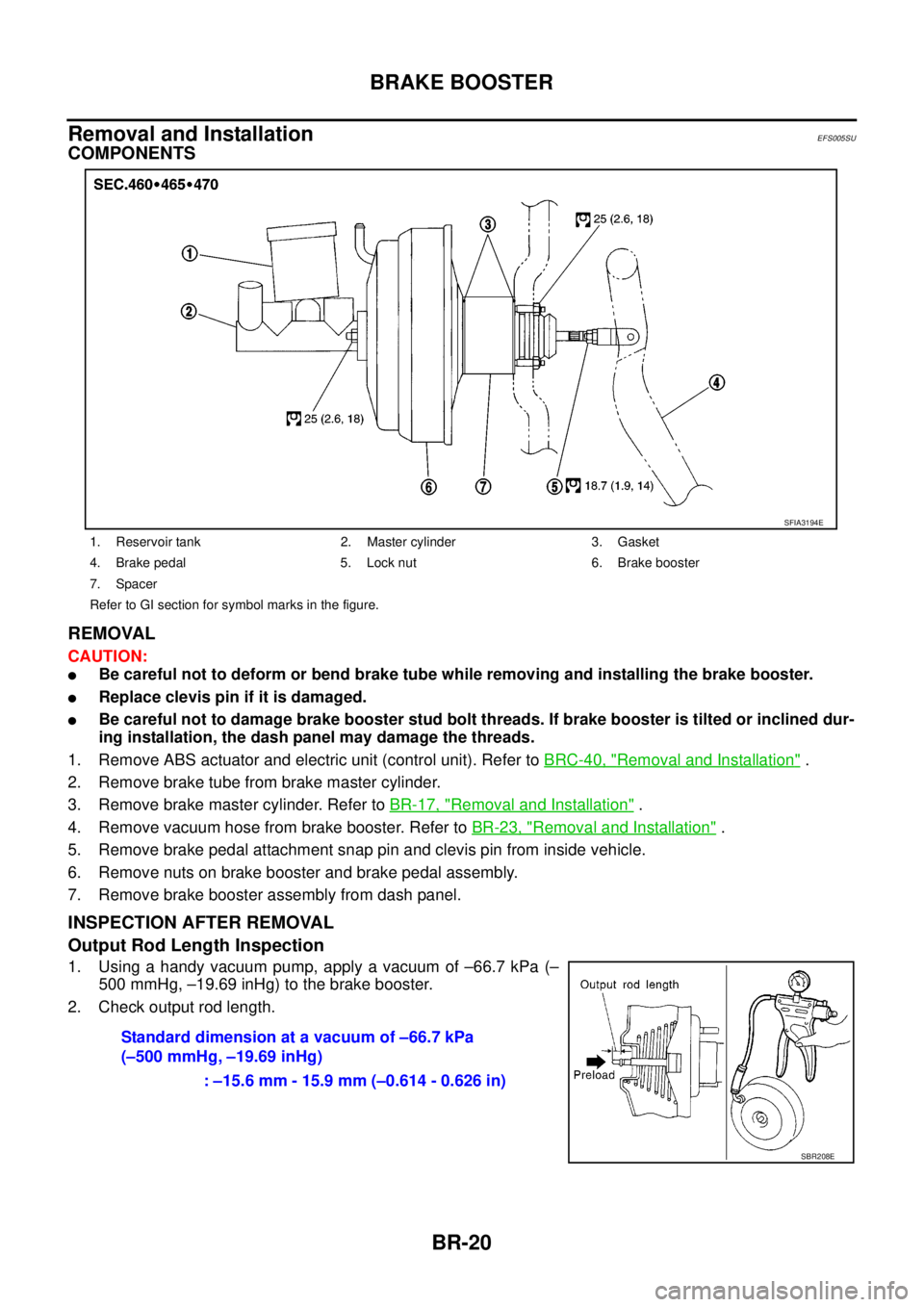

COMPONENTS

REMOVAL

CAUTION:

lBe careful not to deform or bend brake tube while removing and installing the brake booster.

lReplace clevis pin if it is damaged.

lBe careful not to damage brake booster stud bolt threads. If brake booster is tilted or inclined dur-

ing installation, the dash panel may damage the threads.

1. Remove ABS actuator and electric unit (control unit). Refer toBRC-40, "

Removal and Installation".

2. Remove brake tube from brake master cylinder.

3. Remove brake master cylinder. Refer toBR-17, "

Removal and Installation".

4. Remove vacuum hose from brake booster. Refer toBR-23, "

Removal and Installation".

5. Remove brake pedal attachment snap pin and clevis pin from inside vehicle.

6. Remove nuts on brake booster and brake pedal assembly.

7. Remove brake booster assembly from dash panel.

INSPECTION AFTER REMOVAL

Output Rod Length Inspection

1. Using a handy vacuum pump, apply a vacuum of –66.7 kPa (–

500 mmHg, –19.69 inHg) to the brake booster.

2. Check output rod length.

1. Reservoir tank 2. Master cylinder 3. Gasket

4. Brake pedal 5. Lock nut 6. Brake booster

7. Spacer

Refer to GI section for symbol marks in the figure.

SFIA3194E

Standard dimension at a vacuum of –66.7 kPa

(–500 mmHg, –19.69 inHg)

: –15.6 mm - 15.9 mm (–0.614 - 0.626 in)

SBR208E

Page 807 of 3171

BRAKE BOOSTER

BR-21

C

D

E

G

H

I

J

K

L

MA

B

BR

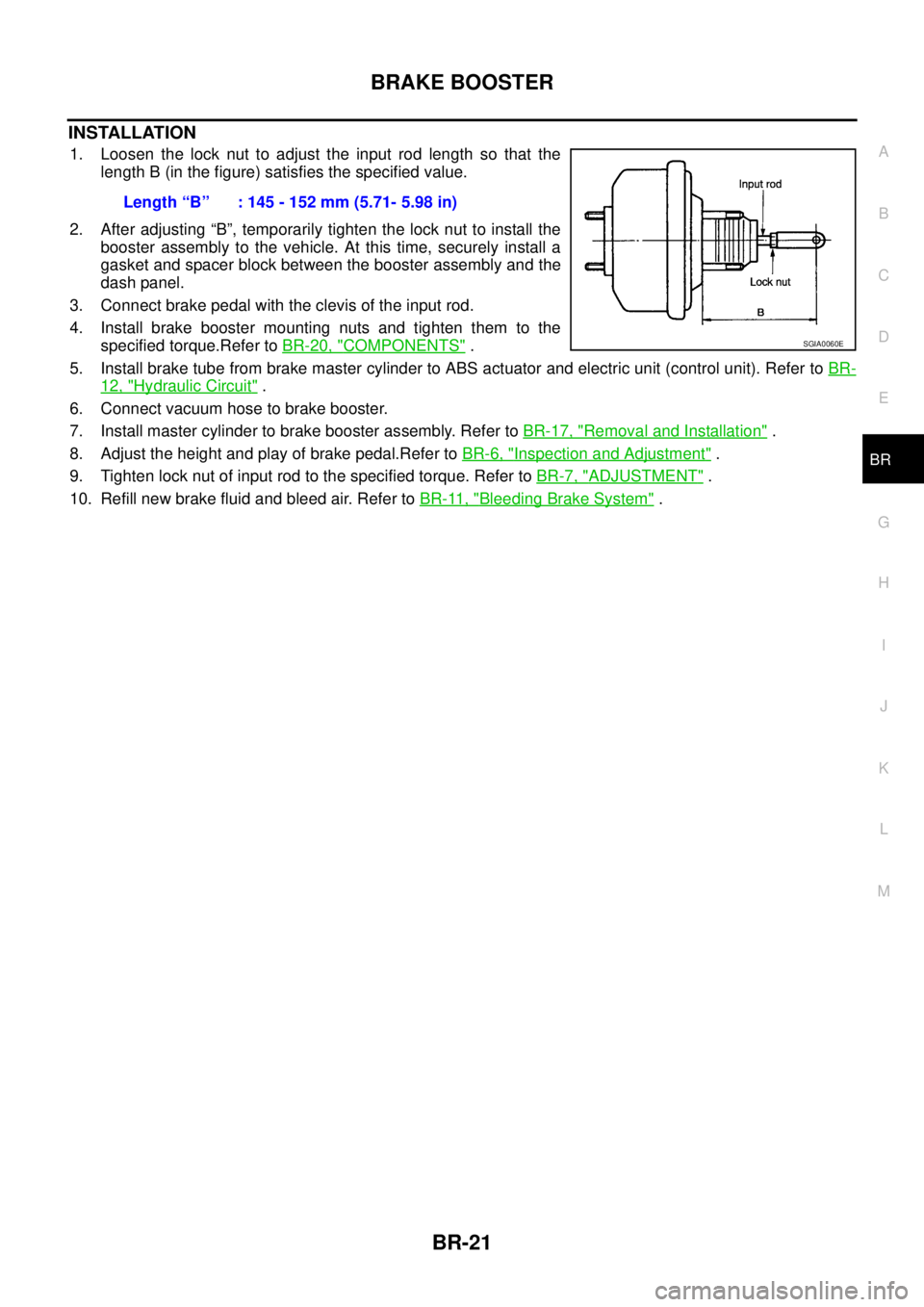

INSTALLATION

1. Loosen the lock nut to adjust the input rod length so that the

length B (in the figure) satisfies the specified value.

2. After adjusting “B”, temporarily tighten the lock nut to install the

booster assembly to the vehicle. At this time, securely install a

gasket and spacer block between the booster assembly and the

dash panel.

3. Connect brake pedal with the clevis of the input rod.

4. Install brake booster mounting nuts and tighten them to the

specified torque.Refer toBR-20, "

COMPONENTS".

5. Install brake tube from brake master cylinder to ABS actuator and electric unit (control unit). Refer toBR-

12, "Hydraulic Circuit".

6. Connect vacuum hose to brake booster.

7. Install master cylinder to brake booster assembly. Refer toBR-17, "

Removal and Installation".

8. Adjust the height and play of brake pedal.Refer toBR-6, "

Inspection and Adjustment".

9. Tighten lock nut of input rod to the specified torque. Refer toBR-7, "

ADJUSTMENT".

10. Refill new brake fluid and bleed air. Refer toBR-11, "

Bleeding Brake System". Length“B” :145-152mm(5.71-5.98in)

SGIA0060E