height NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2792 of 3171

![NISSAN NAVARA 2005 Repair Repair Manual REAR FINAL DRIVE ASSEMBLY

RFD-89

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

4. Remove companion flange using suitable tool.

5. Remove front oil seal using Tool.

CAUTION:

Be care NISSAN NAVARA 2005 Repair Repair Manual REAR FINAL DRIVE ASSEMBLY

RFD-89

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

4. Remove companion flange using suitable tool.

5. Remove front oil seal using Tool.

CAUTION:

Be care](/img/5/57362/w960_57362-2791.png)

REAR FINAL DRIVE ASSEMBLY

RFD-89

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

4. Remove companion flange using suitable tool.

5. Remove front oil seal using Tool.

CAUTION:

Be careful not to damage axle housing.

6. Remove front bearing thrust washer.

7. Press the drive pinion assembly and collapsible spacer from

axle housing.

CAUTION:

Do not drop drive pinion assembly.

8. Remove drive pinion front bearing inner race from axle housing.

9. Tap drive pinion front bearing outer race uniformly with a brass

bar or equivalent to remove.

CAUTION:

Be careful not to damage axle housing.

10. Tap drive pinion rear bearing outer race uniformly with a brass

bar or equivalent for removal.

CAUTION:

Be careful not to damage axle housing.

11. Remove drive pinion rear bearing inner race and drive pinion

height adjusting washer using Tool.

12. Remove the breather.

PDIA0315E

Tool number : KV381054S0

SDIA2586E

PDIA0316E

SDIA2641E

Tool number : ST30021000

SDIA2236E

Page 2793 of 3171

![NISSAN NAVARA 2005 Repair Repair Manual RFD-90

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

INSPECTION AFTER DISASSEMBLY

Drive Gear and Drive Pinion

lIf the gear teeth do not mesh or line-up correctly, determine the caus NISSAN NAVARA 2005 Repair Repair Manual RFD-90

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

INSPECTION AFTER DISASSEMBLY

Drive Gear and Drive Pinion

lIf the gear teeth do not mesh or line-up correctly, determine the caus](/img/5/57362/w960_57362-2792.png)

RFD-90

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

INSPECTION AFTER DISASSEMBLY

Drive Gear and Drive Pinion

lIf the gear teeth do not mesh or line-up correctly, determine the cause and adjust, repair, or replace as

necessary.

lIf the gears are worn, cracked, damaged, pitted or chipped (by friction) noticeably, replace with new gears.

lDrive gear and drive pinion are supplied in matched sets only. Matching numbers on both drive pinion and

drive gear are etched for verification. If a new gear set is being used, verify the numbers of each drive pin-

ion and drive gear before proceeding with assembly.

Bearing

lIf bearings are chipped (by friction), pitted, worn, rusted, scratched, or unusual noise is coming from bear-

ing, replace with new bearing assembly (as a new set).

lBearing must be replaced with a new one whenever disassembled.

Differential Case Assembly

lIf the gears are worn, cracked, damaged, pitted or chipped (by friction) noticeably, replace with new differ-

ential case assembly.

lIf the movement is not smooth when pushing cam ring of differential case assembly by hand, repair or

replace as necessary.

Differential Lock Solenoid

lIf the operating part of differential lock solenoid is not smooth, perform component inspection. Refer to

RFD-68, "

COMPONENT INSPECTION".

SELECTION ADJUSTING WASHERS

Drive Pinion Height Adjusting Washer

lDrive gear and drive pinion are supplied in matched sets only.

Matching numbers on both drive pinion and drive gear are

etched for verification. If a new hypoid gear set is being used,

verify the numbers of each drive pinion and drive gear before

proceeding with assembly.

lThe mounting distance from the center line of drive gear to the back face of drive pinion for the M226 final

drive is 109.5 mm (4.312 in).

On the button end of each drive pinion, there is etched a plus (+) number, a minus (-) number, or a zero

(0), which indicates the best running position for each particular hypoid gear set. This dimension is con-

trolled by a selective drive pinion height adjusting washer between drive pinion rear bearing inner race

and drive pinion.

For example: If a drive pinion is etched m+8 (+3), it would require 0.08 mm (0.003 in) less drive pinion

height adjusting washer than a drive pinion etched “0”. This means decreasing drive pinion height adjust-

ing washer thickness; increases the mounting distance of drive pinion to 109.6 mm (4.315 in). If a drive

pinion is etched m-8 (-3), it would require adding 0.08 mm (0.003 in) more to drive pinion height adjusting

washer than would be required if drive pinion were etched “0”. By adding 0.08 mm (0.003 in), the mount-

ing distance of drive pinion was decreased to 109.4 mm (4.309 in) which is just what a m-8 (-3) etching

indicated.

lTo change drive pinion adjustment, use different drive pinion height adjusting washer which come in differ-

ent thickness.

lUse the following tables as a guide for selecting the correct drive pinion height adjusting washer thickness

to add or subtract from the old drive pinion height adjusting washer.

SDIA2241E

Page 2795 of 3171

![NISSAN NAVARA 2005 Repair Repair Manual RFD-92

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

4. Temporarily install drive pinion height adjusting washer.

When hypoid gear set has been replaced

lSelect drive pinion height NISSAN NAVARA 2005 Repair Repair Manual RFD-92

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

4. Temporarily install drive pinion height adjusting washer.

When hypoid gear set has been replaced

lSelect drive pinion height](/img/5/57362/w960_57362-2794.png)

RFD-92

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

4. Temporarily install drive pinion height adjusting washer.

When hypoid gear set has been replaced

lSelect drive pinion height adjusting washer. Refer toRFD-90,

"Drive Pinion Height Adjusting Washer".

When hypoid gear set has been reused

lTemporarily install the removed drive pinion height adjusting

washer or same thickness washer to drive pinion.

5. Install selected drive pinion height adjusting washer to drive pin-

ion, and press-fit drive pinion rear bearing inner race in it, using

a press and suitable tool.

CAUTION:

Do not reuse drive pinion rear bearing.

6. Apply gear oil to drive pinion rear bearing and drive pinion front

bearing.

7. Install drive pinion front bearing inner race in axle housing.

CAUTION:

Do not reuse drive pinion front bearing.

8. Install front bearing thrust washer to axle housing.

9. Perform checking and adjusting the tooth contact and backlash of the hypoid gear following the procedure

below.

a. Assemble the drive pinion assembly to the axle housing.

CAUTION:

Do not assemble a collapsible spacer.

b. Insert companion flange onto drive pinion. Tap the companion

flange with a soft hammer until fully seated.

CAUTION:

Do not assemble a front oil seal.

c. Temporarily tighten removed drive pinion lock nut and washer to

drive pinion.

NOTE:

Use removed drive pinion lock nut and washer only for the pre-

load measurement.

d. Rotate drive pinion at least 20 times to check for smooth opera-

tion of the bearing.

SDIA1666E

PDIA1053E

PDIA0328E

Tool number : KV40104000

PDIA0313E

Page 2804 of 3171

![NISSAN NAVARA 2005 Repair Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

RFD-101

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

SELECTIVE PARTS

Drive Pinion Height Adjusting Washer

Unit: mm (in)

*Always check with th NISSAN NAVARA 2005 Repair Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

RFD-101

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

SELECTIVE PARTS

Drive Pinion Height Adjusting Washer

Unit: mm (in)

*Always check with th](/img/5/57362/w960_57362-2803.png)

SERVICE DATA AND SPECIFICATIONS (SDS)

RFD-101

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

SELECTIVE PARTS

Drive Pinion Height Adjusting Washer

Unit: mm (in)

*Always check with the Parts Department for the latest parts information.Thickness Package part number*

0.076 (0.030)

0.079 (0.031)

0.081 (0.032)

0.084 (0.033)

0.086 (0.034)38151 8S101

0.089 (0.035)

0.091 (0.036)

0.094 (0.037)

0.097 (0.038)

0.099 (0.039)38151 8S102

0.102 (0.040)

0.104 (0.041)

0.107 (0.042)

0.109 (0.043)

0.112 (0.044)38151 8S103

0.114 (0.045)

0.117 (0.046)

0.119 (0.047)

0.122 (0.048)

0.124 (0.049)38151 8S104

0.127 (0.050)

0.130 (0.051)

0.132 (0.052)

0.135 (0.053)

0.137 (0.054)38151 8S105

Page 2806 of 3171

RSU-1

REAR SUSPENSION

E SUSPENSION

CONTENTS

C

D

F

G

H

I

J

K

L

M

SECTIONRSU

A

B

RSU

REAR SUSPENSION

PRECAUTIONS .......................................................... 2

Precautions .............................................................. 2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 3

NVH Troubleshooting Chart ..................................... 3

REAR SUSPENSION ASSEMBLY ............................. 4

Components ............................................................. 4

On-Vehicle Inspection and Service .......................... 5

SHOCK ABSORBER .................................................. 6

Removal and Installation .......................................... 6

REMOVAL ............................................................. 6

INSPECTION AFTER REMOVAL ......................... 6

INSTALLATION ..................................................... 6LEAF SPRING ............................................................ 7

Removal and Installation .......................................... 7

REMOVAL ............................................................. 8

INSPECTION AFTER REMOVAL ......................... 9

INSTALLATION ..................................................... 9

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 11

General Specifications (Rear) ................................ 11

Wheelarch Height (Unladen*

1) .............................. 11

Page 2816 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

RSU-11

C

D

F

G

H

I

J

K

L

MA

B

RSU

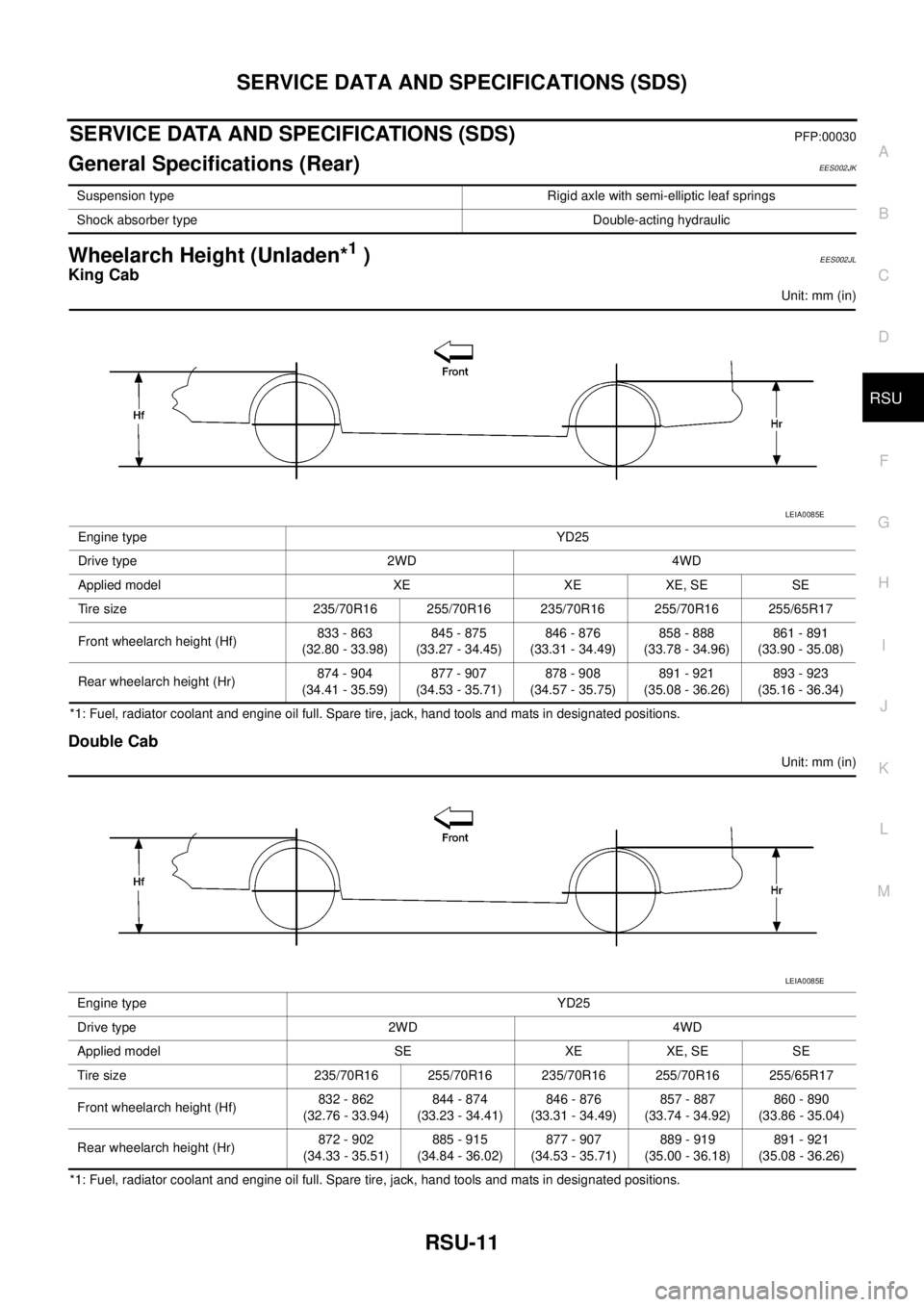

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General Specifications (Rear)EES002JK

Wheelarch Height (Unladen*1)EES002JL

King Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Double Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.Suspension type Rigid axle with semi-elliptic leaf springs

Shock absorber type Double-acting hydraulic

Engine type YD25

Drive type 2WD 4WD

Applied model XE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)833 - 863

(32.80 - 33.98)845 - 875

(33.27 - 34.45)846 - 876

(33.31 - 34.49)858 - 888

(33.78 - 34.96)861 - 891

(33.90 - 35.08)

Rear wheelarch height (Hr)874 - 904

(34.41 - 35.59)877 - 907

(34.53 - 35.71)878 - 908

(34.57 - 35.75)891 - 921

(35.08 - 36.26)893 - 923

(35.16 - 36.34)

LEIA0085E

Engine type YD25

Drive type 2WD 4WD

Applied model SE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)832 - 862

(32.76 - 33.94)844 - 874

(33.23 - 34.41)846 - 876

(33.31 - 34.49)857 - 887

(33.74 - 34.92)860 - 890

(33.86 - 35.04)

Rear wheelarch height (Hr)872 - 902

(34.33 - 35.51)885 - 915

(34.84 - 36.02)877 - 907

(34.53 - 35.71)889 - 919

(35.00 - 36.18)891 - 921

(35.08 - 36.26)

LEIA0085E

Page 2820 of 3171

SEAT BELTS

SB-3

C

D

E

F

G

I

J

K

L

MA

B

SB

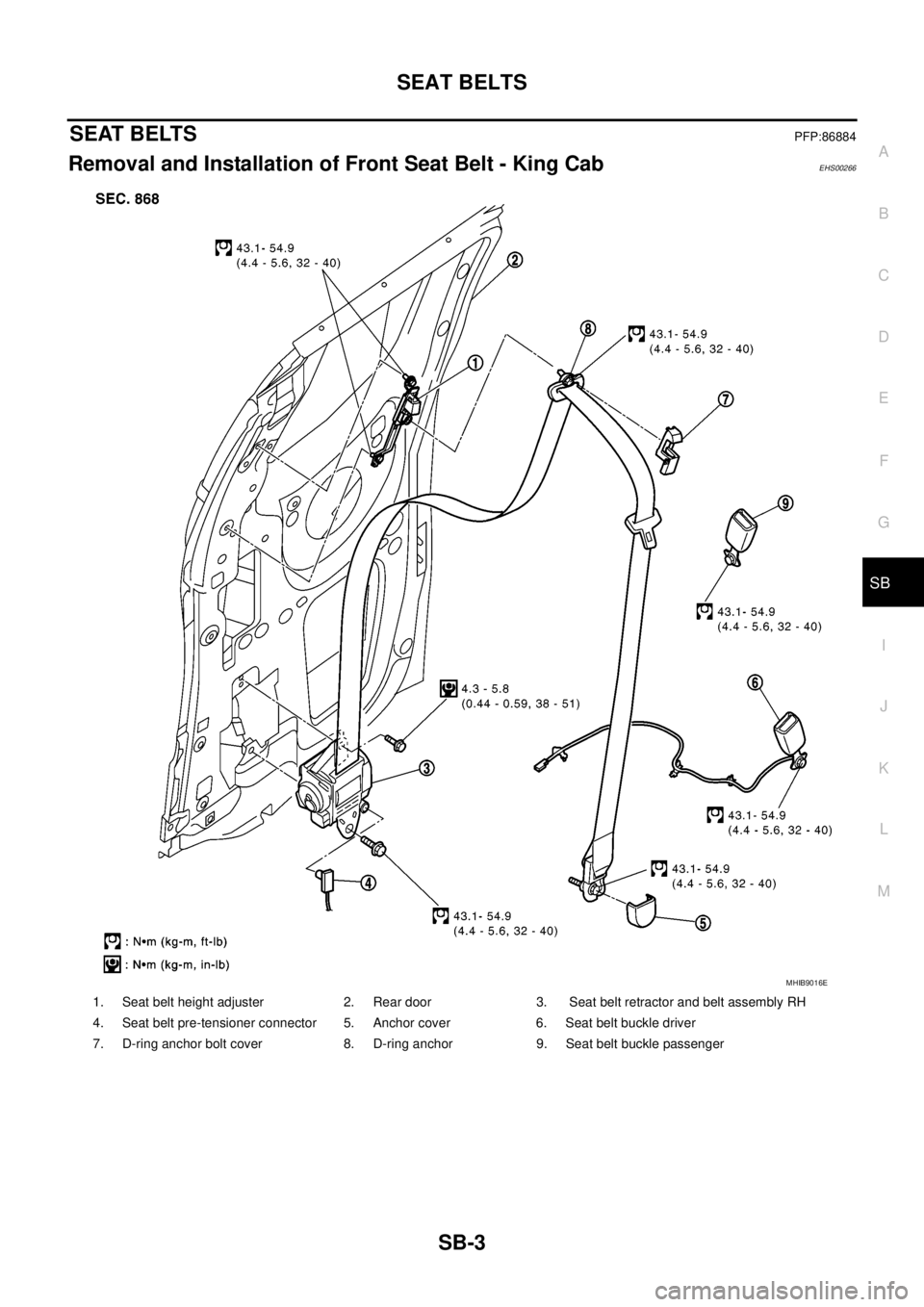

SEAT BELTSPFP:86884

Removal and Installation of Front Seat Belt - King CabEHS00266

1. Seat belt height adjuster 2. Rear door 3. Seat belt retractor and belt assembly RH

4. Seat belt pre-tensioner connector 5. Anchor cover 6. Seat belt buckle driver

7. D-ring anchor bolt cover 8. D-ring anchor 9. Seat belt buckle passenger

MHIB9016E

Page 2821 of 3171

SB-4

SEAT BELTS

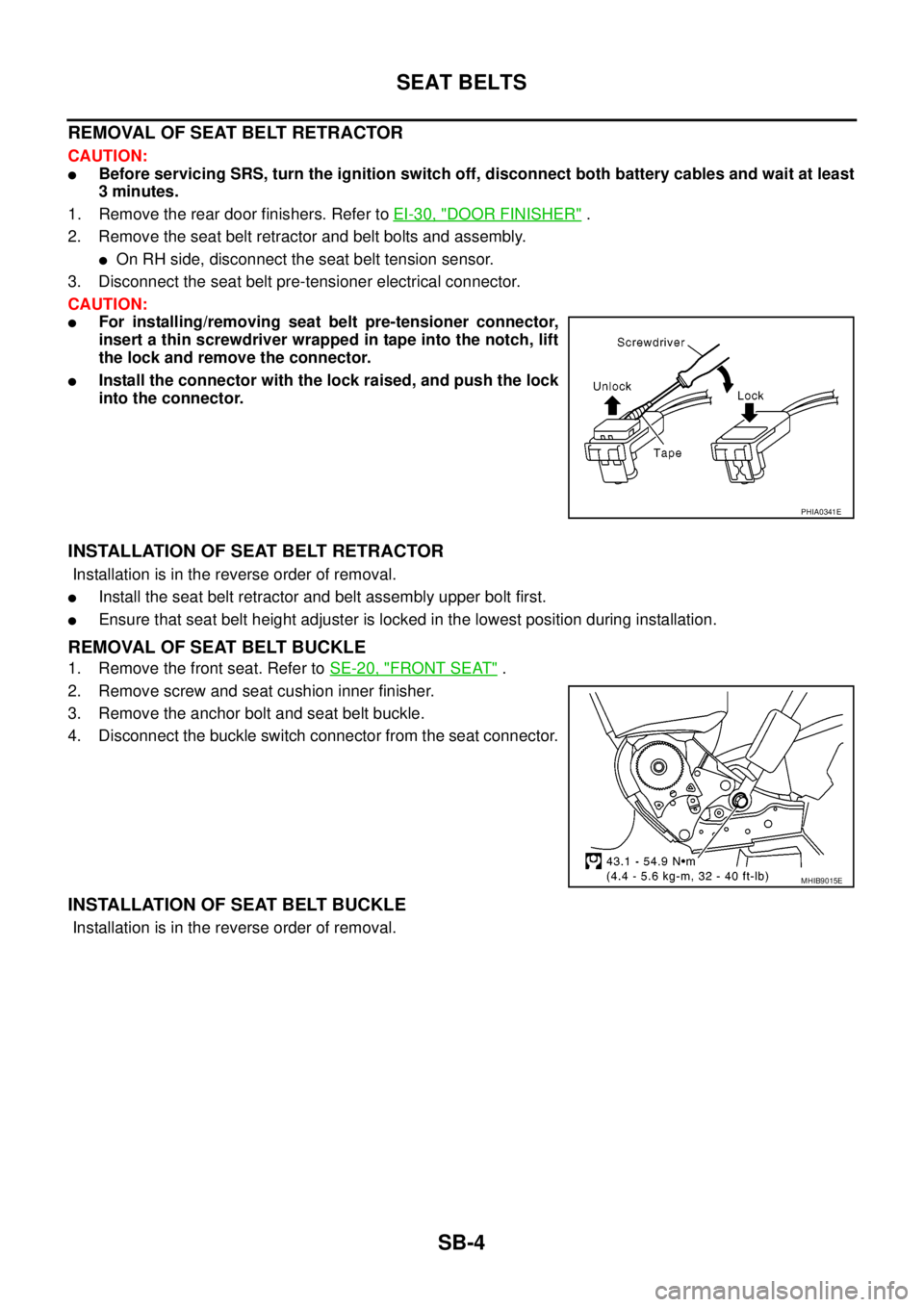

REMOVALOFSEATBELTRETRACTOR

CAUTION:

lBefore servicing SRS, turn the ignition switch off, disconnect both battery cables and wait at least

3 minutes.

1. Remove the rear door finishers. Refer toEI-30, "

DOOR FINISHER".

2. Remove the seat belt retractor and belt bolts and assembly.

lOn RH side, disconnect the seat belt tension sensor.

3. Disconnect the seat belt pre-tensioner electrical connector.

CAUTION:

lFor installing/removing seat belt pre-tensioner connector,

insert a thin screwdriver wrapped in tape into the notch, lift

the lock and remove the connector.

lInstall the connector with the lock raised, and push the lock

into the connector.

INSTALLATION OF SEAT BELT RETRACTOR

Installation is in the reverse order of removal.

lInstall the seat belt retractor and belt assembly upper bolt first.

lEnsure that seat belt height adjuster is locked in the lowest position during installation.

REMOVAL OF SEAT BELT BUCKLE

1. Remove the front seat. Refer toSE-20, "FRONT SEAT".

2. Remove screw and seat cushion inner finisher.

3. Remove the anchor bolt and seat belt buckle.

4. Disconnect the buckle switch connector from the seat connector.

INSTALLATION OF SEAT BELT BUCKLE

Installation is in the reverse order of removal.

PHIA0341E

MHIB9015E

Page 2822 of 3171

SEAT BELTS

SB-5

C

D

E

F

G

I

J

K

L

MA

B

SB

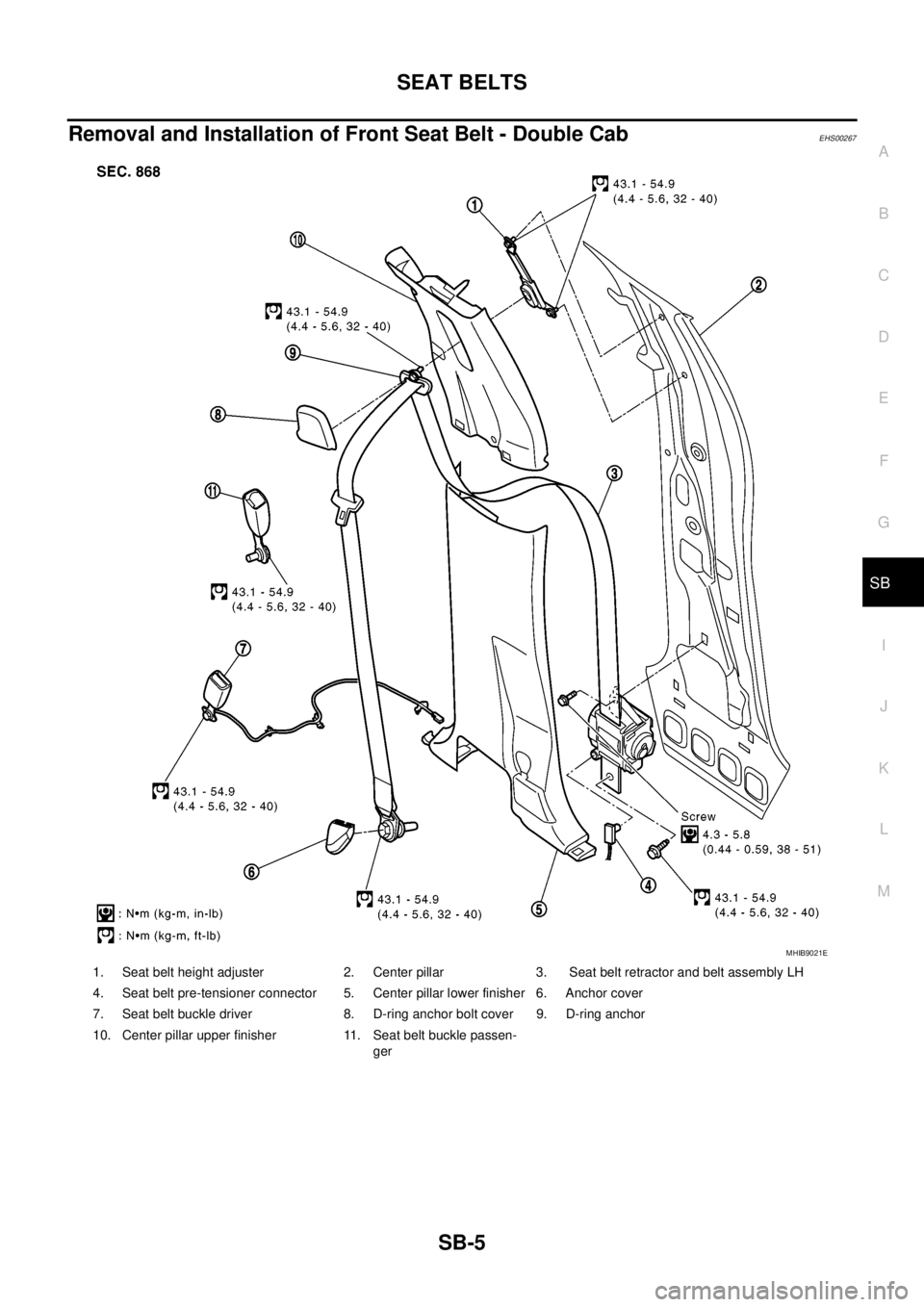

Removal and Installation of Front Seat Belt - Double CabEHS00267

1. Seat belt height adjuster 2. Center pillar 3. Seat belt retractor and belt assembly LH

4. Seat belt pre-tensioner connector 5. Center pillar lower finisher 6. Anchor cover

7. Seat belt buckle driver 8. D-ring anchor bolt cover 9. D-ring anchor

10. Center pillar upper finisher 11. Seat belt buckle passen-

ger

MHIB9021E

Page 2823 of 3171

SB-6

SEAT BELTS

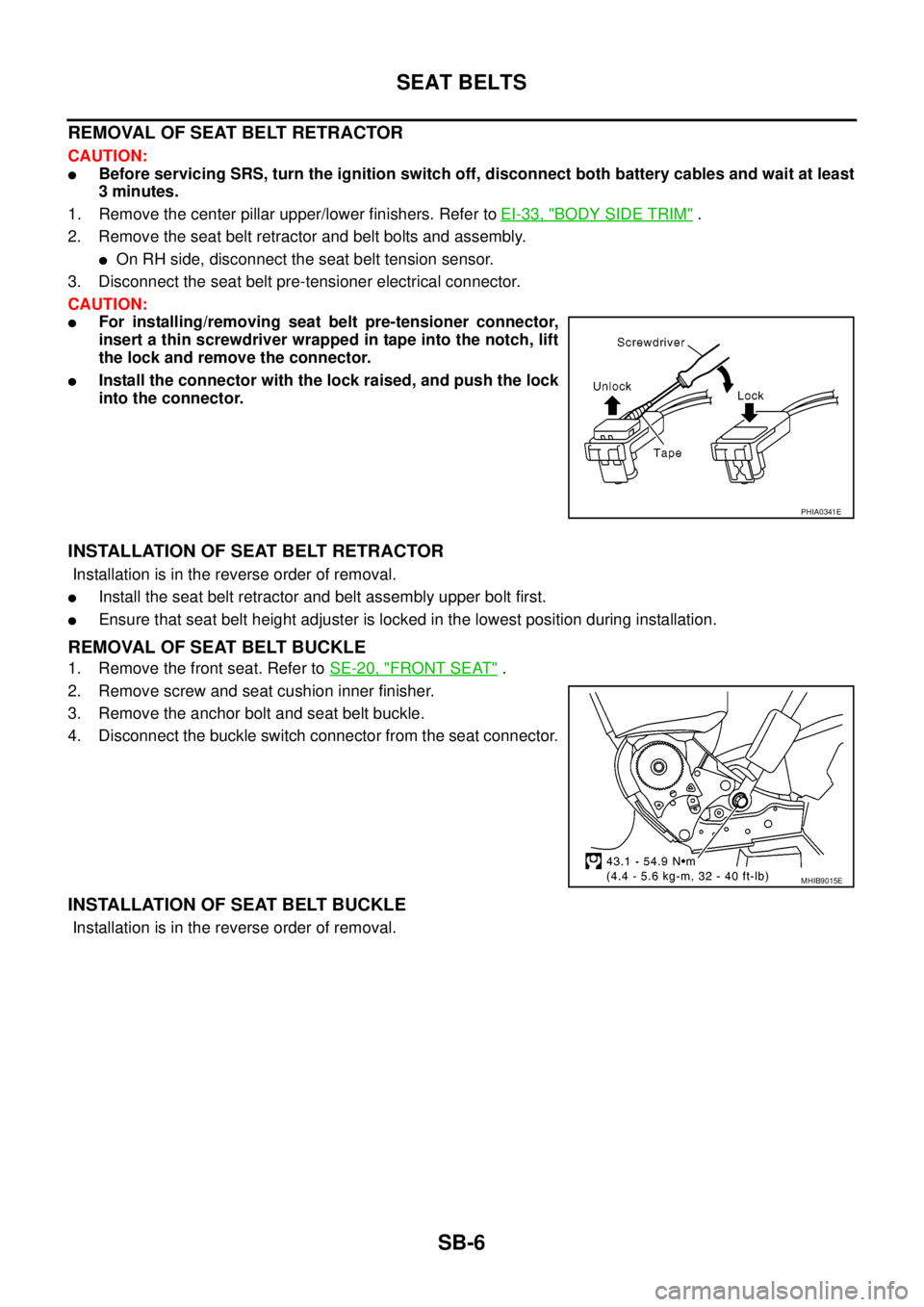

REMOVALOFSEATBELTRETRACTOR

CAUTION:

lBefore servicing SRS, turn the ignition switch off, disconnect both battery cables and wait at least

3 minutes.

1. Remove the center pillar upper/lower finishers. Refer toEI-33, "

BODY SIDE TRIM".

2. Remove the seat belt retractor and belt bolts and assembly.

lOn RH side, disconnect the seat belt tension sensor.

3. Disconnect the seat belt pre-tensioner electrical connector.

CAUTION:

lFor installing/removing seat belt pre-tensioner connector,

insert a thin screwdriver wrapped in tape into the notch, lift

the lock and remove the connector.

lInstall the connector with the lock raised, and push the lock

into the connector.

INSTALLATION OF SEAT BELT RETRACTOR

Installation is in the reverse order of removal.

lInstall the seat belt retractor and belt assembly upper bolt first.

lEnsure that seat belt height adjuster is locked in the lowest position during installation.

REMOVAL OF SEAT BELT BUCKLE

1. Remove the front seat. Refer toSE-20, "FRONT SEAT".

2. Remove screw and seat cushion inner finisher.

3. Remove the anchor bolt and seat belt buckle.

4. Disconnect the buckle switch connector from the seat connector.

INSTALLATION OF SEAT BELT BUCKLE

Installation is in the reverse order of removal.

PHIA0341E

MHIB9015E