fuel NISSAN NAVARA 2005 Repair Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1004 of 3171

EC-24

BASIC SERVICE PROCEDURE

Fuel Pump Learning Value Clearing

EBS01KCL

DESCRIPTION

In order to always keep optimum fuel pressure in fuel rail, the ECM controls fuel pump in high precision with

monitoring the signal of fuel rail pressure sensor.

Accordingly, the ECM always learns characteristic value of fuel pump. Fuel Pump Learning Value Clearing is

an operation to clear the value of the fuel pump learning.

Fuel Pump Learning Value Clearing should be performed under the following conditions.

lFuel pump is changed.

lECM is replaced with used one which stores the fuel pump learning value of other fuel pump.

OPERATION PROCEDURE

NOTE:

When removing fuel pump, perform Fuel Pump Learning Value Clearing before starting engine.

With CONSULT-II

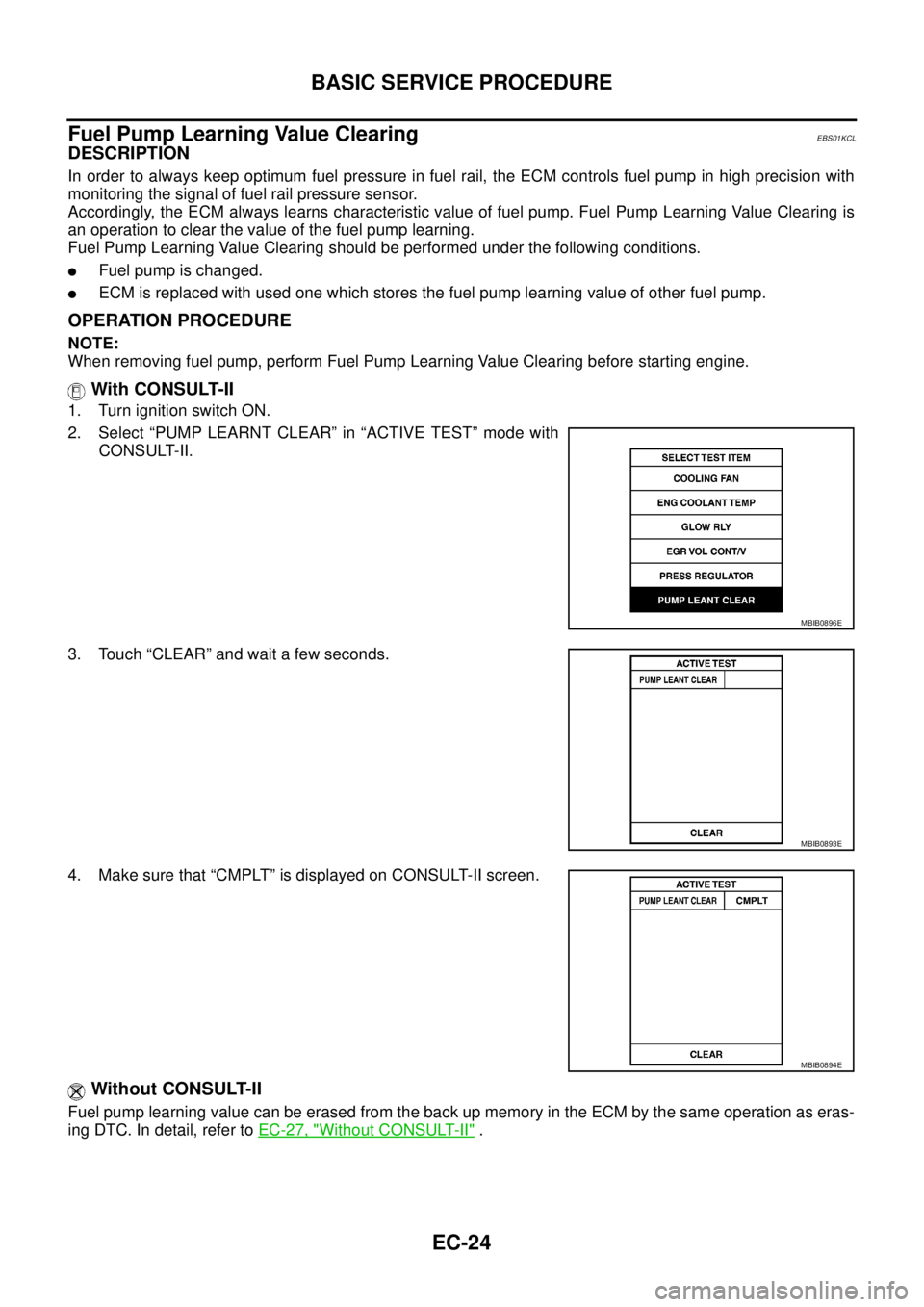

1. Turn ignition switch ON.

2. Select “PUMP LEARNT CLEAR” in “ACTIVE TEST” mode with

CONSULT-II.

3. Touch “CLEAR” and wait a few seconds.

4. Make sure that “CMPLT” is displayed on CONSULT-II screen.

Without CONSULT-II

Fuel pump learning value can be erased from the back up memory in the ECM by the same operation as eras-

ingDTC.Indetail,refertoEC-27, "

Without CONSULT-II".

MBIB0896E

MBIB0893E

MBIB0894E

Page 1005 of 3171

BASIC SERVICE PROCEDURE

EC-25

C

D

E

F

G

H

I

J

K

L

MA

EC

Injector Adjustment Value RegistrationEBS01KCM

DESCRIPTION

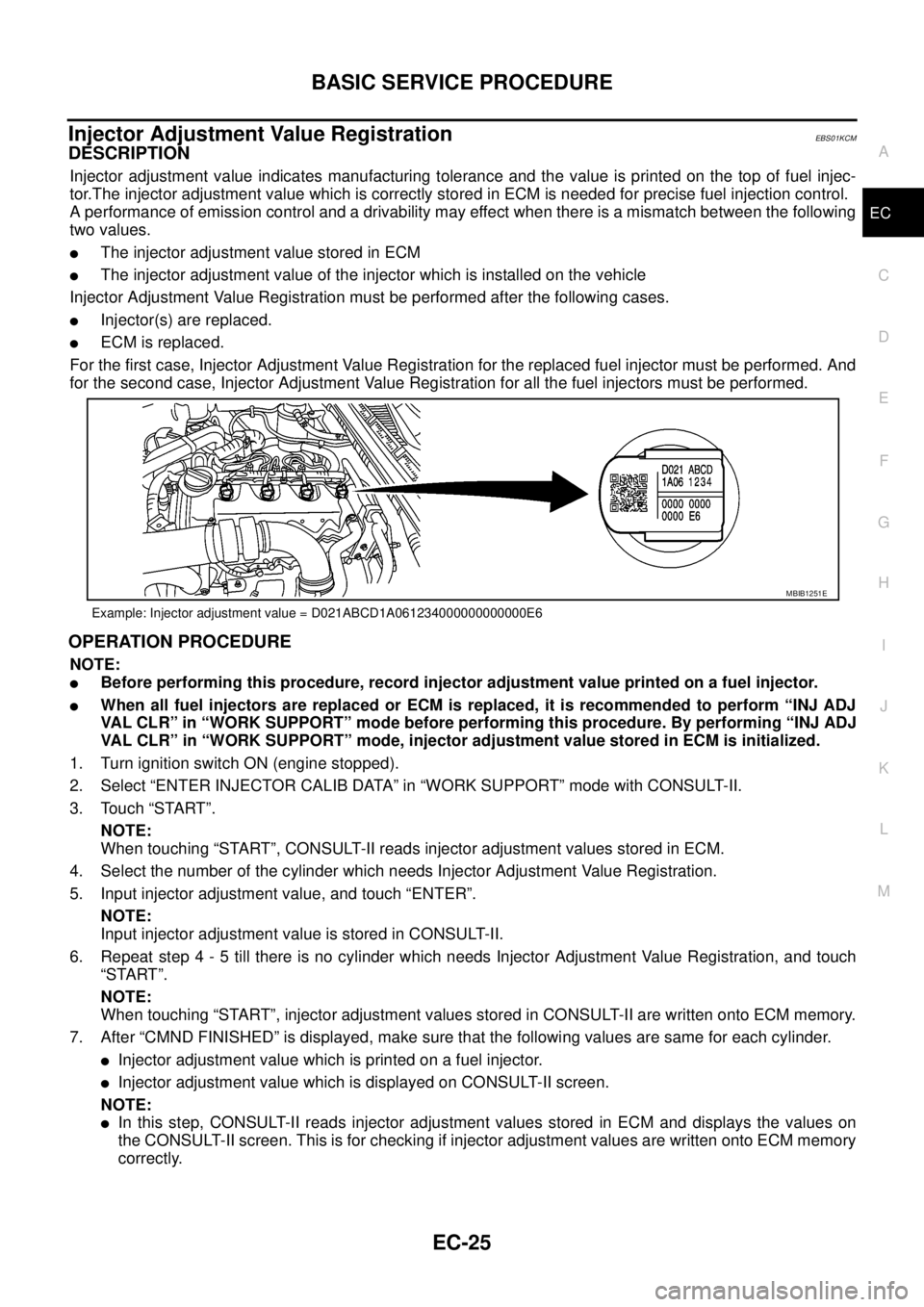

Injector adjustment value indicates manufacturing tolerance and the value is printed on the top of fuel injec-

tor.The injector adjustment value which is correctly stored in ECM is needed for precise fuel injection control.

A performance of emission control and a drivability may effect when there is a mismatch between the following

two values.

lThe injector adjustment value stored in ECM

lThe injector adjustment value of the injector which is installed on the vehicle

Injector Adjustment Value Registration must be performed after the following cases.

lInjector(s) are replaced.

lECM is replaced.

For the first case, Injector Adjustment Value Registration for the replaced fuel injector must be performed. And

for the second case, Injector Adjustment Value Registration for all the fuel injectors must be performed.

OPERATION PROCEDURE

NOTE:

lBefore performing this procedure, record injector adjustment value printed on a fuel injector.

lWhen all fuel injectors are replaced or ECM is replaced, it is recommended to perform “INJ ADJ

VAL CLR” in “WORK SUPPORT” mode before performing this procedure. By performing “INJ ADJ

VAL CLR” in “WORK SUPPORT” mode, injector adjustment value stored in ECM is initialized.

1. Turn ignition switch ON (engine stopped).

2. Select “ENTER INJECTOR CALIB DATA” in “WORK SUPPORT” mode with CONSULT-II.

3. Touch “START”.

NOTE:

When touching “START”, CONSULT-II reads injector adjustment values stored in ECM.

4. Select the number of the cylinder which needs Injector Adjustment Value Registration.

5. Input injector adjustment value, and touch “ENTER”.

NOTE:

Input injector adjustment value is stored in CONSULT-II.

6. Repeat step 4 - 5 till there is no cylinder which needs Injector Adjustment Value Registration, and touch

“START”.

NOTE:

When touching “START”, injector adjustment values stored in CONSULT-II are written onto ECM memory.

7. After “CMND FINISHED” is displayed, make sure that the following values are same for each cylinder.

lInjector adjustment value which is printed on a fuel injector.

lInjector adjustment value which is displayed on CONSULT-II screen.

NOTE:

lIn this step, CONSULT-II reads injector adjustment values stored in ECM and displays the values on

the CONSULT-II screen. This is for checking if injector adjustment values are written onto ECM memory

correctly.

Example: Injector adjustment value = D021ABCD1A061234000000000000E6

MBIB1251E

Page 1008 of 3171

EC-28

ON BOARD DIAGNOSTIC (OBD) SYSTEM

lIf the battery is disconnected, the emission-related diagnostic information will be lost within 24

hours.

lThe following data are cleared when the ECM memory is erased.

–Diagnostic trouble codes

–Freeze frame data

–Fuel pump learning value

Actual work procedures are explained using a DTC as an example. Be careful so that not only the DTC, but all

of the data listed above, are cleared from the ECM memory during work procedures.

Freeze Frame DataEBS01KCP

The ECM records the driving conditions such as calculated load value, engine coolant temperature, engine

speed, vehicle speed and intake manifold pressure at the moment a malfunction is detected.

The data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-II. For

details, seeEC-28, "

Freeze Frame Data".

Only one set of freeze frame data can be stored in the ECM. If freeze frame data is stored in the ECM memory

and another freeze frame data occurs later, the first (original) freeze frame data remains unchanged in the

ECM memory.

Freeze frame data (along with the DTCs) are cleared when the ECM memory is erased. Procedures for clear-

ing the ECM memory are described inEC-27, "

HOW TO ERASE DTC".

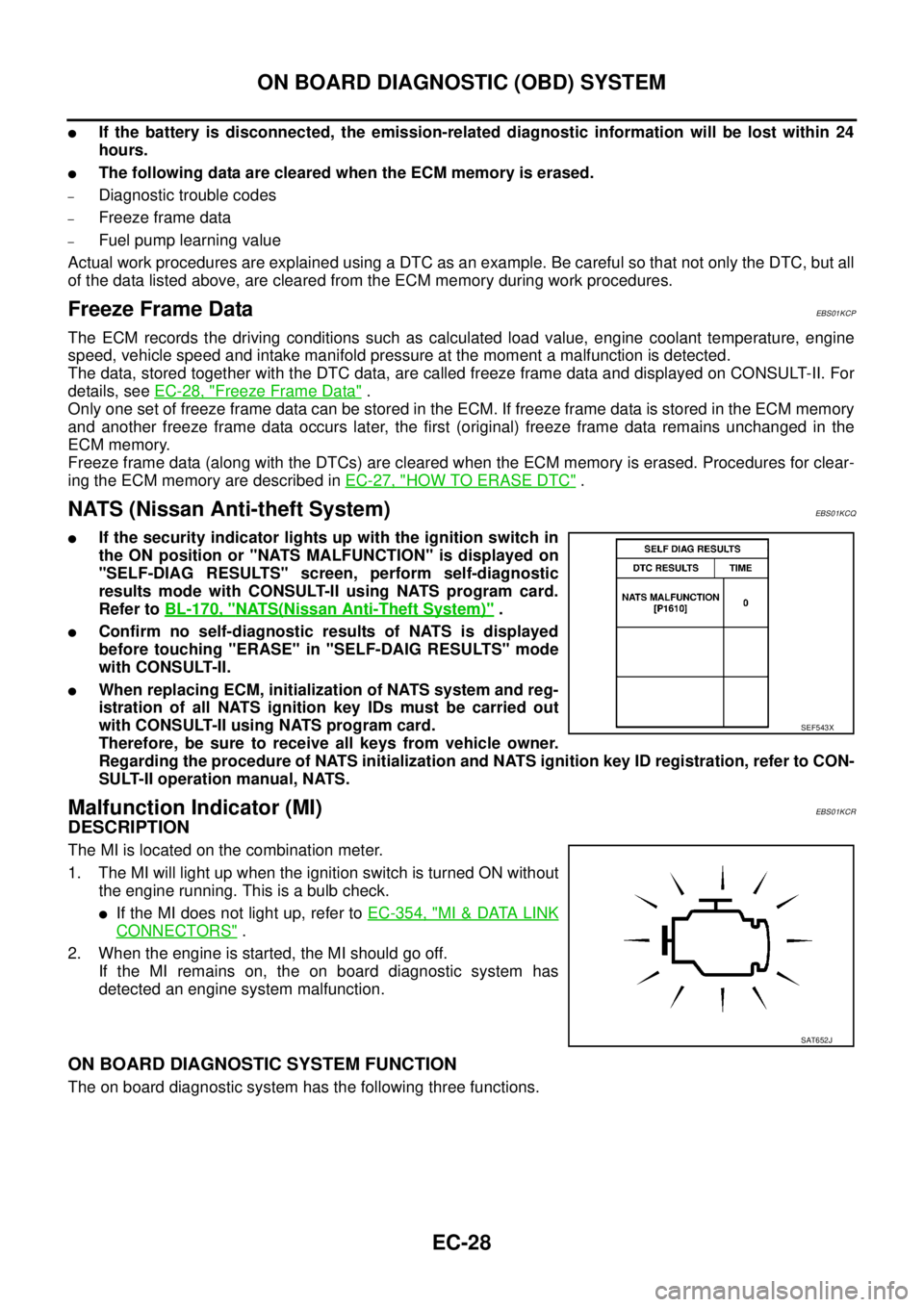

NATS (Nissan Anti-theft System)EBS01KCQ

lIf the security indicator lights up with the ignition switch in

the ON position or "NATS MALFUNCTION" is displayed on

"SELF-DIAG RESULTS" screen, perform self-diagnostic

results mode with CONSULT-II using NATS program card.

Refer toBL-170, "

NATS(Nissan Anti-Theft System)".

lConfirm no self-diagnostic results of NATS is displayed

before touching "ERASE" in "SELF-DAIG RESULTS" mode

with CONSULT-II.

lWhen replacing ECM, initialization of NATS system and reg-

istration of all NATS ignition key IDs must be carried out

with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner.

Regarding the procedure of NATS initialization and NATS ignition key ID registration, refer to CON-

SULT-II operation manual, NATS.

Malfunction Indicator (MI)EBS01KCR

DESCRIPTION

The MI is located on the combination meter.

1. The MI will light up when the ignition switch is turned ON without

the engine running. This is a bulb check.

lIf the MI does not light up, refer toEC-354, "MI&DATA LINK

CONNECTORS".

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

SEF543X

SAT652J

Page 1013 of 3171

TROUBLE DIAGNOSIS

EC-33

C

D

E

F

G

H

I

J

K

L

MA

EC

TROUBLE DIAGNOSISPFP:00004

Trouble Diagnosis IntroductionEBS01KCT

INTRODUCTION

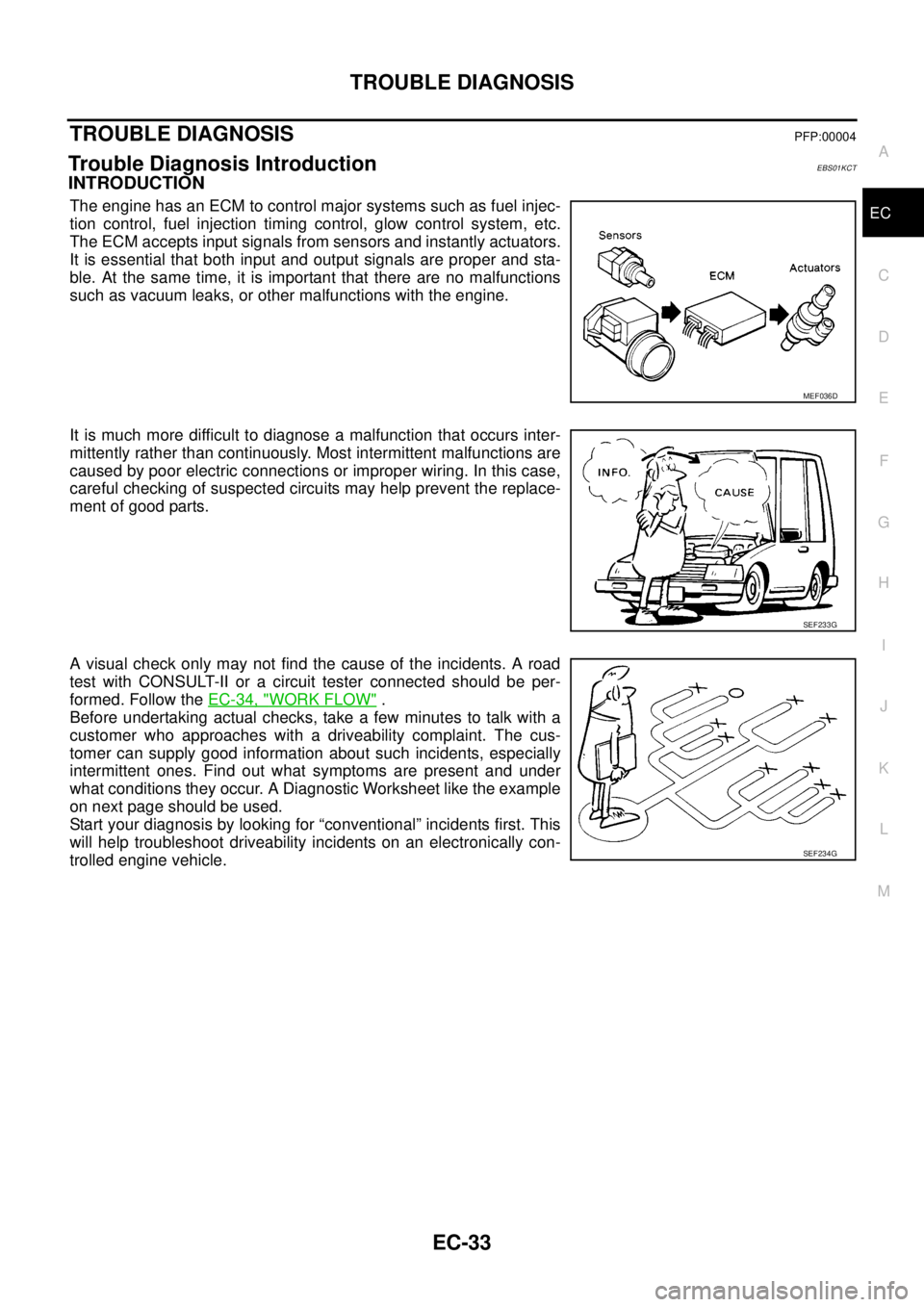

The engine has an ECM to control major systems such as fuel injec-

tion control, fuel injection timing control, glow control system, etc.

The ECM accepts input signals from sensors and instantly actuators.

It is essential that both input and output signals are proper and sta-

ble. At the same time, it is important that there are no malfunctions

such as vacuum leaks, or other malfunctions with the engine.

It is much more difficult to diagnose a malfunction that occurs inter-

mittently rather than continuously. Most intermittent malfunctions are

caused by poor electric connections or improper wiring. In this case,

careful checking of suspected circuits may help prevent the replace-

ment of good parts.

A visual check only may not find the cause of the incidents. A road

test with CONSULT-II or a circuit tester connected should be per-

formed. Follow theEC-34, "

WORK FLOW".

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such incidents, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A Diagnostic Worksheet like the example

on next page should be used.

Start your diagnosis by looking for “conventional” incidents first. This

will help troubleshoot driveability incidents on an electronically con-

trolled engine vehicle.

MEF036D

SEF233G

SEF234G

Page 1017 of 3171

TROUBLE DIAGNOSIS

EC-37

C

D

E

F

G

H

I

J

K

L

MA

EC

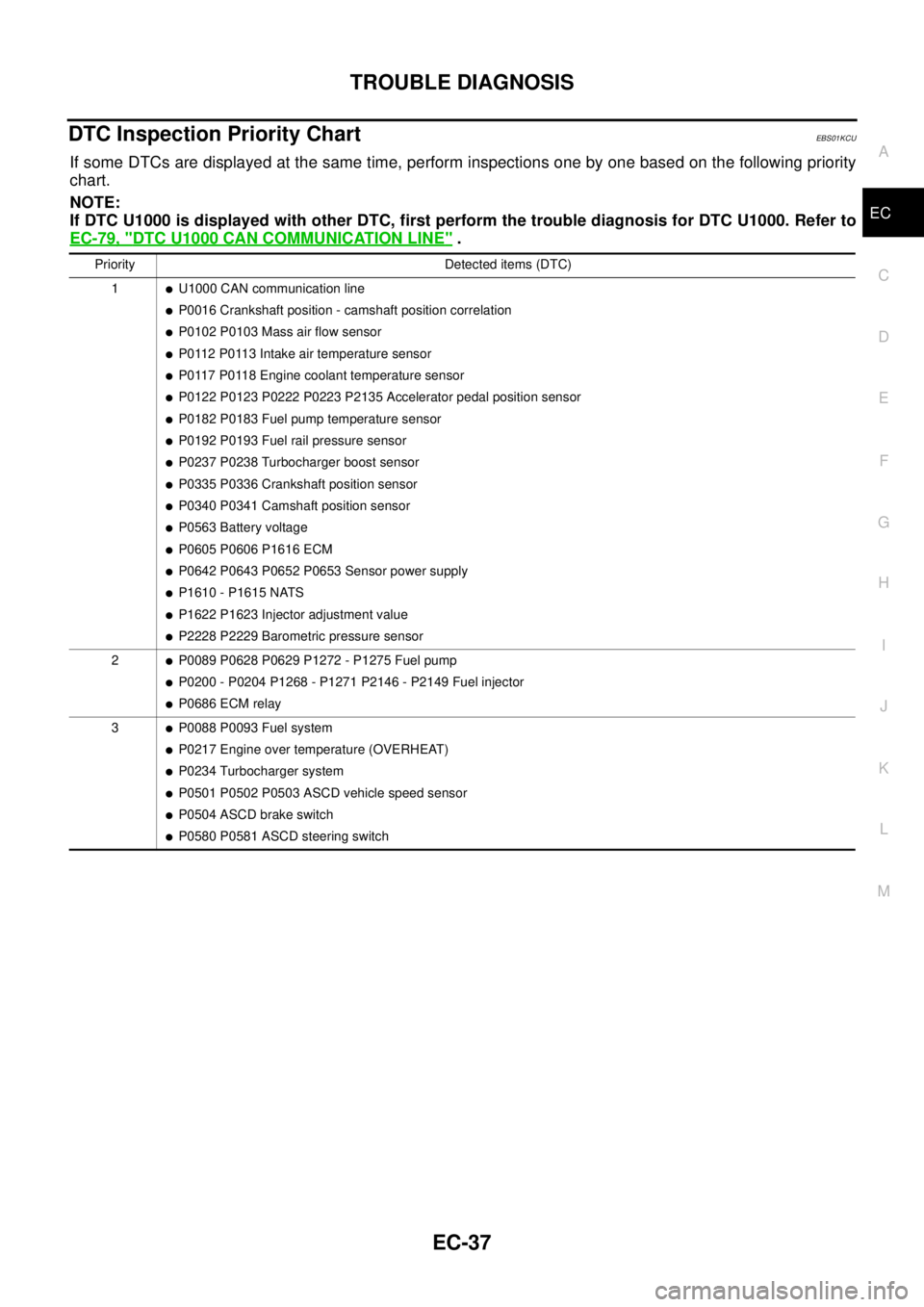

DTC Inspection Priority ChartEBS01KCU

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC U1000 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000. Refer to

EC-79, "

DTC U1000 CAN COMMUNICATION LINE".

Priority Detected items (DTC)

1

lU1000 CAN communication line

lP0016 Crankshaft position - camshaft position correlation

lP0102 P0103 Mass air flow sensor

lP0112 P0113 Intake air temperature sensor

lP0117 P0118 Engine coolant temperature sensor

lP0122 P0123 P0222 P0223 P2135 Accelerator pedal position sensor

lP0182 P0183 Fuel pump temperature sensor

lP0192 P0193 Fuel rail pressure sensor

lP0237 P0238 Turbocharger boost sensor

lP0335 P0336 Crankshaft position sensor

lP0340 P0341 Camshaft position sensor

lP0563 Battery voltage

lP0605 P0606 P1616 ECM

lP0642 P0643 P0652 P0653 Sensor power supply

lP1610 - P1615 NATS

lP1622 P1623 Injector adjustment value

lP2228 P2229 Barometric pressure sensor

2

lP0089 P0628 P0629 P1272 - P1275 Fuel pump

lP0200 - P0204 P1268 - P1271 P2146 - P2149 Fuel injector

lP0686 ECM relay

3

lP0088 P0093 Fuel system

lP0217 Engine over temperature (OVERHEAT)

lP0234 Turbocharger system

lP0501 P0502 P0503 ASCD vehicle speed sensor

lP0504 ASCD brake switch

lP0580 P0581 ASCD steering switch

Page 1018 of 3171

EC-38

TROUBLE DIAGNOSIS

Basic Inspection

EBS01KCV

Precaution:

Perform Basic Inspection without electrical or mechanical loads applied;

lHeadlamp switch is OFF.

lOn vehicles equipped with daytime light systems, set lighting switch to the 1st position to light

only small lamps.

lAir conditioner switch is OFF.

lHeater fan switch is OFF.

lRear defogger switch is OFF.

lHeat up switch is OFF.

lSteering wheel is in the straight-ahead position, etc.

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related incident.

2. Check the current need for scheduled maintenance, especially for fuel filter and air cleaner filter. Refer to

MA-8, "

PERIODIC MAINTENANCE".

3. Open engine hood and check the following:

–Harness connectors for improper connections

–Vacuum hoses for splits, kinks, or improper connections

–Wiring for improper connections, pinches, or cuts

4. Start engine and warm it up to the normal operating tempera-

ture.

>> GO TO 2.

2.PREPARATION FOR CHECKING IDLE SPEED

With CONSULT-II

Connect CONSULT-II to the data link connector.

Without CONSULT-II

Install diesel tacho tester to the vehicle.

>> GO TO 3.

SEF142I

Page 1019 of 3171

TROUBLE DIAGNOSIS

EC-39

C

D

E

F

G

H

I

J

K

L

MA

EC

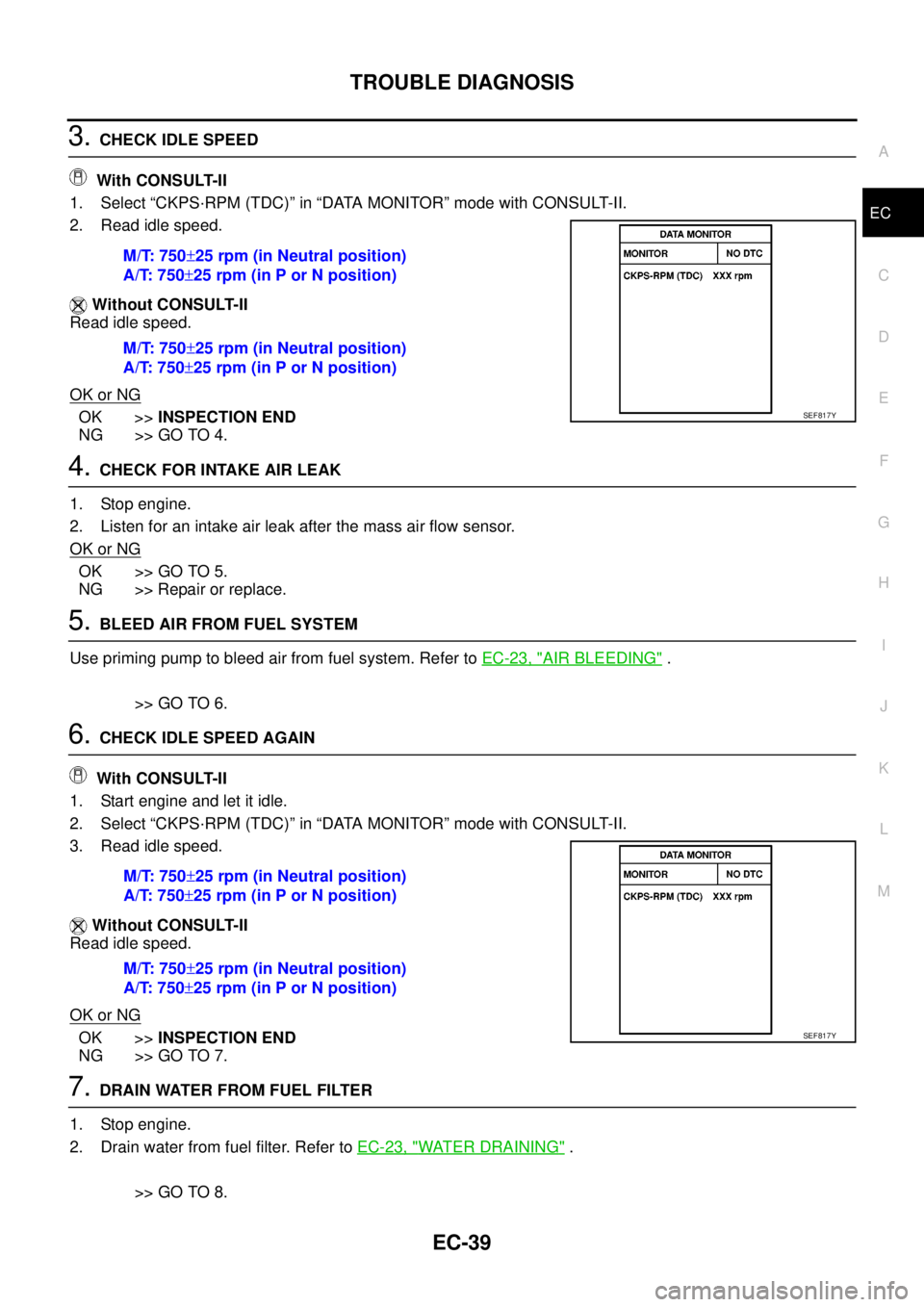

3.CHECK IDLE SPEED

With CONSULT-II

1. Select “CKPS·RPM (TDC)” in “DATA MONITOR” mode with CONSULT-II.

2. Read idle speed.

Without CONSULT-II

Read idle speed.

OK or NG

OK >>INSPECTION END

NG >> GO TO 4.

4.CHECK FOR INTAKE AIR LEAK

1. Stop engine.

2. Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace.

5.BLEED AIR FROM FUEL SYSTEM

Use priming pump to bleed air from fuel system. Refer toEC-23, "

AIR BLEEDING".

>> GO TO 6.

6.CHECK IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and let it idle.

2. Select “CKPS·RPM (TDC)” in “DATA MONITOR” mode with CONSULT-II.

3. Read idle speed.

Without CONSULT-II

Read idle speed.

OK or NG

OK >>INSPECTION END

NG >> GO TO 7.

7.DRAIN WATER FROM FUEL FILTER

1. Stop engine.

2. Drain water from fuel filter. Refer toEC-23, "

WATER DRAINING".

>> GO TO 8. M/T: 750±25 rpm (in Neutral position)

A/T: 750±25 rpm (in P or N position)

M/T: 750±25 rpm (in Neutral position)

A/T: 750±25 rpm (in P or N position)

SEF817Y

M/T: 750±25 rpm (in Neutral position)

A/T: 750±25 rpm (in P or N position)

M/T: 750±25 rpm (in Neutral position)

A/T: 750±25 rpm (in P or N position)

SEF817Y

Page 1021 of 3171

TROUBLE DIAGNOSIS

EC-41

C

D

E

F

G

H

I

J

K

L

MA

EC

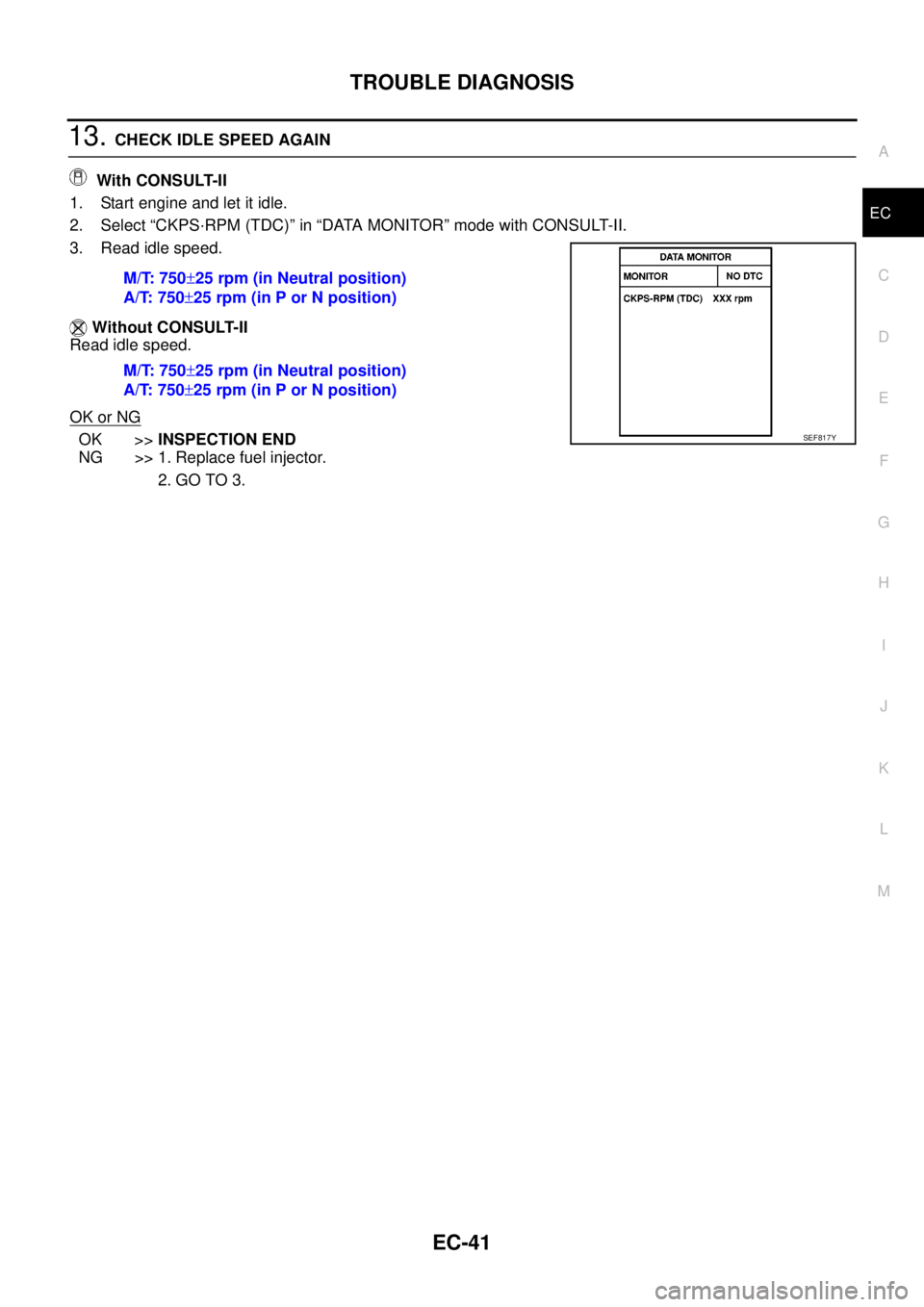

13.CHECK IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and let it idle.

2. Select “CKPS·RPM (TDC)” in “DATA MONITOR” mode with CONSULT-II.

3. Read idle speed.

Without CONSULT-II

Read idle speed.

OK or NG

OK >>INSPECTION END

NG >> 1. Replace fuel injector.

2. GO TO 3. M/T: 750±25 rpm (in Neutral position)

A/T: 750±25 rpm (in P or N position)

M/T: 750±25 rpm (in Neutral position)

A/T: 750±25 rpm (in P or N position)SEF817Y

Page 1022 of 3171

EC-42

TROUBLE DIAGNOSIS

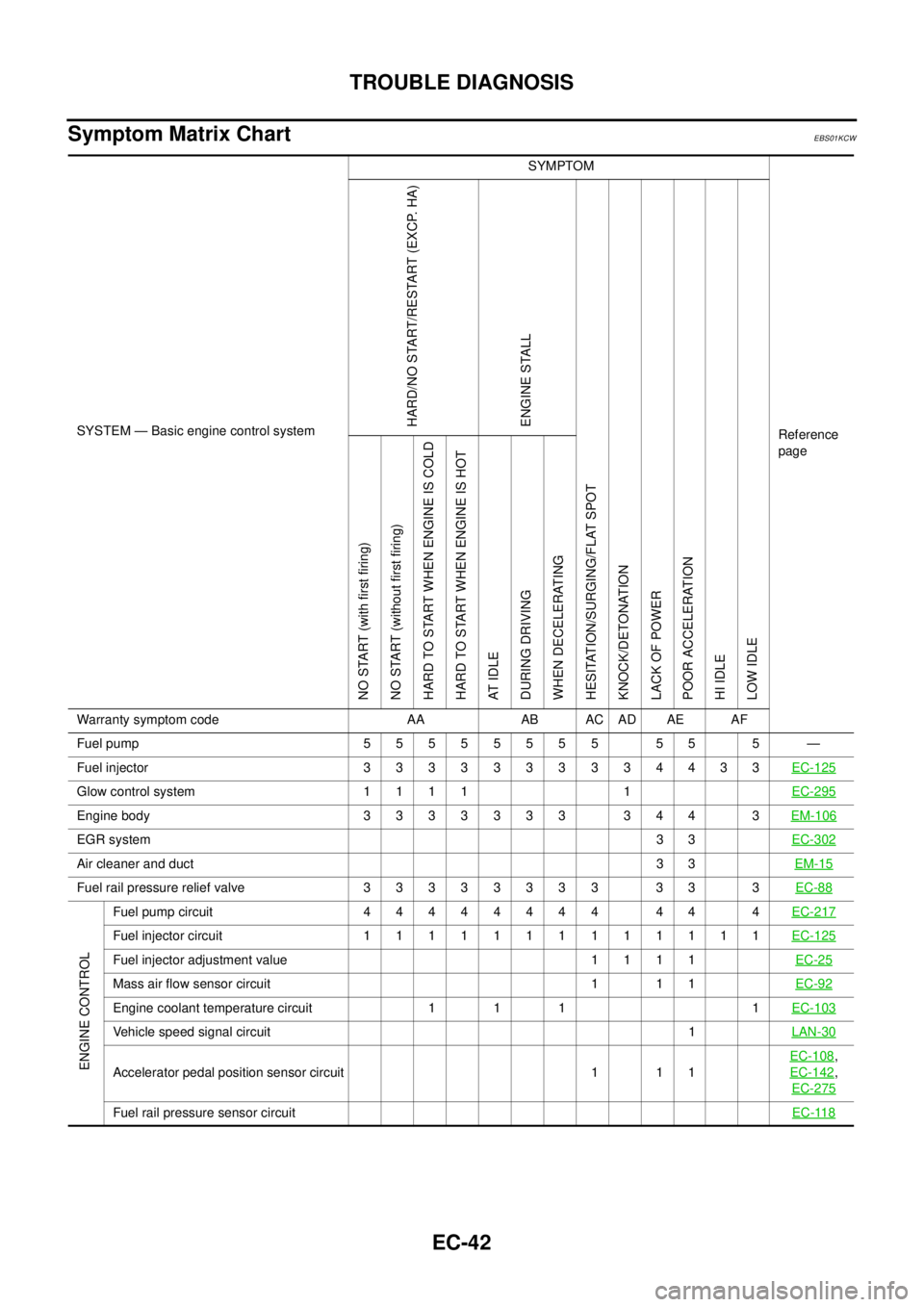

Symptom Matrix Chart

EBS01KCW

SYSTEM — Basic engine control systemSYMPTOM

Reference

pageHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE NO START (with first firing)

NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT I D L E

DURING DRIVING

WHEN DECELERATING

Warranty symptom code AA AB AC AD AE AF

Fuelpump 55555555 55 5 —

Fuelinjector 3333333334433EC-125

Glow control system 1 1 1 1 1EC-295

Engine body 3 3 3 3 3 3 3 3 4 4 3EM-106

EGR system33EC-302

Air cleaner and duct33EM-15

Fuel rail pressure relief valve 3 3 3 3 3 3 3 3 3 3 3EC-88

ENGINE CONTROL

Fuelpumpcircuit 44444444 44 4EC-217

Fuelinjectorcircuit 1111111111111EC-125

Fuel injector adjustment value 1 1 1 1EC-25

Mass air flow sensor circuit 1 1 1EC-92

Engine coolant temperature circuit 1 1 1 1EC-103

Vehicle speed signal circuit1LAN-30

Accelerator pedal position sensor circuit 1 1 1EC-108

,

EC-142

,

EC-275

Fuel rail pressure sensor circuitEC-118

Page 1024 of 3171

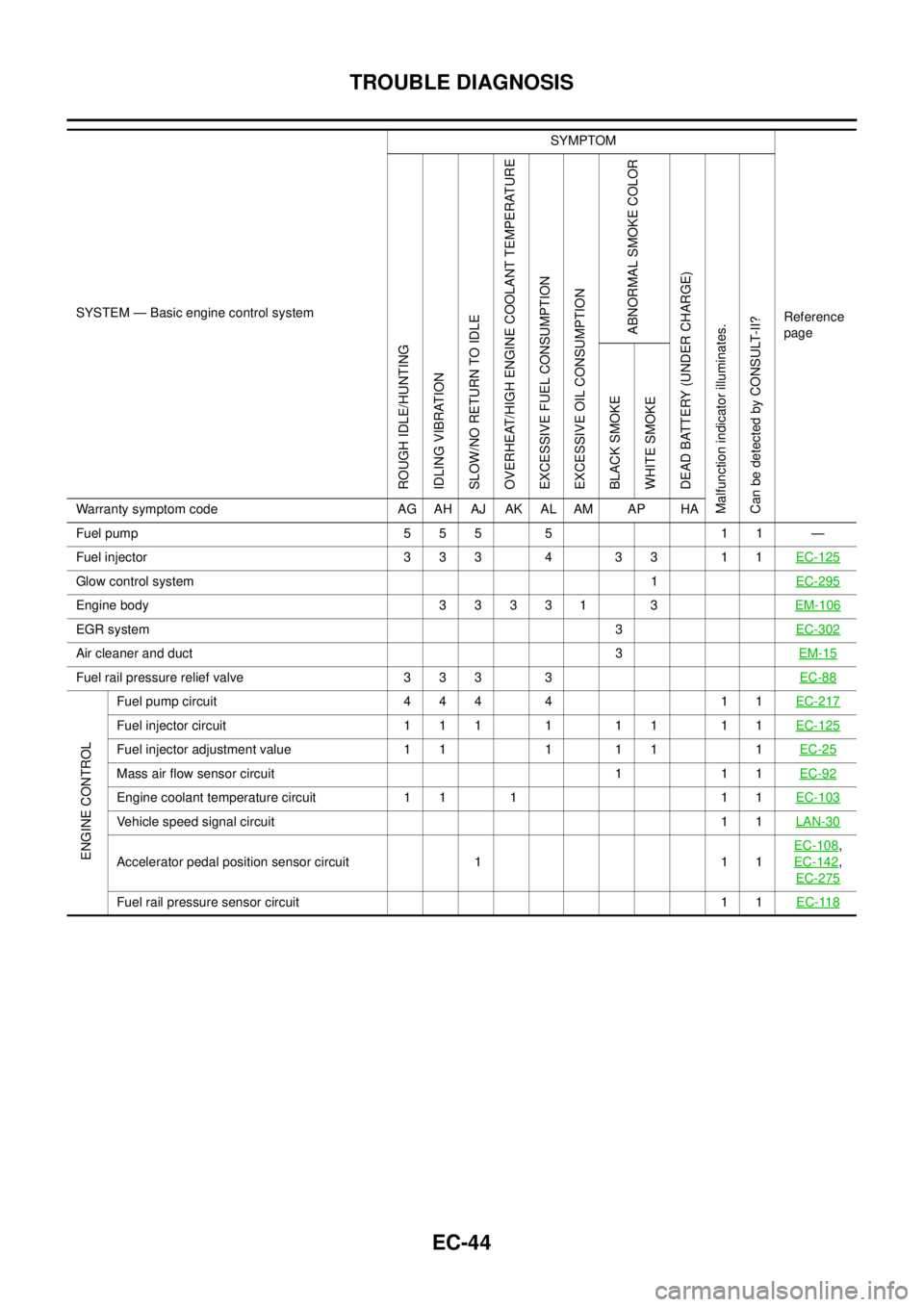

EC-44

TROUBLE DIAGNOSIS

SYSTEM — Basic engine control systemSYMPTOM

Reference

page

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator illuminates.

Can be detected by CONSULT-II?BLACK SMOKE

WHITE SMOKE

Warranty symptom code AG AH AJ AK AL AM AP HA

Fuel pump 5 5 5 5 1 1 —

Fuel injector 3 3 3 4 3 3 1 1EC-125

Glow control system1EC-295

Engine body 3 3 3 3 1 3EM-106

EGR system3EC-302

Air cleaner and duct3EM-15

Fuel rail pressure relief valve 3 3 3 3EC-88

ENGINE CONTROL

Fuel pump circuit 4 4 4 4 1 1EC-217

Fuel injector circuit 1 1 1 1 1 1 1 1EC-125

Fuel injector adjustment value 1 1 1 1 1 1EC-25

Mass air flow sensor circuit 1 1 1EC-92

Engine coolant temperature circuit 1 1 1 1 1EC-103

Vehicle speed signal circuit11LAN-30

Accelerator pedal position sensor circuit 1 1 1EC-108

,

EC-142

,

EC-275

Fuel rail pressure sensor circuit11EC-118