parking brake NISSAN NAVARA 2005 Repair Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2526 of 3171

PARKING BRAKE CONTROL

PB-3

C

D

E

G

H

I

J

K

L

MA

B

PB

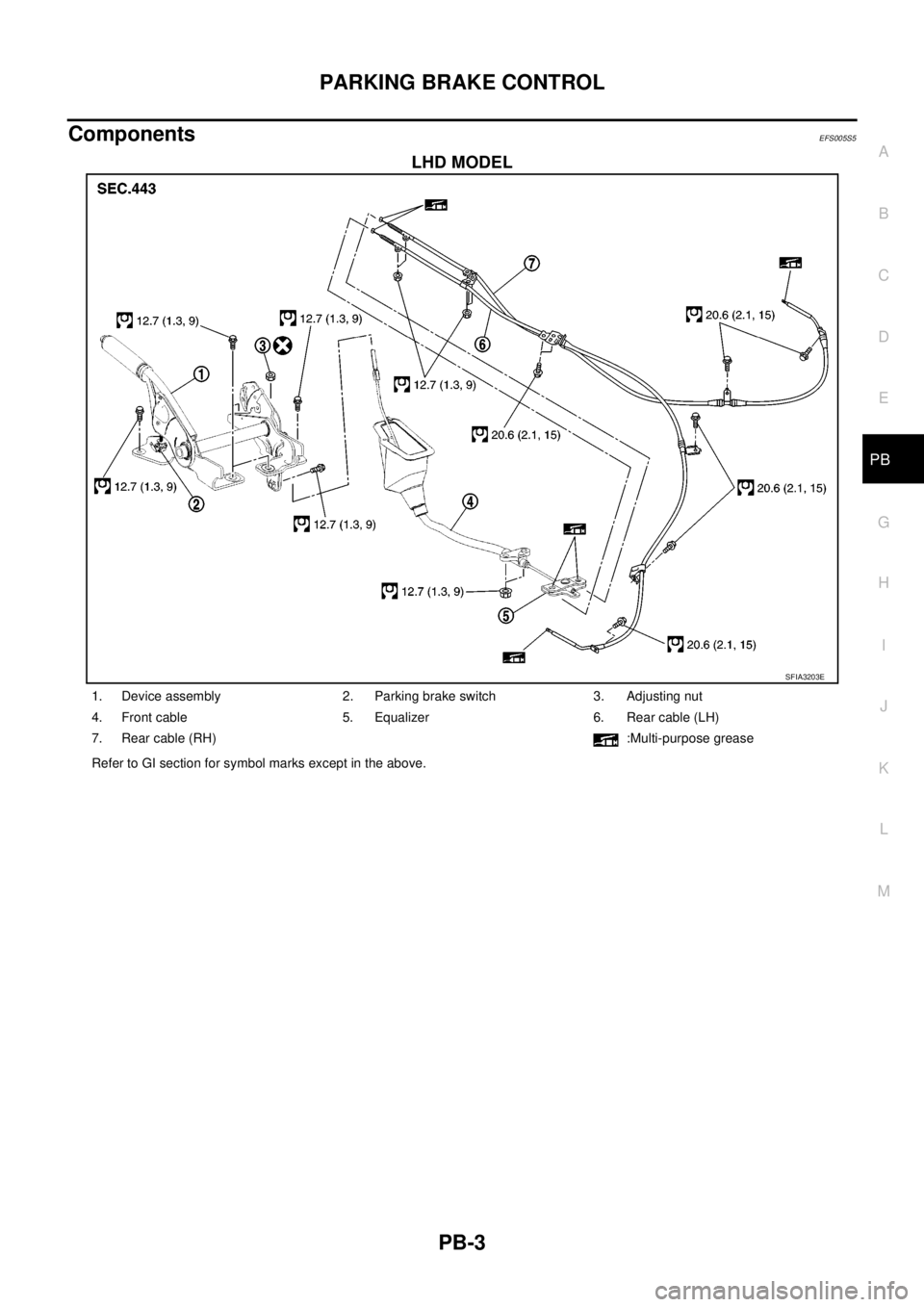

ComponentsEFS005S5

LHD MODEL

SFIA3203E

1. Device assembly 2. Parking brake switch 3. Adjusting nut

4. Front cable 5. Equalizer 6. Rear cable (LH)

7. Rear cable (RH) :Multi-purpose grease

Refer to GI section for symbol marks except in the above.

Page 2527 of 3171

PB-4

PARKING BRAKE CONTROL

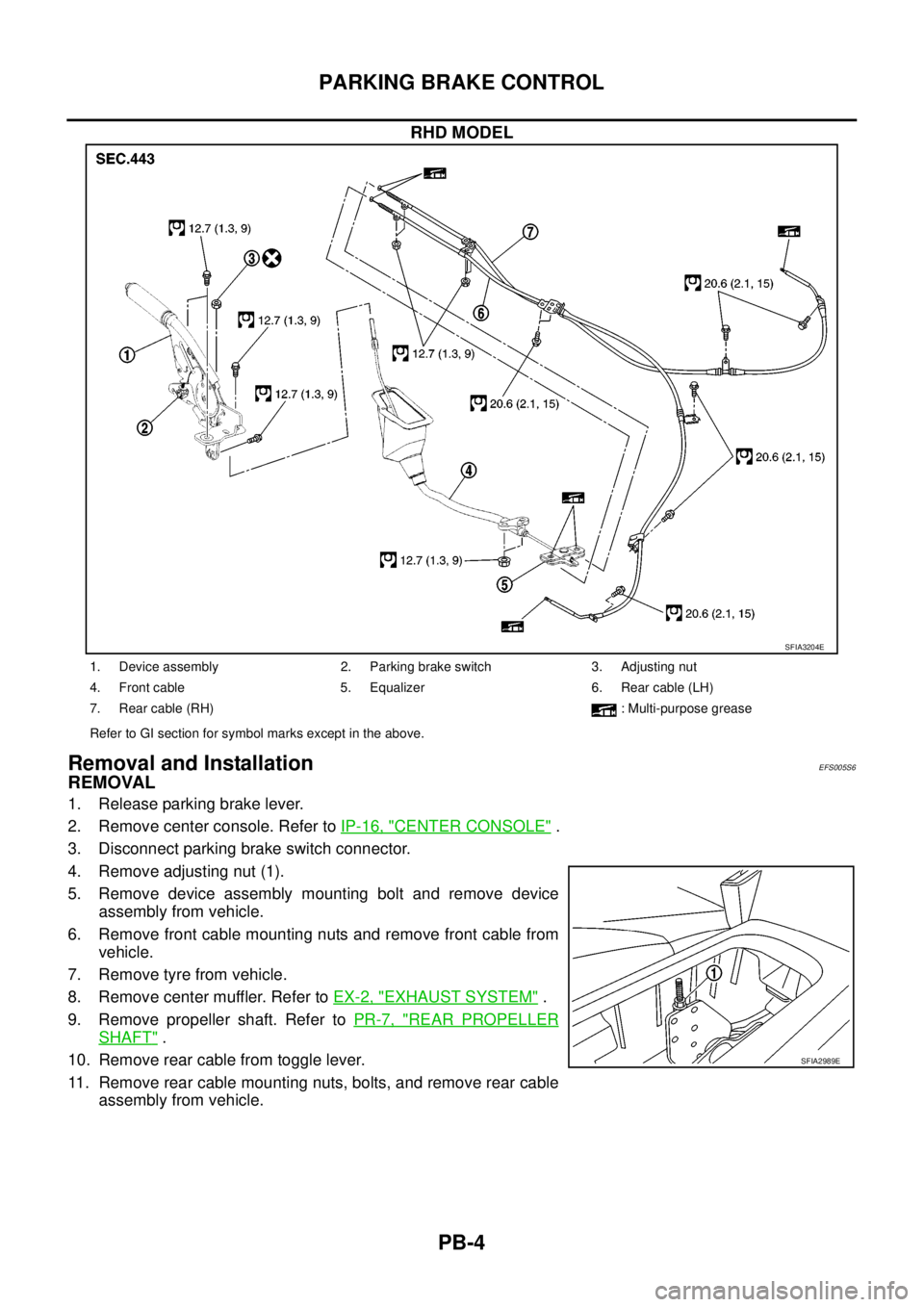

RHD MODEL

Removal and InstallationEFS005S6

REMOVAL

1. Release parking brake lever.

2. Remove center console. Refer toIP-16, "

CENTER CONSOLE".

3. Disconnect parking brake switch connector.

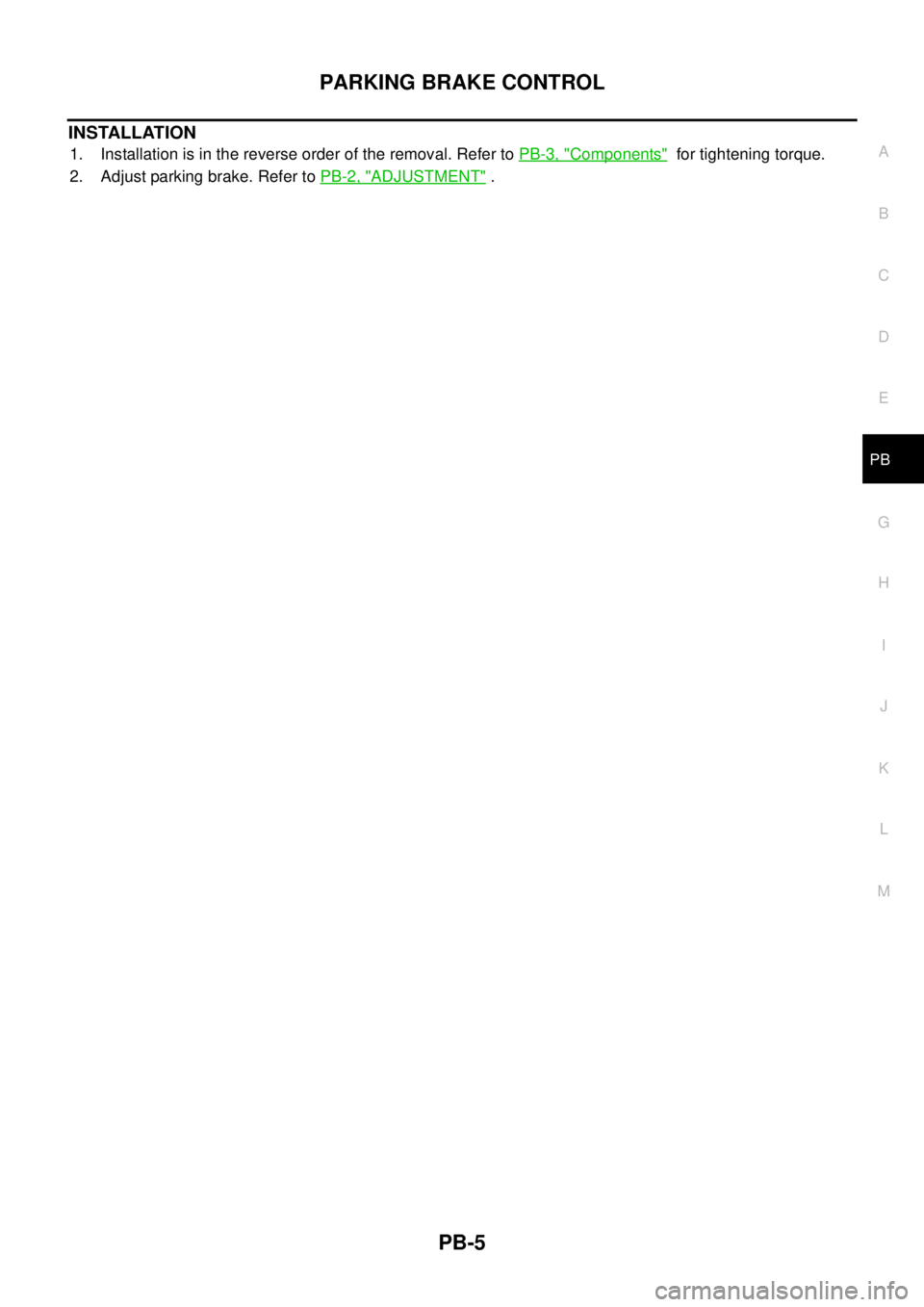

4. Remove adjusting nut (1).

5. Remove device assembly mounting bolt and remove device

assembly from vehicle.

6. Remove front cable mounting nuts and remove front cable from

vehicle.

7. Remove tyre from vehicle.

8. Remove center muffler. Refer toEX-2, "

EXHAUST SYSTEM".

9. Remove propeller shaft. Refer toPR-7, "

REAR PROPELLER

SHAFT".

10. Remove rear cable from toggle lever.

11. Remove rear cable mounting nuts, bolts, and remove rear cable

assembly from vehicle.

SFIA3204E

1. Device assembly 2. Parking brake switch 3. Adjusting nut

4. Front cable 5. Equalizer 6. Rear cable (LH)

7. Rear cable (RH) : Multi-purpose grease

Refer to GI section for symbol marks except in the above.

SFIA2989E

Page 2528 of 3171

PARKING BRAKE CONTROL

PB-5

C

D

E

G

H

I

J

K

L

MA

B

PB

INSTALLATION

1. Installation is in the reverse order of the removal. Refer toPB-3, "Components"for tightening torque.

2. Adjust parking brake. Refer toPB-2, "

ADJUSTMENT".

Page 2529 of 3171

PB-6

SERVICE DATA AND SPECIFICATIONS (SDS)

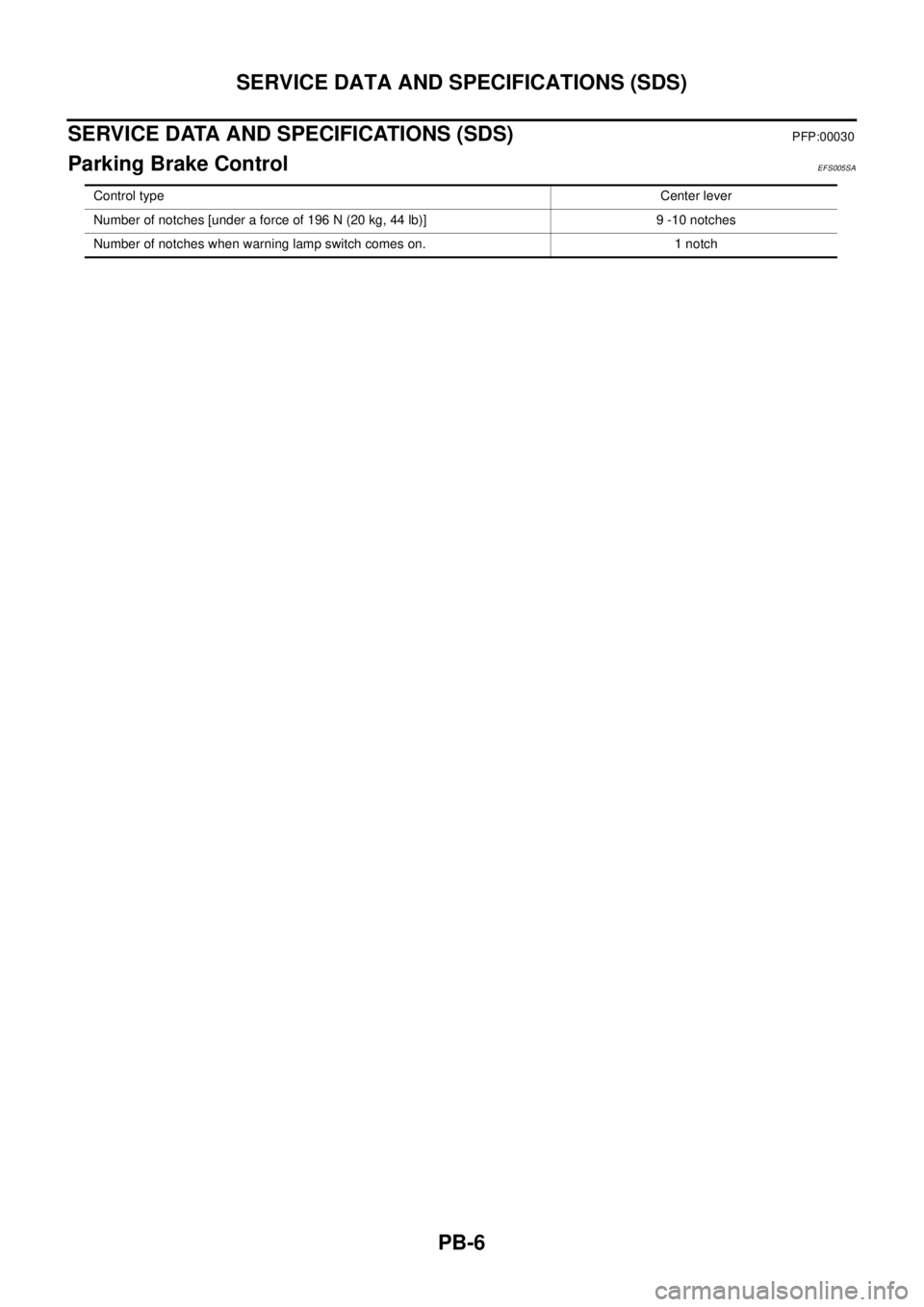

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Parking Brake ControlEFS005SA

Control typeCenter lever

Number of notches [under a force of 196 N (20 kg, 44 lb)] 9 -10 notches

Number of notches when warning lamp switch comes on. 1 notch

Page 2624 of 3171

REAR PROPELLER SHAFT

PR-9

C

E

F

G

H

I

J

K

L

MA

B

PR

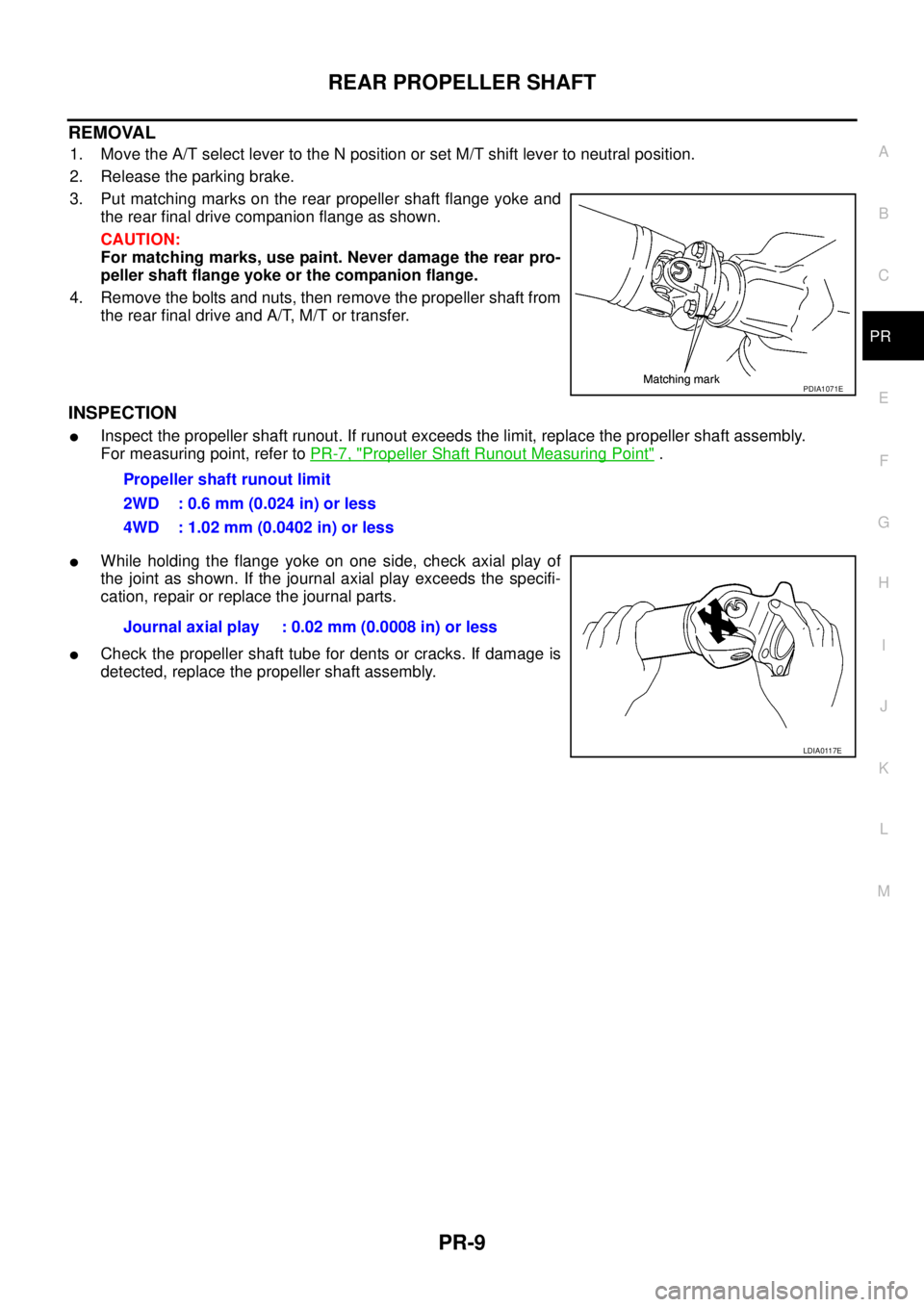

REMOVAL

1. Move the A/T select lever to the N position or set M/T shift lever to neutral position.

2. Release the parking brake.

3. Put matching marks on the rear propeller shaft flange yoke and

the rear final drive companion flange as shown.

CAUTION:

For matching marks, use paint. Never damage the rear pro-

peller shaft flange yoke or the companion flange.

4. Remove the bolts and nuts, then remove the propeller shaft from

the rear final drive and A/T, M/T or transfer.

INSPECTION

lInspect the propeller shaft runout. If runout exceeds the limit, replace the propeller shaft assembly.

For measuring point, refer toPR-7, "

Propeller Shaft Runout Measuring Point".

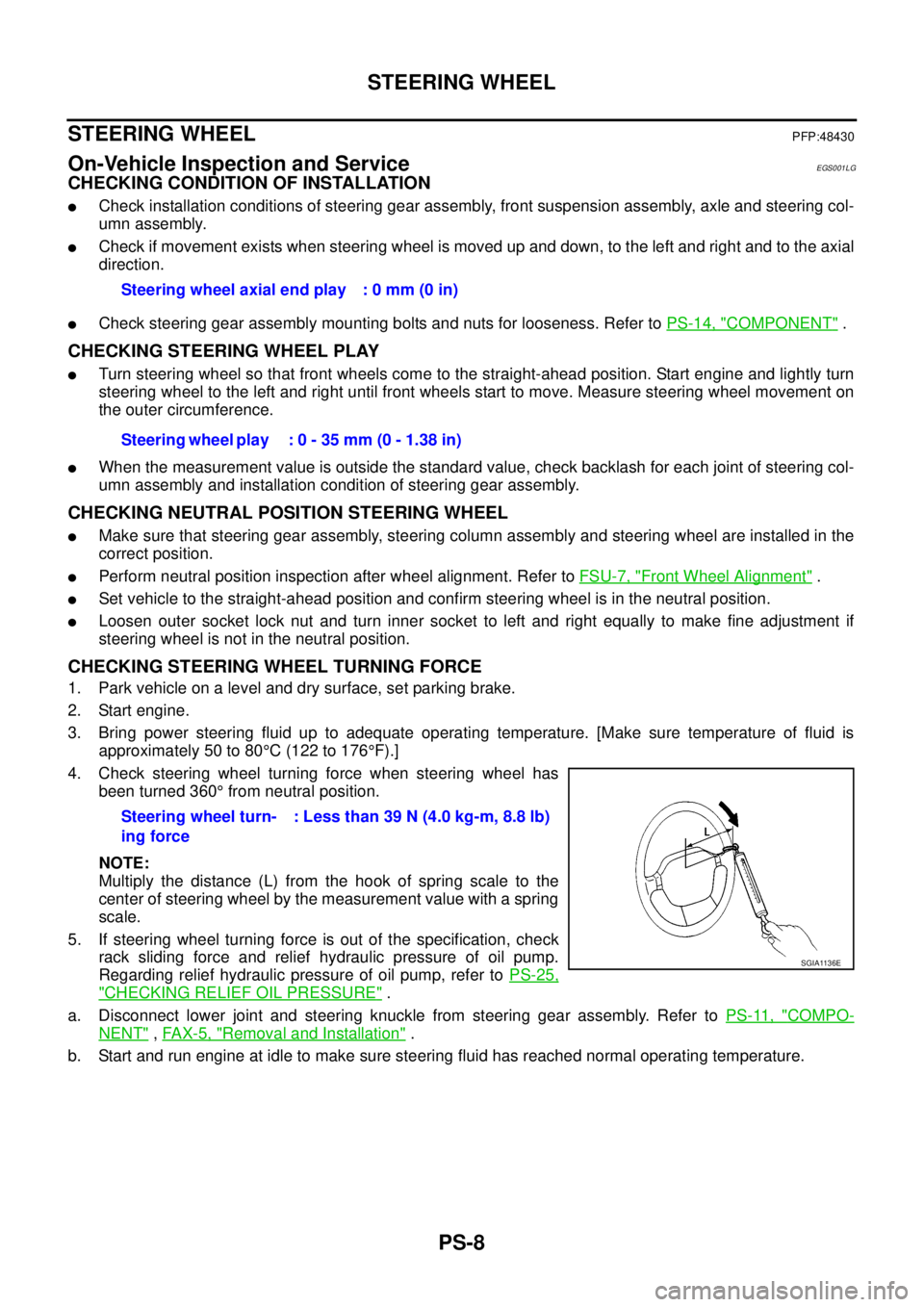

lWhile holding the flange yoke on one side, check axial play of

the joint as shown. If the journal axial play exceeds the specifi-

cation, repair or replace the journal parts.

lCheck the propeller shaft tube for dents or cracks. If damage is

detected, replace the propeller shaft assembly.

PDIA1071E

Propeller shaft runout limit

2WD : 0.6 mm (0.024 in) or less

4WD : 1.02 mm (0.0402 in) or less

Journal axial play : 0.02 mm (0.0008 in) or less

LDIA0117E

Page 2635 of 3171

PS-8

STEERING WHEEL

STEERING WHEEL

PFP:48430

On-Vehicle Inspection and ServiceEGS001LG

CHECKING CONDITION OF INSTALLATION

lCheck installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

lCheck if movement exists when steering wheel is moved up and down, to the left and right and to the axial

direction.

lCheck steering gear assembly mounting bolts and nuts for looseness. Refer toPS-14, "COMPONENT".

CHECKING STEERING WHEEL PLAY

lTurn steering wheel so that front wheels come to the straight-ahead position. Start engine and lightly turn

steering wheel to the left and right until front wheels start to move. Measure steering wheel movement on

the outer circumference.

lWhen the measurement value is outside the standard value, check backlash for each joint of steering col-

umn assembly and installation condition of steering gear assembly.

CHECKING NEUTRAL POSITION STEERING WHEEL

lMake sure that steering gear assembly, steering column assembly and steering wheel are installed in the

correct position.

lPerform neutral position inspection after wheel alignment. Refer toFSU-7, "Front Wheel Alignment".

lSet vehicle to the straight-ahead position and confirm steering wheel is in the neutral position.

lLoosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustment if

steering wheel is not in the neutral position.

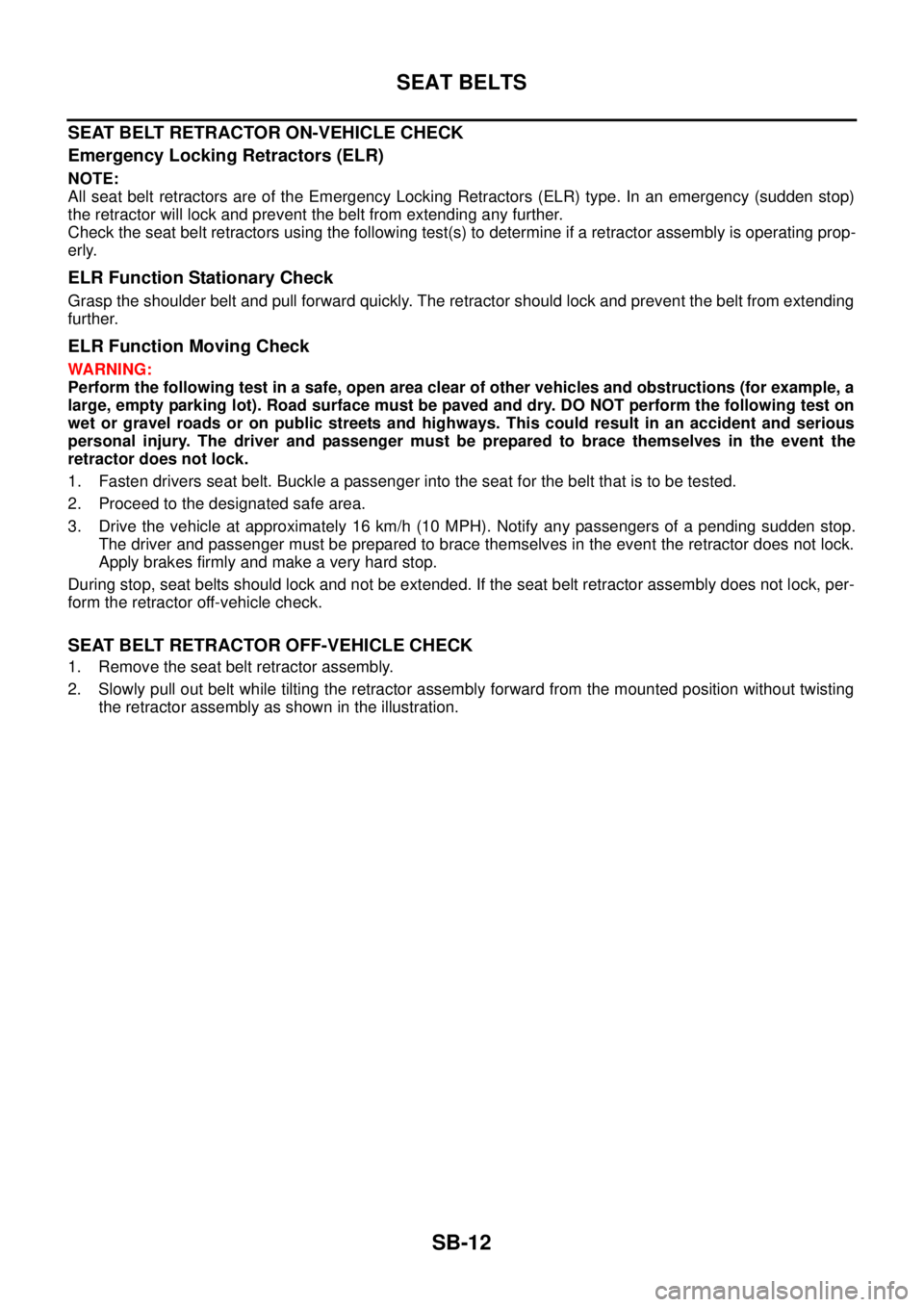

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating temperature. [Make sure temperature of fluid is

approximately 50 to 80°C(122to176°F).]

4. Check steering wheel turning force when steering wheel has

been turned 360°from neutral position.

NOTE:

Multiply the distance (L) from the hook of spring scale to the

center of steering wheel by the measurement value with a spring

scale.

5. If steering wheel turning force is out of the specification, check

rack sliding force and relief hydraulic pressure of oil pump.

Regarding relief hydraulic pressure of oil pump, refer toPS-25,

"CHECKING RELIEF OIL PRESSURE".

a. Disconnect lower joint and steering knuckle from steering gear assembly. Refer toPS-11, "

COMPO-

NENT",FAX-5, "Removal and Installation".

b. Start and run engine at idle to make sure steering fluid has reached normal operating temperature.Steering wheel axial end play : 0 mm (0 in)

Steering wheel play : 0 - 35 mm (0 - 1.38 in)

Steering wheel turn-

ing force: Less than 39 N (4.0 kg-m, 8.8 lb)

SGIA1136E

Page 2671 of 3171

![NISSAN NAVARA 2005 Repair Service Manual RAX-8

[M226]

AXLE SHAFT

REMOVAL

1. Remove the wheel.

2. Remove the rear brake drum. Refer toBR-31, "

Removal and Installation of Drum Brake Assembly".

3. Remove four lock nuts and spring washers secur NISSAN NAVARA 2005 Repair Service Manual RAX-8

[M226]

AXLE SHAFT

REMOVAL

1. Remove the wheel.

2. Remove the rear brake drum. Refer toBR-31, "

Removal and Installation of Drum Brake Assembly".

3. Remove four lock nuts and spring washers secur](/img/5/57362/w960_57362-2670.png)

RAX-8

[M226]

AXLE SHAFT

REMOVAL

1. Remove the wheel.

2. Remove the rear brake drum. Refer toBR-31, "

Removal and Installation of Drum Brake Assembly".

3. Remove four lock nuts and spring washers securing the axle

shaft retainer to the rear axle case.

4. Using a wire, suspend the baffle plate to the sub frame.

NOTE:

Brake hose and brake cable do not need to be disconnected from the baffle plate and wheel cylinder.

CAUTION:

lBe careful not to deform brake tube.

lDo not bend the parking brake cable.

lWhile removing drum, never depress brake pedal because the piston will pop out.

5. Remove the axle shaft assembly from the rear axle case as

shown.

6. Using a puller remove the bearing cup from the rear axle case.

CAUTION:

lThe axle shaft bearing cup may stay in place in the axle

shaft housing. Remove the cup carefully so as not to

damage the inner surface of the axle shaft housing.

7. Usingapuller,removetheaxleshaftguideandoilsealfromthe

rear axle case.

NOTE:

Rear final drive oil will spill while removing the oil seal. Use a drain pan under the rear axle case to drain

oil.

10. Baffle plate 11. Bearing cup 12. Axle shaft guide

13. Oil seal 14. Breather 15. Rear axle case

LDIA0112E

WDIA0182E

Tool number : ST33290001

Tool number : ST33290001

MDIB9050E

Page 2829 of 3171

SB-12

SEAT BELTS

SEAT BELT RETRACTOR ON-VEHICLE CHECK

Emergency Locking Retractors (ELR)

NOTE:

All seat belt retractors are of the Emergency Locking Retractors (ELR) type. In an emergency (sudden stop)

the retractor will lock and prevent the belt from extending any further.

Check the seat belt retractors using the following test(s) to determine if a retractor assembly is operating prop-

erly.

ELR Function Stationary Check

Grasp the shoulder belt and pull forward quickly. The retractor should lock and prevent the belt from extending

further.

ELR Function Moving Check

WARNING:

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example, a

large, empty parking lot). Road surface must be paved and dry. DO NOT perform the following test on

wet or gravel roads or on public streets and highways. This could result in an accident and serious

personal injury. The driver and passenger must be prepared to brace themselves in the event the

retractor does not lock.

1. Fasten drivers seat belt. Buckle a passenger into the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h (10 MPH). Notify any passengers of a pending sudden stop.

The driver and passenger must be prepared to brace themselves in the event the retractor does not lock.

Apply brakes firmly and make a very hard stop.

During stop, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock, per-

form the retractor off-vehicle check.

SEAT BELT RETRACTOR OFF-VEHICLE CHECK

1. Remove the seat belt retractor assembly.

2. Slowly pull out belt while tilting the retractor assembly forward from the mounted position without twisting

the retractor assembly as shown in the illustration.

Page 2985 of 3171

TF-18

4WD SYSTEM

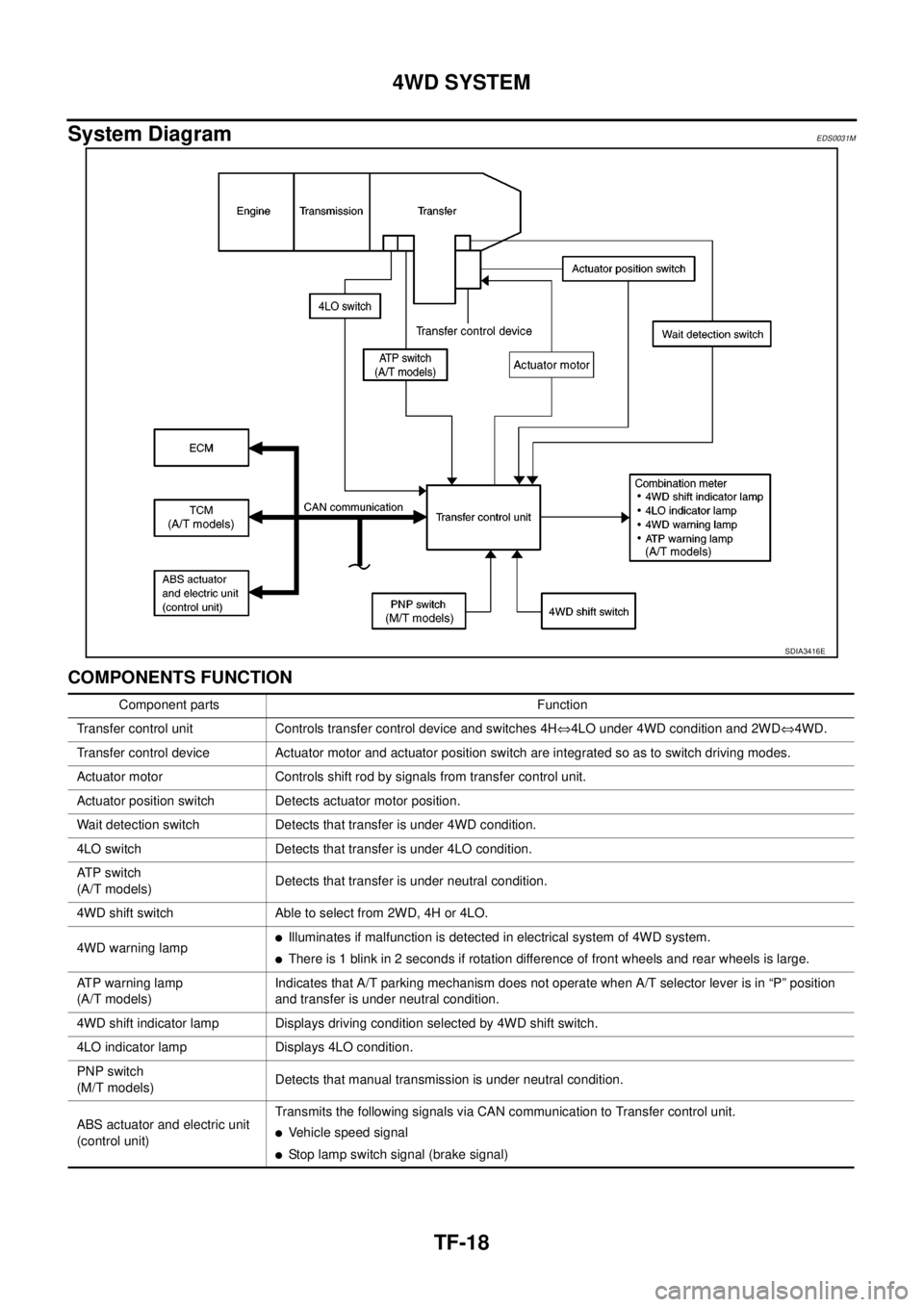

System Diagram

EDS0031M

COMPONENTS FUNCTION

SDIA3416E

Component parts Function

Transfer control unit Controls transfer control device and switches 4HÛ4LO under 4WD condition and 2WDÛ4WD.

Transfer control device Actuator motor and actuator position switch are integrated so as to switch driving modes.

Actuator motor Controls shift rod by signals from transfer control unit.

Actuator position switch Detects actuator motor position.

Wait detection switch Detects that transfer is under 4WD condition.

4LO switch Detects that transfer is under 4LO condition.

AT P s w i t c h

(A/T models)Detects that transfer is under neutral condition.

4WD shift switch Able to select from 2WD, 4H or 4LO.

4WD warning lamp

lIlluminates if malfunction is detected in electrical system of 4WD system.

lThere is 1 blink in 2 seconds if rotation difference of front wheels and rear wheels is large.

ATP warning lamp

(A/T models)Indicates that A/T parking mechanism does not operate when A/T selector lever is in “P” position

and transfer is under neutral condition.

4WD shift indicator lamp Displays driving condition selected by 4WD shift switch.

4LO indicator lamp Displays 4LO condition.

PNP switch

(M/T models)Detects that manual transmission is under neutral condition.

ABS actuator and electric unit

(control unit)Transmits the following signals via CAN communication to Transfer control unit.

lVehicle speed signal

lStop lamp switch signal (brake signal)

Page 3051 of 3171

TF-84

TROUBLE DIAGNOSIS FOR SYSTEM

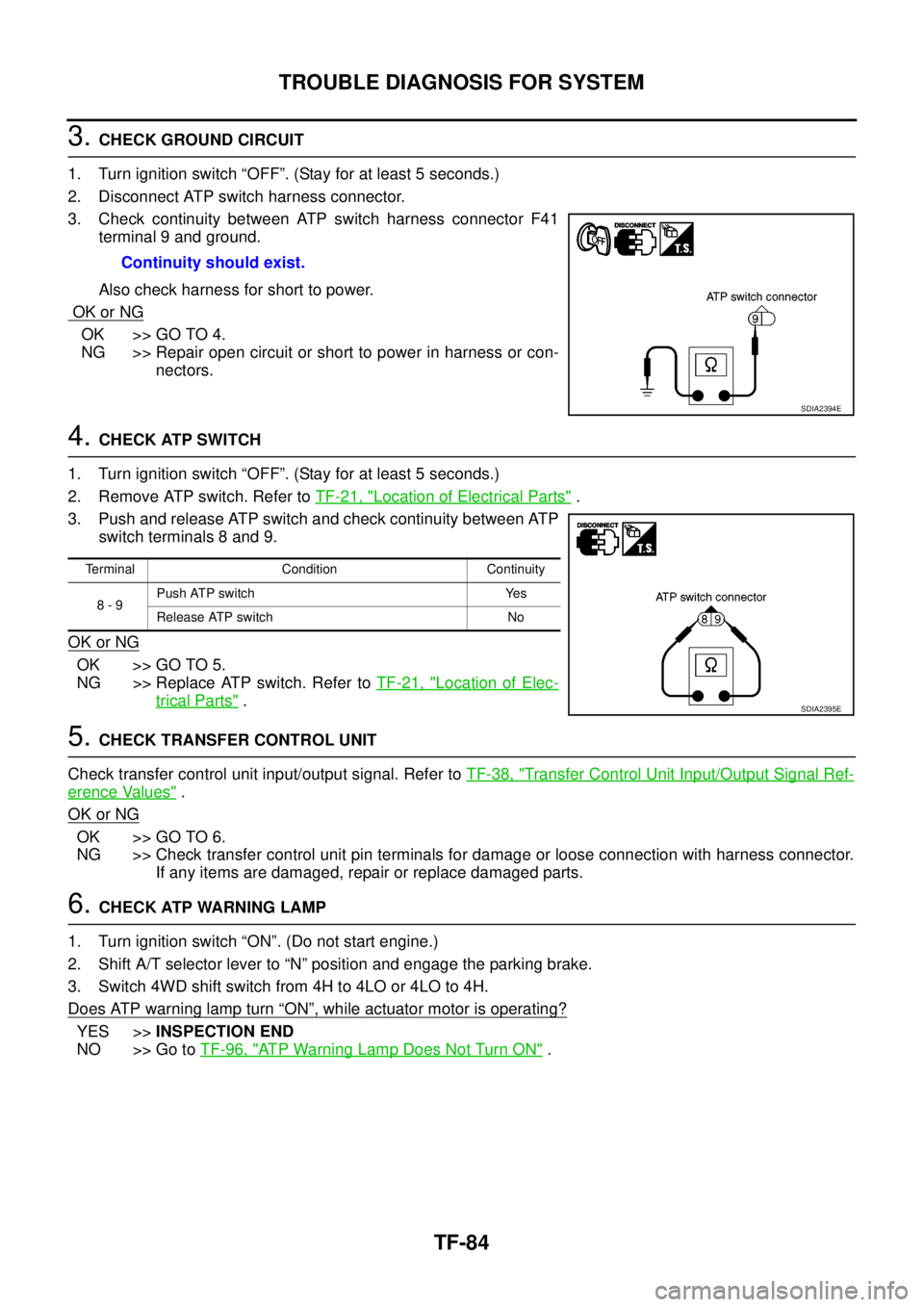

3.CHECK GROUND CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect ATP switch harness connector.

3. Check continuity between ATP switch harness connector F41

terminal 9 and ground.

Also check harness for short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to power in harness or con-

nectors.

4.CHECK ATP SWITCH

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Remove ATP switch. Refer toTF-21, "

Location of Electrical Parts".

3. Push and release ATP switch and check continuity between ATP

switch terminals 8 and 9.

OK or NG

OK >> GO TO 5.

NG >> Replace ATP switch. Refer toTF-21, "

Location of Elec-

trical Parts".

5.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer toTF-38, "

Transfer Control Unit Input/Output Signal Ref-

erence Values".

OK or NG

OK >> GO TO 6.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

6.CHECK ATP WARNING LAMP

1. Turn ignition switch “ON”. (Do not start engine.)

2. Shift A/T selector lever to “N” position and engage the parking brake.

3. Switch 4WD shift switch from 4H to 4LO or 4LO to 4H.

Does ATP warning lamp turn

“ON”, while actuator motor is operating?

YES >>INSPECTION END

NO >> Go toTF-96, "

ATP Warning Lamp Does Not Turn ON". Continuity should exist.

SDIA2394E

Terminal Condition Continuity

8-9Push ATP switch Yes

Release ATP switch No

SDIA2395E