engine NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1626 of 3171

GI-4

PRECAUTIONS

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the²ACC²position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the²LOCK²position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

General PrecautionsEAS001GJ

lDo not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refriger-

ant gas, etc. When working in a pit or other enclosed area, be

sure to properly ventilate the area before working with hazard-

ous materials.

Do not smoke while working on the vehicle.

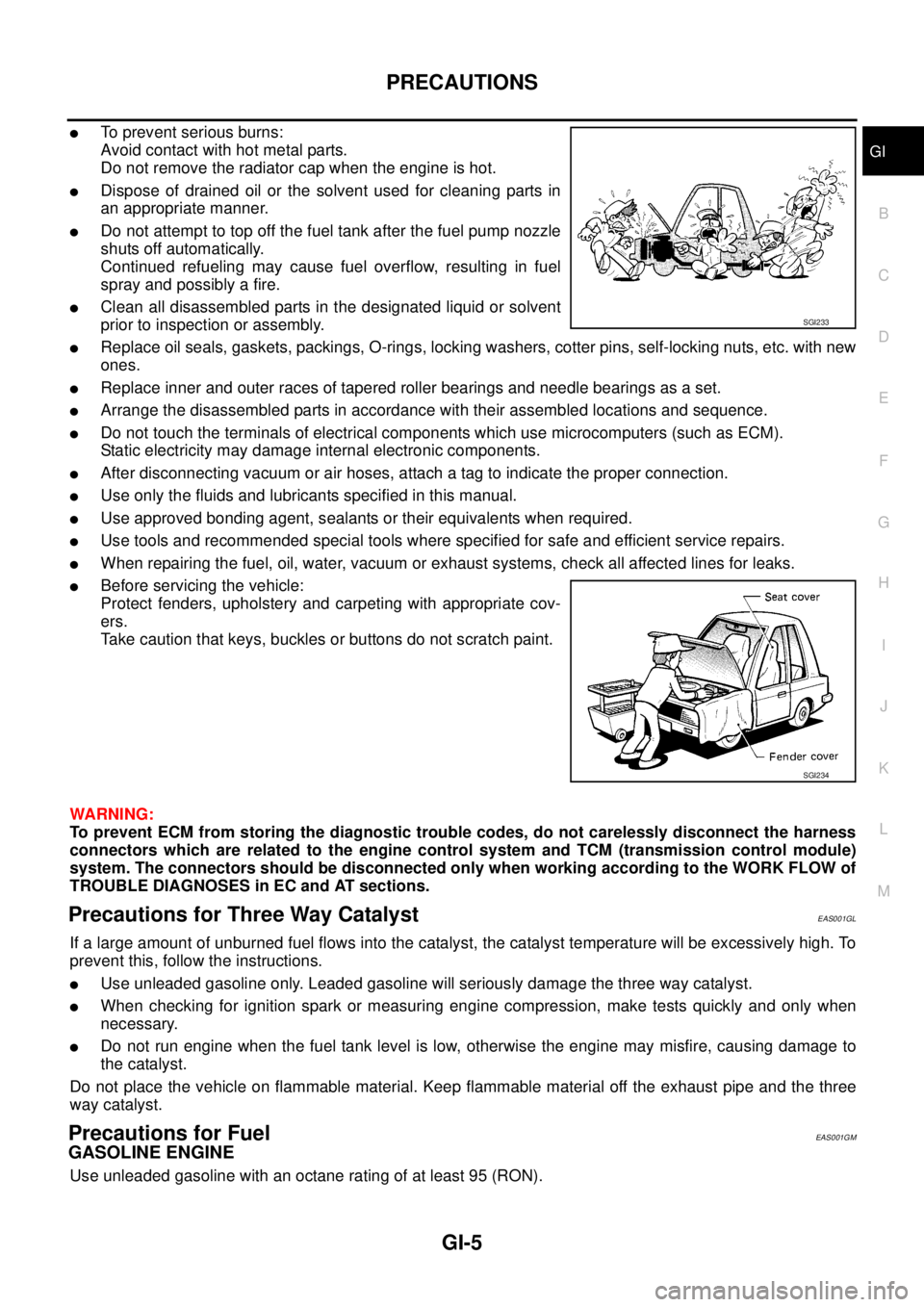

lBefore jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting before working

on the vehicle.

These operations should be done on a level surface.

lWhen removing a heavy component such as the engine or

transaxle/transmission, be careful not to lose your balance and

drop them. Also, do not allow them to strike adjacent parts,

especially the brake tubes and master cylinder.

lBefore starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

lIf the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

SGI285

SGI231

SEF289H

Page 1627 of 3171

PRECAUTIONS

GI-5

C

D

E

F

G

H

I

J

K

L

MB

GI

lTo prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

lDispose of drained oil or the solvent used for cleaning parts in

an appropriate manner.

lDo not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel

spray and possibly a fire.

lClean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

lReplace oil seals, gaskets, packings, O-rings, locking washers, cotter pins, self-locking nuts, etc. with new

ones.

lReplace inner and outer races of tapered roller bearings and needle bearings as a set.

lArrange the disassembled parts in accordance with their assembled locations and sequence.

lDo not touch the terminals of electrical components which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

lAfter disconnecting vacuum or air hoses, attach a tag to indicate the proper connection.

lUse only the fluids and lubricants specified in this manual.

lUse approved bonding agent, sealants or their equivalents when required.

lUse tools and recommended special tools where specified for safe and efficient service repairs.

lWhen repairing the fuel, oil, water, vacuum or exhaust systems, check all affected lines for leaks.

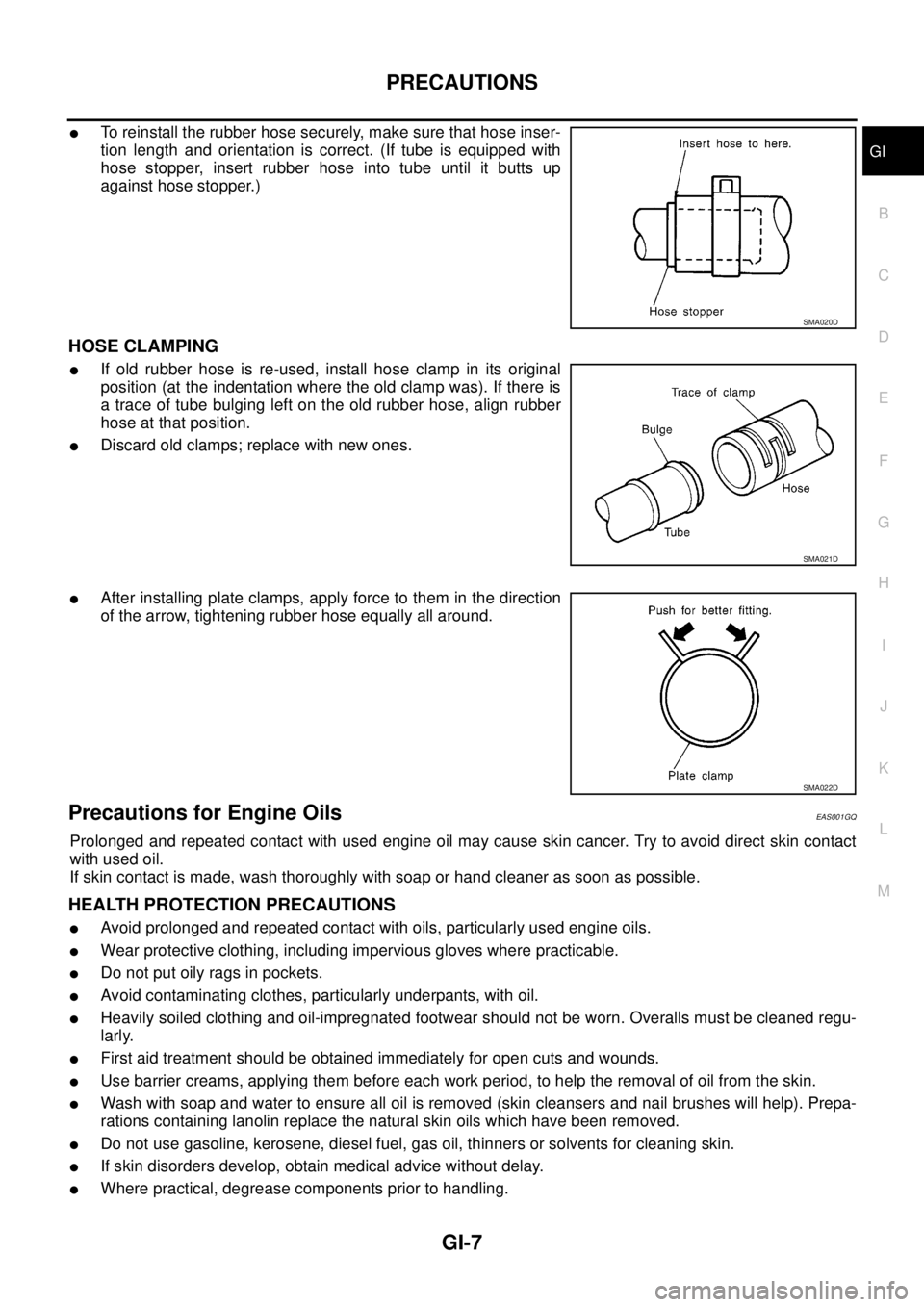

lBefore servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate cov-

ers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precautions for Three Way CatalystEAS001GL

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

lUse unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

lWhen checking for ignition spark or measuring engine compression, make tests quickly and only when

necessary.

lDo not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to

the catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precautions for FuelEAS001GM

GASOLINE ENGINE

Use unleaded gasoline with an octane rating of at least 95 (RON).

SGI233

SGI234

Page 1628 of 3171

GI-6

PRECAUTIONS

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will damage the three way catalyst. Using a fuel

other than that specified could adversely affect the emission control devices and systems, and could

also affect the warranty coverage validity.

DIESEL ENGINE

Diesel fuel of at least 50 cetane.

If two types of diesel fuel are available, use summer or winter fuel properly according to the following temper-

ature conditions.

lAbove –7°C(20°F) ... Summer type diesel fuel.

lBelow –7°C(20°F) ... Winter type diesel fuel.

CAUTION:

lDo not use home heating oil, gasoline or other alternate fuels in your diesel engine. The use of

those can cause engine damage.

lDo not use summer fuel at temperatures below –7°C(20°F). The cold temperatures will cause wax

to form in the fuel. As a result, it may prevent the engine from running smoothly.

lDo not add gasoline or other alternate fuels to diesel fuel.

Precautions for Multiport Fuel Injection System or Engine Control SystemEAS001GN

lBefore connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

lBefore disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

lBe careful not to jar components such as ECM and mass air

flow sensor.

Precautions for Turbocharger (If Equipped)EAS001GO

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean sup-

ply of oil flowing through the turbocharger and to follow all required

maintenance instructions and operating procedures.

lAlways use the recommended oil. Follow the instructions for

proper time to change the oil and proper oil level.

lAvoid accelerating engine to a high rpm immediately after start-

ing.

lIf engine had been operating at high rpm for an extended period

of time, let it idle for a few minutes prior to shutting if off.

Precautions for HosesEAS001GP

HOSE REMOVAL AND INSTALLATION

lTo prevent damage to rubber hose, do not pry off rubber hose

with tapered tool or screwdriver.

SGI787

SGI292

SMA019D

Page 1629 of 3171

PRECAUTIONS

GI-7

C

D

E

F

G

H

I

J

K

L

MB

GI

lTo reinstall the rubber hose securely, make sure that hose inser-

tion length and orientation is correct. (If tube is equipped with

hose stopper, insert rubber hose into tube until it butts up

against hose stopper.)

HOSE CLAMPING

lIf old rubber hose is re-used, install hose clamp in its original

position (at the indentation where the old clamp was). If there is

a trace of tube bulging left on the old rubber hose, align rubber

hose at that position.

lDiscard old clamps; replace with new ones.

lAfter installing plate clamps, apply force to them in the direction

of the arrow, tightening rubber hose equally all around.

Precautions for Engine OilsEAS001GQ

Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin contact

with used oil.

If skin contact is made, wash thoroughly with soap or hand cleaner as soon as possible.

HEALTH PROTECTION PRECAUTIONS

lAvoid prolonged and repeated contact with oils, particularly used engine oils.

lWear protective clothing, including impervious gloves where practicable.

lDo not put oily rags in pockets.

lAvoid contaminating clothes, particularly underpants, with oil.

lHeavily soiled clothing and oil-impregnated footwear should not be worn. Overalls must be cleaned regu-

larly.

lFirst aid treatment should be obtained immediately for open cuts and wounds.

lUse barrier creams, applying them before each work period, to help the removal of oil from the skin.

lWash with soap and water to ensure all oil is removed (skin cleansers and nail brushes will help). Prepa-

rations containing lanolin replace the natural skin oils which have been removed.

lDo not use gasoline, kerosene, diesel fuel, gas oil, thinners or solvents for cleaning skin.

lIf skin disorders develop, obtain medical advice without delay.

lWhere practical, degrease components prior to handling.

SMA020D

SMA021D

SMA022D

Page 1645 of 3171

HOW TO USE THIS MANUAL

GI-23

C

D

E

F

G

H

I

J

K

L

MB

GI

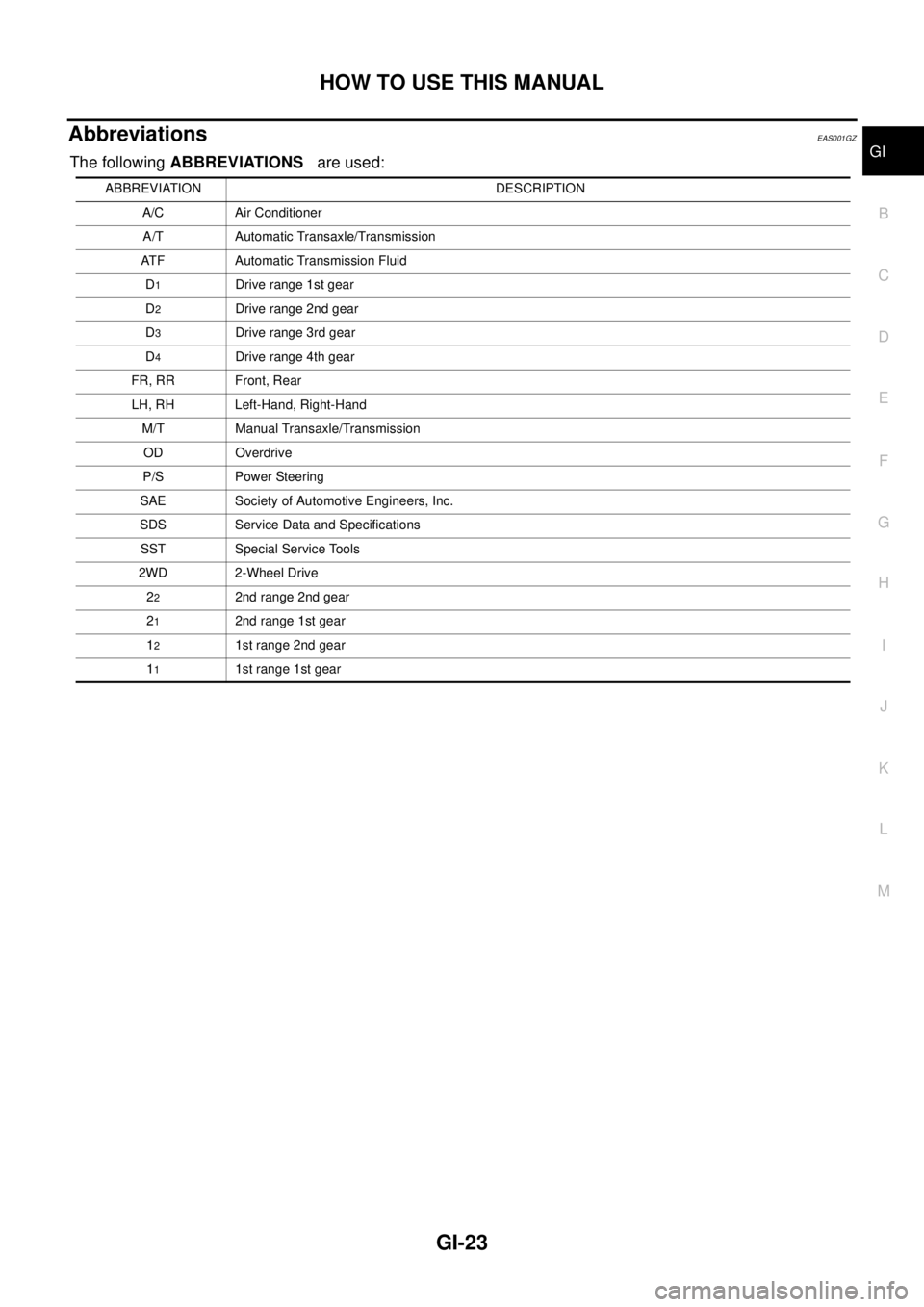

AbbreviationsEAS001GZ

The followingABBREVIATIONSare used:

ABBREVIATION DESCRIPTION

A/C Air Conditioner

A/T Automatic Transaxle/Transmission

ATF Automatic Transmission Fluid

D

1Drive range 1st gear

D

2Drive range 2nd gear

D

3Drive range 3rd gear

D

4Drive range 4th gear

FR, RR Front, Rear

LH, RH Left-Hand, Right-Hand

M/T Manual Transaxle/Transmission

OD Overdrive

P/S Power Steering

SAE Society of Automotive Engineers, Inc.

SDS Service Data and Specifications

SST Special Service Tools

2WD 2-Wheel Drive

2

22nd range 2nd gear

2

12nd range 1st gear

1

21st range 2nd gear

1

11st range 1st gear

Page 1646 of 3171

GI-24

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

PFP:00000

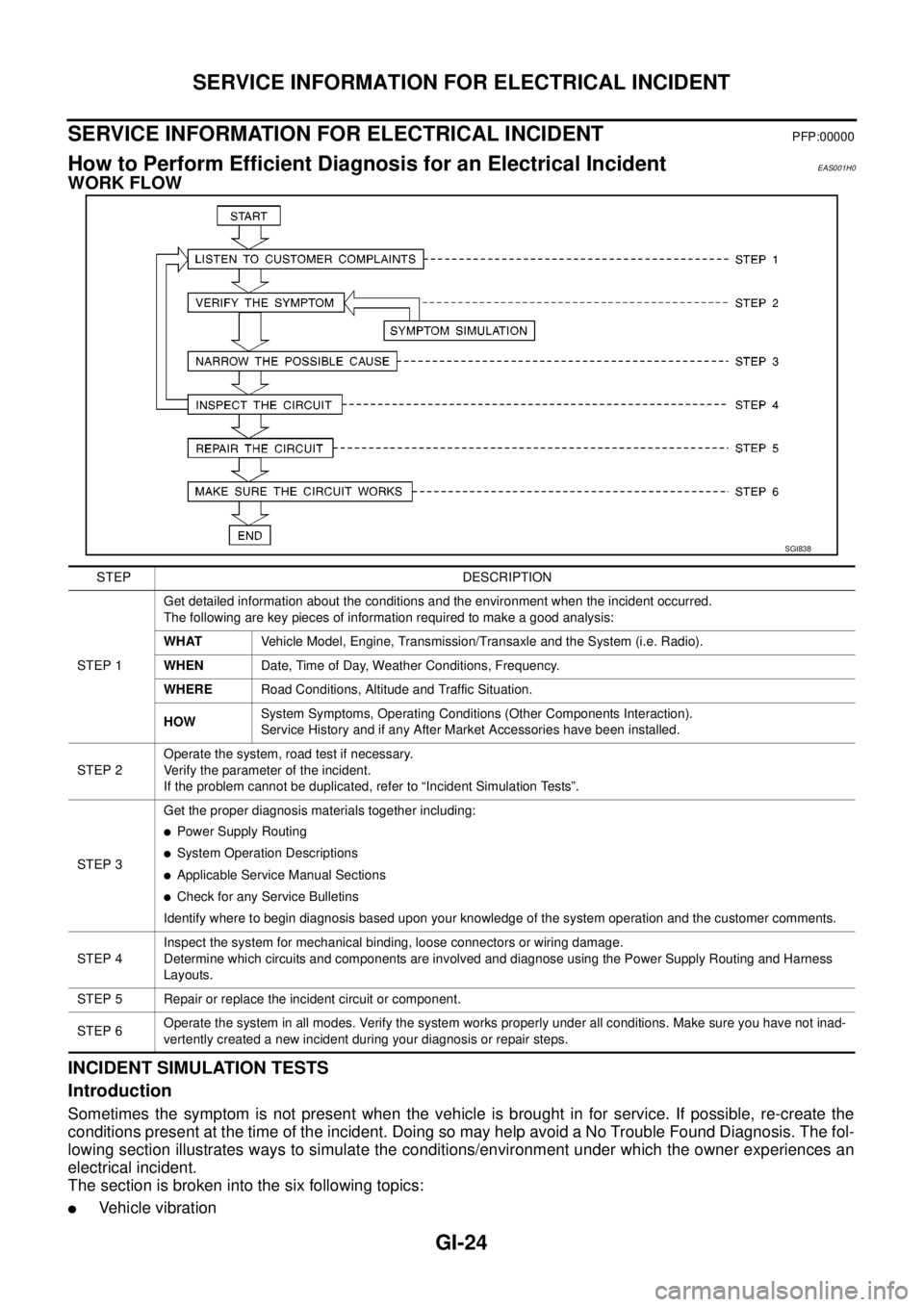

How to Perform Efficient Diagnosis for an Electrical IncidentEAS001H0

WORK FLOW

INCIDENT SIMULATION TESTS

Introduction

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The fol-

lowing section illustrates ways to simulate the conditions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:

lVehicle vibration

SGI838

STEP DESCRIPTION

STEP 1Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHATVehicle Model, Engine, Transmission/Transaxle and the System (i.e. Radio).

WHENDate, Time of Day, Weather Conditions, Frequency.

WHERERoad Conditions, Altitude and Traffic Situation.

HOWSystem Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem cannot be duplicated, refer to “Incident Simulation Tests”.

STEP 3Get the proper diagnosis materials together including:

lPower Supply Routing

lSystem Operation Descriptions

lApplicable Service Manual Sections

lCheck for any Service Bulletins

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness

Layouts.

STEP 5 Repair or replace the incident circuit or component.

STEP 6Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inad-

vertently created a new incident during your diagnosis or repair steps.

Page 1647 of 3171

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

GI-25

C

D

E

F

G

H

I

J

K

L

MB

GI

lHeat sensitive

lFreezing

lWater intrusion

lElectrical load

lCold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of the

problem.

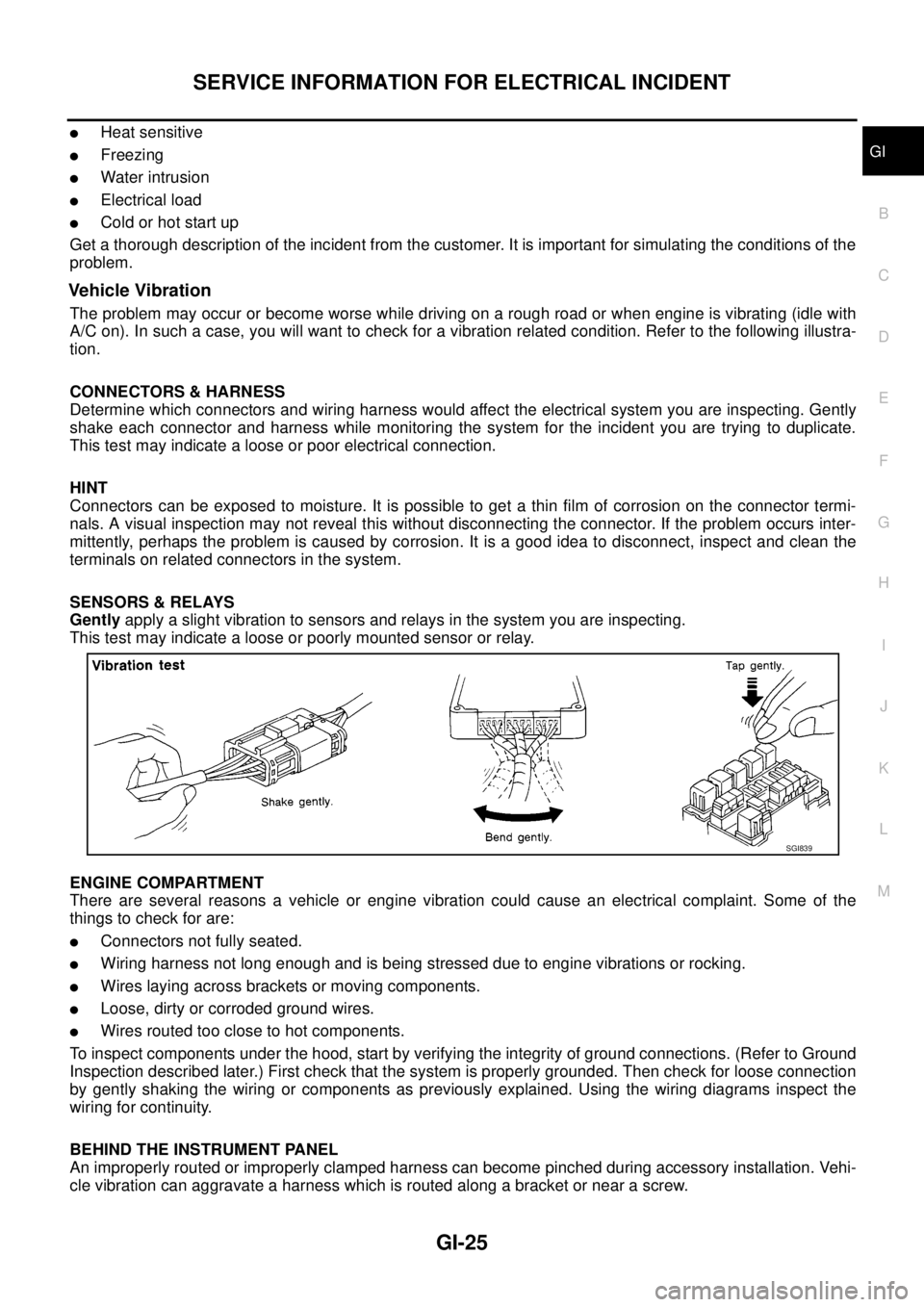

Vehicle Vibration

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the following illustra-

tion.

CONNECTORS & HARNESS

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the system for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

HINT

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

SENSORS & RELAYS

Gentlyapply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

ENGINE COMPARTMENT

There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the

things to check for are:

lConnectors not fully seated.

lWiring harness not long enough and is being stressed due to engine vibrations or rocking.

lWires laying across brackets or moving components.

lLoose, dirty or corroded ground wires.

lWires routed too close to hot components.

To inspect components under the hood, start by verifying the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previously explained. Using the wiring diagrams inspect the

wiring for continuity.

BEHIND THE INSTRUMENT PANEL

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehi-

cle vibration can aggravate a harness which is routed along a bracket or near a screw.

SGI839

Page 1669 of 3171

CONSULT-II CHECKING SYSTEM

GI-47

C

D

E

F

G

H

I

J

K

L

MB

GI

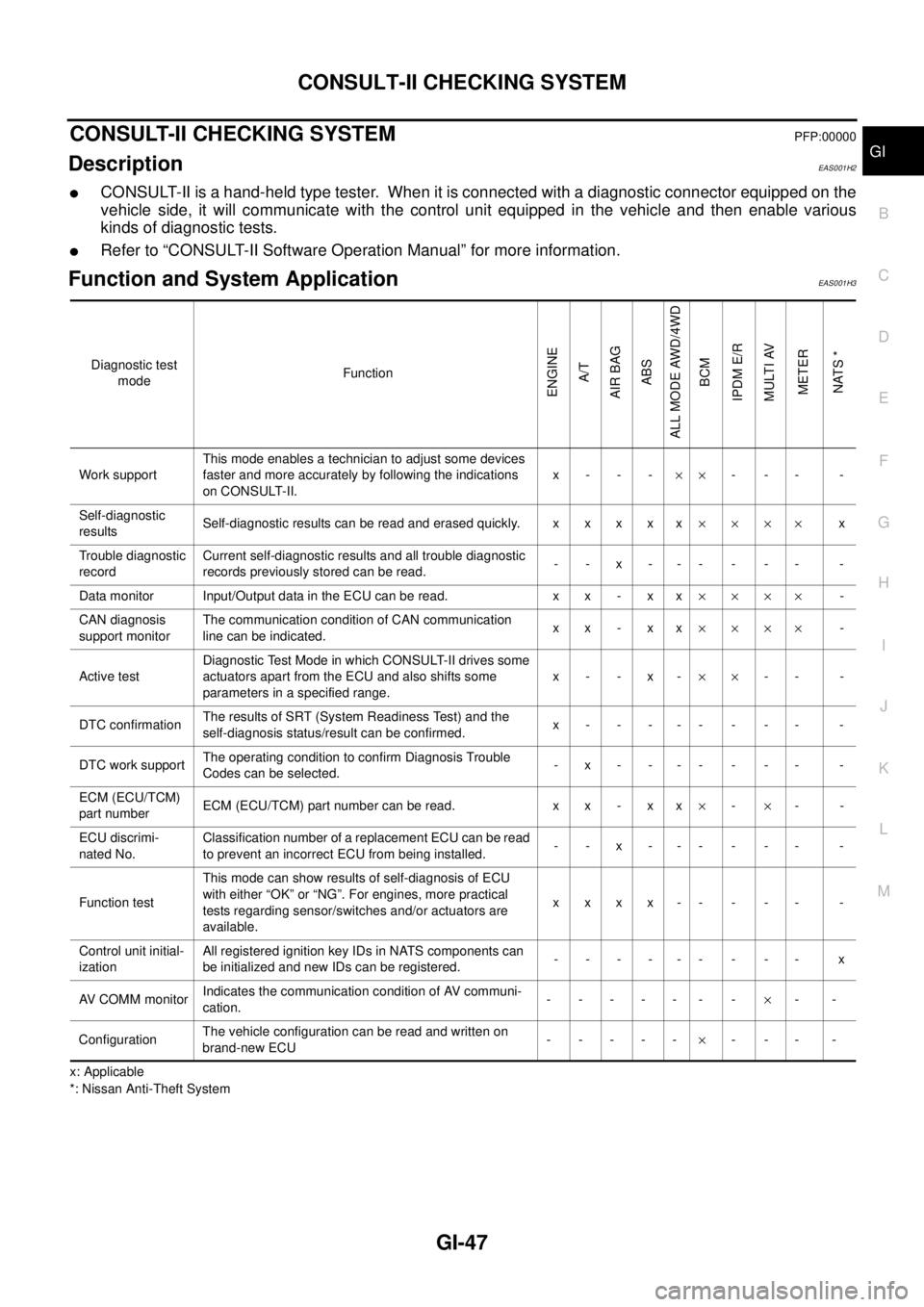

CONSULT-II CHECKING SYSTEMPFP:00000

DescriptionEAS001H2

lCONSULT-II is a hand-held type tester. When it is connected with a diagnostic connector equipped on the

vehicle side, it will communicate with the control unit equipped in the vehicle and then enable various

kinds of diagnostic tests.

lRefer to “CONSULT-II Software Operation Manual” for more information.

Function and System ApplicationEAS001H3

x: Applicable

*: Nissan Anti-Theft SystemDiagnostic test

modeFunction

ENGINE

A/T

AIR BAG

ABS

ALL MODE AWD/4WD

BCM

IPDM E/R

MULTI AV

METER

NATS *

Work supportThis mode enables a technician to adjust some devices

faster and more accurately by following the indications

on CONSULT-II.x---´´--- -

Self-diagnostic

resultsSelf-diagnostic results can be read and erased quickly. x x x x x´´´´x

Trouble diagnostic

recordCurrent self-diagnostic results and all trouble diagnostic

records previously stored can be read.--x------ -

Data monitor Input/Output data in the ECU can be read. x x - x x´´´´-

CAN diagnosis

support monitorThe communication condition of CAN communication

line can be indicated.xx - xx´´´´-

Active testDiagnostic Test Mode in which CONSULT-II drives some

actuators apart from the ECU and also shifts some

parameters in a specified range.x- -x-´´-- -

DTC confirmationThe results of SRT (System Readiness Test) and the

self-diagnosis status/result can be confirmed.x----- - -- -

DTC work supportThe operating condition to confirm Diagnosis Trouble

Codes can be selected.-x------- -

ECM (ECU/TCM)

part numberECM (ECU/TCM) part number can be read. x x - x x´-´--

ECU discrimi-

nated No.Classification number of a replacement ECU can be read

to prevent an incorrect ECU from being installed.--x------ -

Function testThis mode can show results of self-diagnosis of ECU

with either “OK” or “NG”. For engines, more practical

tests regarding sensor/switches and/or actuators are

available.xxxx-- - - - -

Control unit initial-

izationAll registered ignition key IDs in NATS components can

be initialized and new IDs can be registered.------ - -- x

AV C O M M m o n i t o rIndicates the communication condition of AV communi-

cation.- ----- -´--

ConfigurationThe vehicle configuration can be read and written on

brand-new ECU- ----´--- -

Page 1671 of 3171

CONSULT-II CHECKING SYSTEM

GI-49

C

D

E

F

G

H

I

J

K

L

MB

GI

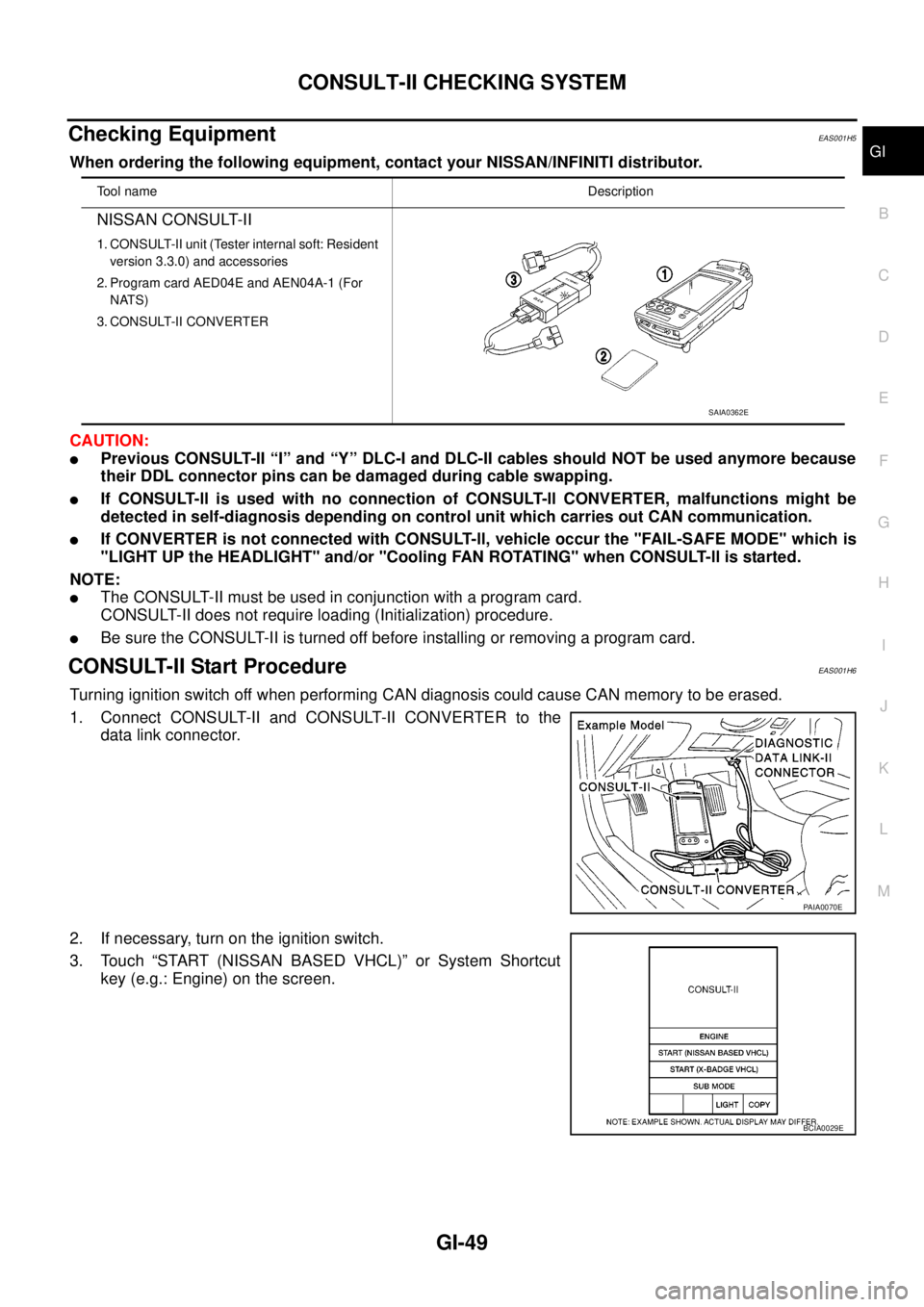

Checking EquipmentEAS001H5

When ordering the following equipment, contact your NISSAN/INFINITI distributor.

CAUTION:

lPrevious CONSULT-II “I” and “Y” DLC-I and DLC-II cables should NOT be used anymore because

their DDL connector pins can be damaged during cable swapping.

lIf CONSULT-ll is used with no connection of CONSULT-ll CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carries out CAN communication.

lIf CONVERTER is not connected with CONSULT-ll, vehicle occur the "FAIL-SAFE MODE" which is

"LIGHT UP the HEADLIGHT" and/or "Cooling FAN ROTATING" when CONSULT-ll is started.

NOTE:

lThe CONSULT-II must be used in conjunction with a program card.

CONSULT-II does not require loading (Initialization) procedure.

lBe sure the CONSULT-II is turned off before installing or removing a program card.

CONSULT-II Start ProcedureEAS001H6

Turning ignition switch off when performing CAN diagnosis could cause CAN memory to be erased.

1. Connect CONSULT-II and CONSULT-II CONVERTER to the

data link connector.

2. If necessary, turn on the ignition switch.

3. Touch “START (NISSAN BASED VHCL)” or System Shortcut

key (e.g.: Engine) on the screen.

Tool nameDescription

NISSAN CONSULT-II

1. CONSULT-II unit (Tester internal soft: Resident

version 3.3.0) and accessories

2. Program card AED04E and AEN04A-1 (For

NATS)

3. CONSULT-II CONVERTER

SAIA0362E

PAIA0070E

BCIA0029E

Page 1678 of 3171

GI-56

IDENTIFICATION INFORMATION

IDENTIFICATION INFORMATION

PFP:00010

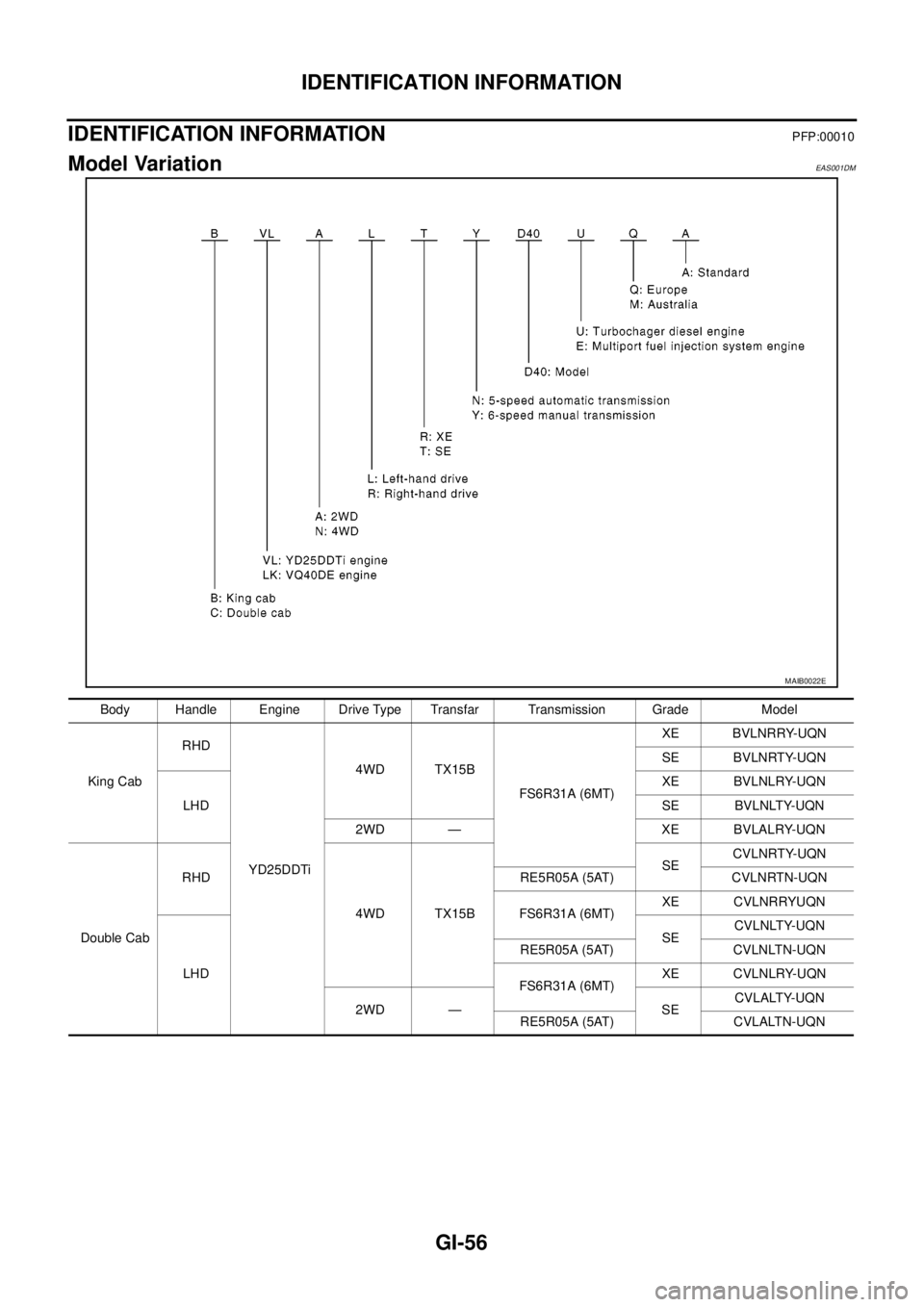

Model VariationEAS001DM

MAIB0022E

Body Handle Engine Drive Type Transfar Transmission Grade Model

King CabRHD

YD25DDTi4WD TX15B

FS6R31A (6MT)XE BVLNRRY-UQN

SE BVLNRTY-UQN

LHDXE BVLNLRY-UQN

SE BVLNLTY-UQN

2WD — XE BVLALRY-UQN

Double CabRHD

4WD TX15BSECVLNRTY-UQN

RE5R05A (5AT) CVLNRTN-UQN

FS6R31A (6MT)XE CVLNRRYUQN

LHDSECVLNLTY-UQN

RE5R05A (5AT) CVLNLTN-UQN

FS6R31A (6MT)XE CVLNLRY-UQN

2WD — SECVLALTY-UQN

RE5R05A (5AT) CVLALTN-UQN