engine NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1597 of 3171

FUEL TANK

FL-13

C

D

E

F

G

H

I

J

K

L

MA

FL

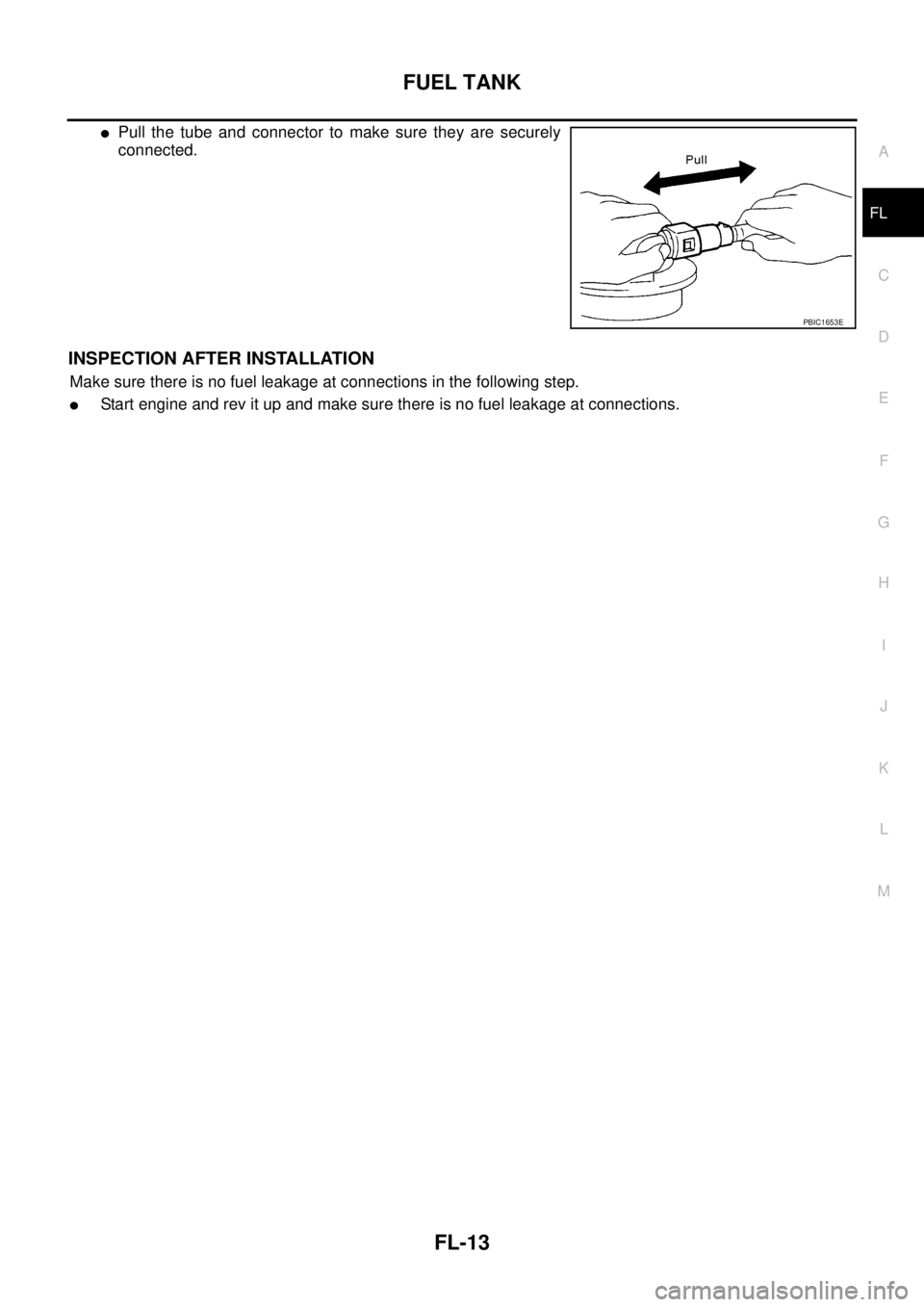

lPull the tube and connector to make sure they are securely

connected.

INSPECTION AFTER INSTALLATION

Make sure there is no fuel leakage at connections in the following step.

lStart engine and rev it up and make sure there is no fuel leakage at connections.

PBIC1653E

Page 1599 of 3171

FUEL LEVEL SENSOR UNIT

FL-15

C

D

E

F

G

H

I

J

K

L

MA

FL

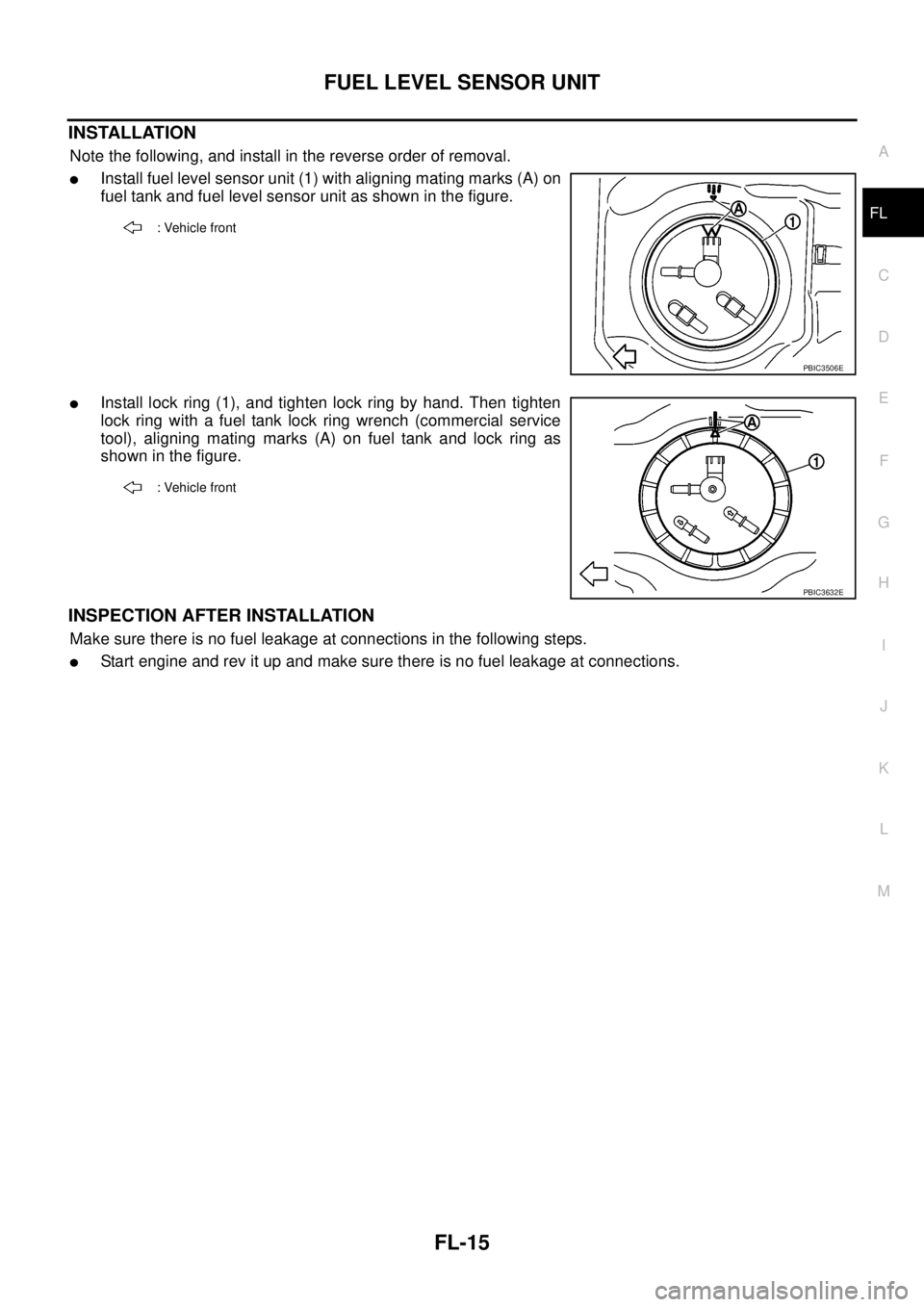

INSTALLATION

Note the following, and install in the reverse order of removal.

lInstall fuel level sensor unit (1) with aligning mating marks (A) on

fuel tank and fuel level sensor unit as shown in the figure.

lInstall lock ring (1), and tighten lock ring by hand. Then tighten

lock ring with a fuel tank lock ring wrench (commercial service

tool), aligning mating marks (A) on fuel tank and lock ring as

showninthefigure.

INSPECTION AFTER INSTALLATION

Make sure there is no fuel leakage at connections in the following steps.

lStart engine and rev it up and make sure there is no fuel leakage at connections.

: Vehicle front

PBIC3506E

: Vehicle front

PBIC3632E

Page 1602 of 3171

FSU-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

PrecautionsEES002KG

lWhen installing the rubber bushings, the final tightening must be done under unladen condition and with

the tires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immedi-

ately.

lUnladen condition means the fuel tank, engine coolant and lubricants are at the full specification. The

spare tire, jack, hand tools, and mats are in their designated positions.

lAfter installing suspension components, check the wheel alignment.

lLock nuts are not reusable. Always use new lock nuts for installation. New lock nuts are pre-oiled, do not

apply any additional lubrication.

Page 1609 of 3171

ON-VEHICLE SERVICE

FSU-9

C

D

F

G

H

I

J

K

L

MA

B

FSU

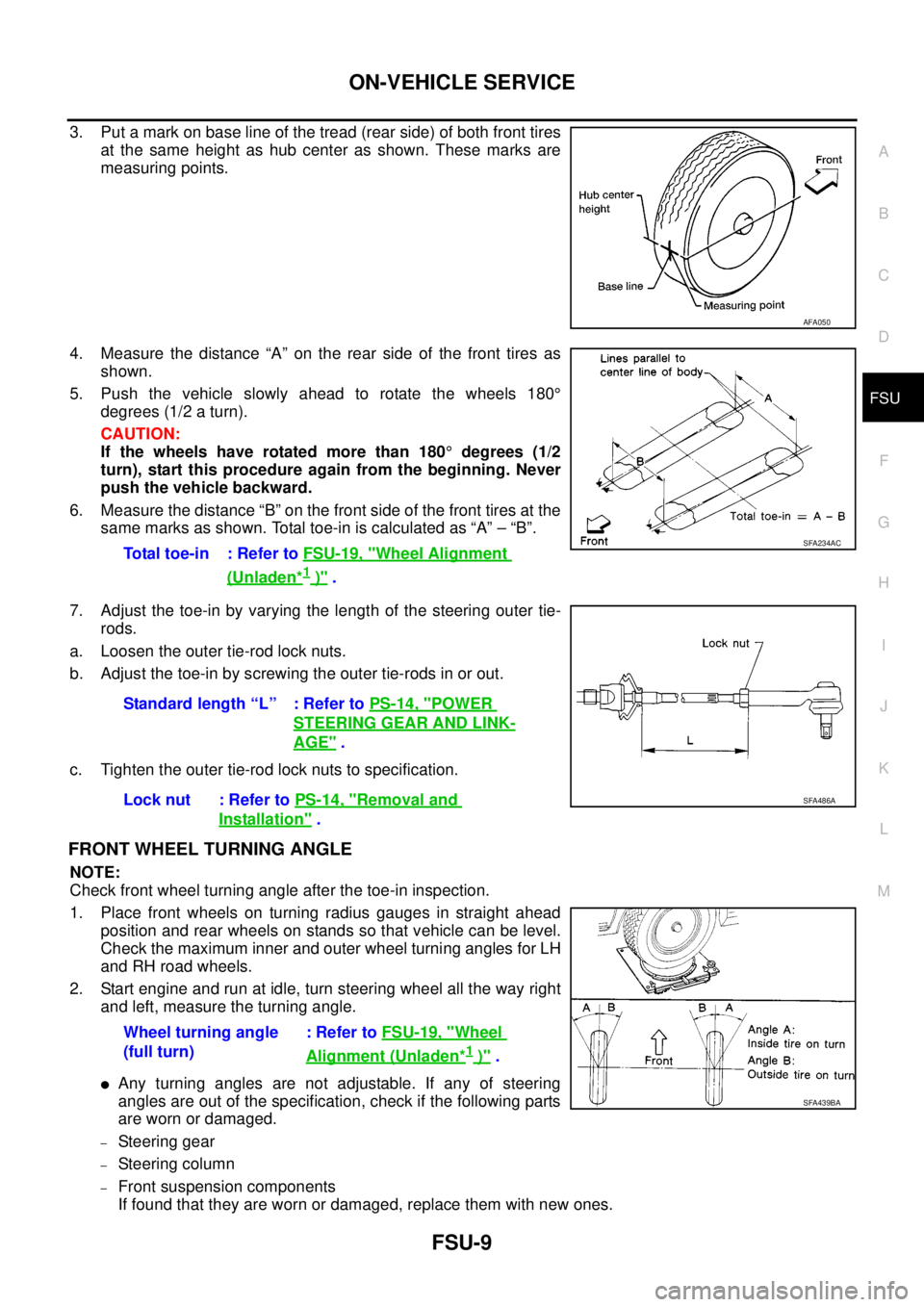

3. Put a mark on base line of the tread (rear side) of both front tires

at the same height as hub center as shown. These marks are

measuring points.

4. Measure the distance “A” on the rear side of the front tires as

shown.

5. Push the vehicle slowly ahead to rotate the wheels 180°

degrees (1/2 a turn).

CAUTION:

If the wheels have rotated more than 180°degrees (1/2

turn), start this procedure again from the beginning. Never

push the vehicle backward.

6. Measure the distance “B” on the front side of the front tires at the

same marks as shown. Total toe-in is calculated as “A” – “B”.

7. Adjust the toe-in by varying the length of the steering outer tie-

rods.

a. Loosen the outer tie-rod lock nuts.

b. Adjust the toe-in by screwing the outer tie-rods in or out.

c. Tighten the outer tie-rod lock nuts to specification.

FRONT WHEEL TURNING ANGLE

NOTE:

Check front wheel turning angle after the toe-in inspection.

1. Place front wheels on turning radius gauges in straight ahead

position and rear wheels on stands so that vehicle can be level.

Check the maximum inner and outer wheel turning angles for LH

and RH road wheels.

2. Start engine and run at idle, turn steering wheel all the way right

and left, measure the turning angle.

lAny turning angles are not adjustable. If any of steering

angles are out of the specification, check if the following parts

are worn or damaged.

–Steering gear

–Steering column

–Front suspension components

If found that they are worn or damaged, replace them with new ones.

AFA050

Total toe-in : Refer toFSU-19, "Wheel Alignment

(Unladen*1)".

SFA234AC

Standard length “L” : Refer toPS-14, "POWER

STEERING GEAR AND LINK-

AGE".

Lock nut : Refer toPS-14, "

Removal and

Installation".

SFA486A

Wheel turning angle

(full turn):RefertoFSU-19, "Wheel

Alignment (Unladen*1)".

SFA439BA

Page 1612 of 3171

FSU-12

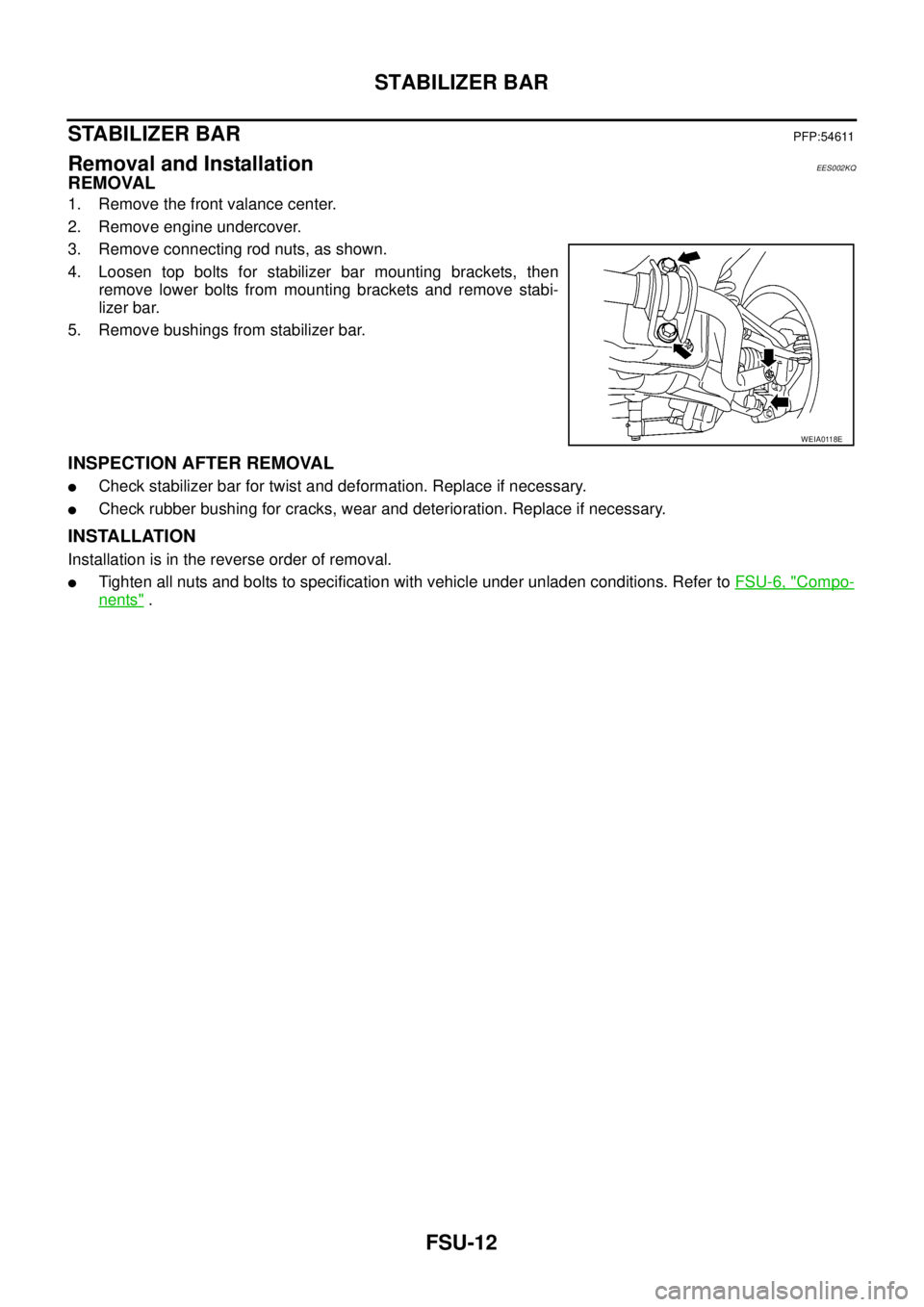

STABILIZER BAR

STABILIZER BAR

PFP:54611

Removal and InstallationEES002KQ

REMOVAL

1. Remove the front valance center.

2. Remove engine undercover.

3. Remove connecting rod nuts, as shown.

4. Loosen top bolts for stabilizer bar mounting brackets, then

remove lower bolts from mounting brackets and remove stabi-

lizer bar.

5. Remove bushings from stabilizer bar.

INSPECTION AFTER REMOVAL

lCheck stabilizer bar for twist and deformation. Replace if necessary.

lCheck rubber bushing for cracks, wear and deterioration. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

lTighten all nuts and bolts to specification with vehicle under unladen conditions. Refer toFSU-6, "Compo-

nents".

WEIA0118E

Page 1619 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

FSU-19

C

D

F

G

H

I

J

K

L

MA

B

FSU

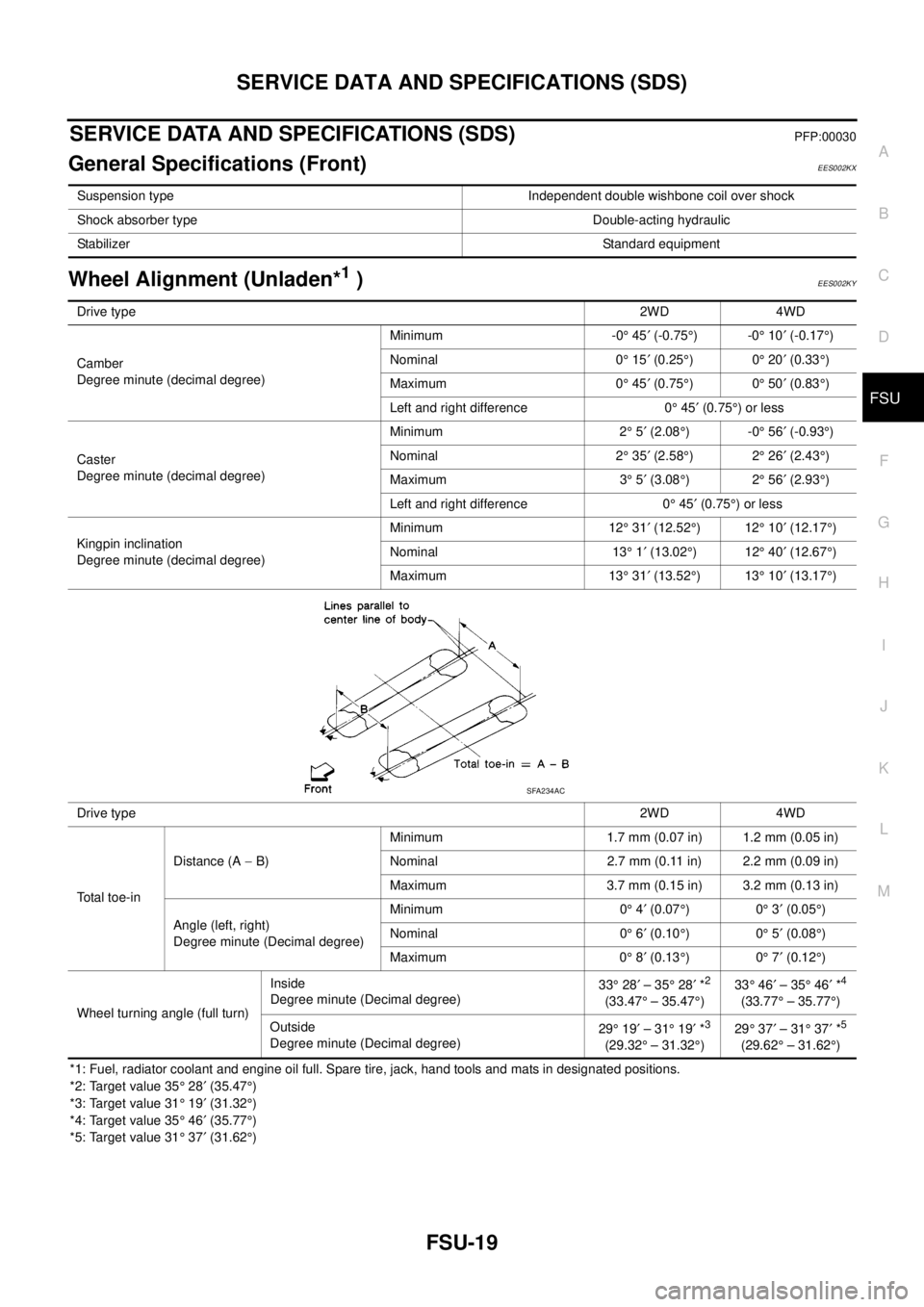

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General Specifications (Front)EES002KX

Wheel Alignment (Unladen*1)EES002KY

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Target value 35°28¢(35.47°)

*3: Target value 31°19¢(31.32°)

*4: Target value 35°46¢(35.77°)

*5: Target value 31°37¢(31.62°) Suspension type Independent double wishbone coil over shock

Shock absorber type Double-acting hydraulic

StabilizerStandard equipment

Drive type2WD 4WD

Camber

Degree minute (decimal degree)Minimum -0°45¢(-0.75°)-0°10¢(-0.17°)

Nominal 0°15¢(0.25°)0°20¢(0.33°)

Maximum 0°45¢(0.75°)0°50¢(0.83°)

Left and right difference 0°45¢(0.75°)orless

Caster

Degree minute (decimal degree)Minimum 2°5¢(2.08°)-0°56¢(-0.93°)

Nominal 2°35¢(2.58°)2°26¢(2.43°)

Maximum 3°5¢(3.08°)2°56¢(2.93°)

Left and right difference 0°45¢(0.75°)orless

Kingpin inclination

Degree minute (decimal degree)Minimum 12°31¢(12.52°)12°10¢(12.17°)

Nominal 13°1¢(13.02°)12°40¢(12.67°)

Maximum 13°31¢(13.52°)13°10¢(13.17°)

Drive type2WD 4WD

Total toe-inDistance (A-B)Minimum 1.7 mm (0.07 in) 1.2 mm (0.05 in)

Nominal 2.7 mm (0.11 in) 2.2 mm (0.09 in)

Maximum 3.7 mm (0.15 in) 3.2 mm (0.13 in)

Angle (left, right)

Degree minute (Decimal degree)Minimum 0°4¢(0.07°)0°3¢(0.05°)

Nominal 0°6¢(0.10°)0°5¢(0.08°)

Maximum 0°8¢(0.13°)0°7¢(0.12°)

Wheel turning angle (full turn)Inside

Degree minute (Decimal degree)33°28¢–35°28¢*

2

(33.47°– 35.47°)33°46¢–35°46¢*

4

(33.77°– 35.77°)

Outside

Degree minute (Decimal degree)29°19¢–31°19¢*

3

(29.32°– 31.32°)29°37¢–31°37¢*

5

(29.62°– 31.62°)

SFA234AC

Page 1621 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

FSU-21

C

D

F

G

H

I

J

K

L

MA

B

FSU

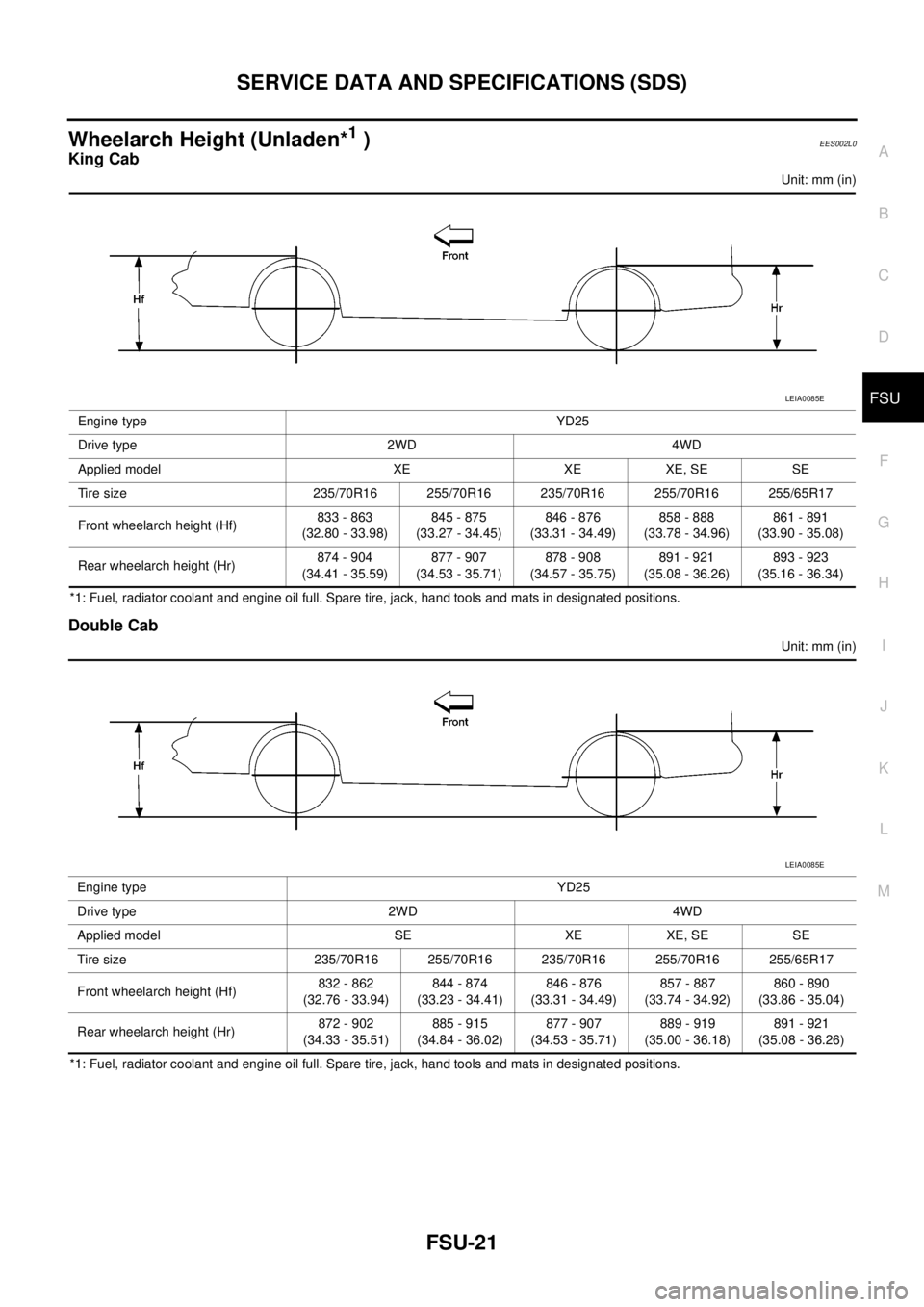

Wheelarch Height (Unladen*1)EES002L0

King Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Double Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.Engine type YD25

Drive type 2WD 4WD

Applied model XE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)833 - 863

(32.80 - 33.98)845 - 875

(33.27 - 34.45)846 - 876

(33.31 - 34.49)858 - 888

(33.78 - 34.96)861 - 891

(33.90 - 35.08)

Rear wheelarch height (Hr)874 - 904

(34.41 - 35.59)877 - 907

(34.53 - 35.71)878 - 908

(34.57 - 35.75)891 - 921

(35.08 - 36.26)893 - 923

(35.16 - 36.34)

LEIA0085E

Engine type YD25

Drive type 2WD 4WD

Applied model SE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)832 - 862

(32.76 - 33.94)844 - 874

(33.23 - 34.41)846 - 876

(33.31 - 34.49)857 - 887

(33.74 - 34.92)860 - 890

(33.86 - 35.04)

Rear wheelarch height (Hr)872 - 902

(34.33 - 35.51)885 - 915

(34.84 - 36.02)877 - 907

(34.53 - 35.71)889 - 919

(35.00 - 36.18)891 - 921

(35.08 - 36.26)

LEIA0085E

Page 1623 of 3171

GI-1

GENERAL INFORMATION

A GENERAL INFORMATION

CONTENTS

C

D

E

F

G

H

I

J

K

L

MB

GI

SECTIONGI

GENERAL INFORMATION

PRECAUTIONS .......................................................... 3

Description ............................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions for NATS (NISSAN ANTI-THEFT SYS-

TEM) ........................................................................ 3

Precautions Necessary for Steering Wheel Rotation

After Battery Disconnect .......................................... 3

OPERATION PROCEDURE ................................. 4

General Precautions ................................................ 4

Precautions for Three Way Catalyst ......................... 5

Precautions for Fuel ................................................. 5

GASOLINE ENGINE ............................................. 5

DIESEL ENGINE ................................................... 6

Precautions for Multiport Fuel Injection System or

Engine Control System ............................................ 6

Precautions for Turbocharger (If Equipped) ............. 6

Precautions for Hoses .............................................. 6

HOSE REMOVAL AND INSTALLATION ............... 6

HOSE CLAMPING ................................................ 7

Precautions for Engine Oils ...................................... 7

HEALTH PROTECTION PRECAUTIONS ............. 7

ENVIRONMENTAL PROTECTION PRECAU-

TIONS ................................................................... 8

Precautions for Air Conditioning ............................... 8

HOW TO USE THIS MANUAL ................................... 9

Description ............................................................... 9

Terms ....................................................................... 9

Units ......................................................................... 9

Contents ................................................................... 9

Components ........................................................... 10

SYMBOLS ........................................................... 10

How to Follow Trouble Diagnoses ........................... 11

DESCRIPTION ..................................................... 11

HOW TO FOLLOW TEST GROUPS IN TROU-

BLE DIAGNOSES ................................................ 11

HARNESS WIRE COLOR AND CONNECTOR

NUMBER INDICATION ....................................... 12

KEY TO SYMBOLS SIGNIFYING MEASURE-MENTS OR PROCEDURES ............................... 13

How to Read Wiring Diagrams ............................... 15

CONNECTOR SYMBOLS ................................... 15

SAMPLE/WIRING DIAGRAM - EXAMPL - .......... 16

DESCRIPTION .................................................... 17

Abbreviations .......................................................... 23

SERVICE INFORMATION FOR ELECTRICAL INCI-

DENT ......................................................................... 24

How to Perform Efficient Diagnosis for an Electrical

Incident ................................................................... 24

WORK FLOW ...................................................... 24

INCIDENT SIMULATION TESTS ........................ 24

CIRCUIT INSPECTION ....................................... 27

Control Units and Electrical Parts ........................... 32

PRECAUTIONS .................................................. 32

CONTROL UNIT CONFIGURATION PROCEDURE... 34

Description .............................................................. 34

Part Replacement procedure Reference Table ...... 34

Work Procedure ...................................................... 36

Configuration (BCM) ............................................... 37

DESCRIPTION .................................................... 37

READ CONFIGURATION PROCEDURE ............ 37

WRITE CONFIGURATION PROCEDURE .......... 41

CONSULT-II CHECKING SYSTEM .......................... 47

Description .............................................................. 47

Function and System Application ........................... 47

Nickel Metal Hydride Battery Replacement ............ 48

Checking Equipment .............................................. 49

CONSULT-II Start Procedure .................................. 49

CONSULT-II Data Link Connector (DLC) Circuit .... 50

INSPECTION PROCEDURE .............................. 51

LIFTING POINT ......................................................... 52

Pantograph Jack, Garage Jack and Safety Stand... 52

2-Pole Lift ............................................................... 52

TOW TRUCK TOWING ............................................. 53

Tow Truck Towing ................................................... 53

4X2 MODEL ........................................................ 53

4X4 MODEL ........................................................ 54

TOWING POINT .................................................. 54

Vehicle Recovery (Freeing a Stuck Vehicle) ........... 54

Page 1624 of 3171

GI-2

TIGHTENING TORQUE OF STANDARD BOLTS .... 55

Tightening Torque Table ......................................... 55

IDENTIFICATION INFORMATION ............................ 56

Model Variation ....................................................... 56

Identification Number .............................................. 57

VEHICLE IDENTIFICATION NUMBER

ARRANGEMENT ................................................. 57

IDENTIFICATION PLATE .................................... 58

ENGINE SERIAL NUMBER ................................ 58TRANSFER SERIAL NUMBER ........................... 58

AUTOMATIC TRANSMISSION NUMBER ........... 58

MANUAL TRANSMISSION NUMBER ................. 59

Dimensions ............................................................. 60

KING CAB ............................................................ 60

DOUBLE CAB ...................................................... 60

Wheels & Tyres ....................................................... 60

TERMINOLOGY ........................................................ 61

ISO 15031-2 Terminology List ................................. 61

Page 1625 of 3171

PRECAUTIONS

GI-3

C

D

E

F

G

H

I

J

K

L

MB

GI

PRECAUTIONSPFP:00001

DescriptionEAS001GG

Observe the following precautions to ensure safe and proper servicing. These precautions are not

described in each individual section.

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EAS001GH

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for NATS (NISSAN ANTI-THEFT SYSTEM)EAS001GI

NATS will immobilize the engine if someone tries to start it without the registered key of NATS.

Both of the originally supplied ignition key IDs have been NATS registered.

The security indicator is located on the instrument panel. The indicator blinks when the immobilizer system is

functioning.

Therefore, NATS warns outsiders that the vehicle is equipped with the anti-theft system.

lWhen NATS detects trouble, the security indicator lamp lights up while ignition switch is in "ON" position.

This lighting up indicates that the anti-theft is not functioning, so prompt service is required.

lWhen servicing NATS (trouble diagnoses, system initialization and additional registration of other NATS

ignition key IDs), CONSULT-II hardware and CONSULT-II NATS software is necessary.

Regarding the procedures of NATS initialization and NATS ignition key ID registration, refer to CONSULT-

II operation manual, NATS.

Therefore, CONSULT-II NATS software (program card and operation manual) must be kept strictly con-

fidential to maintain the integrity of the anti-theft function.

lWhen servicing NATS (trouble diagnoses, system initialization and additional registration of other NATS

ignition key IDs), it may be necessary to re-register original key identification. Therefore, be sure to

receive all keys from vehicle owner. A maximum of four or five key IDs can be registered into NATS.

lWhen failing to start the engine first time using the key of NATS, start as follows.

1. Leave the ignition key in "ON" position for approximately 5 seconds.

2. Turn ignition key to "OFF" or "LOCK" position and wait approximately 5 seconds.

3. Repeat step 1 and 2 again.

4. Restart the engine while keeping the key separate from any others on key-chain.

Precautions Necessary for Steering Wheel Rotation After Battery DisconnectEAS001HY

NOTE:

lThis Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT

SYSTEM).

lRemove and install all control units after disconnecting both battery cables with the ignition knob in the

²LOCK²position.

lAlways use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.