SRS NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2638 of 3171

STEERING COLUMN

PS-11

C

D

E

F

H

I

J

K

L

MA

B

PS

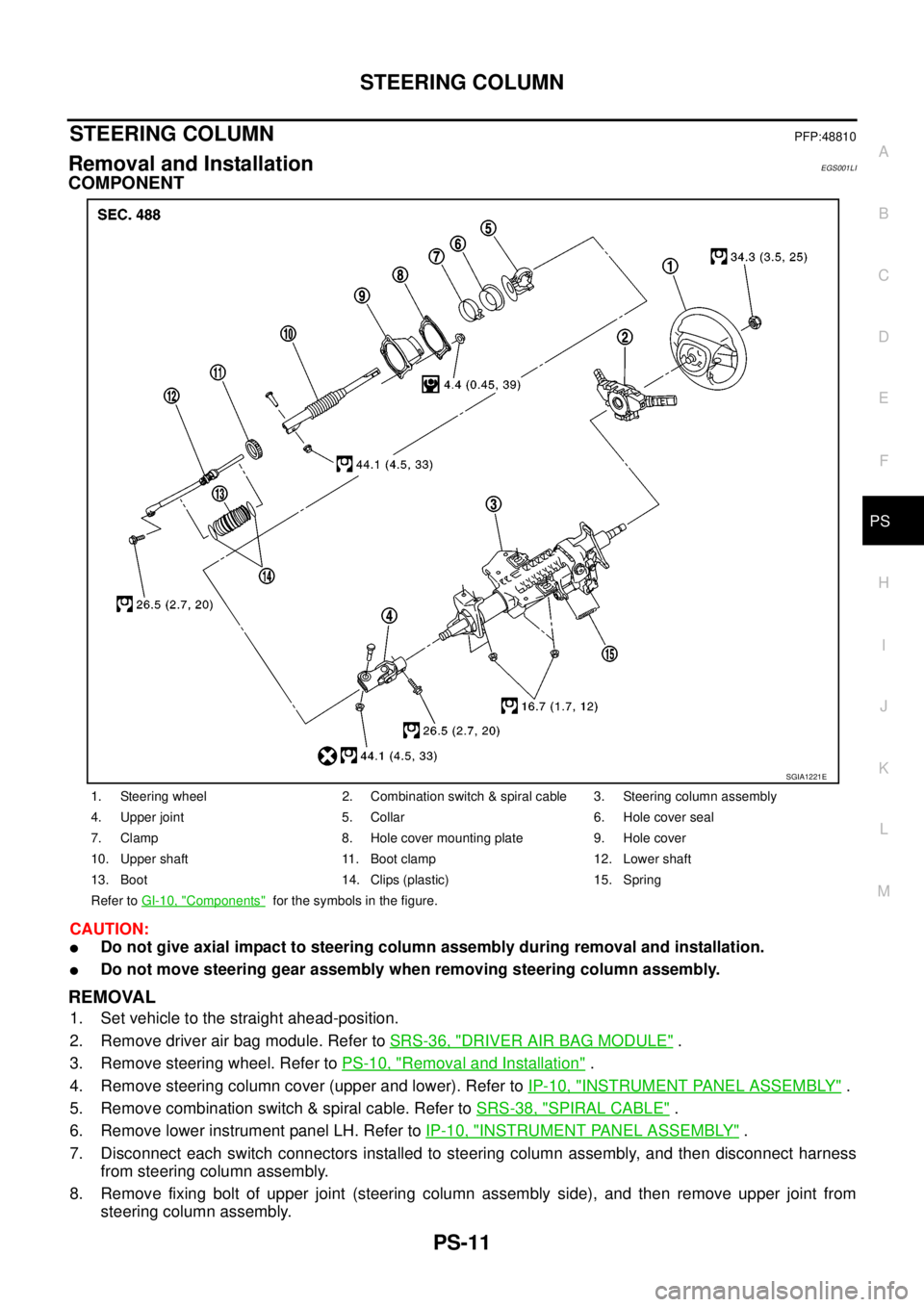

STEERING COLUMNPFP:48810

Removal and InstallationEGS001LI

COMPONENT

CAUTION:

lDo not give axial impact to steering column assembly during removal and installation.

lDo not move steering gear assembly when removing steering column assembly.

REMOVAL

1. Set vehicle to the straight ahead-position.

2. Remove driver air bag module. Refer toSRS-36, "

DRIVER AIR BAG MODULE".

3. Remove steering wheel. Refer toPS-10, "

Removal and Installation".

4. Remove steering column cover (upper and lower). Refer toIP-10, "

INSTRUMENT PANEL ASSEMBLY".

5. Remove combination switch & spiral cable. Refer toSRS-38, "

SPIRAL CABLE".

6. Remove lower instrument panel LH. Refer toIP-10, "

INSTRUMENT PANEL ASSEMBLY".

7. Disconnect each switch connectors installed to steering column assembly, and then disconnect harness

from steering column assembly.

8. Remove fixing bolt of upper joint (steering column assembly side), and then remove upper joint from

steering column assembly.

1. Steering wheel 2. Combination switch & spiral cable 3. Steering column assembly

4. Upper joint 5. Collar 6. Hole cover seal

7. Clamp 8. Hole cover mounting plate 9. Hole cover

10. Upper shaft 11. Boot clamp 12. Lower shaft

13. Boot 14. Clips (plastic) 15. Spring

Refer toGI-10, "

Components"for the symbols in the figure.

SGIA1221E

Page 2678 of 3171

RF-1

ROOF

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONRF

A

B

RF

ROOF

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 2

Precautions .............................................................. 2

PREPARATION ........................................................... 3

Commercial Service Tool ......................................... 3

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 4

Work Flow ................................................................ 4

CUSTOMER INTERVIEW ..................................... 4

DUPLICATE THE NOISE AND TEST DRIVE ....... 5

CHECK RELATED SERVICE BULLETINS ........... 5

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 5

REPAIR THE CAUSE ........................................... 5

CONFIRM THE REPAIR ....................................... 6

Generic Squeak and Rattle Troubleshooting ........... 6

INSTRUMENT PANEL .......................................... 6

CENTER CONSOLE ............................................. 6

DOORS ................................................................. 6

TRUNK .................................................................. 7

SUNROOF/HEADLINING ..................................... 7

SEATS ................................................................... 7

UNDERHOOD ....................................................... 7

Diagnostic Worksheet .............................................. 8

SUNROOF ................................................................ 10

Component Parts and Harness Connector Location... 10

System Description ................................................. 11

TILT UP / SLIDE CLOSE OPERATION ................ 11

TILT DOWN / SLIDE OPEN OPERATION ........... 11AUTO OPERATION ............................................. 11

ANTI-PINCH FUNCTION .................................... 11

MEMORY RESET PROCEDURE ....................... 12

INITIALIZATION PROCEDURE .......................... 12

CAN Communication System Description .............. 13

CAN Communication Unit ....................................... 13

Wiring Diagram — SROOF — ................................ 14

Terminals and Reference Value for BCM ............... 15

Terminals and Reference Value for Sunroof Motor

Assembly ................................................................ 15

Work Flow ............................................................... 16

Trouble Diagnosis Symptom Chart ......................... 16

BCM Power Supply and Ground Circuit Check ...... 16

Sunroof Motor Assembly Power Supply and Ground

Circuit Check .......................................................... 17

Sunroof Switch System Check ............................... 18

Fitting Adjustment ................................................... 20

GAP ADJUSTMENT ............................................ 20

HEIGHT DIFFERENCE ADJUSTMENT .............. 20

Removal and Installation ........................................ 21

SUNROOF UNIT ................................................. 22

GLASS LID .......................................................... 22

WIND DEFLECTOR ............................................ 23

SUNSHADE ........................................................ 23

SUNROOF MOTOR ............................................ 23

DRAIN HOSES .................................................... 25

WEATHERSTRIP ................................................ 25

REAR DRAIN ASSEMBLY .................................. 25

LINK AND WIRE ASSEMBLY ............................. 26

Page 2679 of 3171

RF-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EIS00CE9

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

PrecautionsEIS00B92

lDisconnect both battery cables in advance.

lNever tamper with or force air bag lid open, as this may adversely affect air bag performance.

lBe careful not to scratch pad and other parts.

lWhen removing or disassembling any part, be careful not to damage or deform it. Protect parts which may

get in the way with cloth.

lWhen removing parts with a screwdriver or other tool, protect parts by wrapping them with vinyl or tape.

lKeep removed parts protected with cloth.

lIf a clip is deformed or damaged, replace it.

lIf an unreusable part is removed, replace it with a new one.

lTighten bolts and nuts firmly to the specified torque.

lAfter re-assembly has been completed, make sure each part functions correctly.

lRemove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tightly. After wiping the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain

with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely.

Thenwipetheareawithasoftdrycloth.

lDo not use any organic solvent, such as thinner or benzine.

Page 2704 of 3171

RFD-1

REAR FINAL DRIVE

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTIONRFD

A

B

RFD

REAR FINAL DRIVE

WITH LIMITED SLIP DIFFERENTIAL

PRECAUTIONS .......................................................... 3

Limited Slip Differential (LSD) Performance Judge-

ment ......................................................................... 3

METHOD FOR TROUBLESHOOTING ................. 3

Service Notice or Precautions .................................. 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 5

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 7

NVH Troubleshooting Chart ..................................... 7

DESCRIPTION ............................................................ 8

Cross-Sectional View ............................................... 8

DIFFERENTIAL GEAR OIL ........................................ 9

Changing Differential Gear Oil ................................. 9

DRAINING ............................................................. 9

FILLING ................................................................. 9

Checking Differential Gear Oil .................................. 9

OIL LEAKAGE AND OIL LEVEL ........................... 9

FRONT OIL SEAL .................................................... 10

Removal and Installation ........................................ 10

REMOVAL ........................................................... 10

INSTALLATION .................................................... 11

CARRIER COVER .................................................... 13

Removal and Installation ........................................ 13

REMOVAL ........................................................... 13

INSTALLATION ................................................... 13

REAR FINAL DRIVE ASSEMBLY ............................ 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 14

Disassembly and Assembly ................................... 15

COMPONENTS .................................................. 15

ASSEMBLY INSPECTION AND ADJUSTMENT... 16

DISASSEMBLY ................................................... 19

INSPECTION AFTER DISASSEMBLY ............... 22

SELECTION ADJUSTING WASHERS ............... 23

ASSEMBLY ......................................................... 24SERVICE DATA AND SPECIFICATIONS (SDS) ...... 31

General Specifications ............................................ 31

Inspection and Adjustment ..................................... 31

PRELOAD TORQUE ........................................... 31

BACKLASH ......................................................... 31

COMPANION FLANGE RUNOUT ....................... 31

SELECTIVE PARTS ............................................ 32

WITH ELECTRONIC LOCKING DIFFEREN-

TIAL

PRECAUTIONS ........................................................ 33

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” ................................................................. 33

Precautions for Differential Case Assembly and Dif-

ferential Lock Control Unit Replacement ................ 33

CHECK DIFF LOCK INDICATOR LAMP ............. 33

METHOD FOR ADJUSTMENT ........................... 34

Precautions ............................................................. 34

Service Notice or Precaution .................................. 35

Wiring Diagrams and Trouble Diagnosis ................ 35

PREPARATION ......................................................... 36

Special Service Tools ............................................. 36

Commercial Service Tools ...................................... 37

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .............................................. 39

NVH Troubleshooting Chart ................................... 39

DIFFERENTIAL GEAR OIL ...................................... 40

Changing Differential Gear Oil ................................ 40

DRAINING ........................................................... 40

FILLING ............................................................... 40

Checking Differential Gear Oil ................................ 40

OIL LEAKAGE AND OIL LEVEL ......................... 40

DIFFERENTIAL LOCK SYSTEM .............................. 41

Cross-sectional View .............................................. 41

Differential Lock Operation ..................................... 42

System Description ................................................. 42

DIFFERENTIAL LOCK SOLENOID .................... 42

DIFFERENTIAL LOCK POSITION SWITCH ....... 42

Page 2736 of 3171

![NISSAN NAVARA 2005 Repair Repair Manual PRECAUTIONS

RFD-33

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH ELECTRONIC LOCKING DIFFERENTIAL]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “A NISSAN NAVARA 2005 Repair Repair Manual PRECAUTIONS

RFD-33

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH ELECTRONIC LOCKING DIFFERENTIAL]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “A](/img/5/57362/w960_57362-2735.png)

PRECAUTIONS

RFD-33

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH ELECTRONIC LOCKING DIFFERENTIAL]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EDS003IE

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Differential Case Assembly and Differential Lock Control Unit

Replacement

EDS003AG

lWhen replacing differential case assembly or differential lock control unit, check the DIFF LOCK indicator

pattern and adjustment of the position between differential case assembly and differential lock control unit

if necessary.

CHECK DIFF LOCK INDICATOR LAMP

1. Start engine. Run engine for at least 10 seconds.

2. Turn 4WD shift switch to “4LO” and confirm 4LO indicator lamp is turned on. Refer toTF-16, "

4WD SHIFT

SWITCH AND INDICATOR LAMP".

3. Stop vehicle and turn differential lock mode switch to “ON”.

4. Drive vehicle at 7 km/h (4 MPH) or less.

NOTE:

Differential case assembly must be given a rotation from rear left wheel and rear right wheel.

5. Check if DIFF LOCK indicator lamp flashes to turn on.

6. Check if DIFF LOCK indicator lamp and 4LO indicator lamp are changed properly as follows.

lIf each indication and state is OK, rear final drive assembly and differential lock control unit is working cor-

rectly.

lIf each indication and state is NG, rear final drive assembly and differential lock control unit is not working

correctly. Refer toRFD-34, "

METHOD FOR ADJUSTMENT".

Differential lock mode

switch4LO indicator lamp Vehicle speed (VSS)Differential case assem-

bly stateDIFF LOCK indicator

lamp

ONOFF7 km/h (4 MPH) < VSS

Disengage Flash VSS£7km/h(4MPH)

ON7 km/h (4 MPH) < VSS

VSS£7 km/h (4 MPH) Disengage®Engage Flash®ON

OFFOFF7 km/h (4 MPH) < VSS

Disengage OFF VSS£7km/h(4MPH)

ON7 km/h (4 MPH) < VSS

VSS£7km/h(4MPH)

Page 2818 of 3171

SB-1

SEAT BELTS

H RESTRAINTS

CONTENTS

C

D

E

F

G

I

J

K

L

M

SECTIONSB

A

B

SB

SEAT BELTS

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 2

Precautions for Seat Belt Service ............................ 2

AFTER A COLLISION ........................................... 2

SEAT BELTS .............................................................. 3

Removal and Installation of Front Seat Belt - King

Cab ........................................................................... 3

REMOVAL OF SEAT BELT RETRACTOR ............ 4

INSTALLATION OF SEAT BELT RETRACTOR..... 4

REMOVAL OF SEAT BELT BUCKLE .................... 4

INSTALLATION OF SEAT BELT BUCKLE ............ 4

Removal and Installation of Front Seat Belt - Double

Cab ........................................................................... 5

REMOVAL OF SEAT BELT RETRACTOR ............ 6

INSTALLATION OF SEAT BELT RETRACTOR..... 6

REMOVAL OF SEAT BELT BUCKLE .................... 6

INSTALLATION OF SEAT BELT BUCKLE ............ 6

Removal and Installation of Rear Seat Belt - King

Cab ........................................................................... 7

REMOVAL ............................................................. 8

INSTALLATION ..................................................... 8

REMOVAL OF SEAT BELT BUCKLE .................... 8

INSTALLATION OF SEAT BELT BUCKLE ............ 8

Removal and Installation of Rear Seat Belt - DoubleCab ........................................................................... 9

REMOVAL OF SEAT BELT RETRACTOR - OUT-

BOARD ................................................................ 10

INSTALLATION OF SEAT BELT RETRACTOR -

OUTBOARD ........................................................ 10

REMOVALOFSEATBELTRETRACTOR-CEN-

TER ..................................................................... 10

INSTALLATION OF SEAT BELT RETRACTOR -

CENTER .............................................................. 10

REMOVAL OF SEAT BELT BUCKLE .................. 10

INSTALLATION OF SEAT BELT BUCKLE .......... 10

Seat Belt Inspection ................................................ 11

AFTER A COLLISION ......................................... 11

PRELIMINARY CHECKS .................................... 11

SEAT BELT RETRACTOR ON-VEHICLE

CHECK ................................................................ 12

SEAT BELT RETRACTOR OFF-VEHICLE

CHECK ................................................................ 12

SEAT BELT WARNING SYSTEM ............................. 14

Description .............................................................. 14

LATCH (LOWER ANCHORS AND TETHER FOR

CHILDREN) SYSTEM ............................................... 15

Removal and Installation - Double Cab .................. 15

TOP TETHER STRAP CHILD RESTRAINT ............. 16

Removal and Installation - Double Cab .................. 16

Page 2819 of 3171

SB-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EHS0026D

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Seat Belt ServiceEHS00265

CAUTION:

lBefore removing the seat belt pre-tensioner assembly, turn the ignition switch OFF, disconnect

both battery cables and wait at least 3 minutes.

lDo not use electrical test equipment for seat belt pre-tensioner connector.

lAfter replacing or reinstalling seat belt pre-tensioner assembly, or reconnecting seat belt pre-

tensioner assembly connector, ensure entire SRS operates properly. Refer toSRS-18, "

SRS Oper-

ation Check".

lDeploy seat belt pre-tensioner assembly before disposing. Refer toSRS-49, "DISPOSAL OF AIR

BAG MODULE AND SEAT BELT PRE-TENSIONER".

lDo not disassemble buckle or seat belt assembly.

lReplace anchor bolts if they are deformed or worn out.

lNever oil tongue and buckle.

lIf any component of seat belt assembly is questionable, do not repair. Replace the whole seat belt

assembly.

lIf webbing is cut, frayed, or damaged, replace seat belt assembly.

lWhen replacing seat belt assembly, use a genuine NISSAN seat belt assembly.

AFTER A COLLISION

WARNING:

lInspect all seat belt assemblies including retractors and attaching hardware after any collision.

lNISSAN recommends that all seat belt assemblies in use during a collision be replaced unless the

collision was minor and the belts show no damage and continue to operate properly. Failure to do

so could result in serious personal injury in an accident. Seat belt assemblies not in use during a

collision should also be replaced if either damage or improper operation is noted. Seat belt pre-

tensioner should be replaced even if the seat belts are not in use during a frontal collision in which

the air bags are deployed.

Replace any seat belt assembly (including anchor bolts) if:

lThe seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and

buckles show no damage and continue to operate properly).

lThe seat belt was damaged in an accident. (i.e., torn webbing, bent retractor or guide, etc.)

lThe seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for damage

or distortion and repair as necessary before installing a new seat belt assembly.

lAnchor bolts are deformed or worn out.

lThe seat belt pre-tensioner should be replaced even if the seat belts are not in use during the collision in

which the air bags are deployed.

Page 2821 of 3171

SB-4

SEAT BELTS

REMOVALOFSEATBELTRETRACTOR

CAUTION:

lBefore servicing SRS, turn the ignition switch off, disconnect both battery cables and wait at least

3 minutes.

1. Remove the rear door finishers. Refer toEI-30, "

DOOR FINISHER".

2. Remove the seat belt retractor and belt bolts and assembly.

lOn RH side, disconnect the seat belt tension sensor.

3. Disconnect the seat belt pre-tensioner electrical connector.

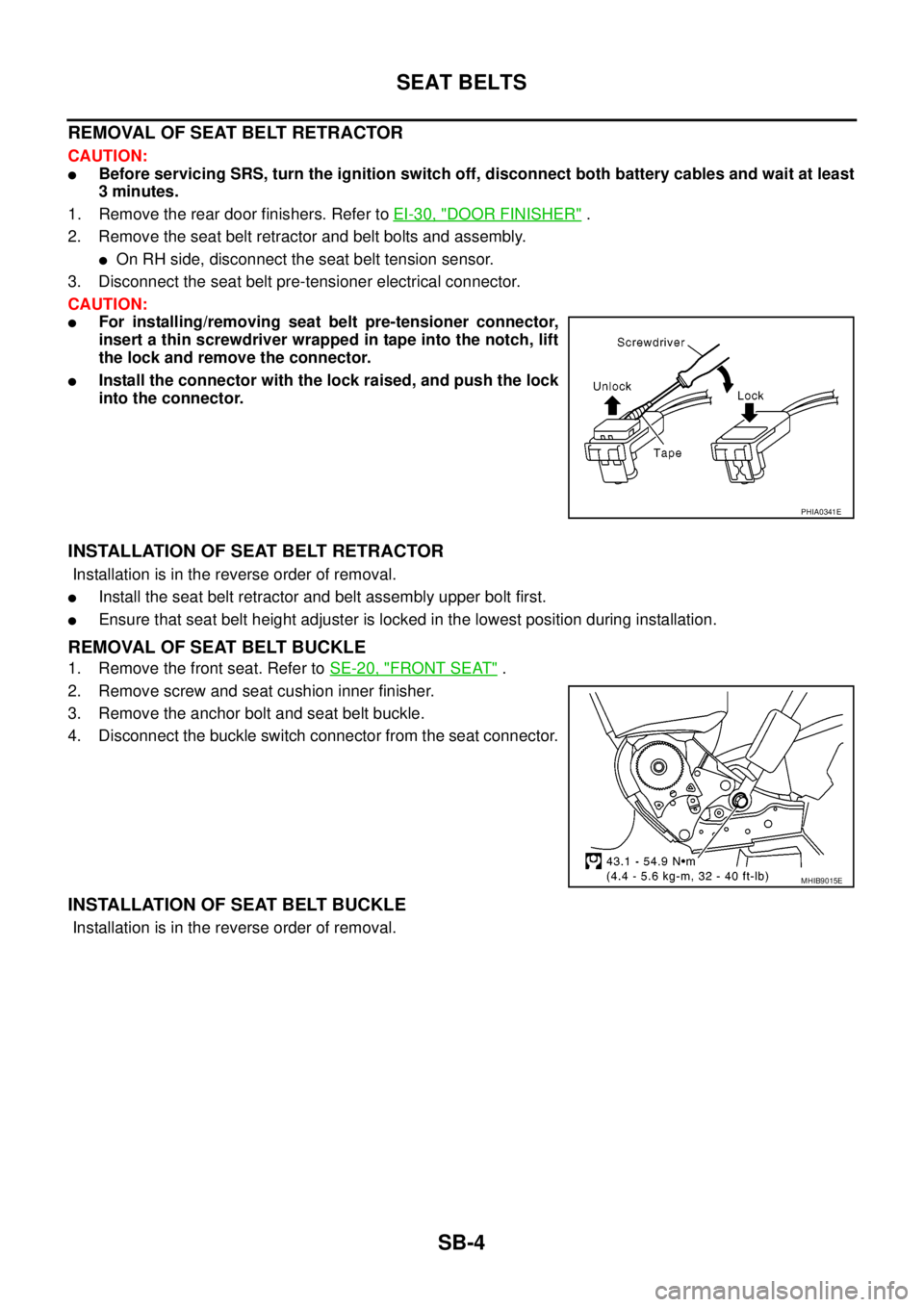

CAUTION:

lFor installing/removing seat belt pre-tensioner connector,

insert a thin screwdriver wrapped in tape into the notch, lift

the lock and remove the connector.

lInstall the connector with the lock raised, and push the lock

into the connector.

INSTALLATION OF SEAT BELT RETRACTOR

Installation is in the reverse order of removal.

lInstall the seat belt retractor and belt assembly upper bolt first.

lEnsure that seat belt height adjuster is locked in the lowest position during installation.

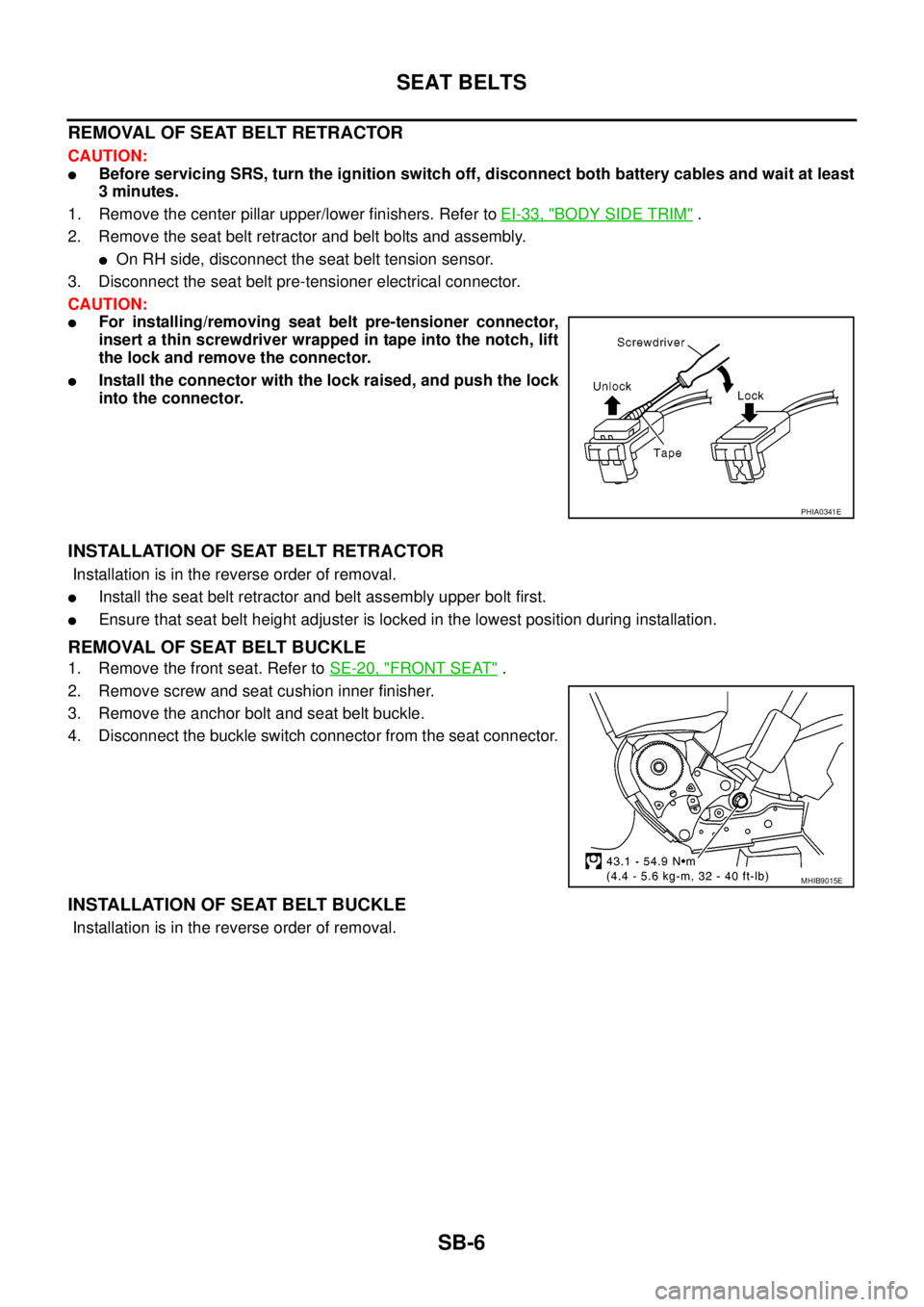

REMOVAL OF SEAT BELT BUCKLE

1. Remove the front seat. Refer toSE-20, "FRONT SEAT".

2. Remove screw and seat cushion inner finisher.

3. Remove the anchor bolt and seat belt buckle.

4. Disconnect the buckle switch connector from the seat connector.

INSTALLATION OF SEAT BELT BUCKLE

Installation is in the reverse order of removal.

PHIA0341E

MHIB9015E

Page 2823 of 3171

SB-6

SEAT BELTS

REMOVALOFSEATBELTRETRACTOR

CAUTION:

lBefore servicing SRS, turn the ignition switch off, disconnect both battery cables and wait at least

3 minutes.

1. Remove the center pillar upper/lower finishers. Refer toEI-33, "

BODY SIDE TRIM".

2. Remove the seat belt retractor and belt bolts and assembly.

lOn RH side, disconnect the seat belt tension sensor.

3. Disconnect the seat belt pre-tensioner electrical connector.

CAUTION:

lFor installing/removing seat belt pre-tensioner connector,

insert a thin screwdriver wrapped in tape into the notch, lift

the lock and remove the connector.

lInstall the connector with the lock raised, and push the lock

into the connector.

INSTALLATION OF SEAT BELT RETRACTOR

Installation is in the reverse order of removal.

lInstall the seat belt retractor and belt assembly upper bolt first.

lEnsure that seat belt height adjuster is locked in the lowest position during installation.

REMOVAL OF SEAT BELT BUCKLE

1. Remove the front seat. Refer toSE-20, "FRONT SEAT".

2. Remove screw and seat cushion inner finisher.

3. Remove the anchor bolt and seat belt buckle.

4. Disconnect the buckle switch connector from the seat connector.

INSTALLATION OF SEAT BELT BUCKLE

Installation is in the reverse order of removal.

PHIA0341E

MHIB9015E

Page 2828 of 3171

SEAT BELTS

SB-11

C

D

E

F

G

I

J

K

L

MA

B

SB

Seat Belt InspectionEHS0026A

AFTER A COLLISION

WARNING:

Inspect all seat belt assemblies including retractors and attaching hardware after any collision.

NISSAN recommends that all seat belt assemblies in use during a collision be replaced unless the col-

lision was minor and the belts show no damage and continue to operate properly. Failure to do so

could result in serious personal injury in an accident. Seat belt assemblies not in use during a colli-

sion should also be replaced if either damage or improper operation is noted. Seat belt pre-tensioners

should be replaced even if the seat belts are not in use during a frontal collision in which the air bags

are deployed.

Replace any seat belt assembly (including anchor bolts) if:

lThe seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and

buckles show no damage and continue to operate properly).

lThe seat belt was damaged in an accident. (i.e. torn webbing, bent retractor or guide).

lThe seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for damage

or distortion and repair as necessary before installing a new seat belt assembly.

lAnchor bolts are deformed or worn out.

lThe seat belt pre-tensioner should be replaced even if the seat belts are not in use during the collision in

which the air bags are deployed.

PRELIMINARY CHECKS

1. Check the seat belt warning lamp for proper operation as follows:

a. Switch ignition ON. The seat belt warning lamp should illuminate.

b. Fasten driver's seat belt. The seat belt warning lamp should go out. If warning lamp remains illuminated,

Refer toDI-28, "

WARNING LAMPS".

2. If the air bag warning lamp is blinking, conduct self-diagnosis using CONSULT-II, and air bag warning

lamp. Refer toSRS-18, "

SRS Operation Check".

3. Check that the seat belt retractor, seat belt anchor and buckle bolts are securely attached.

4. Check the shoulder seat belt guide and shoulder belt height adjuster for front seats. Ensure guide swivels

freely and that belt lays flat and does not bind in guide. Ensure height adjuster operates properly and

holds securely.

5. Check retractor operation:

a. Fully extend the seat belt webbing and check for twists, tears or other damage.

b. Allow the seat belt to retract. Ensure that belt returns smoothly and completely into the retractor. If the

seat belt does not return smoothly, wipe the inside of the loops with a clean paper cloth, because dirt built

up in the loops of the upper anchors can cause the seat belts to retract slowly.

c. Fasten the seat belt. Check the seat belt returns smoothly and completely to the retractor. If the belt does

not return smoothly, the cause may be an accumulation of dust or dirt. Use the “SEAT BELT TAPE SET”

and perform the following steps.

Inspect the front seat belt through-anchor:

1. Pull the seat belt out to a length of 500 mm (19.69 in) or more.

2. Use a clip or other device to hold the seat belt at the center pillar belt opening.

3. Pass a thin wire through the through-anchor belt opening. Hold both ends of the wire and pull taut while

moving it up and down several times along the belt opening surface to remove dirt.

4. Any dirt that cannot be removed with the wire can be removed by cleaning the opening with a clean

cloth.

5. Apply tape at the point where the belt contacts the through-anchor belt opening.

NOTE:

Apply the tape so that there is no looseness or wrinkling.

6. Remove the clip holding the seat belt and check that the belt returns smoothly.

7. Repeat steps above as necessary to check the other seat belts.