ECO mode NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 771 of 3171

NATS(NISSAN ANTI-THEFT SYSTEM)

BL-187

C

D

E

F

G

H

J

K

L

MA

B

BL

Diagnostic Procedure 6EIS00DB6

Self-diagnostic results:

“LOCK MODE” displayed on CONSULT-II screen

1.CONFIRM SELF-DIAGNOSTIC RESULTS

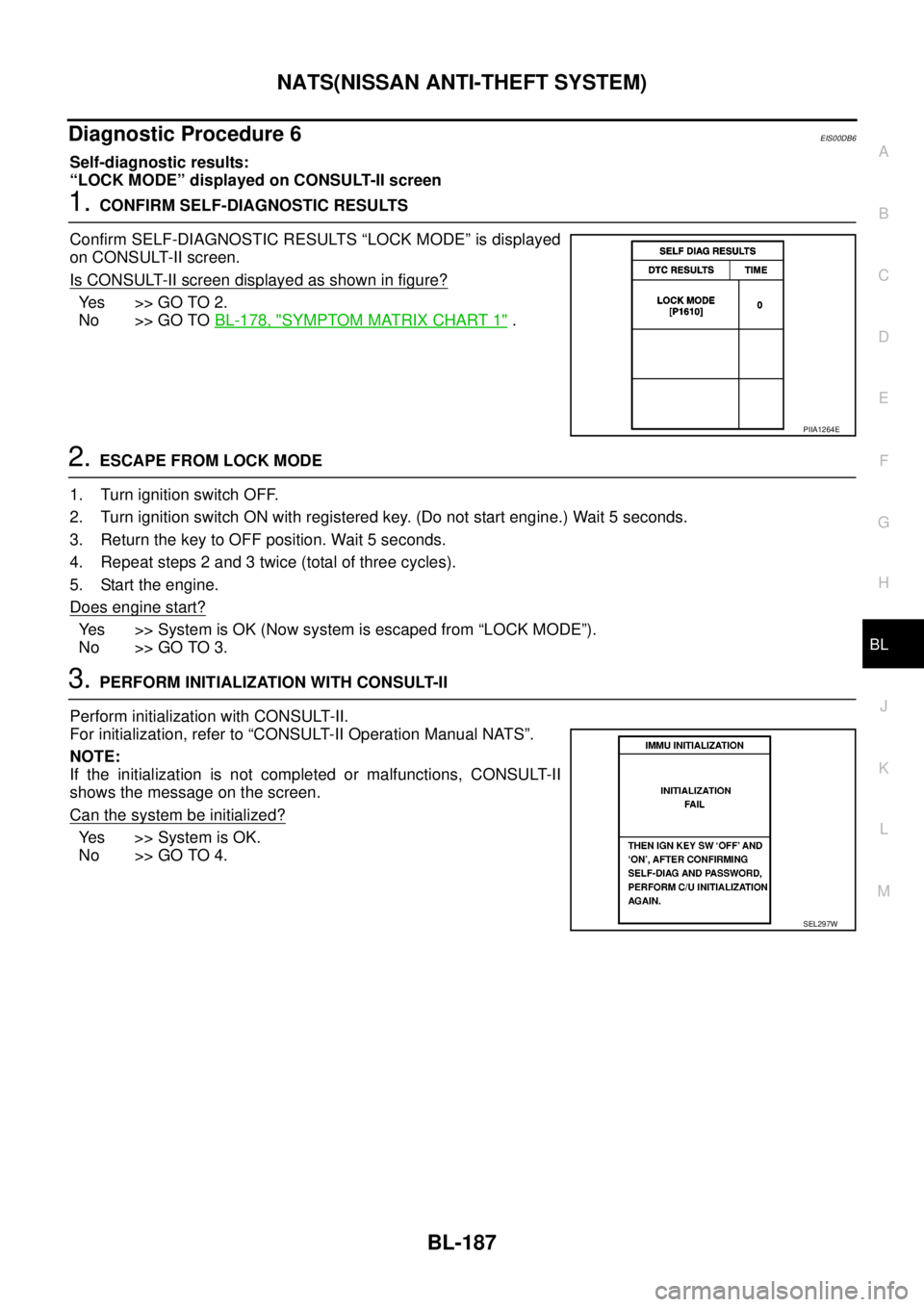

Confirm SELF-DIAGNOSTIC RESULTS “LOCK MODE” is displayed

on CONSULT-II screen.

Is CONSULT-II screen displayed as shown in figure?

Ye s > > G O T O 2 .

No >> GO TOBL-178, "

SYMPTOM MATRIX CHART 1".

2.ESCAPE FROM LOCK MODE

1. Turn ignition switch OFF.

2. Turn ignition switch ON with registered key. (Do not start engine.) Wait 5 seconds.

3. Return the key to OFF position. Wait 5 seconds.

4. Repeat steps 2 and 3 twice (total of three cycles).

5. Start the engine.

Does engine start?

Yes >>SystemisOK(Nowsystemisescapedfrom“LOCKMODE”).

No >> GO TO 3.

3.PERFORM INITIALIZATION WITH CONSULT-II

Perform initialization with CONSULT-II.

For initialization, refer to “CONSULT-II Operation Manual NATS”.

NOTE:

If the initialization is not completed or malfunctions, CONSULT-II

shows the message on the screen.

Can the system be initialized?

Yes >>SystemisOK.

No >> GO TO 4.

PIIA1264E

SEL297W

Page 821 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-35

C

D

E

G

H

I

J

K

L

MA

B

BR

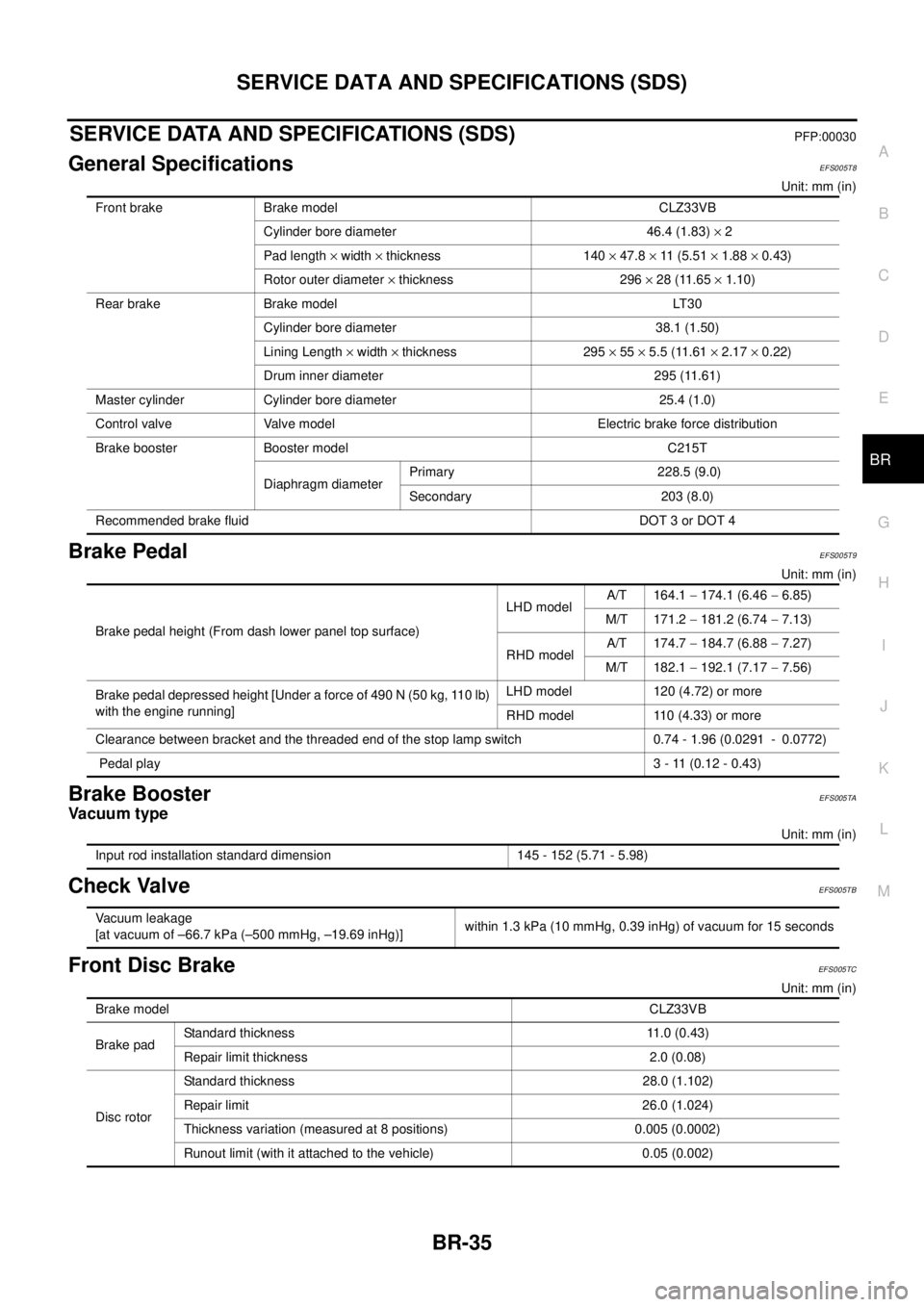

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsEFS005T8

Unit: mm (in)

Brake PedalEFS005T9

Unit: mm (in)

Brake BoosterEFS005TA

Va c u u m t y p e

Unit: mm (in)

Check ValveEFS005TB

Front Disc BrakeEFS005TC

Unit: mm (in) Front brake Brake model CLZ33VB

Cylinder bore diameter 46.4 (1.83)´2

Pad length´width´thickness 140´47.8´11 ( 5 . 5 1´1.88´0.43)

Rotor outer diameter´thickness 296´28 (11.65´1.10)

Rear brake Brake model LT30

Cylinder bore diameter 38.1 (1.50)

Lining Length´width´thickness 295´55´5.5 (11.61´2.17´0.22)

Drum inner diameter 295 (11.61)

Master cylinder Cylinder bore diameter 25.4 (1.0)

Control valve Valve model Electric brake force distribution

Brake booster Booster model C215T

Diaphragm diameterPrimary 228.5 (9.0)

Secondary 203 (8.0)

Recommended brake fluid DOT 3 or DOT 4

Brake pedal height (From dash lower panel top surface)LHD modelA/T 164.1-174.1 (6.46-6.85)

M/T 171.2-181.2 (6.74-7.13)

RHD modelA/T 174.7-184.7 (6.88-7.27)

M/T 182.1-192.1 (7.17-7.56)

Brake pedal depressed height [Under a force of 490 N (50 kg, 110 lb)

with the engine running]LHD model 120 (4.72) or more

RHD model 110 (4.33) or more

Clearance between bracket and the threaded end of the stop lamp switch 0.74 - 1.96 (0.0291 - 0.0772)

Pedal play3-11(0.12-0.43)

Input rod installation standard dimension 145 - 152 (5.71 - 5.98)

Vacuum leakage

[at vacuum of –66.7 kPa (–500 mmHg, –19.69 inHg)]within 1.3 kPa (10 mmHg, 0.39 inHg) of vacuum for 15 seconds

Brake modelCLZ33VB

Brake padStandard thickness 11.0 (0.43)

Repair limit thickness 2.0 (0.08)

Disc rotorStandard thickness 28.0 (1.102)

Repair limit 26.0 (1.024)

Thickness variation (measured at 8 positions) 0.005 (0.0002)

Runout limit (with it attached to the vehicle) 0.05 (0.002)

Page 872 of 3171

CL-8

CLUTCH FLUID

CLUTCH FLUID

PFP:00017

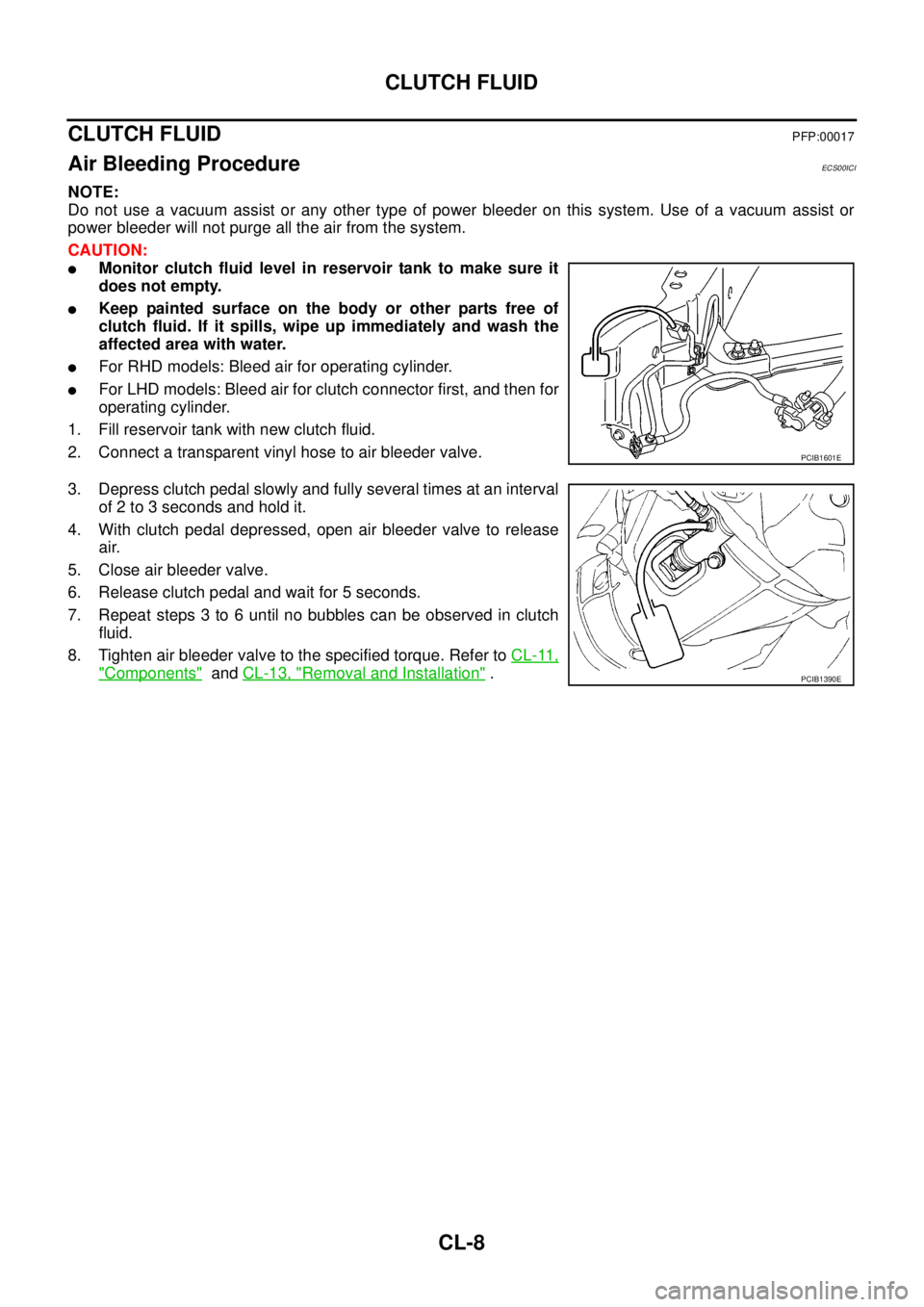

Air Bleeding ProcedureECS00ICI

NOTE:

Do not use a vacuum assist or any other type of power bleeder on this system. Use of a vacuum assist or

power bleeder will not purge all the air from the system.

CAUTION:

lMonitor clutch fluid level in reservoir tank to make sure it

does not empty.

lKeep painted surface on the body or other parts free of

clutch fluid. If it spills, wipe up immediately and wash the

affected area with water.

lFor RHD models: Bleed air for operating cylinder.

lFor LHD models: Bleed air for clutch connector first, and then for

operating cylinder.

1. Fill reservoir tank with new clutch fluid.

2. Connect a transparent vinyl hose to air bleeder valve.

3. Depress clutch pedal slowly and fully several times at an interval

of 2 to 3 seconds and hold it.

4. With clutch pedal depressed, open air bleeder valve to release

air.

5. Close air bleeder valve.

6. Release clutch pedal and wait for 5 seconds.

7. Repeat steps 3 to 6 until no bubbles can be observed in clutch

fluid.

8. Tighten air bleeder valve to the specified torque. Refer toCL-11,

"Components"andCL-13, "Removal and Installation".

PCIB1601E

PCIB1390E

Page 893 of 3171

ENGINE COOLANT

CO-9

C

D

E

F

G

H

I

J

K

L

MA

CO

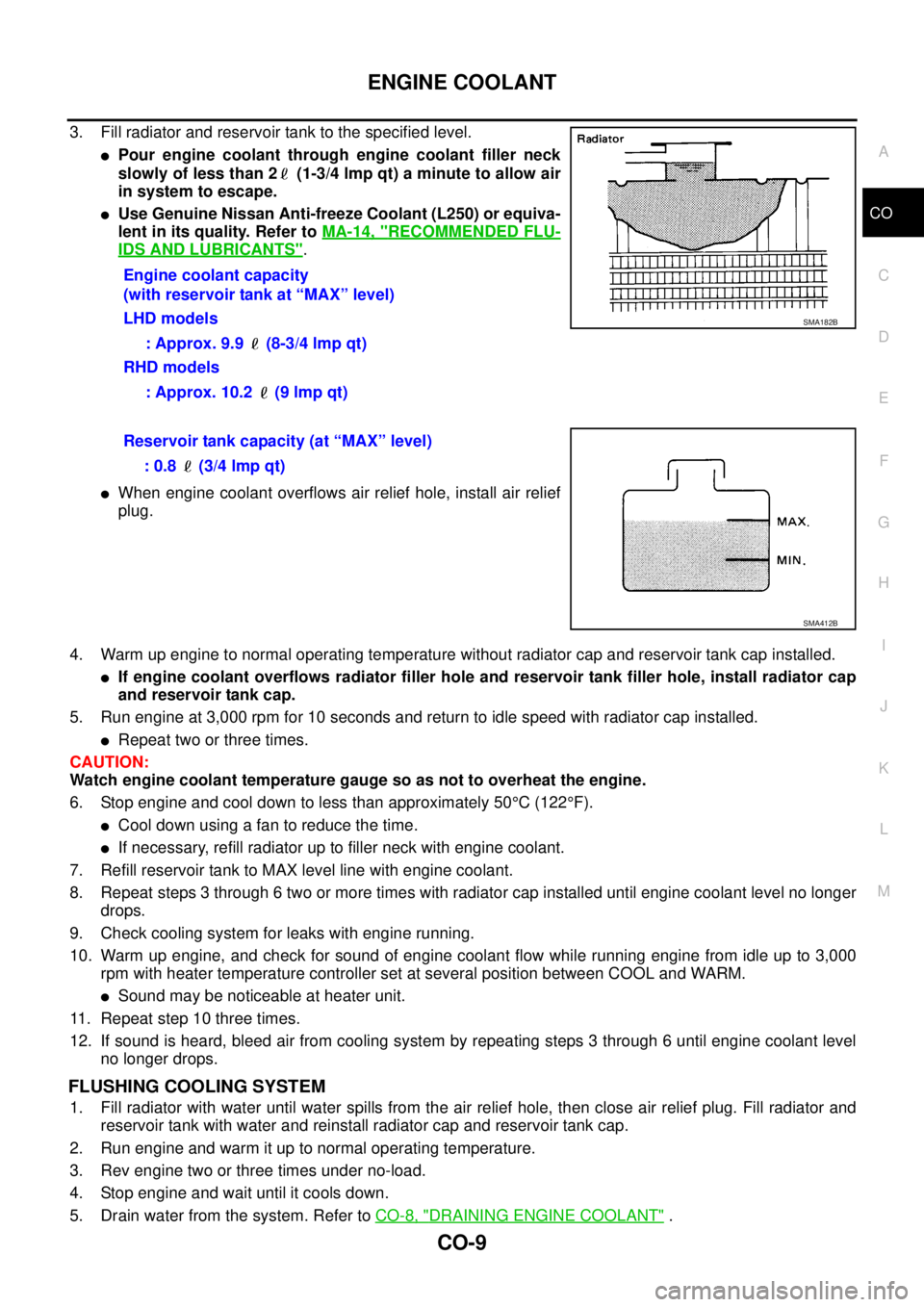

3. Fill radiator and reservoir tank to the specified level.

lPour engine coolant through engine coolant filler neck

slowly of less than 2 (1-3/4 lmp qt) a minute to allow air

in system to escape.

lUse Genuine Nissan Anti-freeze Coolant (L250) or equiva-

lent in its quality. Refer toMA-14, "

RECOMMENDED FLU-

IDS AND LUBRICANTS".

lWhen engine coolant overflows air relief hole, install air relief

plug.

4. Warm up engine to normal operating temperature without radiator cap and reservoir tank cap installed.

lIf engine coolant overflows radiator filler hole and reservoir tank filler hole, install radiator cap

and reservoir tank cap.

5. Run engine at 3,000 rpm for 10 seconds and return to idle speed with radiator cap installed.

lRepeat two or three times.

CAUTION:

Watch engine coolant temperature gauge so as not to overheat the engine.

6. Stop engine and cool down to less than approximately 50°C(122°F).

lCool down using a fan to reduce the time.

lIf necessary, refill radiator up to filler neck with engine coolant.

7. Refill reservoir tank to MAX level line with engine coolant.

8. Repeat steps 3 through 6 two or more times with radiator cap installed until engine coolant level no longer

drops.

9. Check cooling system for leaks with engine running.

10. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.

11. Repeat step 10 three times.

12. If sound is heard, bleed air from cooling system by repeating steps 3 through 6 until engine coolant level

no longer drops.

FLUSHING COOLING SYSTEM

1. Fill radiator with water until water spills from the air relief hole, then close air relief plug. Fill radiator and

reservoir tank with water and reinstall radiator cap and reservoir tank cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water from the system. Refer toCO-8, "

DRAINING ENGINE COOLANT". Engine coolant capacity

(with reservoir tank at “MAX” level)

LHD models

: Approx. 9.9 (8-3/4 lmp qt)

RHD models

: Approx. 10.2 (9 lmp qt)

SMA182B

Reservoir tank capacity (at “MAX” level)

: 0.8 (3/4 lmp qt)

SMA412B

Page 915 of 3171

COMBINATION METERS

DI-5

C

D

E

F

G

H

I

J

L

MA

B

DI

FUEL GAUGE

The fuel gauge indicates the approximate fuel level in the fuel tank.

Combination meter reads a resistor signal from fuel level sensor unit.

Signal is supplied

lto combination meter terminal 9

lthrough fuel level sensor unit terminal 1 and 2

lfrom combination meter terminal 4.

ODO/TRIP METER

lABS actuator and electric unit (control unit) converses a pulse signal from wheel sensor to vehicle speed

signal, and transmits vehicle speed signal to combination meter with CAN communication.

lCombination meter uses the vehicle speed signal to calculate the mileage, and it displays.

How to Change/ Reset Indication

lIndication can be changed in the following order by momentarily

pressing the odo/trip meter switch (1).

–Trip A®Trip B®DTE®Average fuel economy®Average

vehicle speed®Running time®Trip A ···.

lHolding the switch for more than 1 second resets displayed

mode (except DTE).

lHolding the switch for more than 3 seconds resets all functions

(except trip A and DTE).

NOTE:

lAfter the display changes automatically, the indication can be

changed to the next mode by pressing the odo/trip meter switch.

lThe record of the odometer is kept even if the battery cable is disconnected.

TRIP COMPUTER

Function

The trip computer can indicate the following items.

lDTE (distance to empty)

lAverage fuel economy

lAverage vehicle speed

lRunning time

DTE (Distance to Empty) Indication

The DTE indication provides the driver with the distance estimation that can be driven before refueling. The

DTE is calculated by signals from the fuel level sensor unit (fuel remaining), ECM (fuel consumption) and ABS

actuator and electric unit (control unit) (vehicle speed). The indication is refreshed every 30 seconds. When

fuel remaining is less than approximately 11.6 (2 1/2 Imp gal), the indication blinks as a warning. If the fuel

remaining is less than approximately 9.6 (2 1/8 Imp gal), the indication shows “---”. In this case, the display

changes to the DTE mode from the different mode. When the battery cable is disconnected and reconnected,

DTE mode displays “---” until the vehicle is driven 0.5 km.

Average Vehicle Speed Indication

Average vehicle speed indication is calculated by running distance and running time. The indication is

refreshed every 30 seconds. If average vehicle speed is reset, average fuel consumption is reset at the same

time. At about 0.5 km and for 30 seconds after resetting, the display shows “- ”®“- ”®“-”®“ -”.

Average Fuel Economy Indication

Average fuel consumption indication is calculated by signals from ABS actuator and electric unit (vehicle

speed) and the ECM (fuel consumption). The indication is refreshed every 30 seconds. At about 0.5 km and

for 30 seconds after resetting, the display shows “- ”®“- ”®“-”®“ -”.

Running Time Indication

Trip time displays ignition switch ON time cumulatively. If trip time is reset, trip distance is reset at the same

time.

SKIB4848E

Page 916 of 3171

DI-6

COMBINATION METERS

ENGINE OIL MAINTENANCE INFORMATION

lEngine oil maintenance information displays maintenance intervals of engine oil.

lWith ignition switch ON position, engine oil maintenance information is displayed on odo/trip meter display

for 5 seconds.

NOTE:

Refer to Owner's Manual for setting.

METER ILLUMINATION CONTROL

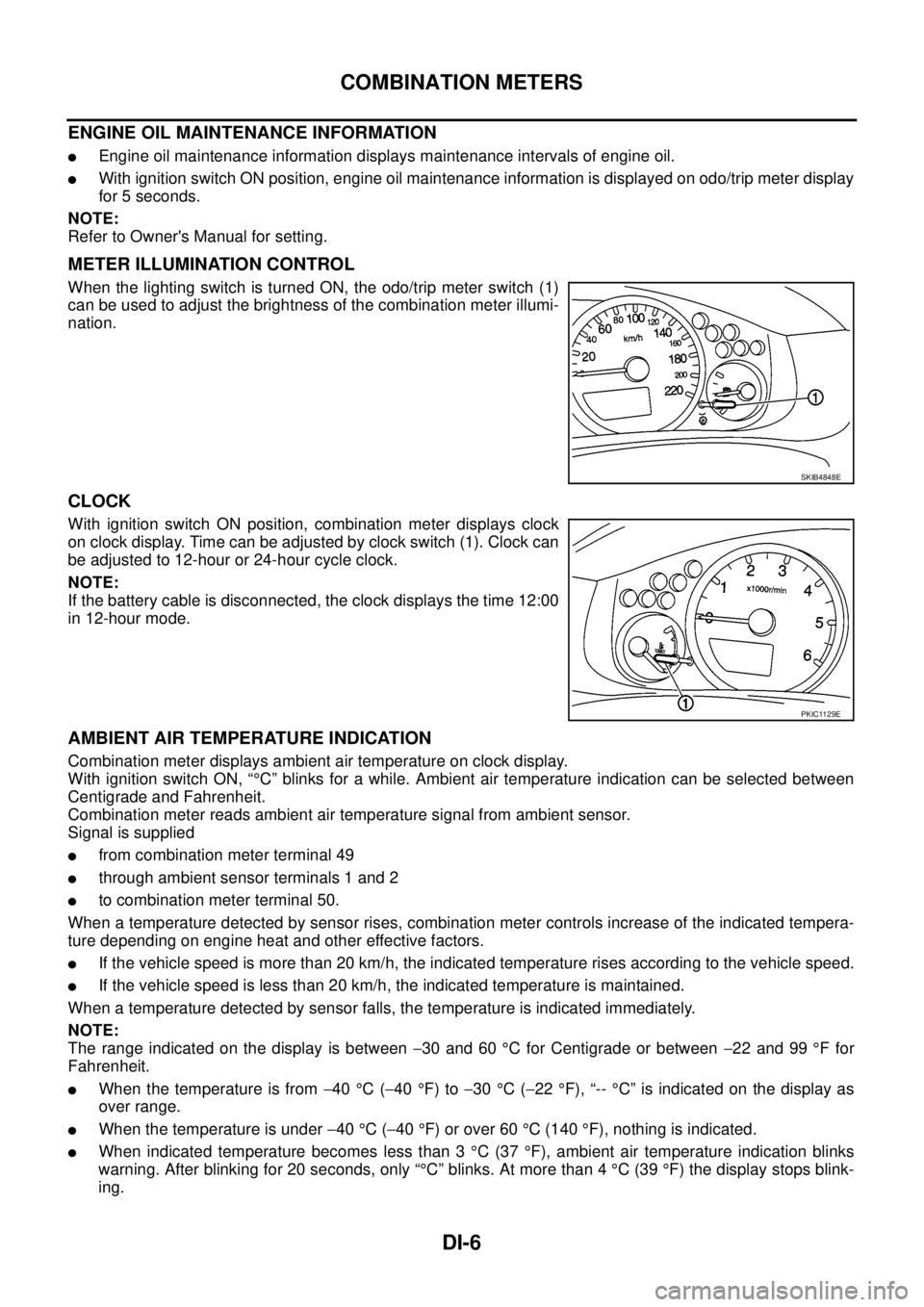

When the lighting switch is turned ON, the odo/trip meter switch (1)

can be used to adjust the brightness of the combination meter illumi-

nation.

CLOCK

With ignition switch ON position, combination meter displays clock

on clock display. Time can be adjusted by clock switch (1). Clock can

be adjusted to 12-hour or 24-hour cycle clock.

NOTE:

If the battery cable is disconnected, the clock displays the time 12:00

in 12-hour mode.

AMBIENT AIR TEMPERATURE INDICATION

Combination meter displays ambient air temperature on clock display.

With ignition switch ON, “°C” blinks for a while. Ambient air temperature indication can be selected between

Centigrade and Fahrenheit.

Combination meter reads ambient air temperature signal from ambient sensor.

Signal is supplied

lfrom combination meter terminal 49

lthrough ambient sensor terminals 1 and 2

lto combination meter terminal 50.

When a temperature detected by sensor rises, combination meter controls increase of the indicated tempera-

ture depending on engine heat and other effective factors.

lIf the vehicle speed is more than 20 km/h, the indicated temperature rises according to the vehicle speed.

lIf the vehicle speed is less than 20 km/h, the indicated temperature is maintained.

When a temperature detected by sensor falls, the temperature is indicated immediately.

NOTE:

The range indicated on the display is between-30 and 60°C for Centigrade or between-22 and 99°Ffor

Fahrenheit.

lWhen the temperature is from-40°C(-40°F) to-30°C(-22°F), “--°C” is indicated on the display as

over range.

lWhen the temperature is under-40°C(-40°F) or over 60°C(140°F), nothing is indicated.

lWhen indicated temperature becomes less than 3°C(37°F), ambient air temperature indication blinks

warning. After blinking for 20 seconds, only “°C” blinks. At more than 4°C(39°F) the display stops blink-

ing.

SKIB4848E

PKIC1129E

Page 923 of 3171

COMBINATION METERS

DI-13

C

D

E

F

G

H

I

J

L

MA

B

DI

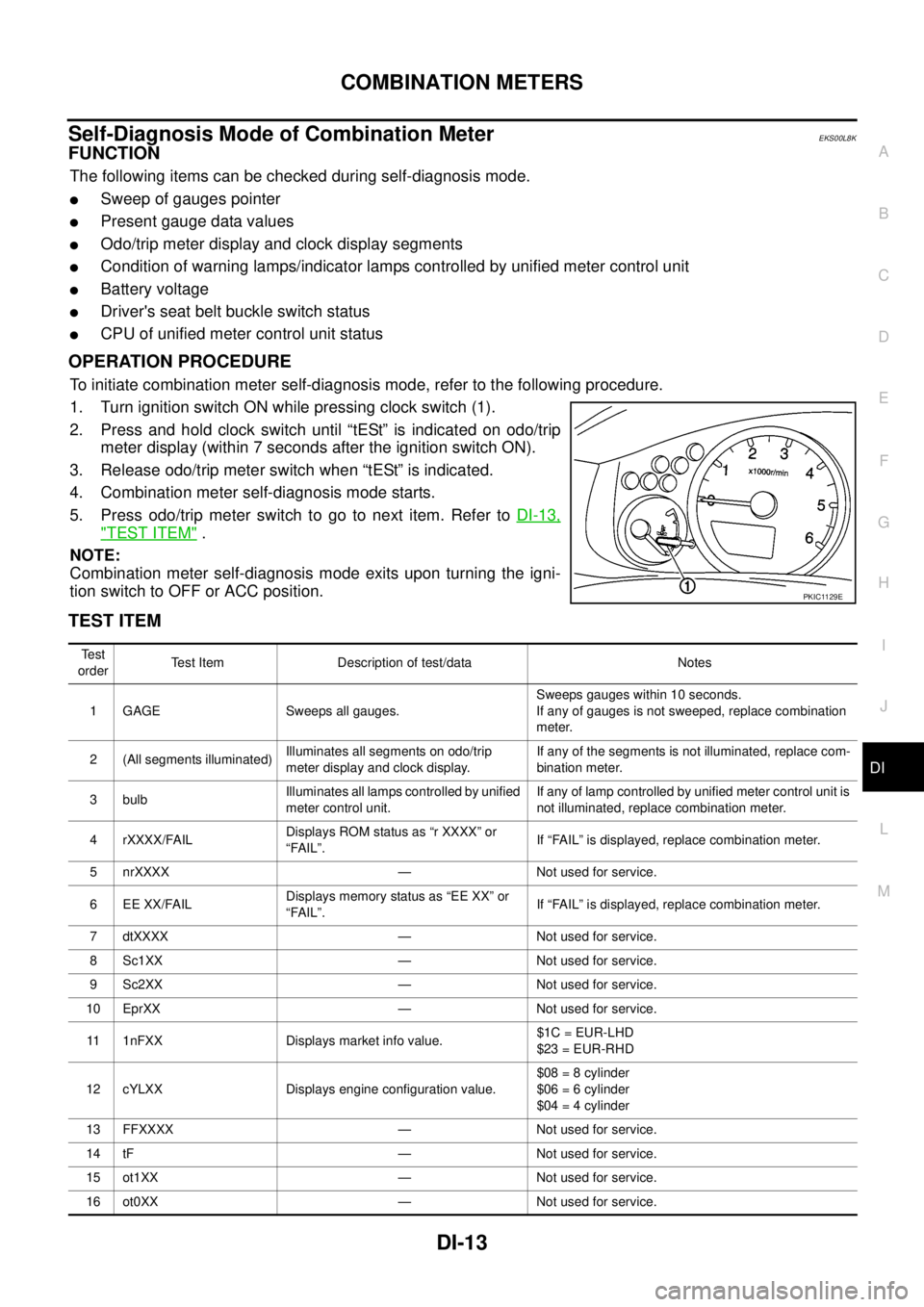

Self-Diagnosis Mode of Combination MeterEKS00L8K

FUNCTION

The following items can be checked during self-diagnosis mode.

lSweep of gauges pointer

lPresent gauge data values

lOdo/trip meter display and clock display segments

lCondition of warning lamps/indicator lamps controlled by unified meter control unit

lBattery voltage

lDriver's seat belt buckle switch status

lCPU of unified meter control unit status

OPERATION PROCEDURE

To initiate combination meter self-diagnosis mode, refer to the following procedure.

1. Turn ignition switch ON while pressing clock switch (1).

2. Press and hold clock switch until “tESt” is indicated on odo/trip

meter display (within 7 seconds after the ignition switch ON).

3. Release odo/trip meter switch when “tESt” is indicated.

4. Combination meter self-diagnosis mode starts.

5. Pressodo/tripmeterswitchtogotonextitem.RefertoDI-13,

"TEST ITEM".

NOTE:

Combination meter self-diagnosis mode exits upon turning the igni-

tion switch to OFF or ACC position.

TEST ITEM

PKIC1129E

Te s t

orderTest Item Description of test/data Notes

1 GAGE Sweeps all gauges.Sweeps gauges within 10 seconds.

If any of gauges is not sweeped, replace combination

meter.

2 (All segments illuminated)Illuminates all segments on odo/trip

meter display and clock display.If any of the segments is not illuminated, replace com-

bination meter.

3 bulbIlluminates all lamps controlled by unified

meter control unit.If any of lamp controlled by unified meter control unit is

not illuminated, replace combination meter.

4 rXXXX/FAILDisplays ROM status as “r XXXX” or

“FAIL”.If “FAIL” is displayed, replace combination meter.

5 nrXXXX — Not used for service.

6 EE XX/FAILDisplays memory status as “EE XX” or

“FAIL”.If “FAIL” is displayed, replace combination meter.

7 dtXXXX — Not used for service.

8 Sc1XX — Not used for service.

9 Sc2XX — Not used for service.

10 EprXX — Not used for service.

11 1nFXX Displays market info value.$1C = EUR-LHD

$23 = EUR-RHD

12 cYLXX Displays engine configuration value.$08 = 8 cylinder

$06 = 6 cylinder

$04 = 4 cylinder

13 FFXXXX — Not used for service.

14 tF — Not used for service.

15 ot1XX — Not used for service.

16 ot0XX — Not used for service.

Page 926 of 3171

DI-16

COMBINATION METERS

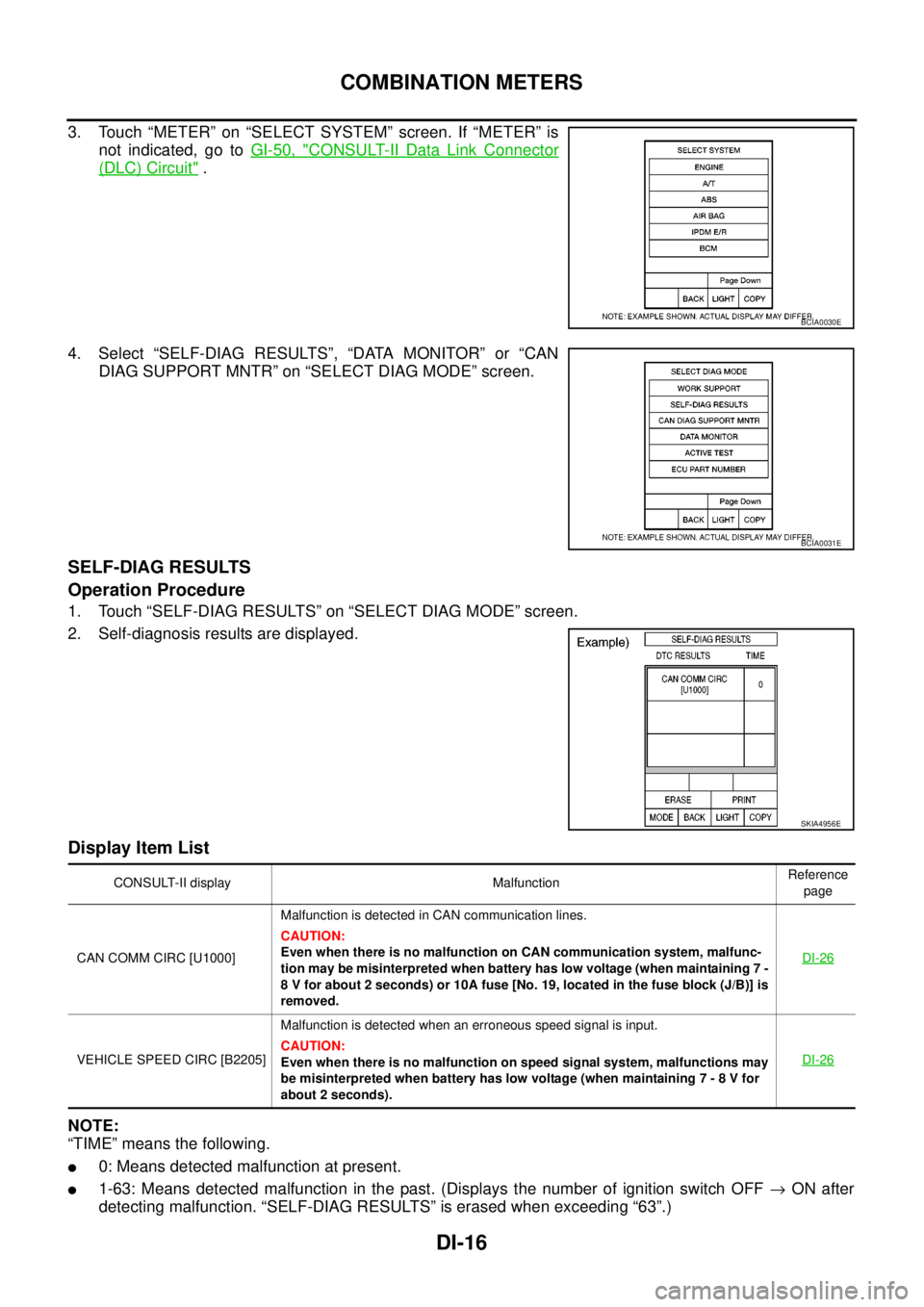

3. Touch “METER” on “SELECT SYSTEM” screen. If “METER” is

not indicated, go toGI-50, "

CONSULT-II Data Link Connector

(DLC) Circuit".

4. Select “SELF-DIAG RESULTS”, “DATA MONITOR” or “CAN

DIAG SUPPORT MNTR” on “SELECT DIAG MODE” screen.

SELF-DIAG RESULTS

Operation Procedure

1. Touch “SELF-DIAG RESULTS” on “SELECT DIAG MODE” screen.

2. Self-diagnosis results are displayed.

Display Item List

NOTE:

“TIME” means the following.

l0: Means detected malfunction at present.

l1-63: Means detected malfunction in the past. (Displays the number of ignition switch OFF®ON after

detecting malfunction. “SELF-DIAG RESULTS” is erased when exceeding “63”.)

BCIA0030E

BCIA0031E

SKIA4956E

CONSULT-II display MalfunctionReference

page

CAN COMM CIRC [U1000]Malfunction is detected in CAN communication lines.

CAUTION:

Even when there is no malfunction on CAN communication system, malfunc-

tion may be misinterpreted when battery has low voltage (when maintaining 7 -

8 V for about 2 seconds) or 10A fuse [No. 19, located in the fuse block (J/B)] is

removed.DI-26

VEHICLE SPEED CIRC [B2205]Malfunction is detected when an erroneous speed signal is input.

CAUTION:

Even when there is no malfunction on speed signal system, malfunctions may

be misinterpreted when battery has low voltage (when maintaining 7 - 8 V for

about 2 seconds).DI-26

Page 927 of 3171

COMBINATION METERS

DI-17

C

D

E

F

G

H

I

J

L

MA

B

DI

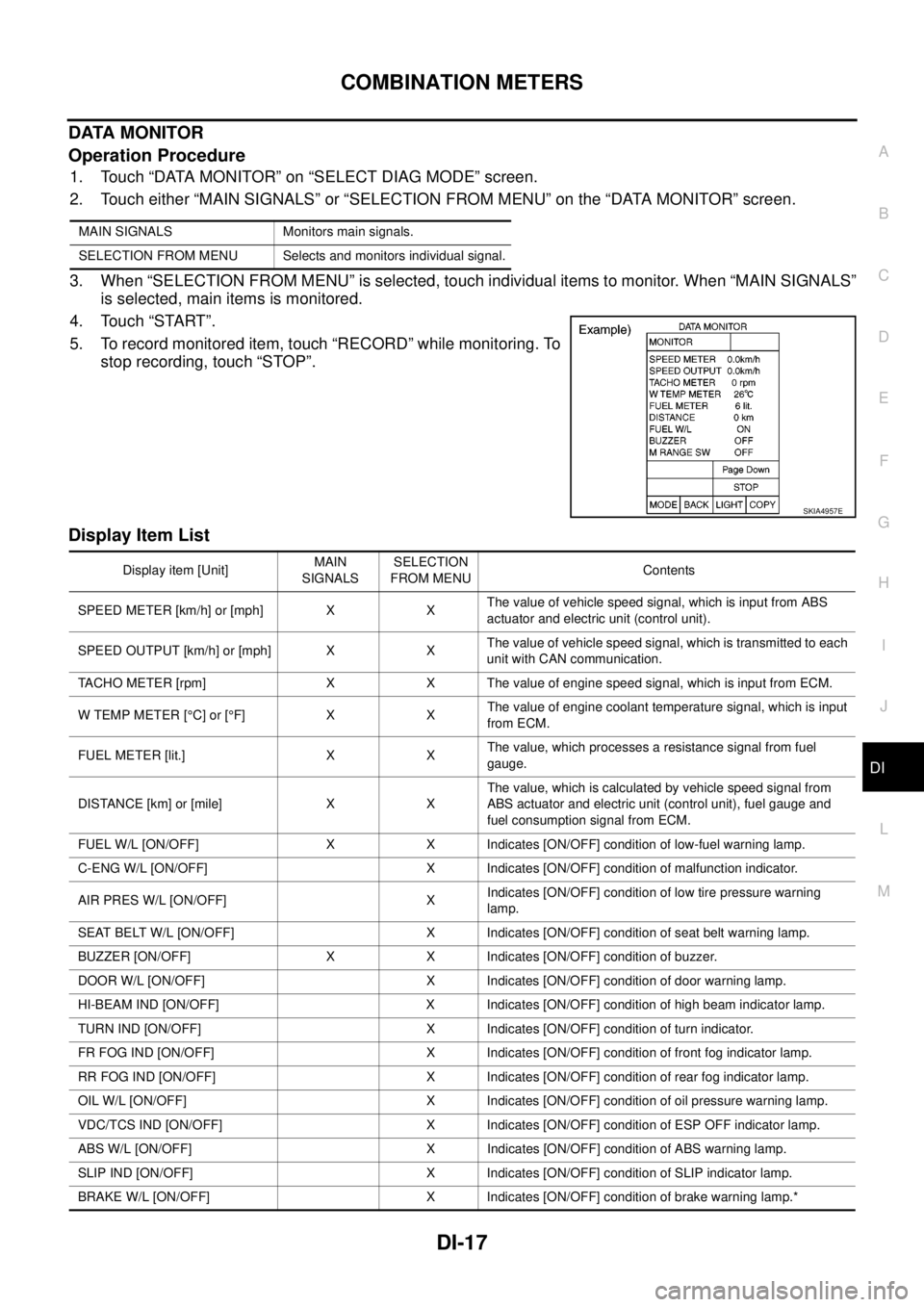

DATA MONITOR

Operation Procedure

1. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Touch either “MAIN SIGNALS” or “SELECTION FROM MENU” on the “DATA MONITOR” screen.

3. When “SELECTION FROM MENU” is selected, touch individual items to monitor. When “MAIN SIGNALS”

is selected, main items is monitored.

4. Touch “START”.

5. To record monitored item, touch “RECORD” while monitoring. To

stop recording, touch “STOP”.

Display Item List

MAIN SIGNALS Monitors main signals.

SELECTION FROM MENU Selects and monitors individual signal.

SKIA4957E

Display item [Unit]MAIN

SIGNALSSELECTION

FROM MENUContents

SPEED METER [km/h] or [mph] X XThe value of vehicle speed signal, which is input from ABS

actuator and electric unit (control unit).

SPEED OUTPUT [km/h] or [mph] X XThe value of vehicle speed signal, which is transmitted to each

unit with CAN communication.

TACHO METER [rpm] X X The value of engine speed signal, which is input from ECM.

W TEMP METER [°C] or [°F] X XThe value of engine coolant temperature signal, which is input

from ECM.

FUEL METER [lit.] X XThe value, which processes a resistance signal from fuel

gauge.

DISTANCE [km] or [mile] X XThe value, which is calculated by vehicle speed signal from

ABS actuator and electric unit (control unit), fuel gauge and

fuel consumption signal from ECM.

FUEL W/L [ON/OFF] X X Indicates [ON/OFF] condition of low-fuel warning lamp.

C-ENG W/L [ON/OFF] X Indicates [ON/OFF] condition of malfunction indicator.

AIR PRES W/L [ON/OFF] XIndicates [ON/OFF] condition of low tire pressure warning

lamp.

SEAT BELT W/L [ON/OFF] X Indicates [ON/OFF] condition of seat belt warning lamp.

BUZZER [ON/OFF] X X Indicates [ON/OFF] condition of buzzer.

DOOR W/L [ON/OFF] X Indicates [ON/OFF] condition of door warning lamp.

HI-BEAM IND [ON/OFF] X Indicates [ON/OFF] condition of high beam indicator lamp.

TURN IND [ON/OFF] X Indicates [ON/OFF] condition of turn indicator.

FR FOG IND [ON/OFF] X Indicates [ON/OFF] condition of front fog indicator lamp.

RR FOG IND [ON/OFF] X Indicates [ON/OFF] condition of rear fog indicator lamp.

OIL W/L [ON/OFF] X Indicates [ON/OFF] condition of oil pressure warning lamp.

VDC/TCS IND [ON/OFF] X Indicates [ON/OFF] condition of ESP OFF indicator lamp.

ABS W/L [ON/OFF] X Indicates [ON/OFF] condition of ABS warning lamp.

SLIP IND [ON/OFF] X Indicates [ON/OFF] condition of SLIP indicator lamp.

BRAKE W/L [ON/OFF] X Indicates [ON/OFF] condition of brake warning lamp.*

Page 962 of 3171

DI-52

WARNING CHIME

SEAT BELT WARNING CHIME

Seat belt warning chime sound for approximately 90 seconds, when vehicle speed becomes more than 25 km/

h (16 MPH) with driver seat belt unfastened.

When driver seat belt is unfastened, ground is supplied as signal

lto combination meter terminal 24

lthrough seat belt buckle switch (driver side) terminals 1 and 2

lthrough grounds B9 and B25 (LHD models), B106 and B121 (RHD models).

ABS actuator and electric unit (control unit) provides a vehicle speed signal to the combination meter.

Combination meter detects that driver seat belt is unfastened (seat belt buckle switch ON) and vehicle speed

more than 25 km/h (16 MPH). And then it sounds seat belt warning chime for 90 seconds.

NOTE:

Warning chime should be turned off under the following conditions.

lDriver seat belt is fastened (seat belt buckle switch OFF)

l90 seconds elapsed since warning chime start

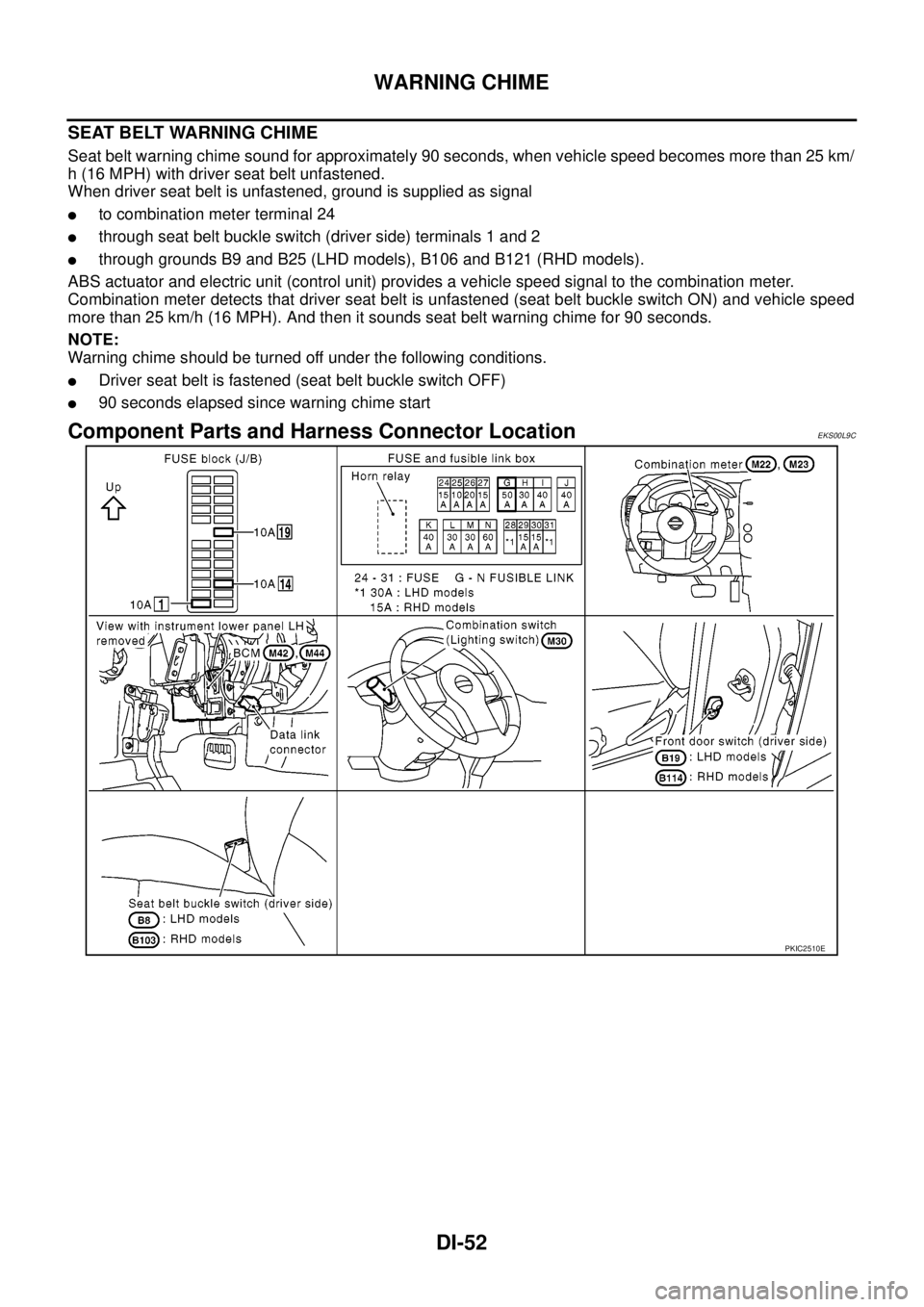

Component Parts and Harness Connector LocationEKS00L9C

PKIC2510E