maintenance NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2312 of 3171

CHASSIS AND BODY MAINTENANCE

MA-37

C

D

E

F

G

H

I

J

K

MA

B

MA

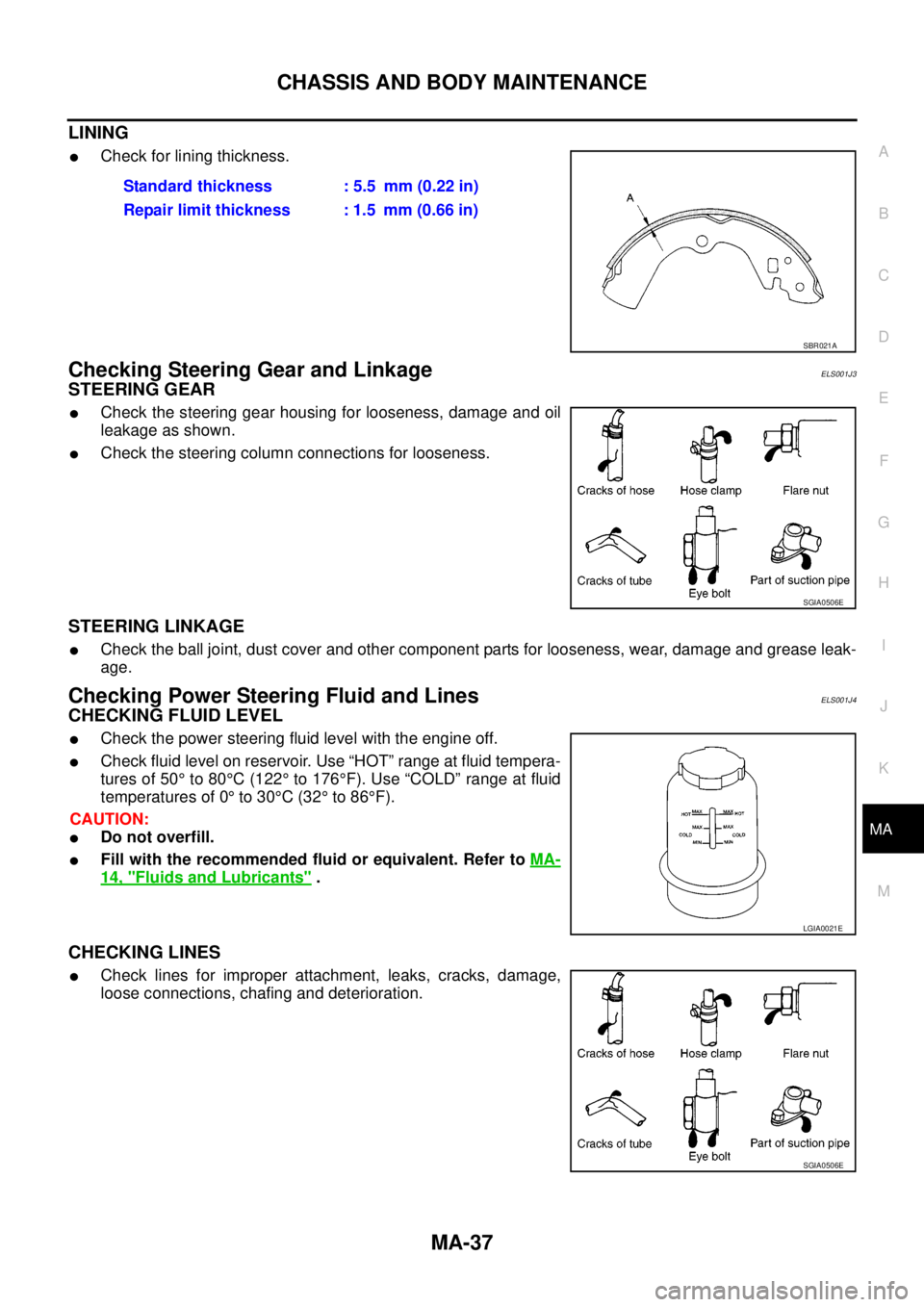

LINING

lCheck for lining thickness.

Checking Steering Gear and LinkageELS001J3

STEERING GEAR

lCheck the steering gear housing for looseness, damage and oil

leakage as shown.

lCheck the steering column connections for looseness.

STEERING LINKAGE

lCheck the ball joint, dust cover and other component parts for looseness, wear, damage and grease leak-

age.

Checking Power Steering Fluid and LinesELS001J4

CHECKING FLUID LEVEL

lCheck the power steering fluid level with the engine off.

lCheck fluid level on reservoir. Use “HOT” range at fluid tempera-

tures of 50°to 80°C(122°to 176°F). Use “COLD” range at fluid

temperatures of 0°to 30°C(32°to 86°F).

CAUTION:

lDo not overfill.

lFill with the recommended fluid or equivalent. Refer toMA-

14, "Fluids and Lubricants".

CHECKING LINES

lCheck lines for improper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.Standard thickness : 5.5 mm (0.22 in)

Repair limit thickness : 1.5 mm (0.66 in)

SBR021A

SGIA0506E

LGIA0021E

SGIA0506E

Page 2313 of 3171

MA-38

CHASSIS AND BODY MAINTENANCE

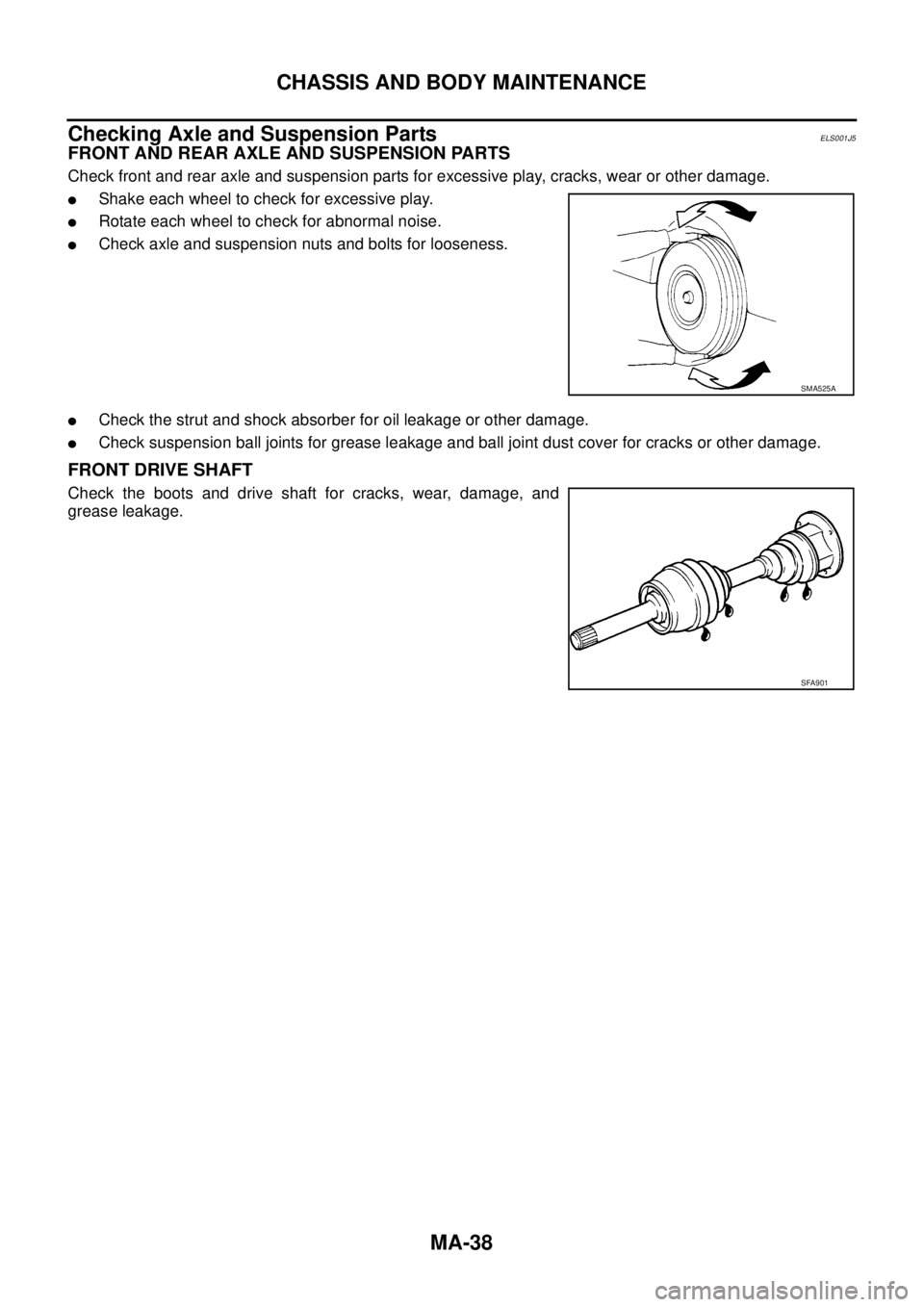

Checking Axle and Suspension Parts

ELS001J5

FRONT AND REAR AXLE AND SUSPENSION PARTS

Check front and rear axle and suspension parts for excessive play, cracks, wear or other damage.

lShake each wheel to check for excessive play.

lRotate each wheel to check for abnormal noise.

lCheck axle and suspension nuts and bolts for looseness.

lCheck the strut and shock absorber for oil leakage or other damage.

lCheck suspension ball joints for grease leakage and ball joint dust cover for cracks or other damage.

FRONT DRIVE SHAFT

Check the boots and drive shaft for cracks, wear, damage, and

grease leakage.

SMA525A

SFA901

Page 2314 of 3171

CHASSIS AND BODY MAINTENANCE

MA-39

C

D

E

F

G

H

I

J

K

MA

B

MA

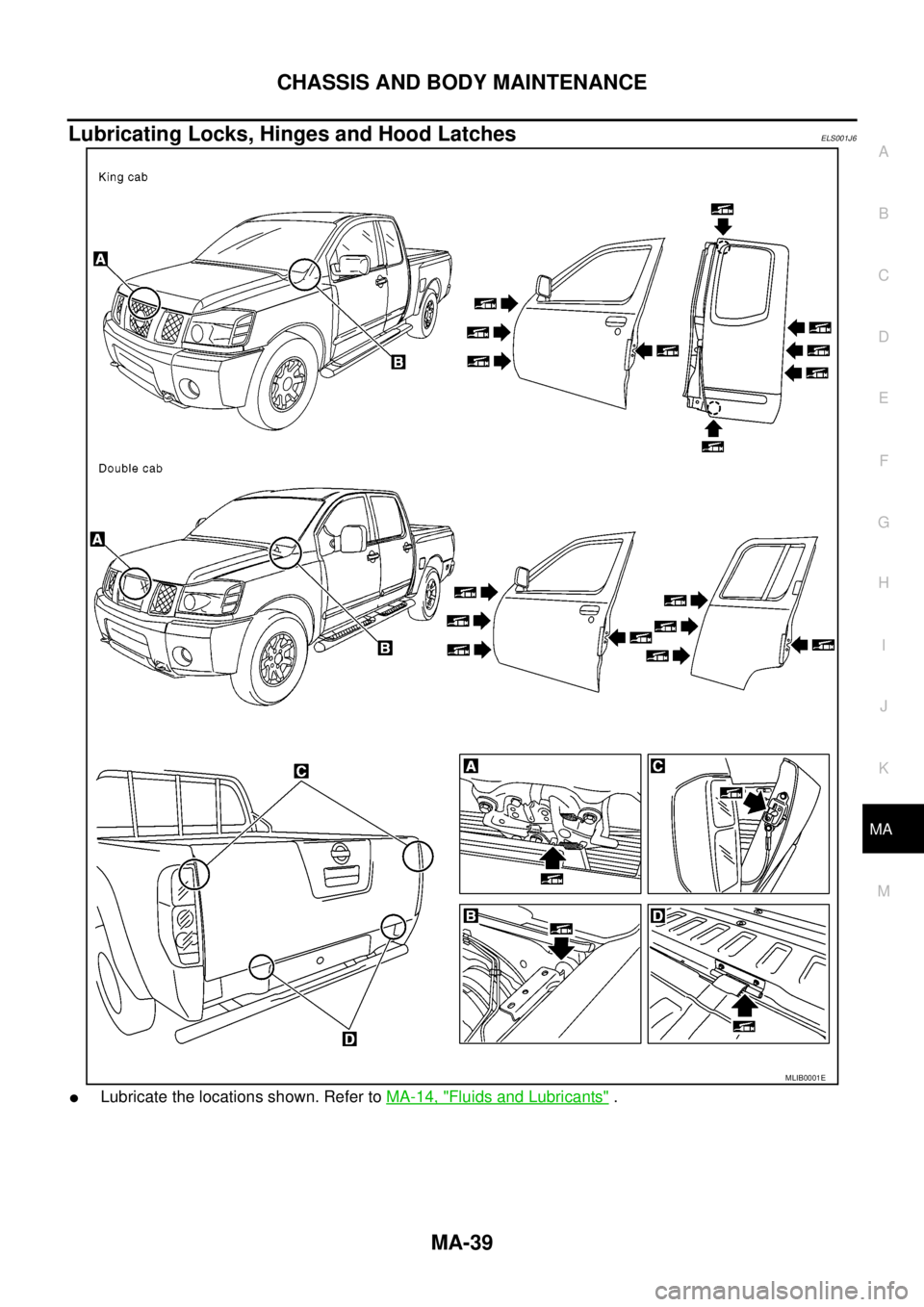

Lubricating Locks, Hinges and Hood LatchesELS001J6

lLubricate the locations shown. Refer toMA-14, "Fluids and Lubricants".

MLIB0001E

Page 2315 of 3171

MA-40

CHASSIS AND BODY MAINTENANCE

Checking Seat Belts, Buckles, Retractors, Anchors and Adjusters

ELS001J7

Check the seat belt buckles, webbing, retractors, anchors and adjusters. Replace any seat belt assembly as

necessary. Refer toSB-11, "

Seat Belt Inspection".

lCheck the seat belt anchors for loose mounting bolts, damage, or excessive wear.

lCheck the seat belt webbing for any damage, cuts, fraying, or excessive wear.

lCheck the retractor for smooth operation.

lCheck the function of the buckles by inserting the seat belt tongue and checking for proper engagement of

the buckle and press the button on the buckle to check for proper release of the seat belt tongue.

CAUTION:

lAfter any collision, inspect all seat belt assemblies, including retractors and other attached com-

ponents, such as the guide rail set. NISSAN recommends replacing all seat belt assemblies in use

during a collision, unless they are not damaged and are inspected to confirm they are operating

properly after a minor collision.

Also inspect all seat belt assemblies that are not in use during a collision, and replace any compo-

nents if damaged or not operating properly. The seat belt pre-tensioner should be replaced even if

the seat belts are not in use during a frontal collision where the driver and passenger air bags

have been deployed.

lIf any component of the seat belt assembly is suspected of being damaged or not operating prop-

erly, do not repair the component. Replace the components as an assembly.

lIf the seat belt webbing is cut, frayed, or damaged then replace the seat belt assembly.

lNever lubricate the seat belt buckle or tongue.

lWhen replacing any seat belt assembly always use a Genuine NISSAN seat belt assembly.

Checking Body CorrosionELS001K3

Visually check body panels for collision damage (scratches, chipping, rubbing, etc.) or damage to the anti-cor-

rosion materials. In particular, check the following locations.

HEMMED PANELS

Hood front end, door lower end, trunk lid rear end, etc.

PANEL JOINT

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine com-

partment, etc.

PANEL EDGE

Trunk lid opening, sunroof opening, fender wheel-arch flange, fuel filler lid flange, around holes in panel, etc.

PARTS CONTACT

Waist moulding, windshield moulding, bumper, etc.

PROTECTORS

Damage or condition of mudguard, fender protector, chipping protector, etc.

ANTI-CORROSION MATERIALS

Damage or separation of anti-corrosion materials under the body.

DRAIN HOLES

Condition of drain holes at door and side sill. When repairing corroded areas, refer to the Corrosion Repair

Manual.

Page 2388 of 3171

MTC-1

MANUAL AIR CONDITIONER

J AIR CONDITIONER

CONTENTS

C

D

E

F

G

H

I

K

L

M

SECTIONMTC

A

B

MTC

MANUAL AIR CONDITIONER

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 4

Precautions for Working with HFC-134a (R-134a)..... 4

Contaminated Refrigerant ........................................ 4

General Refrigerant Precautions .............................. 5

Precautions for Refrigerant Connection ................... 5

ABOUT ONE-TOUCH JOINT ................................ 5

FEATURES OF NEW TYPE REFRIGERANT

CONNECTION ...................................................... 7

O-RING AND REFRIGERANT CONNECTION..... 9

Precautions for Servicing Compressor ................... 12

Precautions for Service Equipment ........................ 12

RECOVERY/RECYCLING EQUIPMENT ............ 12

ELECTRONIC LEAK DETECTOR ...................... 12

VACUUM PUMP ................................................. 13

MANIFOLD GAUGE SET .................................... 13

SERVICE HOSES ............................................... 13

SERVICE COUPLERS ........................................ 14

REFRIGERANT WEIGHT SCALE ...................... 14

CALIBRATING ACR4 WEIGHT SCALE .............. 14

CHARGING CYLINDER ...................................... 14

Precautions for Leak Detection Dye ....................... 14

IDENTIFICATION ................................................ 15

IDENTIFICATION LABEL FOR VEHICLE ........... 15

Wiring Diagrams and Trouble Diagnosis ................ 15

PREPARATION ......................................................... 16

Special Service Tools ............................................. 16

HFC-134a (R-134a) Service Tools and Equipment... 16

Commercial Service Tools ...................................... 19

REFRIGERATION SYSTEM ..................................... 20

Refrigerant Cycle ................................................... 20

REFRIGERANT FLOW ....................................... 20

FREEZE PROTECTION ..................................... 20

Refrigerant System Protection ............................... 20

REFRIGERANT PRESSURE SENSOR ............. 20

PRESSURE RELIEF VALVE ............................... 21

Component Layout ................................................. 22

REFRIGERATION SYSTEM ............................... 22LUBRICANT .............................................................. 24

Maintenance of Lubricant Quantity in Compressor... 24

LUBRICANT ........................................................ 24

CHECKING AND ADJUSTING ............................ 24

AIR CONDITIONER CONTROL ............................... 26

Description .............................................................. 26

Operation ................................................................ 26

AIR MIX DOOR CONTROL ................................. 26

BLOWER SPEED CONTROL ............................. 26

INTAKE DOORS CONTROL ............................... 26

MODE DOOR CONTROL ................................... 26

DEFROSTER DOOR CONTROL ........................ 26

MAGNET CLUTCH CONTROL ........................... 27

SELF-DIAGNOSTIC SYSTEM ............................ 27

Description of Control System ................................ 28

Control Operation ................................................... 28

DISPLAY SCREEN .............................................. 29

TEMPERATURE SWITCH (TEMPERATURE

CONTROL) (FRONT) .......................................... 29

RECIRCULATION () SWITCH ............................. 29

REAR WINDOW DEFOGGER SWITCH ............. 29

OFF SWITCH (BLOWER SPEED SET TO 0) ..... 29

A/C SWITCH ....................................................... 29

MODE SWITCH .................................................. 29

Discharge Air Flow ................................................. 30

FRONT ................................................................ 30

System Description ................................................. 31

SWITCHES AND THEIR CONTROL FUNCTION... 31

CAN Communication System Description .............. 32

TROUBLE DIAGNOSIS ............................................ 33

CONSULT-II ............................................................ 33

CONSULT-II BASIC OPERATION ....................... 33

DATA MONITOR ................................................. 34

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ...................................................... 35

WORK FLOW ...................................................... 35

SYMPTOM TABLE .............................................. 35

Component Parts and Harness Connector Location... 36

ENGINE COMPARTMENT .................................. 36

FRONT PASSENGER COMPARTMENT ............ 37

Page 2391 of 3171

MTC-4

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EJS005QE

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Working with HFC-134a (R-134a)EJS00627

WARNING:

lCFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. These refrigerants

must never be mixed, even in the smallest amounts. If the refrigerants are mixed and compressor

malfunction is likely occur.

lUse only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. If lubricant other than that specified is used, compressor malfunction is likely to occur.

lThe specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

–When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

–When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as possi-

ble to minimize the entry of moisture into system.

–Only use the specified lubricant from a sealed container. Immediately reseal containers of lubri-

cant. Without proper sealing, lubricant will become moisture saturated and should not be used.

–Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refriger-

ant. If accidental system discharge occurs, ventilate work area before resuming service. Addi-

tional health and safety information may be obtained from refrigerant and lubricant

manufacturers.

–Do not allow lubricant (Nissan A/C System Oil Type S) to come in contact with styrofoam parts.

Damage may result.

Contaminated RefrigerantEJS0063C

If a refrigerant other than pure HFC-134a (R-134a) is identified in a vehicle, your options are:

lExplain to the customer that environmental regulations prohibit the release of contaminated refrigerant

into the atmosphere.

lExplain that recovery of the contaminated refrigerant could damage your service equipment and refriger-

ant supply.

lSuggest the customer return the vehicle to the location of previous service where the contamination may

have occurred.

lIf you choose to perform the repair, recover the refrigerant using onlydedicated equipment and contain-

ers. Do not recover contaminated refrigerant into your existing service equipment.If your facility

does not have dedicated recovery equipment, you may contact a local refrigerant product retailer for avail-

able service. This refrigerant must be disposed of in accordance with all federal and local regulations. In

addition, replacement of all refrigerant system components on the vehicle is recommended.

Page 2399 of 3171

MTC-12

PRECAUTIONS

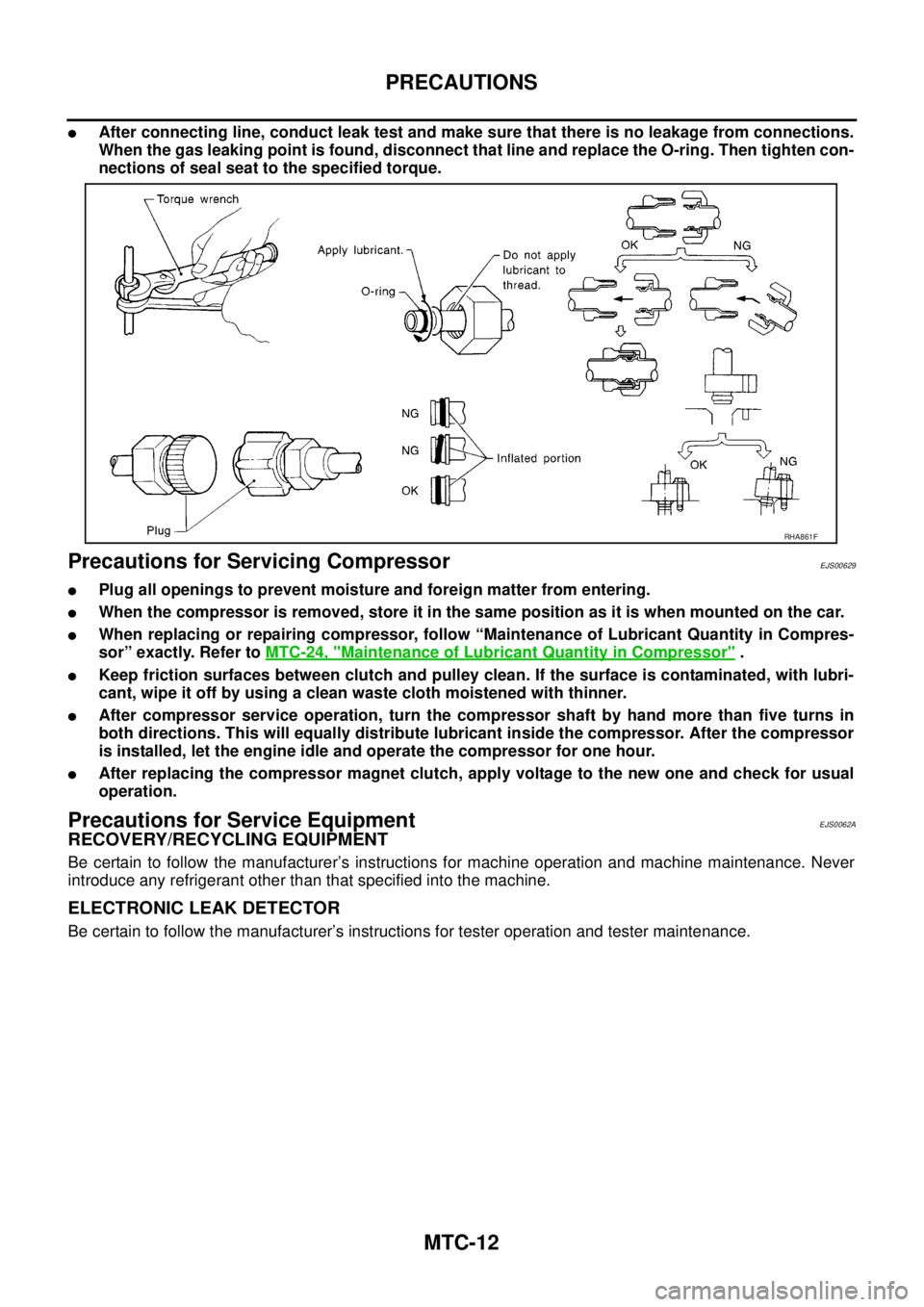

lAfter connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten con-

nections of seal seat to the specified torque.

Precautions for Servicing CompressorEJS00629

lPlug all openings to prevent moisture and foreign matter from entering.

lWhen the compressor is removed, store it in the same position as it is when mounted on the car.

lWhen replacing or repairing compressor, follow “Maintenance of Lubricant Quantity in Compres-

sor” exactly. Refer toMTC-24, "

Maintenance of Lubricant Quantity in Compressor".

lKeep friction surfaces between clutch and pulley clean. If the surface is contaminated, with lubri-

cant, wipe it off by using a clean waste cloth moistened with thinner.

lAfter compressor service operation, turn the compressor shaft by hand more than five turns in

both directions. This will equally distribute lubricant inside the compressor. After the compressor

is installed, let the engine idle and operate the compressor for one hour.

lAfter replacing the compressor magnet clutch, apply voltage to the new one and check for usual

operation.

Precautions for Service EquipmentEJS0062A

RECOVERY/RECYCLING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Never

introduce any refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Be certain to follow the manufacturer’s instructions for tester operation and tester maintenance.

RHA861F

Page 2411 of 3171

MTC-24

LUBRICANT

LUBRICANT

PFP:KLG00

Maintenance of Lubricant Quantity in CompressorEJS005FV

The lubricant in the compressor circulates through the system with the refrigerant. Add lubricant to compres-

sor when replacing any component or after a large refrigerant leakage has occurred. It is important to maintain

the specified amount.

If lubricant quantity is not maintained properly, the following malfunctions may result:

lLack of lubricant: May lead to a seized compressor

lExcessive lubricant: Inadequate cooling (thermal exchange interference)

LUBRICANT

Name: NISSAN A/C System Lubricant Type S (DH-PS)

Part number: KLH00-PAGS0

CHECKING AND ADJUSTING

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant return operation.

Start the engine and set the following conditions:

test condition

lEngine speed: Idling to 1,200 rpm

lA/C switch: On

lBlower speed: Max. position

lTemp. control: Optional [Set so that intake air temperature is 25°to 30°C(77°to 86°F).]

lIntake position: Recirculation ( )

lPerform lubricant return operation for about ten minutes

Adjust the lubricant quantity according to the following table.

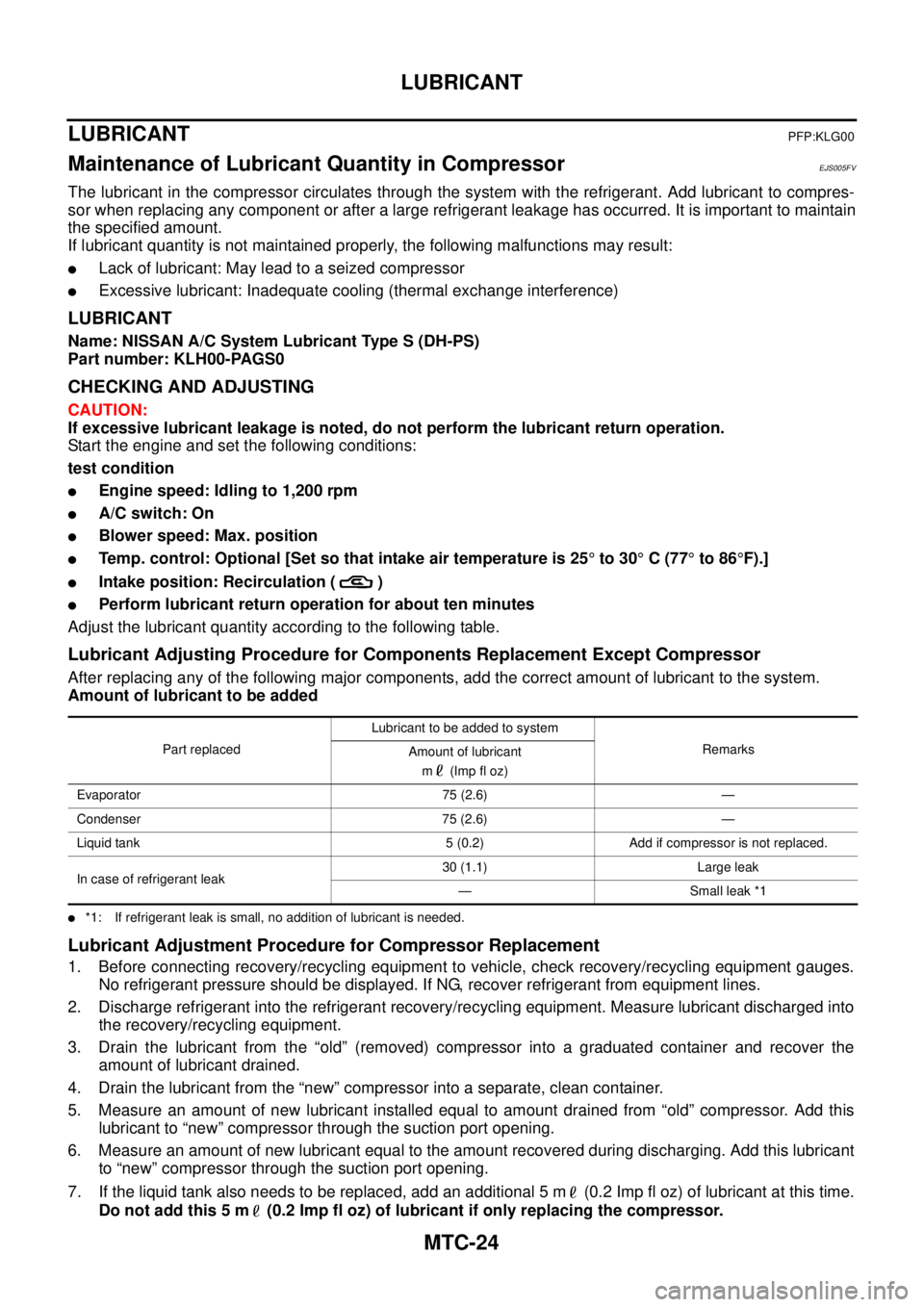

Lubricant Adjusting Procedure for Components Replacement Except Compressor

After replacing any of the following major components, add the correct amount of lubricant to the system.

Amount of lubricant to be added

l*1: If refrigerant leak is small, no addition of lubricant is needed.

Lubricant Adjustment Procedure for Compressor Replacement

1. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauges.

No refrigerant pressure should be displayed. If NG, recover refrigerant from equipment lines.

2. Discharge refrigerant into the refrigerant recovery/recycling equipment. Measure lubricant discharged into

the recovery/recycling equipment.

3. Drain the lubricant from the “old” (removed) compressor into a graduated container and recover the

amount of lubricant drained.

4. Drain the lubricant from the “new” compressor into a separate, clean container.

5. Measure an amount of new lubricant installed equal to amount drained from “old” compressor. Add this

lubricant to “new” compressor through the suction port opening.

6. Measure an amount of new lubricant equal to the amount recovered during discharging. Add this lubricant

to “new” compressor through the suction port opening.

7. If the liquid tank also needs to be replaced, add an additional 5 m (0.2 Imp fl oz) of lubricant at this time.

Do not add this 5 m (0.2 Imp fl oz) of lubricant if only replacing the compressor.

Part replacedLubricant to be added to system

Remarks

Amount of lubricant

m(Impfloz)

Evaporator 75 (2.6) —

Condenser 75 (2.6) —

Liquid tank 5 (0.2) Add if compressor is not replaced.

In case of refrigerant leak30 (1.1) Large leak

— Small leak *1

Page 2482 of 3171

TROUBLE DIAGNOSIS

MTC-95

C

D

E

F

G

H

I

K

L

MA

B

MTC

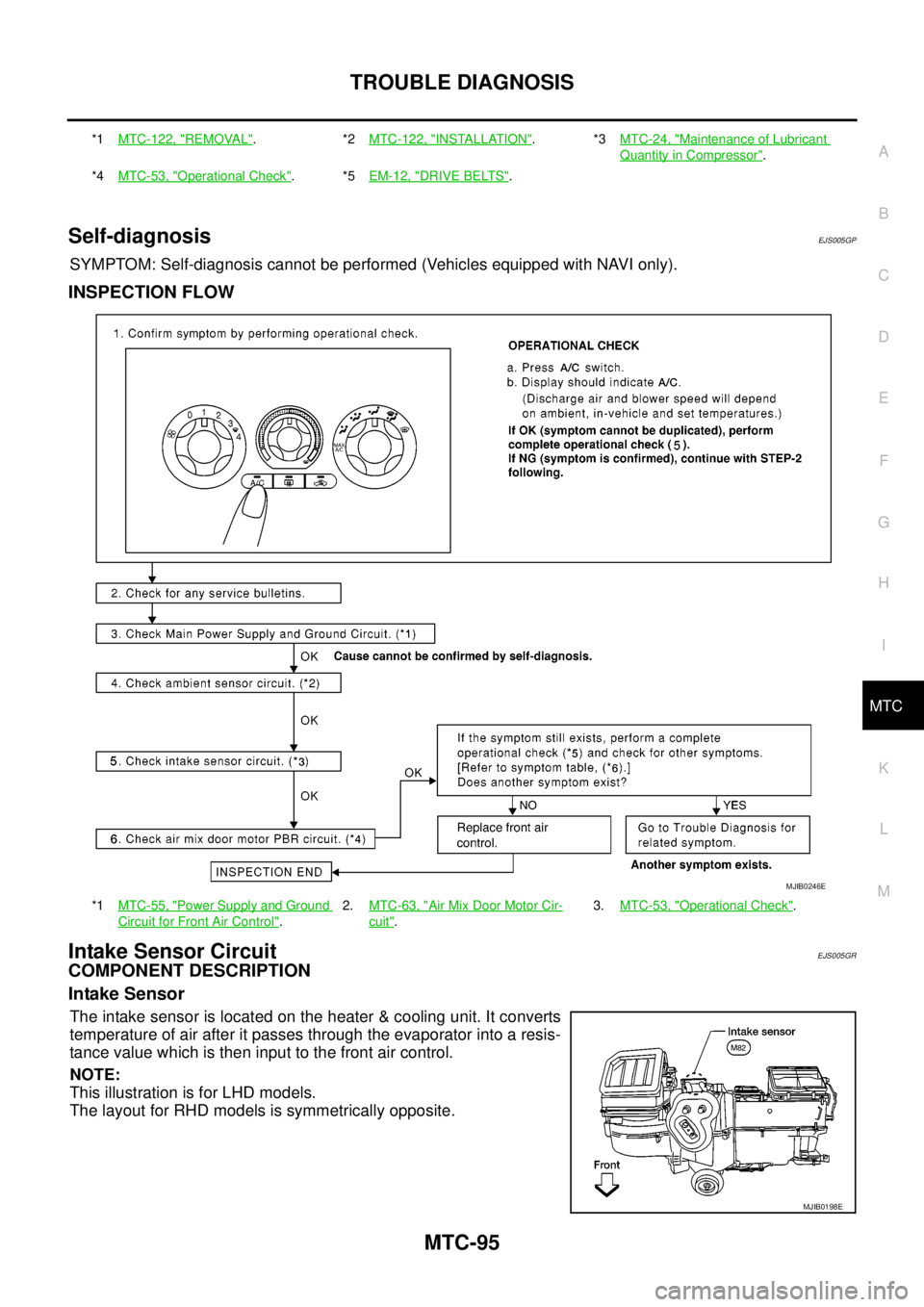

Self-diagnosisEJS005GP

SYMPTOM: Self-diagnosis cannot be performed (Vehicles equipped with NAVI only).

INSPECTION FLOW

Intake Sensor CircuitEJS005GR

COMPONENT DESCRIPTION

Intake Sensor

The intake sensor is located on the heater & cooling unit. It converts

temperature of air after it passes through the evaporator into a resis-

tance value which is then input to the front air control.

NOTE:

This illustration is for LHD models.

The layout for RHD models is symmetrically opposite.

*1MTC-122, "REMOVAL".*2MTC-122, "INSTALLATION".*3MTC-24, "Maintenance of Lubricant

Quantity in Compressor".

*4MTC-53, "

Operational Check".*5EM-12, "DRIVE BELTS".

*1MTC-55, "

Power Supply and Ground

Circuit for Front Air Control".2.MTC-63, "

Air Mix Door Motor Cir-

cuit".3.MTC-53, "

Operational Check".

MJIB0246E

MJIB0198E

Page 2488 of 3171

AIR CONDITIONER FILTER

MTC-101

C

D

E

F

G

H

I

K

L

MA

B

MTC

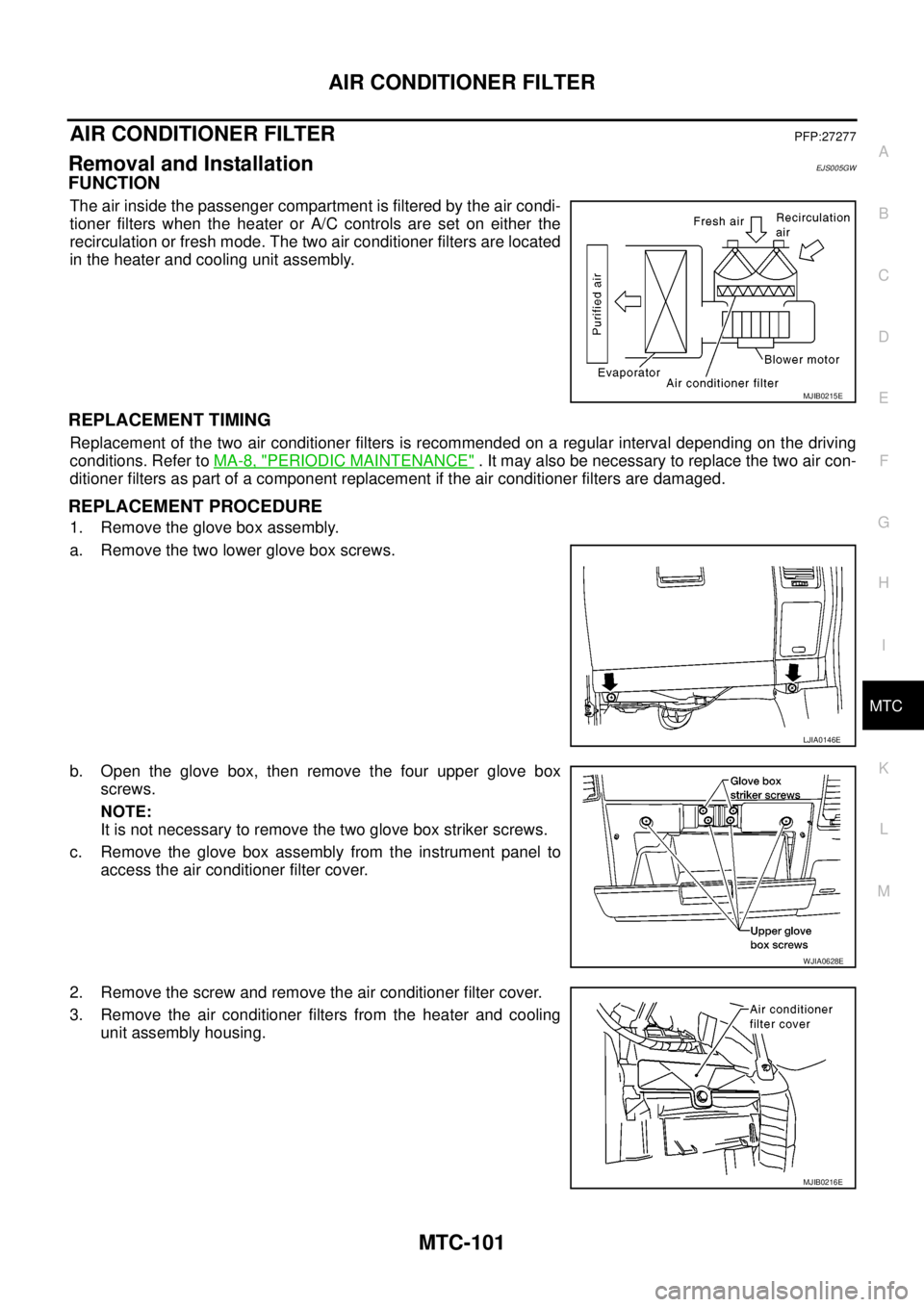

AIR CONDITIONER FILTERPFP:27277

Removal and InstallationEJS005GW

FUNCTION

The air inside the passenger compartment is filtered by the air condi-

tioner filters when the heater or A/C controls are set on either the

recirculation or fresh mode. The two air conditioner filters are located

in the heater and cooling unit assembly.

REPLACEMENT TIMING

Replacement of the two air conditioner filters is recommended on a regular interval depending on the driving

conditions. Refer toMA-8, "

PERIODIC MAINTENANCE". It may also be necessary to replace the two air con-

ditioner filters as part of a component replacement if the air conditioner filters are damaged.

REPLACEMENT PROCEDURE

1. Remove the glove box assembly.

a. Remove the two lower glove box screws.

b. Open the glove box, then remove the four upper glove box

screws.

NOTE:

It is not necessary to remove the two glove box striker screws.

c. Remove the glove box assembly from the instrument panel to

access the air conditioner filter cover.

2. Remove the screw and remove the air conditioner filter cover.

3. Remove the air conditioner filters from the heater and cooling

unit assembly housing.

MJIB0215E

LJIA0146E

WJIA0628E

MJIB0216E