heating NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 336 of 3171

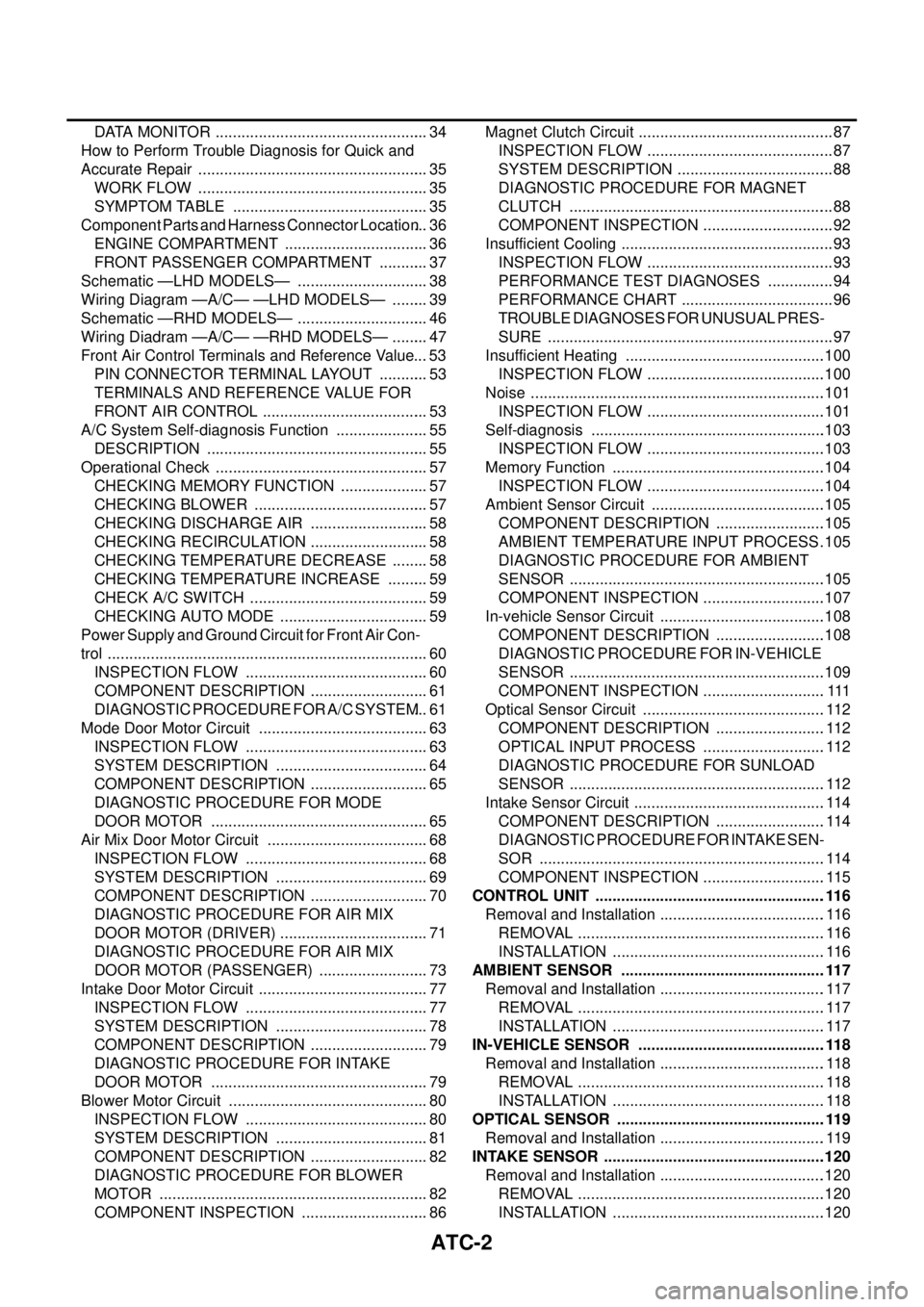

ATC-2

DATA MONITOR .................................................. 34

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ...................................................... 35

WORK FLOW ...................................................... 35

SYMPTOM TABLE .............................................. 35

Component Parts and Harness Connector Location... 36

ENGINE COMPARTMENT .................................. 36

FRONT PASSENGER COMPARTMENT ............ 37

Schematic —LHD MODELS— ............................... 38

Wiring Diagram —A/C— —LHD MODELS— ......... 39

Schematic —RHD MODELS— ............................... 46

Wiring Diadram —A/C— —RHD MODELS— ......... 47

Front Air Control Terminals and Reference Value... 53

PIN CONNECTOR TERMINAL LAYOUT ............ 53

TERMINALS AND REFERENCE VALUE FOR

FRONT AIR CONTROL ....................................... 53

A/C System Self-diagnosis Function ...................... 55

DESCRIPTION .................................................... 55

Operational Check .................................................. 57

CHECKING MEMORY FUNCTION ..................... 57

CHECKING BLOWER ......................................... 57

CHECKING DISCHARGE AIR ............................ 58

CHECKING RECIRCULATION ............................ 58

CHECKING TEMPERATURE DECREASE ......... 58

CHECKING TEMPERATURE INCREASE .......... 59

CHECK A/C SWITCH .......................................... 59

CHECKING AUTO MODE ................................... 59

Power Supply and Ground Circuit for Front Air Con-

trol ........................................................................... 60

INSPECTION FLOW ........................................... 60

COMPONENT DESCRIPTION ............................ 61

DIAGNOSTIC PROCEDURE FOR A/C SYSTEM... 61

Mode Door Motor Circuit ........................................ 63

INSPECTION FLOW ........................................... 63

SYSTEM DESCRIPTION .................................... 64

COMPONENT DESCRIPTION ............................ 65

DIAGNOSTIC PROCEDURE FOR MODE

DOOR MOTOR ................................................... 65

Air Mix Door Motor Circuit ...................................... 68

INSPECTION FLOW ........................................... 68

SYSTEM DESCRIPTION .................................... 69

COMPONENT DESCRIPTION ............................ 70

DIAGNOSTIC PROCEDURE FOR AIR MIX

DOOR MOTOR (DRIVER) ................................... 71

DIAGNOSTIC PROCEDURE FOR AIR MIX

DOOR MOTOR (PASSENGER) .......................... 73

Intake Door Motor Circuit ........................................ 77

INSPECTION FLOW ........................................... 77

SYSTEM DESCRIPTION .................................... 78

COMPONENT DESCRIPTION ............................ 79

DIAGNOSTIC PROCEDURE FOR INTAKE

DOOR MOTOR ................................................... 79

Blower Motor Circuit ............................................... 80

INSPECTION FLOW ........................................... 80

SYSTEM DESCRIPTION .................................... 81

COMPONENT DESCRIPTION ............................ 82

DIAGNOSTIC PROCEDURE FOR BLOWER

MOTOR ............................................................... 82

COMPONENT INSPECTION .............................. 86Magnet Clutch Circuit .............................................. 87

INSPECTION FLOW ............................................ 87

SYSTEM DESCRIPTION ..................................... 88

DIAGNOSTIC PROCEDURE FOR MAGNET

CLUTCH .............................................................. 88

COMPONENT INSPECTION ............................... 92

Insufficient Cooling .................................................. 93

INSPECTION FLOW ............................................ 93

PERFORMANCE TEST DIAGNOSES ................ 94

PERFORMANCE CHART .................................... 96

TROUBLE DIAGNOSES FOR UNUSUAL PRES-

SURE ................................................................... 97

Insufficient Heating ...............................................100

INSPECTION FLOW ..........................................100

Noise .....................................................................101

INSPECTION FLOW ..........................................101

Self-diagnosis .......................................................103

INSPECTION FLOW ..........................................103

Memory Function ..................................................104

INSPECTION FLOW ..........................................104

Ambient Sensor Circuit .........................................105

COMPONENT DESCRIPTION ..........................105

AMBIENT TEMPERATURE INPUT PROCESS.105

DIAGNOSTIC PROCEDURE FOR AMBIENT

SENSOR ............................................................105

COMPONENT INSPECTION .............................107

In-vehicle Sensor Circuit .......................................108

COMPONENT DESCRIPTION ..........................108

DIAGNOSTIC PROCEDURE FOR IN-VEHICLE

SENSOR ............................................................109

COMPONENT INSPECTION ............................. 111

Optical Sensor Circuit ...........................................112

COMPONENT DESCRIPTION ..........................112

OPTICAL INPUT PROCESS .............................112

DIAGNOSTIC PROCEDURE FOR SUNLOAD

SENSOR ............................................................112

Intake Sensor Circuit .............................................114

COMPONENT DESCRIPTION ..........................114

DIAGNOSTIC PROCEDURE FOR INTAKE SEN-

SOR ...................................................................114

COMPONENT INSPECTION .............................115

CONTROL UNIT ......................................................116

Removal and Installation .......................................116

REMOVAL ..........................................................116

INSTALLATION ..................................................116

AMBIENT SENSOR ................................................117

Removal and Installation .......................................117

REMOVAL ..........................................................117

INSTALLATION ..................................................117

IN-VEHICLE SENSOR ............................................118

Removal and Installation .......................................118

REMOVAL ..........................................................118

INSTALLATION ..................................................118

OPTICAL SENSOR .................................................119

Removal and Installation .......................................119

INTAKE SENSOR ....................................................120

Removal and Installation .......................................120

REMOVAL ..........................................................120

INSTALLATION ..................................................120

Page 369 of 3171

TROUBLE DIAGNOSIS

ATC-35

C

D

E

F

G

H

I

K

L

MA

B

AT C

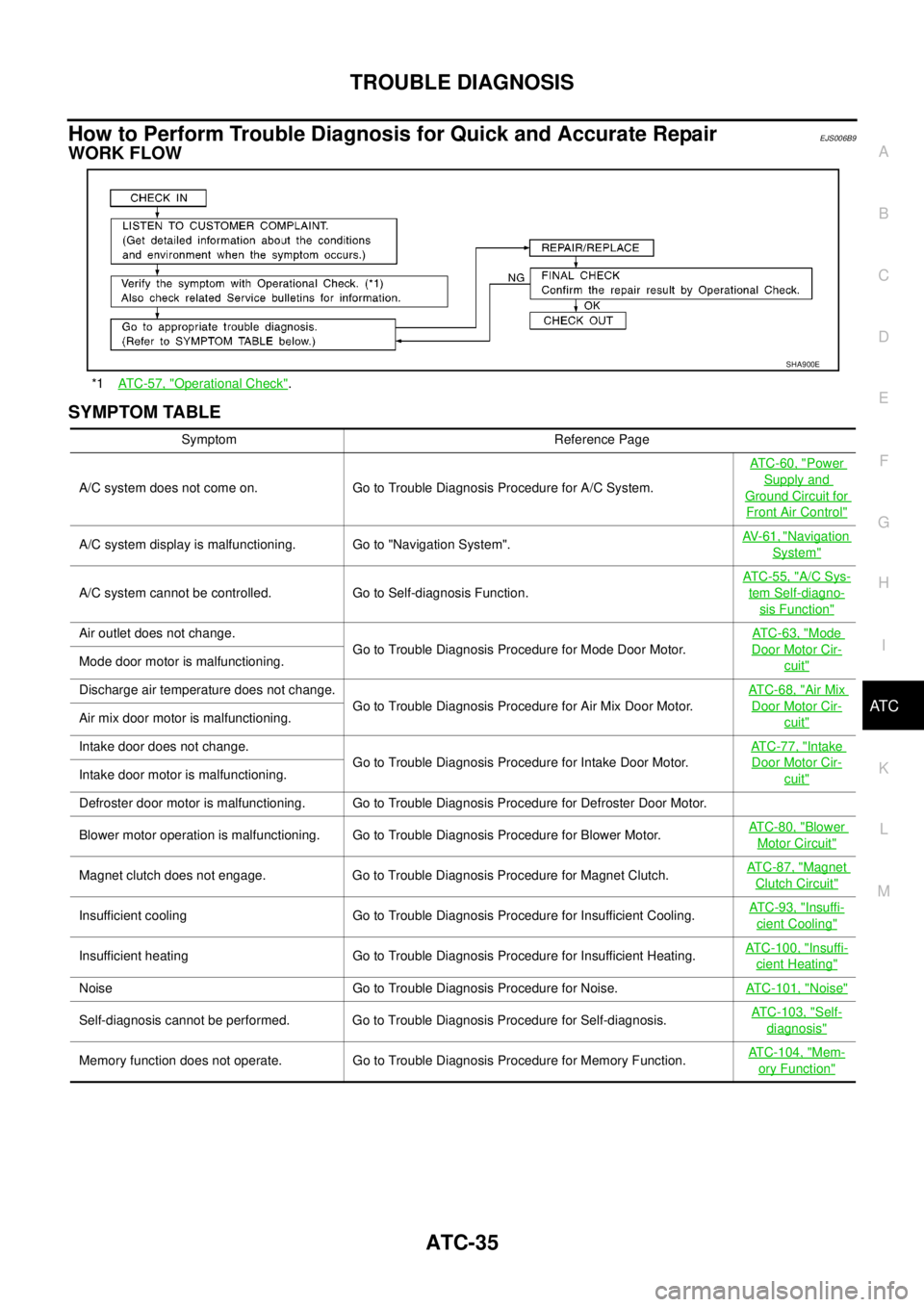

How to Perform Trouble Diagnosis for Quick and Accurate RepairEJS006B9

WORK FLOW

SYMPTOM TABLE

*1AT C - 5 7 , "Operational Check".

SHA900E

Symptom Reference Page

A/C system does not come on. Go to Trouble Diagnosis Procedure for A/C System.ATC-60, "

Power

Supply and

Ground Circuit for

Front Air Control"

A/C system display is malfunctioning. Go to "Navigation System".AV-61, "Navigation

System"

A/C system cannot be controlled. Go to Self-diagnosis Function.AT C - 5 5 , "

A/C Sys-

tem Self-diagno-

sis Function"

Air outlet does not change.

Go to Trouble Diagnosis Procedure for Mode Door Motor.AT C - 6 3 , "Mode

Door Motor Cir-

cuit"Mode door motor is malfunctioning.

Discharge air temperature does not change.

Go to Trouble Diagnosis Procedure for Air Mix Door Motor.ATC-68, "

Air Mix

Door Motor Cir-

cuit"Air mix door motor is malfunctioning.

Intake door does not change.

Go to Trouble Diagnosis Procedure for Intake Door Motor.AT C - 7 7 , "

Intake

Door Motor Cir-

cuit"Intake door motor is malfunctioning.

Defroster door motor is malfunctioning. Go to Trouble Diagnosis Procedure for Defroster Door Motor.

Blower motor operation is malfunctioning. Go to Trouble Diagnosis Procedure for Blower Motor.ATC-80, "

Blower

Motor Circuit"

Magnet clutch does not engage. Go to Trouble Diagnosis Procedure for Magnet Clutch.AT C - 8 7 , "Magnet

Clutch Circuit"

Insufficient cooling Go to Trouble Diagnosis Procedure for Insufficient Cooling.AT C - 9 3 , "Insuffi-

cient Cooling"

Insufficient heating Go to Trouble Diagnosis Procedure for Insufficient Heating.ATC-100, "Insuffi-

cient Heating"

Noise Go to Trouble Diagnosis Procedure for Noise.ATC-101, "Noise"

Self-diagnosis cannot be performed. Go to Trouble Diagnosis Procedure for Self-diagnosis.ATC-103, "Self-

diagnosis"

Memory function does not operate. Go to Trouble Diagnosis Procedure for Memory Function.ATC-104, "Mem-

ory Function"

Page 393 of 3171

TROUBLE DIAGNOSIS

ATC-59

C

D

E

F

G

H

I

K

L

MA

B

AT C

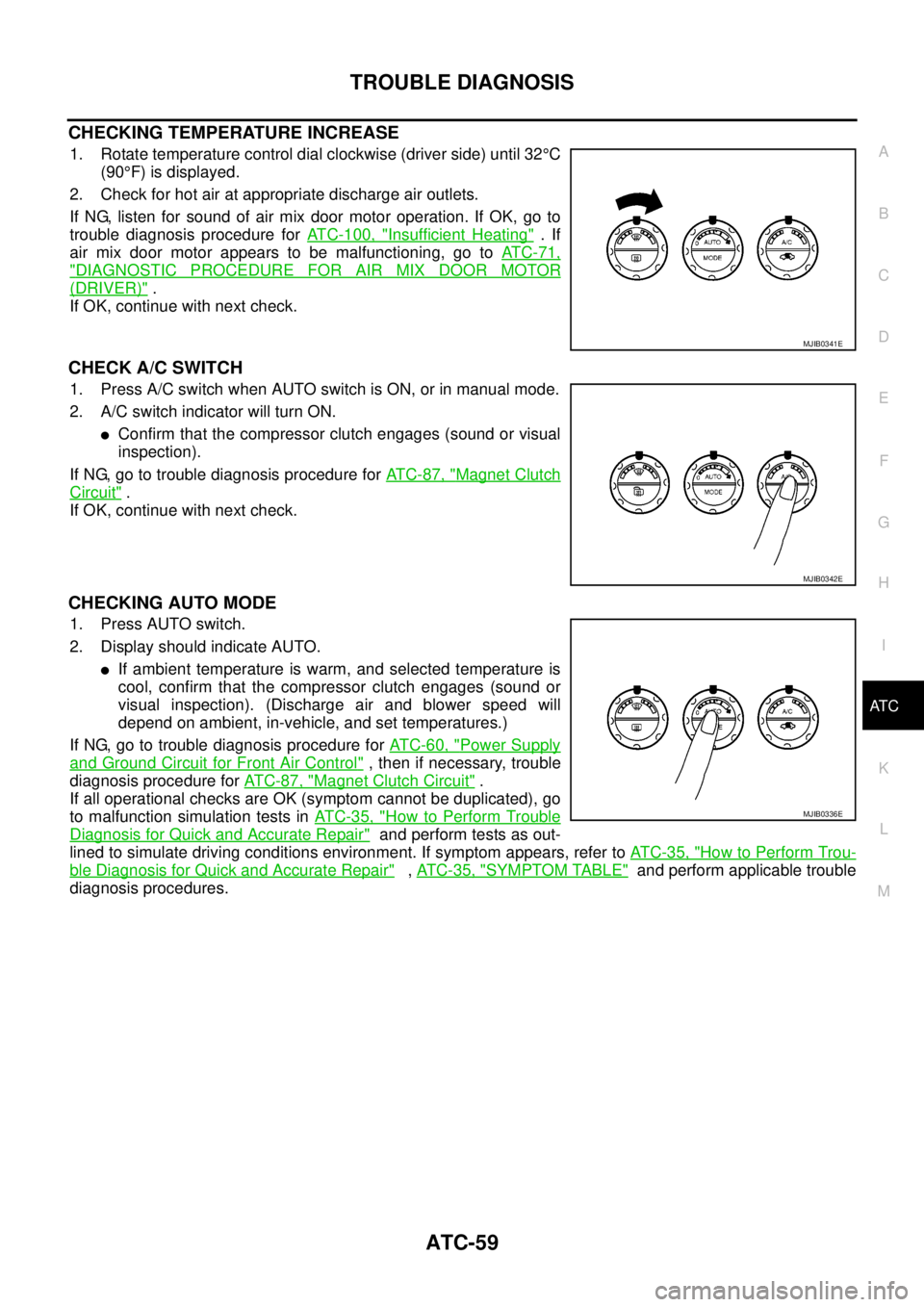

CHECKING TEMPERATURE INCREASE

1. Rotate temperature control dial clockwise (driver side) until 32°C

(90°F) is displayed.

2. Check for hot air at appropriate discharge air outlets.

If NG, listen for sound of air mix door motor operation. If OK, go to

trouble diagnosis procedure forATC-100, "

Insufficient Heating".If

air mix door motor appears to be malfunctioning, go toAT C - 7 1 ,

"DIAGNOSTIC PROCEDURE FOR AIR MIX DOOR MOTOR

(DRIVER)".

If OK, continue with next check.

CHECK A/C SWITCH

1. Press A/C switch when AUTO switch is ON, or in manual mode.

2. A/C switch indicator will turn ON.

lConfirm that the compressor clutch engages (sound or visual

inspection).

If NG, go to trouble diagnosis procedure forAT C - 8 7 , "

Magnet Clutch

Circuit".

If OK, continue with next check.

CHECKING AUTO MODE

1. Press AUTO switch.

2. Display should indicate AUTO.

lIf ambient temperature is warm, and selected temperature is

cool, confirm that the compressor clutch engages (sound or

visual inspection). (Discharge air and blower speed will

depend on ambient, in-vehicle, and set temperatures.)

If NG, go to trouble diagnosis procedure forAT C - 6 0 , "

Power Supply

and Ground Circuit for Front Air Control", then if necessary, trouble

diagnosis procedure forAT C - 8 7 , "

Magnet Clutch Circuit".

If all operational checks are OK (symptom cannot be duplicated), go

to malfunction simulation tests inAT C - 3 5 , "

How to Perform Trouble

Diagnosis for Quick and Accurate Repair"and perform tests as out-

lined to simulate driving conditions environment. If symptom appears, refer toAT C - 3 5 , "

How to Perform Trou-

ble Diagnosis for Quick and Accurate Repair",AT C - 3 5 , "SYMPTOM TABLE"and perform applicable trouble

diagnosis procedures.

MJIB0341E

MJIB0342E

MJIB0336E

Page 434 of 3171

ATC-100

TROUBLE DIAGNOSIS

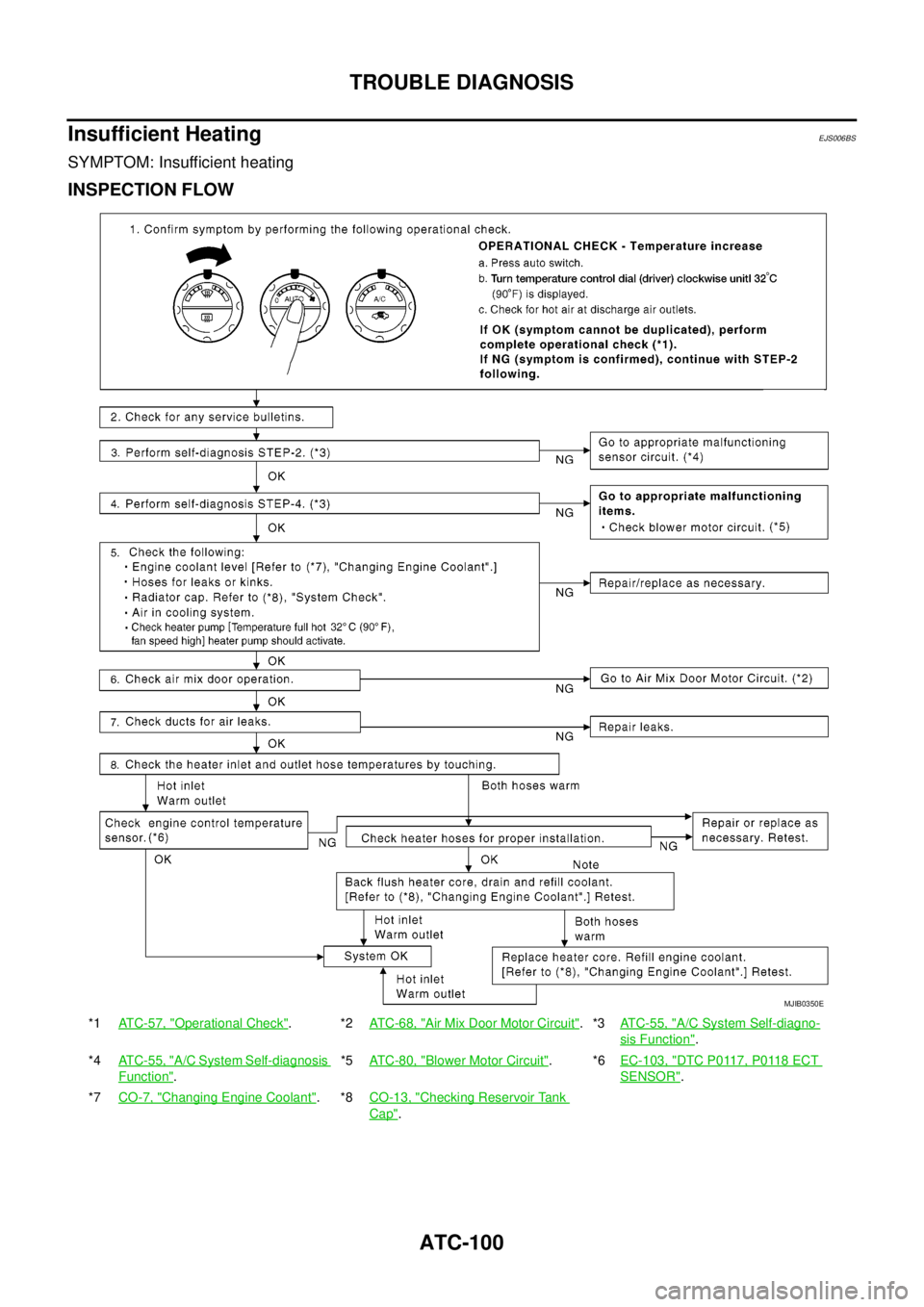

Insufficient Heating

EJS006BS

SYMPTOM: Insufficient heating

INSPECTION FLOW

*1ATC-57, "Operational Check".*2AT C - 6 8 , "Air Mix Door Motor Circuit".*3ATC-55, "A/C System Self-diagno-

sis Function".

*4ATC-55, "

A/C System Self-diagnosis

Function".*5AT C - 8 0 , "

Blower Motor Circuit".*6EC-103, "DTC P0117, P0118 ECT

SENSOR".

*7CO-7, "

Changing Engine Coolant".*8CO-13, "Checking Reservoir Tank

Cap".

MJIB0350E

Page 885 of 3171

CO-1

ENGINE COOLING SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTIONCO

A

CO

ENGINE COOLING SYSTEM

PRECAUTIONS .......................................................... 2

Precautions For Liquid Gasket ................................. 2

LIQUID GASKET APPLICATION PROCEDURE..... 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 3

OVERHEATING CAUSE ANALYSIS .......................... 4

Troubleshooting Chart .............................................. 4

COOLING SYSTEM .................................................... 6

Cooling Circuit .......................................................... 6

ENGINE COOLANT .................................................... 7

Inspection ................................................................. 7

LEVEL CHECK ..................................................... 7

CHECKING RADIATOR SYSTEM FOR LEAKS..... 7

Changing Engine Coolant ........................................ 7

DRAINING ENGINE COOLANT ........................... 8

REFILLING ENGINE COOLANT .......................... 8

FLUSHING COOLING SYSTEM ........................... 9

RADIATOR .................................................................11

Components ............................................................ 11

Removal and Installation ......................................... 11

REMOVAL ............................................................ 11

INSPECTION AFTER REMOVAL ....................... 13

INSTALLATION ................................................... 14

INSPECTION AFTER INSTALLATION ............... 14

RADIATOR (ALUMINUM TYPE) .............................. 15

Components ........................................................... 15

Disassembly and Assembly ................................... 15

PREPARATION ................................................... 15

DISASSEMBLY ................................................... 15

ASSEMBLY ......................................................... 16

INSPECTION ...................................................... 18COOLING FAN .......................................................... 19

Components (Crankshaft Driven Type) .................. 19

Removal and Installation ........................................ 19

REMOVAL ........................................................... 19

INSPECTION AFTER REMOVAL ....................... 19

INSTALLATION ................................................... 19

Removal and Installation (Motor Driven Type) (Mod-

els with A/C) ........................................................... 19

REMOVAL ........................................................... 19

INSTALLATION ................................................... 20

WATER PUMP .......................................................... 21

Components ........................................................... 21

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21

INSPECTION AFTER REMOVAL ....................... 22

INSTALLATION ................................................... 22

INSPECTION AFTER INSTALLATION ................ 22

THERMOSTAT AND WATER PIPING ...................... 23

Components ........................................................... 23

Removal and Installation ........................................ 24

REMOVAL ........................................................... 24

INSPECTION AFTER REMOVAL ....................... 24

INSTALLATION ................................................... 24

INSPECTION AFTER INSTALLATION ................ 25

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 26

Standard and Limit .................................................. 26

ENGINE COOLANT CAPACITY .......................... 26

THERMOSTAT .................................................... 26

RESERVOIR TANK ............................................. 26

Page 886 of 3171

CO-2

PRECAUTIONS

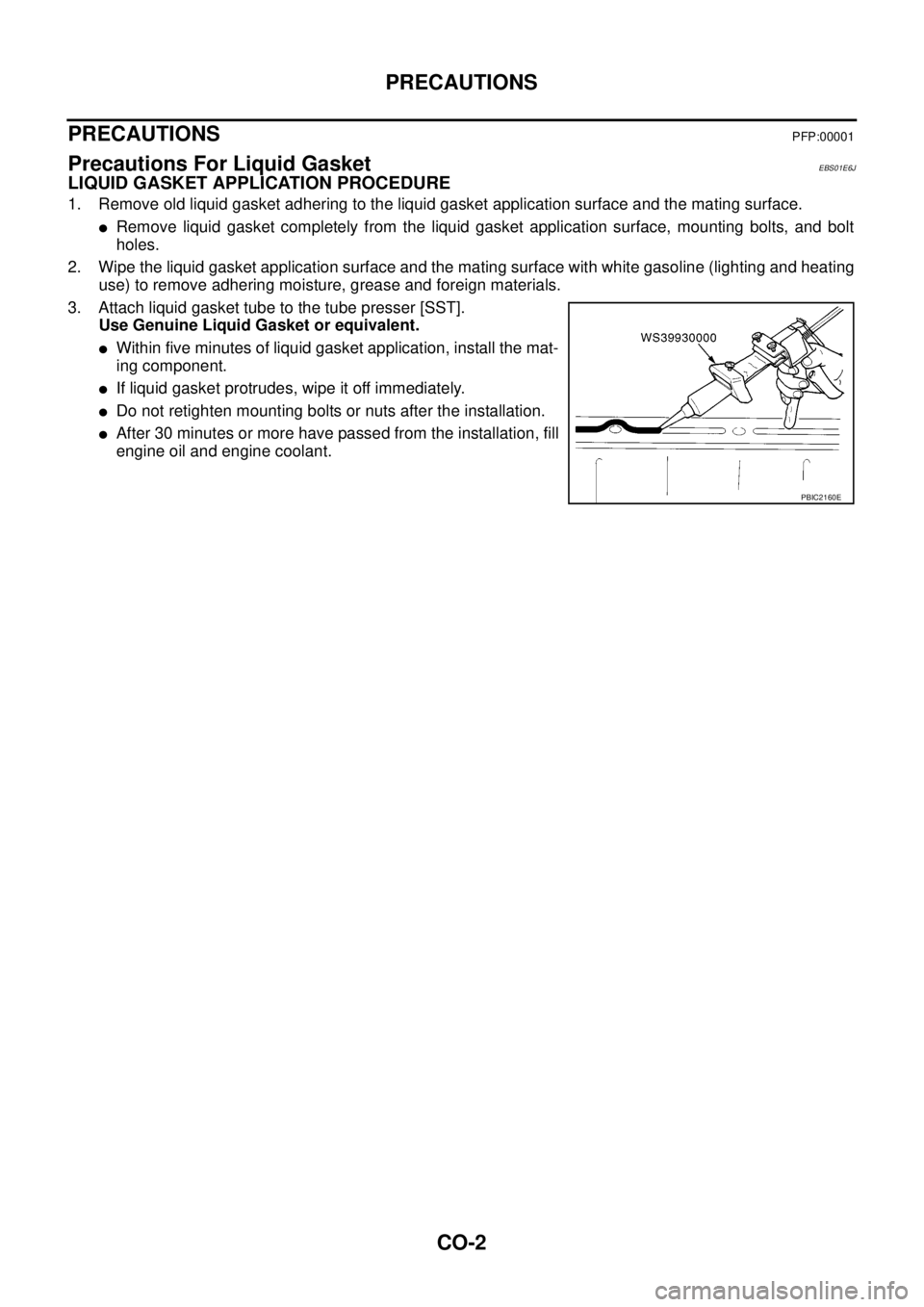

PRECAUTIONS

PFP:00001

Precautions For Liquid GasketEBS01E6J

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

lRemove liquid gasket completely from the liquid gasket application surface, mounting bolts, and bolt

holes.

2. Wipe the liquid gasket application surface and the mating surface with white gasoline (lighting and heating

use) to remove adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to the tube presser [SST].

Use Genuine Liquid Gasket or equivalent.

lWithin five minutes of liquid gasket application, install the mat-

ing component.

lIf liquid gasket protrudes, wipe it off immediately.

lDo not retighten mounting bolts or nuts after the installation.

lAfter 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

PBIC2160E

Page 888 of 3171

CO-4

OVERHEATING CAUSE ANALYSIS

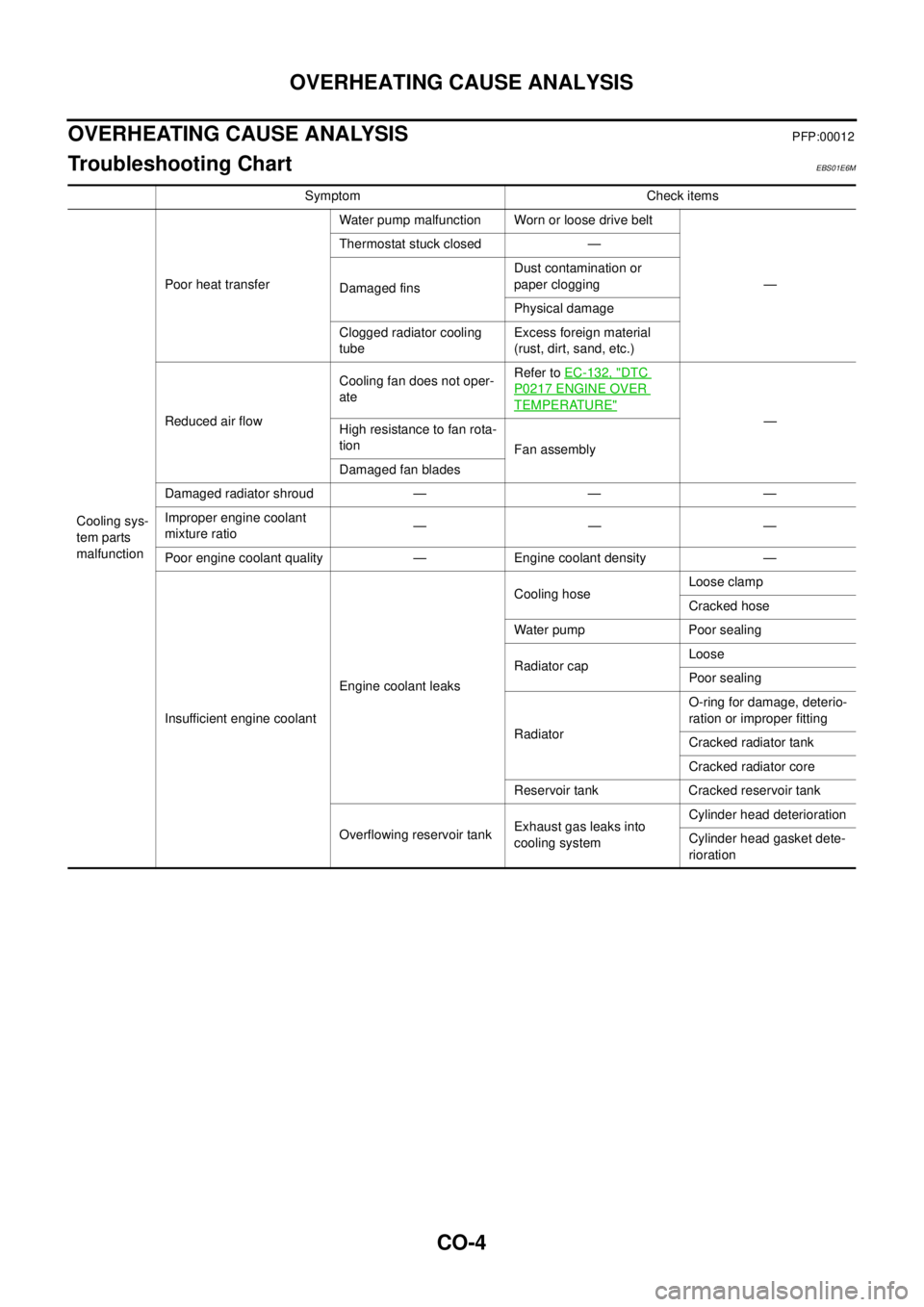

OVERHEATING CAUSE ANALYSIS

PFP:00012

Troubleshooting ChartEBS01E6M

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

— Thermostat stuck closed —

Damaged finsDust contamination or

paper clogging

Physical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ateRefer toEC-132, "

DTC

P0217 ENGINE OVER

TEMPERATURE"

—

Highresistancetofanrota-

tion

Fan assembly

Damaged fan blades

Damaged radiator shroud — — —

Improper engine coolant

mixture ratio—— —

Poor engine coolant quality — Engine coolant density —

Insufficient engine coolantEngine coolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deterioration

Cylinder head gasket dete-

rioration

Page 889 of 3171

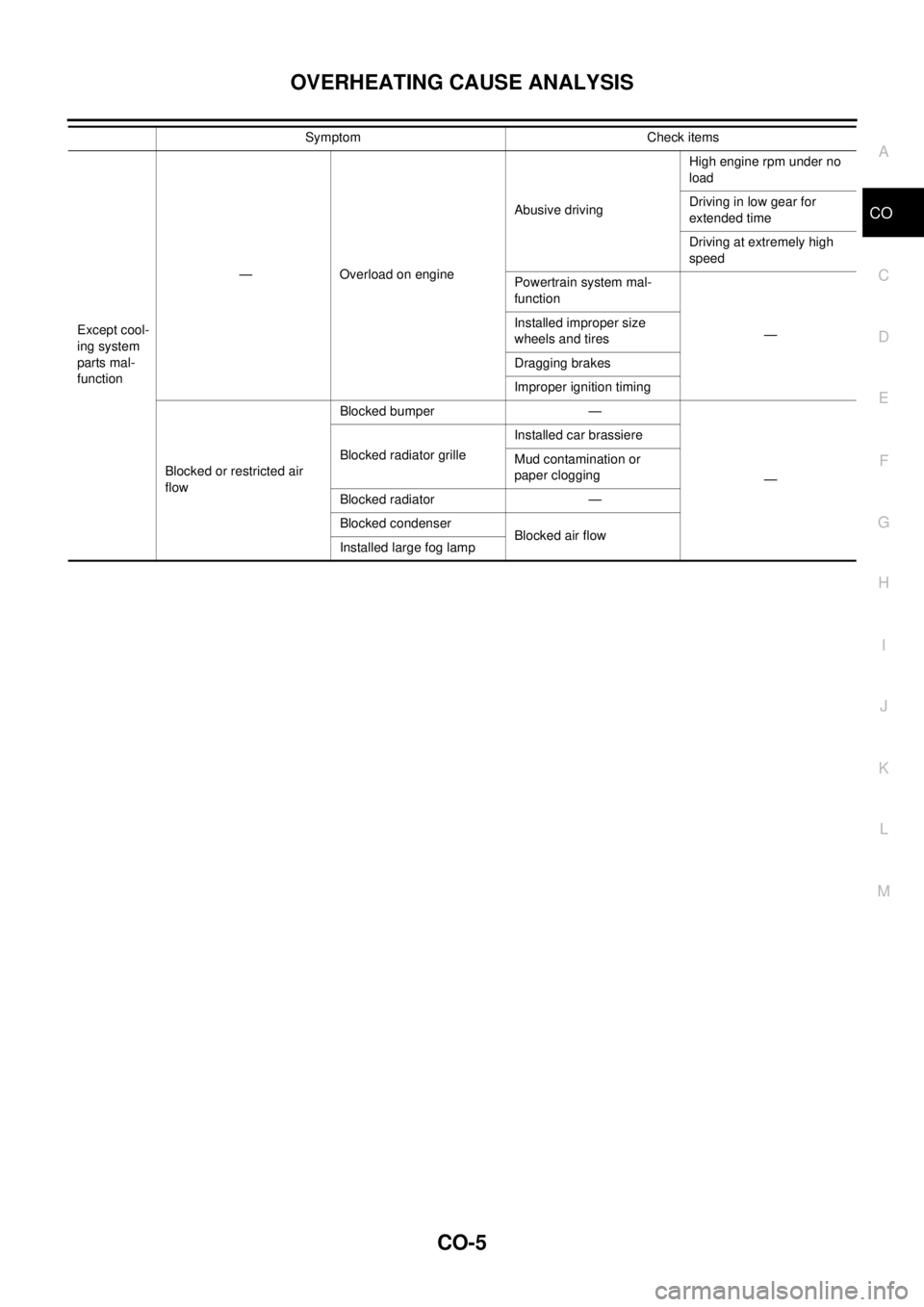

OVERHEATING CAUSE ANALYSIS

CO-5

C

D

E

F

G

H

I

J

K

L

MA

CO

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system mal-

function

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator —

Blocked condenser

Blocked air flow

Installed large fog lamp Symptom Check items

Page 908 of 3171

CO-24

THERMOSTAT AND WATER PIPING

Removal and Installation

EBS01E6X

WARNING:

Do not remove radiator cap and/or reservoir tank cap when engine is hot. Serious burns could occur

from high pressure engine coolant escaping from radiator and/or reservoir tank.

REMOVAL

1. Remove front engine undercover and middle engine undercover. Refer toEI-15, "FRONT BUMPER".

2. Drain engine coolant from radiator drain plug at the bottom of radiator, and from water drain plug at the

side of cylinder block. Refer toCO-7, "

Changing Engine Coolant"andEM-110, "CYLINDER BLOCK".

CAUTION:

Perform this step when engine is cold.

3. Remove engine cover. Refer toEM-20, "

INTAKE MANIFOLD".

4. Disconnect radiator hoses (upper and lower) from engine side. Refer toCO-11, "

RADIATOR".

5. Remove air inlet pipe and air duct between air cleaner case and turbocharger. Refer toEM-15, "

AIR

CLEANER AND AIR DUCT"andEM-28, "TURBO CHARGER".

6. Remove water outlet, water inlet and thermostat.

7. Remove thermostat housing.

8. Disconnect heater return hose and water hoses at heater return pipe side, and remove heater return pipe.

9. Remove oil level gauge guide mounting bolt, vacuum hoses (to turbocharger boost control solenoid valve)

and spill hose. Refer toEM-36, "

OIL PAN AND OIL STRAINER",EM-20, "INTAKE MANIFOLD"andEM-

44, "INJECTION TUBE AND FUEL INJECTOR".

10. Disconnect water hoses (to EGR cooler) (A/T models), vacuum hoses and heater feed hose at heater

feed pipe side, and remove heater feed pipe. Refer toEM-20, "

INTAKE MANIFOLD".

INSPECTION AFTER REMOVAL

Thermostat

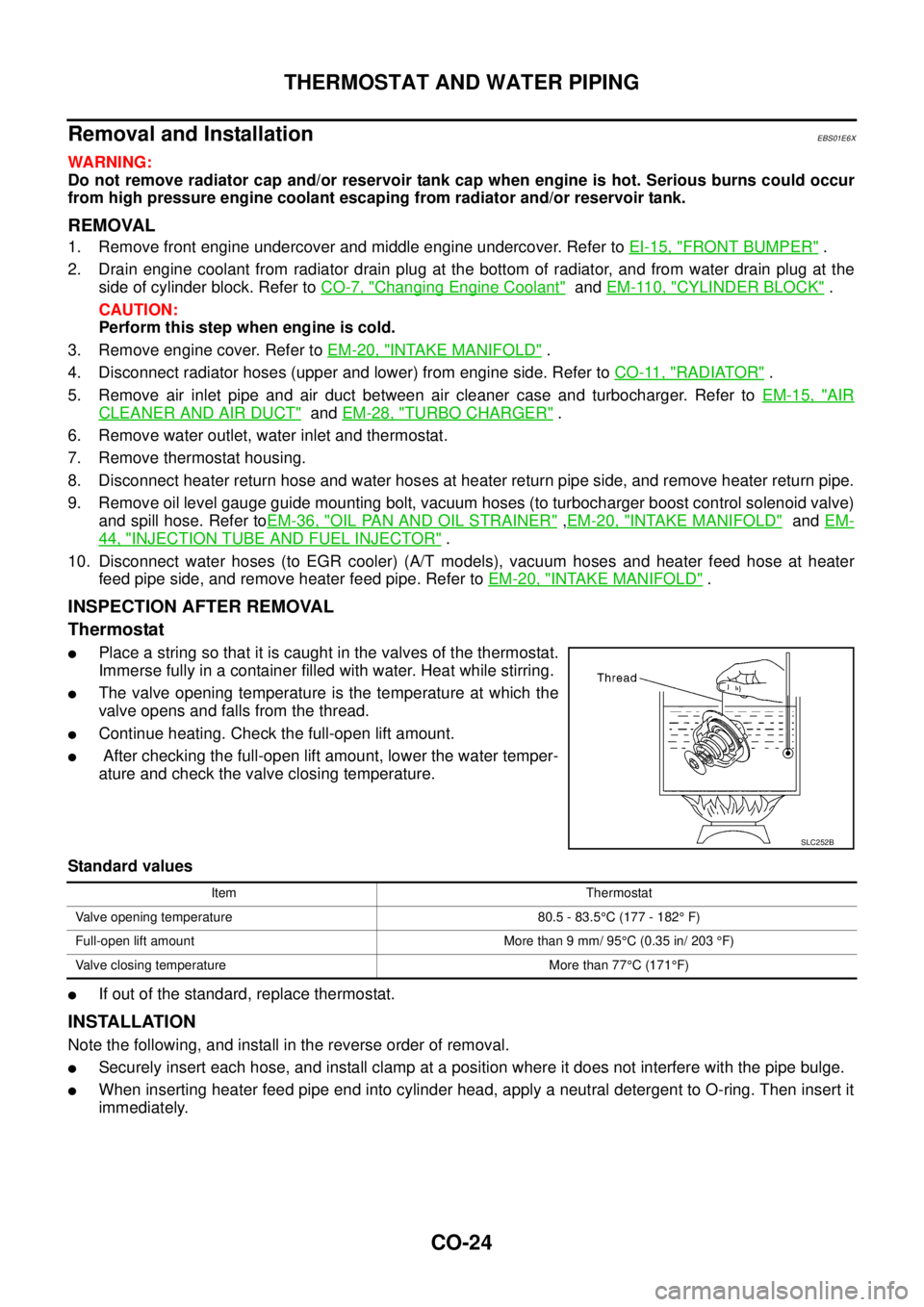

lPlace a string so that it is caught in the valves of the thermostat.

Immerse fully in a container filled with water. Heat while stirring.

lThe valve opening temperature is the temperature at which the

valve opens and falls from the thread.

lContinue heating. Check the full-open lift amount.

lAfter checking the full-open lift amount, lower the water temper-

ature and check the valve closing temperature.

Standard values

lIf out of the standard, replace thermostat.

INSTALLATION

Note the following, and install in the reverse order of removal.

lSecurely insert each hose, and install clamp at a position where it does not interfere with the pipe bulge.

lWhen inserting heater feed pipe end into cylinder head, apply a neutral detergent to O-ring. Then insert it

immediately.

SLC252B

Item Thermostat

Valve opening temperature 80.5 - 83.5°C (177 - 182°F)

Full-open lift amount More than 9 mm/ 95°C (0.35 in/ 203°F)

Valve closing temperature More than 77°C(171°F)

Page 982 of 3171

EC-2

DTC Confirmation Procedure ................................. 88

Diagnostic Procedure ............................................. 89

Component Inspection ............................................ 90

Removal and Installation ........................................ 91

DTC P0102, P0103 MAF SENSOR ........................... 92

Component Description .......................................... 92

CONSULT-II Reference Value in Data Monitor Mode

... 92

ECM Terminals and Reference Value ..................... 92

On Board Diagnosis Logic ...................................... 93

DTC Confirmation Procedure ................................. 93

Wiring Diagram ....................................................... 94

Diagnostic Procedure ............................................. 95

Component Inspection ............................................ 96

Removal and Installation ........................................ 97

DTC P0112, P0113 IAT SENSOR ............................. 98

Component Description .......................................... 98

On Board Diagnosis Logic ...................................... 98

DTC Confirmation Procedure ................................. 98

Wiring Diagram .....................................................100

Diagnostic Procedure ...........................................101

Component Inspection ..........................................102

Removal and Installation ......................................102

DTC P0117, P0118 ECT SENSOR ..........................103

Description ............................................................103

On Board Diagnosis Logic ....................................103

DTC Confirmation Procedure ...............................103

Wiring Diagram .....................................................105

Diagnostic Procedure ...........................................106

Component Inspection ..........................................107

Removal and Installation ......................................107

DTC P0122, P0123 APP SENSOR .........................108

Description ............................................................108

CONSULT-II Reference Value in Data Monitor Mode

.108

ECM Terminals and Reference Value ...................108

On Board Diagnosis Logic ....................................109

DTC Confirmation Procedure ...............................109

Wiring Diagram .....................................................110

Diagnostic Procedure ............................................111

Component Inspection ..........................................112

Removal and Installation ......................................112

DTC P0182, P0183 FUEL PUMP TEMPERATURE

SENSOR ..................................................................113

Description ............................................................113

CONSULT-II Reference Value in Data Monitor Mode

.113

ECM Terminals and Reference Value ...................113

On Board Diagnosis Logic ....................................113

DTC Confirmation Procedure ...............................114

Wiring Diagram .....................................................115

Diagnostic Procedure ...........................................116

Removal and Installation ......................................117

DTC P0192, P0193 FRP SENSOR .........................118

Description ............................................................118

CONSULT-II Reference Value in Data Monitor Mode

.118

ECM Terminals and Reference Value ...................118

On Board Diagnosis Logic ....................................118DTC Confirmation Procedure ................................119

Wiring Diagram .....................................................120

Diagnostic Procedure ............................................121

Component Inspection ..........................................122

Removal and Installation .......................................122

DTC P0200 FUEL INJECTOR .................................123

On Board Diagnosis Logic ....................................123

DTC Confirmation Procedure ................................123

Diagnostic Procedure ............................................123

DTC P0201 - P0204 FUEL INJECTOR ...................125

Component Description ........................................125

CONSULT-II Reference Value in Data Monitor Mode

.125

ECM Terminals and Reference Value ...................125

On Board Diagnosis Logic ....................................126

DTC Confirmation Procedure ................................127

Wiring Diagram .....................................................128

Diagnostic Procedure ............................................129

Component Inspection ..........................................130

Removal and Installation .......................................131

DTC P0217 ENGINE OVER TEMPERATURE ........132

Description ............................................................132

CONSULT-II Reference Value in Data Monitor Mode

.133

On Board Diagnosis Logic ....................................133

Overall Function Check .........................................133

Wiring Diagram .....................................................135

Diagnostic Procedure ............................................137

Main 12 Causes of Overheating ...........................140

Component Inspection ..........................................141

DTC P0222, P0223 APP SENSOR .........................142

Description ............................................................142

CONSULT-II Reference Value in Data Monitor Mode

.142

ECM Terminals and Reference Value ...................142

On Board Diagnosis Logic ....................................143

DTC Confirmation Procedure ................................143

Wiring Diagram .....................................................144

Diagnostic Procedure ............................................145

Component Inspection ..........................................146

Removal and Installation .......................................146

DTC P0234 TC SYSTEM .........................................147

Description ............................................................147

ECM Terminals and Reference Value ...................147

On Board Diagnosis Logic ....................................148

Overall Function Check .........................................148

Wiring Diagram .....................................................149

Diagnostic Procedure ............................................150

Component Inspection ..........................................152

Removal and Installation .......................................152

DTC P0237, P0238 TC BOOST SENSOR ..............153

Component Description ........................................153

CONSULT-II Reference Value in Data Monitor Mode

.153

ECM Terminals and Reference Value ...................153

On Board Diagnosis Logic ....................................154

DTC Confirmation Procedure ................................154

Wiring Diagram .....................................................155

Diagnostic Procedure ............................................156