instrument cluster NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 225 of 3171

KEY INTERLOCK CABLE

AT-217

D

E

F

G

H

I

J

K

L

MA

B

AT

REMOVAL

1. Remove center console. Refer toIP-16, "CENTER CONSOLE".

2. Remove lower instrument panel LH (for LHD models) or lower instrument panel RH (for RHD models) and

cluster lid A. Refer toIP-13, "

LOWER INSTRUMENT PANEL LH",IP-15, "LOWER INSTRUMENT

PANEL RH AND GLOVE BOX",IP-10, "INSTRUMENT PANEL".

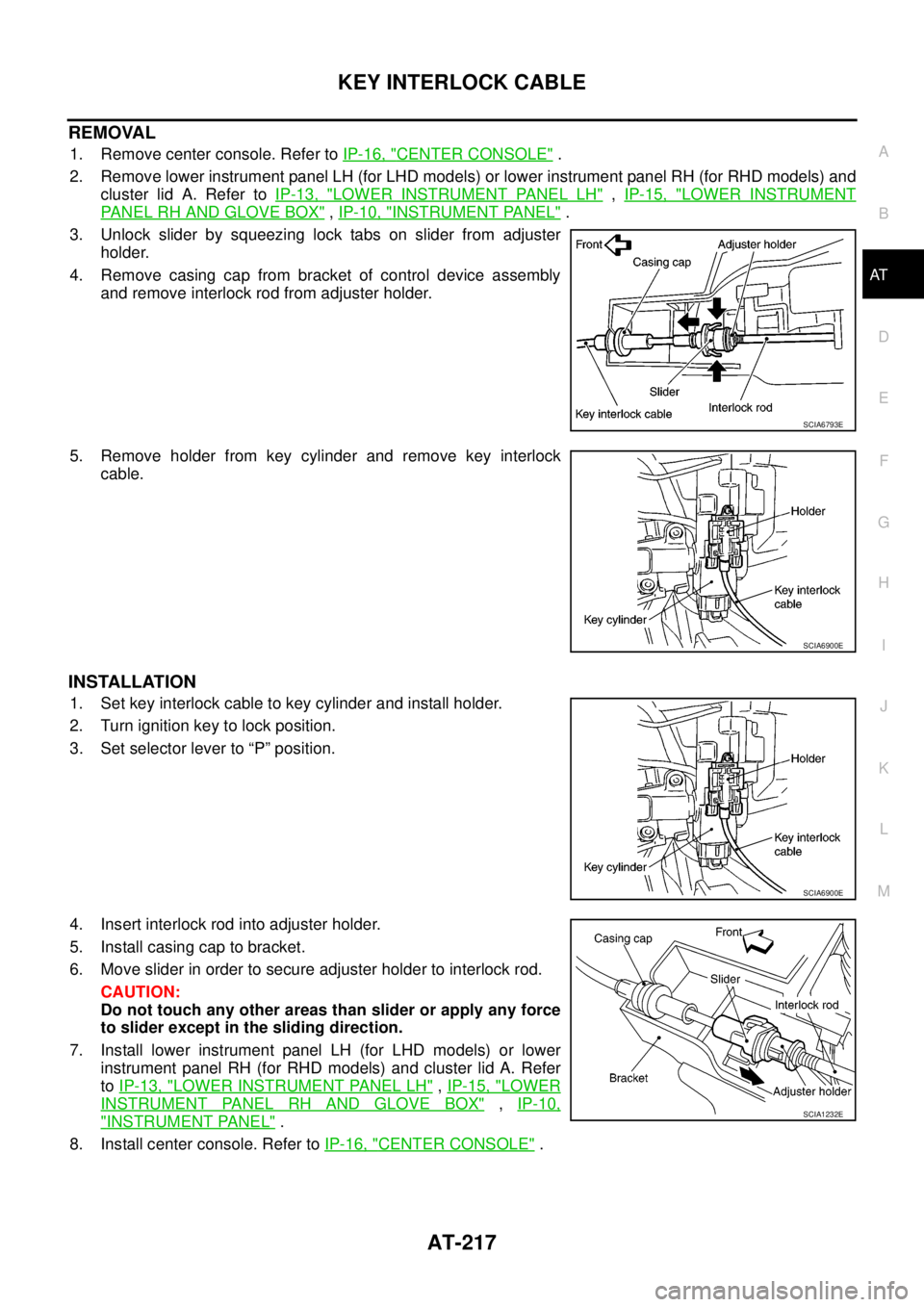

3. Unlock slider by squeezing lock tabs on slider from adjuster

holder.

4. Remove casing cap from bracket of control device assembly

and remove interlock rod from adjuster holder.

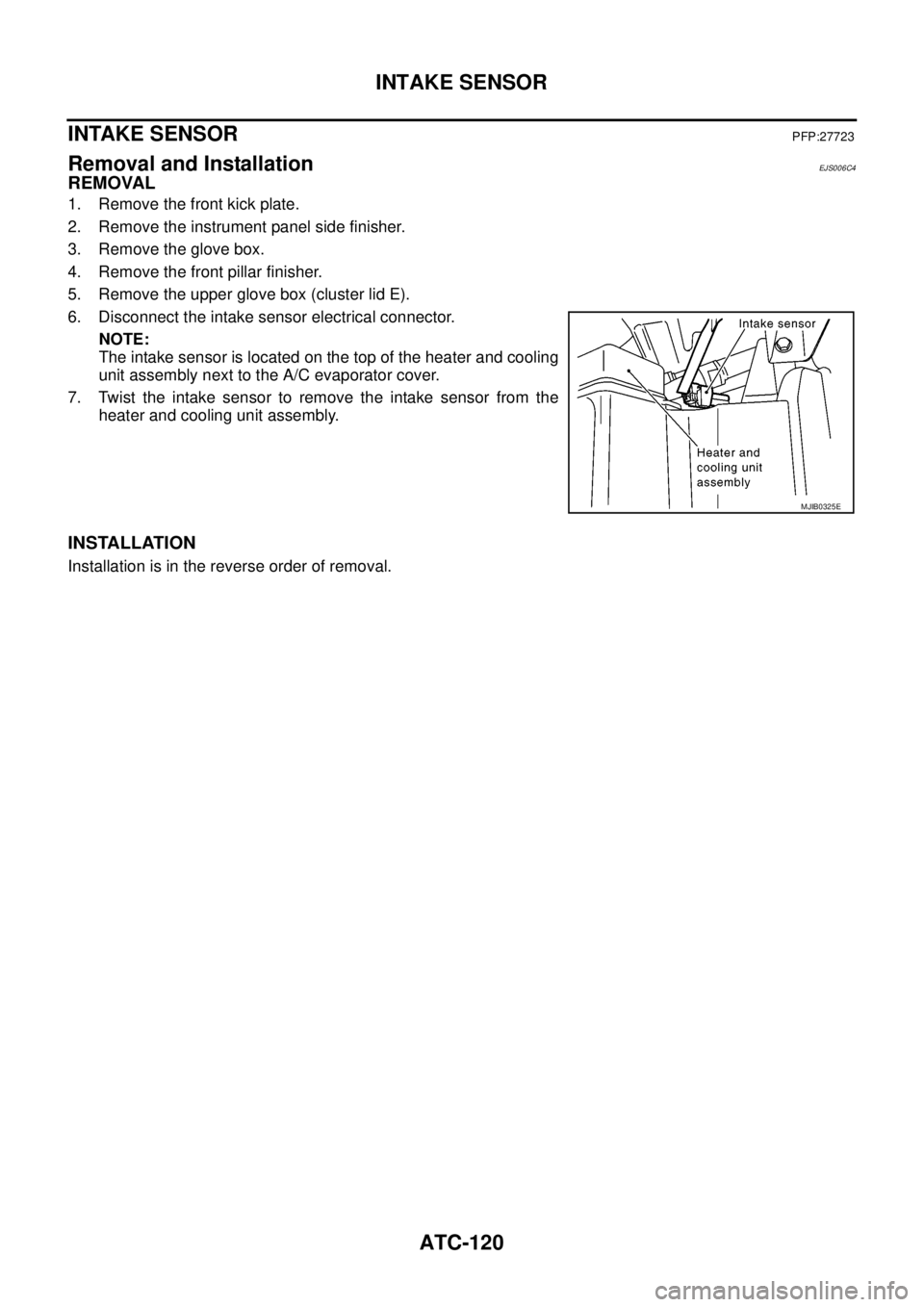

5. Remove holder from key cylinder and remove key interlock

cable.

INSTALLATION

1. Set key interlock cable to key cylinder and install holder.

2. Turn ignition key to lock position.

3. Set selector lever to “P” position.

4. Insert interlock rod into adjuster holder.

5. Install casing cap to bracket.

6. Move slider in order to secure adjuster holder to interlock rod.

CAUTION:

Do not touch any other areas than slider or apply any force

to slider except in the sliding direction.

7. Install lower instrument panel LH (for LHD models) or lower

instrument panel RH (for RHD models) and cluster lid A. Refer

toIP-13, "

LOWER INSTRUMENT PANEL LH",IP-15, "LOWER

INSTRUMENT PANEL RH AND GLOVE BOX",IP-10,

"INSTRUMENT PANEL".

8. Install center console. Refer toIP-16, "

CENTER CONSOLE".

SCIA6793E

SCIA6900E

SCIA6900E

SCIA1232E

Page 454 of 3171

ATC-120

INTAKE SENSOR

INTAKE SENSOR

PFP:27723

Removal and InstallationEJS006C4

REMOVAL

1. Remove the front kick plate.

2. Remove the instrument panel side finisher.

3. Remove the glove box.

4. Remove the front pillar finisher.

5. Remove the upper glove box (cluster lid E).

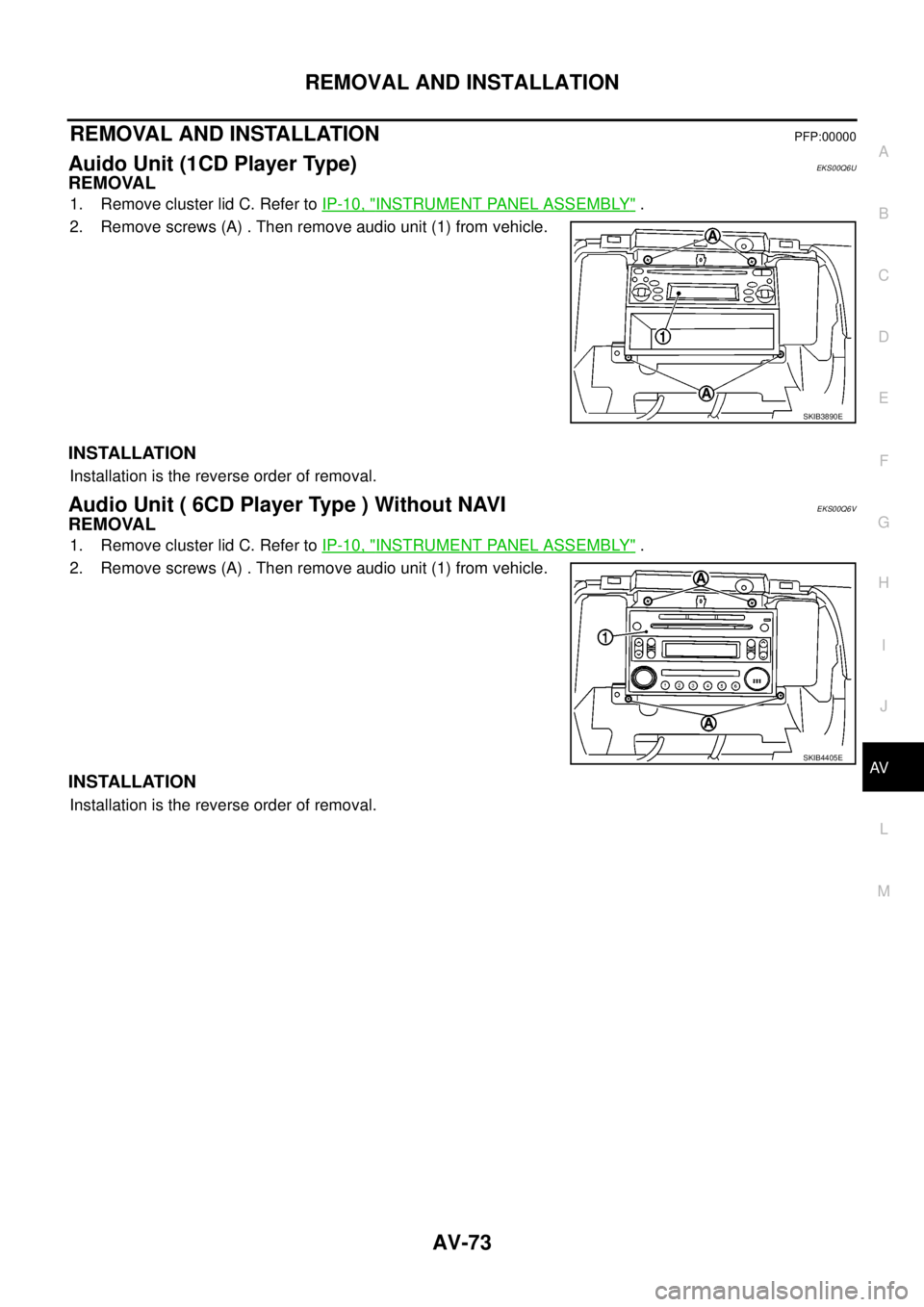

6. Disconnect the intake sensor electrical connector.

NOTE:

The intake sensor is located on the top of the heater and cooling

unit assembly next to the A/C evaporator cover.

7. Twist the intake sensor to remove the intake sensor from the

heater and cooling unit assembly.

INSTALLATION

Installation is in the reverse order of removal.

MJIB0325E

Page 561 of 3171

REMOVAL AND INSTALLATION

AV-73

C

D

E

F

G

H

I

J

L

MA

B

AV

REMOVAL AND INSTALLATIONPFP:00000

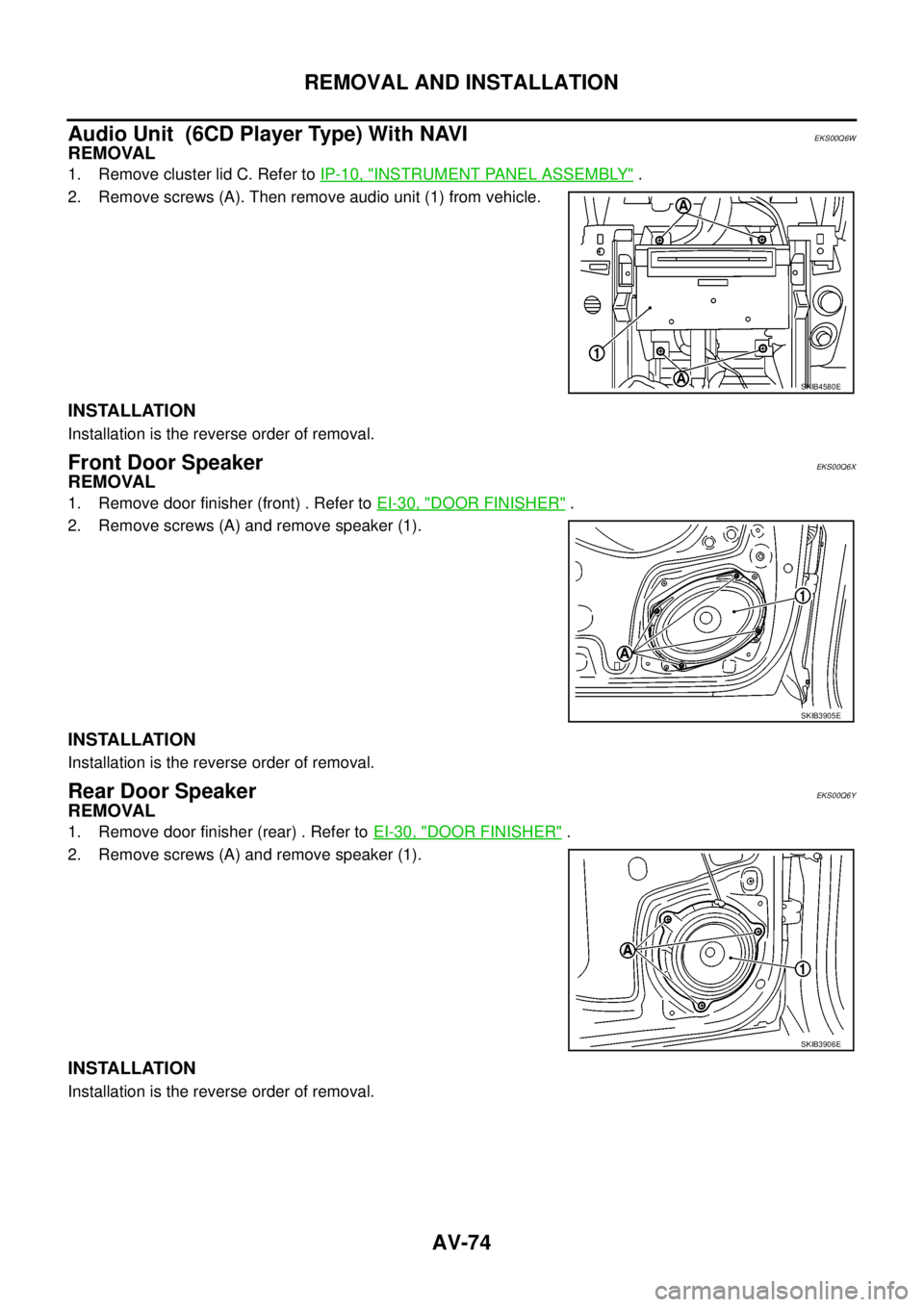

Auido Unit (1CD Player Type)EKS00Q6U

REMOVAL

1. Remove cluster lid C. Refer toIP-10, "INSTRUMENT PANEL ASSEMBLY".

2. Remove screws (A) . Then remove audio unit (1) from vehicle.

INSTALLATION

Installation is the reverse order of removal.

Audio Unit ( 6CD Player Type ) Without NAVIEKS00Q6V

REMOVAL

1. Remove cluster lid C. Refer toIP-10, "INSTRUMENT PANEL ASSEMBLY".

2. Remove screws (A) . Then remove audio unit (1) from vehicle.

INSTALLATION

Installation is the reverse order of removal.

SKIB3890E

SKIB4405E

Page 562 of 3171

AV-74

REMOVAL AND INSTALLATION

Audio Unit (6CD Player Type) With NAVI

EKS00Q6W

REMOVAL

1. Remove cluster lid C. Refer toIP-10, "INSTRUMENT PANEL ASSEMBLY".

2. Remove screws (A). Then remove audio unit (1) from vehicle.

INSTALLATION

Installation is the reverse order of removal.

Front Door SpeakerEKS00Q6X

REMOVAL

1. Remove door finisher (front) . Refer toEI-30, "DOOR FINISHER".

2. Remove screws (A) and remove speaker (1).

INSTALLATION

Installation is the reverse order of removal.

Rear Door SpeakerEKS00Q6Y

REMOVAL

1. Remove door finisher (rear) . Refer toEI-30, "DOOR FINISHER".

2. Remove screws (A) and remove speaker (1).

INSTALLATION

Installation is the reverse order of removal.

SKIB4580E

SKIB3905E

SKIB3906E

Page 565 of 3171

REMOVAL AND INSTALLATION

AV-77

C

D

E

F

G

H

I

J

L

MA

B

AV

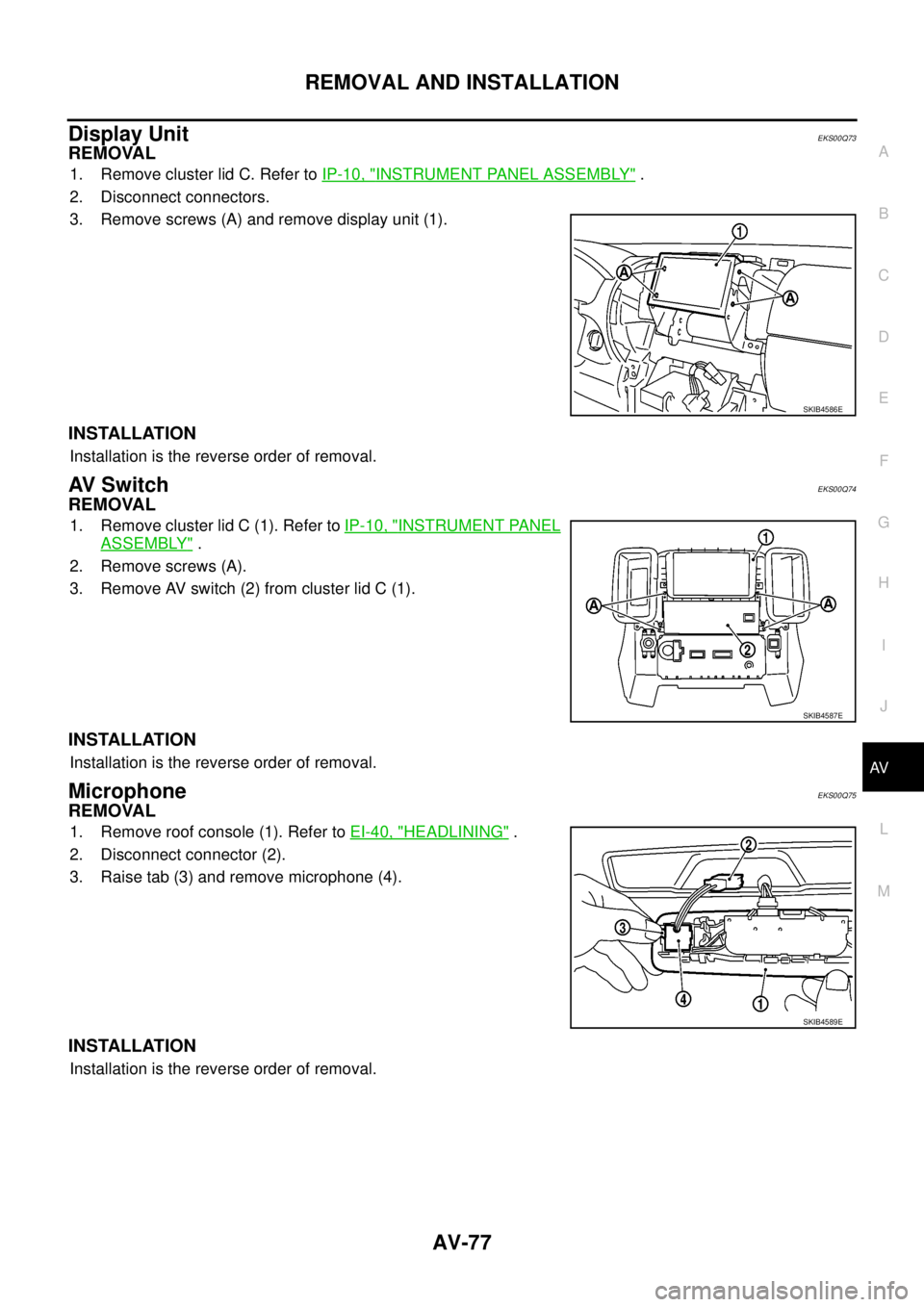

Display UnitEKS00Q73

REMOVAL

1. Remove cluster lid C. Refer toIP-10, "INSTRUMENT PANEL ASSEMBLY".

2. Disconnect connectors.

3. Remove screws (A) and remove display unit (1).

INSTALLATION

Installation is the reverse order of removal.

AV S w i t c hEKS00Q74

REMOVAL

1. Remove cluster lid C (1). Refer toIP-10, "INSTRUMENT PANEL

ASSEMBLY".

2. Remove screws (A).

3. Remove AV switch (2) from cluster lid C (1).

INSTALLATION

Installation is the reverse order of removal.

MicrophoneEKS00Q75

REMOVAL

1. Remove roof console (1). Refer toEI-40, "HEADLINING".

2. Disconnect connector (2).

3. Raise tab (3) and remove microphone (4).

INSTALLATION

Installation is the reverse order of removal.

SKIB4586E

SKIB4587E

SKIB4589E

Page 592 of 3171

BL-8

SQUEAK AND RATTLE TROUBLE DIAGNOSES

FELT CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15´25 mm (0.59´0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not available through NISSAN Parts Department, can also be used to repair squeaks

and rattles.

UHMW(TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingEIS00DI3

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks to

repair the noise.

Page 772 of 3171

BL-188

NATS(NISSAN ANTI-THEFT SYSTEM)

4.PERFORM INITIALIZATION WITH CONSULT-II AGAIN

1. Replace BCM.

2. Perform initialization with CONSULT-II.

For initialization, refer to “CONSULT-II Operation Manual

NATS”.

NOTE:

If the initialization is not completed or malfunctions, CONSULT-II

shows the message on the screen.

Can the system be initialized?

Yes >>SystemisOK.(BCMismalfunctioning.)

No >> ECM is malfunctioning.

lReplace ECM.

lPerform initialization with CONSULT-II

lFor initialization, refer to “CONSULT-II Operation

Manual NATS”

Removal and Installation of NATS Antenna AmpEIS00DB7

REMOVAL

CAUTION:

Before servicing SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3 min-

utes.

1. Remove the cluster lid A. Refer toIP-10, "

INSTRUMENT PANEL ASSEMBLY".

2. Disconnect the NATS antenna amp connector, remove the

screw and antenna amp.

INSTALLATION

Install in the reverse order of removal.

NOTE:

lIf NATS antenna amp. is not installed correctly, NATS system will not operate properly and SELF-

DIAG RESULTS on CONSULT-II screen will show “LOCK MODE” or “CHAIN OF IMMU-KEY”.

lInitialization is not necessary only when NATS antenna amp. is replaced with a new one.

SEL297W

MIIB0713E

Page 937 of 3171

COMBINATION METERS

DI-27

C

D

E

F

G

H

I

J

L

MA

B

DI

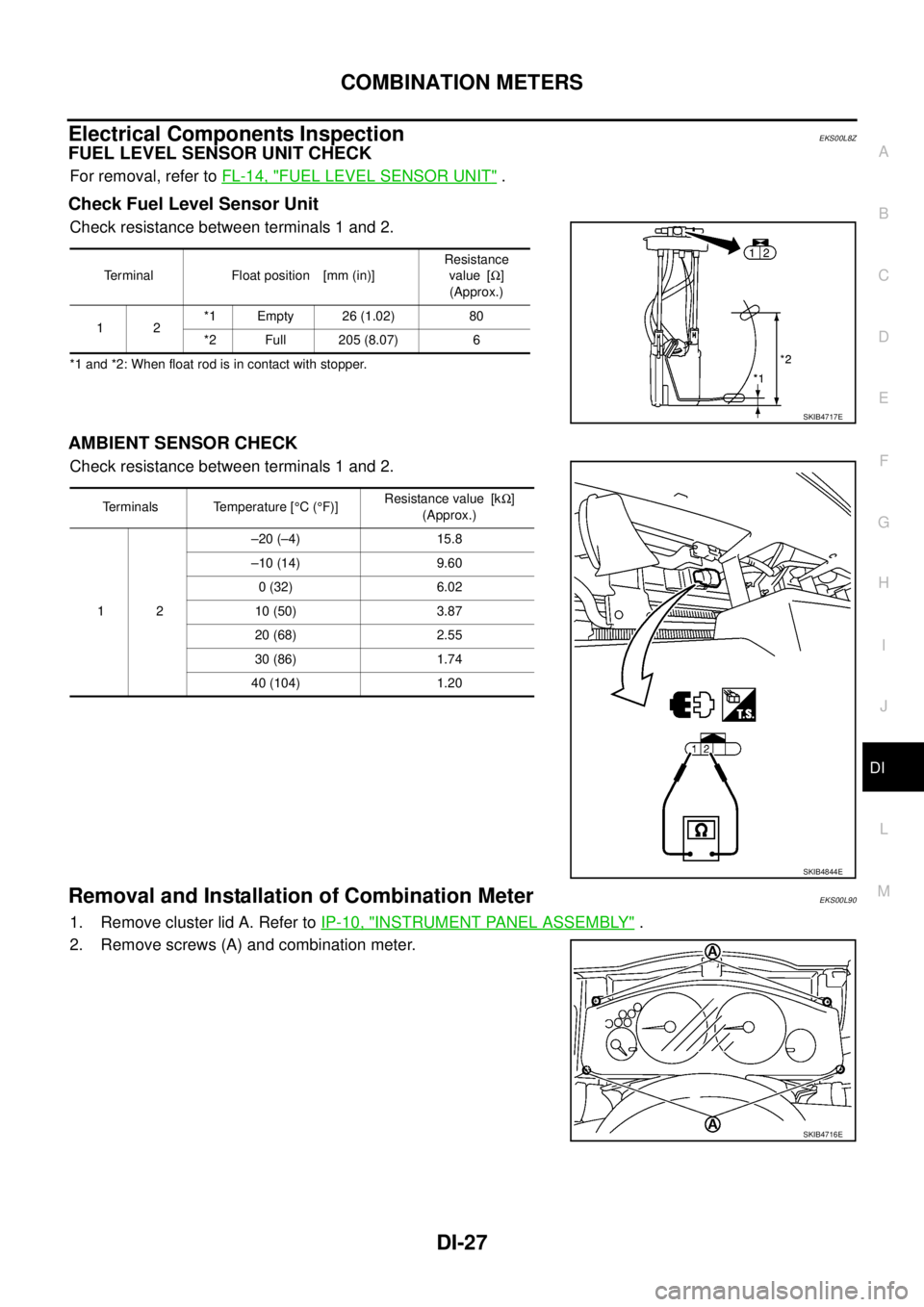

Electrical Components InspectionEKS00L8Z

FUEL LEVEL SENSOR UNIT CHECK

For removal, refer toFL-14, "FUEL LEVEL SENSOR UNIT".

Check Fuel Level Sensor Unit

Check resistance between terminals 1 and 2.

*1 and *2: When float rod is in contact with stopper.

AMBIENT SENSOR CHECK

Check resistance between terminals 1 and 2.

Removal and Installation of Combination MeterEKS00L90

1. Remove cluster lid A. Refer toIP-10, "INSTRUMENT PANEL ASSEMBLY".

2. Remove screws (A) and combination meter.

Terminal Float position [mm (in)]Resistance

value [W]

(Approx.)

12*1 Empty 26 (1.02) 80

*2 Full 205 (8.07) 6

SKIB4717E

Terminals Temperature [°C(°F)]Resistance value [kW]

(Approx.)

12–20 (–4) 15.8

–10 (14) 9.60

0 (32) 6.02

10 (50) 3.87

20 (68) 2.55

30 (86) 1.74

40 (104) 1.20

SKIB4844E

SKIB4716E

Page 1345 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

EI-7

C

D

E

F

G

H

J

K

L

MA

B

EI

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raisethevehicleonahoistandhitatirewitharubberhammer.

lDrive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

lIf it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool

(Engine Ear and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

lremoving the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be bro-

ken or lost during the repair, resulting in the creation of new noise.

ltapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

lfeeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

lplacing a piece of paper between components that you suspect are causing the noise.

llooking for loose components and contact marks.

Refer toEI-7, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

lIf the cause is a loose component, tighten the component securely.

lIf the cause is insufficient clearance between components:

–separate components by repositioning or loosening and retightening the component, if possible.

–insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingEIS00DY6

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

Page 1346 of 3171

EI-8

SQUEAK AND RATTLE TROUBLE DIAGNOSES

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.