belt NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2176 of 3641

BODY SIDE TRIMINT-25

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

Installation

Installation is in the reverse order of removal.

CENTER PILLAR LOWER FINISHER

CENTER PILLAR LOWER FINISHER

: Removal and InstallationINFOID:0000000012431869

REMOVAL

1. Remove front kicking plate and rear kicking plate. Refer to INT-22, "KICKING PLATE : Removal and

Installation".

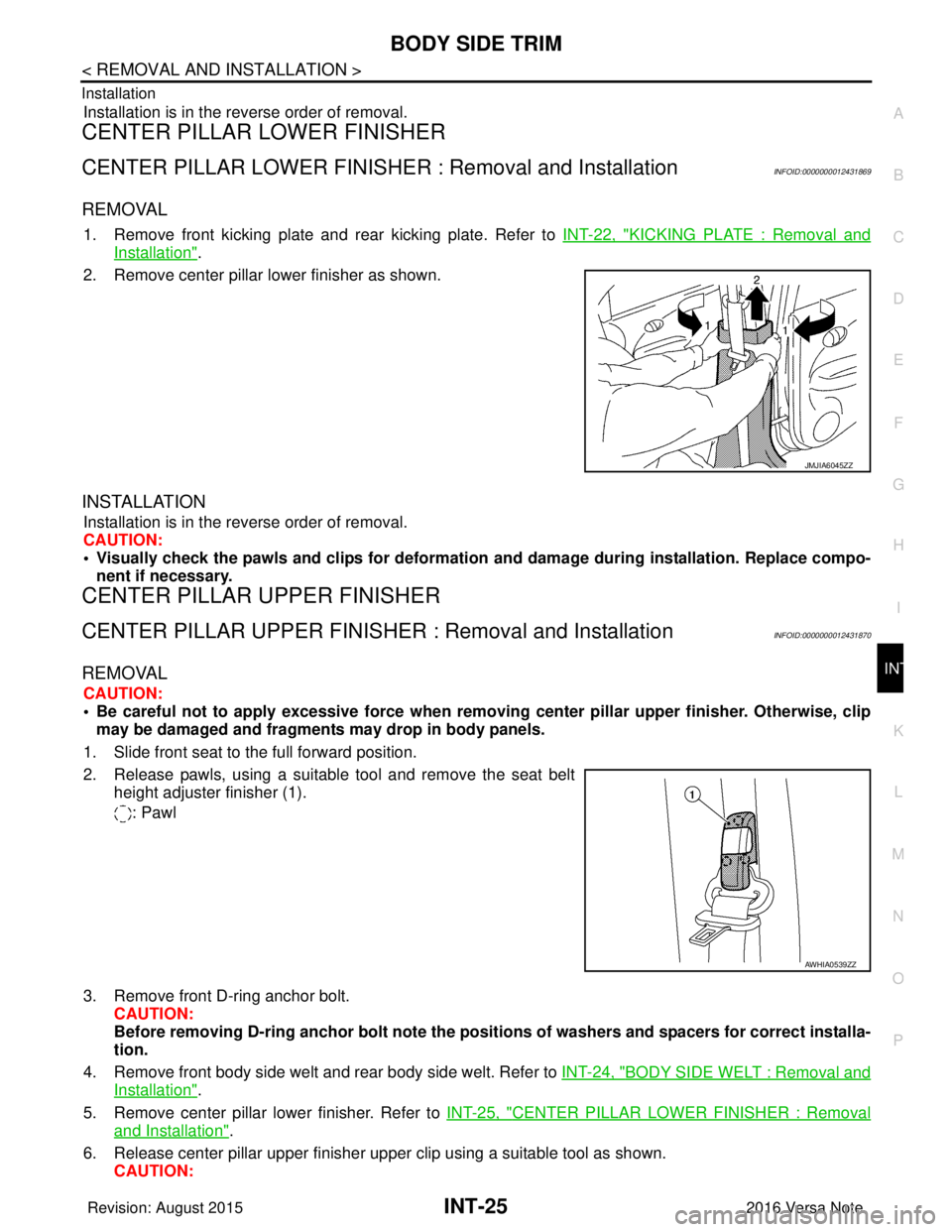

2. Remove center pillar lower finisher as shown.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Visually check the pawls and clips for deformation and damage during installation. Replace compo-

nent if necessary.

CENTER PILLAR UPPER FINISHER

CENTER PILLAR UPPER FINISHER : Removal and InstallationINFOID:0000000012431870

REMOVAL

CAUTION:

• Be careful not to apply excessive for ce when removing center pillar upper finisher. Otherwise, clip

may be damaged and fragments may drop in body panels.

1. Slide front seat to the full forward position.

2. Release pawls, using a suitable tool and remove the seat belt height adjuster finisher (1).

: Pawl

3. Remove front D-ring anchor bolt. CAUTION:

Before removing D-ring anchor bolt note the positions of washers and spacers for correct installa-

tion.

4. Remove front body side welt and rear body side welt. Refer to INT-24, "

BODY SIDE WELT : Removal and

Installation".

5. Remove center pillar lower finisher. Refer to INT-25, "

CENTER PILLAR LOWER FINISHER : Removal

and Installation".

6. Release center pillar upper finisher upper clip using a suitable tool as shown. CAUTION:

JMJIA6045ZZ

AWHIA0539ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2178 of 3641

FLOOR TRIMINT-27

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

FLOOR TRIM

Exploded ViewINFOID:0000000012431871

Removal and InstallationINFOID:0000000012431872

WARNING:

• Before servicing the SRS, turn the ignition switch off, disconnect both battery terminals then wait at

least three minutes.

• Do not drop the seat belt retractor. Always handle it with care.

• Always point pretensioner cylinder away from body when handling.

REMOVAL

1. Remove front seats. Refer to SE-20, "DRIVER SIDE : Removal and Installation" (Driver side) and SE-22,

"PASSENGER SIDE : Removal and Installation" (Passenger side).

2. Remove rear seatback hinge. Refer to SE-27, "

SEATBACK HINGE : Removal and Installation".

3. Remove center console lower. Refer to IP-20, "

Removal and Installation".

4. Remove dash side finishers (LH/RH). Refer to INT-24, "

DASH SIDE FINISHER : Removal and Installa-

tion".

5. Remove center pillar lower finishers (LH/RH). Refer to INT-25, "

CENTER PILLAR LOWER FINISHER :

Removal and Installation".

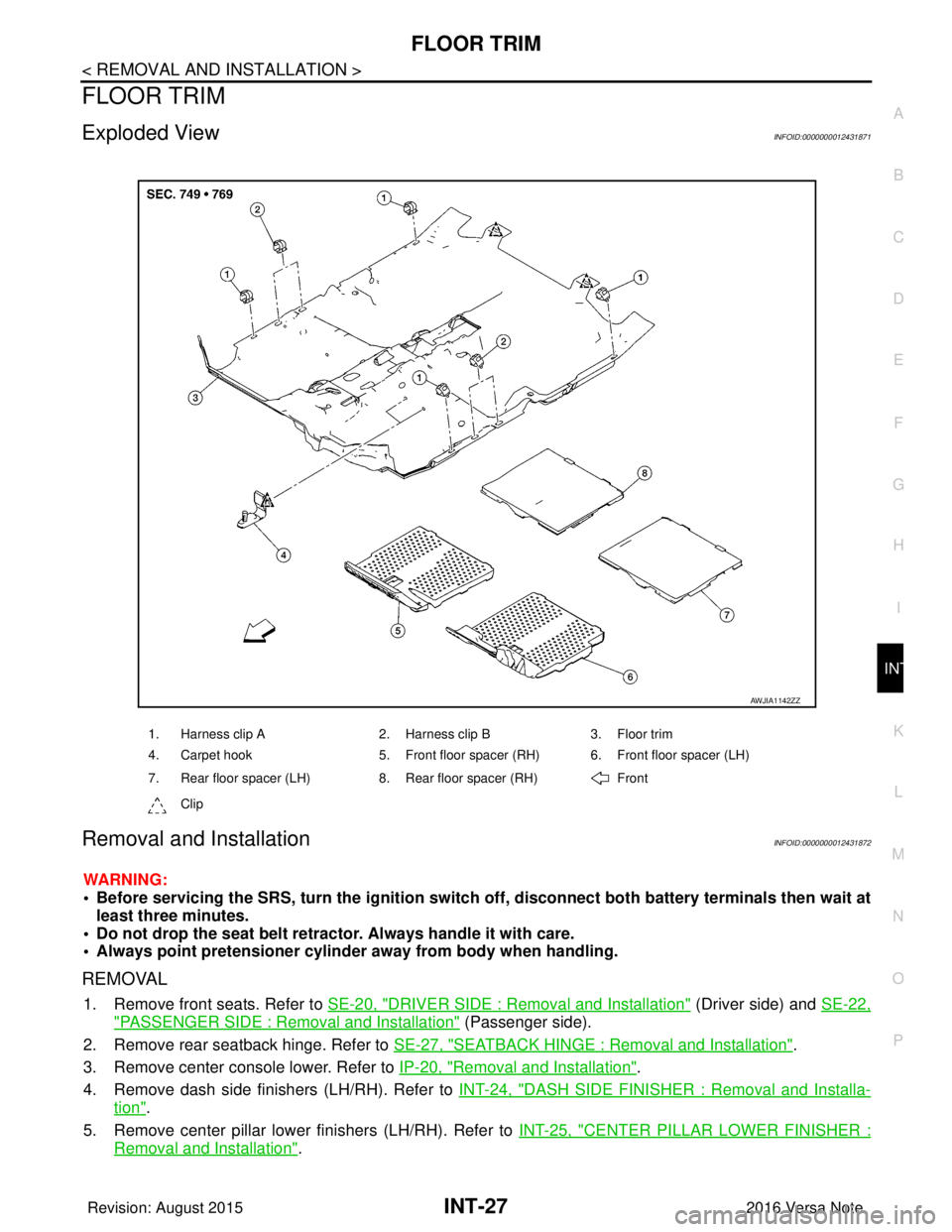

1. Harness clip A2. Harness clip B3. Floor trim

4. Carpet hook 5. Front floor spacer (RH) 6. Front floor spacer (LH)

7. Rear floor spacer (LH) 8. Rear floor spacer (RH) Front

Clip

AWJIA1142ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2179 of 3641

INT-28

< REMOVAL AND INSTALLATION >

FLOOR TRIM

6. Disconnect negative and positive battery terminals, then wait at least three minutes. Refer to PG-70,

"Removal and Installation (Battery)".

WARNING:

Before servicing the SRS, turn th e ignition switch off, disconnect both battery terminals then wait

at least three minutes.

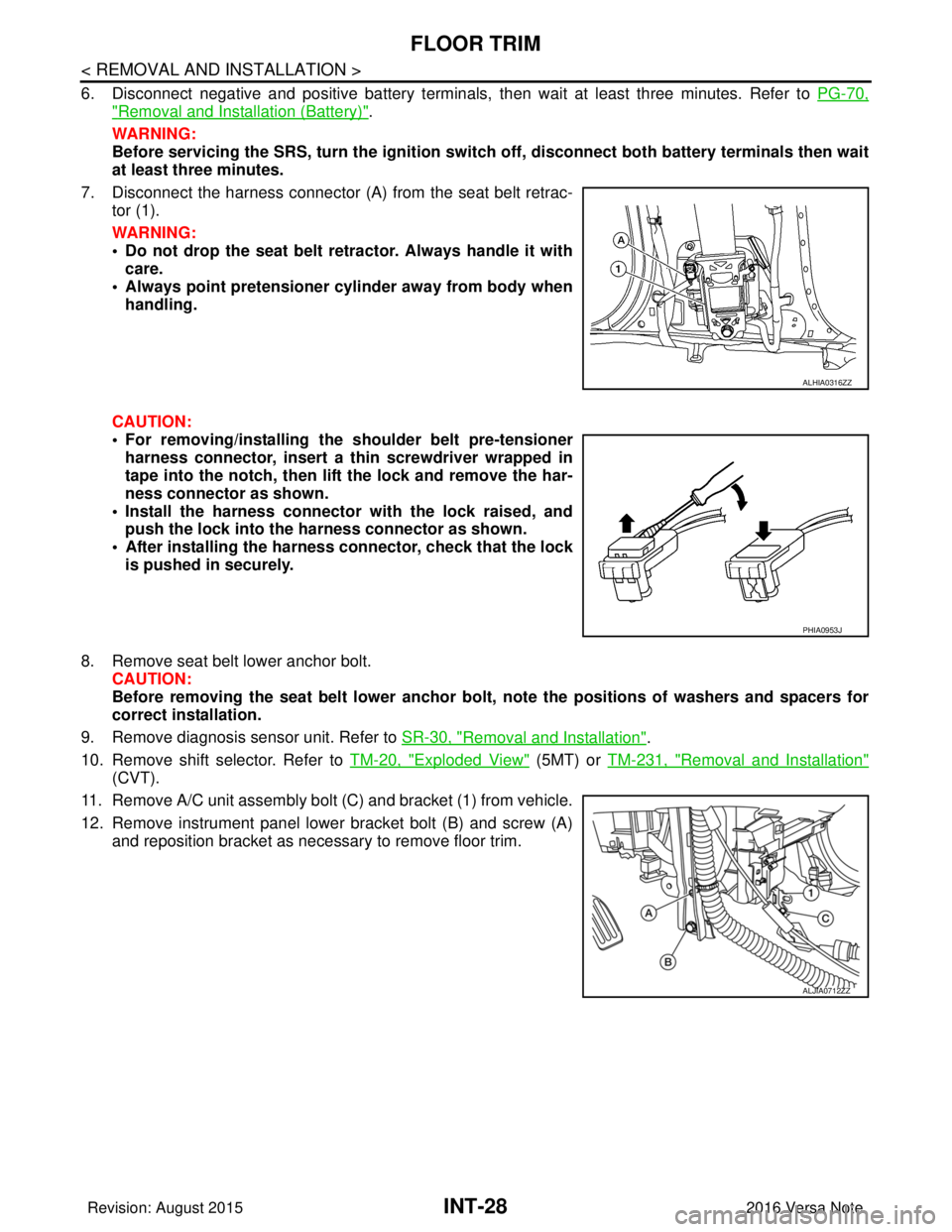

7. Disconnect the harness connector (A ) from the seat belt retrac-

tor (1).

WARNING:

• Do not drop the seat belt retractor. Always handle it with care.

• Always point pretensioner cylinder away from body when handling.

CAUTION:

• For removing/installing the shoulder belt pre-tensioner harness connector, insert a thin screwdriver wrapped in

tape into the notch, then lift the lock and remove the har-

ness connector as shown.

• Install the harness connector with the lock raised, and push the lock into the harness connector as shown.

• After installing the harness connector, check that the lock

is pushed in securely.

8. Remove seat belt lower anchor bolt. CAUTION:

Before removing the seat belt lower anchor bolt , note the positions of washers and spacers for

correct installation.

9. Remove diagnosis sensor unit. Refer to SR-30, "

Removal and Installation".

10. Remove shift selector. Refer to TM-20, "

Exploded View" (5MT) or TM-231, "Removal and Installation"

(CVT).

11. Remove A/C unit assembly bolt (C) and bracket (1) from vehicle.

12. Remove instrument panel lower bracket bolt (B) and screw (A) and reposition bracket as necessary to remove floor trim.

ALHIA0316ZZ

PHIA0953J

ALJIA0712ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2186 of 3641

LUGGAGE TRIMINT-35

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

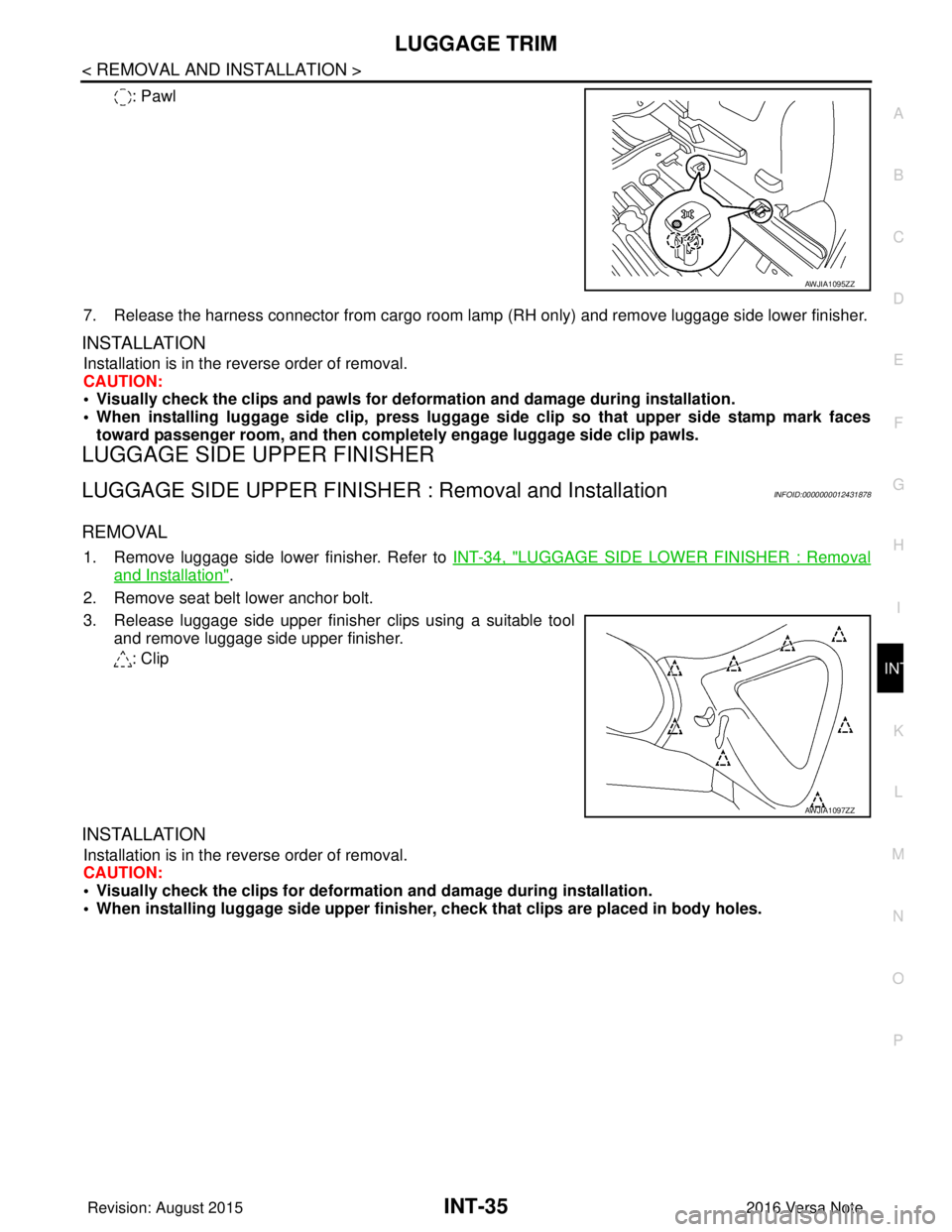

: Pawl

7. Release the harness connector from cargo room lamp (RH only) and remove luggage side lower finisher.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Visually check the clips and pawls for defo rmation and damage during installation.

• When installing lu ggage side clip, press luggag e side clip so that upper side stamp mark faces

toward passenger room, and then completely engage luggage side clip pawls.

LUGGAGE SIDE UPPER FINISHER

LUGGAGE SIDE UPPER FINISHER : Removal and InstallationINFOID:0000000012431878

REMOVAL

1. Remove luggage side lower finisher. Refer to INT-34, "LUGGAGE SIDE LOWER FINISHER : Removal

and Installation".

2. Remove seat belt lower anchor bolt.

3. Release luggage side upper finisher clips using a suitable tool and remove luggage side upper finisher.

: Clip

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Visually check the clips for deformation and damage during installation.

• When installing luggage side upper finisher, check that clips are placed in body holes.

AWJIA1095ZZ

AWJIA1097ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2189 of 3641

LAN

LAN-1

ELECTRICAL & POWER CONTROL

C

DE

F

G H

I

J

K L

B

SECTION LAN

A

O P

N

CONTENTS

LAN SYSTEM

CAN FUNDAMENTAL

HOW TO USE THIS MANU AL ......................

5

HOW TO USE THIS SECTION ....................... .....5

Information .......................................................... ......5

PRECAUTION ...............................................6

PRECAUTIONS .............................................. .....6

Precautions for Trouble Diagnosis ...................... ......6

Precautions for Harness Repair ................................6

SYSTEM DESCRIPTION . .............................7

SYSTEM ......................................................... .....7

CAN COMMUNICATION SYSTEM .............................7

CAN COMMUNICATION SYSTEM : System De-

scription ............................................................... ......

7

DIAG ON CAN ....................................................... ......7

DIAG ON CAN : System Description ........................7

TROUBLE DIAGNOSIS ......................................9

Component Description ....................................... ......9

Condition of Error Detection ......................................9

Symptom When Error Occurs in CAN Communi-

cation System ...................................................... ....

10

CAN Diagnosis with CONSULT ..............................12

Self-Diagnosis .........................................................13

CAN Diagnostic Support Monitor ............................13

How to Use CAN Communication Signal Chart ......15

BASIC INSPECTION ...................................16

DIAGNOSIS AND REPAIR WORKFLOW ..... ....16

Trouble Diagnosis Flow Chart ............................. ....16

CAN

HOW TO USE THIS MANU AL .....................

21

HOW TO USE THIS SECTION ....................... ....21

Information ........................................................... ....21

Abbreviation List ......................................................21

PRECAUTION ..............................................22

PRECAUTIONS .................................................22

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

22

Precautions for Trouble Diagnosis ..........................22

Precautions for Harness Repair ..............................22

SYSTEM DESCRIPTION .............................24

COMPONENT PARTS ......................................24

Component Parts Location .................................. ....24

SYSTEM ............................................................25

CAN COMMUNICATION SYSTEM ........................ ....25

CAN COMMUNICATION SYSTEM : System De-

scription ............................................................... ....

25

CAN COMMUNICATION SYSTEM : CAN Com-

munication Control Circuit .......................................

28

CAN COMMUNICATION SYSTEM : CAN System

Specification Chart ..................................................

29

CAN COMMUNICATION SYSTEM : CAN Com-

munication Signal Chart ..........................................

30

WIRING DIAGRAM ......................................33

CAN SYSTEM .. .................................................33

Wiring Diagram .................................................... ....33

BASIC INSPECTION ...................................39

DIAGNOSIS AND REPAIR WORKFLOW ........39

Interview Sheet .................................................... ....39

DTC/CIRCUIT DIAGNOSIS .........................40

MALFUNCTION AREA CHART ........................40

Main Line ............................................................. ....40

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2210 of 3641

![NISSAN NOTE 2016 Service Repair Manual LAN-22

< PRECAUTION >[CAN]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012433342

The Supplemental Rest NISSAN NOTE 2016 Service Repair Manual LAN-22

< PRECAUTION >[CAN]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012433342

The Supplemental Rest](/img/5/57363/w960_57363-2209.png)

LAN-22

< PRECAUTION >[CAN]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012433342

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precautions for Trouble DiagnosisINFOID:0000000012433343

CAUTION:

Follow the instructions listed below. Fail ure to do this may cause damage to parts:

• Never apply 7.0 V or more to the measurement terminal.

• Use a tester with open terminal voltage of 7.0 V or less.

• Turn the ignition switch OFF and disconnect th e battery cable from the negative terminal when

checking the harness.

Precautions for Harness RepairINFOID:0000000012433344

• Solder the repaired area and wrap tape around the soldered area. NOTE:

A fray of twisted lines must be within 110 mm (4.33 in).

SKIB8766E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2316 of 3641

MA-1

MAINTENANCE

C

DE

F

G H

I

J

K L

M B

MA

SECTION MA

N

O A

CONTENTS

MAINTENANCE

PRECAUTION .......

........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

PERIODIC MAINTENANCE ..........................5

GENERAL MAINTE NANCE ........................... .....5

Explanation of General Maintenance .................. ......5

PERIODIC MAINTENANCE ................................7

Introduction of Periodic Maintenance .................. ......7

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

11

Fluids and Lubricants .......................................... ....11

Engine Oil Recommendation ..................................12

Anti-Freeze Coolant Mixture Ratio ..........................12

ENGINE MAINTENANCE ...................................13

DRIVE BELT .......................................................... ....13

DRIVE BELT : Exploded View ................................13

DRIVE BELT : Removal and Installation .................13

DRIVE BELT : Inspection .................................... ....14

DRIVE BELT : Adjustment ......................................14

ENGINE COOLANT ............................................... ....15

ENGINE COOLANT : Inspection .............................15

ENGINE COOLANT : Draining Engine Coolant ......16

ENGINE COOLANT : Refilling ................................16

ENGINE COOLANT : Flushing Cooling System .....18

FUEL LINES .......................................................... ....18

FUEL LINES : Inspection ........................................18

AIR CLEANER FILTER ......................................... ....18

AIR CLEANER FILTER : Exploded View ................19

AIR CLEANER FILTER : Removal and Installation

....

19

ENGINE OIL ........................................................... ....20

ENGINE OIL : Inspection .........................................20

ENGINE OIL : Draining ............................................21

ENGINE OIL : Refilling ............................................21

OIL FILTER ............................................................ ....22

OIL FILTER : Removal and Installation ...................22

SPARK PLUG ........................................................ ....22

SPARK PLUG : Exploded View ...............................23

SPARK PLUG : Removal and Installation ...............23

EVAP VAPOR LINES ............................................ ....25

EVAP VAPOR LINES : Inspection ...........................25

CHASSIS AND BODY MAINTENANCE ...........26

EXHAUST SYSTEM . ..................................................26

EXHAUST SYSTEM : Inspec tion ............................26

CVT FLUID ............................................................. ....26

CVT FLUID : Inspection ...........................................26

CVT FLUID : Replacement ......................................26

CVT FLUID : Adjustment .........................................28

CLUTCH FLUID ..................................................... ....29

CLUTCH FLUID : Inspection ...................................29

CLUTCH FLUID : Draining ......................................29

CLUTCH FLUID : Refilling .......................................30

GEAR OIL .............................................................. ....31

GEAR OIL : Inspection ............................................31

GEAR OIL : Draining ...............................................31

GEAR OIL : Refilling ................................................32

WHEELS ................................................................ ....32

WHEELS : Inspection ..............................................32

WHEELS : Adjustment ............................................32

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2317 of 3641

MA-2

BRAKE FLUID LEVEL AND LEAKS ........................34

BRAKE FLUID LEVEL AND LEAKS : Inspection ...34

BRAKE LINES AND CABLES ............................... ...34

BRAKE LINES AND CABLES : Inspection .............34

BRAKE FLUID ....................................................... ...35

BRAKE FLUID : Inspection .....................................35

BRAKE FLUID : Draining ........................................35

BRAKE FLUID : Refilling ........................................35

BRAKE FLUID : Bleeding Brake System ................36

DISC BRAKE ......................................................... ...36

DISC BRAKE : Inspection ......................................36

DISC BRAKE : Brake Burnishing ...........................37

DISC BRAKE : Inspection ......................................37

DRUM BRAKE ....................................................... ...37

DRUM BRAKE : Inspection ....................................38

DRUM BRAKE : Brake Burn ishing .........................38

DRUM BRAKE : Inspection ....................................38

STEERING GEAR AND LINKAGE ........................ ...39

STEERING GEAR AND LINKAGE : Inspection ......39

AXLE AND SUSPENSION PARTS ........................ ...39

AXLE AND SUSPENSION PARTS : Inspection .....39

DRIVE SHAFT ........................................................ ...39

DRIVE SHAFT : Inspection .....................................40

LOCKS, HINGES AND HOOD LATCH .................. ...40

LOCKS, HINGES AND HOOD LATCH : Exploded

View ..................................................................... ...

40

LOCKS, HINGES AND HOOD LATCH : Exploded

View ..................................................................... ...

41

LOCKS, HINGES AND HOOD LATCH : Exploded

View ..................................................................... ...

42

LOCKS, HINGES AND HOOD LATCH : Exploded

View ..................................................................... ...

42

SEAT BELT, BUCKLES, RETRACTORS, AN-

CHORS AND ADJUSTERS ................................... ...

43

SEAT BELT, BUCKLES, RETRACTORS, AN-

CHORS AND ADJUSTERS : Inspection .................

43

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2318 of 3641

PRECAUTIONSMA-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432240

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2319 of 3641

MA-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

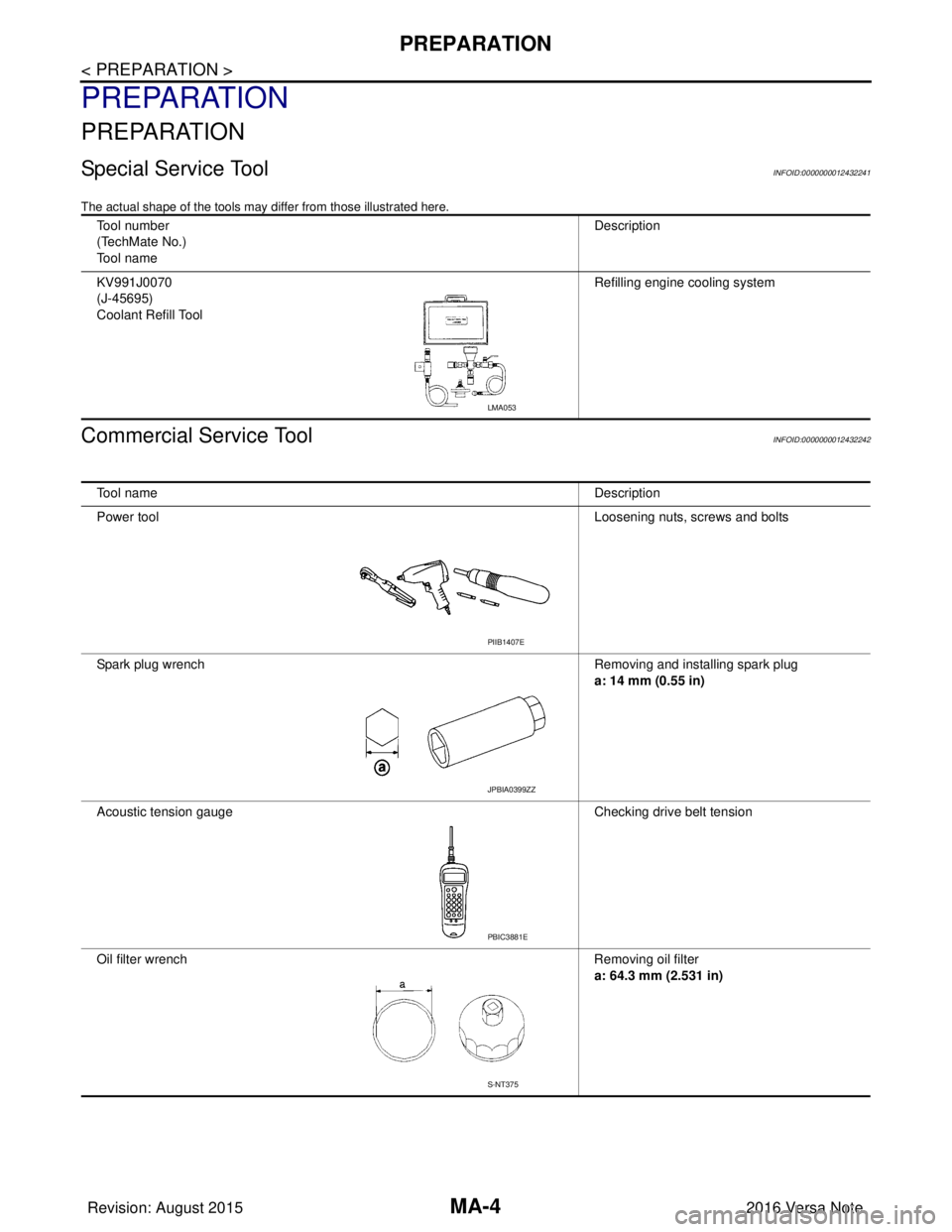

Special Service ToolINFOID:0000000012432241

The actual shape of the tools may differ from those illustrated here.

Commercial Service ToolINFOID:0000000012432242

Tool number

(TechMate No.)

Tool nameDescription

KV991J0070

(J-45695)

Coolant Refill Tool Refilling engine cooling system

LMA053

Tool name

Description

Power tool Loosening nuts, screws and bolts

Spark plug wrench Removing and installing spark plug a: 14 mm (0.55 in)

Acoustic tension gauge Checking drive belt tension

Oil filter wrench Removing oil filter

a: 64.3 mm (2.531 in)

PIIB1407E

JPBIA0399ZZ

PBIC3881E

S-NT375

Revision: August 2015 2016 Versa Note

cardiagn.com