belt NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2599 of 3641

PG-12

< SYSTEM DESCRIPTION >

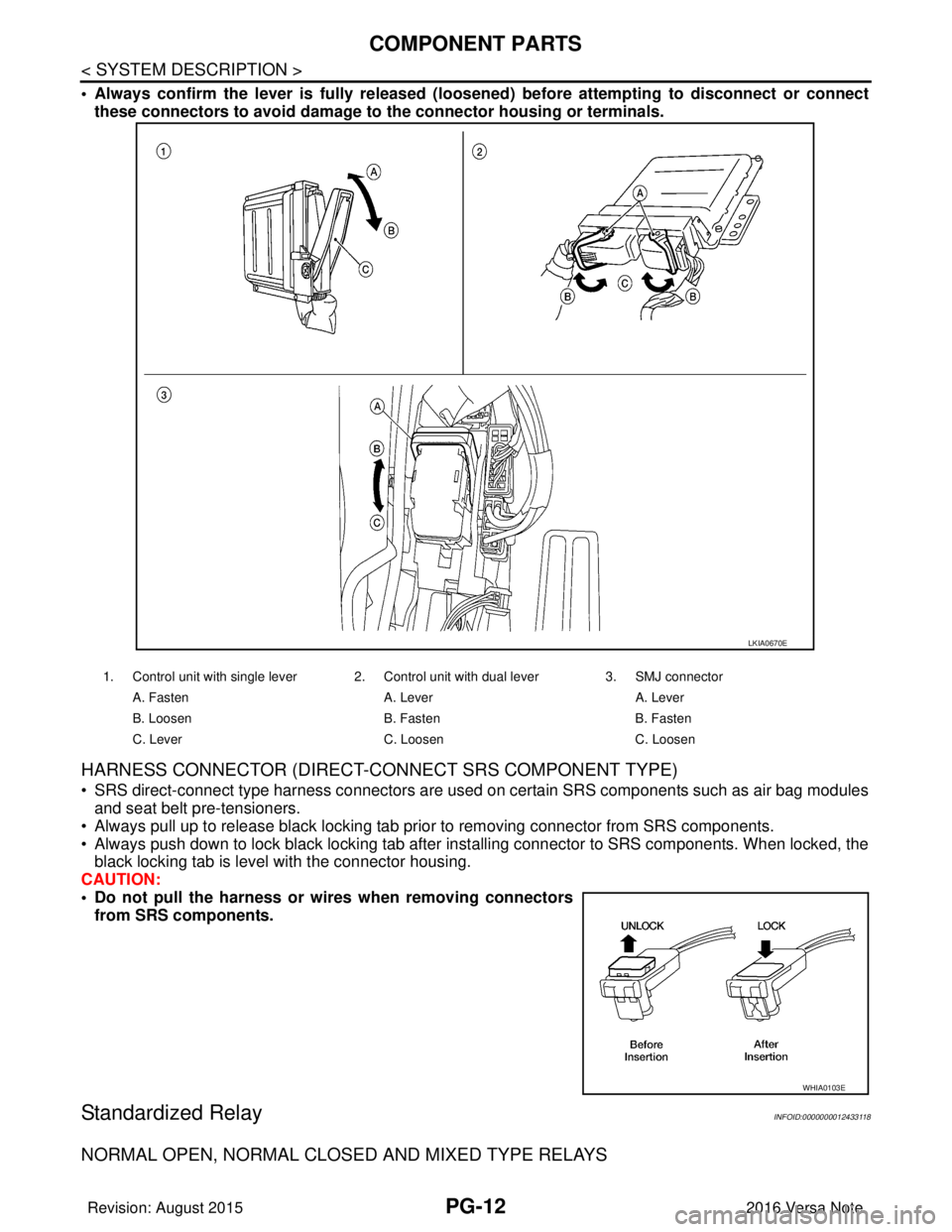

COMPONENT PARTS

• Always confirm the lever is fully released (loosened) before attempting to disconnect or connect

these connectors to avoid damage to the connector housing or terminals.

HARNESS CONNECTOR (DIRECT-CONNECT SRS COMPONENT TYPE)

• SRS direct-connect type harness connectors are used on certain SRS components such as air bag modules

and seat belt pre-tensioners.

• Always pull up to release black locking tab prior to removing connector from SRS components.

• Always push down to lock black locking tab after inst alling connector to SRS components. When locked, the

black locking tab is level with the connector housing.

CAUTION:

• Do not pull the harness or wi res when removing connectors

from SRS components.

Standardized RelayINFOID:0000000012433118

NORMAL OPEN, NORMAL CLOS ED AND MIXED TYPE RELAYS

1. Control unit with single lever 2. Control unit with dual lever 3. SMJ connector

A. Fasten A. LeverA. Lever

B. Loosen B. FastenB. Fasten

C. Lever C. LoosenC. Loosen

LKIA0670E

WHIA0103E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2638 of 3641

PG

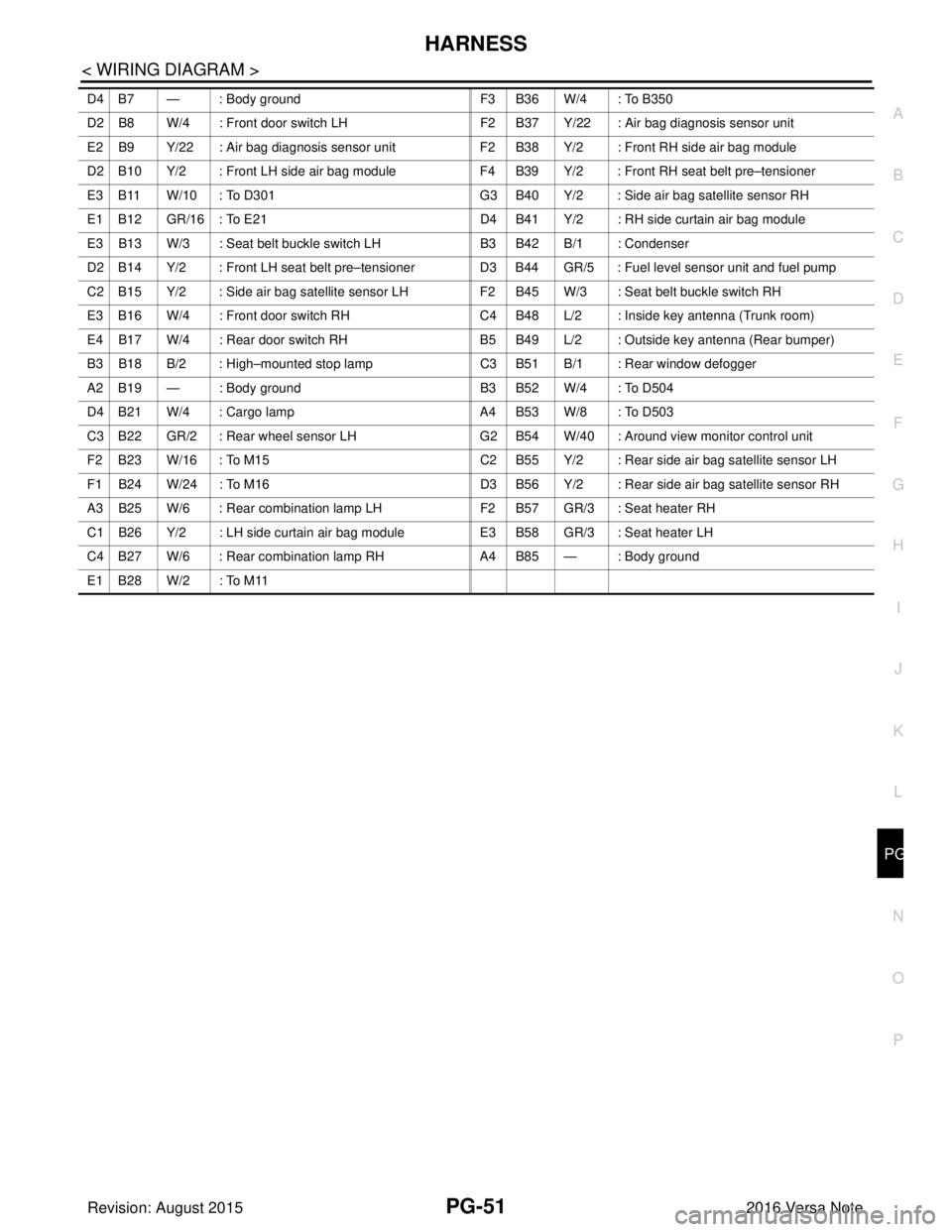

HARNESSPG-51

< WIRING DIAGRAM >

C

DE

F

G H

I

J

K L

B A

O P

N

D4 B7 — : Body ground

F3 B36 W/4 : To B350

D2 B8 W/4 : Front door switch LH F2 B37 Y/22 : Air bag diagnosis sensor unit

E2 B9 Y/22 : Air bag diagnosis sensor unit F2 B38 Y/2 : Front RH side air bag module

D2 B10 Y/2 : Front LH side air bag module F4 B39 Y/2 : Front RH seat belt pre–tensioner

E3 B11 W/10 : To D301 G3 B40 Y/2 : Side air bag satellite sensor RH

E1 B12 GR/16 : To E21 D4 B41 Y/2 : RH side curtain air bag module

E3 B13 W/3 : Seat belt buckle switch LH B3 B42 B/1 : Condenser

D2 B14 Y/2 : Front LH seat belt pre–tensioner D3 B44 GR/5 : Fuel level sensor unit and fuel pump

C2 B15 Y/2 : Side air bag satellite sensor LH F2 B45 W/3 : Seat belt buckle switch RH

E3 B16 W/4 : Front door switch RH C4 B48 L/2 : Inside key antenna (Trunk room)

E4 B17 W/4 : Rear door switch RH B5 B49 L/2 : Outside key antenna (Rear bumper)

B3 B18 B/2 : High–mounted stop lamp C3 B51 B/1 : Rear window defogger

A2 B19 — : Body ground B3 B52 W/4 : To D504

D 4 B 2 1 W / 4 : C a r g o l a m p A 4 B 5 3 W / 8 : To D 5 0 3

C3 B22 GR/2 : Rear wheel sensor LH G2 B54 W/40 : Around view monitor control unit

F2 B23 W/16 : To M15 C2 B55 Y/2 : Rear side air bag satellite sensor LH

F1 B24 W/24 : To M16 D3 B56 Y/2 : Rear side air bag satellite sensor RH

A3 B25 W/6 : Rear combination lamp LH F2 B57 GR/3 : Seat heater RH

C1 B26 Y/2 : LH side curtain air bag module E3 B58 GR/3 : Seat heater LH

C4 B27 W/6 : Rear combination lamp RH A4 B85 — : Body ground

E 1 B 2 8 W / 2 : To M 1 1

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2662 of 3641

PWC-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

DE

F

G H

I

J

L

M

SECTION PWC

A

B

PWC

N

O P

CONTENTS

POWER WINDOW CONTROL SYSTEM

PRECAUTION ....... ........................................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution for Work ..................................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Main Power Window And Door Lock/Unlock

Switch ........................................................................

7

Power Window Switch ...............................................7

Power Window Motor ................................................7

SYSTEM ..............................................................8

System Description ............................................. ......8

DIAGNOSIS SYSTEM (BCM) (WITH INTELLI-

GENT KEY SYSTEM) ..........................................

9

COMMON ITEM ..................................................... ......9

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .......................................................

9

RETAINED PWR .......................................................10

RETAINED PWR : CONSULT Function (BCM -

RETAINED PWR) ...................................................

10

DIAGNOSIS SYSTEM (BCM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) ...............................

11

COMMON ITEM ..................................................... ....11

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .....................................................

11

RETAINED PWR .................................................... ....12

RETAINED PWR : CONSULT Function (BCM -

RETAINED PWR) ....................................................

12

ECU DIAGNOSIS INFORMATION ..............13

BCM ...................................................................13

List of ECU Reference ......................................... ....13

POWER WINDOW MAIN SWITCH ...................14

Reference Value ......................................................14

Fail Safe ..................................................................15

WIRING DIAGRAM ......................................16

POWER WINDOW SYSTEM .............................16

Wiring Diagram .................................................... ....16

BASIC INSPECTION ...................................23

DIAGNOSIS AND REPAIR WORK FLOW .......23

Work Flow ............................................................ ....23

DTC/CIRCUIT DIAGNOSIS .........................25

POWER SUPPLY AND GROUND CIRCUIT . ...25

BCM (BODY CONTROL SYSTEM) (WITH INTEL-

LIGENT KEY SYSTEM) ........

.....................................

25

BCM (BODY CONTROL SYSTEM) (WITH INTEL-

LIGENT KEY SYSTEM) : Diagnosis Procedure .. ....

25

BCM (BODY CONTROL SYSTEM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) .................................. ....

25

BCM (BODY CONTROL SYSTEM) (WITHOUT

INTELLIGENT KEY SYSTEM) : Diagnosis Proce-

dure ..................................................................... ....

25

POWER WINDOW MAIN SWITCH ........................ ....26

POWER WINDOW MAIN SWITCH : Diagnosis

Procedure ................................................................

26

FRONT POWER WINDOW SWITCH (PASSEN-

GER SIDE) .................................................................

27

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2665 of 3641

PWC-4

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431791

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for WorkINFOID:0000000012431792

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2719 of 3641

RAX-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION RAX

A

B

RAX

N

O P

CONTENTS

REAR AXLE

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precautions for Wheel Hub .......................................2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Special Service Tools .......................................... ......3

Commercial Service Tool ..........................................3

SYMPTOM DIAGNOSIS ...............................4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

4

NVH Troubleshooting Chart ................................ ......4

PERIODIC MAINTENANCE .........................5

REAR WHEEL HUB ...........................................5

Inspection ............................................................ .....5

REMOVAL AND INSTALLATION ................6

REAR WHEEL HUB ...........................................6

Exploded View ..................................................... .....6

Removal and Installation ..........................................6

Disassembly and Assembly ......................................7

Inspection .................................................................9

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

10

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

10

Wheel Bearing ..................................................... ....10

Wheel Hub ...............................................................10

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2720 of 3641

RAX-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431904

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precautions for Wheel HubINFOID:0000000012431905

Observe the following precautions when assembling wheel hub.

• Perform work in a location that is free from dust, dirt and debris.

• Use paper shop towels while performing repairs. Fabric shop cloths must not be used because of the danger of lint adhering to parts.

• Do not drop any of the components such as the brake drum, wheel bearing, spindle, or wheel hub lock nut. If

any of these parts have been dropped, they must be replaced.

• Always check that the tools used to press-fit the wheel bearing to the brake drum have no wear and defor-

mation. Damaged tools will not guarantee that pre ssure can be applied vertically and damage parts.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2729 of 3641

RSU-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION RSU

A

B

RSU

N

O PCONTENTS

REAR SUSPENSION

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution for Suspension ........................................2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Special Service Tool ........................................... ......3

Commercial Service Tools ........................................3

SYMPTOM DIAGNOSIS ...............................4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

4

NVH Troubleshooting Chart ................................ ......4

PERIODIC MAINTENANCE ..........................5

REAR SUSPENSION ASSEMBLY ................ .....5

Inspection ............................................................ ......5

WHEEL ALIGNMENT ..........................................6

Inspection ............................................................ ......6

REMOVAL AND INSTALLATION ................8

REAR SHOCK ABSORBER ..............................8

Exploded View ..................................................... .....8

Removal and Installation ..........................................8

Inspection .................................................................9

Disposal ...................................................................10

COIL SPRING ...................................................11

Exploded View .........................................................11

Removal and Installation .........................................11

Inspection ................................................................12

REAR SUSPENSION BEAM ............................13

Exploded View ..................................................... ....13

Removal and Installation .........................................13

Inspection ................................................................14

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

15

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

15

Wheel Alignment (Unladen*1) ..................................15

Wheelarch Height (Unladen*) .............................. ....15

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2730 of 3641

RSU-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431916

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for SuspensionINFOID:0000000012431917

• When installing rubber bushings, the final tightening mu st be carried out under unladen conditions with tires

on ground. Spilled oil might shorten the life of rubber bushings. Be sure to wipe off any spilled oil.

- Unladen conditions mean that fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.

• After servicing suspension parts, be sure to check wheel alignment.

• Self-lock nuts are not reusable. Always use new ones when installing. Since new self-lock nuts are pre-oiled,

tighten as they are.

• The tightening surface must be kept free of oil/grease.

• When jacking up the vehicle with a floor jack, do not hang the jack on the suspension beam.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2744 of 3641

WT-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION WT

A

B

WT

N

O PCONTENTS

ROAD WHEELS & TIRES

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Service Notice and Precautions for TPMS ................3

Service Notice and Precautions for Road Wheel ......3

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Component Description .............................................6

BCM ..........................................................................6

Remote Keyless Entry Receiver ...............................6

Transmitter ................................................................7

Low Tire Pressure Warning Lamp .............................7

SYSTEM ......................................................... .....8

TIRE PRESSURE MONITORING SYSTEM .......... ......8

TIRE PRESSURE MONITORING SYSTEM : Sys-

tem Diagram ..............................................................

8

TIRE PRESSURE MONITORING SYSTEM : Sys-

tem Description .........................................................

8

TIRE PRESSURE MONITORING SYSTEM :

Easy Fill Tire Alert Function ......................................

8

DIAGNOSIS SYSTEM (BCM) ............................10

WITH INTELLIGENT KEY ..................................... ....10

WITH INTELLIGENT KEY : CONSULT Function

(BCM - COMMON ITEM) ........................................

10

WITH INTELLIGENT KEY : CONSULT Function

(BCM - AIR PRESSURE MONITOR) ......................

11

WITHOUT INTELLIGENT KEY .............................. ....11

WITHOUT INTELLIGENT KEY : CONSULT Func-

tion (BCM - COMMON ITEM) ..................................

11

WITHOUT INTELLIGENT KEY : CONSULT Func-

tion (BCM - AIR PRESSURE MONITOR) ...............

12

ECU DIAGNOSIS INFORMATION ..............14

BCM ...................................................................14

List of ECU Reference ......................................... ....14

WIRING DIAGRAM ......................................15

TIRE PRESSURE MONITORING SYSTEM ......15

Wiring Diagram - With Inte lligent Key ......................15

Wiring Diagram - Without Intelligent Ke y .................18

BASIC INSPECTION ....... ............................21

DIAGNOSIS AND REPAIR WORK FLOW .......21

Work Flow ............................................................ ....21

ID REGISTRATION PROCEDURE ...................22

Description ...............................................................22

Work Procedure .......................................................22

DTC/CIRCUIT DIAGNOSIS .........................25

C1704, C1705, C1706, C1707 LOW TIRE

PRESSURE .......................................................

25

DTC Logic ............................................................ ....25

Diagnosis Procedure ...............................................25

C1708, C1709, C1710, C1711 TRANSMITTER

(NO DATA) ........................................................

27

DTC Logic ............................................................ ....27

Diagnosis Procedure ...............................................27

C1716, C1717, C1718, C1719 TRANSMITTER

(PRESSURE DATA) ..........................................

30

DTC Logic ............................................................ ....30

Diagnosis Procedure ...............................................30

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2746 of 3641

PRECAUTIONSWT-3

< PRECAUTION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432421

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Service Notice and Precautions for TPMSINFOID:0000000012432422

WARNING:

Radio waves could adversely affect electric medical equipment. Those who use a pacemaker should

contact the electric medical equipment manufacturer for the possible influences before use.

• Low tire pressure warning lamp blinks for 1 minute, then turns ON when occurring any malfunction except low tire pressure. Erase the self-diagnosis memories fo r Tire Pressure Monitoring System (TPMS), or regis-

ter the ID to turn low tire pressure warning lamp OFF. For ID registration, refer to WT-22, "

Work Procedure".

• ID registration is required when replacing or rotating wheels, replacing tire pressure sensor or BCM. Refer to WT-22, "

Work Procedure".

• Replace grommet seal, valve core and valve cap of tire pressure sensor in TPMS, when replacing each tire by reaching the wear limit. Refer to WT-49, "

Removal and Installation".

• Because the tire pressure sensor conforms to North America radio law, the following items must be

observed.

- The sensor may be used only in North America.

- It may not be used in any method other than the specified method.

- It must not be disassembled or modified.

Service Notice and Pr ecautions for Road WheelINFOID:0000000012432423

• Genuine NISSAN aluminum wheel is designed for each type of vehicle. Use it on the specified vehicle only.

• Use Genuine NISSAN parts for the road wheels, valve caps and wheel nuts.

• Always use them after adjusting the wheel balance. For the balance weights, use Genuine NISSAN alumi-

num wheel weights.

• Use caution when handling the aluminum wheels, because they can be easily scratched. When removing

dirt, do not use any abrasives, a wire brush, or other items that may scratch the coating. Use a neutral deter-

gent if a detergent is needed.

• After driving on roads scattered with anti-icing salts, wash off the wheels completely.

• When installing road wheels onto the vehicle, always wipe off any dirt or foreign substances to prevent them

from being trapped between the contact surfaces of wheel.

Revision: August 2015 2016 Versa Note

cardiagn.com