belt NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2321 of 3641

MA-6

< PERIODIC MAINTENANCE >

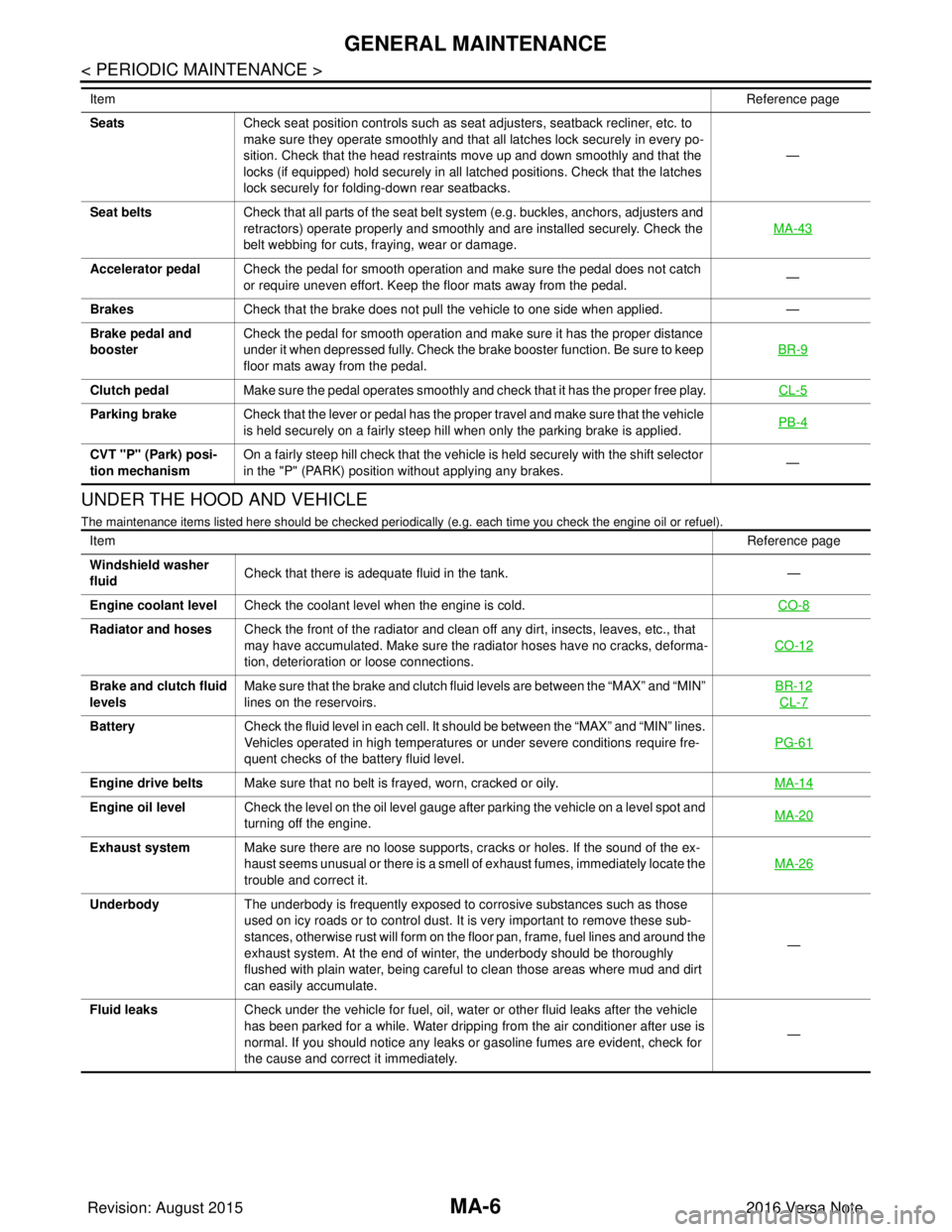

GENERAL MAINTENANCE

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

SeatsCheck seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restraints move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seatbacks. —

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage. MA-43

Accelerator pedal

Check the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. —

Brakes Check that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to keep

floor mats away from the pedal. BR-9

Clutch pedal

Make sure the pedal operates smoothly and check that it has the proper free play. CL-5

Parking brakeCheck that the lever or pedal has the proper travel and make sure that the vehicle

is held securely on a fairly steep hill when only the parking brake is applied. PB-4

CVT "P" (Park) posi-

tion mechanismOn a fairly steep hill check that the vehicle is held securely with the shift selector

in the "P" (PARK) position without applying any brakes.

—

Item

Reference page

Item Reference page

Windshield washer

fluid Check that there is adequate fluid in the tank.

—

Engine coolant level Check the coolant level when the engine is cold. CO-8

Radiator and hosesCheck the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the radiator hoses have no cracks, deforma-

tion, deterioration or loose connections. CO-12

Brake and clutch fluid

levelsMake sure that the brake and clutch fluid levels are between the “MAX” and “MIN”

lines on the reservoirs. BR-12

CL-7

Battery

Check the fluid level in each cell. It should be between the “MAX” and “MIN” lines.

Vehicles operated in high temperatures or under severe conditions require fre-

quent checks of the battery fluid level. PG-61

Engine drive belts

Make sure that no belt is frayed, worn, cracked or oily. MA-14

Engine oil levelCheck the level on the oil level gauge after parking the vehicle on a level spot and

turning off the engine. MA-20

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate the

trouble and correct it. MA-26

Underbody

The underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these sub-

stances, otherwise rust will form on the floor pan, frame, fuel lines and around the

exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately. —

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2322 of 3641

PERIODIC MAINTENANCEMA-7

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

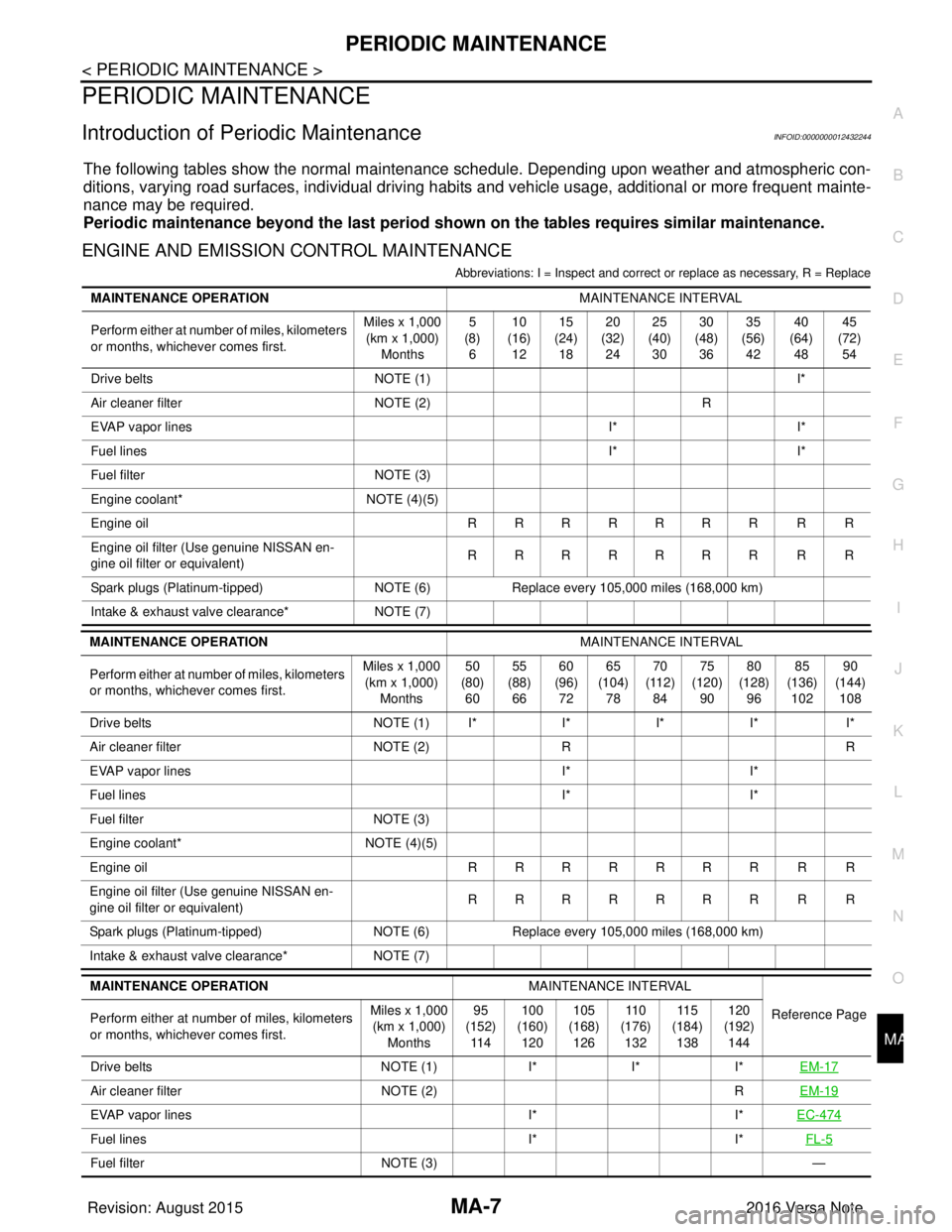

PERIODIC MAINTENANCE

Introduction of Periodic MaintenanceINFOID:0000000012432244

The following tables show the normal maintenanc

e schedule. Depending upon weather and atmospheric con-

ditions, varying road surfaces, indi vidual driving habits and vehicle usage, additional or more frequent mainte-

nance may be required.

Periodic maintenance beyond th e last period shown on the tables requires similar maintenance.

ENGINE AND EMISSION CONTROL MAINTENANCE

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000) Months 5

(8) 6 10

(16) 12 15

(24) 18 20

(32) 24 25

(40) 30 30

(48) 36 35

(56) 42 40

(64) 48 45

(72) 54

Drive belts NOTE (1) I*

Air cleaner filter NOTE (2) R

EVAP vapor lines I*I*

Fuel lines I*I*

Fuel filter NOTE (3)

Engine coolant* NOTE (4)(5)

Engine oil RRRRRRR R R

Engine oil filter (Use genuine NISSAN en-

gine oil filter or equivalent) RRRRRRR R R

Spark plugs (Platinum-tipped) NOTE (6)Replace every 105,000 miles (168,000 km)

Intake & exhaust valve clearance* NOTE (7)

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000) Months 50

(80) 60 55

(88) 66 60

(96) 72 65

(104) 78 70

(112) 84 75

(120) 90 80

(128) 96 85

(136) 102 90

(144) 108

Drive belts NOTE (1) I*I*I* I* I*

Air cleaner filter NOTE (2)R R

EVAP vapor lines I*I*

Fuel lines I*I*

Fuel filter NOTE (3)

Engine coolant* NOTE (4)(5)

Engine oil RRRRRRR R R

Engine oil filter (Use genuine NISSAN en-

gine oil filter or equivalent) RRRRRRR R R

Spark plugs (Platinum-tipped) NOTE (6)Replace every 105,000 miles (168,000 km)

Intake & exhaust valve clearance* NOTE (7)

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Page

Perform either at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 95

(152)

11 4 100

(160)

120 105

(168)

126 11 0

(176)

132 11

5

(184)

138 12

0

(192)

14

4

Drive belts NOTE (1)I*I*I*EM-17

Air cleaner filter NOTE (2) REM-19

EVAP vapor lines I*I*EC-474

Fuel lines I*I*FL-5

Fuel filter NOTE (3) —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2323 of 3641

MA-8

< PERIODIC MAINTENANCE >

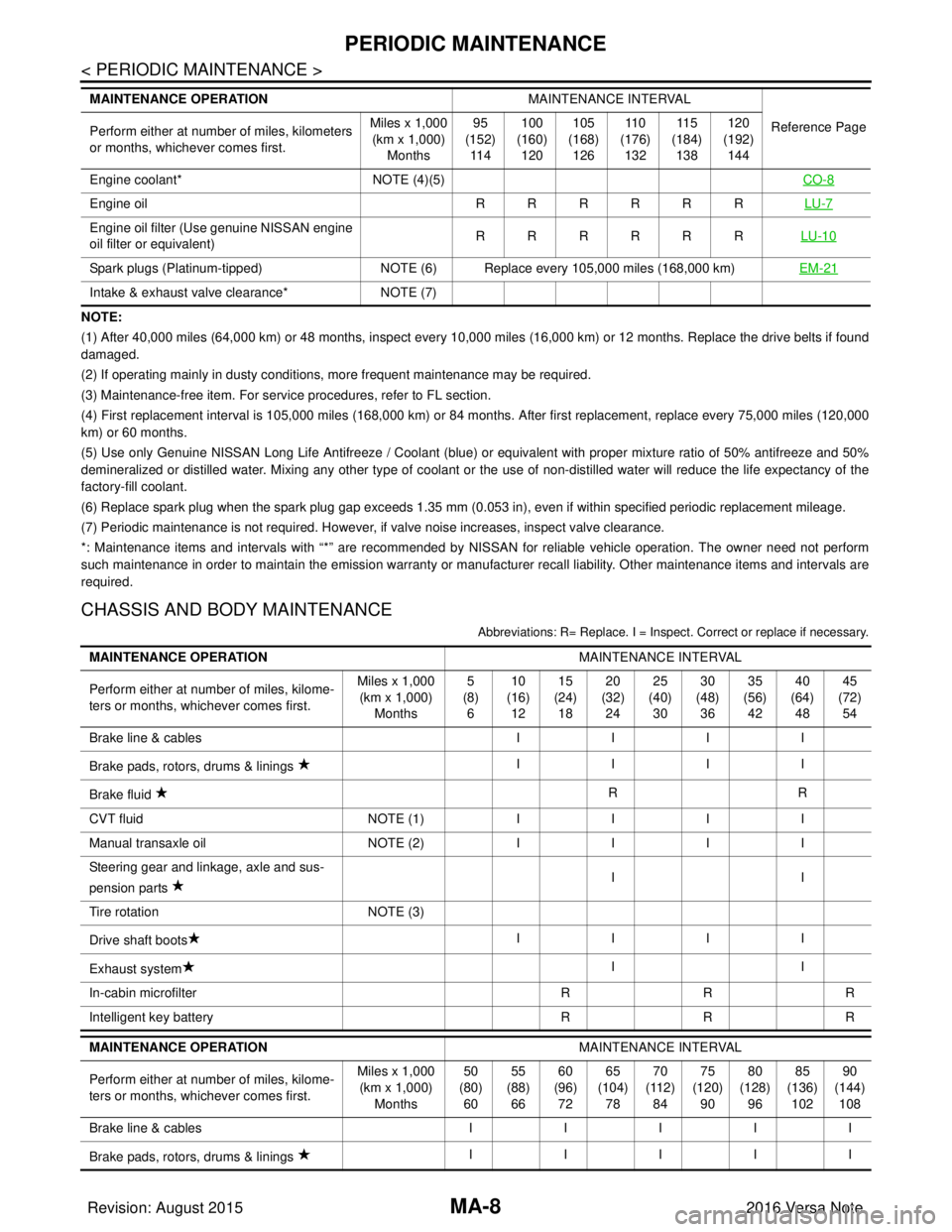

PERIODIC MAINTENANCE

NOTE:

(1) After 40,000 miles (64,000 km) or 48 months, inspect every 10,000 miles (16,000 km) or 12 months. Replace the drive belts if found

damaged.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, refer to FL section.

(4) First replacement interval is 105,000 miles (168,000 km) or 84 months. After first replacement, replace every 75,000 miles (120,000

km) or 60 months.

(5) Use only Genuine NISSAN Long Life Antifreeze / Coolant (blue) or equivalent with proper mixture ratio of 50% antifreeze and 50%

demineralized or distilled water. Mixing any other type of coolant or the use of non-distilled water will reduce the life expec tancy of the

factory-fill coolant.

(6) Replace spark plug when the spark plug gap exceeds 1.35 mm (0.053 in), even if within specified periodic replacement mileag e.

(7) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

*: Maintenance items and intervals with “*” are recommended by NISSAN for reli able vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required.

CHASSIS AND BODY MAINTENANCE

Abbreviations: R= Replace. I = Inspec t. Correct or replace if necessary.

Engine coolant* NOTE (4)(5) CO-8

Engine oil RRRRRRLU-7

Engine oil filter (Use genuine NISSAN engine

oil filter or equivalent) RRRRRR

LU-10

Spark plugs (Platinum-tipped)NOTE (6) Replace every 105,000 miles (168,000 km) EM-21

Intake & exhaust valve clearance*NOTE (7)

MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Reference Page

Perform either at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 95

(152)

11 4 100

(160)

120 105

(168)

126 11 0

(176)

132 11 5

(184)

138 120

(192)

144

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilome-

ters or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 5

(8)

6 10

(16)

12 15

(24)

18 20

(32)

24 25

(40)

30 30

(48)

36 35

(56)

42 40

(64)

48 45

(72)

54

Brake line & cables IIII

Brake pads, rotors, drums & linings IIII

Brake fluid RR

CVT fluid NOTE (1)IIII

Manual transaxle oil NOTE (2)IIII

Steering gear and linkage, axle and sus-

pension parts II

Tire rotation NOTE (3)

Drive shaft boots IIII

Exhaust system II

In-cabin microfilter RRR

Intelligent key battery RRR

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilome-

ters or months, whichever comes first. Miles x 1,000

(km x 1,000) Months 50

(80) 60 55

(88) 66 60

(96) 72 65

(104) 78 70

(112) 84 75

(120) 90 80

(128) 96 85

(136) 102 90

(144) 108

Brake line & cables III II

Brake pads, rotors, drums & linings IIIII

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2328 of 3641

ENGINE MAINTENANCEMA-13

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

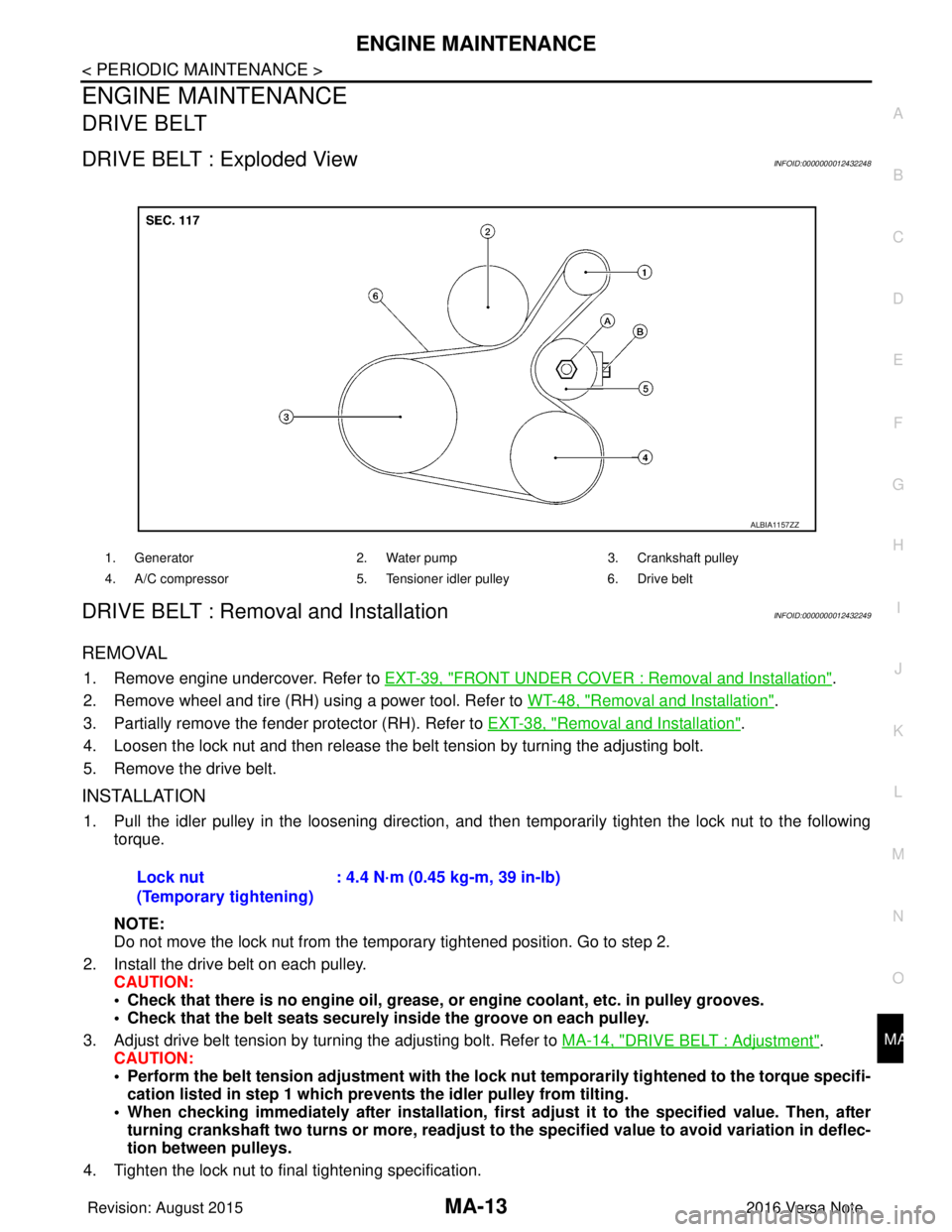

ENGINE MAINTENANCE

DRIVE BELT

DRIVE BELT : Exploded ViewINFOID:0000000012432248

DRIVE BELT : Removal and InstallationINFOID:0000000012432249

REMOVAL

1. Remove engine undercover. Refer to

EXT-39, "FRONT UNDER COVER : Removal and Installation".

2. Remove wheel and tire (RH) using a power tool. Refer to WT-48, "

Removal and Installation".

3. Partially remove the fender protector (RH). Refer to EXT-38, "

Removal and Installation".

4. Loosen the lock nut and then release the belt tension by turning the adjusting bolt.

5. Remove the drive belt.

INSTALLATION

1. Pull the idler pulley in the loosening direction, and then temporarily tighten the lock nut to the following

torque.

NOTE:

Do not move the lock nut from the temporary tightened position. Go to step 2.

2. Install the drive belt on each pulley. CAUTION:

• Check that there is no engine oil, grease, or engine coolant, etc. in pulley grooves.

• Check that the belt seats securely inside the groove on each pulley.

3. Adjust drive belt tension by turning the adjusting bolt. Refer to MA-14, "

DRIVE BELT : Adjustment".

CAUTION:

• Perform the belt tension adjustment with the lock nut temporarily tightened to the torque specifi-

cation listed in step 1 which preven ts the idler pulley from tilting.

• When checking immediately after in stallation, first adjust it to the specified value. Then, after

turning crankshaft two turns or more, readjust to the specified value to avoid variation in deflec-

tion between pulleys.

4. Tighten the lock nut to final tightening specification.

1. Generator 2. Water pump3. Crankshaft pulley

4. A/C compressor 5. Tensioner idler pulley6. Drive belt

ALBIA1157ZZ

Lock nut

(Temporary tightening): 4.4 N·m (0.45 kg-m, 39 in-lb)

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2329 of 3641

MA-14

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

5. Check that belt tension is within the specification using suitable tool. Refer to EM-116, "Drive Belt".

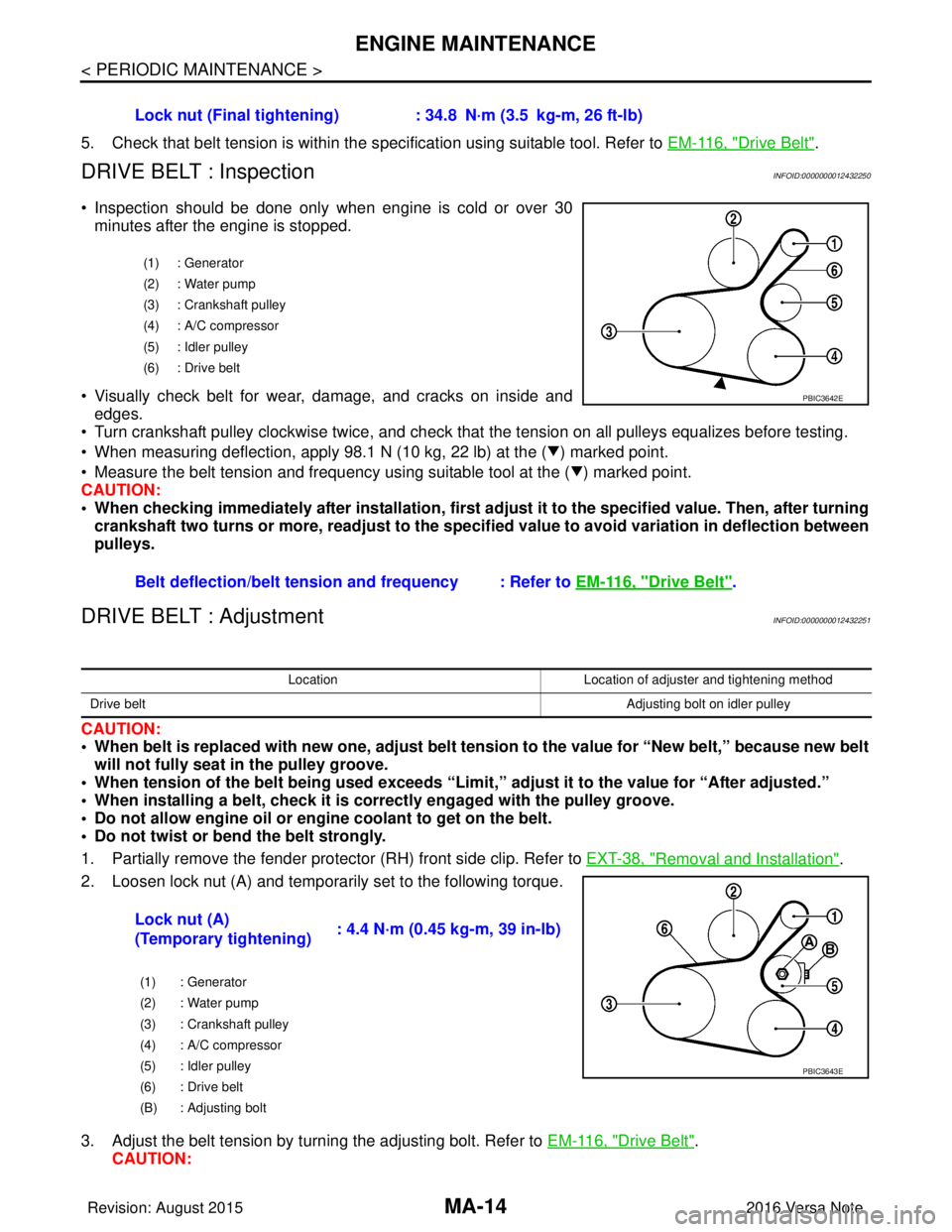

DRIVE BELT : InspectionINFOID:0000000012432250

• Inspection should be done only when engine is cold or over 30

minutes after the engine is stopped.

• Visually check belt for wear, damage, and cracks on inside and edges.

• Turn crankshaft pulley clockwise twice, and check that the tension on all pulleys equalizes before testing.

• When measuring deflection, apply 98.1 N (10 kg, 22 lb) at the ( ) marked point.

• Measure the belt tension and frequency using suitable tool at the ( ) marked point.

CAUTION:

• When checking immediately after installation, first ad just it to the specified value. Then, after turning

crankshaft two turns or more, readjust to the speci fied value to avoid variation in deflection between

pulleys.

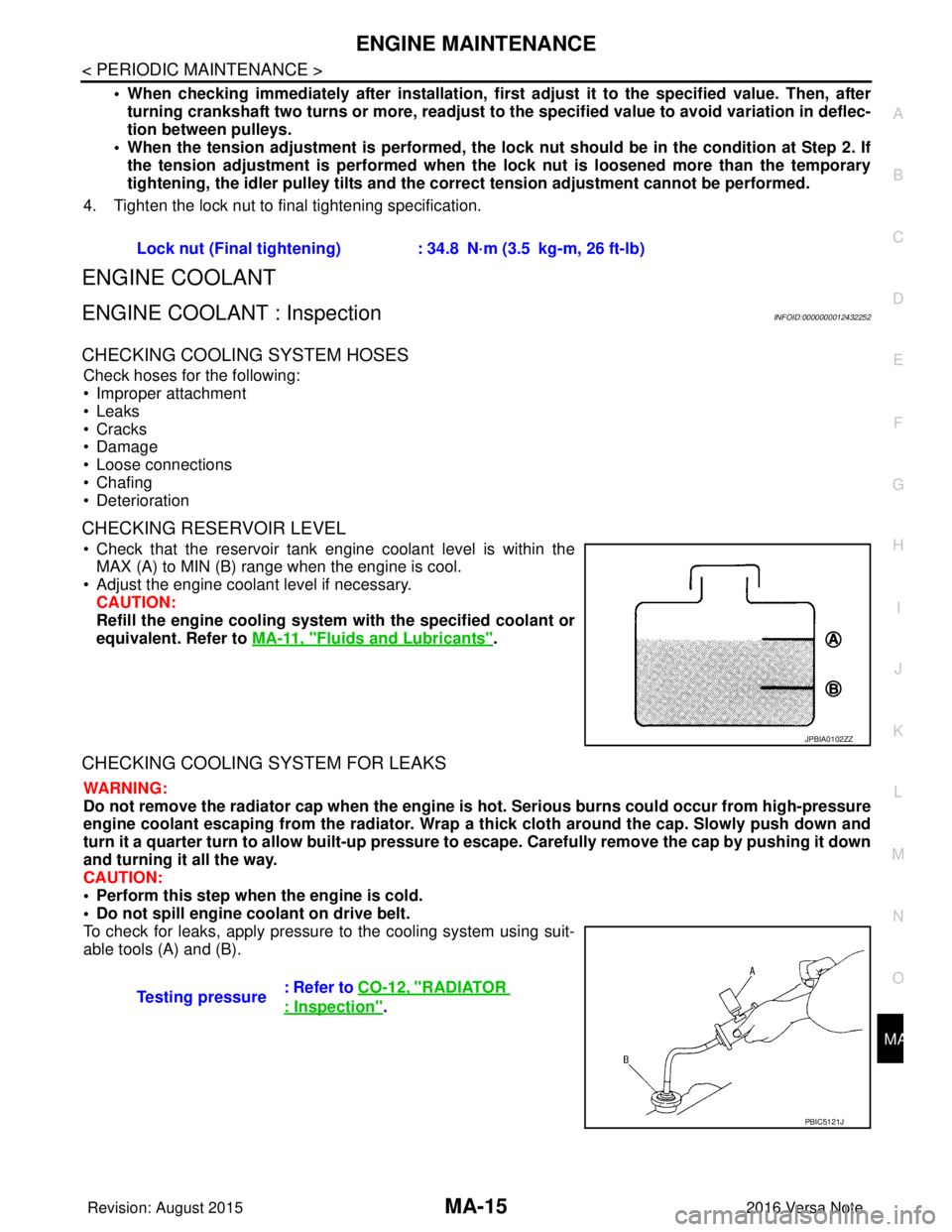

DRIVE BELT : AdjustmentINFOID:0000000012432251

CAUTION:

• When belt is replaced with new one, adjust belt tension to the value for “New belt,” because new belt will not fully seat in the pulley groove.

• When tension of the belt being used exceeds “Limit,” adjust it to the value for “After adjusted.”

• When installing a belt, check it is co rrectly engaged with the pulley groove.

• Do not allow engine oil or engine coolant to get on the belt.

• Do not twist or bend the belt strongly.

1. Partially remove the fender protector (RH) front side clip. Refer to EXT-38, "

Removal and Installation".

2. Loosen lock nut (A) and temporarily set to the following torque.

3. Adjust the belt tension by turning the adjusting bolt. Refer to EM-116, "

Drive Belt".

CAUTION: Lock nut (Final tightening) :

34.8 N·m (3.5 kg-m, 26 ft-lb)

(1) : Generator

(2) : Water pump

(3) : Crankshaft pulley

(4) : A/C compressor

(5) : Idler pulley

(6) : Drive belt

Belt deflection/belt tension and frequency : Refer to EM-116, "Drive Belt".

PBIC3642E

LocationLocation of adjuster and tightening method

Drive belt Adjusting bolt on idler pulley

Lock nut (A)

(Temporary tightening): 4.4 N·m (0.45 kg-m, 39 in-lb)

(1) : Generator

(2) : Water pump

(3) : Crankshaft pulley

(4) : A/C compressor

(5) : Idler pulley

(6) : Drive belt

(B) : Adjusting bolt

PBIC3643E

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2330 of 3641

ENGINE MAINTENANCEMA-15

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

• When checking immediately after in

stallation, first adjust it to the specified value. Then, after

turning crankshaft two turns or more, readjust to the specified value to avoid variation in deflec-

tion between pulleys.

• When the tension adjustment is performed, the lo ck nut should be in the condition at Step 2. If

the tension adjustment is perfo rmed when the lock nut is loosened more than the temporary

tightening, the idler pulley tilts and the co rrect tension adjustment cannot be performed.

4. Tighten the lock nut to final tightening specification.

ENGINE COOLANT

ENGINE COOLANT : InspectionINFOID:0000000012432252

CHECKING COOLING SYSTEM HOSES

Check hoses for the following:

• Improper attachment

• Leaks

•Cracks

• Damage

• Loose connections

• Chafing

• Deterioration

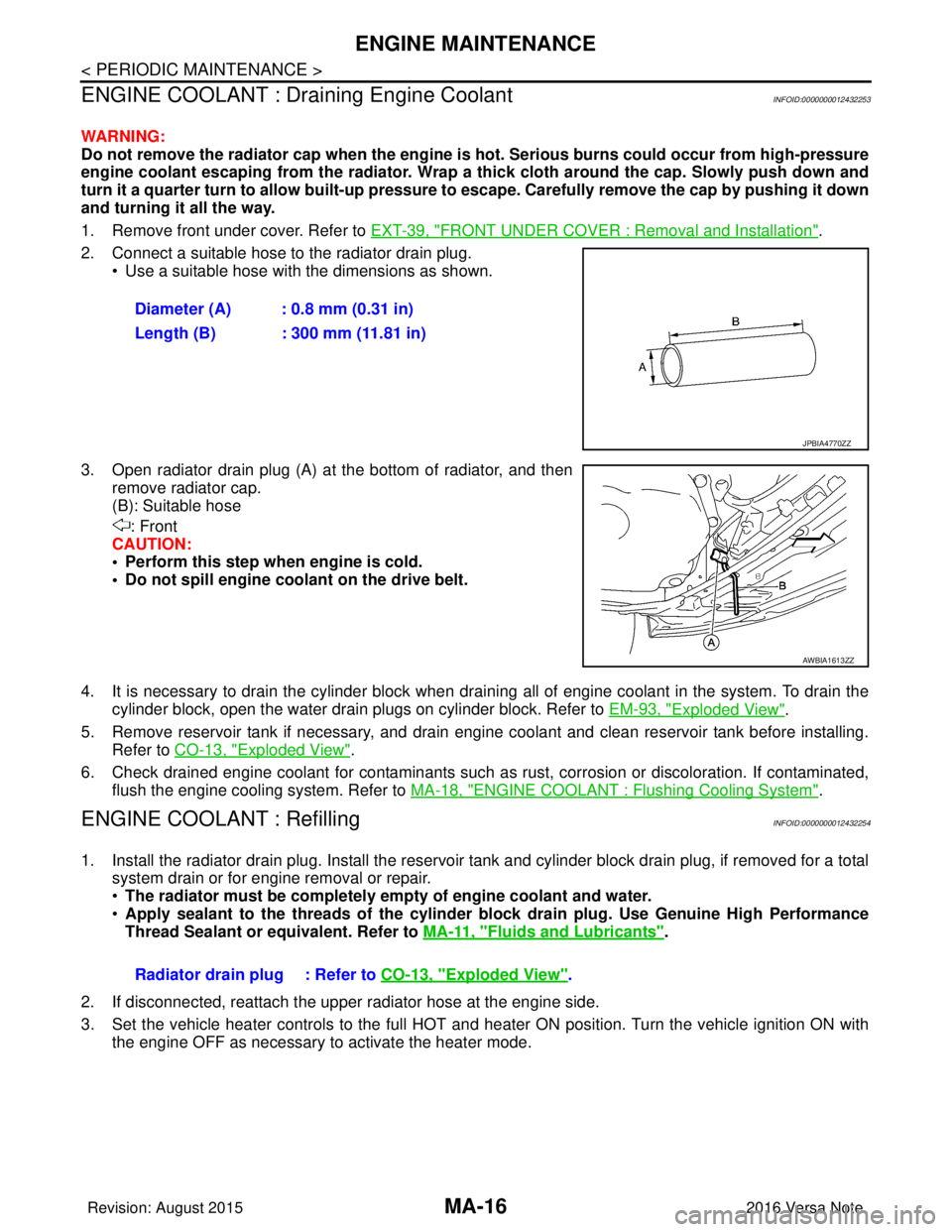

CHECKING RESERVOIR LEVEL

• Check that the reservoir tank engine coolant level is within the MAX (A) to MIN (B) range when the engine is cool.

• Adjust the engine coolant level if necessary. CAUTION:

Refill the engine cooling system with the specified coolant or

equivalent. Refer to MA-11, "

Fluids and Lubricants".

CHECKING COOLING SYSTEM FOR LEAKS

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

CAUTION:

• Perform this step when the engine is cold.

• Do not spill engine coolant on drive belt.

To check for leaks, apply pressure to the cooling system using suit-

able tools (A) and (B). Lock nut (Final tightening) :

34.8 N·m (3.5 kg-m, 26 ft-lb)

JPBIA0102ZZ

Testing pressure: Refer to CO-12, "RADIATOR

: Inspection".

PBIC5121J

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2331 of 3641

MA-16

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

ENGINE COOLANT : Draining Engine Coolant

INFOID:0000000012432253

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a th ick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

1. Remove front under cover. Refer to EXT-39, "

FRONT UNDER COVER : Removal and Installation".

2. Connect a suitable hose to the radiator drain plug. • Use a suitable hose with the dimensions as shown.

3. Open radiator drain plug (A) at the bottom of radiator, and then remove radiator cap.

(B): Suitable hose

: Front

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on the drive belt.

4. It is necessary to drain the cylinder block when drai ning all of engine coolant in the system. To drain the

cylinder block, open the water drain plugs on cylinder block. Refer to EM-93, "

Exploded View".

5. Remove reservoir tank if necessary, and drain engine coolant and clean reservoir tank before installing. Refer to CO-13, "

Exploded View".

6. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system. Refer to MA-18, "

ENGINE COOLANT : Flushing Cooling System".

ENGINE COOLANT : RefillingINFOID:0000000012432254

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be completely empty of engine coolant and water.

• Apply sealant to the threads of the cylinder block drain plug. Use Genuine High Performance

Thread Sealant or equivalent. Refer to MA-11, "

Fluids and Lubricants".

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode. Diameter (A) : 0.8 mm (0.31 in)

Length (B) : 300 mm (11.81 in)

JPBIA4770ZZ

AWBIA1613ZZ

Radiator drain plug : Refer to

CO-13, "Exploded View".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2337 of 3641

MA-22

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

CAUTION:

• The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

• Always use oil level gauge to determine the pr oper amount of engine oil in the engine.

3. Warm up engine and check area around drain plug and oil filter for engine oil leaks. Repair as necessary.

4. Stop engine and wait for 10 minutes.

5. Check the engine oil level. Refer to MA-20, "

ENGINE OIL : Inspection".

OIL FILTER

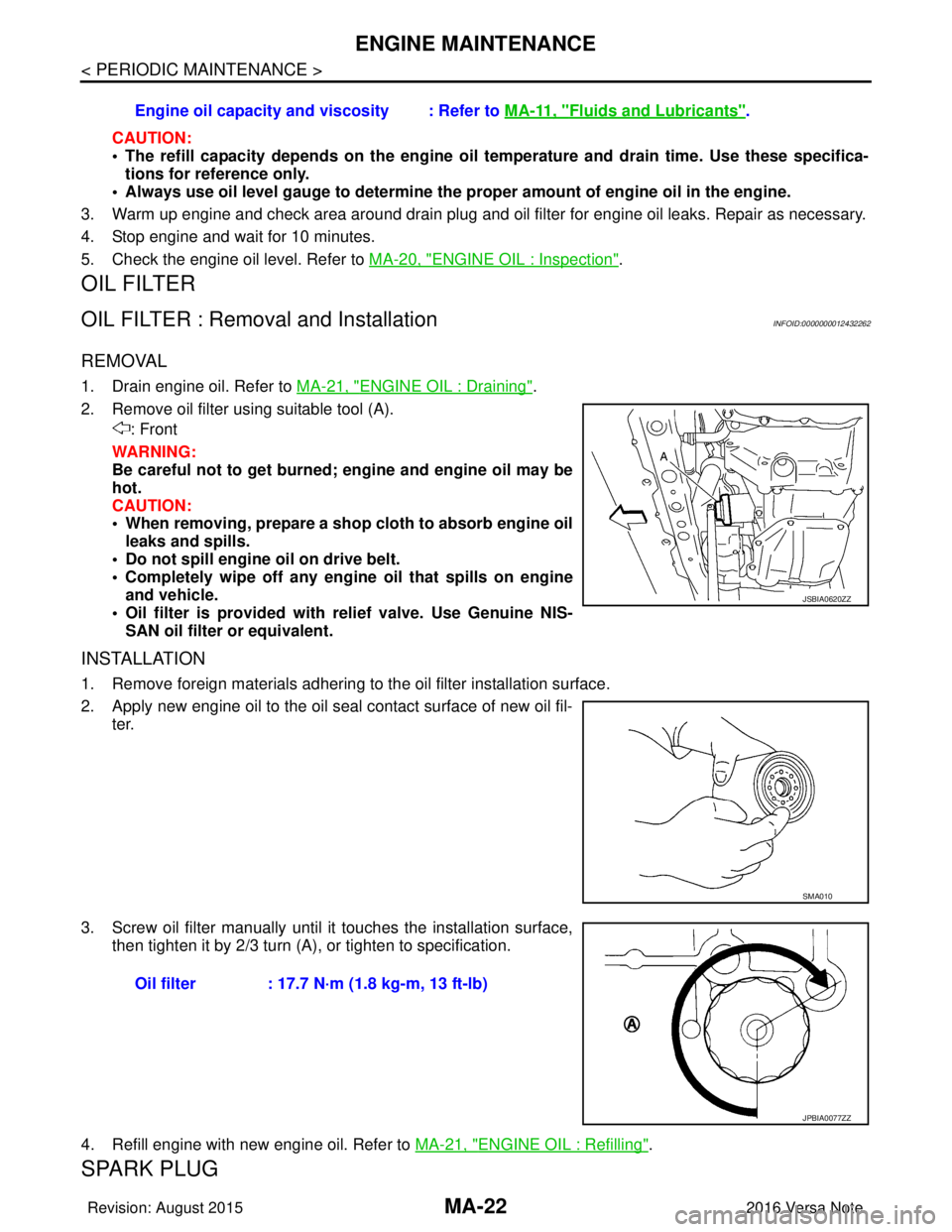

OIL FILTER : Removal and InstallationINFOID:0000000012432262

REMOVAL

1. Drain engine oil. Refer to MA-21, "ENGINE OIL : Draining".

2. Remove oil filter using suitable tool (A). : Front

WARNING:

Be careful not to get burned; engine and engine oil may be

hot.

CAUTION:

• When removing, prepare a shop cloth to absorb engine oil leaks and spills.

• Do not spill engine oil on drive belt.

• Completely wipe off any engine oil that spills on engine

and vehicle.

• Oil filter is provided with relief valve. Use Genuine NIS- SAN oil filter or equivalent.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal contact surface of new oil fil- ter.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn (A), or tighten to specification.

4. Refill engine with new engine oil. Refer to MA-21, "

ENGINE OIL : Refilling".

SPARK PLUG

Engine oil capacity and viscosity : Refer to MA-11, "Fluids and Lubricants".

JSBIA0620ZZ

SMA010

Oil filter : 17.7 N·m (1.8 kg-m, 13 ft-lb)

JPBIA0077ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2358 of 3641

CHASSIS AND BODY MAINTENANCEMA-43

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

SEAT BELT, BUCKLES, RETRAC

TORS, ANCHORS AND ADJUSTERS

SEAT BELT, BUCKLES, RETRACTORS, ANCHORS AND ADJUSTERS : Inspection

INFOID:0000000012432297

Check the seat belt buckles, webbing, retractors, anc hors and adjusters. Replace any seat belt assembly as

necessary. Refer to SB-5, "

Inspection".

• Check the seat belt anchors for loose bolts, damage, or excessive wear.

• Check the seat belt webbing for any damage, cuts, fraying, or excessive wear.

• Check the retractor for smooth operation.

• Check the function of the buckles by inserting the seat belt tongue and checking for proper engagement of

the buckle and press the button on the buckle to c heck for proper release of the seat belt tongue.

CAUTION:

• After any collision, inspect al l seat belt assemblies, including retractors and other attached compo-

nents, such as the guide rail set. NISSAN recomme nds replacing all seat belt assemblies in use dur-

ing a collision, unless they are not damaged an d are inspected to confirm they are operating

properly after a minor collision.

Also inspect all seat belt assemblies that are not in use during a collision, and replace any compo-

nents if damaged or not operating properly. The seat belt pre-tensioner should be replaced even if

the seat belts are not in use during a frontal collision where the driver and passenger air bags have

been deployed.

• If any component of the seat belt assembly is susp ected of being damaged or not operating prop-

erly, do not repair the component. Replace the components as an assembly.

• If the seat belt webbing is cut, frayed, or damaged then replace the seat belt assembly.

• Do not lubricate the seat belt buckle or tongue.

• When replacing any seat belt assembly alw ays use a Genuine NISSAN seat belt assembly.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2359 of 3641

MWI

MWI-1

DRIVER INFORMATION & MULTIMEDIA

C

DE

F

G H

I

J

K L

M B

SECTION MWI

A

O P

CONTENTS

METER, WARNING LAMP & INDICATOR

TYPE A

HOW TO USE THIS MANU AL ......................

5

APPLICATION NOTICE ................................. .....5

Information .......................................................... ......5

PRECAUTION ...............................................6

PRECAUTIONS .............................................. .....6

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

6

PREPARATION ............................................7

PREPARATION .............................................. .....7

Commercial Service Tools .................................. ......7

SYSTEM DESCRIPTION ..............................8

COMPONENT PARTS ................................... .....8

METER SYSTEM .........................................................8

METER SYSTEM : Compo nent Parts Location ........8

METER SYSTEM : Combinat ion Meter ....................9

SYSTEM ......................................................... ....10

METER SYSTEM .......................................................10

METER SYSTEM : System Description ..................10

METER SYSTEM : Fail-safe ...................................11

SPEEDOMETER ................ ........................................12

SPEEDOMETER : System Description ............... ....12

TACHOMETER ...................................................... ....12

TACHOMETER : System Description .....................12

SHIFT POSITION INDICATOR .............................. ....12

SHIFT POSITION INDICATOR : System Descrip-

tion ...................................................................... ....

13

OIL PRESSURE WARNING LAMP ...........................13

OIL PRESSURE WARNING LAMP : System De-

scription ............................................................... ....

13

METER ILLUMINATION CONTROL ..................... ....13

METER ILLUMINATION CONTROL : System De-

scription ...................................................................

13

INFORMATION DISPLAY ...................................... ....14

INFORMATION DISPLAY : System Description .....14

OPERATION .....................................................16

Switch Name and Function ......................................16

DIAGNOSIS SYSTEM (COMBINATION

METER) .............................................................

17

On Board Diagnosis Function ..................................17

CONSULT Function (METER/M&A) ........................18

ECU DIAGNOSIS INFORMATION ..............21

COMBINATION METER ...................................21

Reference Value .................................................. ....21

Fail-safe ...................................................................23

DTC Index ...............................................................24

BCM (BODY CONTROL MODULE) .................25

List of ECU Reference .............................................25

WIRING DIAGRAM ......................................26

METER SYSTEM ..............................................26

Wiring Diagram .................................................... ....26

BASIC INSPECTION ...................................37

DIAGNOSIS AND REPAIR WORK FLOW .......37

Work Flow ............................................................ ....37

DTC/CIRCUIT DIAGNOSIS .........................38

U1000 CAN COMM CIRCUIT ...........................38

DTC Logic ............................................................ ....38

Diagnosis Procedure ..............................................38

Revision: August 2015 2016 Versa Note

cardiagn.com