battery NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 620 of 3641

CHG

L TERMINAL CIRCUIT (OPEN)CHG-25

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

NIs the inspection result normal?

YES >> Replace the combination meter. Refer to

MWI-54, "Removal and Installation" (Type A) or MWI-

115, "Removal and Installation" (Type B).

NO >> Repair or replace the harness or connectors.

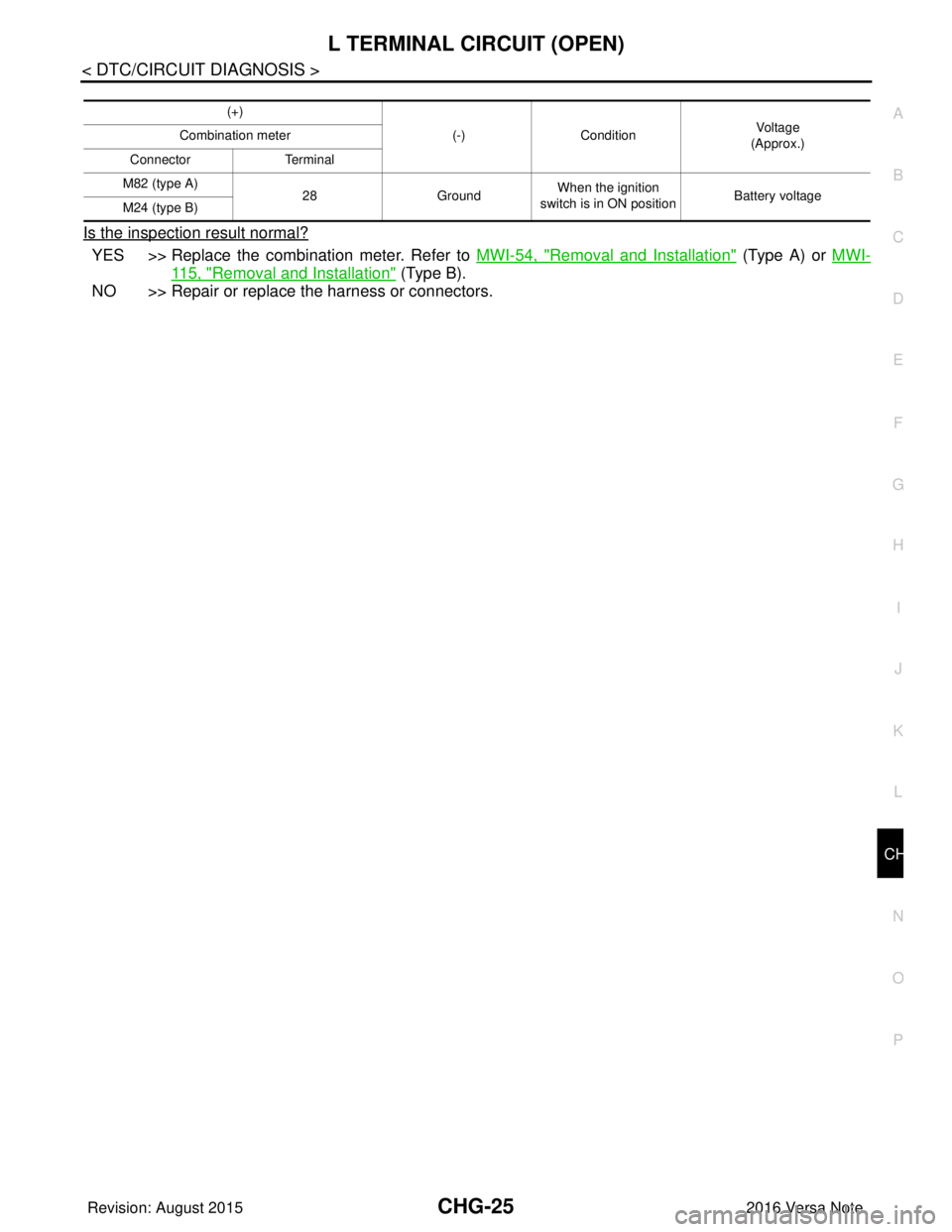

(+)

(-)Condition Voltag e

(Approx.)

Combination meter

Connector Terminal

M82 (type A) 28GroundWhen the ignition

switch is in ON position Battery voltage

M24 (type B)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 621 of 3641

CHG-26

< DTC/CIRCUIT DIAGNOSIS >

L TERMINAL CIRCUIT (SHORT)

L TERMINAL CIRCUIT (SHORT)

DescriptionINFOID:0000000012431255

The terminal “L” circuit controls the charge warning lamp. The charge warning lamp turns ON when the igni-

tion switch is set to ON or START. When the generator is providing sufficient voltage with the engine running,

the charge warning lamp turns off. If the charge warning lamp illuminates with the engine running, a malfunc-

tion is indicated.

Diagnosis ProcedureINFOID:0000000012431256

Regarding Wiring Diagram information, refer to CHG-9, "Wiring Diagram".

1.CHECK “L” TERMINAL CIRCUIT (SHORT)

1. Turn ignition switch OFF.

2. Disconnect generator connector.

3. Turn ignition switch ON.

Does charge warning lamp illuminate?

YES >> GO TO 2.

NO >> Refer to CHG-14, "

Work Flow (With EXP-800 NI or GR8-1200 NI)" or CHG-17, "Work Flow (With-

out EXP-800 NI or GR8-1200 NI)".

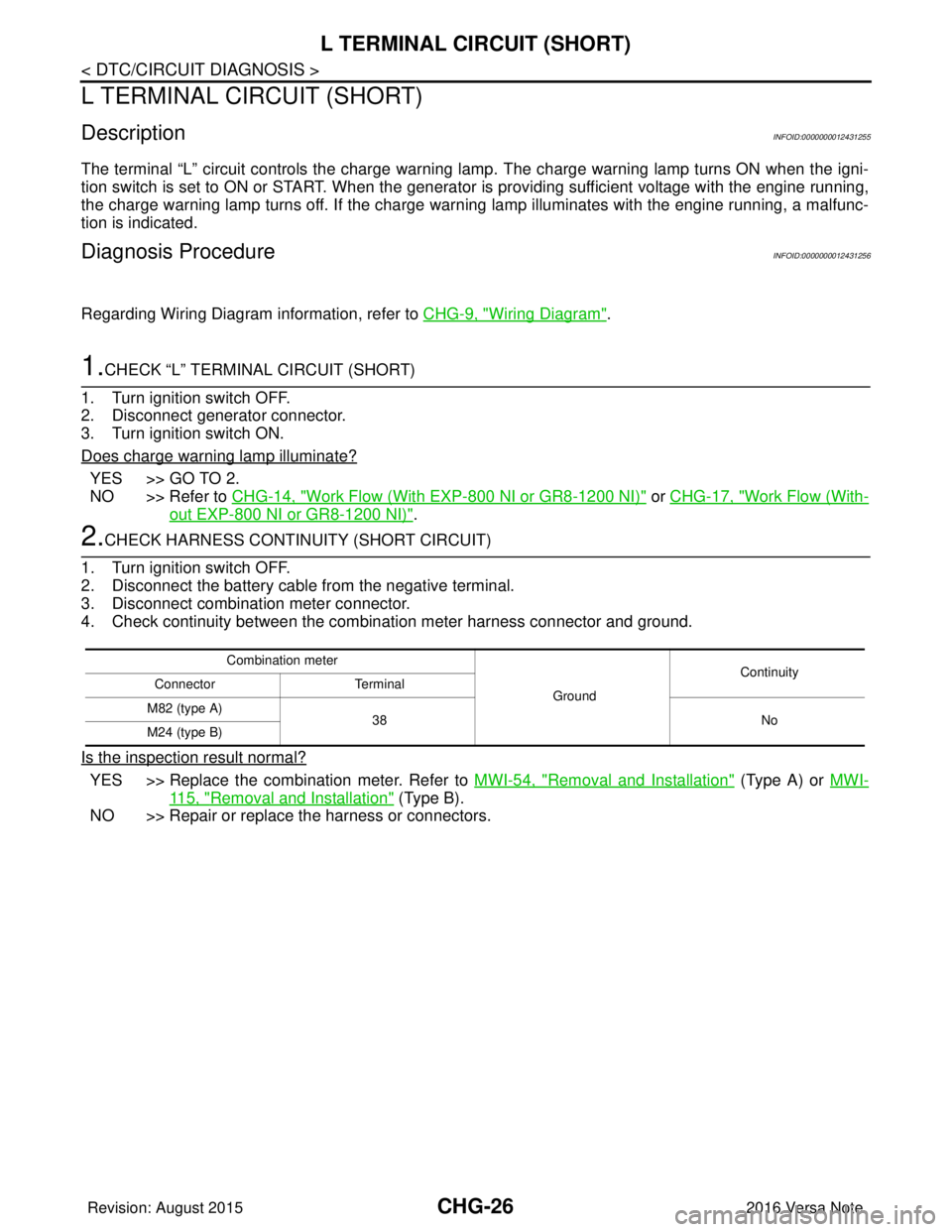

2.CHECK HARNESS CONTI NUITY (SHORT CIRCUIT)

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect combination meter connector.

4. Check continuity between the combination meter harness connector and ground.

Is the inspection result normal?

YES >> Replace the combination meter. Refer to MWI-54, "Removal and Installation" (Type A) or MWI-

115, "Removal and Installation" (Type B).

NO >> Repair or replace the harness or connectors.

Combination meter

GroundContinuity

Connector Terminal

M82 (type A) 38 No

M24 (type B)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 622 of 3641

CHG

S TERMINAL CIRCUITCHG-27

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

S TERMINAL CIRCUIT

DescriptionINFOID:0000000012431257

The output voltage of the generator is controlled by the IC

regulator at terminal “S” detecting the input voltage

from battery.

The “S” terminal circuit detects the battery voltage to adjust the generator output voltage with the IC voltage

regulator.

Diagnosis ProcedureINFOID:0000000012431258

Regarding Wiring Diagram information. Refer to CHG-9, "Wiring Diagram".

1.CHECK “S” TERMINAL CONNECTION

1. Turn ignition switch OFF.

2. Check if “S” terminal is clean and tight.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair “S” terminal connection. Confirm repair by performing complete Charging system test using EXP-800 NI or GR8-1200 NI (if available). Refer to the applicable Instruction Manual for

proper testing procedures.

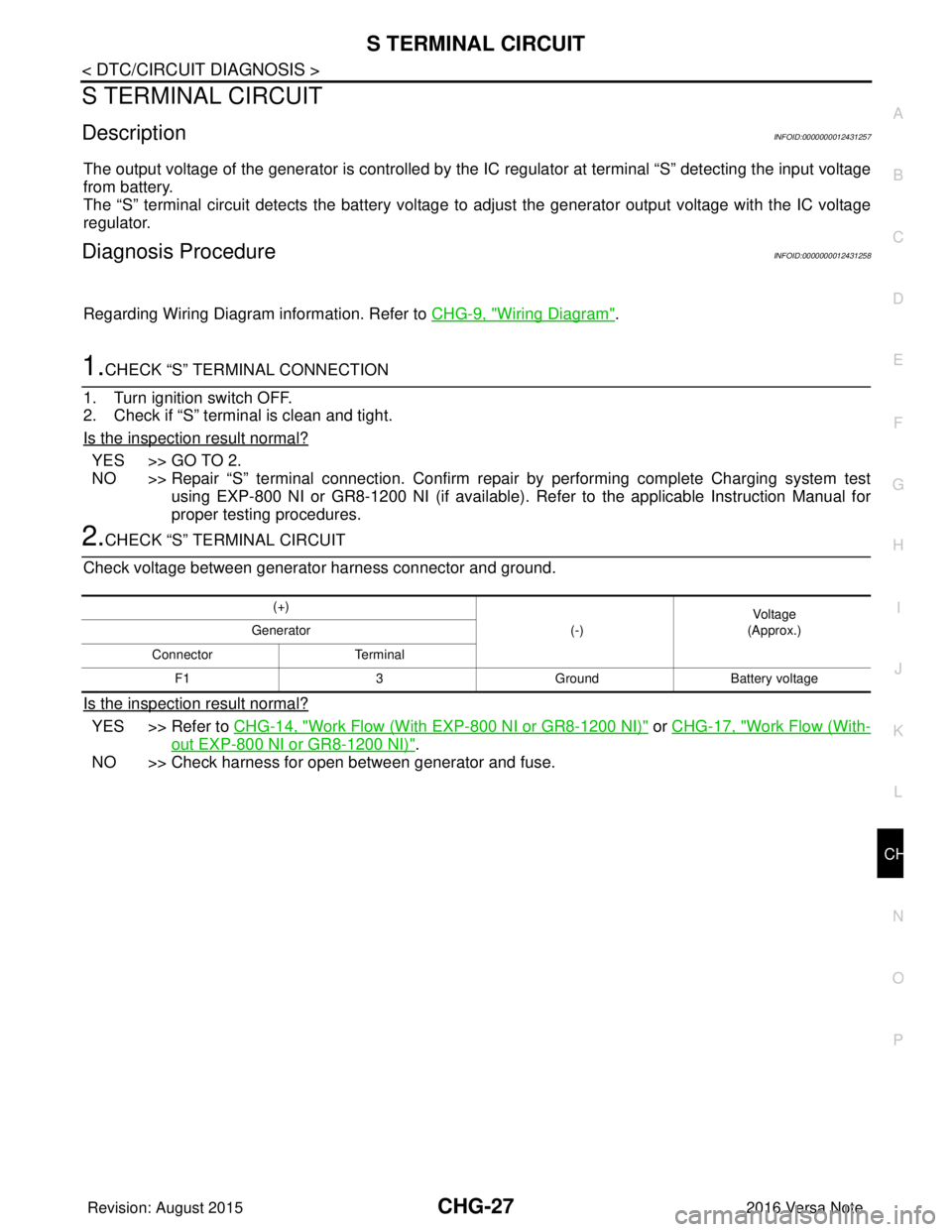

2.CHECK “S” TERMINAL CIRCUIT

Check voltage between generator harness connector and ground.

Is the inspection result normal?

YES >> Refer to CHG-14, "Work Flow (With EXP-800 NI or GR8-1200 NI)" or CHG-17, "Work Flow (With-

out EXP-800 NI or GR8-1200 NI)".

NO >> Check harness for open between generator and fuse.

(+)

(-)Voltage

(Approx.)

Generator

Connector Terminal F1 3GroundBattery voltage

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 623 of 3641

CHG-28

< SYMPTOM DIAGNOSIS >

CHARGING SYSTEM

SYMPTOM DIAGNOSIS

CHARGING SYSTEM

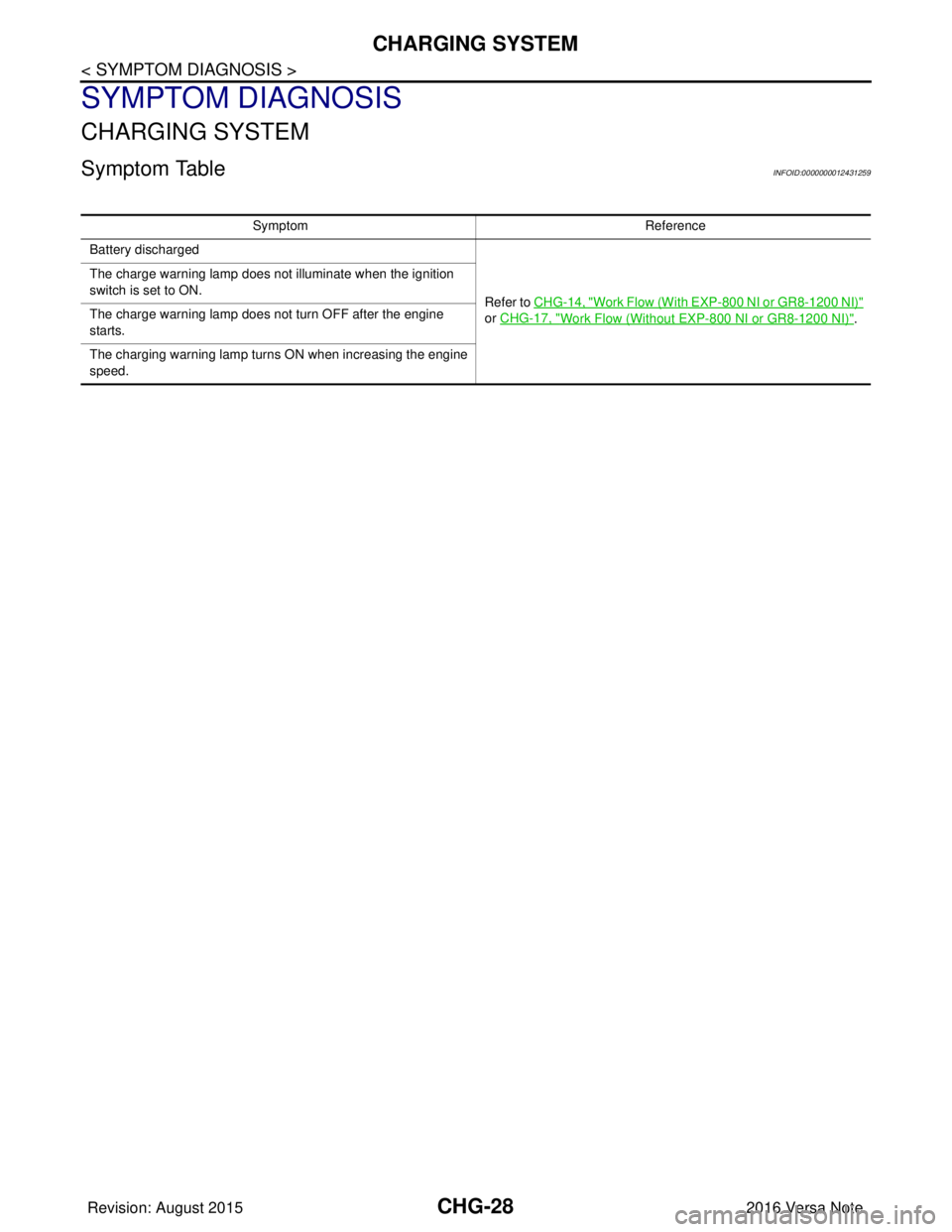

Symptom TableINFOID:0000000012431259

SymptomReference

Battery discharged

Refer to CHG-14, "

Work Flow (With EXP-800 NI or GR8-1200 NI)"

or CHG-17, "

Work Flow (Without EXP-800 NI or GR8-1200 NI)".

The charge warning lamp does not illuminate when the ignition

switch is set to ON.

The charge warning lamp does not turn OFF after the engine

starts.

The charging warning lamp turns ON when increasing the engine

speed.

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 624 of 3641

CHG

GENERATORCHG-29

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

B A

O P

N

REMOVAL AND INSTALLATION

GENERATOR

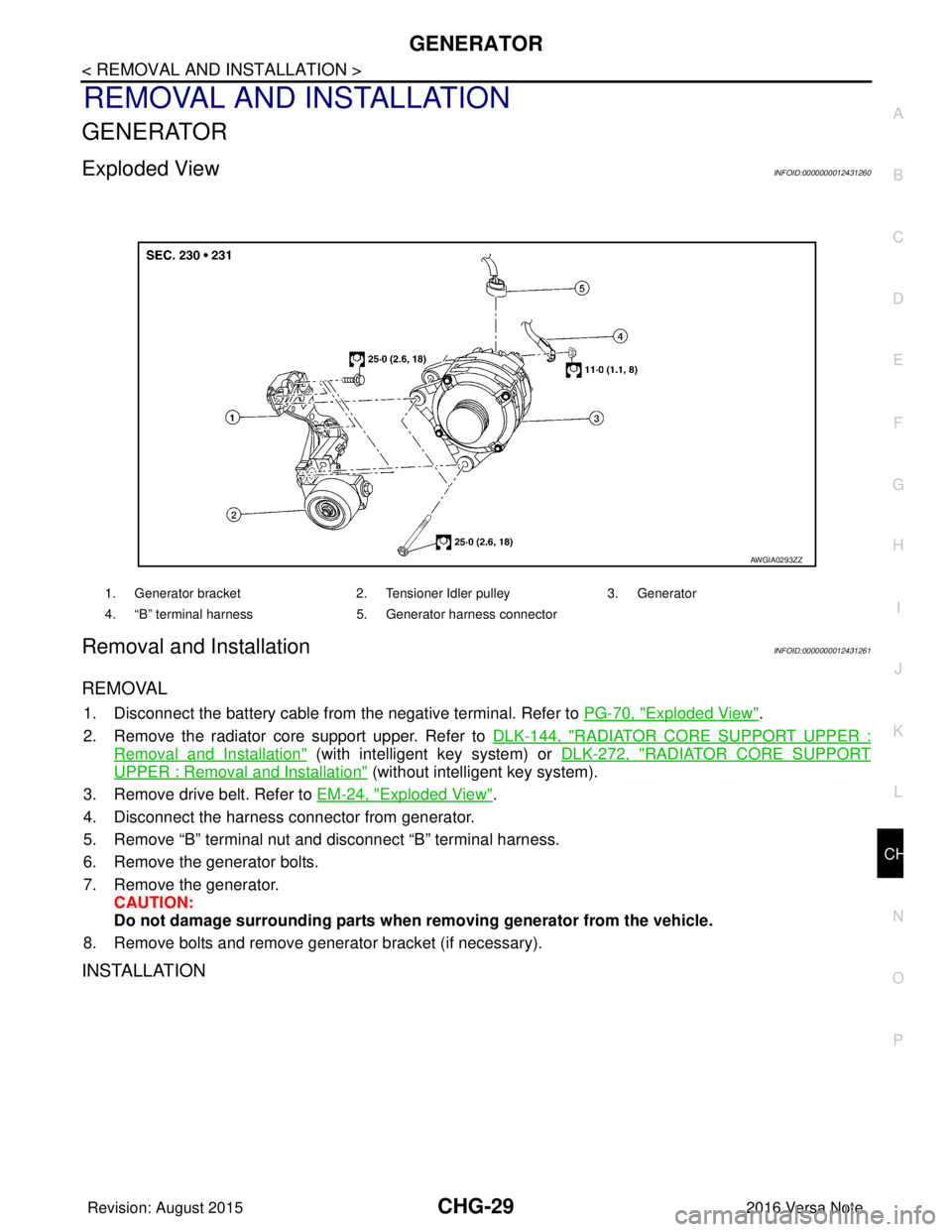

Exploded ViewINFOID:0000000012431260

Removal and InstallationINFOID:0000000012431261

REMOVAL

1. Disconnect the battery cable from

the negative terminal. Refer to PG-70, "Exploded View".

2. Remove the radiator core support upper. Refer to DLK-144, "

RADIATOR CORE SUPPORT UPPER :

Removal and Installation" (with intelligent key system) or DLK-272, "RADIATOR CORE SUPPORT

UPPER : Removal and Installation" (without intelligent key system).

3. Remove drive belt. Refer to EM-24, "

Exploded View".

4. Disconnect the harness connector from generator.

5. Remove “B” terminal nut and disconnect “B” terminal harness.

6. Remove the generator bolts.

7. Remove the generator. CAUTION:

Do not damage surrounding parts when removing generator from the vehicle.

8. Remove bolts and remove generator bracket (if necessary).

INSTALLATION

1. Generator bracket 2. Tensioner Idler pulley3. Generator

4. “B” terminal harness 5. Generator harness connector

AWGIA0293ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 628 of 3641

CL-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432210

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

General PrecautionsINFOID:0000000012432211

WARNING:

After cleaning clutch disc, wipe it with a dust collector. Do not use compressed air.

CAUTION:

• Always use recommended clutch fluid. Refer to MA-11, "

Fluids and Lubricants".

• Do not reuse drained clutch fluid.

• Keep painted surface on the body and other parts free of clutch fluid. If fluid spills, wipe up immedi-

ately and wash the affected area with water.

• Do not use mineral oils, such as gasoline or kerosen e. It will ruin the rubber parts of the hydraulic

system.

• Do not reuse CSC (Concentric Slave Cylinder). CS C slides back to the original position every time

when removing transaxle assembly. At this time, dust on the sliding parts may damage the seal of

CSC and may cause clutch fluid leakage. Refer to CL-17, "

Removal and Installation".

• Do not disassemble clutch master cylinder and CSC.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 639 of 3641

CLUTCH MASTER CYLINDERCL-13

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

CL

N

O P

CLUTCH MASTER CYLINDER

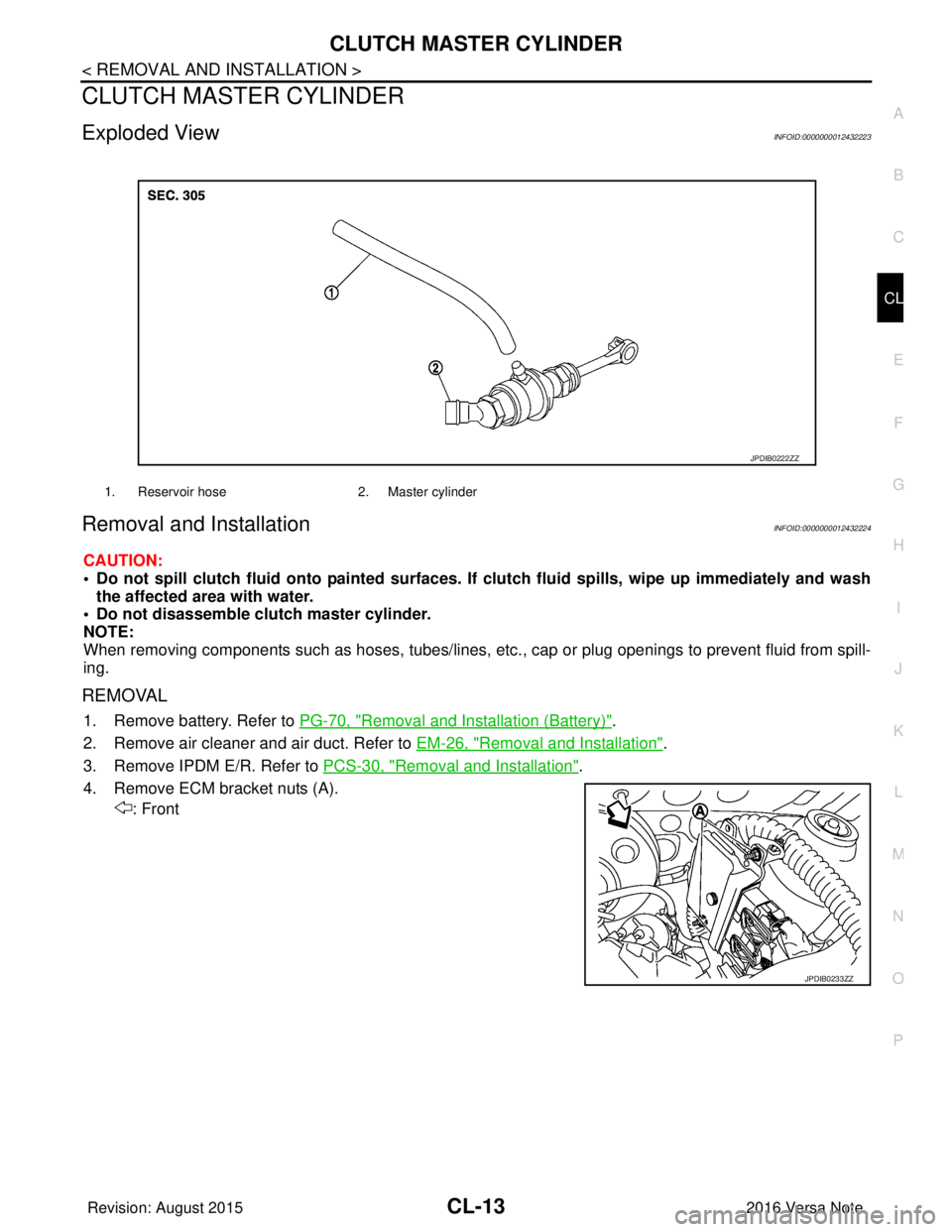

Exploded ViewINFOID:0000000012432223

Removal and InstallationINFOID:0000000012432224

CAUTION:

• Do not spill clutch fluid onto pa inted surfaces. If clutch fluid spills, wipe up immediately and wash

the affected area with water.

• Do not disassemble clut ch master cylinder.

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Remove battery. Refer to PG-70, "Removal and Installation (Battery)".

2. Remove air cleaner and air duct. Refer to EM-26, "

Removal and Installation".

3. Remove IPDM E/R. Refer to PCS-30, "

Removal and Installation".

4. Remove ECM bracket nuts (A). : Front

1. Reservoir hose 2. Master cylinder

JPDIB0222ZZ

JPDIB0233ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 642 of 3641

CL-16

< REMOVAL AND INSTALLATION >

CLUTCH PIPING

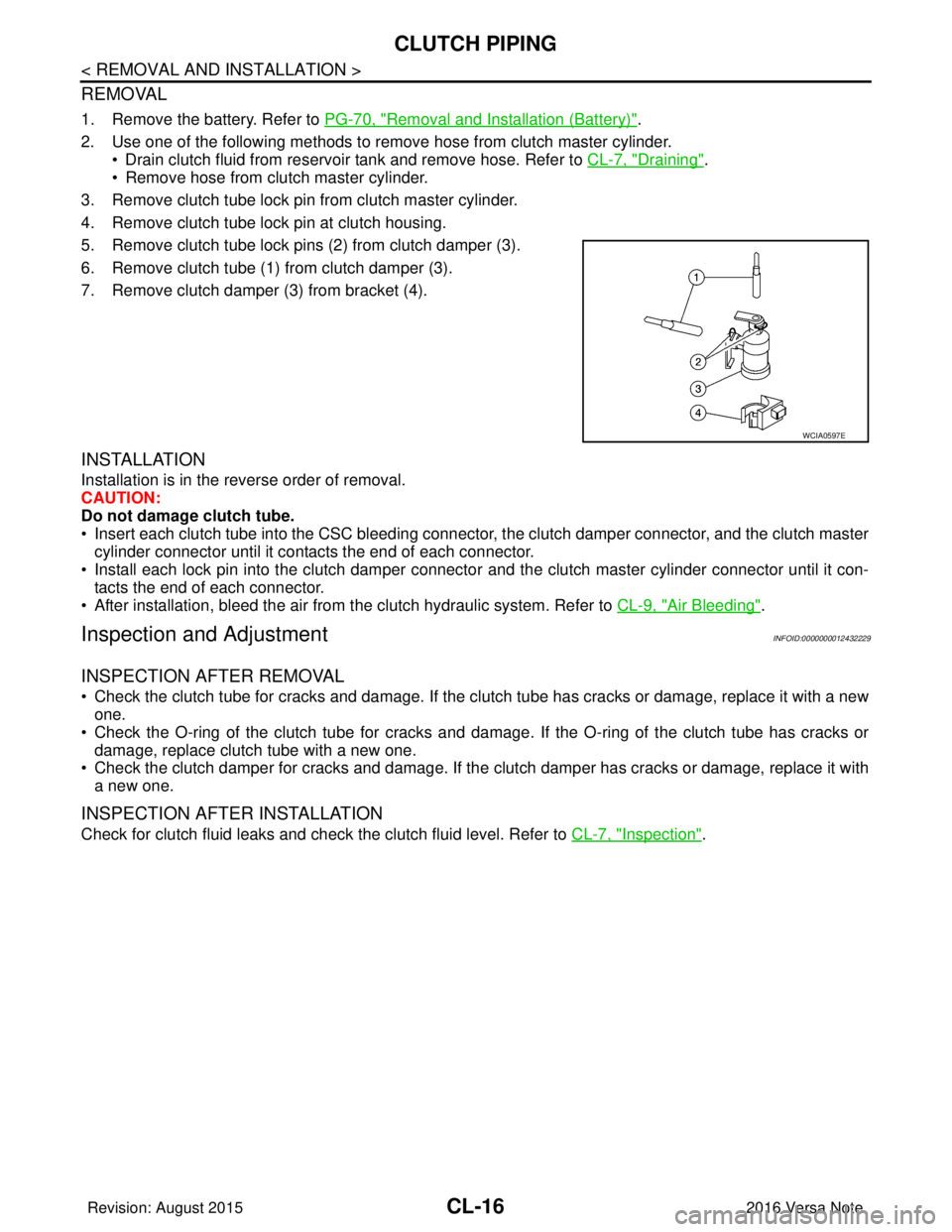

REMOVAL

1. Remove the battery. Refer to PG-70, "Removal and Installation (Battery)".

2. Use one of the following methods to remove hose from clutch master cylinder. • Drain clutch fluid from reservoir tank and remove hose. Refer to CL-7, "

Draining".

• Remove hose from clutch master cylinder.

3. Remove clutch tube lock pin from clutch master cylinder.

4. Remove clutch tube lock pin at clutch housing.

5. Remove clutch tube lock pins (2) from clutch damper (3).

6. Remove clutch tube (1) from clutch damper (3).

7. Remove clutch damper (3) from bracket (4).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not damage clutch tube.

• Insert each clutch tube into the CSC bleeding connector, the clutch damper connector, and the clutch master cylinder connector until it contacts the end of each connector.

• Install each lock pin into the clutch damper connecto r and the clutch master cylinder connector until it con-

tacts the end of each connector.

• After installation, bleed the air from the clutch hydraulic system. Refer to CL-9, "

Air Bleeding".

Inspection and AdjustmentINFOID:0000000012432229

INSPECTION AFTER REMOVAL

• Check the clutch tube for cracks and damage. If the cl utch tube has cracks or damage, replace it with a new

one.

• Check the O-ring of the clutch tube for cracks and dam age. If the O-ring of the clutch tube has cracks or

damage, replace clutch tube with a new one.

• Check the clutch damper for cracks and damage. If the clutch damper has cracks or damage, replace it with

a new one.

INSPECTION AFTER INSTALLATION

Check for clutch fluid leaks and check the clutch fluid level. Refer to CL-7, "Inspection".

WCIA0597E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 650 of 3641

![NISSAN NOTE 2016 Service Repair Manual CCS-2

< PRECAUTION >[ASCD]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012542559

The Supplemental Rest NISSAN NOTE 2016 Service Repair Manual CCS-2

< PRECAUTION >[ASCD]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012542559

The Supplemental Rest](/img/5/57363/w960_57363-649.png)

CCS-2

< PRECAUTION >[ASCD]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012542559

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 654 of 3641

PRECAUTIONSDEF-3

< PRECAUTION >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431751

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Revision: August 2015 2016 Versa Note

cardiagn.com