check transmission fluid NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 450 of 3641

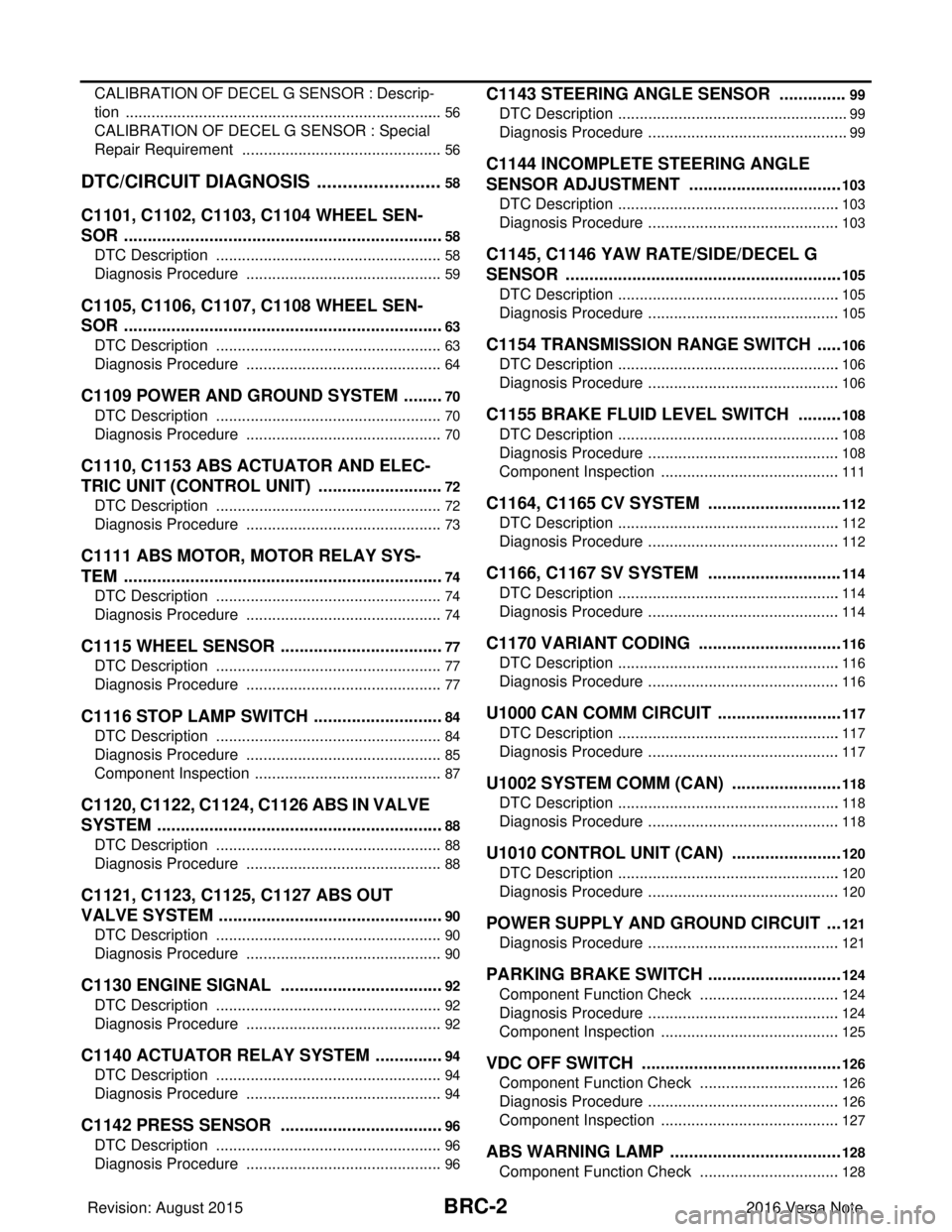

BRC-2

CALIBRATION OF DECEL G SENSOR : Descrip-

tion ..........................................................................

56

CALIBRATION OF DECEL G SENSOR : Special

Repair Requirement ..... ..........................................

56

DTC/CIRCUIT DIAGNOSIS ...................... ...58

C1101, C1102, C1103, C1104 WHEEL SEN-

SOR ................................................................. ...

58

DTC Description .................................................. ...58

Diagnosis Procedure ..............................................59

C1105, C1106, C1107, C1108 WHEEL SEN-

SOR ....................................................................

63

DTC Description .................................................. ...63

Diagnosis Procedure ..............................................64

C1109 POWER AND GROUND SYSTEM .........70

DTC Description .................................................. ...70

Diagnosis Procedure ..............................................70

C1110, C1153 ABS ACTUATOR AND ELEC-

TRIC UNIT (CONTROL UNIT) ...........................

72

DTC Description .....................................................72

Diagnosis Procedure ..............................................73

C1111 ABS MOTOR, MOTOR RELAY SYS-

TEM ....................................................................

74

DTC Description .................................................. ...74

Diagnosis Procedure ..............................................74

C1115 WHEEL SENSOR ...................................77

DTC Description .................................................. ...77

Diagnosis Procedure ..............................................77

C1116 STOP LAMP SWITCH ............................84

DTC Description .................................................. ...84

Diagnosis Procedure ..............................................85

Component Inspection ............................................87

C1120, C1122, C1124, C1126 ABS IN VALVE

SYSTEM .......................................................... ...

88

DTC Description .................................................. ...88

Diagnosis Procedure ..............................................88

C1121, C1123, C1125, C1127 ABS OUT

VALVE SYSTEM ................................................

90

DTC Description .................................................. ...90

Diagnosis Procedure ..............................................90

C1130 ENGINE SIGNAL ...................................92

DTC Description .................................................. ...92

Diagnosis Procedure ..............................................92

C1140 ACTUATOR RELAY SYSTEM ...............94

DTC Description .................................................. ...94

Diagnosis Procedure ..............................................94

C1142 PRESS SENSOR ...................................96

DTC Description .................................................. ...96

Diagnosis Procedure ..............................................96

C1143 STEERING ANGLE SENSOR ...............99

DTC Description ................................................... ...99

Diagnosis Procedure ...............................................99

C1144 INCOMPLETE STEERING ANGLE

SENSOR ADJUSTMENT .................................

103

DTC Description ................................................... .103

Diagnosis Procedure .............................................103

C1145, C1146 YAW RATE/SIDE/DECEL G

SENSOR ...........................................................

105

DTC Description ................................................... .105

Diagnosis Procedure .............................................105

C1154 TRANSMISSION RANGE SWITCH ......106

DTC Description ................................................... .106

Diagnosis Procedure .............................................106

C1155 BRAKE FLUID LEVEL SWITCH ..........108

DTC Description ................................................... .108

Diagnosis Procedure .............................................108

Component Inspection ..........................................111

C1164, C1165 CV SYSTEM .............................112

DTC Description ....................................................112

Diagnosis Procedure .............................................112

C1166, C1167 SV SYSTEM .............................114

DTC Description ....................................................114

Diagnosis Procedure .............................................114

C1170 VARIANT CODING ...............................116

DTC Description ................................................... .116

Diagnosis Procedure .............................................116

U1000 CAN COMM CIRCUIT ...........................117

DTC Description ................................................... .117

Diagnosis Procedure .............................................117

U1002 SYSTEM COMM (CAN) ........................118

DTC Description ................................................... .118

Diagnosis Procedure .............................................118

U1010 CONTROL UNIT (CAN) ........................120

DTC Description ................................................... .120

Diagnosis Procedure .............................................120

POWER SUPPLY AND GROUND CIRCUIT ....121

Diagnosis Procedure ............................................ .121

PARKING BRAKE SWITCH .............................124

Component Function Check ................................ .124

Diagnosis Procedure .............................................124

Component Inspection ..........................................125

VDC OFF SWITCH ...........................................126

Component Function Check ................................ .126

Diagnosis Procedure .............................................126

Component Inspection ..........................................127

ABS WARNING LAMP .....................................128

Component Function Check ................................ .128

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1040 of 3641

![NISSAN NOTE 2016 Service Repair Manual OIL PAN AND OIL STRAINEREM-39

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

c. Press-fit the rear oil seal using a suitable drift (A) with outer

diameter 113 mm (4.45 in) and i NISSAN NOTE 2016 Service Repair Manual OIL PAN AND OIL STRAINEREM-39

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

c. Press-fit the rear oil seal using a suitable drift (A) with outer

diameter 113 mm (4.45 in) and i](/img/5/57363/w960_57363-1039.png)

OIL PAN AND OIL STRAINEREM-39

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

c. Press-fit the rear oil seal using a suitable drift (A) with outer

diameter 113 mm (4.45 in) and inner diameter 90 mm (3.54 in).

• Press-fit to the specified dimensions as shown.

CAUTION:

• Do not touch the grease applied to the oil seal lip.

• Be careful not to damage the rear oil seal mounting partof oil pan (upper) and cylinder block or the crankshaft.

• Press-fit straight and check that oil seal does not curl or tilt.

d. After press-fitting the rear oil seal, completely wipe off any liquid gasket protruding to rear end surface side.

3. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels, includi ng engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak- age at connection points.

• Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

PBIC3660E

(1) : Rear oil seal

(A) : Rear end surface of cylinder block

PBIC3149J

Item Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakageLeakage

Exhaust gas —Leakage —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1060 of 3641

![NISSAN NOTE 2016 Service Repair Manual TIMING CHAINEM-59

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Secure crankshaft pulley with a suitable tool and tighten crankshaft pulley bolt.

a. Apply new engine oil to NISSAN NOTE 2016 Service Repair Manual TIMING CHAINEM-59

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Secure crankshaft pulley with a suitable tool and tighten crankshaft pulley bolt.

a. Apply new engine oil to](/img/5/57363/w960_57363-1059.png)

TIMING CHAINEM-59

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

• Secure crankshaft pulley with a suitable tool and tighten crankshaft pulley bolt.

a. Apply new engine oil to thread and seat surfaces of crankshaft pulley bolt.

b. Tighten crankshaft pulley bolt.

c. Put a paint mark (B) on crankshaft pulley, mating with any one of six easy to recognize angle marks (A) on crankshaft bolt flange

(1).

d. Turn another 60 degrees clockwise (angle tightening). • Check the tightening angle with movement of one angle mark.

10. Check that crankshaft turns smoothly by rotating by hand clockwise using suitable tool.

11. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels, includi ng engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leaks.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leaks at connection points.

• Start engine. With engine speed increased, check again for fuel leaks at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there are no lea ks of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

Crankshaft pulley bolt : 35.0 N·m (3.6 kg-m, 26 ft-lb)

PBIC3726E

ItemBefore starting engine Engine runningAfter engine stopped

Engine coolant LevelLeaks Level

Engine oil LevelLeaks Level

Transmission/

transaxle fluid CVT Models

LeaksLevel/Leaks Leaks

M/T Models Level/Leaks LeaksLevel/Leaks

Other oils and fluids* LevelLeaks Level

Fuel LeaksLeaks Leaks

Exhaust gas —Leaks —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1069 of 3641

![NISSAN NOTE 2016 Service Repair Manual EM-68

< REMOVAL AND INSTALLATION >[HR16DE]

CAMSHAFT

• Before starting engine, check oil/fluid levels, including engine coolant and engine oil. If less than required

quantity, fill to the specified l NISSAN NOTE 2016 Service Repair Manual EM-68

< REMOVAL AND INSTALLATION >[HR16DE]

CAMSHAFT

• Before starting engine, check oil/fluid levels, including engine coolant and engine oil. If less than required

quantity, fill to the specified l](/img/5/57363/w960_57363-1068.png)

EM-68

< REMOVAL AND INSTALLATION >[HR16DE]

CAMSHAFT

• Before starting engine, check oil/fluid levels, including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leaks.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leaks

at connection points.

• Start engine. With engine speed increased, che ck again for fuel leaks at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leak s of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

InspectionINFOID:0000000012431722

INSPECTION AFTER REMOVAL

Oil Filter

• Check that there is no foreign material on the oil filter (1) and check it for clogging.

• Check the oil filter for damage.

• If there is some damage, replace the oil filter, the plug, and the washer as a set.

CAUTION:

Do not reuse the washer.

Camshaft Runout

1. Put V-block on a precise flat table, and support No. 2 and 5 jour- nals of camshaft.

CAUTION:

Do not support No. 1 journal (on the side of camshaft

sprocket) because it has a differe nt diameter from the other

four locations.

2. Set a suitable tool vertically to No. 3 journal.

3. Turn camshaft to one direction, and measure the camshaft runout using suitable tool. (Total indicator reading)

Item Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeaks Level

Engine oil LevelLeaks Level

Transmission/

transaxle fluid CVT Models

LeaksLevel/Leaks Leaks

M/T Models Level/Leaks LeaksLevel/Leaks

Other oils and fluids* LevelLeaks Level

Fuel LeaksLeaksLeaks

Exhaust gas —Leaks —

PBIC3693E

PBIC2499E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1088 of 3641

![NISSAN NOTE 2016 Service Repair Manual ENGINE ASSEMBLYEM-87

< UNIT REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

Check that the stud bolt (*2) is tigh

t at the specified torque before tightening the nut (*1) NISSAN NOTE 2016 Service Repair Manual ENGINE ASSEMBLYEM-87

< UNIT REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

Check that the stud bolt (*2) is tigh

t at the specified torque before tightening the nut (*1)](/img/5/57363/w960_57363-1087.png)

ENGINE ASSEMBLYEM-87

< UNIT REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

Check that the stud bolt (*2) is tigh

t at the specified torque before tightening the nut (*1) shown. [Stud

bolt (*2) may be loosened after loosening the nut (*1)]

Removal and InstallationINFOID:0000000012431732

WARNING:

• Position the vehicle on a flat and solid surface.

• Place chocks at front and back of rear wheels.

• Attach proper slingers and bolts described in PARTS CATALOG if engine is not already equipped.

CAUTION:

• Always be careful to work safely.

• Do not start working until exhaust system and coolant are cool enough.

• If items or work required are not covered by th e engine section, refer to the applicable sections.

• Always use the support poin t specified for lifting.

• Use either 2-pole lift type or separate type lift. If board-on type must be used, support the rear axle

jacking point with a transmission jack or similar to ol before starting work, in preparation for the

backward shift of center of gravity.

• For supporting points for lifting and j acking point at rear axle, refer to GI-29, "

2-Pole Lift".

NOTE:

• When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from

spilling.

1. Engine mounting (RH) stay 2. Engine mount (RH) stay 3. Engine mounting insulator (RH)

4. Rear engine mounting bracket 5. Rear torque rod 6. Engine mounting bracket (LH)

7. Mass damper 8. Engine mounting insulator (LH) 9. Engine mounting bracket (LH)

10. Engine mount bracket (LH) A. Front mark B. Transaxle (upper)

C. Transaxle (lower) D. M/T models

AWBIA1587ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1091 of 3641

![NISSAN NOTE 2016 Service Repair Manual EM-90

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

• Before starting engine, check oil/fluid levels incl

uding engine coolant and engine oil. If less than required

quantity, fill to the NISSAN NOTE 2016 Service Repair Manual EM-90

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

• Before starting engine, check oil/fluid levels incl

uding engine coolant and engine oil. If less than required

quantity, fill to the](/img/5/57363/w960_57363-1090.png)

EM-90

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

• Before starting engine, check oil/fluid levels incl

uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leaks.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leaks

at connection points.

• Start engine. With engine speed increased, che ck again for fuel leaks at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there are no l eaks of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeaks Level

Engine oil LevelLeaks Level

Transmission/

transaxle fluid CVT Models

LeaksLevel/Leaks Leaks

M/T Models Level/Leaks LeaksLevel/Leaks

Other oils and fluids* LevelLeaks Level

Fuel LeaksLeaksLeaks

Exhaust gas —Leaks —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1278 of 3641

![NISSAN NOTE 2016 Service Repair Manual TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-151

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC/CIRCUIT DIAGNOSIS

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000 NISSAN NOTE 2016 Service Repair Manual TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-151

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC/CIRCUIT DIAGNOSIS

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000](/img/5/57363/w960_57363-1277.png)

TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-151

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC/CIRCUIT DIAGNOSIS

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000012431370

The specification (SP) value indicates the tolerance of

the value that is displayed in “SPEC” of “DATA MONI-

TOR” mode of CONSULT during normal operation of the Engine Control System. When the value in “SPEC” of

“DATA MONITOR” mode is within the SP value, the Engine Control System is confirmed OK. When the value

in “SPEC” of “DATA MONITOR” mode is NOT within the SP value, the Engine Control System may have one

or more malfunctions.

The SP value is used to detect malfunctions that may af fect the Engine Control System, but will not light the

MIL.

The SP value will be displayed for the following three items:

• B/FUEL SCHDL (The fuel injection pulse width programmed into ECM prior to any learned on board correc- tion)

• A/F ALPHA-B1 (The mean value of air-fuel ratio feedback correction factor per cycle)

• MAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Component Function CheckINFOID:0000000012431371

1.START

Make sure that all of the following conditions are satisfied.

• Vehicle driven distance: More than 5,000 km (3,107 miles)

• Barometric pressure: 98.3 - 104.3 kPa (1.003 - 1.064 kg/cm

2, 14.25 - 15.12 psi)

• Atmospheric temperature: 20 - 30 °C (68 - 86° F)

• Engine coolant temperature: 75 - 95 °C (167 - 203° F)

• Transmission: Warmed-up

- CVT models: After the engine is warmed up to normal operating temperature, drive vehicle until “FLUID TEMP SE” (CVT fluid temperature sensor signal) indicates more than 60 °C (140° F).

- M/T models: After the engine is warmed up to normal operating temperature, drive vehicle for 5 minutes.

• Electrical load: Not applied

- Rear window defogger switch, air conditioner switch, lighting switch are OFF. Steering wheel is straight

ahead.

• Engine speed: Idle

>> GO TO 2.

2.PERFORM “SPEC” OF “DATA MONITOR” MODE

With CONSULT

NOTE:

Perform “SPEC” in “DATA MONITOR” mode in maximum scale display.

1. Perform EC-133, "

Work Procedure".

2. Select “B/FUEL SCHDL”, “A/F ALPHA-B1” and “MAS A/F SE-B1” in “SPEC” of “DATA MONITOR” mode

with CONSULT.

3. Make sure that monitor items are within the SP value.

Is the inspection result normal?

YES >> END

NO >> Go to EC-152, "

Diagnosis Procedure".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1615 of 3641

![NISSAN NOTE 2016 Service Repair Manual CO-10

< PERIODIC MAINTENANCE >[HR16DE]

ENGINE COOLANT

4. Install the Tool by installing the radiator cap adapter onto the

radiator neck opening. Then attach the gauge body assembly

with the refill tub NISSAN NOTE 2016 Service Repair Manual CO-10

< PERIODIC MAINTENANCE >[HR16DE]

ENGINE COOLANT

4. Install the Tool by installing the radiator cap adapter onto the

radiator neck opening. Then attach the gauge body assembly

with the refill tub](/img/5/57363/w960_57363-1614.png)

CO-10

< PERIODIC MAINTENANCE >[HR16DE]

ENGINE COOLANT

4. Install the Tool by installing the radiator cap adapter onto the

radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the engine coolant mixture container that is placed at floor level. Make sure the ball valve is in the

closed position.

•Use recommended engine coolant or equivalent.

Refer to MA-11, "

Fluids and Lubricants".

CAUTION:

Do not use any cooling system additives such as radiator

sealer. Additives may clog th e cooling system and cause

damage to the engine, transmission and/or cooling system.

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Engine coolant wi ll be visible rising in the refill hose. Once the refill

hose is full of engine coolant, close the ball valve. This will purge any air trapped in the refill hose.

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specifi ed amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to bring the vacuum to the specified amount. Recheck for any leaks.

10. Place the engine coolant container (with the refill hose inserted) at the same level as the top of the radia- tor. Then open the ball valve on the refill hose so the engine coolant will be drawn up to fill the cooling sys-

tem. The cooling system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the engine coolant co ntainer to get too low when filling, to avoid air from being drawn

into the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specified level and install the radiator cap. Run the engine to warm up the cooling system and t op up the system as necessary.

13. Install the front under cover. Refer to EXT-39, "

FRONT UNDER COVER : Removal and Installation".

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank)

: Refer to MA-11, "

Fluids and

Lubricants".

Compressed air

supply pressure : 549 - 824 kPa (5.6 - 8.4 kg/cm

2,

80 - 119 psi)LLIA0058E

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

LLIA0057E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1624 of 3641

![NISSAN NOTE 2016 Service Repair Manual WATER PUMPCO-19

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

INSPECTION AFTER REMOVAL

• Visually check for significant dirt or rust on the water pump body

and vane (A) and r NISSAN NOTE 2016 Service Repair Manual WATER PUMPCO-19

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

INSPECTION AFTER REMOVAL

• Visually check for significant dirt or rust on the water pump body

and vane (A) and r](/img/5/57363/w960_57363-1623.png)

WATER PUMPCO-19

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

INSPECTION AFTER REMOVAL

• Visually check for significant dirt or rust on the water pump body

and vane (A) and replace as necessary.

• Check that the vane shaft turns smoothly by hand and is not excessively loose.

• Replace the water pump assembly if the water pump does not per-

form properly.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten water pump bolts in order as shown.

CAUTION:

• Do not allow the water pump vane to contact any other parts.

• Water pump cannot be disassembled and must be replaced asan assembly.

• Do not reuse gasket.

• Sealing surface must be clean and free of dents or flaws.

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels, includi ng engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leaks.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leaks at connection points.

• Start engine. With engine speed increased, check again for fuel leaks at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no lea ks of fuel, exhaust gas, or any oils/fluids, including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels, including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

PBIC3808E

KBIA3393J

Item Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeaks Level

Engine oil LevelLeaks Level

Transmission/

transaxle fluid CVT Models

LeaksLevel/Leaks Leaks

M/T Models Level/Leaks LeaksLevel/Leaks

Other oils and fluids* LevelLeaks Level

Fuel LeaksLeaks Leaks

Exhaust gas —Leaks —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1627 of 3641

![NISSAN NOTE 2016 Service Repair Manual CO-22

< REMOVAL AND INSTALLATION >[HR16DE]

THERMOSTAT

• Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and install NISSAN NOTE 2016 Service Repair Manual CO-22

< REMOVAL AND INSTALLATION >[HR16DE]

THERMOSTAT

• Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and install](/img/5/57363/w960_57363-1626.png)

CO-22

< REMOVAL AND INSTALLATION >[HR16DE]

THERMOSTAT

• Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leaks of fuel, exhaust gas, or any oils/fluids, including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels, including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeaks Level

Engine oil LevelLeaks Level

Transmission/

transaxle fluid CVT Models

LeaksLevel/Leaks Leaks

M/T Models Level/Leaks LeaksLevel/Leaks

Other oils and fluids* LevelLeaks Level

Fuel LeaksLeaksLeaks

Exhaust gas —Leaks —

Revision: August 2015 2016 Versa Note

cardiagn.com