exhaust NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1913 of 3641

PRECAUTIONSGI-25

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

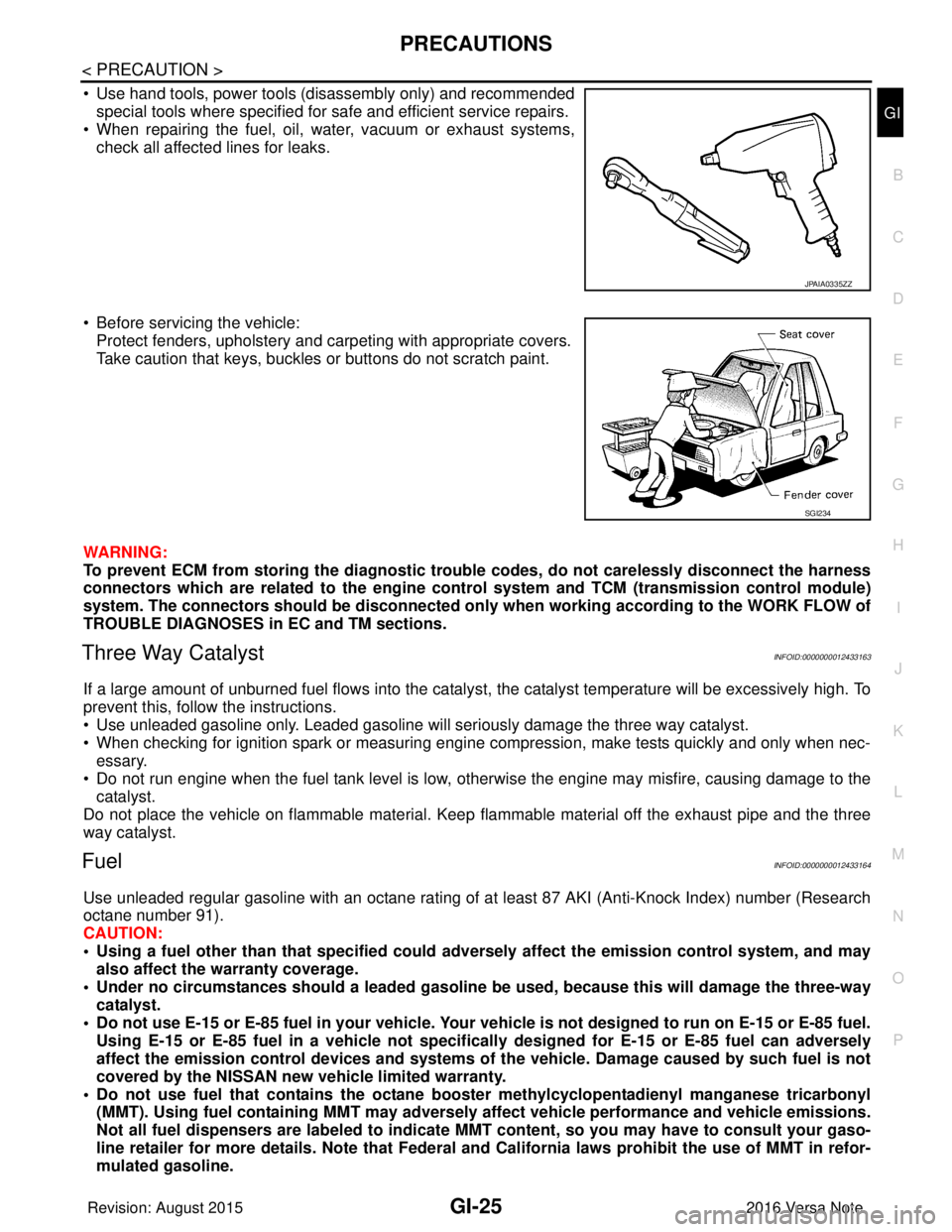

• Use hand tools, power tools (disassembly only) and recommended special tools where specified for safe and efficient service repairs.

• When repairing the fuel, oil, water, vacuum or exhaust systems,

check all affected lines for leaks.

• Before servicing the vehicle: Protect fenders, upholstery and carpeting with appropriate covers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trou ble codes, do not carelessly disconnect the harness

connectors which are related to the engine cont rol system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and TM sections.

Three Way CatalystINFOID:0000000012433163

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

• Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

• When checking for ignition spark or measuring engine compression, make tests quickly and only when nec-

essary.

• Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to the

catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

FuelINFOID:0000000012433164

Use unleaded regular gasoline with an octane rating of at least 87 AKI (Anti-Knock Index) number (Research

octane number 91).

CAUTION:

• Using a fuel other than that specified could adversely affect th e emission control system, and may

also affect the warranty coverage.

• Under no circumstances should a leaded gasoline be used, because this will damage the three-way

catalyst.

• Do not use E-15 or E-85 fuel in your vehicle. Your vehicle is not designed to run on E-15 or E-85 fuel. Using E-15 or E-85 fuel in a vehicle not specifically designed for E-15 or E-85 fuel can adversely

affect the emission control devices and systems of the vehicle. Damage caused by such fuel is not

covered by the NISSAN new vehicle limited warranty.

• Do not use fuel that contains the octane boo ster methylcyclopentadienyl manganese tricarbonyl

(MMT). Using fuel containing MM T may adversely affect vehicle pe rformance and vehicle emissions.

Not all fuel dispensers are labeled to indicate MMT content, so you may have to consult your gaso-

line retailer for more details. Note that Federal and California laws prohibit the use of MMT in refor-

mulated gasoline.

JPAIA0335ZZ

SGI234

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1974 of 3641

![NISSAN NOTE 2016 Service Repair Manual HAC-6

< PRECAUTION >[MANUAL AIR CONDITIONING]

PRECAUTIONS

• The fluorescent leak detection dye is not a replacem

ent for an electronic leak detector. The fluores-

cent leak detection dye should be u NISSAN NOTE 2016 Service Repair Manual HAC-6

< PRECAUTION >[MANUAL AIR CONDITIONING]

PRECAUTIONS

• The fluorescent leak detection dye is not a replacem

ent for an electronic leak detector. The fluores-

cent leak detection dye should be u](/img/5/57363/w960_57363-1973.png)

HAC-6

< PRECAUTION >[MANUAL AIR CONDITIONING]

PRECAUTIONS

• The fluorescent leak detection dye is not a replacem

ent for an electronic leak detector. The fluores-

cent leak detection dye should be u sed in conjunction with an electronic leak detector to pin-point

refrigerant leaks.

• Read and follow all manufacture’s operating inst ructions and precautions prior to performing the

work for the purpose of safet y and customer’s satisfaction.

• A compressor shaft seal should not necessarily be repaired becau se of dye seepage. The compres-

sor shaft seal should only be repaired after conf irming the leak with an electronic leak detector.

• Always remove any remaining dye from the leak area after repairs are completed to avoid a misdiag-

nosis during a future service.

• Do not allow dye to come into contact with painted body panels or interior components. Clean imme- diately with the approved dye cl eaner if dye is spilled. Fluorescent dye left on a surface for an

extended period of time cannot be removed.

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bottle [1/4 ounce (7.4 cc)] per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R-12) A/C systems are different. Do not use

HFC-134a (R-134a) leak detection dye in CFC-12 (R-12) A/C system, or CFC-12 (R-12) leak detection

dye in HFC-134a (R-134a) A/C system, or A/C system damage may result.

• The fluorescent properties of the dye remains fo r three or more years unless a compressor malfunc-

tion occurs.

NOTE: Identification

• Vehicles with factory installed fluorescent dye have a green label.

• Vehicles without factory installed fluorescent dye have a blue label.

Service EquipmentINFOID:0000000012430713

RECOVERY/RECYCLING RECHARGING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Do not

introduce any refrigerant other than that specified into the machine.

ELECTRICAL LEAK DETECTOR

Be certain to follow the manufacturer’s instruct ions for tester operation and tester maintenance.

VACUUM PUMP

The oil contained inside the vacuum pump is not compatible with the

specified oil for HFC-134a (R-134a) A/C systems. The vent side of

the vacuum pump is exposed to atmospheric pressure. Vacuum

pump oil may migrate out of the pump into the service hose. This is

possible when the pump is switc hed OFF after evacuation (vacuum-

ing) and hose is connected to it.

To prevent this migration, use a manual valve placed near the hose-

to-pump connection, as per the following.

• Vacuum pumps usually have a manual isolator valve as part of the pump. Close this valve to isolat e the service hose from the pump.

• Use a hose equipped with a manual shut-off valve near the pump

end for pumps without an isolator. Close the valve to isolate the

hose from the pump.

• Disconnect the hose from the pump if the hose has an automatic

shut-off valve. As long as the hose is connected, the valve is open

and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under no vacuum condition. Such valves may restrict the pump’s

ability to pull a deep vacuum and are not recommended.

MANIFOLD GAUGE SET

RHA270DA

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2031 of 3641

HA-6

< PRECAUTION >

PRECAUTIONS

• The air conditioner warranty is void if the vehicle is within the warranty period. Please contact Nissan Cus-tomer Affairs for further assistance.

COMPRESSOR

CAUTION:

• Cap or plug all openings to prevent moisture and fo reign matter from entering.

• Store it in the same way as it is when moun ted on the car when the compressor is removed.

• Follow “Maintenance of Oil Level” exactly when replacing or repairing compressor. Refer to HA-22,

"Description".

• Keep friction surfaces between clut ch and pulley clean. Wipe it off by using a clean waste cloth

moistened with thinner if the su rface is contaminated with oil.

• Turn the compressor shaft by hand more than five turns in both directions after compressor service

operation. This distributes oil e qually inside the compressor. Let the engine idle and operate the

compressor for one hour after the compressor is installed.

• Apply voltage to the new one and check for norma l operation after replacing the compressor magnet

clutch.

LEAK DETECTION DYE

CAUTION:

• The A/C system contains a fluorescent leak detect ion dye used for locating refrigerant leaks. An

ultraviolet (UV) lamp is required to il luminate the dye when inspecting for leaks.

• Always wear fluorescence enhancing UV safety goggles to protect eyes and enhance the visibility of the fluorescent dye.

• The fluorescent dye leak detector is not a replacement for an electrical l eak detector (SST: J-41995).

The fluorescent dye leak detector sh ould be used in conjunction with an electrical leak detector

(SST: J-41995) to pin-point refrigerant leaks.

• Read and follow all manufacture’s operating inst ructions and precautions prior to performing the

work for the purpose of safet y and customer’s satisfaction.

• A compressor shaft seal should not necessarily be repaired becau se of dye seepage. The compres-

sor shaft seal should only be repaired after confi rming the leak with an electrical leak detector (SST:

J-41995).

• Always remove any remaining dye from the leak area after repairs are completed to avoid a misdiag-

nosis during a future service.

• Do not allow dye to come into contact with painted body panels or interior components. Clean imme- diately with the approved dye cl eaner if dye is spilled. Fluorescent dye left on a surface for an

extended period of time cannot be removed.

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bottle [1/4 ounce (7.4 cc)] per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R-12) A/C systems are different. Do not use

HFC-134a (R-134a) leak detection dye in CFC-12 (R- 12) A/C system or CFC-12 (R-12) leak detection

dye in HFC-134a (R-134a) A/C system or A/C system damage may result.

• The fluorescent properties of the dye remains fo r three or more years unless a compressor malfunc-

tion occurs.

NOTE: Identification

• Vehicles with factory installed fluorescent dye have a green label.

• Vehicles without factory installed fluorescent dye have a blue label.

Service EquipmentINFOID:0000000012431988

RECOVERY/RECYCLING RECHARGING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Do not

introduce any refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Be certain to follow the manufacturer’s instruct ions for tester operation and tester maintenance.

VACUUM PUMP

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2316 of 3641

MA-1

MAINTENANCE

C

DE

F

G H

I

J

K L

M B

MA

SECTION MA

N

O A

CONTENTS

MAINTENANCE

PRECAUTION .......

........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

PERIODIC MAINTENANCE ..........................5

GENERAL MAINTE NANCE ........................... .....5

Explanation of General Maintenance .................. ......5

PERIODIC MAINTENANCE ................................7

Introduction of Periodic Maintenance .................. ......7

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

11

Fluids and Lubricants .......................................... ....11

Engine Oil Recommendation ..................................12

Anti-Freeze Coolant Mixture Ratio ..........................12

ENGINE MAINTENANCE ...................................13

DRIVE BELT .......................................................... ....13

DRIVE BELT : Exploded View ................................13

DRIVE BELT : Removal and Installation .................13

DRIVE BELT : Inspection .................................... ....14

DRIVE BELT : Adjustment ......................................14

ENGINE COOLANT ............................................... ....15

ENGINE COOLANT : Inspection .............................15

ENGINE COOLANT : Draining Engine Coolant ......16

ENGINE COOLANT : Refilling ................................16

ENGINE COOLANT : Flushing Cooling System .....18

FUEL LINES .......................................................... ....18

FUEL LINES : Inspection ........................................18

AIR CLEANER FILTER ......................................... ....18

AIR CLEANER FILTER : Exploded View ................19

AIR CLEANER FILTER : Removal and Installation

....

19

ENGINE OIL ........................................................... ....20

ENGINE OIL : Inspection .........................................20

ENGINE OIL : Draining ............................................21

ENGINE OIL : Refilling ............................................21

OIL FILTER ............................................................ ....22

OIL FILTER : Removal and Installation ...................22

SPARK PLUG ........................................................ ....22

SPARK PLUG : Exploded View ...............................23

SPARK PLUG : Removal and Installation ...............23

EVAP VAPOR LINES ............................................ ....25

EVAP VAPOR LINES : Inspection ...........................25

CHASSIS AND BODY MAINTENANCE ...........26

EXHAUST SYSTEM . ..................................................26

EXHAUST SYSTEM : Inspec tion ............................26

CVT FLUID ............................................................. ....26

CVT FLUID : Inspection ...........................................26

CVT FLUID : Replacement ......................................26

CVT FLUID : Adjustment .........................................28

CLUTCH FLUID ..................................................... ....29

CLUTCH FLUID : Inspection ...................................29

CLUTCH FLUID : Draining ......................................29

CLUTCH FLUID : Refilling .......................................30

GEAR OIL .............................................................. ....31

GEAR OIL : Inspection ............................................31

GEAR OIL : Draining ...............................................31

GEAR OIL : Refilling ................................................32

WHEELS ................................................................ ....32

WHEELS : Inspection ..............................................32

WHEELS : Adjustment ............................................32

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2321 of 3641

MA-6

< PERIODIC MAINTENANCE >

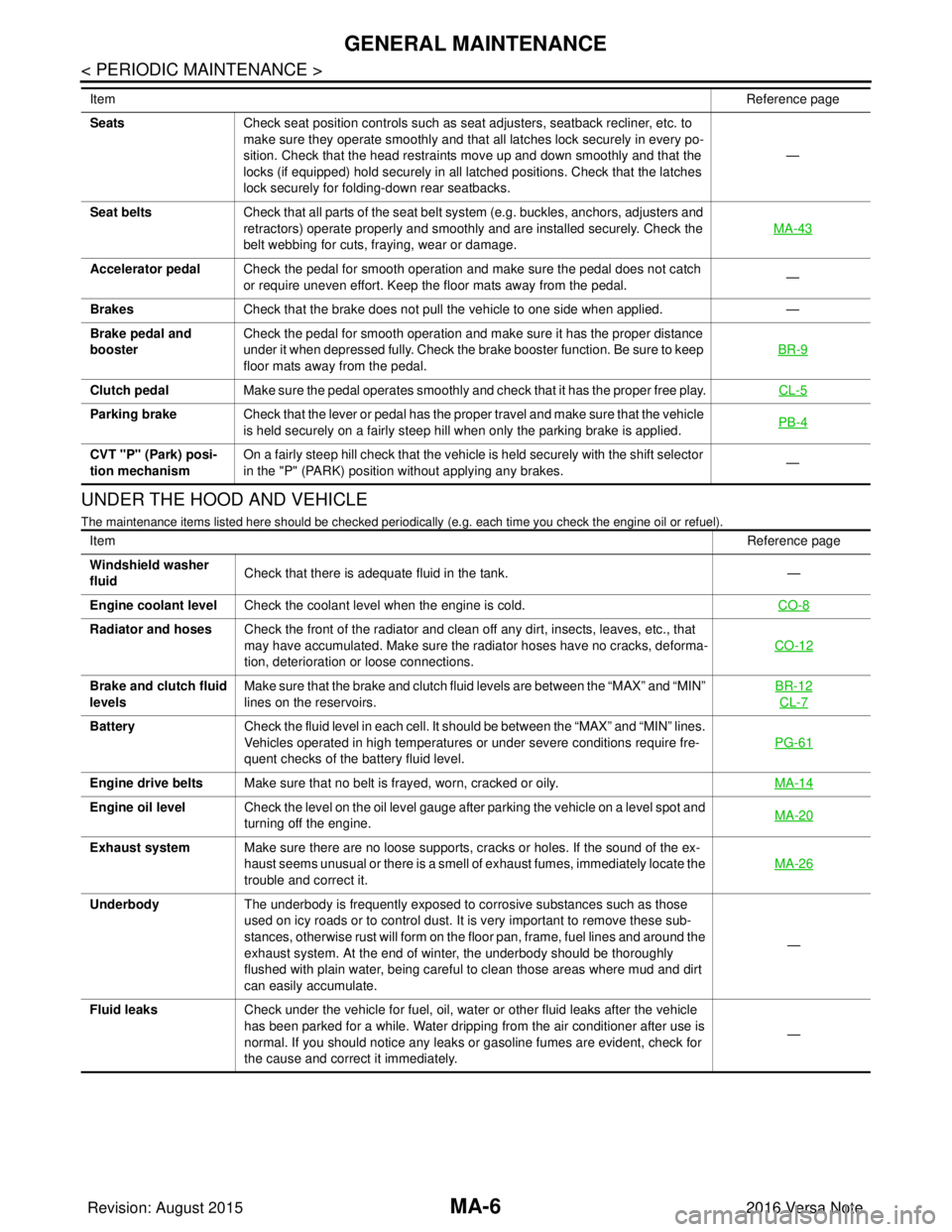

GENERAL MAINTENANCE

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

SeatsCheck seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restraints move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seatbacks. —

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage. MA-43

Accelerator pedal

Check the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. —

Brakes Check that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to keep

floor mats away from the pedal. BR-9

Clutch pedal

Make sure the pedal operates smoothly and check that it has the proper free play. CL-5

Parking brakeCheck that the lever or pedal has the proper travel and make sure that the vehicle

is held securely on a fairly steep hill when only the parking brake is applied. PB-4

CVT "P" (Park) posi-

tion mechanismOn a fairly steep hill check that the vehicle is held securely with the shift selector

in the "P" (PARK) position without applying any brakes.

—

Item

Reference page

Item Reference page

Windshield washer

fluid Check that there is adequate fluid in the tank.

—

Engine coolant level Check the coolant level when the engine is cold. CO-8

Radiator and hosesCheck the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the radiator hoses have no cracks, deforma-

tion, deterioration or loose connections. CO-12

Brake and clutch fluid

levelsMake sure that the brake and clutch fluid levels are between the “MAX” and “MIN”

lines on the reservoirs. BR-12

CL-7

Battery

Check the fluid level in each cell. It should be between the “MAX” and “MIN” lines.

Vehicles operated in high temperatures or under severe conditions require fre-

quent checks of the battery fluid level. PG-61

Engine drive belts

Make sure that no belt is frayed, worn, cracked or oily. MA-14

Engine oil levelCheck the level on the oil level gauge after parking the vehicle on a level spot and

turning off the engine. MA-20

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate the

trouble and correct it. MA-26

Underbody

The underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these sub-

stances, otherwise rust will form on the floor pan, frame, fuel lines and around the

exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately. —

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2322 of 3641

PERIODIC MAINTENANCEMA-7

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

PERIODIC MAINTENANCE

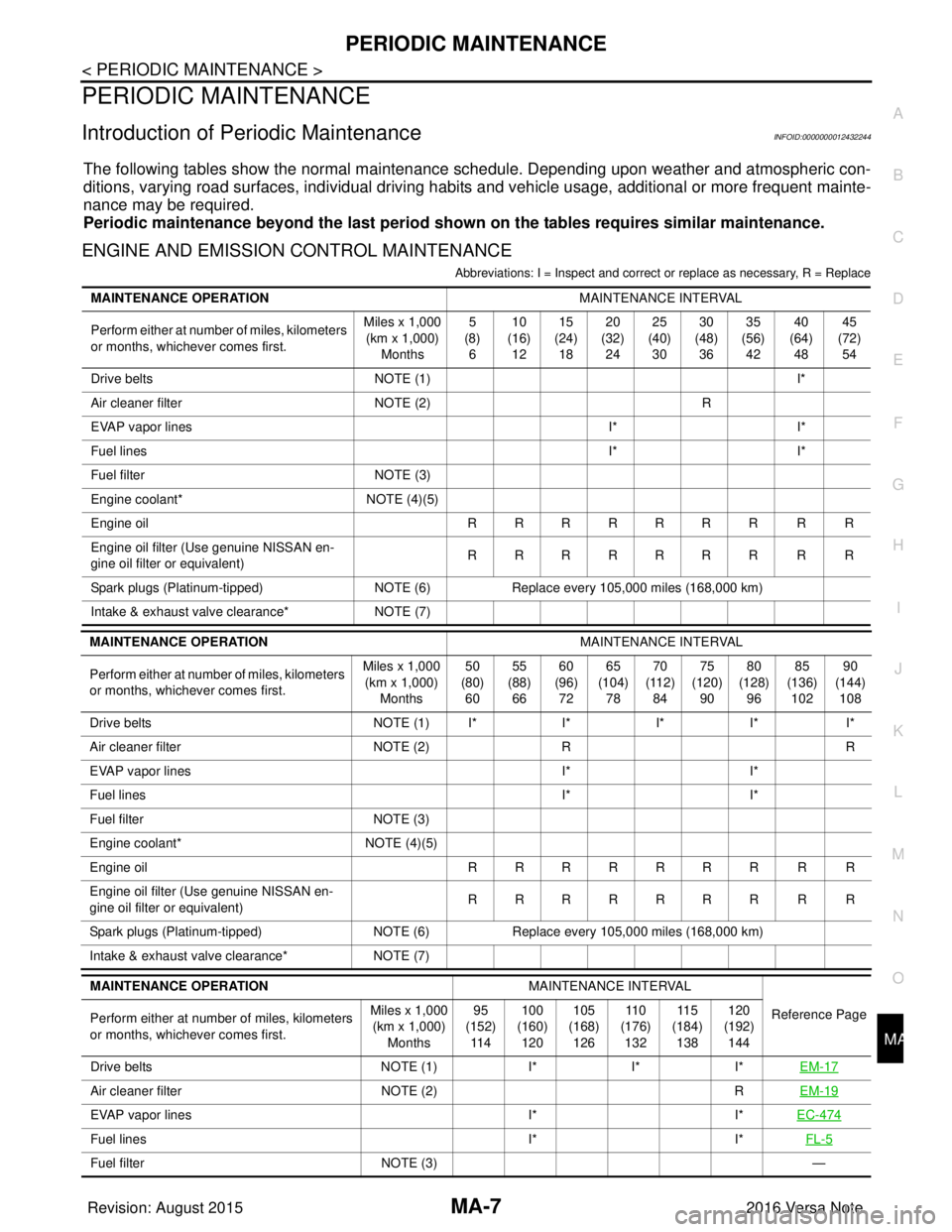

Introduction of Periodic MaintenanceINFOID:0000000012432244

The following tables show the normal maintenanc

e schedule. Depending upon weather and atmospheric con-

ditions, varying road surfaces, indi vidual driving habits and vehicle usage, additional or more frequent mainte-

nance may be required.

Periodic maintenance beyond th e last period shown on the tables requires similar maintenance.

ENGINE AND EMISSION CONTROL MAINTENANCE

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000) Months 5

(8) 6 10

(16) 12 15

(24) 18 20

(32) 24 25

(40) 30 30

(48) 36 35

(56) 42 40

(64) 48 45

(72) 54

Drive belts NOTE (1) I*

Air cleaner filter NOTE (2) R

EVAP vapor lines I*I*

Fuel lines I*I*

Fuel filter NOTE (3)

Engine coolant* NOTE (4)(5)

Engine oil RRRRRRR R R

Engine oil filter (Use genuine NISSAN en-

gine oil filter or equivalent) RRRRRRR R R

Spark plugs (Platinum-tipped) NOTE (6)Replace every 105,000 miles (168,000 km)

Intake & exhaust valve clearance* NOTE (7)

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000) Months 50

(80) 60 55

(88) 66 60

(96) 72 65

(104) 78 70

(112) 84 75

(120) 90 80

(128) 96 85

(136) 102 90

(144) 108

Drive belts NOTE (1) I*I*I* I* I*

Air cleaner filter NOTE (2)R R

EVAP vapor lines I*I*

Fuel lines I*I*

Fuel filter NOTE (3)

Engine coolant* NOTE (4)(5)

Engine oil RRRRRRR R R

Engine oil filter (Use genuine NISSAN en-

gine oil filter or equivalent) RRRRRRR R R

Spark plugs (Platinum-tipped) NOTE (6)Replace every 105,000 miles (168,000 km)

Intake & exhaust valve clearance* NOTE (7)

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Page

Perform either at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 95

(152)

11 4 100

(160)

120 105

(168)

126 11 0

(176)

132 11

5

(184)

138 12

0

(192)

14

4

Drive belts NOTE (1)I*I*I*EM-17

Air cleaner filter NOTE (2) REM-19

EVAP vapor lines I*I*EC-474

Fuel lines I*I*FL-5

Fuel filter NOTE (3) —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2323 of 3641

MA-8

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE

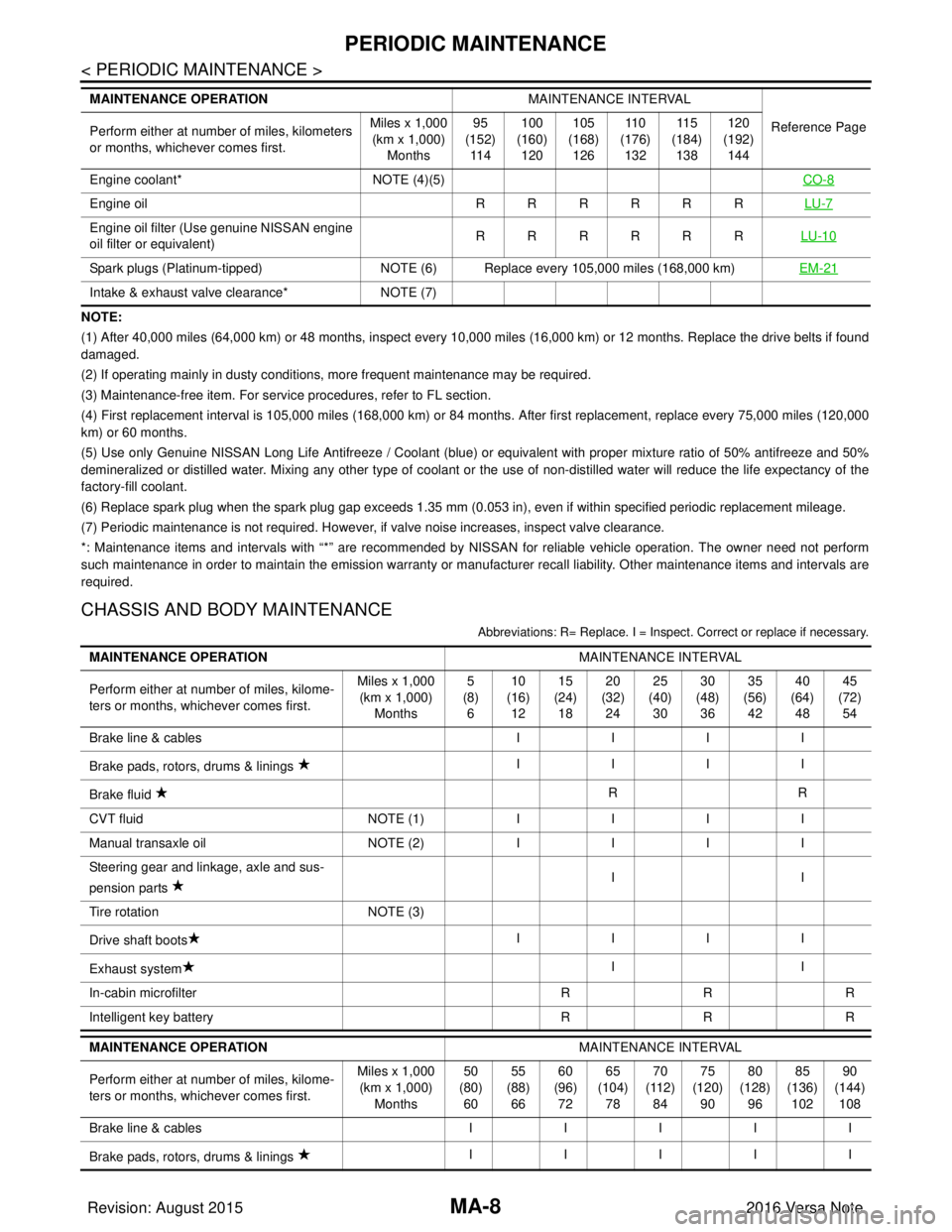

NOTE:

(1) After 40,000 miles (64,000 km) or 48 months, inspect every 10,000 miles (16,000 km) or 12 months. Replace the drive belts if found

damaged.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, refer to FL section.

(4) First replacement interval is 105,000 miles (168,000 km) or 84 months. After first replacement, replace every 75,000 miles (120,000

km) or 60 months.

(5) Use only Genuine NISSAN Long Life Antifreeze / Coolant (blue) or equivalent with proper mixture ratio of 50% antifreeze and 50%

demineralized or distilled water. Mixing any other type of coolant or the use of non-distilled water will reduce the life expec tancy of the

factory-fill coolant.

(6) Replace spark plug when the spark plug gap exceeds 1.35 mm (0.053 in), even if within specified periodic replacement mileag e.

(7) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

*: Maintenance items and intervals with “*” are recommended by NISSAN for reli able vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required.

CHASSIS AND BODY MAINTENANCE

Abbreviations: R= Replace. I = Inspec t. Correct or replace if necessary.

Engine coolant* NOTE (4)(5) CO-8

Engine oil RRRRRRLU-7

Engine oil filter (Use genuine NISSAN engine

oil filter or equivalent) RRRRRR

LU-10

Spark plugs (Platinum-tipped)NOTE (6) Replace every 105,000 miles (168,000 km) EM-21

Intake & exhaust valve clearance*NOTE (7)

MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Reference Page

Perform either at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 95

(152)

11 4 100

(160)

120 105

(168)

126 11 0

(176)

132 11 5

(184)

138 120

(192)

144

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilome-

ters or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 5

(8)

6 10

(16)

12 15

(24)

18 20

(32)

24 25

(40)

30 30

(48)

36 35

(56)

42 40

(64)

48 45

(72)

54

Brake line & cables IIII

Brake pads, rotors, drums & linings IIII

Brake fluid RR

CVT fluid NOTE (1)IIII

Manual transaxle oil NOTE (2)IIII

Steering gear and linkage, axle and sus-

pension parts II

Tire rotation NOTE (3)

Drive shaft boots IIII

Exhaust system II

In-cabin microfilter RRR

Intelligent key battery RRR

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilome-

ters or months, whichever comes first. Miles x 1,000

(km x 1,000) Months 50

(80) 60 55

(88) 66 60

(96) 72 65

(104) 78 70

(112) 84 75

(120) 90 80

(128) 96 85

(136) 102 90

(144) 108

Brake line & cables III II

Brake pads, rotors, drums & linings IIIII

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2324 of 3641

PERIODIC MAINTENANCEMA-9

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

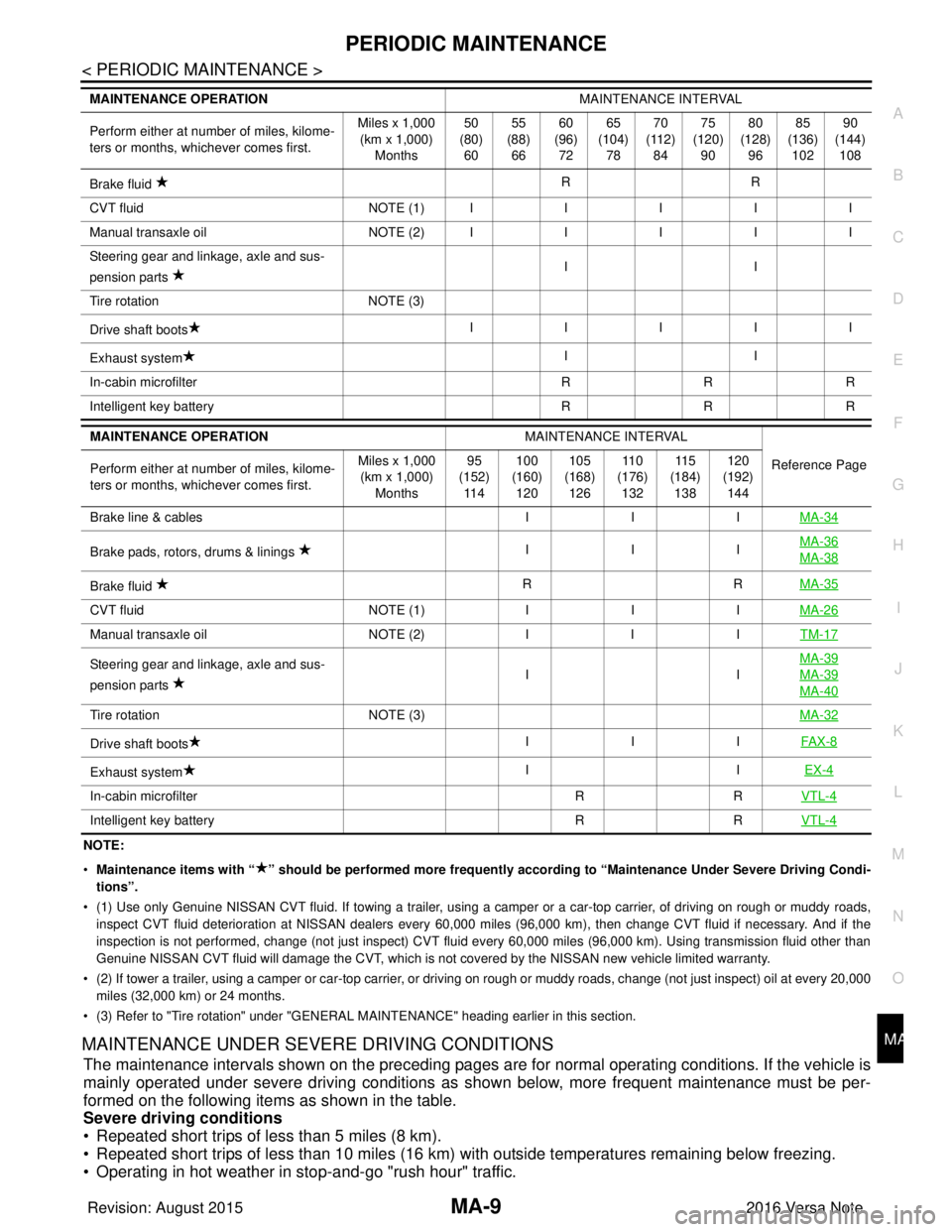

NOTE:

•

Maintenance items with “ ” shoul d be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

• (1) Use only Genuine NISSAN CVT fluid. If towing a trailer, using a camper or a car-top carrier, of driving on rough or muddy roads,

inspect CVT fluid deterioration at NISSAN dealers every 60,000 miles (96,000 km), then change CVT fluid if necessary. And if th e

inspection is not performed, change (not just inspect) CVT fluid every 60,000 miles (96,000 km). Using transmission fluid other than

Genuine NISSAN CVT fluid will damage the CVT, which is not covered by the NISSAN new vehicle limited warranty.

• (2) If tower a trailer, using a camper or car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil a t every 20,000

miles (32,000 km) or 24 months.

• (3) Refer to "Tire rotation" under "GENERAL MAINTENANCE" heading earlier in this section.

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

• Repeated short trips of less than 5 miles (8 km).

• Repeated short trips of less than 10 miles (16 km) wi th outside temperatures remaining below freezing.

• Operating in hot weather in stop-and-go "rush hour" traffic.

Brake fluid RR

C VT flu id NO TE (1)IIIII

M anu al t ra nsa xle o il NO TE (2)IIIII

Steering gear and linkage, axle and sus-

pension parts II

Tire rotation NOTE (3)

Drive shaft boots IIIII

Exhaust system II

In-cabin microfilter RRR

Intelligent key battery RRR

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Page

Perform either at number of miles, kilome-

ters or months, whichever comes first. Miles x 1,000

(km x 1,000) Months 95

(152) 11 4 100

(160) 120 105

(168) 126 11 0

(176) 132 11 5

(184) 138 120

(192) 144

Brake line & cables IIIMA-34

Brake pads, rotors, drums & linings IIIMA-36MA-38

Brake fluid

RR

MA-35

CVT fluid NOTE (1)IIIMA-26

Manual transaxle oil NOTE (2)IIITM-17

Steering gear and linkage, axle and sus-

pension parts IIMA-39MA-39

MA-40

Tire rotation

NOTE (3) MA-32

Drive shaft boots III

FAX-8

Exhaust system II

EX-4

In-cabin microfilter RRVTL-4

Intelligent key battery RRVTL-4

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of miles, kilome-

ters or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 50

(80)

60 55

(88)

66 60

(96)

72 65

(104)

78 70

(112)

84 75

(120)

90 80

(128)

96 85

(136)

102 90

(144)

108

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2325 of 3641

MA-10

< PERIODIC MAINTENANCE >

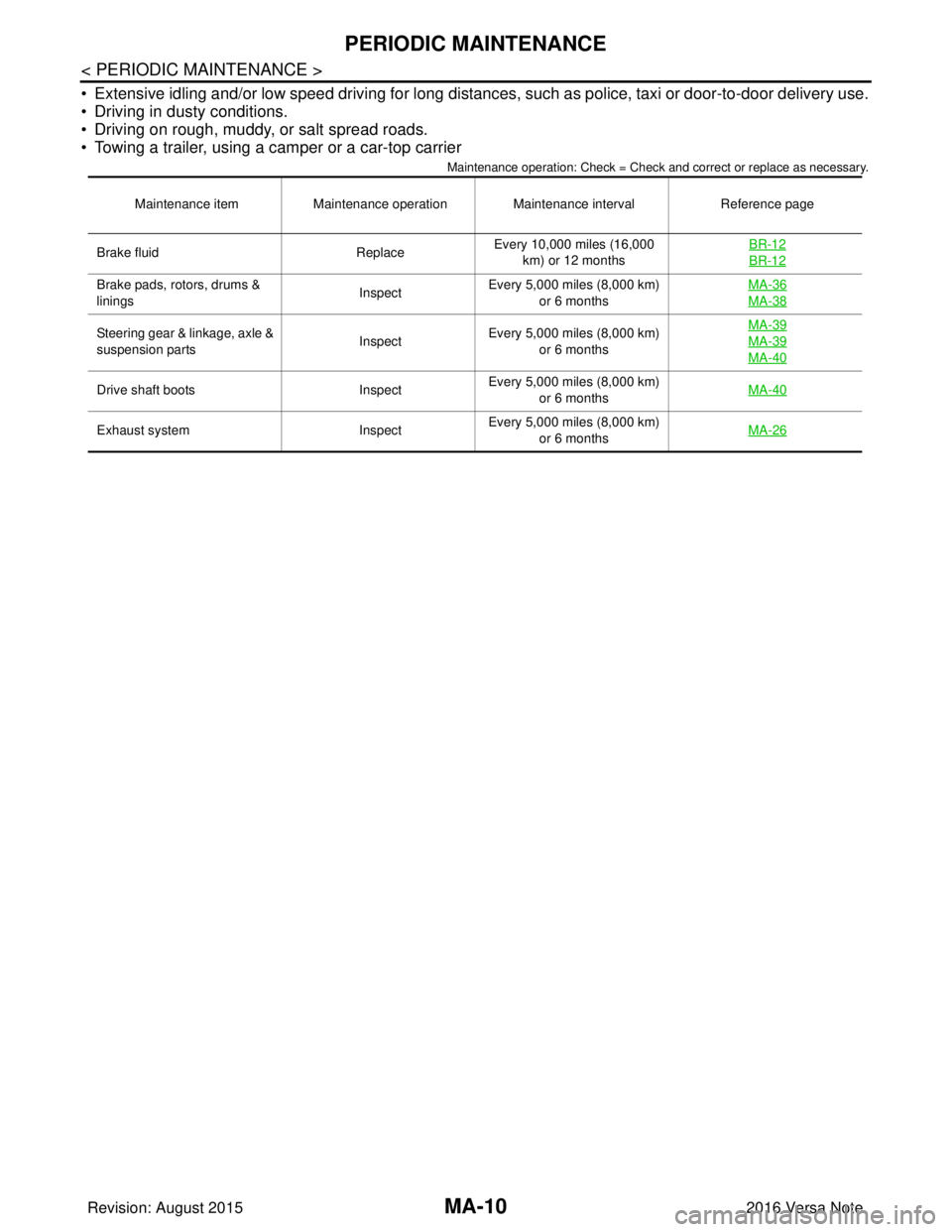

PERIODIC MAINTENANCE

• Extensive idling and/or low speed driving for long distances, such as police, taxi or door-to-door delivery use.

• Driving in dusty conditions.

• Driving on rough, muddy, or salt spread roads.

• Towing a trailer, using a camper or a car-top carrier

Maintenance operation: Check = Check and correct or replace as necessary.

Maintenance itemMaintenance operation Maintenance interval Reference page

Brake fluid ReplaceEvery 10,000 miles (16,000

km) or 12 months BR-12

BR-12

Brake pads, rotors, drums &

linings

InspectEvery 5,000 miles (8,000 km)

or 6 months MA-36

MA-38

Steering gear & linkage, axle &

suspension parts

InspectEvery 5,000 miles (8,000 km)

or 6 months MA-39MA-39

MA-40

Drive shaft boots

InspectEvery 5,000 miles (8,000 km)

or 6 months MA-40

Exhaust system

InspectEvery 5,000 miles (8,000 km)

or 6 months MA-26

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2335 of 3641

MA-20

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

2. Remove the air cleaner filter (1) from the air cleaner body.

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

Check that the air cleaner filter is securely placed in the air cleaner body.

ENGINE OIL

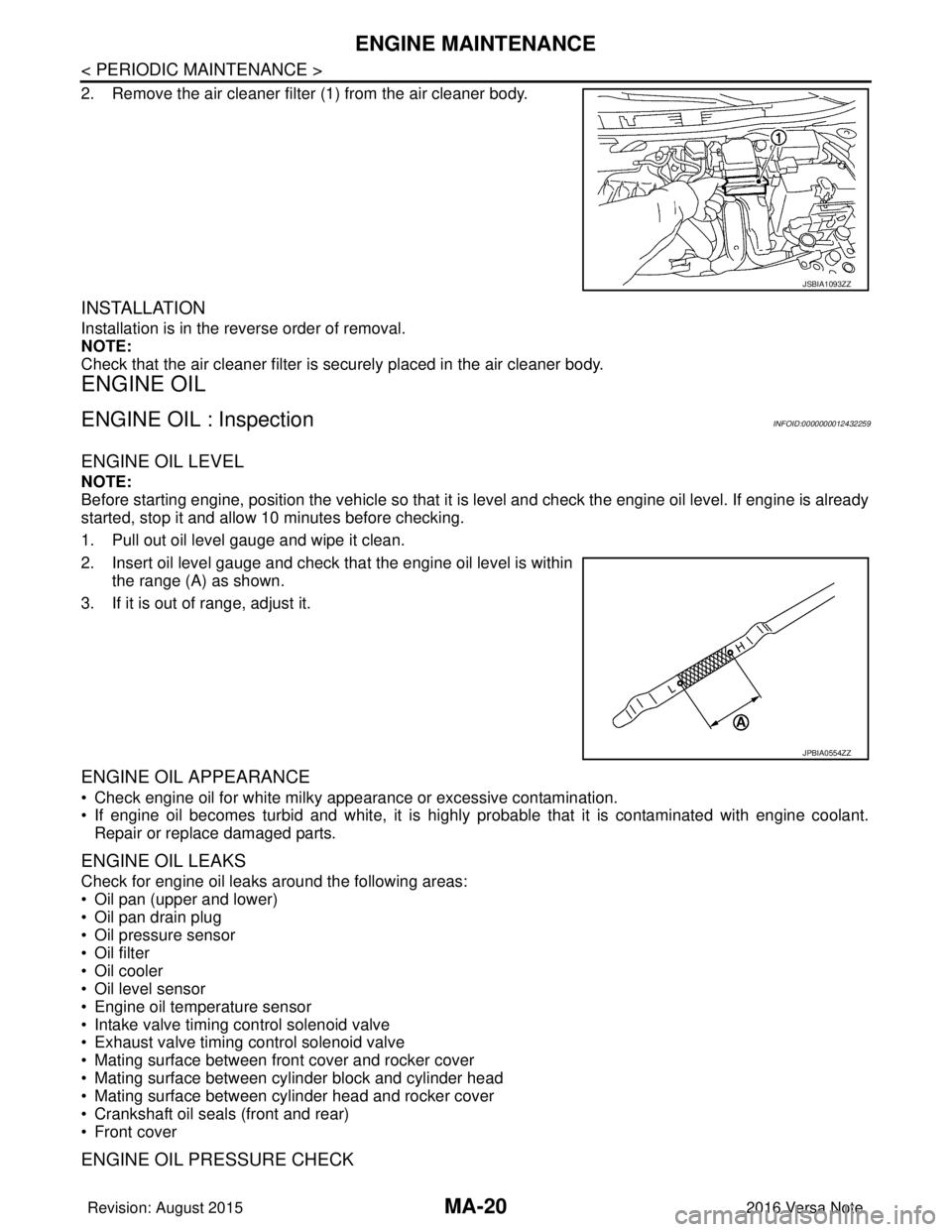

ENGINE OIL : InspectionINFOID:0000000012432259

ENGINE OIL LEVEL

NOTE:

Before starting engine, position the vehicle so that it is level and check the engine oil level. If engine is already

started, stop it and allow 10 minutes before checking.

1. Pull out oil level gauge and wipe it clean.

2. Insert oil level gauge and check that the engine oil level is withinthe range (A) as shown.

3. If it is out of range, adjust it.

ENGINE OIL APPEARANCE

• Check engine oil for white milky appearance or excessive contamination.

• If engine oil becomes turbid and white, it is highl y probable that it is contaminated with engine coolant.

Repair or replace damaged parts.

ENGINE OIL LEAKS

Check for engine oil leaks around the following areas:

• Oil pan (upper and lower)

• Oil pan drain plug

• Oil pressure sensor

• Oil filter

• Oil cooler

• Oil level sensor

• Engine oil temperature sensor

• Intake valve timing control solenoid valve

• Exhaust valve timing control solenoid valve

• Mating surface between front cover and rocker cover

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seals (front and rear)

• Front cover

ENGINE OIL PRESSURE CHECK

JSBIA1093ZZ

JPBIA0554ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com