Heat NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2827 of 3641

SE-14

< WIRING DIAGRAM >

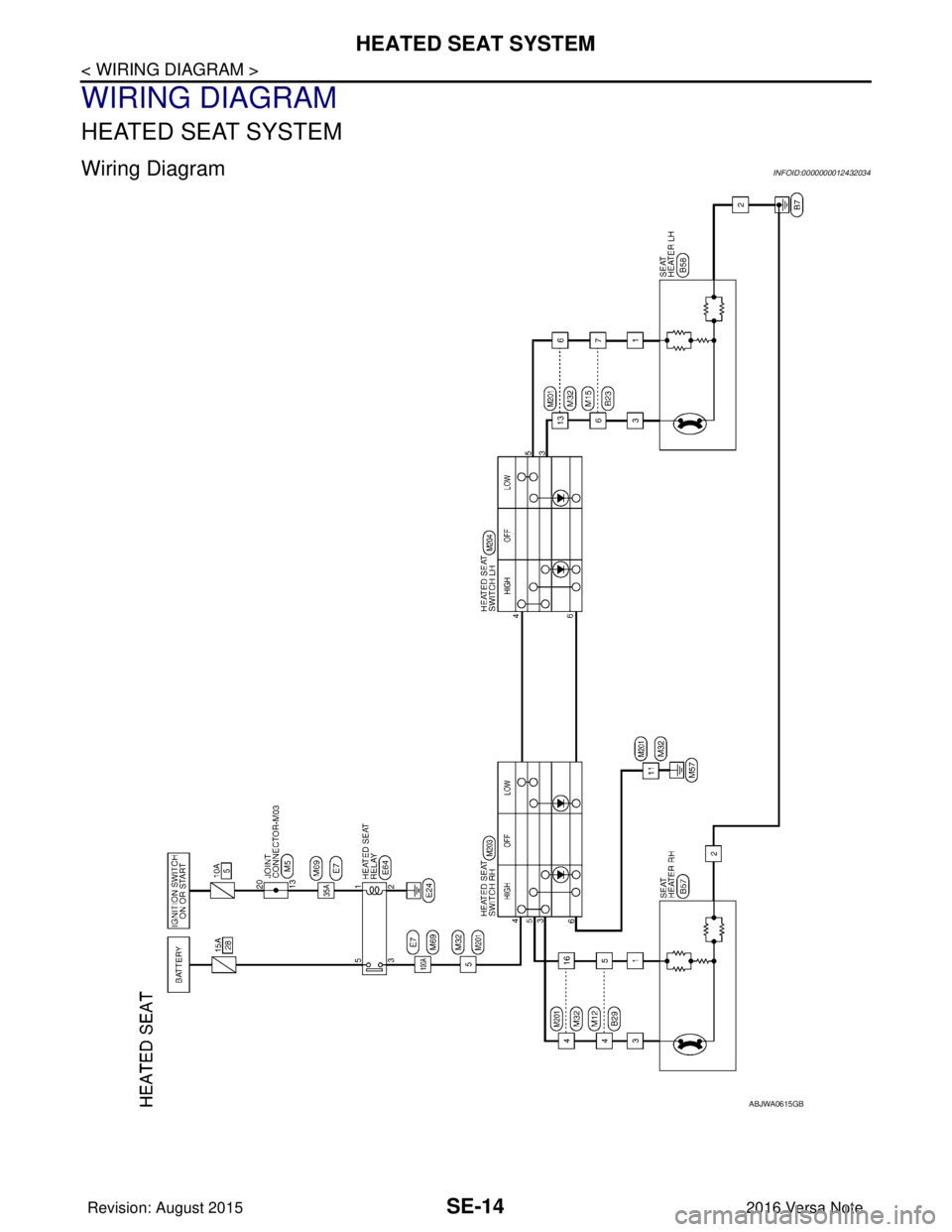

HEATED SEAT SYSTEM

WIRING DIAGRAM

HEATED SEAT SYSTEM

Wiring DiagramINFOID:0000000012432034

ABJWA0615GB

Revision: August 20152016 Versa Note

cardiagn.com

Page 2828 of 3641

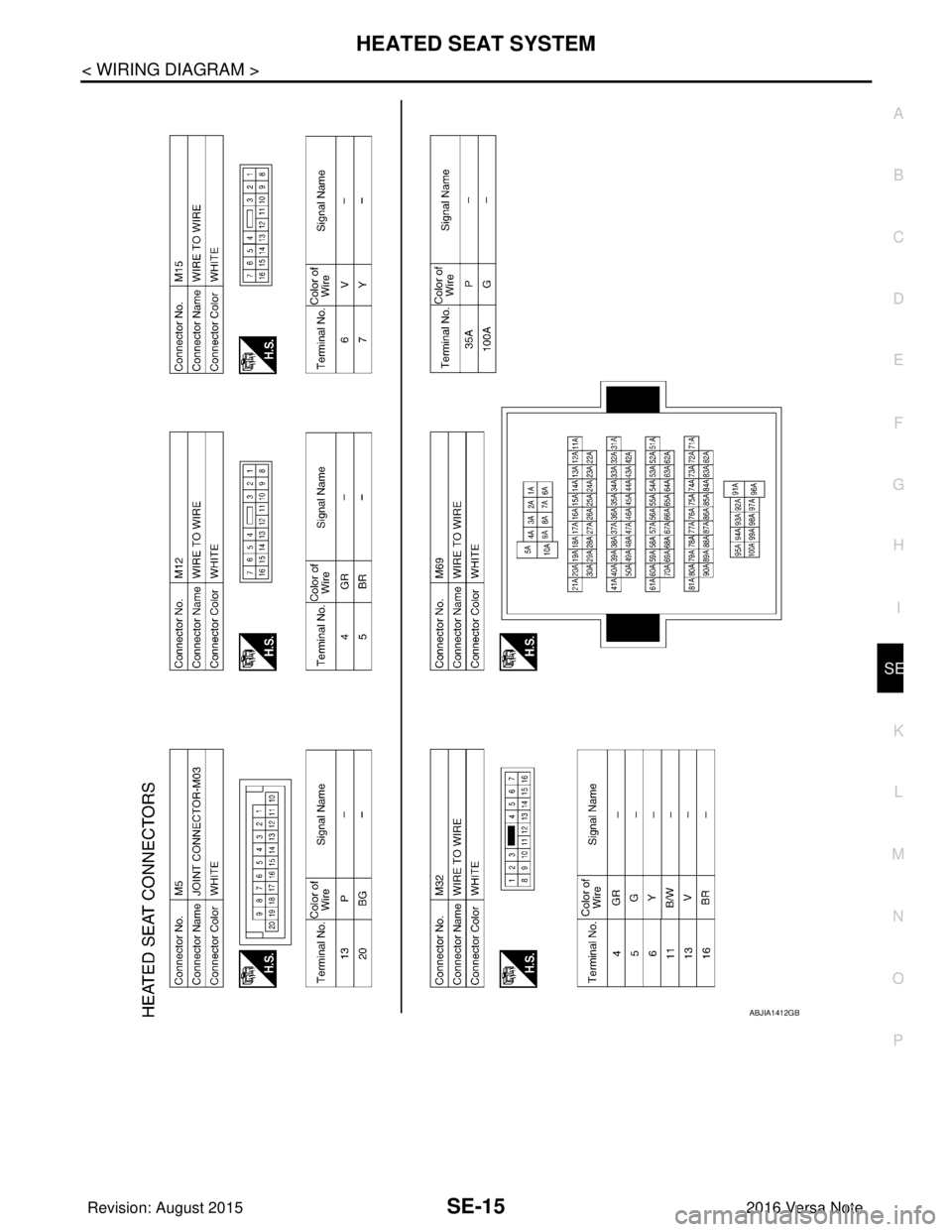

HEATED SEAT SYSTEMSE-15

< WIRING DIAGRAM >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

ABJIA1412GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2829 of 3641

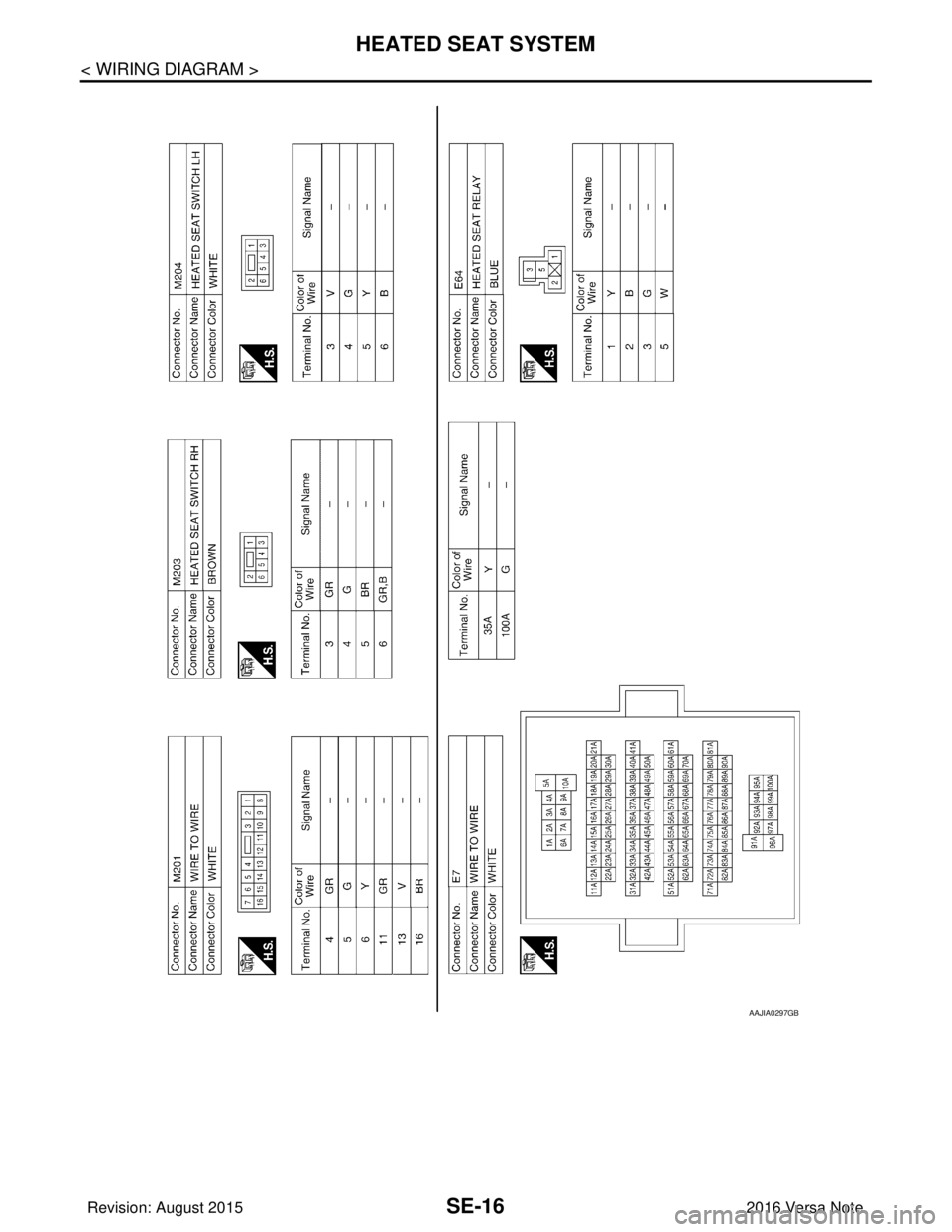

SE-16

< WIRING DIAGRAM >

HEATED SEAT SYSTEM

AAJIA0297GB

Revision: August 20152016 Versa Note

cardiagn.com

Page 2830 of 3641

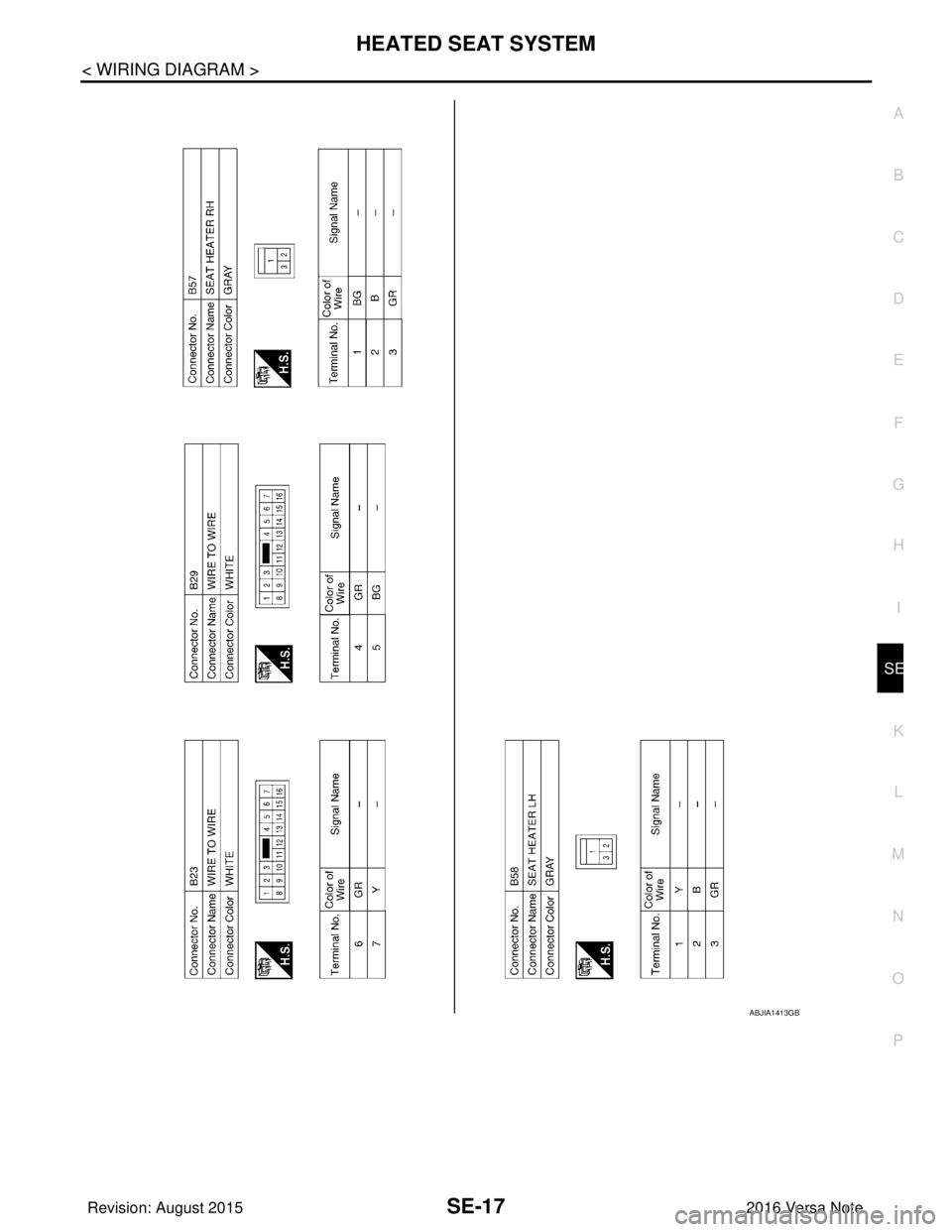

HEATED SEAT SYSTEMSE-17

< WIRING DIAGRAM >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

ABJIA1413GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2842 of 3641

FRONT HEATED SEAT SWITCHSE-29

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

FRONT HEATED SEAT SWITCH

Removal and InstallationINFOID:0000000012432047

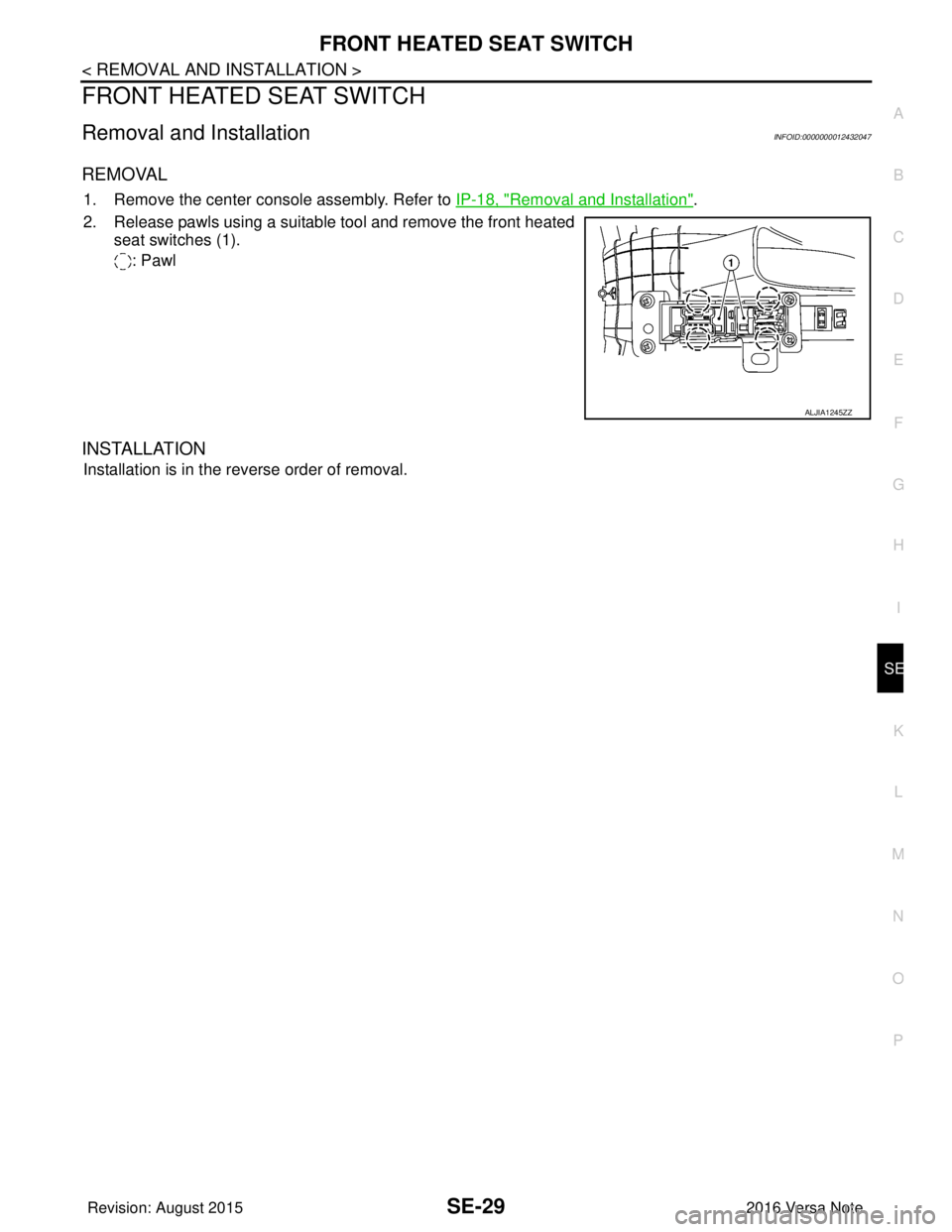

REMOVAL

1. Remove the center console assembly. Refer to IP-18, "Removal and Installation".

2. Release pawls using a suitable tool and remove the front heated seat switches (1).

: Pawl

INSTALLATION

Installation is in the reverse order of removal.

ALJIA1245ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3223 of 3641

ST-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430493

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Service Notice or Precautions for Steering SystemINFOID:0000000012430494

• In case of removing the steering gear, make the final tightening with grounded and unloaded vehicle condi- tion, and then check wheel alignment.

• Observe the following precautions when disassembling.

- Before disassembly, thoroughly clean the outside of the unit.

- Disassembly should be done in a clean work area. It is im portant to prevent the internal parts from becoming

contaminated by dirt or other foreign matter.

- For easier and proper assembly, place disassembled parts in order on a parts rack.

- Use nylon cloth or paper towels to clean the parts; co mmon shop rags can leave lint that might interfere with

their operation.

- Do not reuse non-reusable parts.

- Before assembling, apply the specified grease to the directed parts.

FOR ELECTRIC POWER STEERING (EPS)

• During quick steering, rasping noise may be heard from around the steering wheel. This is not a malfunction.

The noise is an operating noise of the EPS system under normal conditions. If the rasping noise occurs dur-

ing slow steering, this may not be an operating noise of the system. In this case, it is necessary to find out

the location of the noise and repair, if necessary.

• Do not repeat static steering. (Mot or and EPS control unit could be heated.)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3249 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-8

< PRECAUTION >[5MT: RS5F91R]

PRECAUTIONS

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty

area.

• Then dip a cloth in NISSAN NOTE 2016 Service Repair Manual TM-8

< PRECAUTION >[5MT: RS5F91R]

PRECAUTIONS

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty

area.

• Then dip a cloth in](/img/5/57363/w960_57363-3248.png)

TM-8

< PRECAUTION >[5MT: RS5F91R]

PRECAUTIONS

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty

area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Liquid GasketINFOID:0000000012430939

REMOVAL OF LIQUID GASKET SEALING

• After removing the bolts and nuts, separate the mating surface and remove the liquid gasket using Tool (A).

CAUTION:

Be careful not to damage the mating surfaces.

• In areas where the cutter is difficult to use, use a plastic hammer to lightly tap (1) the cutter where the liquid gasket is applied. Use a

plastic hammer to slide (2) the cutter by tapping on the side.

CAUTION:

Do not damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using suitable tool (A), remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

• Remove liquid gasket completely from the groove of the liquidgasket application surface, mounting bolts, and bolt holes.

2. Wipe the liquid gasket application surface and the mating sur- face with white gasoline (lighting and heating use) to remove

adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to the suitable tool. Use Genuine Silicone RTV Seal ant, or equivalent. Refer to

GI-22, "

Recommended Chemical Products and Sealants".

4. Apply liquid gasket without gaps to the specified location accord- ing to the specified dimensions.

• If there is a groove for liquid gasket application, apply liquid

gasket to the groove.

• As for bolt holes (B), normally apply liquid gasket inside the holes. Occasionally, it should be applied outside the holes.

Check to read the text of this manual.

• Within five minutes of liquid gasket application, install the mat- ing component.

• If liquid gasket protrudes, wipe it off immediately.

• Do not retighten mounting bolts or nuts after the installation. Tool Number : KV10111100 (J-37228)

AWBIA1249GB

JPBIA0053ZZ

EMA0622D

(A) : Groove

: Inside

JPBIA0010ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3262 of 3641

![NISSAN NOTE 2016 Service Repair Manual CONTROL LINKAGETM-21

< REMOVAL AND INSTALLATION > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

a. While pressing the lock of the selector cable in the direction of the arrows shown, remove the selec NISSAN NOTE 2016 Service Repair Manual CONTROL LINKAGETM-21

< REMOVAL AND INSTALLATION > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

a. While pressing the lock of the selector cable in the direction of the arrows shown, remove the selec](/img/5/57363/w960_57363-3261.png)

CONTROL LINKAGETM-21

< REMOVAL AND INSTALLATION > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

a. While pressing the lock of the selector cable in the direction of the arrows shown, remove the selector cable from the shift

selector assembly.

b. While pressing the lock of the shifter cable in the direction of the arrows shown, remove the shifter cable from the shift selector

assembly.

10. Remove the shift selector assembly.

11. Remove center muffler, exhaust front tube, and heat plate. Refer to EX-5, "

Exploded View".

12. Remove the bracket from the vehicle.

13. Remove the grommet and then remove the shifter cable and selector cable from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Install each cable without causing in terference with other parts. Do not allow cable to bend less than

120 mm (4.72 in), or exceed 180 degree twist.

• Install boot of each cable without causing interference with other parts. Do not exceed 90 degree twist.

• Fit boot to center console assembly an d the groove on shift selector handle.

• To install the shift selector handle, press it onto the shift selector. CAUTION:

• Do not reuse shift selector handle.

• Be careful with orientation of shift selector handle.

• Bolt hole is not threaded on new clutch housing. Self-tapping bolt is used to attach lock plate to clutch hous-

ing.

CAUTION:

Do not reuse self-tapping bolt.

• Insert each cable until it reaches the cable mounting bracket and shift selector assembly.

• Insert each cable until it reaches the shifter lever A and the selector lever.

• Move the shift selector to the neutral position.

InspectionINFOID:0000000012430956

INSPECTION AFTER INSTALLATION

Shift Selector Handle

Check that the shift selector handle is installed in the right position.

Shifter Cable and Selector Cable

• Pull each cable in the removal direction to check that it does not disconnect from the cable mounting

bracket.

• Pull each cable in the removal direction to check that it does not disconnect from the shift selector assembly.

• Pull grommet in the removal direction to che ck that it does not disconnect from the vehicle.

Shift Selector Assembly and Shift Selector

• Check that there is no unusual noise, binding, bending, looseness, and interference when the shift selector

is moved to each position. If there is a malfuncti on, then repair or replace the malfunctioning part.

• Check that the shift selector smoothl y returns to the neutral position after moving the shift selector from 1st

to 2nd gear and releasing it. If there is a malfunction, then repair or replace the malfunctioning part.

• Check that the shift selector smoothly returns to the neutral position after moving the shift selector from 5th to the reverse gear position and releasing it. If there is a malfunction, then repair or replace the malfunction-

ing part.

JPDIC0793ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3476 of 3641

![NISSAN NOTE 2016 Service Repair Manual CONTROL CABLETM-235

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

10. Remove the lock plate (1).

11. Remove the heat plate.

12. Remove the control cable (1) from the brac NISSAN NOTE 2016 Service Repair Manual CONTROL CABLETM-235

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

10. Remove the lock plate (1).

11. Remove the heat plate.

12. Remove the control cable (1) from the brac](/img/5/57363/w960_57363-3475.png)

CONTROL CABLETM-235

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

10. Remove the lock plate (1).

11. Remove the heat plate.

12. Remove the control cable (1) from the bracket (2).

13. Remove the control cable from the vehicle.

14. Remove bracket.

INSTALLATION

Installation is in the reverse order of removal.

• From below the vehicle, press the grommet (A) into place until the pawls (B) make a click sound.

CAUTION:

Check that pulling down on the grommet does not disconnect

it.

• Pay attention to the following when connecting the control cable to the shift selector.

1. When connecting the control cable (1) to the shift selector assembly (2), face the grooved surface of the rib (A) up and

insert the control cable until it stops.

JSDIA1812ZZ

: Front

JPDIA0107ZZ

JSDIA1809ZZ

JSDIA1624ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3492 of 3641

![NISSAN NOTE 2016 Service Repair Manual WATER HOSETM-251

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

WATER HOSE

Exploded ViewINFOID:0000000012431207

Removal and InstallationINFOID:0000000012431208

REMOVAL

WAR NISSAN NOTE 2016 Service Repair Manual WATER HOSETM-251

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

WATER HOSE

Exploded ViewINFOID:0000000012431207

Removal and InstallationINFOID:0000000012431208

REMOVAL

WAR](/img/5/57363/w960_57363-3491.png)

WATER HOSETM-251

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

WATER HOSE

Exploded ViewINFOID:0000000012431207

Removal and InstallationINFOID:0000000012431208

REMOVAL

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

CAUTION:

Perform these steps after the engine cool ant temperature has cooled sufficiently.

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

1. Remove the hose clamp and pull out the water hose A.

2. Remove the hose clamp and pull out the water hose B.

3. Remove the hose clamp and pull out the water hose C.

4. Pull out the heater hose and remove the water bypass pipe.

5. Remove the heater thermostat assembly.

1. Hose clamp 2. Water hose A3. Clip

4. Bracket A 5. Bracket B6. CVT oil warner

7. Water hose B 8. Water bypass pipe9. Hose clamp

10. Water hose C 11. Water outlet

A. To heater core : Always replace after every disassembly.

: N·m (kg-m, in-lb)

JSDIA4111GB

Revision: August 2015 2016 Versa Note

cardiagn.com