Heat NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1877 of 3641

FUEL TANKFL-11

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

3. Open fuel filler lid.

4. Open fuel filler cap and release

the pressure inside fuel tank.

5. Remove the rear seat cushion. Refer to SE-26, "

SEAT CUSHION : Removal and Installation".

6. Remove the inspection hole cover. NOTE:

Inspection hole cover is held by an adhesive.

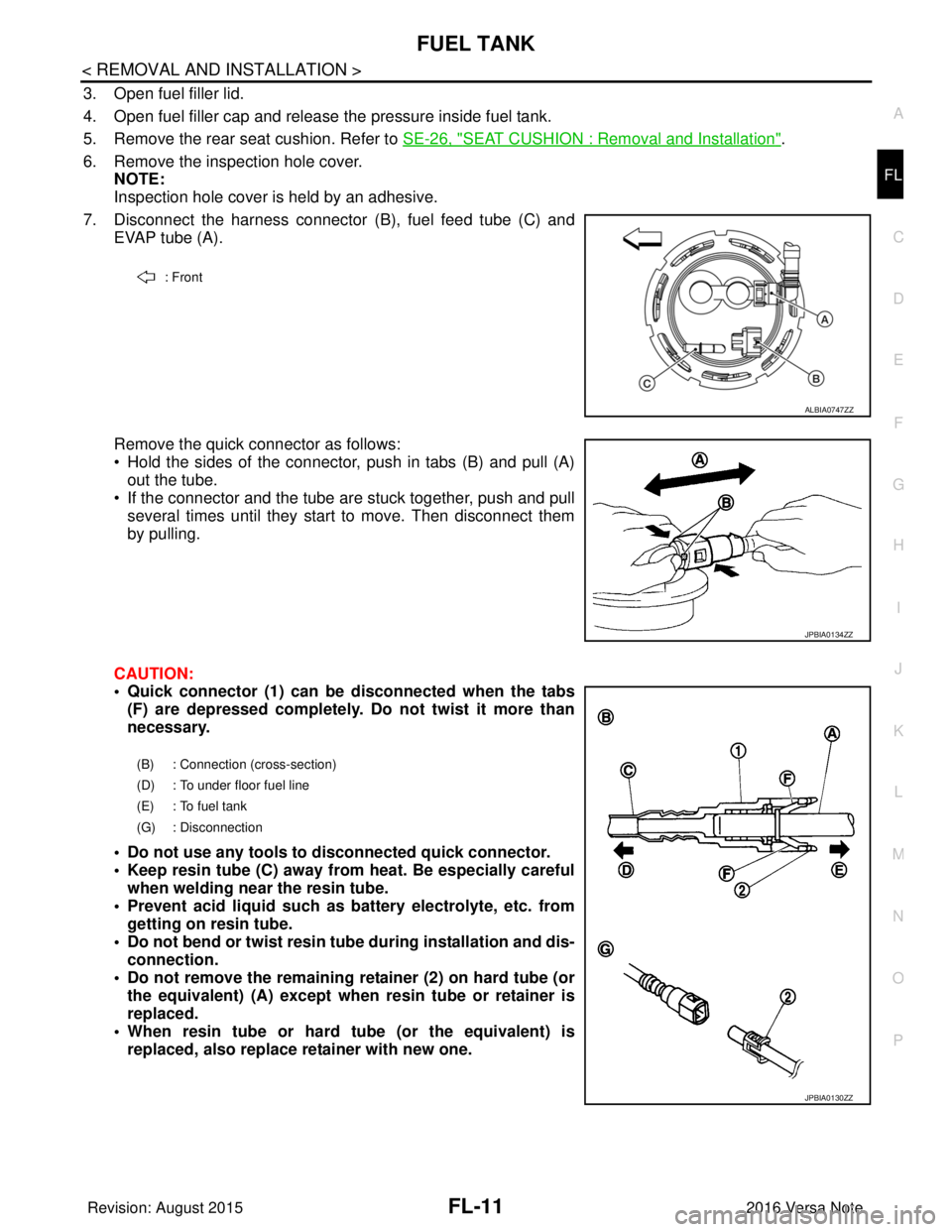

7. Disconnect the harness connector (B), fuel feed tube (C) and

EVAP tube (A).

Remove the quick connector as follows:

• Hold the sides of the connector, push in tabs (B) and pull (A) out the tube.

• If the connector and the tube are stuck together, push and pull several times until they start to move. Then disconnect them

by pulling.

CAUTION:

• Quick connector (1) can be disconnected when the tabs (F) are depressed completely. Do not twist it more than

necessary.

• Do not use any tools to disconnected quick connector.

• Keep resin tube (C) away from heat. Be especially careful when welding near the resin tube.

• Prevent acid liquid such as battery electrolyte, etc. from getting on resin tube.

• Do not bend or twist resin tube during installation and dis- connection.

• Do not remove the remaining retainer (2) on hard tube (or the equivalent) (A) except when resin tube or retainer is

replaced.

• When resin tube or hard tube (or the equivalent) is replaced, also replace retainer with new one.

: Front

ALBIA0747ZZ

JPBIA0134ZZ

(B) : Connection (cross-section)

(D) : To under floor fuel line

(E) : To fuel tank

(G) : Disconnection

JPBIA0130ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1903 of 3641

ABBREVIATIONSGI-15

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

E

F

G

H

DLC Data link connector

DTC Diagnostic trouble code

ABBREVIATION DESCRIPTION

E/T Exhaust temperature

EBD Electric brake force distribution

EC Engine control

ECL Engine coolant level

ECM Engine control module

ECT Engine coolant temperature

ECV Electrical control valve

EEPROM Electrically erasable programmable read only memory EFT Engine fuel temperature

EGR Exhaust gas recirculation

EGRT Exhaust gas recirculation temperature EGT Exhaust gas temperature

EOP Engine oil pressure

EP Exhaust pressure

EPR Exhaust pressure regulator

EPS Electronically controlled power steering

ESP Electronic stability program system

EVAP canister Evaporative emission canister EVSE Electric vehicle supply equipment

EXC Exhaust control

ABBREVIATION DESCRIPTION

FC Fan control

FCW Forward collision warning

FIC Fuel injector control

FP Fuel pump

FR Front

FRP Fuel rail pressure

FRT Fuel rail temperature

FTP Fuel tank pressure

FTT Fuel tank temperature

ABBREVIATION DESCRIPTION

GND Ground

GPS Global positioning system

GST Generic scan tool

ABBREVIATION DESCRIPTION

HBMC Hydraulic body-motion control system HDD Hard disk drive

HO2S Heated oxygen sensor

ABBREVIATION

DESCRIPTION

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1904 of 3641

GI-16

< HOW TO USE THIS MANUAL >

ABBREVIATIONS

I

K

L

M

N

HOCHeated oxidation catalyst

HPCM Hybrid power train control module

ABBREVIATION DESCRIPTION

I/M Inspection and maintenance

IA Intake air

IAC Idle air control

IAT Intake air temperature

IBA Intelligent brake assist

IC Ignition control

ICC Intelligent cruise control

ICM Ignition control module

IPDM E/R Intelligent power distribution module engine room ISC Idle speed control

ISS Input shaft speed

ITS Information technology suite

ABBREVIATION DESCRIPTION

KS Knock sensor

ABBREVIATION DESCRIPTION

LBC Li-ion battery controller

LCD Liquid crystal display

LCU Local control unit

LDP Lane departure prevention

LDW Lane departure warning

LED Light emitting diode

LH Left-hand

LHD Left-hand drive

LIN Local interconnect network

ABBREVIATION DESCRIPTION

M/T Manual transaxle/transmission

MAF Mass airflow

MAP Manifold absolute pressure

MDU Multi display unit

MI Malfunction indicator

MIL Malfunction indicator lamp

MOD Moving object detection

ABBREVIATION DESCRIPTION

NOX Nitrogen oxides

ABBREVIATION

DESCRIPTION

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1919 of 3641

TOW TRUCK TOWINGGI-31

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O PTOW TRUCK TOWING

To w T r u c k To w i n gINFOID:0000000012433173

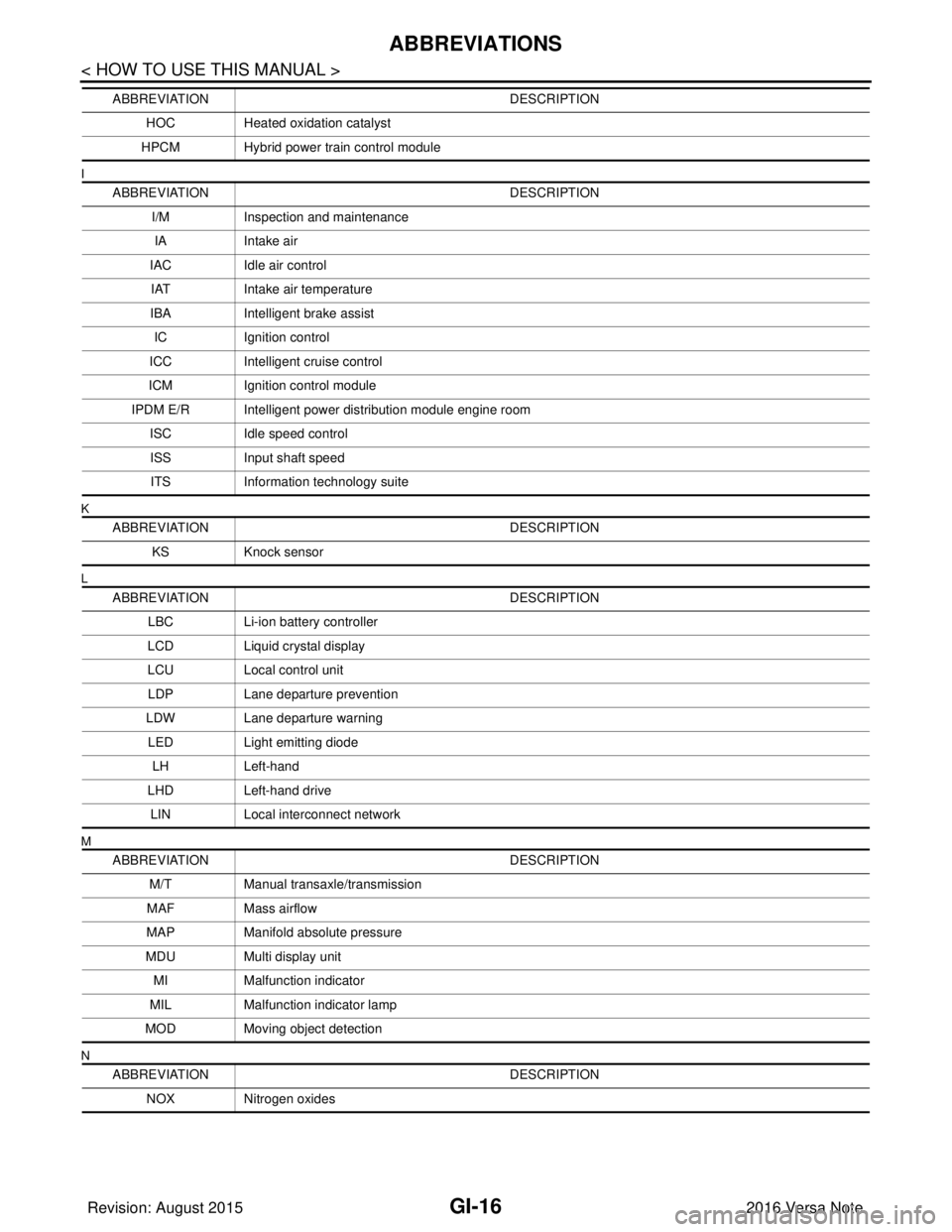

CAUTION:

• Never tow a CVT model with the rear wheels raised and the front wheels on the ground. This may

cause serious and expensive damage to the transaxle. If it is necessary to tow the vehicle with the

rear wheels raised, always use towin g dollies under the front wheels.

• Never tow a CVT model from the rear (that is b ackward) with four wheels on the ground. This may

cause serious and expensive damage to the transaxle.

NISSAN recommends that the vehicle be towed with the driving

(front) wheels off the ground.

CAUTION:

• Always release the parking br ake when towing the vehicle

with the front wheels raised with the rear wheels on the

ground.

• When towing manual transaxle models with the front wheels on the ground (if a towing dolly is not used), turn the ignition

key to the OFF position, and secu re the steering wheel in the

straight-ahead position with a rope or similar device.

Move the shift lever to th e N (Neutral) position.

Vehicle Recovery (Freeing a Stuck Vehicle)INFOID:0000000012433174

FRONT

WARNING:

• Stand clear of a stuck vehicle.

• Do not spin your tires at high speed. This could cause them to explode and result in serious injury.

Parts of your vehicle could also overheat and be damaged.

CAUTION:

• Tow chains or cables must be attached only to the vehicle recovery hooks or main structural mem-

bers of the vehicle. Otherwise, the vehicle body will be damaged.

• Do not use the vehicle tie downs to free a vehicle stuck in sand, snow, mud, etc. Never tow the vehi-

cle using the vehicle tie downs or recovery hooks.

• Always pull the cable straight out from the front of the vehicle. Never pull on the hook at an angle.

• Pulling devices should be routed so they do not touch any part of the suspension, steering, brake or

cooling systems.

• Pulling devices such as ropes or canvas straps ar e not recommended for use in vehicle towing or

recovery.

CVT

To tow a vehicle equipped with a CVT, an appropriate vehicle dolly MUST be placed under the towed vehicle's

drive wheels. Always follow the dolly manufacture's re commendations when using their product.

If the vehicle is stuck in sand, snow , mud, etc., use the following procedure:

1. Make sure the area in front and behind the vehicle is clear of obstructions.

2. Turn the steering wheel right and left to clear an area around the front tires.

SGI986

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1930 of 3641

GI-42

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

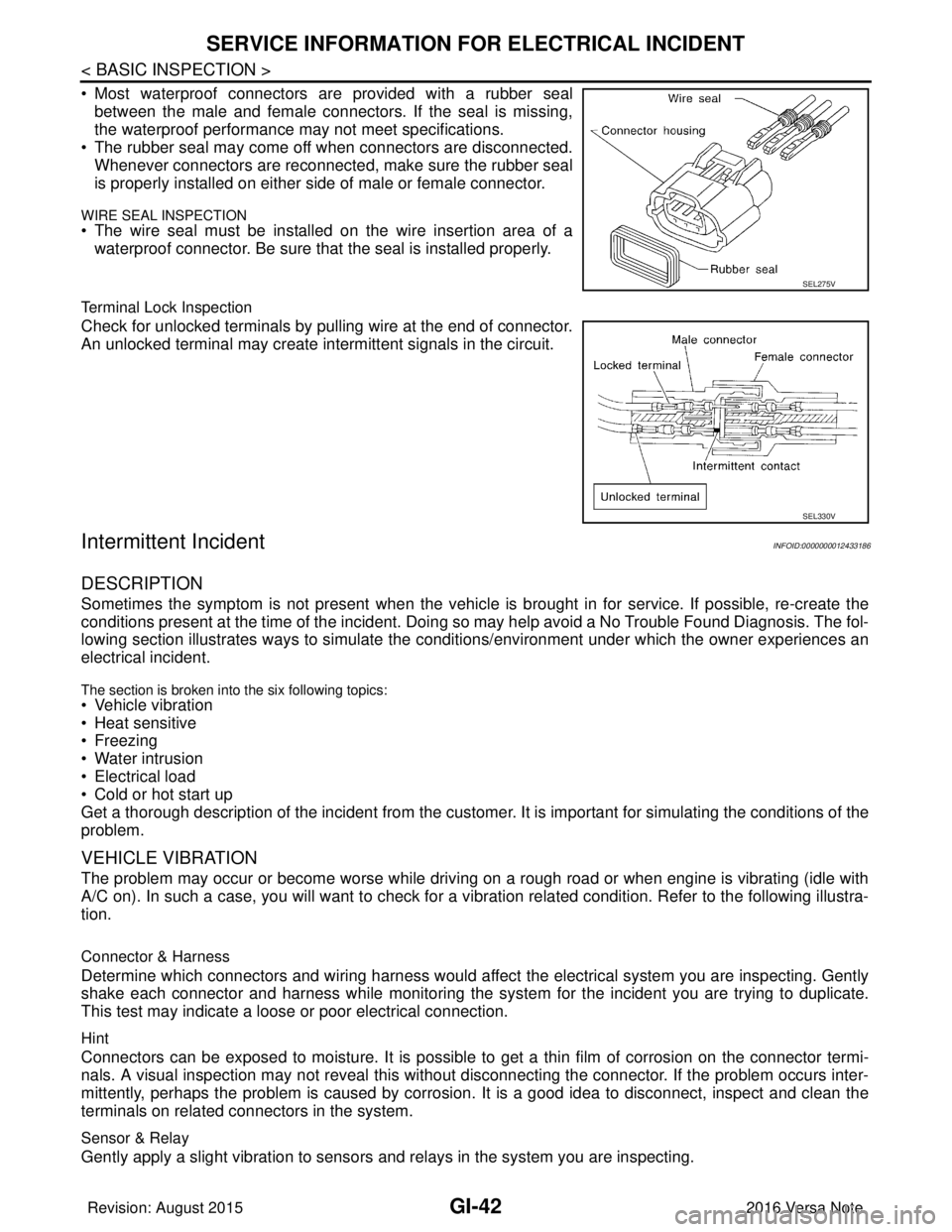

• Most waterproof connectors are provided with a rubber sealbetween the male and female connectors. If the seal is missing,

the waterproof performance may not meet specifications.

• The rubber seal may come off when connectors are disconnected. Whenever connectors are reconnected, make sure the rubber seal

is properly installed on either side of male or female connector.

WIRE SEAL INSPECTION

• The wire seal must be installed on the wire insertion area of awaterproof connector. Be sure that the seal is installed properly.

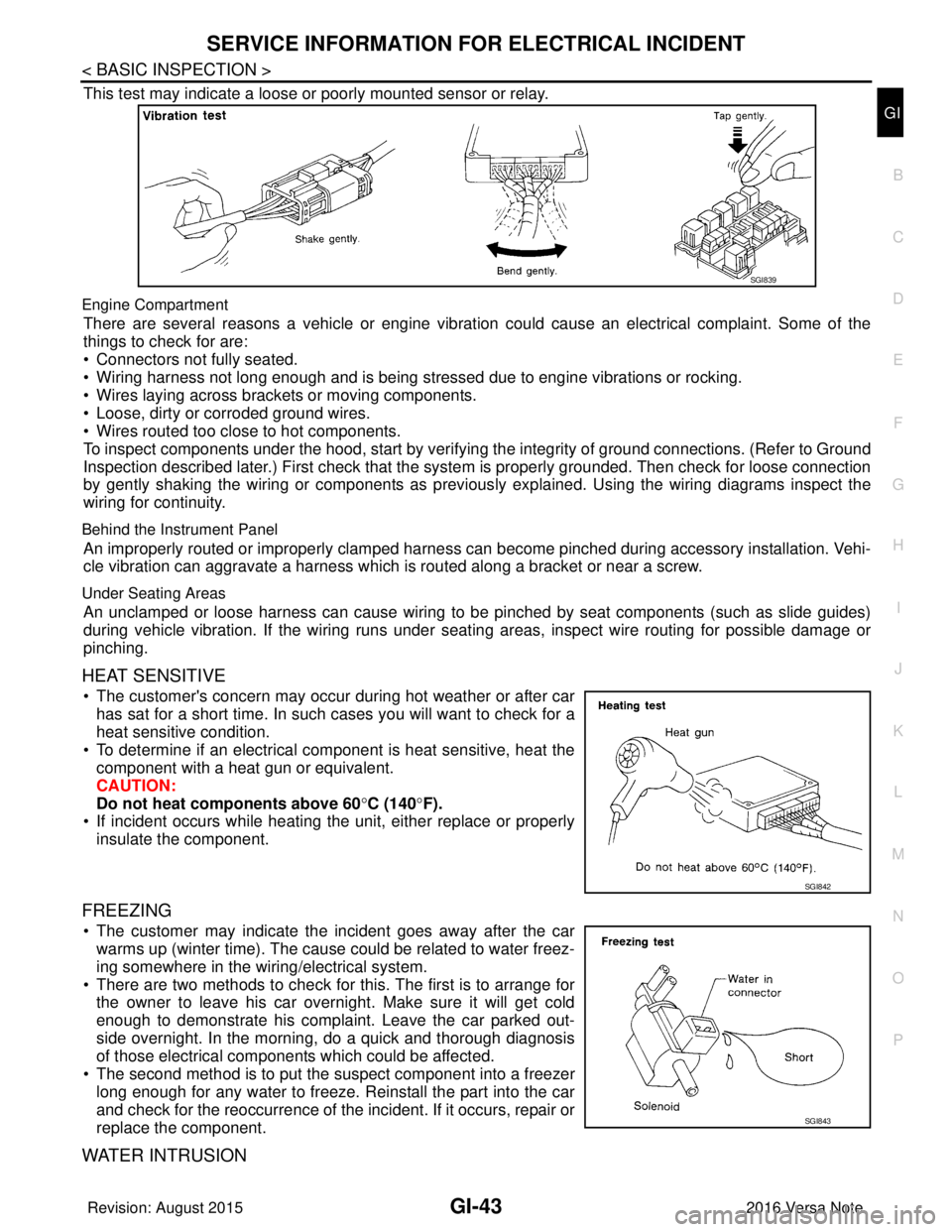

Terminal Lock Inspection

Check for unlocked terminals by pulling wire at the end of connector.

An unlocked terminal may create intermittent signals in the circuit.

Intermittent IncidentINFOID:0000000012433186

DESCRIPTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doi ng so may help avoid a No Trouble Found Diagnosis. The fol-

lowing section illustrates ways to simulate the condi tions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:

• Vehicle vibration

• Heat sensitive

• Freezing

• Water intrusion

• Electrical load

• Cold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of the

problem.

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vi bration related condition. Refer to the following illustra-

tion.

Connector & Harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the sy stem for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

Sensor & Relay

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

SEL275V

SEL330V

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1931 of 3641

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-43

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

This test may indicate a loose or poorly mounted sensor or relay.

Engine Compartment

There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the

things to check for are:

• Connectors not fully seated.

• Wiring harness not long enough and is being stressed due to engine vibrations or rocking.

• Wires laying across brackets or moving components.

• Loose, dirty or corroded ground wires.

• Wires routed too close to hot components.

To inspect components under the hood, start by verifyi ng the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previous ly explained. Using the wiring diagrams inspect the

wiring for continuity.

Behind the Instrument Panel

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehi-

cle vibration can aggravate a harness which is routed along a bracket or near a screw.

Under Seating Areas

An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibration. If the wiring runs under s eating areas, inspect wire routing for possible damage or

pinching.

HEAT SENSITIVE

• The customer's concern may occur during hot weather or after car has sat for a short time. In such cases you will want to check for a

heat sensitive condition.

• To determine if an electrical component is heat sensitive, heat the component with a heat gun or equivalent.

CAUTION:

Do not heat components above 60 °C (140° F).

• If incident occurs while heating t he unit, either replace or properly

insulate the component.

FREEZING

• The customer may indicate the incident goes away after the car warms up (winter time). The cause could be related to water freez-

ing somewhere in the wiring/electrical system.

• There are two methods to check for this. The first is to arrange for the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked out-

side overnight. In the morning, do a quick and thorough diagnosis

of those electrical components which could be affected.

• The second method is to put the suspect component into a freezer long enough for any water to freeze. Reinstall the part into the car

and check for the reoccurrence of the incident. If it occurs, repair or

replace the component.

WATER INTRUSION

SGI839

SGI842

SGI843

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1952 of 3641

GW-12

< REMOVAL AND INSTALLATION >

WINDSHIELD GLASS

Removal and Installation

INFOID:0000000012430531

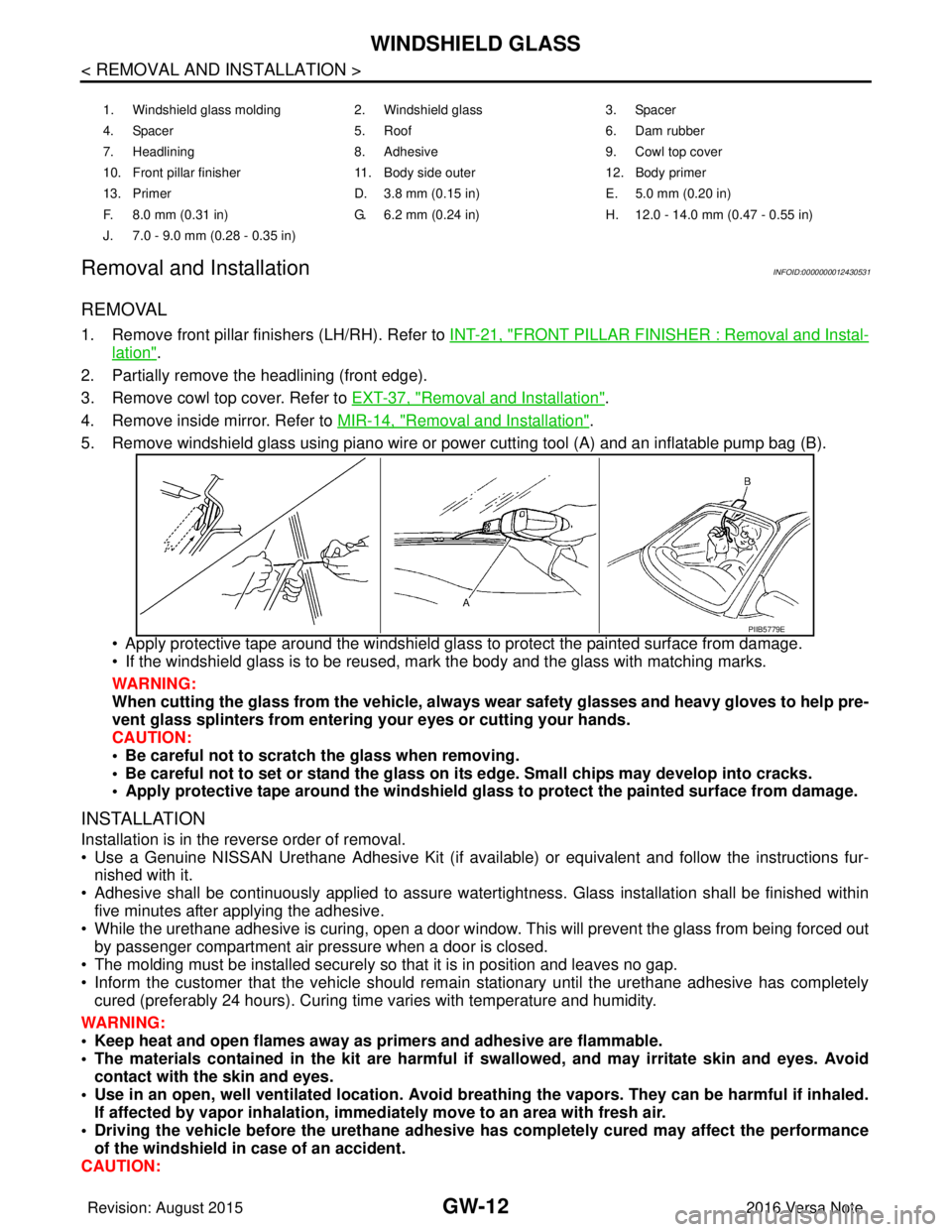

REMOVAL

1. Remove front pillar finishers (LH/RH). Refer to INT-21, "FRONT PILLAR FINISHER : Removal and Instal-

lation".

2. Partially remove the headlining (front edge).

3. Remove cowl top cover. Refer to EXT-37, "

Removal and Installation".

4. Remove inside mirror. Refer to MIR-14, "

Removal and Installation".

5. Remove windshield glass using piano wire or pow er cutting tool (A) and an inflatable pump bag (B).

• Apply protective tape around the windshield gla ss to protect the painted surface from damage.

• If the windshield glass is to be reused, mark the body and the glass with matching marks.

WARNING:

When cutting the glass from the vehicle, always wear safety glasses and heavy gloves to help pre-

vent glass splinters from entering your eyes or cutting your hands.

CAUTION:

• Be careful not to scratch the glass when removing.

• Be careful not to set or stand the glass on its edge. Small chips may develop into cracks.

• Apply protective tape around th e windshield glass to protect the painted surface from damage.

INSTALLATION

Installation is in the reverse order of removal.

• Use a Genuine NISSAN Urethane Adhesive Kit (if availabl e) or equivalent and follow the instructions fur-

nished with it.

• Adhesive shall be continuously applied to assure watert ightness. Glass installation shall be finished within

five minutes after applying the adhesive.

• While the urethane adhesive is curing, open a door window . This will prevent the glass from being forced out

by passenger compartment air pressure when a door is closed.

• The molding must be installed securely so that it is in position and leaves no gap.

• Inform the customer that the vehicle should remain stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin and eyes.

• Use in an open, well ventilated location. Avoid breathing the vapors. They can be harmful if inhaled. If affected by vapor inhalation, imme diately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the windshield in case of an accident.

CAUTION:

1. Windshield glass molding 2. Windshield glass 3. Spacer

4. Spacer 5. Roof 6. Dam rubber

7. Headlining 8. Adhesive 9. Cowl top cover

10. Front pillar finisher 11. Body side outer 12. Body primer

13. Primer D. 3.8 mm (0.15 in) E. 5.0 mm (0.20 in)

F. 8.0 mm (0.31 in) G. 6.2 mm (0.24 in) H. 12.0 - 14.0 mm (0.47 - 0.55 in)

J. 7.0 - 9.0 mm (0.28 - 0.35 in)

PIIB5779E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1955 of 3641

OPERA WINDOWGW-15

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

When cutting glass from the vehicle, always wear safety glasses and heavy gloves to prevent

glass splinters from entering your eyes or cutting your hands.

CAUTION:

• Be careful not to scratch the glass when removing.

• Do not set or stand the glass on its ed ge. Small chips may develop into cracks.

• Apply protective tape around the opera windo w glass to protect the painted surface from dam-

age.

INSTALLATION

• Use a Genuine NISSAN Urethane Adhesive Kit (if avail able) or equivalent and follow the instructions fur-

nished with it.

• Adhesive shall be continuously applied to assure watert ightness. Glass installation shall be finished within

five minutes after applying the adhesive.

• The start and finisher of the urethane adhesive applicati on should be located at the bottom to assure water-

tightness.

• While the urethane adhesive is curing, open a door window . This will prevent the glass from being forced out

by passenger compartment air pressure when a door is closed.

• Inform the customer that the vehicle should rema in stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with skin and eyes.

• Use in an open, well ventilated lo cation. Avoid breathing the vapors. They can be harmful if inhaled.

If affected by vapor inhalation, imme diately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive is completely cured may affect the performance of

the opera window glass in case of an accident.

CAUTION:

• Do not use an adhesive which is past its usable te rm. Shelf life of this product is limited to six

months after the date of manufacture. Carefully ad here to the expiration or manufacture date printed

on the box.

• Keep primers and adhesive in a cool, dry place. Id eally, they should be stored in a refrigerator.

• Do not leave primers or adhesive cartridge unattended with their caps open or off.

• The vehicle should not be driven for at least 24 hours or until the urethane adhesive is completely

cured. Curing time varies depe nding on temperature and humidity. The curing time increases under

lower temperature and lower humidity.

REPAIRING WATER LEAKS FOR OPERA WINDOW GLASS

• Leaks can be repaired without removing and reinstalling opera window glass.

• If water is leaking between the urethane adhesive materi al and body or glass, determine the extent of the

leak.

• This can be done by applying water to the opera window glass area while pushing glass outward.

• To stop the leak, apply primer (if necessary ) and then urethane adhesive to the leak point.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1957 of 3641

SIDE WINDOW GLASSGW-17

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

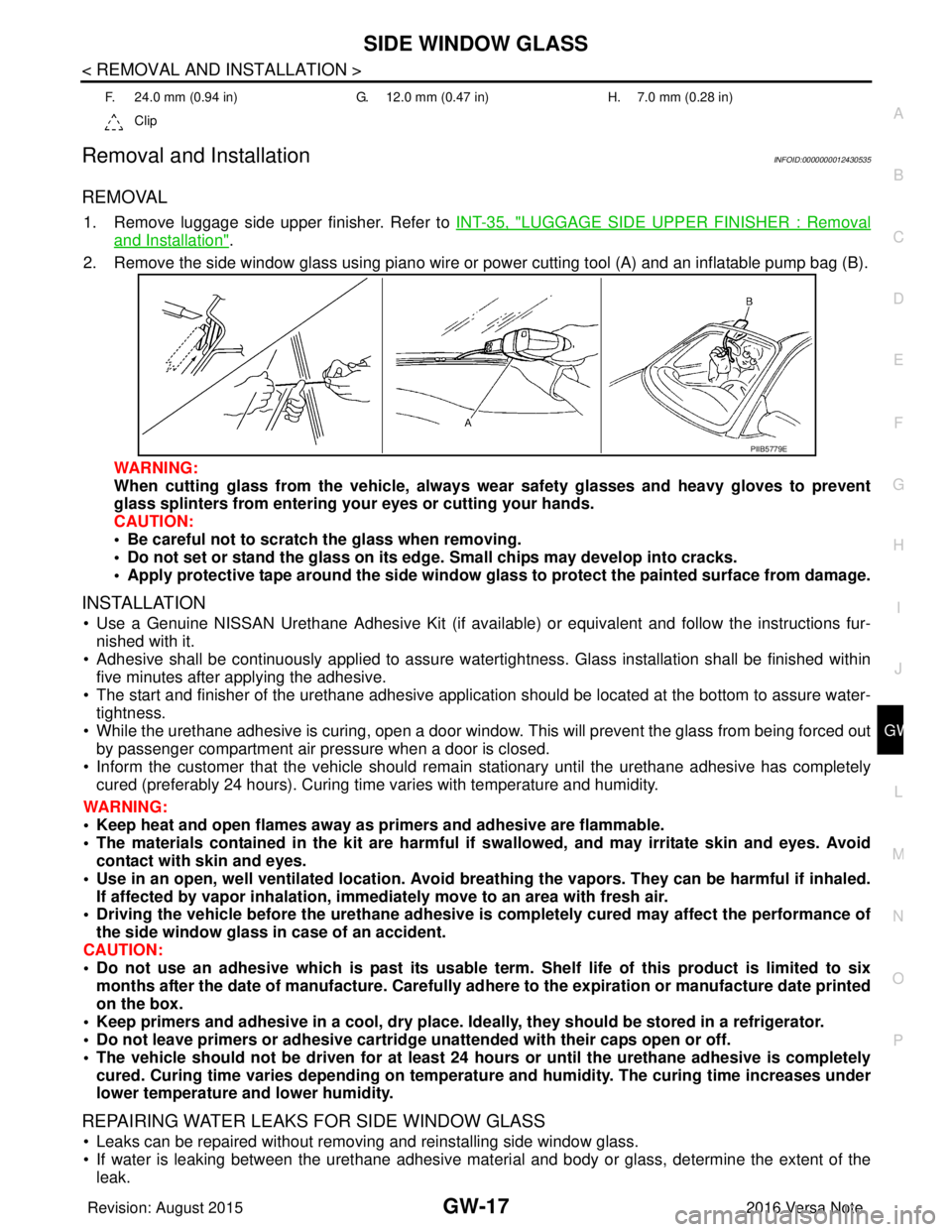

Removal and InstallationINFOID:0000000012430535

REMOVAL

1. Remove luggage side upper finisher. Refer to INT-35, "LUGGAGE SIDE UPPER FINISHER : Removal

and Installation".

2. Remove the side window glass using piano wire or power cutting tool (A) and an inflatable pump bag (B).

WARNING:

When cutting glass from the vehicle, always wear safety glasses and heavy gloves to prevent

glass splinters from entering your eyes or cutting your hands.

CAUTION:

• Be careful not to scratch the glass when removing.

• Do not set or stand the glass on its ed ge. Small chips may develop into cracks.

• Apply protective tape around the side window gl ass to protect the painted surface from damage.

INSTALLATION

• Use a Genuine NISSAN Urethane Adhesive Kit (if avail able) or equivalent and follow the instructions fur-

nished with it.

• Adhesive shall be continuously applied to assure watert ightness. Glass installation shall be finished within

five minutes after applying the adhesive.

• The start and finisher of the urethane adhesive applicati on should be located at the bottom to assure water-

tightness.

• While the urethane adhesive is curing, open a door window . This will prevent the glass from being forced out

by passenger compartment air pressure when a door is closed.

• Inform the customer that the vehicle should rema in stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with skin and eyes.

• Use in an open, well ventilated lo cation. Avoid breathing the vapors. They can be harmful if inhaled.

If affected by vapor inhalation, imme diately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive is completely cured may affect the performance of

the side window glass in case of an accident.

CAUTION:

• Do not use an adhesive which is past its usable te rm. Shelf life of this product is limited to six

months after the date of manufacture. Carefully ad here to the expiration or manufacture date printed

on the box.

• Keep primers and adhesive in a cool, dry place. Id eally, they should be stored in a refrigerator.

• Do not leave primers or adhesive cartridge unattended with their caps open or off.

• The vehicle should not be driven for at least 24 hours or until the urethane adhesive is completely

cured. Curing time varies depe nding on temperature and humidity. The curing time increases under

lower temperature and lower humidity.

REPAIRING WATER LEAKS FO R SIDE WINDOW GLASS

• Leaks can be repaired without removing and reinstalling side window glass.

• If water is leaking between the urethane adhesive materi al and body or glass, determine the extent of the

leak.

F. 24.0 mm (0.94 in) G. 12.0 mm (0.47 in)H. 7.0 mm (0.28 in)

Clip

PIIB5779E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1960 of 3641

GW-20

< REMOVAL AND INSTALLATION >

BACK DOOR WINDOW GLASS

• Be careful not to scratch the glass when removing.

• Do not set or stand the glass on its ed ge. Small chips may develop into cracks.

• Apply protective tape around the back door window glass to pr otect the painted surface from

damage.

INSTALLATION

Installation is in the reverse order of removal.

• Use a Genuine NISSAN Urethane Adhesive Kit (if availabl e) or equivalent and follow the instructions fur-

nished with it.

• Adhesive shall be continuously applied to assure watert ightness. Glass installation shall be finished within

five minutes after applying the adhesive.

• While the urethane adhesive is curing, open a door window . This will prevent the glass from being forced out

by passenger compartment air pressure when a door is closed.

• The molding must be installed securely so that it is in position and leaves no gap.

• Inform the customer that the vehicle should remain stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin and eyes.

• Use in an open, well ventilated location. Avoid breathing the vapors. They can be harmful if inhaled. If affected by vapor inhalation, imme diately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the back door window gl ass in case of an accident.

CAUTION:

• Do not use an adhesive which is past its usable te rm. Shelf life of this product is limited to six

months after the date of manufacture. Carefully a dhere to the expiration or manufacture date printed

on the box.

• Keep primers and adhesive in a c ool, dry place. Ideally, they should be stored in a refrigerator.

• Do not leave primers or adhesive cartridge unattended with their caps open or off.

• The vehicle should not be driven for at least 24 hours or until the urethane adhesive has completely cured. Curing time varies depe nding on temperature and humidity . The curing time will increase

under lower temperatures and lower humidity.

REPAIRING WATER LEAKS FOR BACK DOOR WINDOW GLASS

• Leaks can be repaired without removing and reinstalling back door window glass.

• If water is leaking between the urethane adhesive materi al and body or glass, determine the extent of the

leak.

• This can be done by applying water to the back door window glass area while pushing glass outward.

• To stop the leak, apply primer (if necessary) and urethane adhesive to the leak point.

Revision: August 2015 2016 Versa Note

cardiagn.com