Heat NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2026 of 3641

HA-1

VENTILATION, HEATER & AIR CONDITIONER

C

DE

F

G H

J

K L

M

SECTION HA

A

B

HA

N

O P

CONTENTS

HEATER & AIR CONDITIONING SYSTEM

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Work ..................................................3

Precaution for Procedure without Cowl Top Cover ......4

Precautions For Refrigerant System Service ............4

Service Equipment .............................................. ......6

PREPARATION ............................................9

PREPARATION .............................................. .....9

Special Service Tool ........................................... ......9

Commercial Service Tool ..........................................9

Sealant and/or Oil ...................................................11

SYSTEM DESCRIPTION .............................12

COMPONENT PARTS ................................... ....12

Component Parts Location .................................. ....12

BASIC INSPECTION ...................................13

DIAGNOSIS AND REPAIR WORKFLOW ..... ....13

Workflow ............................................................. ....13

SYMPTOM DIAGNOSIS ..............................15

REFRIGERATION SYSTEM SYMPTOMS ..... ....15

Trouble Diagnosis For Unusual Pressure ........... ....15

Symptom Table .......................................................15

NOISE .................................................................17

Symptom Table ................................................... ....17

PERIODIC MAINTENANCE .........................18

REFRIGERANT .............................................. ....18

Description .......................................................... ....18

Leak Test ................................................................18

Recycle Refrigerant .................................................20

Charge Refrigerant .............................................. ....20

OIL .....................................................................22

Description ...............................................................22

Inspection ................................................................22

Perform Oil Return Operation ..................................22

Oil Adjusting Procedure for Components Replace-

ment Except Compressor .................................... ....

22

Oil Adjusting Procedure for Compressor Replace-

ment .........................................................................

23

PERFORMANCE TEST ....................................24

Inspection ................................................................24

REMOVAL AND INSTALLATION ...............26

COMPRESSOR .................................................26

Exploded View ..................................................... ....26

Removal and Installation .........................................26

Inspection ................................................................27

COOLER PIPE AND HOSE ..............................28

Exploded View .........................................................28

LOW-PRESSURE FLEXIBLE HOSE ..................... ....28

LOW-PRESSURE FLEXIBLE HOSE : Removal

and Installation ........................................................

28

HIGH-PRESSURE FLEXIBLE HOSE ........................29

HIGH-PRESSURE FLEXIBLE HOSE : Removal

and Installation .................................................... ....

29

HIGH-PRESSURE PIPE ............................................29

HIGH-PRESSURE PIPE : Removal and Installa-

tion ....................................................................... ....

29

CONDENSER ....................................................31

Exploded View .........................................................31

CONDENSER ......................................................... ....31

CONDENSER : Removal and Installation ...............31

LIQUID TANK ........................................................ ....32

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2027 of 3641

HA-2

LIQUID TANK : Removal and Installation of Liquid

Tank ........................................................................

32

REFRIGERANT PRESSURE SENSOR ....................32

REFRIGERANT PRESSURE SENSOR : Remov-

al and Installation ................................................. ...

32

HEATING AND COOLING UNIT ASSEMBLY ...33

Exploded View ..................................................... ...33

HEATING AND COOLING UNIT ASSEMBLY ....... ...34

HEATING AND COOLING UNIT ASSEMBLY :

Removal and Installation ........................................

34

HEATER CORE ...................................................... ...35

HEATER CORE : Removal and Installation ...........35

EVAPORATOR ....................................................... ...35

EVAPORATOR : Removal and Installation .............35

EXPANSION VALVE .............................................. ...35

EXPANSION VALVE : Removal and Installation ....36

SERVICE DATA AND SPECIFICATIONS

(SDS) .......... ................................. ...............

37

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

37

Compressor ......................................................... ...37

Oil ............................................................................37

Refrigerant ..............................................................37

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2029 of 3641

HA-4

< PRECAUTION >

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000012431986

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc to prevent damage to

windshield.

Precautions For Refrigerant System ServiceINFOID:0000000012431987

WORKING WITH HFC-134a (R-134a)

CAUTION:

• CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. Compressor mal-

function is likely to occur if the refrigerants are mixed, refe r to “CONTAMINATED REFRIGERANT”

below. To determine the purity of HFC-134a (R-134a) in the vehicle and recovery tank, use Refriger-

ant recovery/recycling recharging equi pment and Refrigerant Identifier.

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components.

Compressor malfunction is likely to occur if oil other than that specified is used.

• The specified HFC-134a (R-134a) oi l rapidly absorbs moisture from the atmosphere. The following

handling precautions must be observed:

- Cap (seal) the component immediately to minimize the entry of moisture from the atmosphere when removing refrigerant components from a vehicle.

- Do not remove the caps (unseal) unti l just before connecting the components when installing refrig-

erant components to a vehicle. Connect all refr igerant loop components as quickly as possible to

minimize the entry of moisture into system.

- Use only the specified oil from a sealed container. Reseal containers of oil immediately. Oil becomes

moisture saturated and should no t be used without proper sealing.

- Do not allow oil to come in contact with styrene foam parts. Damage may result.

GENERAL REFRIGERANT PRECAUTION

WARNING:

• Do not breathe A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Remove HFC-134a (R-134a) from the A/C system, usin g certified service equipment meeting require-

ments of SAE J-2210 [HFC-134a (R-134a) recycling equipment] or J-2209 [HFC-134a (R-134a) recov-

ery equipment]. Ventilate work area before resumi ng service if accidental system discharge occurs.

Additional health and safety in formation may be obtained from refrigerant and oil manufacturers.

• Do not release refrigerant into the air. Use ap proved recovery/recycling recharging equipment to

capture the refrigerant each time an air conditioning system is discharged.

• Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

• Do not store or heat refrigerant containers above 52 °C (126° F).

• Do not heat a refrigerant containe r with an open flame; Place the bottom of the container in a warm

pail of water if container warming is required.

• Do not intentionally drop, puncture or incinerate refrigerant containers.

• Do not refrigerant away from op en flames; poisonous gas is produced if refrigerant burns.

• Refrigerant displaces oxygen; therefore be certain to work in well ventilated areas to prevent suffo- cation.

• Do not pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air condition-

ing systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a) have

been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause injury or

property damage. Additional heal th and safety information may be obtained from refrigerant manu-

facturers.

REFRIGERANT CONNECTION

A new type of refrigerant connection has been introduced to al l refrigerant lines except the following locations:

PIIB3706J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2037 of 3641

HA-12

< SYSTEM DESCRIPTION >

COMPONENT PARTS

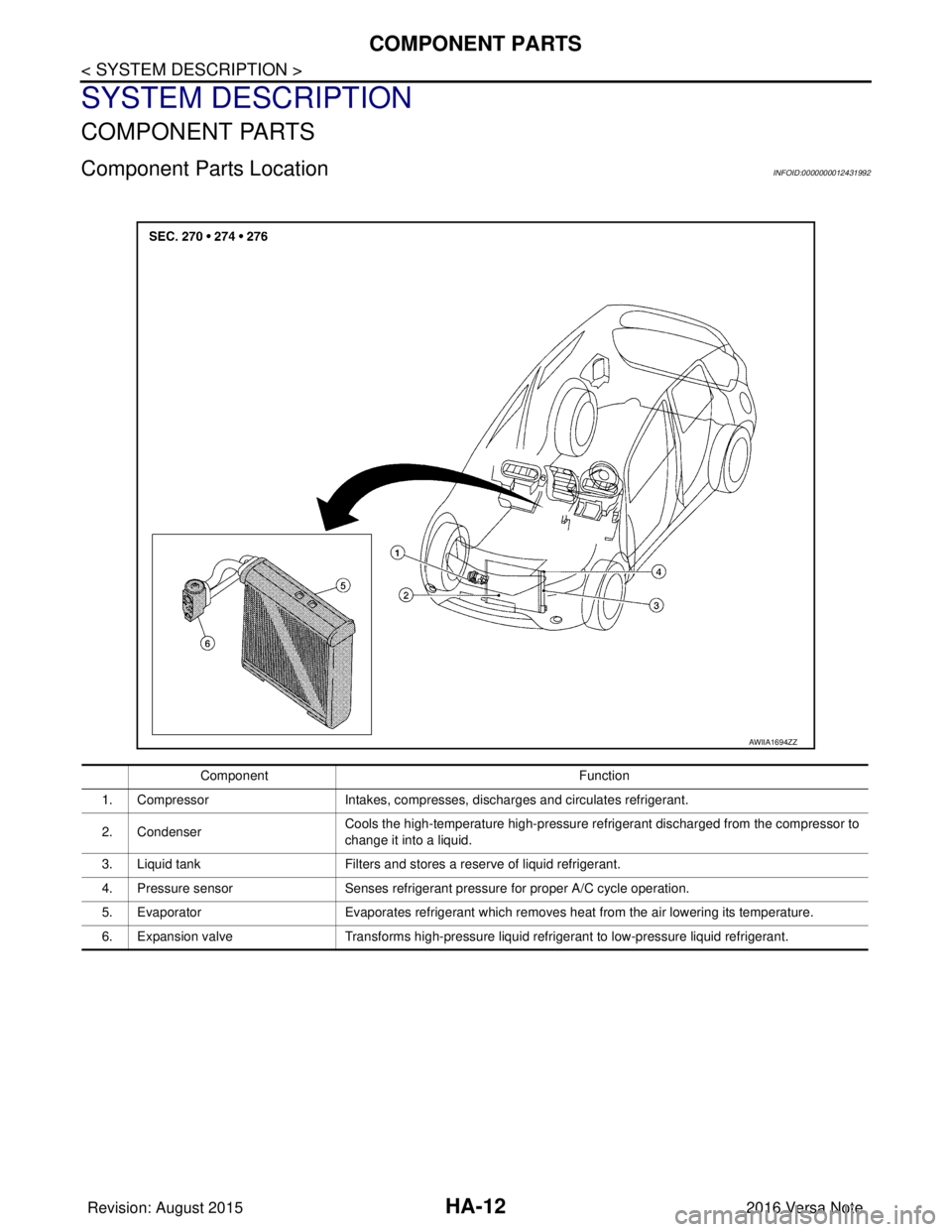

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000012431992

AWIIA1694ZZ

ComponentFunction

1. Compressor Intakes, compresses, discharges and circulates refrigerant.

2. Condenser Cools the high-temperature high-pressure refrigerant discharged from the compressor to

change it into a liquid.

3. Liquid tank Filters and stores a reserve of liquid refrigerant.

4. Pressure sensor Senses refrigerant pressure for proper A/C cycle operation.

5. Evaporator Evaporates refrigerant which removes heat from the air lowering its temperature.

6. Expansion valve Transforms high-pressure liquid refrigerant to low-pressure liquid refrigerant.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2047 of 3641

HA-22

< PERIODIC MAINTENANCE >

OIL

OIL

DescriptionINFOID:0000000012432001

MAINTENANCE OF OIL LEVEL

The compressor oil circulates in the system together with the refrigerant. It is necessary to add oil to the com-

pressor when replacing A/C system components or when a large amount of refrigerant leaks from the system.

It is important to always maintain oil level within t he specified level. Otherwise, the following conditions may

occur.

• Insufficient oil amount: Stuck compressor

• Excessive oil amount: Insufficient cooling (caused by insufficient heat exchange)

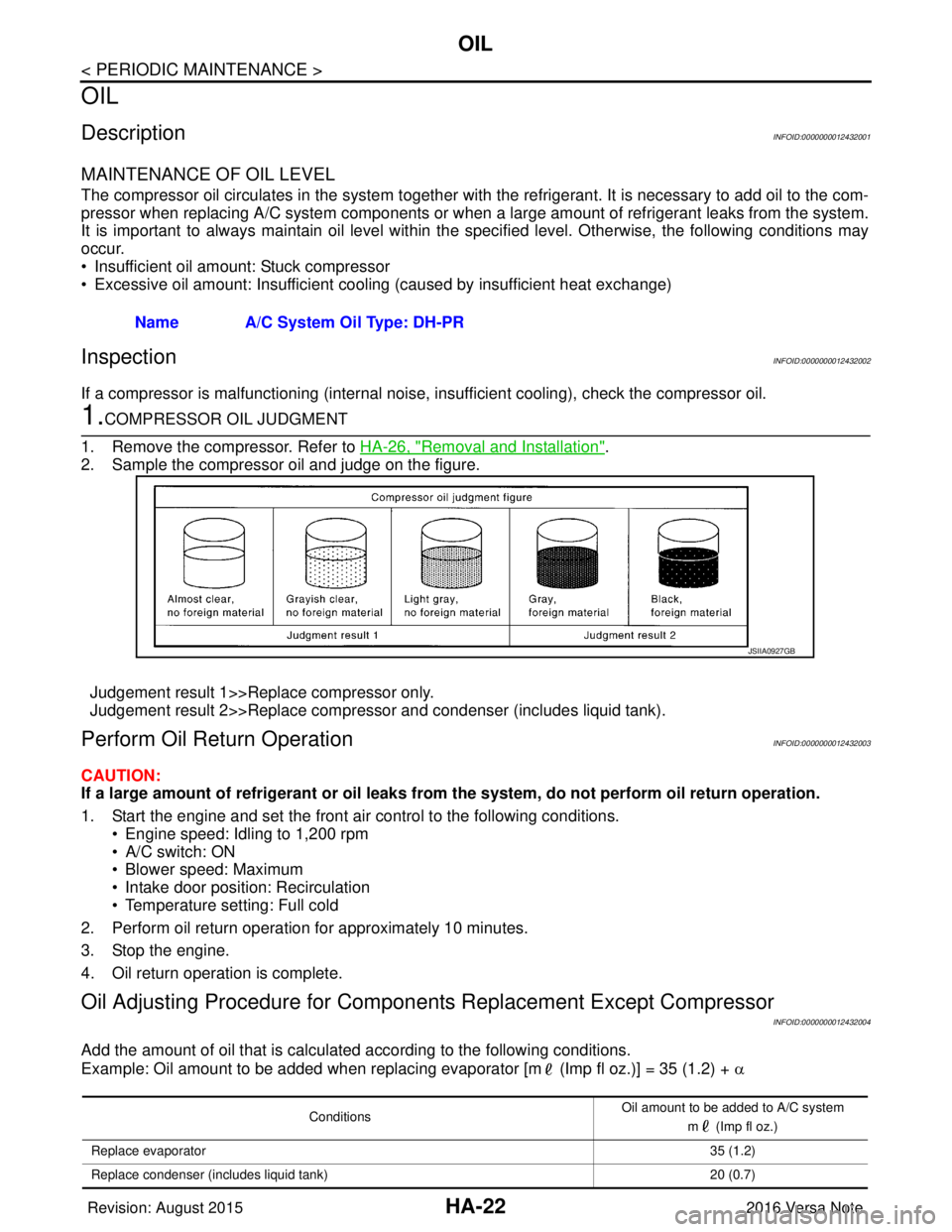

InspectionINFOID:0000000012432002

If a compressor is malfunctioning (internal noise, insufficient cooling), check the compressor oil.

1.COMPRESSOR OIL JUDGMENT

1. Remove the compressor. Refer to HA-26, "

Removal and Installation".

2. Sample the compressor oil and judge on the figure.

Judgement result 1>>Replace compressor only.

Judgement result 2>>Replace compressor and condenser (includes liquid tank).

Perform Oil Retu rn OperationINFOID:0000000012432003

CAUTION:

If a large amount of refrigerant or oil leaks from the system, do not perform oil return operation.

1. Start the engine and set the front air control to the following conditions. • Engine speed: Idling to 1,200 rpm

• A/C switch: ON

• Blower speed: Maximum

• Intake door position: Recirculation

• Temperature setting: Full cold

2. Perform oil return operation for approximately 10 minutes.

3. Stop the engine.

4. Oil return operation is complete.

Oil Adjusting Procedure for Compon ents Replacement Except Compressor

INFOID:0000000012432004

Add the amount of oil that is calculated according to the following conditions.

Example: Oil amount to be added when replacing evaporator [m (Imp fl oz.)] = 35 (1.2) + α

Name A/C System Oil Type: DH-PR

JSIIA0927GB

Conditions

Oil amount to be added to A/C system

m (Imp fl oz.)

Replace evaporator 35 (1.2)

Replace condenser (includes liquid tank) 20 (0.7)

Revision: August 20152016 Versa Note

cardiagn.com

Page 2053 of 3641

HA-28

< REMOVAL AND INSTALLATION >

COOLER PIPE AND HOSE

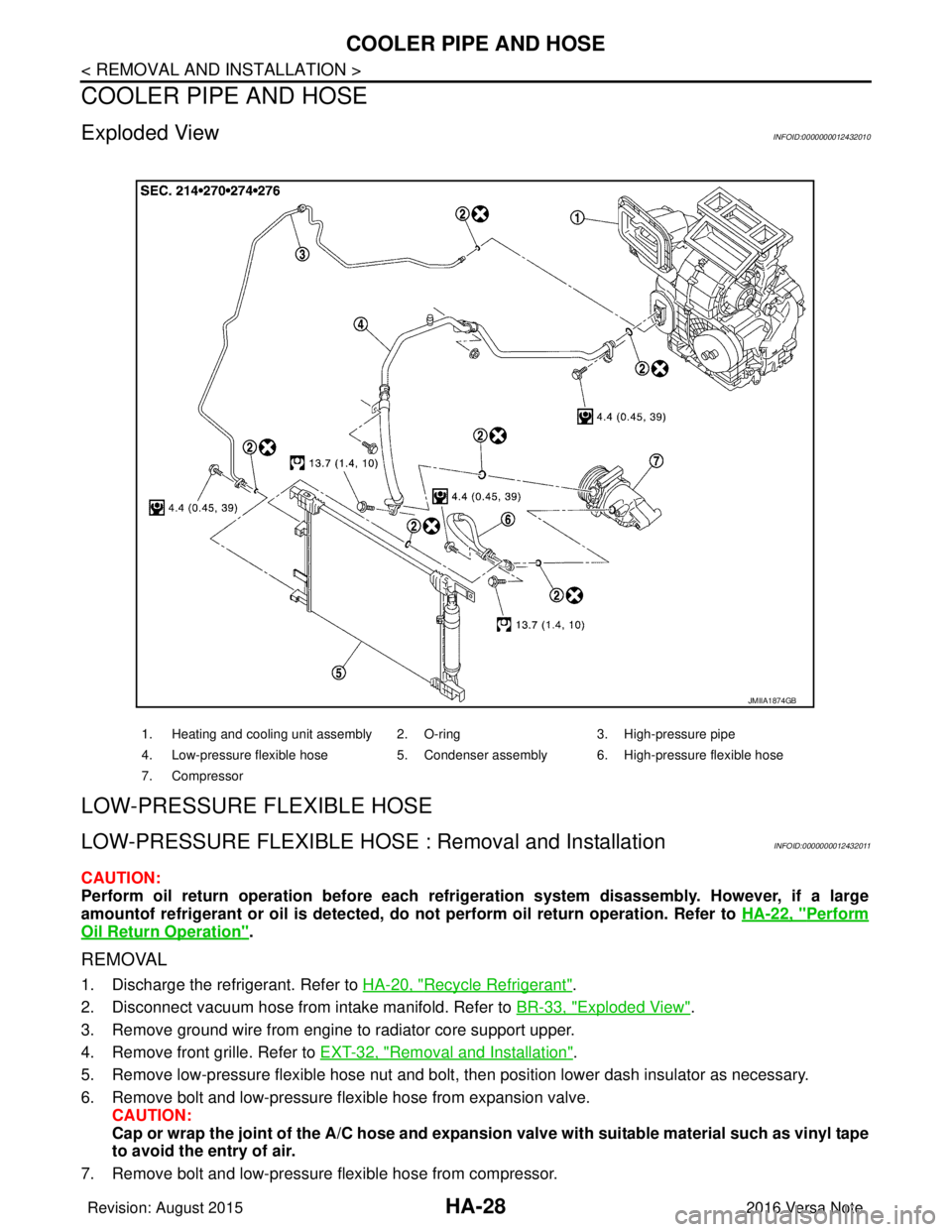

COOLER PIPE AND HOSE

Exploded ViewINFOID:0000000012432010

LOW-PRESSURE FLEXIBLE HOSE

LOW-PRESSURE FLEXIBLE HOSE : Removal and InstallationINFOID:0000000012432011

CAUTION:

Perform oil return operation before each refrigeration system disassembly. However, if a large

amountof refrigerant or oil is detected, do not perform oil return operation. Refer to HA-22, "

Perform

Oil Return Operation".

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "Recycle Refrigerant".

2. Disconnect vacuum hose from intake manifold. Refer to BR-33, "

Exploded View".

3. Remove ground wire from engine to radiator core support upper.

4. Remove front grille. Refer to EXT-32, "

Removal and Installation".

5. Remove low-pressure flexible hose nut and bolt, then position lower dash insulator as necessary.

6. Remove bolt and low-pressure flexible hose from expansion valve. CAUTION:

Cap or wrap the joint of the A/C hose and expansion valve with suitable material such as vinyl tape

to avoid the entry of air.

7. Remove bolt and low-pressure flexible hose from compressor.

1. Heating and cooling unit assembly 2. O-ring 3. High-pressure pipe

4. Low-pressure flexible hose 5. Condenser assembly 6. High-pressure flexible hose

7. Compressor

JMIIA1874GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2058 of 3641

HEATING AND COOLING UNIT ASSEMBLYHA-33

< REMOVAL AND INSTALLATION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

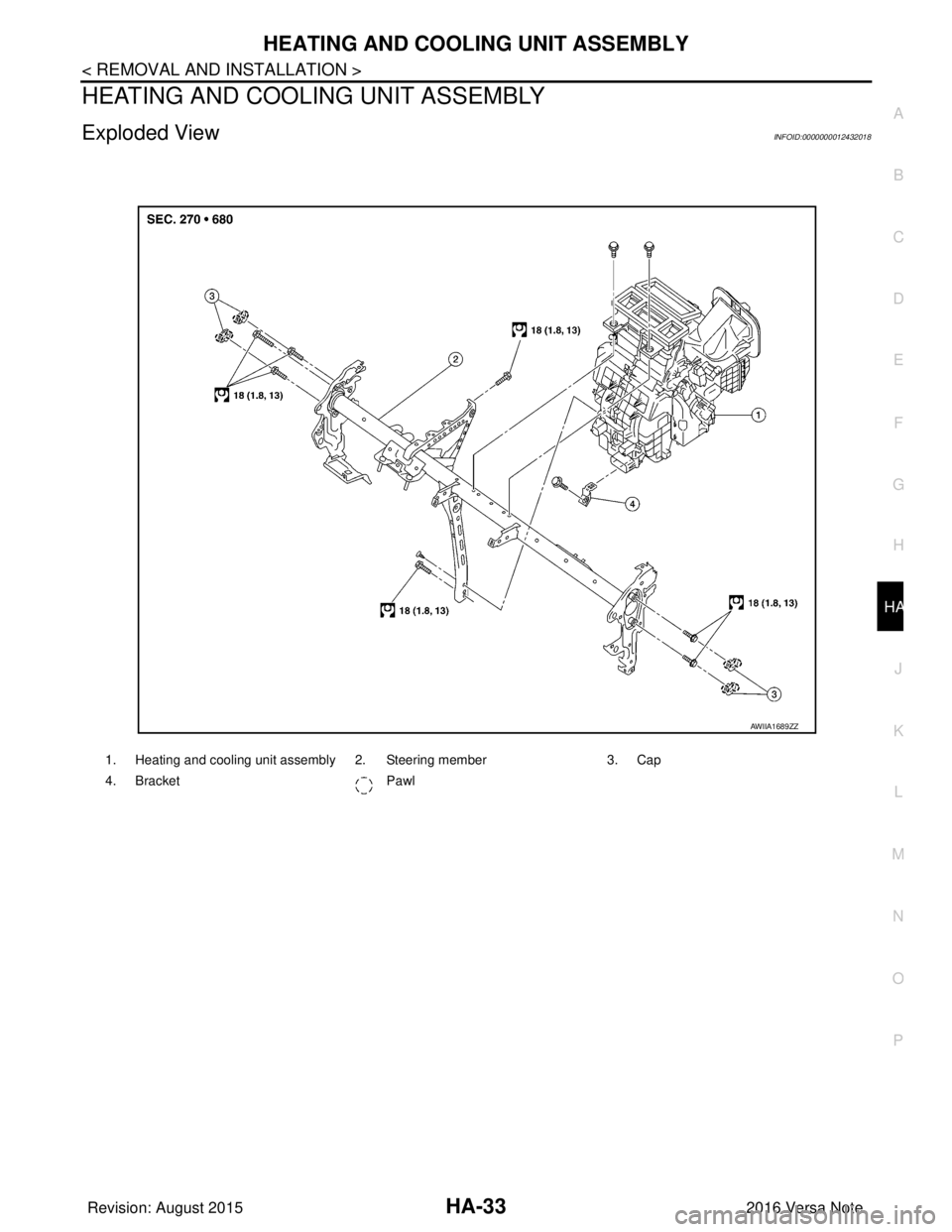

HEATING AND COOLING UNIT ASSEMBLY

Exploded ViewINFOID:0000000012432018

1. Heating and cooling unit assembly 2. Steering member 3. Cap

4. Bracket Pawl

AWIIA1689ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2059 of 3641

HA-34

< REMOVAL AND INSTALLATION >

HEATING AND COOLING UNIT ASSEMBLY

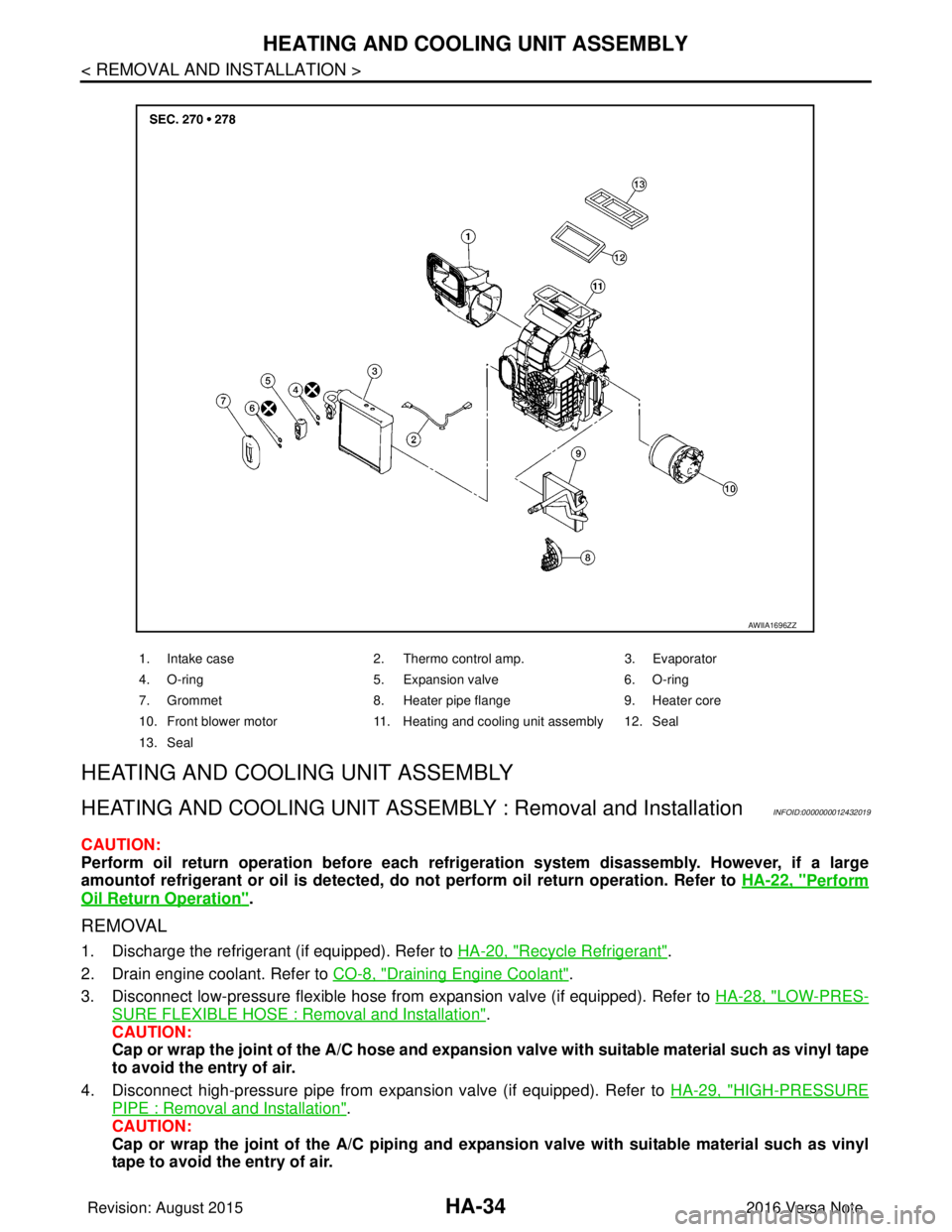

HEATING AND COOLING UNIT ASSEMBLY

HEATING AND COOLING UNIT ASSEMBLY : Removal and InstallationINFOID:0000000012432019

CAUTION:

Perform oil return operation before each refrigeration system disassembly. However, if a large

amountof refrigerant or oil is detected, do not perform oil return operation. Refer to HA-22, "

Perform

Oil Return Operation".

REMOVAL

1. Discharge the refrigerant (if equipped). Refer to HA-20, "Recycle Refrigerant".

2. Drain engine coolant. Refer to CO-8, "

Draining Engine Coolant".

3. Disconnect low-pressure flexible hose from expansion valve (if equipped). Refer to HA-28, "

LOW-PRES-

SURE FLEXIBLE HOSE : Removal and Installation".

CAUTION:

Cap or wrap the joint of the A/C hose and expansion valve with suitable material such as vinyl tape

to avoid the entry of air.

4. Disconnect high-pressure pipe from expansion valve (if equipped). Refer to HA-29, "

HIGH-PRESSURE

PIPE : Removal and Installation".

CAUTION:

Cap or wrap the joint of the A/C piping and expans ion valve with suitable material such as vinyl

tape to avoid the entry of air.

1. Intake case 2. Thermo control amp. 3. Evaporator

4. O-ring 5. Expansion valve 6. O-ring

7. Grommet 8. Heater pipe flange 9. Heater core

10. Front blower motor 11. Heating and cooling unit assembly 12. Seal

13. Seal

AWIIA1696ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2060 of 3641

HEATING AND COOLING UNIT ASSEMBLYHA-35

< REMOVAL AND INSTALLATION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

5. Disconnect heater hoses from heater core.

6. Remove instrument panel assembly. Refer to IP-15, "

Removal and Installation".

7. Disconnect evaporator drain hose from heating and cooling unit assembly.

8. Disconnect harness connectors, grounds, retainers, etc. , and remove bolts required to remove steering

member.

9. Remove steering member and heating and cooling unit assembly.

10. Remove heating and cooling unit assembly from steering member. Refer to HA-33, "

Exploded View".

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply compressor oil to new O-rings of the low-pressure flexible hose and high-pressure pipe for

installation.

• After charging refrigerant, check for leaks. Refer to HA-18, "

Leak Test".

NOTE:

When refilling engine coolant, refer to CO-9, "

Refilling".

HEATER CORE

HEATER CORE : Removal and InstallationINFOID:0000000012432020

REMOVAL

1. Remove the heating and cooling unit assembly. Refer to HA-34, "HEATING AND COOLING UNIT

ASSEMBLY : Removal and Installation".

2. Remove foot duct (LH). Refer to VTL-7, "

FOOT DUCT : Removal and Installation".

3. Remove heater packing.

4. Remove heater pipe flange.

5. Remove heater core.

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

When refilling engine coolant, refer to CO-9, "

Refilling".

EVAPORATOR

EVAPORATOR : Removal and InstallationINFOID:0000000012432021

REMOVAL

1. Remove heating and cooling unit assembly. Refer to HA-34, "HEATING AND COOLING UNIT ASSEM-

BLY : Removal and Installation".

2. Remove foot duct (RH). Refer to VTL-7, "

FOOT DUCT : Removal and Installation".

3. Remove intake case. Refer to HA-33, "

Exploded View".

4. Remove expansion valve. Refer to HA-36, "

EXPANSION VALVE : Removal and Installation".

5. Remove evaporator cover and evaporator assembly.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply compressor oil to ne w O-rings for installation.

• Perform oil adjusting procedure afte r installing new evaporator. Refer to HA-22, "

Oil Adjusting Pro-

cedure for Components Replacement Except Compressor".

• After charging refrigerant, check for leaks. Refer to HA-18, "

Leak Test".

EXPANSION VALVE

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2061 of 3641

HA-36

< REMOVAL AND INSTALLATION >

HEATING AND COOLING UNIT ASSEMBLY

EXPANSION VALVE : Removal and Installation

INFOID:0000000012432022

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "Recycle Refrigerant".

2. Disconnect low-pressure flexible hose from expansion valve. Refer to HA-28, "

LOW-PRESSURE FLEXI-

BLE HOSE : Removal and Installation".

3. Disconnect high-pressure pipe from expansion valve. Refer to HA-29, "

HIGH-PRESSURE PIPE :

Removal and Installation".

4. Remove bolts and expansion valve. CAUTION:

Cap or wrap the joint of the eva porator and expansion valve with su itable material such as vinyl

tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply compressor oil to new O-rings of the low- pressure flexible hose and high-pressure pipe for

installation.

• After charging refrigerant, check for leaks. Refer to HA-18, "

Leak Test".

Revision: August 2015 2016 Versa Note

cardiagn.com