maintenance NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2733 of 3641

REAR SUSPENSION ASSEMBLYRSU-5

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

PERIODIC MAINTENANCE

REAR SUSPENSION ASSEMBLY

InspectionINFOID:0000000012431921

COMPONENT PART

Check the mounting conditions (looseness, backlash) of each component. Verify the component conditions

(wear, damage) are normal.

SHOCK ABSORBER

Check the shock absorber for oil leaks or damage. Replace the components if necessary.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2734 of 3641

RSU-6

< PERIODIC MAINTENANCE >

WHEEL ALIGNMENT

WHEEL ALIGNMENT

InspectionINFOID:0000000012431922

DESCRIPTION

Measure the wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-44, "

Inspection".

3. Wheel bearing axial end play. Refer to RAX-10, "

Wheel Bearing".

4. Shock absorber operation.

5. Each mounting part of suspension for looseness and deformation.

6. Rear suspension beam for cracks, deformation, and other damage.

7. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed. • This type of alignment is recommended for any NISSAN/INFINITI vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be capabl e of accepting any NISSAN/INFINITI vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific al ignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to RSU-15, "Wheel

Alignment (Unladen*1)".

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators may not be correct.

• This may result in an ERROR.

2. Most camera-type alignment machines are equipped with both "Rolling Compensation" method and optional "Jacking Compensation" method to "com pensate" the alignment targets or head units.

"Rolling Compensation" is the preferred method.

• If using the "Rolling Compensation" method, after installing the alignment targets or head units, push or pull on the rear wheel to move the vehicle. Do not push or pull the vehicle body.

• If using the "Jacking Compensation" method, after in stalling the alignment targets or head units, raise

the vehicle and rotate the wheels 1/2 turn both ways.

NOTE:

Do not use the "rolling compensation" if you are using sensor-type alignment equipment.

• Follow all instructions for the alignment machine you're using for more information.

CAMBER INSPECTION

• Measure camber of both right and left wheels with a suitable alignment gauge.

• If it is out of the specificati on value, inspect and replace any damaged or worn rear suspension parts.

Camber : Refer to RSU-15, "

Wheel Alignment

(Unladen*1)".

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2735 of 3641

WHEEL ALIGNMENTRSU-7

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

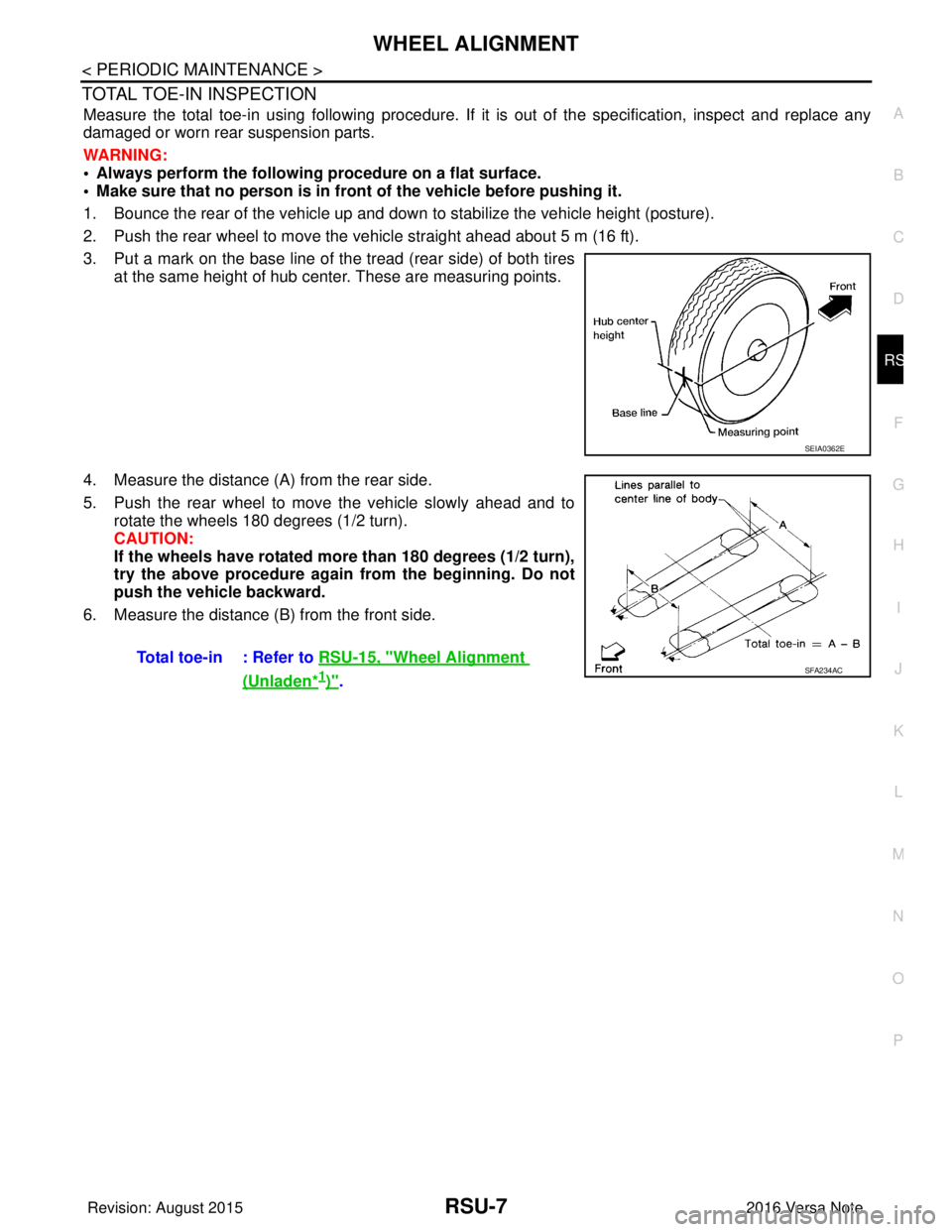

TOTAL TOE-IN INSPECTION

Measure the total toe-in using following procedure. If it is out of the specification, inspect and replace any

damaged or worn rear suspension parts.

WARNING:

• Always perform the following procedure on a flat surface.

• Make sure that no person is in front of the vehicle before pushing it.

1. Bounce the rear of the vehicle up and down to stabilize the vehicle height (posture).

2. Push the rear wheel to move the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on the base line of the tread (rear side) of both tires at the same height of hub center. These are measuring points.

4. Measure the distance (A) from the rear side.

5. Push the rear wheel to move the vehicle slowly ahead and to rotate the wheels 180 degrees (1/2 turn).

CAUTION:

If the wheels have rotated more than 180 degrees (1/2 turn),

try the above procedure again from the beginning. Do not

push the vehicle backward.

6. Measure the distance (B) from the front side.

SEIA0362E

Total toe-in : Refer to RSU-15, "Wheel Alignment

(Unladen*1)".SFA234AC

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2745 of 3641

WT-2

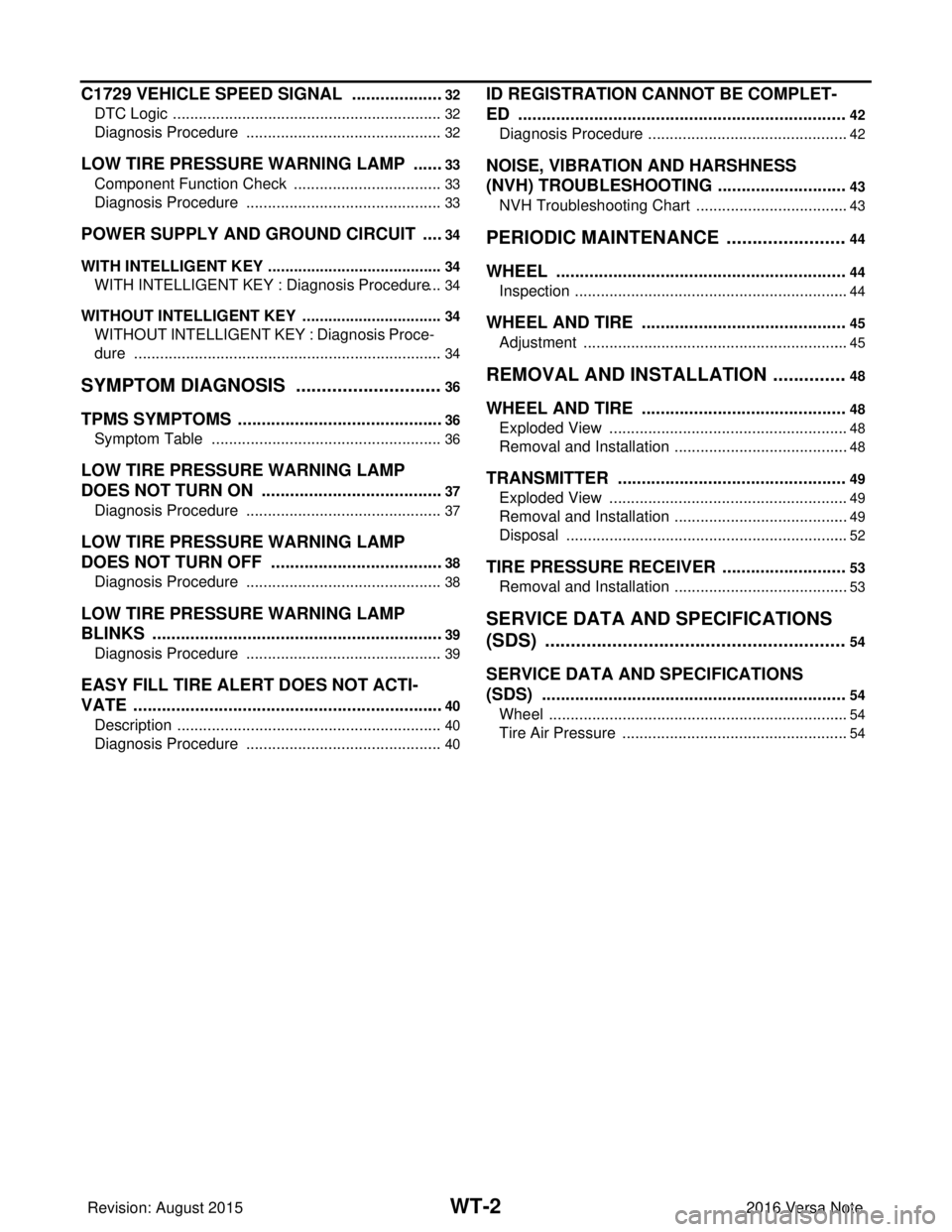

C1729 VEHICLE SPEED SIGNAL ....................32

DTC Logic ............................................................ ...32

Diagnosis Procedure ..............................................32

LOW TIRE PRESSURE WARNING LAMP .......33

Component Function Check ................................ ...33

Diagnosis Procedure ..............................................33

POWER SUPPLY AND GROUND CIRCUIT .....34

WITH INTELLIGENT KEY ...................................... ...34

WITH INTELLIGENT KEY : Diagnosis Procedure ...34

WITHOUT INTELLIGENT KEY .............................. ...34

WITHOUT INTELLIGENT KEY : Diagnosis Proce-

dure ........................................................................

34

SYMPTOM DIAGNOSIS .............................36

TPMS SYMPTOMS ......................................... ...36

Symptom Table ................................................... ...36

LOW TIRE PRESSURE WARNING LAMP

DOES NOT TURN ON .......................................

37

Diagnosis Procedure ..............................................37

LOW TIRE PRESSURE WARNING LAMP

DOES NOT TURN OFF .....................................

38

Diagnosis Procedure ........................................... ...38

LOW TIRE PRESSURE WARNING LAMP

BLINKS ..............................................................

39

Diagnosis Procedure ........................................... ...39

EASY FILL TIRE ALERT DOES NOT ACTI-

VATE ..................................................................

40

Description ........................................................... ...40

Diagnosis Procedure ..............................................40

ID REGISTRATION CANNOT BE COMPLET-

ED ......................................................................

42

Diagnosis Procedure ............................................ ...42

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................

43

NVH Troubleshooting Chart ....................................43

PERIODIC MAINTENANCE .......................44

WHEEL ........................................................... ...44

Inspection ............................................................. ...44

WHEEL AND TIRE ............................................45

Adjustment ........................................................... ...45

REMOVAL AND INSTALLATION ..............48

WHEEL AND TIRE ......................................... ...48

Exploded View ..................................................... ...48

Removal and Installation .........................................48

TRANSMITTER .............................................. ...49

Exploded View ..................................................... ...49

Removal and Installation .........................................49

Disposal ............................................................... ...52

TIRE PRESSURE RECEIVER ...........................53

Removal and Installation .........................................53

SERVICE DATA AND SPECIFICATIONS

(SDS) .......... ................................. ...............

54

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

54

Wheel ................................................................... ...54

Tire Air Pressure .....................................................54

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2746 of 3641

PRECAUTIONSWT-3

< PRECAUTION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432421

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Service Notice and Precautions for TPMSINFOID:0000000012432422

WARNING:

Radio waves could adversely affect electric medical equipment. Those who use a pacemaker should

contact the electric medical equipment manufacturer for the possible influences before use.

• Low tire pressure warning lamp blinks for 1 minute, then turns ON when occurring any malfunction except low tire pressure. Erase the self-diagnosis memories fo r Tire Pressure Monitoring System (TPMS), or regis-

ter the ID to turn low tire pressure warning lamp OFF. For ID registration, refer to WT-22, "

Work Procedure".

• ID registration is required when replacing or rotating wheels, replacing tire pressure sensor or BCM. Refer to WT-22, "

Work Procedure".

• Replace grommet seal, valve core and valve cap of tire pressure sensor in TPMS, when replacing each tire by reaching the wear limit. Refer to WT-49, "

Removal and Installation".

• Because the tire pressure sensor conforms to North America radio law, the following items must be

observed.

- The sensor may be used only in North America.

- It may not be used in any method other than the specified method.

- It must not be disassembled or modified.

Service Notice and Pr ecautions for Road WheelINFOID:0000000012432423

• Genuine NISSAN aluminum wheel is designed for each type of vehicle. Use it on the specified vehicle only.

• Use Genuine NISSAN parts for the road wheels, valve caps and wheel nuts.

• Always use them after adjusting the wheel balance. For the balance weights, use Genuine NISSAN alumi-

num wheel weights.

• Use caution when handling the aluminum wheels, because they can be easily scratched. When removing

dirt, do not use any abrasives, a wire brush, or other items that may scratch the coating. Use a neutral deter-

gent if a detergent is needed.

• After driving on roads scattered with anti-icing salts, wash off the wheels completely.

• When installing road wheels onto the vehicle, always wipe off any dirt or foreign substances to prevent them

from being trapped between the contact surfaces of wheel.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2787 of 3641

WT-44

< PERIODIC MAINTENANCE >

WHEEL

PERIODIC MAINTENANCE

WHEEL

InspectionINFOID:0000000012432465

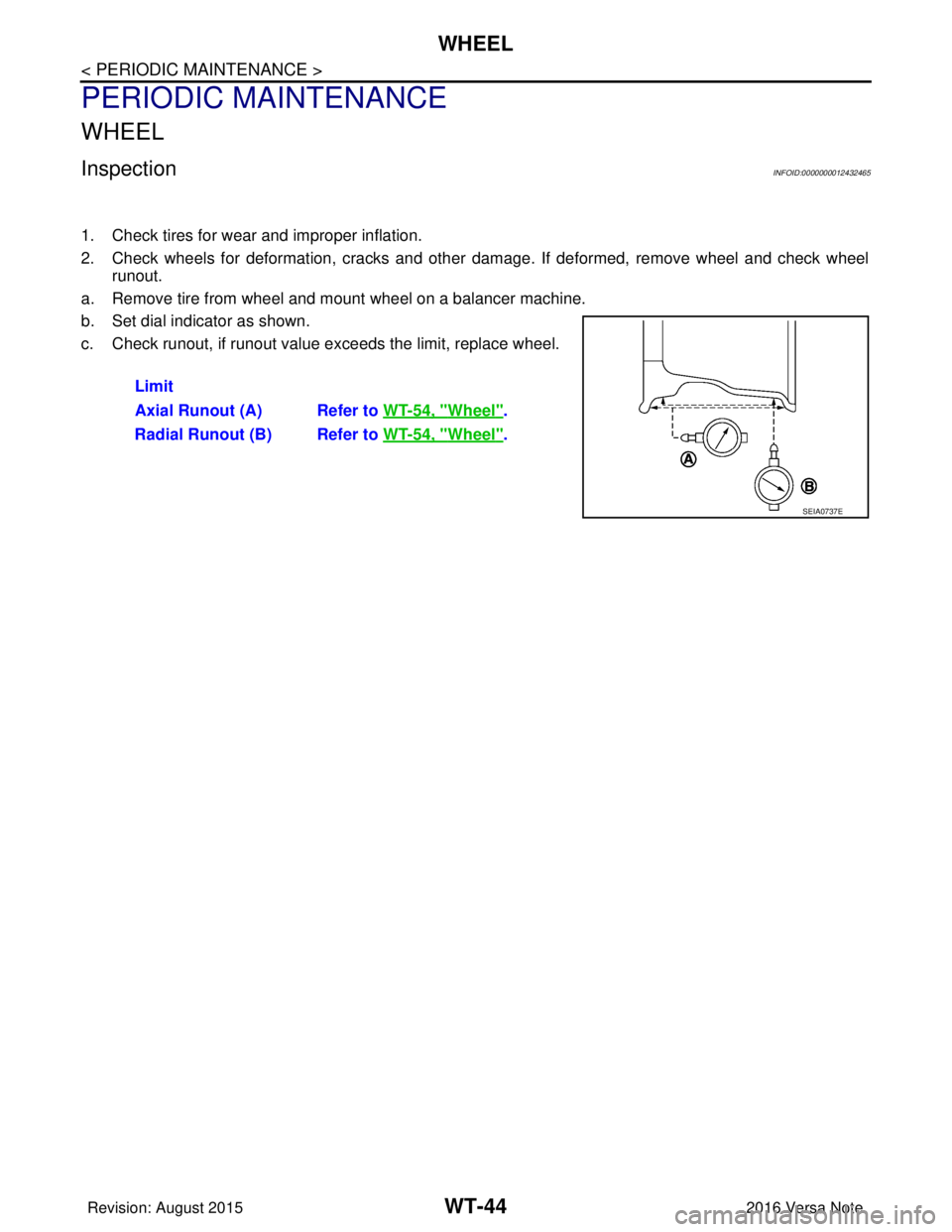

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheel

runout.

a. Remove tire from wheel and mount wheel on a balancer machine.

b. Set dial indicator as shown.

c. Check runout, if runout value exceeds the limit, replace wheel.

Limit

Axial Runout (A) Refer to WT-54, "

Wheel".

Radial Runout (B) Refer to WT-54, "

Wheel".

SEIA0737E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2788 of 3641

WHEEL AND TIREWT-45

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

WHEEL AND TIRE

AdjustmentINFOID:0000000012432466

BALANCING WHEELS (ADH ESIVE WEIGHT TYPE)

Preparation Before Adjustment

Remove inner and outer balance weights from the wheel and tire. Using releasing agent, remove double-faced

adhesive tape from the wheel and tire.

CAUTION:

• Be careful not to scratch the wheel and tire during removal.

• After removing double-faced ad hesive tape, wipe clean all traces of releasing agent from the wheel

and tire.

Wheel Balance Adjustment

CAUTION:

• DO NOT use center hole cone-type clamping machin es to hold the wheel during tire removal/installa-

tion or balancing or damage to the wheel paint, cl adding or chrome may result. Use only rim-type or

universal lug-type clamping machines to hold the wheel during servicing.

• If a balancer machine has an adhesive weight mode setting, select the adhesive weight mode setting and

skip Step 2 below. If a balancer machine only has the clip-on (rim flange) weight mode setting, follow Step 2

to calculate the correct size adhesive weight.

1. Set wheel and tire on balancer machine using the center hole as a guide. Start the balancer machine.

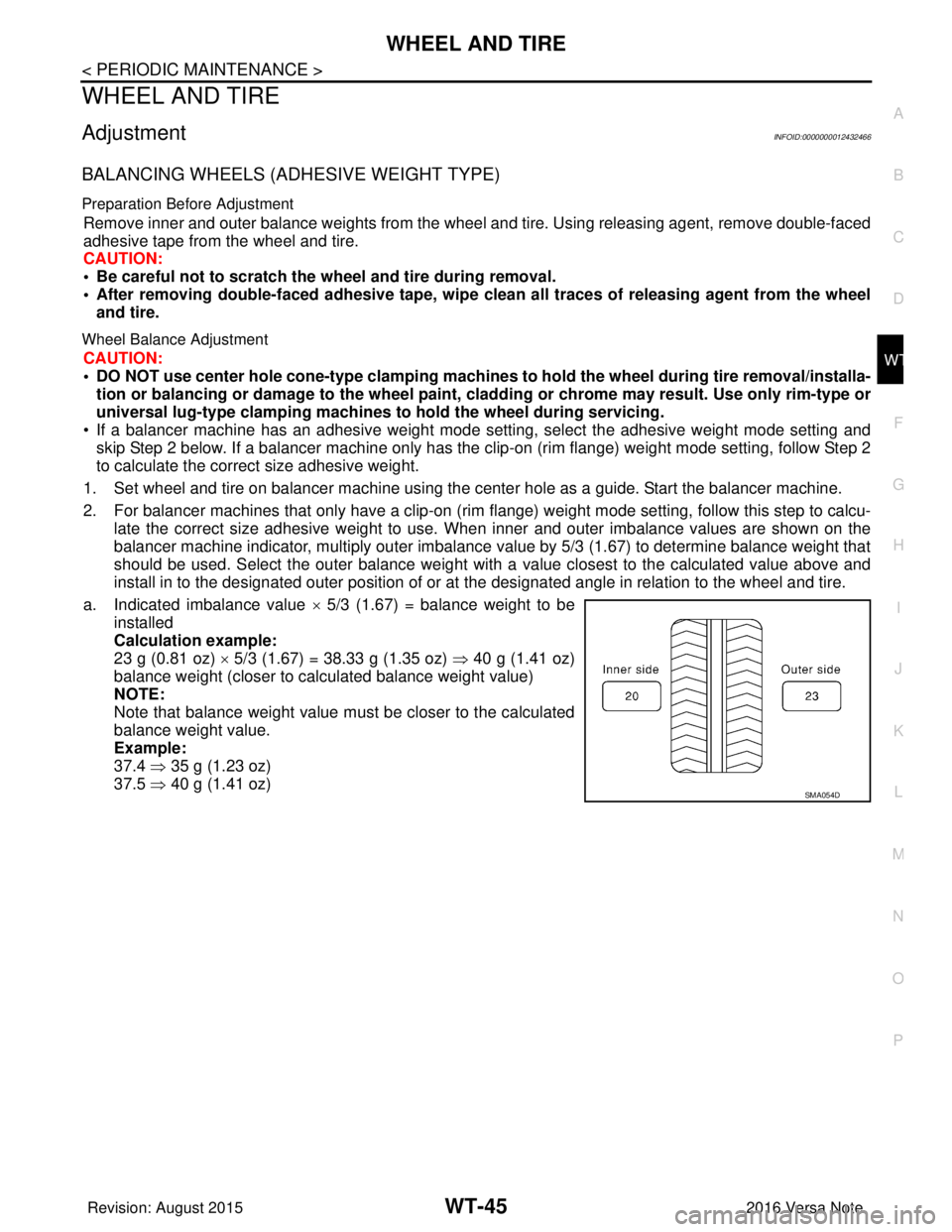

2. For balancer machines that only have a clip-on (rim fl ange) weight mode setting, follow this step to calcu-

late the correct size adhesive weight to use. W hen inner and outer imbalance values are shown on the

balancer machine indicator, multiply outer imbalance value by 5/3 (1.67) to determine balance weight that

should be used. Select the outer balance weight with a value closest to the calculated value above and

install in to the designated outer position of or at the designated angle in relation to the wheel and tire.

a. Indicated imbalance value × 5/3 (1.67) = balance weight to be

installed

Calculation example:

23 g (0.81 oz) × 5/3 (1.67) = 38.33 g (1.35 oz) ⇒ 40 g (1.41 oz)

balance weight (closer to calculated balance weight value)

NOTE:

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

37.4 ⇒ 35 g (1.23 oz)

37.5 ⇒ 40 g (1.41 oz)

SMA054D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2789 of 3641

WT-46

< PERIODIC MAINTENANCE >

WHEEL AND TIRE

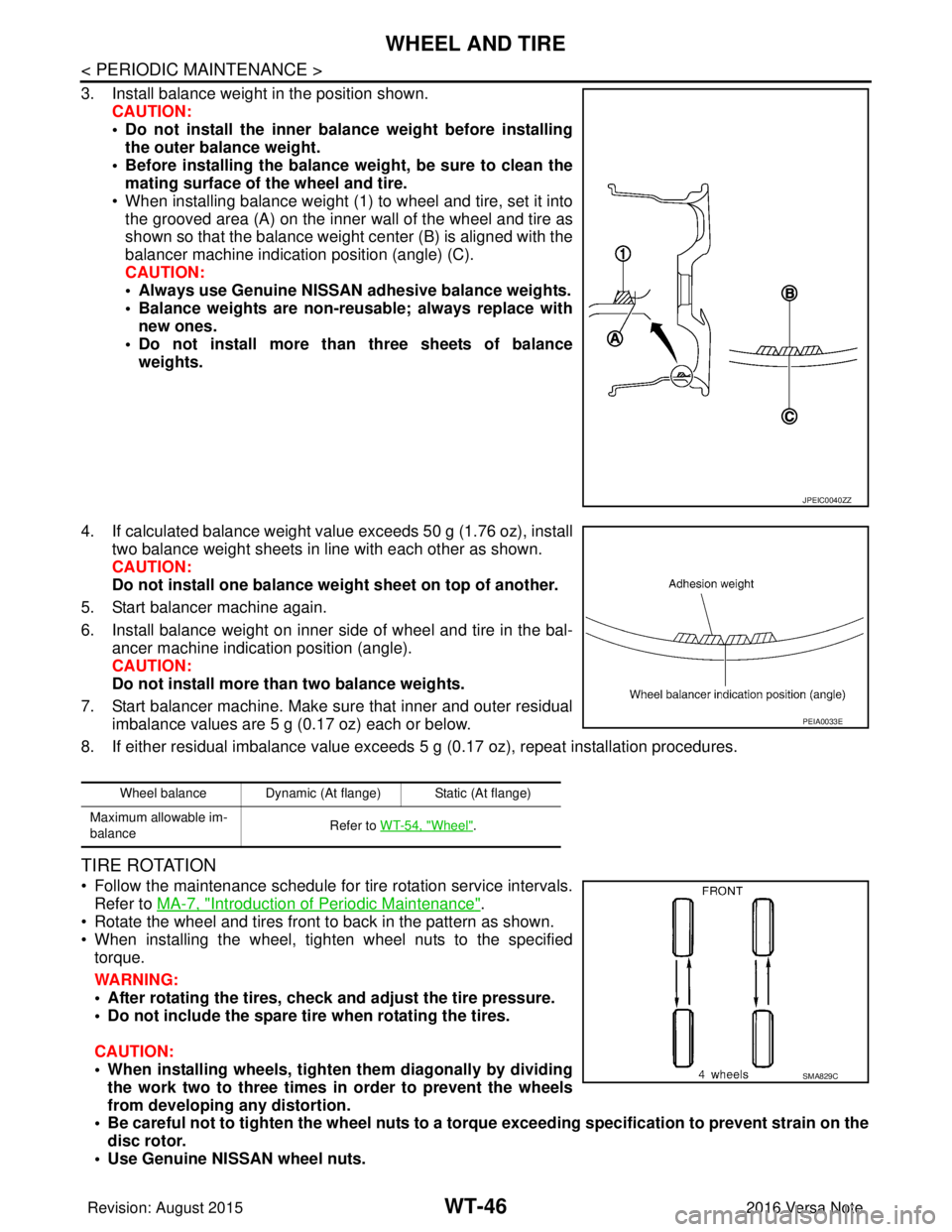

3. Install balance weight in the position shown.CAUTION:

• Do not install the inner bala nce weight before installing

the outer balance weight.

• Before installing the balance weight, be sure to clean the mating surface of the wheel and tire.

• When installing balance weight (1) to wheel and tire, set it into the grooved area (A) on the inner wall of the wheel and tire as

shown so that the balance weight center (B) is aligned with the

balancer machine indication position (angle) (C).

CAUTION:

• Always use Genuine NISSAN adhesive balance weights.

• Balance weights are non-reusable; always replace withnew ones.

• Do not install more than three sheets of balance weights.

4. If calculated balance weight value exceeds 50 g (1.76 oz), install two balance weight sheets in line with each other as shown.

CAUTION:

Do not install one balance weight sheet on top of another.

5. Start balancer machine again.

6. Install balance weight on inner side of wheel and tire in the bal- ancer machine indication position (angle).

CAUTION:

Do not install more than two balance weights.

7. Start balancer machine. Make sure that inner and outer residual imbalance values are 5 g (0.17 oz) each or below.

8. If either residual imbalance value exceeds 5 g (0.17 oz), repeat installation procedures.

TIRE ROTATION

• Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-7, "

Introduction of Periodic Maintenance".

• Rotate the wheel and tires front to back in the pattern as shown.

• When installing the wheel, tighten wheel nuts to the specified torque.

WARNING:

• After rotating the tires, check and adjust the tire pressure.

• Do not include the spare tire when rotating the tires.

CAUTION:

• When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten the wh eel nuts to a torque exceeding speci fication to prevent strain on the

disc rotor.

• Use Genuine NISSAN wheel nuts.

JPEIC0040ZZ

Wheel balance Dynamic (At flange) Static (At flange)

Maximum allowable im-

balance Refer to WT-54, "

Wheel".

PEIA0033E

SMA829C

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2790 of 3641

WHEEL AND TIREWT-47

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

• Perform the ID registration after tire rotation. Refer to WT-22, "Work Procedure".

Wheel nut tightening

torque

:

WT-48, "

Exploded View"

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2799 of 3641

SB-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430695

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for Seat Belt ServiceINFOID:0000000012430696

CAUTION:

• Before removing the seat belt pre-tensioner assembl y, turn the ignition switch OFF, disconnect both

battery terminals and wait at least three minutes. For approximately three minutes after the battery

terminals have been removed, it is still possible for the air bag and seat belt pre-tensioner to deploy.

Therefore, do not attempt work on any SRS connectors or wires until at least three minutes have

passed.

• After replacing or reinstalling seat belt pre -tensioner assembly or reconnecting seat belt pre-ten-

sioner assembly connector, make sure entire SRS operates properly. Refer to SRC-14, "

Description".

• Do not disassemble buckle or seat belt assembly.

• Replace anchor bolts if th ey are deformed or worn out.

• Do not oil tongue or buckle.

• If any component of seat belt assembly is questionable, do not re pair. Replace the whole seat belt

assembly.

• If webbing is cut, frayed or damaged, replace seat belt assembly.

• When replacing seat belt assembly, use a genuine NISSAN seat belt assembly.

Precaution for WorkINFOID:0000000012430697

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

Revision: August 2015 2016 Versa Note

cardiagn.com