star stop NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 3219 of 3641

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIATION)

STC-35

< SYMPTOM DIAGNOSIS >

C

D E

F

H I

J

K L

M A

B

STC

N

O P

UNBALANCE STEERING WHEEL TU RNING FORCE (TORQUE VARIA-

TION)

DescriptionINFOID:0000000012431981

Unbalance steering wheel turning force (torque variation).

Diagnosis ProcedureINFOID:0000000012431982

1.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform “Self Diagnostic Result” of “EPS”.

Is any DTC detected?

YES >> Check the DTC. Refer to STC-10, "DTC Index".

NO >> GO TO 2.

2.CHECK THE ILLUMINATION OF THE EPS WARNING LAMP

Check the EPS warning lamp while the engine is started.

Does the EPS warning lamp turn OFF?

YES >> GO TO 3.

NO >> Refer to STC-29, "

Diagnosis Procedure".

3.CHECK STEERING COLU MN AND STEERING GEAR

Check the steering column assembly and steering gear assembly.

• Steering column assembly. Refer to ST-9, "

Exploded View".

• Steering gear assembly. Refer to ST-14, "

Exploded View".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace the specific malfunctioning part.

4.CHECK EPS CONTROL UNIT SIGNAL (1)

With CONSULT

1. Start the engine. CAUTION:

Never drive the vehicle.

2. Turn steering wheel from full left stop to full right stop.

3. Select “ASSIST LEVEL” in “Data Monitor” of “EPS”.

Does the item in

“Data Monitor” maintain “100%”?

YES >> GO TO 7.

NO >> GO TO 5.

5.CHECK EPS CONTROL UNIT SIGNAL (2)

With CONSULT

Select “BATTERY VOLT” in “Data Monitor” of “EPS”.

Does the item in

“Data Monitor” indicate 10 V or more?

YES >> GO TO 6.

NO >> Perform trouble diagnosis of EPS control unit power supply and ground. Refer to STC-18, "

Diag-

nosis Procedure".

6.CHECK EPS CONTROL UNIT SIGNAL (3)

With CONSULT

1. Select “ASSIST LEVEL” in “Data Monitor” of “EPS”.

2. Stop the EPS system until the item in “Data Monitor” becomes “100%”. NOTE:

While stopping the EPS system, do not turn steering wheel.

3. Check that the symptom continues.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3220 of 3641

STC-36

< SYMPTOM DIAGNOSIS >

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIATION)

Does the symptom continue?

YES >> GO TO 7.

NO >> The assist torque decreases because of protection function. This is not malfunction. Inspection

End.

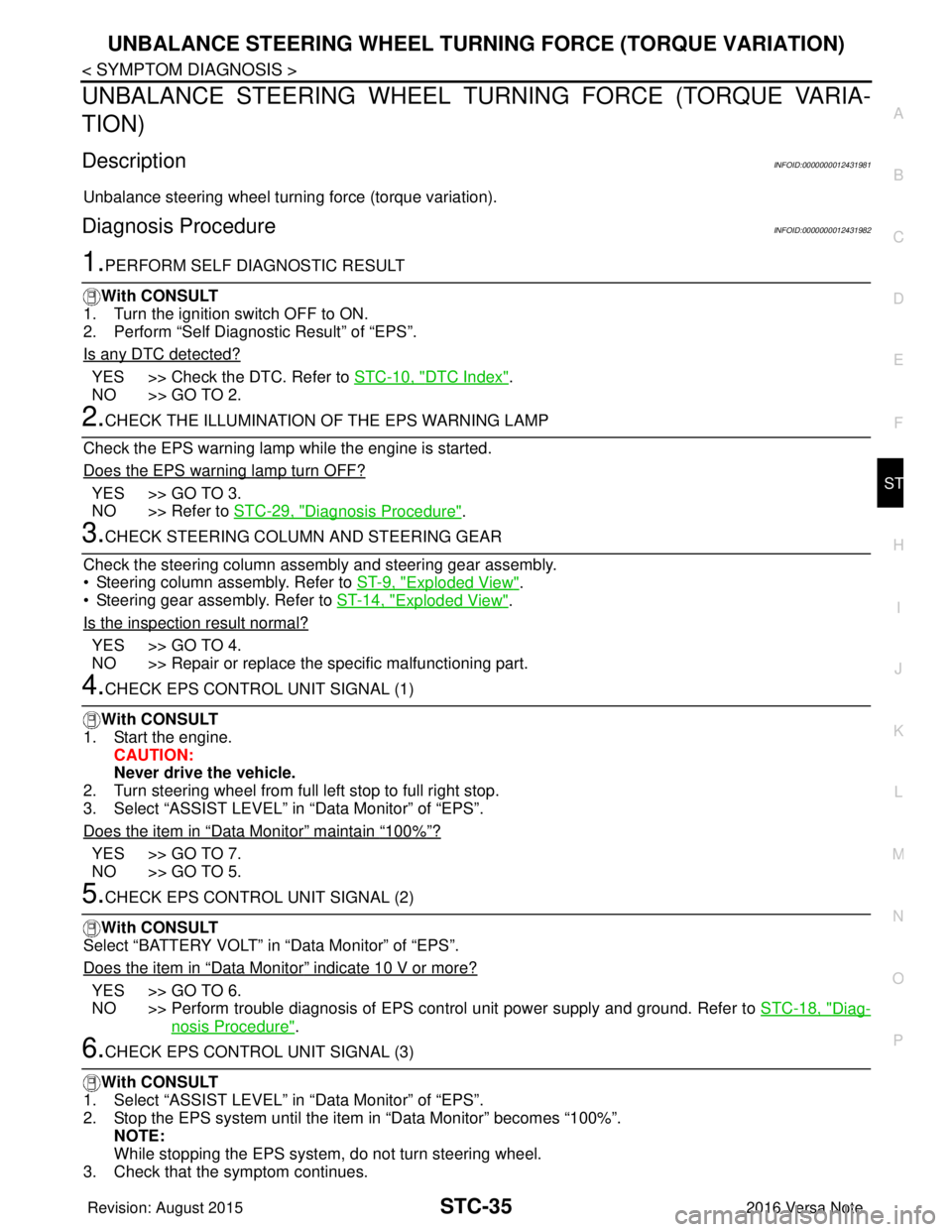

7.CHECK EPS CONTROL UNIT SIGNAL (4)

With CONSULT

1. Start the engine.

CAUTION:

Never drive the vehicle.

2. Turn steering wheel from full left stop to full right stop.

3. Select “TORQUE SENSOR” in “Data Monitor” of “EPS”.

4. Perform the torque sensor inspection.

Is the inspection result normal?

YES >> GO TO 9.

NO >> GO TO 8.

8.CHECK EPS MOTOR

Perform the trouble diagnosis of EPS motor. Refer to STC-23, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair or replace the specific malfunctioning part.

9.CHECK STEERING WHEEL TURNING FORCE

Check the steering wheel turning force. Refer to ST-19, "

Steering Wheel Turning Force".

Is the inspection result normal?

YES >> Inspection End.

NO >> Check the steering wheel turning force for mechanical malfunction. Refer to ST-19, "

Steering

Wheel Turning Force".

Monitor item ConditionDisplay value

TORQUE SENSOR Steering wheel: Not steering (There is no

steering force)

Approx. 0 Nm

Steering wheel: Right turn Positive value (Nm)

Steering wheel: Left turn Negative value (Nm)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3258 of 3641

![NISSAN NOTE 2016 Service Repair Manual GEAR OILTM-17

< PERIODIC MAINTENANCE > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

PERIODIC MAINTENANCE

GEAR OIL

InspectionINFOID:0000000012430947

GEAR OIL LEAKS

Make sure that gear oil is not l ea NISSAN NOTE 2016 Service Repair Manual GEAR OILTM-17

< PERIODIC MAINTENANCE > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

PERIODIC MAINTENANCE

GEAR OIL

InspectionINFOID:0000000012430947

GEAR OIL LEAKS

Make sure that gear oil is not l ea](/img/5/57363/w960_57363-3257.png)

GEAR OILTM-17

< PERIODIC MAINTENANCE > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

PERIODIC MAINTENANCE

GEAR OIL

InspectionINFOID:0000000012430947

GEAR OIL LEAKS

Make sure that gear oil is not l eaking from transaxle or around it.

GEAR OIL LEVEL

1. Remove filler plug (1) and gasket from transaxle case.

2. Check the gear oil level from filler plug hole as shown.

CAUTION:

Do not start engine whil e checking gear oil level.

3. Install a new gasket on filler plug and then install filler plug to transaxle case.

CAUTION:

Do not reuse gasket.

4. Tighten filler plug to the specified torque. Refer to TM-26,

"Exploded View".

DrainingINFOID:0000000012430948

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and gasket, using suitable

tool and then drain gear oil.

3. Install a new gasket on drain plug (1) and install drain plug to clutch housing, using suitable tool.

CAUTION:

Do not reuse gasket.

4. Tighten drain plug (1) to the specified torque. Refer to TM-26,

"Exploded View".

RefillingINFOID:0000000012430949

1. Remove filler plug (1) and gasket from transaxle case.

2. Fill with new gear oil until gear oil level reaches the specified limit at filler plug hole as shown.

CAUTION:

Do not start engine whil e checking gear oil level.

3. Install a new gasket on filler plug and then install filler plug to transaxle case.

CAUTION:

Do not reuse gasket.

4. Tighten filler plug to the specified torque. Refer to TM-26, "

Exploded View".

SCIA7119E

PCIB1504E

Oil capacity

and viscosity: Refer to

MA-11, "Fluids and Lubri-

cants".

SCIA7119E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3266 of 3641

![NISSAN NOTE 2016 Service Repair Manual TRANSAXLE ASSEMBLYTM-25

< UNIT REMOVAL AND INSTALLATION > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

• Do not reuse self-tapping bolt.

• Tighten transaxle assembly bolts to the specified torqu NISSAN NOTE 2016 Service Repair Manual TRANSAXLE ASSEMBLYTM-25

< UNIT REMOVAL AND INSTALLATION > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

• Do not reuse self-tapping bolt.

• Tighten transaxle assembly bolts to the specified torqu](/img/5/57363/w960_57363-3265.png)

TRANSAXLE ASSEMBLYTM-25

< UNIT REMOVAL AND INSTALLATION > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

• Do not reuse self-tapping bolt.

• Tighten transaxle assembly bolts to the specified torque. The illus- tration is the view from the engine.

InspectionINFOID:0000000012430963

INSPECTION AFTER INSTALLATION

• Check the operation of the control linkage. Refer to TM-21, "Inspection".

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leaks.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leaks at connection points.

• Start engine. With engine speed increased, check again for fuel leaks at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no lea ks of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec-

ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

Bolt symbol

ABC D

Insertion direction Transaxle to

engine Engine to transaxle

Quantity 2321

Bolt length

() mm (in) 55 (2.17)

49 (1.93) 69 (2.72)

Tightening torque

N·m (kg-m, ft-lb) 48.0 (4.9, 35)

JPDIC0813ZZ

Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeaks Level

Engine oil LevelLeaks Level

Transmission/

transaxle fluid CVT Models

LeaksLevel/Leaks Leaks

M/T Models Level/Leaks LeaksLevel/Leaks

Other oils and fluids* LevelLeaks Level

Fuel LeaksLeaks Leaks

Exhaust gas —Leaks —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3325 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-84

< SYSTEM DESCRIPTION >[CVT: RE0F11A]

SYSTEM

Gear shifting is performed in all shifting ranges from the lowest to the

highest gear ratio.

D Position (OD OFF)

The gear ratio is generally high by NISSAN NOTE 2016 Service Repair Manual TM-84

< SYSTEM DESCRIPTION >[CVT: RE0F11A]

SYSTEM

Gear shifting is performed in all shifting ranges from the lowest to the

highest gear ratio.

D Position (OD OFF)

The gear ratio is generally high by](/img/5/57363/w960_57363-3324.png)

TM-84

< SYSTEM DESCRIPTION >[CVT: RE0F11A]

SYSTEM

Gear shifting is performed in all shifting ranges from the lowest to the

highest gear ratio.

D Position (OD OFF)

The gear ratio is generally high by limiting the shifting range on the

high side, and this always generates a large driving power.

L Position

By limiting the shifting range only to the lowest of the gear ratio, a

large driving force and engine brake are obtained.

Hill Climbing And Descending Control

If a downhill is detected with the accelerator pedal is released, the system performs dow

nshift to increase the

engine brake force so that vehicle may not be accelerated more than necessary. If a climbing hill is detected,

the system improves the acceleration performance in re-acceleration by limiting the gear shift range on the

high side.

NOTE:

For engine brake control on a downhill, the control can be stopped with CONSULT.

Control In Acceleration

From change of the vehicle speed or accelerator pedal posit ion, the acceleration request level of the driver or

driving scene is evaluated. In start or acceleration during driving, the gear shift characteristics with linearity of

revolution increase and vehicle speed increase are gained to improve the acceleration feel.

SELECT CONTROL

SCIA1953E

SCIA8229E

SCIA8240E

JSDIA2060GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3329 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-88

< SYSTEM DESCRIPTION >[CVT: RE0F11A]

SYSTEM

Provides idle neutral control when st

op/start operation is not performed.

Idle Neutral Control Start Condition

Idle neutral control is started when NISSAN NOTE 2016 Service Repair Manual TM-88

< SYSTEM DESCRIPTION >[CVT: RE0F11A]

SYSTEM

Provides idle neutral control when st

op/start operation is not performed.

Idle Neutral Control Start Condition

Idle neutral control is started when](/img/5/57363/w960_57363-3328.png)

TM-88

< SYSTEM DESCRIPTION >[CVT: RE0F11A]

SYSTEM

Provides idle neutral control when st

op/start operation is not performed.

Idle Neutral Control Start Condition

Idle neutral control is started when all of the following conditions are fulfilled. However, during idle neutral con-

trol, idle neutral control is stopped when any of the following conditions is not met or idle neutral control contin-

ues 30 seconds.

NOTE:

Stops or prohibits the idle neutral control when the TC M and ECM detect that the vehicle is in one of the fol-

lowing conditions.

• Engine coolant temperature and CVT fluid temperature are the specified temperature or more, or the speci-

fied temperature or less.

• When a transaxle malfunction occurs.

• When the vehicle detects DTC and is in the fail-safe mode.

• When idle speed increases due to heavy electric load*. *: When any one of rear window defogger switch, A/C s witch, headlamp, fog lamp is turned ON. In addition,

when the steering wheel is operated.

JPDIA1215GB

Driving environment : Flat road or road with mild gradient

Selector lever position : “D” position

Vehicle speed : 0 km/h (0 MPH)

Accelerator pedal position : 0.0/8

Brake pedal : Depressed

Engine speed : Idle speed

Turn signal lamp/hazard signal lamp : Not activated

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3341 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-100

< ECU DIAGNOSIS INFORMATION >[CVT: RE0F11A]

TCM

TOTAL GEAR RATIOAuxiliary gearbox: 1GR

Counter gear ratio

×Pulley ratio Auxiliary

gearbox gear ratio

Auxiliary gearbox: 2GR Counter gear rati NISSAN NOTE 2016 Service Repair Manual TM-100

< ECU DIAGNOSIS INFORMATION >[CVT: RE0F11A]

TCM

TOTAL GEAR RATIOAuxiliary gearbox: 1GR

Counter gear ratio

×Pulley ratio Auxiliary

gearbox gear ratio

Auxiliary gearbox: 2GR Counter gear rati](/img/5/57363/w960_57363-3340.png)

TM-100

< ECU DIAGNOSIS INFORMATION >[CVT: RE0F11A]

TCM

TOTAL GEAR RATIOAuxiliary gearbox: 1GR

Counter gear ratio

×Pulley ratio Auxiliary

gearbox gear ratio

Auxiliary gearbox: 2GR Counter gear ratio ×Pulley ratio

PULLEY GEAR RATIO In driving (forward)

2.20 − 0.55

In driving (reverse) 2.20

AUX GEARBOX Vehicle started with selector lever in “L” position

1st

Release the accelerator pedal after the follow-

ing conditions are satisfied

• Selector lever: “D” position

• Accelerator pedal position: 1/8 or less

• Vehicle speed: 50 km/h (31 MPH) or more 2nd

In gear shifting of auxiliary gearbox 1st ⇔ 2nd

G SPEED Vehicle stopped

0.00 G

During acceleration The value changes to the positive side

along with acceleration.

During deceleration The value changes to the positive side

along with deceleration.

ACCEL POSI SEN 1 Accelerator pedal released

0.00 deg

Accelerator pedal fully depressed 80.00 deg

VENG TRQ While driving The value changes along with acceleration/

deceleration.

PRI TRQ While driving The value changes along with acceleration/

deceleration.

TRQ RTO While driving The value changes along with acceleration/

deceleration.

LINE PRESSURE Selector lever: “P” position 0.575 MPa

FLUID TEMP Ignition switch ON. Displays the CVT fluid temperature.

DSR REV While driving It varies along with the driving condition.

TRGT GEAR RATIO While driving It varies along with the driving condition.

TGT PLLY GR RATIO In driving (forward)

2.20 − 0.55

In driving (reverse) 2.20

TRGT AUX GEARBOX Vehicle started with selector lever in “L” position

1st

Release the accelerator pedal after the follow-

ing conditions are satisfied

• Selector lever: “D” position

• Accelerator pedal position: 1/8 or less

• Vehicle speed: 50 km/h (31 MPH) or more 2nd

In gear shifting of auxiliary gearbox Display gear position after gear shifting

LU PRS • Engine started

• Vehicle is stopped.

−

0.500 MPa

• Selector lever: “D” position

• Accelerator pedal position: 1/8 or less

• Vehicle speed: 20 km/h (12 MPH) or more 0.450 MPa

LINE PRS • After engine warm up

• Selector lever: “N” position

•At idle

0.500 MPa

• After engine warming up

• Selector lever: “D” position

• Depress the accelerator pedal fully 4.930 – 5.430 MPa

TRGT PRI PRESSURE • Selector lever: “L” position

• Vehicle speed: 20 km/h (12 MPH) 0.325 MPa

Monitor item

ConditionValue/Status (Approx.)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3346 of 3641

![NISSAN NOTE 2016 Service Repair Manual TCM

TM-105

< ECU DIAGNOSIS INFORMATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P37

(BR/W) GroundHigh clutch & re-

verse brake sole-

noid valve OutputIn driving at “L” position

Release the NISSAN NOTE 2016 Service Repair Manual TCM

TM-105

< ECU DIAGNOSIS INFORMATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P37

(BR/W) GroundHigh clutch & re-

verse brake sole-

noid valve OutputIn driving at “L” position

Release the](/img/5/57363/w960_57363-3345.png)

TCM

TM-105

< ECU DIAGNOSIS INFORMATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P37

(BR/W) GroundHigh clutch & re-

verse brake sole-

noid valve OutputIn driving at “L” position

Release the accelerator pedal after

the following conditions are satisfied

• Selector lever: “D” position

• Accelerator pedal position: 1/8 or

less

• Vehicle speed: 50 km/h (31 MPH) or more

38

(G) Ground Torque converter

clutch solenoid

valve Output• Selector lever: “D” position

• Accelerator pedal position: 1/8 or

less

• Vehicle speed: 20 km/h (12 MPH) or more

• Engine started

• Vehicle is stopped

39

(G/B) Ground

Low brake solenoid

valve Output• Selector lever: “L” position

• Vehicle speed: 20 km/h (12 MPH)

Release the accelerator pedal after

the following conditions are satisfied

• Selector lever: “D” position

• Accelerator pedal position: 1/8 or

less

• Vehicle speed: 50 km/h (31 MPH) or more

Te r m i n a l N o .

(Wire color) Description

ConditionValue (Approx.)

+ − Signal Input/

OutputJSDIA1897GB

JSDIA3653GB

JSDIA1900GB

JSDIA1901GB

JSDIA1902GB

JSDIA1903GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3368 of 3641

![NISSAN NOTE 2016 Service Repair Manual ADDITIONAL SERVICE WHEN REPLACING CONTROL VALVE OR TRANSAXLE

ASSEMBLY

TM-127

< BASIC INSPECTION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

ADDITIONAL SERVICE WHEN REPL ACING CONTROL VALVE OR TR NISSAN NOTE 2016 Service Repair Manual ADDITIONAL SERVICE WHEN REPLACING CONTROL VALVE OR TRANSAXLE

ASSEMBLY

TM-127

< BASIC INSPECTION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

ADDITIONAL SERVICE WHEN REPL ACING CONTROL VALVE OR TR](/img/5/57363/w960_57363-3367.png)

ADDITIONAL SERVICE WHEN REPLACING CONTROL VALVE OR TRANSAXLE

ASSEMBLY

TM-127

< BASIC INSPECTION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

ADDITIONAL SERVICE WHEN REPL ACING CONTROL VALVE OR TRAN-

SAXLE ASSEMBLY

DescriptionINFOID:0000000012431044

When replacing the control valve or transaxle assembly , perform the following work. For work procedure, refer

to TM-130, "

Work Procedure".

ERASING, LOADING AND STORING OF CALIBRATION DATA• The TCM acquires calibration data (individual characteristic value) of each solenoid that is stored in the

ROM assembly (in the control valve). This enables the TCM to perform accurate control. For this reason,

after the control valve or transaxle assembly is replaced, it is necessary to erase the calibration data previ-

ously stored in TCM, to load new calibration data, and to store them.

ERASING THE LEARNED VALUE DATA• TCM learns indicated pressure for appropriate control of the transaxle assembly and records the learned

values. For this reason, the leaned values stored in TCM must be erased after replacing a transaxle assem-

bly.

ERASING CVT FLUID DEGR ADATION LEVEL DATA • TCM records the degradation level of the CVT fluid calculated from the vehicle driving status. Therefore, if

the transaxle assembly is replaced, it is necessary to erase the CVT fluid degradation level data recorded by

TCM.

Work ProcedureINFOID:0000000012431045

1.INITIALIZE TCM

With CONSULT

1. Set parking brake.

2. Turn ignition switch ON.

3. Select “Work Support” in “TRANSMISSION”.

4. Select “ERASE MEMORY DATA”.

5. While maintaining the conditions below, touch “Start”.

- Vehicle stop status

- With engine stopped

- Selector lever: “R” position

- Accelerator pedal: Depressed

NOTE:

Select “Start” and complete within approximately 20 seconds.

Is

“COMPLETED” displayed?

YES >> GO TO 2.

NO >> Turn the ignition switch OFF and wait for a minimum of 10 seconds then perform the work again.

2.CHECK AFTER TCM IS INITIALIZED

With CONSULT

1. Turn ignition switch OFF with the selector lever in “R” position and wait for 10 seconds or more.

2. Turn ignition switch ON with the selector lever in “R” position. CAUTION:

Never start the engine.

3. Select “Special function” in “TRANSMISSION”.

4. Select “CALIB DATA”.

5. Check that indicated value of “CALIB DATA” is equal to the value shown in the following table.

Item name Display value Item nameDisplay value

UNIT CLB ID1 00MAP NO HC/RB 00

UNIT CLB ID2 00MAP NO L/B 00

UNIT CLB ID3 00OFFSET2 LU 0

UNIT CLB ID4 00OFFSET2 PL 0

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3373 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-132

< BASIC INSPECTION >[CVT: RE0F11A]

LINE PRESSURE TEST

LINE PRESSURE TEST

Work ProcedureINFOID:0000000012431049

INSPECTION

1. Check the engine oil level. Replenish if necessary. Refer to

LU-7, NISSAN NOTE 2016 Service Repair Manual TM-132

< BASIC INSPECTION >[CVT: RE0F11A]

LINE PRESSURE TEST

LINE PRESSURE TEST

Work ProcedureINFOID:0000000012431049

INSPECTION

1. Check the engine oil level. Replenish if necessary. Refer to

LU-7,](/img/5/57363/w960_57363-3372.png)

TM-132

< BASIC INSPECTION >[CVT: RE0F11A]

LINE PRESSURE TEST

LINE PRESSURE TEST

Work ProcedureINFOID:0000000012431049

INSPECTION

1. Check the engine oil level. Replenish if necessary. Refer to

LU-7, "Inspection".

2. Check for CVT fluid leaks. Refer to TM-228, "

Inspection".

3. Drive for about 10 minutes to warm up the vehicle so that the CVT fluid temperature is 50 to 80°C (122 to

176° F).

4. Stop the vehicle, apply the parking brake and block the tires.

5. Start the engine.

6. Select “Data Monitor” in “TRANSMISSION”.

7. Select “LINE PRESSURE”.

8. Measure the line pressure at both idle and the stall speed. CAUTION:

Keep brake pedal pressed all the way down during measurement.

NARROWING-DOWN MALFUNCTIONING PARTS

Line pressure : TM-265, "Line Pressure"

Judgment Possible cause

Idle speed Low for all positions

(“P”, “R”, “N”, “D”, “L”)

Possible causes include malfunctions in the pressure supply system and low oil pump output.

For example:

• Oil pump wear

• Damage of chain and sprocket

• Pressure regulator valve or plug sticking or spring fatigue

• Oil strainer

⇒ oil pump ⇒ pressure regulator valve passage oil leak

• Engine idle speed too low

Only low for a specific

position Possible causes include an oil pressure leak in a passage or device related to the position after

the pressure is distributed by the manual valve.

High Possible causes include a sensor malfunction or malfunction in the line pressure adjustment

function.

For example:

• Accelerator pedal position signal malfunction

• CVT fluid temperature sensor malfunction

• Line pressure solenoid malfunction (sticking in OFF state, filter clog, cut line)

• Pressure regulator valve or plug sticking

Stal l s pe ed Line pressure does not

rise higher than the line

pressure for idle.

Possible causes include a sensor malfunction or malfunction in the pressure adjustment func-

tion.

For example:

•TCM malfunction

• Line pressure solenoid malfunction (shorting, sticking in ON state)

• Pressure regulator valve or plug sticking

The pressure rises, but

does not enter the

standard position. Possible causes include malfunctions in the pressure supply system and malfunction in the pres-

sure adjustment function.

For example:

• Oil pump wear

• Line pressure solenoid malfunction (sticking, filter clog)

• Pressure regulator valve or plug sticking

Only low for a specific

position Possible causes include an oil pressure leak in a passage or device related to the position after

the pressure is distributed by the manual valve.

Revision: August 2015

2016 Versa Note

cardiagn.com