star stop NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 3470 of 3641

![NISSAN NOTE 2016 Service Repair Manual CVT FLUIDTM-229

< PERIODIC MAINTENANCE > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Hold the lever at each position for 5 seconds.

13. Check that the CONSULT “Data monitor” in “FLUID TEMP� NISSAN NOTE 2016 Service Repair Manual CVT FLUIDTM-229

< PERIODIC MAINTENANCE > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Hold the lever at each position for 5 seconds.

13. Check that the CONSULT “Data monitor” in “FLUID TEMP�](/img/5/57363/w960_57363-3469.png)

CVT FLUIDTM-229

< PERIODIC MAINTENANCE > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Hold the lever at each position for 5 seconds.

13. Check that the CONSULT “Data monitor” in “FLUID TEMP” is 35°C (95°F) to 45 °C (113 °F).

14. Stop the engine.

15. Lift up the vehicle.

16. Remove the drain plug, and then drain CVT fluid from oil pan.

17. Repeat steps 6 to 16 (one time).

18. Install the overflow tube. Refer to TM-242, "

Removal and Installation".

CAUTION:

Be sure to tighten to the specified torque. If it is not tightened to the specified torque, the tube may

be damaged.

19. Install the charging pipe set (KV311039S0) (A) into the drain hole.

CAUTION:

Tighten the charging pipe by hand.

20. Install the ATF changer hose (B) to the charging pipe. CAUTION:

Press the ATF changer hose all the way onto the charging

pipe until it stops.

21. Fill approximately 3 liter (2-5 /8 lmp qt) of the CVT fluid.

22. Remove the ATF changer hose and charging pipe, then install the drain plug.

NOTE:

Perform this work quickly because CVT fluid leaks.

23. Lift down the vehicle.

24. Start the engine.

25. While depressing the brake pedal, shift the selector leve r to the entire position from “P” to “L”, and shift it

to the “P” position.

NOTE:

Hold the lever at each position for 5 seconds.

26. Check that the CONSULT “Data monitor” in “FLUID TEMP” is 35°C (95°F) to 45 °C (113 °F).

27. Lift up the vehicle.

28. Remove the drain plug and confirm that the CV T fluid is drained from the overflow tube.

CAUTION:

Perform this work with the vehicle idling.

NOTE:

If the CVT fluid is not drained, refer to “Adjustment” and refill with the CVT fluid.

29. When the flow of CVT fluid slows to a drip, tighten the drain plug to the specified torque. TM-242,

"Removal and Installation".

CAUTION:

Never reuse drain plug gasket.

30. Lift down the vehicle.

31. Select “Work Support” in “T RANSMISSION” using CONSULT.

32. Select “CONFORM CVTF DETERIORTN”.

33. Select “Erase”.

34. Stop the engine.

AdjustmentINFOID:0000000012431174

CAUTION:

• Use only Genuine NISSAN CVT Fluid NS-3. Using transmission fluid other than Genuine NISSAN CVT Fluid NS-3 will damage the CVT, which is not covered by the (NISSAN new vehicle limited) war-

ranty.

JSDIA1876ZZ

CVT fluid : Refer to TM-265, "General Specification".

Fluid capacity : Refer to TM-265, "

General Specification".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3471 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-230

< PERIODIC MAINTENANCE >[CVT: RE0F11A]

CVT FLUID

• During adjustment of the CVT fluid level, check CO

NSULT so that the oil temperature may be main-

tained from 35 to 45 °C (95 to 113 °F).

NISSAN NOTE 2016 Service Repair Manual TM-230

< PERIODIC MAINTENANCE >[CVT: RE0F11A]

CVT FLUID

• During adjustment of the CVT fluid level, check CO

NSULT so that the oil temperature may be main-

tained from 35 to 45 °C (95 to 113 °F).](/img/5/57363/w960_57363-3470.png)

TM-230

< PERIODIC MAINTENANCE >[CVT: RE0F11A]

CVT FLUID

• During adjustment of the CVT fluid level, check CO

NSULT so that the oil temperature may be main-

tained from 35 to 45 °C (95 to 113 °F).

• Use caution when looking into the drain hole as th ere is a risk of dripping fluid entering the eye.

1. Check that the selector lever is in the “P ” position, then completely engage the parking brake.

2. Start the engine.

3. Adjust the CVT fluid temperature to be approximately 40 °C (104° F).

NOTE:

The CVT fluid is largely affected by temperature. Therefore be sure to use CONSULT and check the

“FLUID TEMP” under “TRANSMISSION” in “Data Monitor” while adjusting.

4. While depressing the brake pedal, shift the selector lever to the entire position from “P” to “L”, and shift it to the “P” position.

NOTE:

Hold the lever at each position for 5 seconds.

5. Lift up the vehicle.

6. Check that there is no CVT fluid leakage.

7. Remove the drain plug. Refer to TM-242, "

Removal and Installation".

8. Install the charging pipe set (KV311039S0) (A) into the drain plug hole.

CAUTION:

Tighten the charging pipe by hand.

9. Install the ATF changer hose (B) to the charging pipe. CAUTION:

Press the ATF changer hose all the way onto the charging

pipe until it stops.

10. Fill approximately 0.5 liter (1/2 lmp qt) of the CVT fluid.

11. Remove the ATF changer hose from the charging pipe, and check that the CVT fluid drains out from the charging pipe. If it

does not drain out, perform charging again.

CAUTION:

Perform this work with the vehicle idling.

12. When the flow of CVT fluid slows to a drip, remove the charging pipe from the oil pan.

13. Tighten the drain plug to the specified torque. Refer to TM-242, "

Removal and Installation".

CAUTION:

Never reuse drain plug gasket.

14. Lift down the vehicle.

15. Stop the engine.

JSDIA1876ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3503 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-262

< UNIT REMOVAL AND INSTALLATION >[CVT: RE0F11A]

TRANSMISSION ASSEMBLY

INSPECTION AFTER INSTALLATION

Check the following items:

• For CVT position, refer to

TM-232, "

Inspection".

• Before NISSAN NOTE 2016 Service Repair Manual TM-262

< UNIT REMOVAL AND INSTALLATION >[CVT: RE0F11A]

TRANSMISSION ASSEMBLY

INSPECTION AFTER INSTALLATION

Check the following items:

• For CVT position, refer to

TM-232, "

Inspection".

• Before](/img/5/57363/w960_57363-3502.png)

TM-262

< UNIT REMOVAL AND INSTALLATION >[CVT: RE0F11A]

TRANSMISSION ASSEMBLY

INSPECTION AFTER INSTALLATION

Check the following items:

• For CVT position, refer to

TM-232, "

Inspection".

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

• Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

ADJUSTMENT AFTER INSTALLATION

• Adjust the CVT fluid level. TM-229, "Adjustment".

• Perform "ADDITIONAL SERVICE WHEN REPL ACING TRANSAXLE ASSEMBLY". Refer to TM-127,

"Description".

ItemBefore starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakageLeakage

Exhaust gas —Leakage —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3575 of 3641

WW-10

< SYSTEM DESCRIPTION >

SYSTEM

2. Front washer switch ON.

3. The front washer switch provides ground for the front and rear washer motor.

4. BCM reads the combination switch position and transmi ts the front wiper request signal (LO) to IPDM E/R

using CAN communication.

5. BCM transmits the front wiper request signal (LO) to IPDM E/R using CAN communication.

6. IPDM E/R turns ON the front wiper relay.

7. The front wiper operates.

NOTE:

BCM transmits the front wiper request signal (LO) so t hat the front wiper operates approximately 3 times after

front washer switch OFF is detected.

FRONT WIPER AND WASHER SYSTEM : Fail-SafeINFOID:0000000012433200

FA I L −SAFE OPERATION

IPDM E/R performs the fail-safe function when the front wiper auto stop circuit is malfunctioning. Refer to

PCS-19, "

Fail-safe".

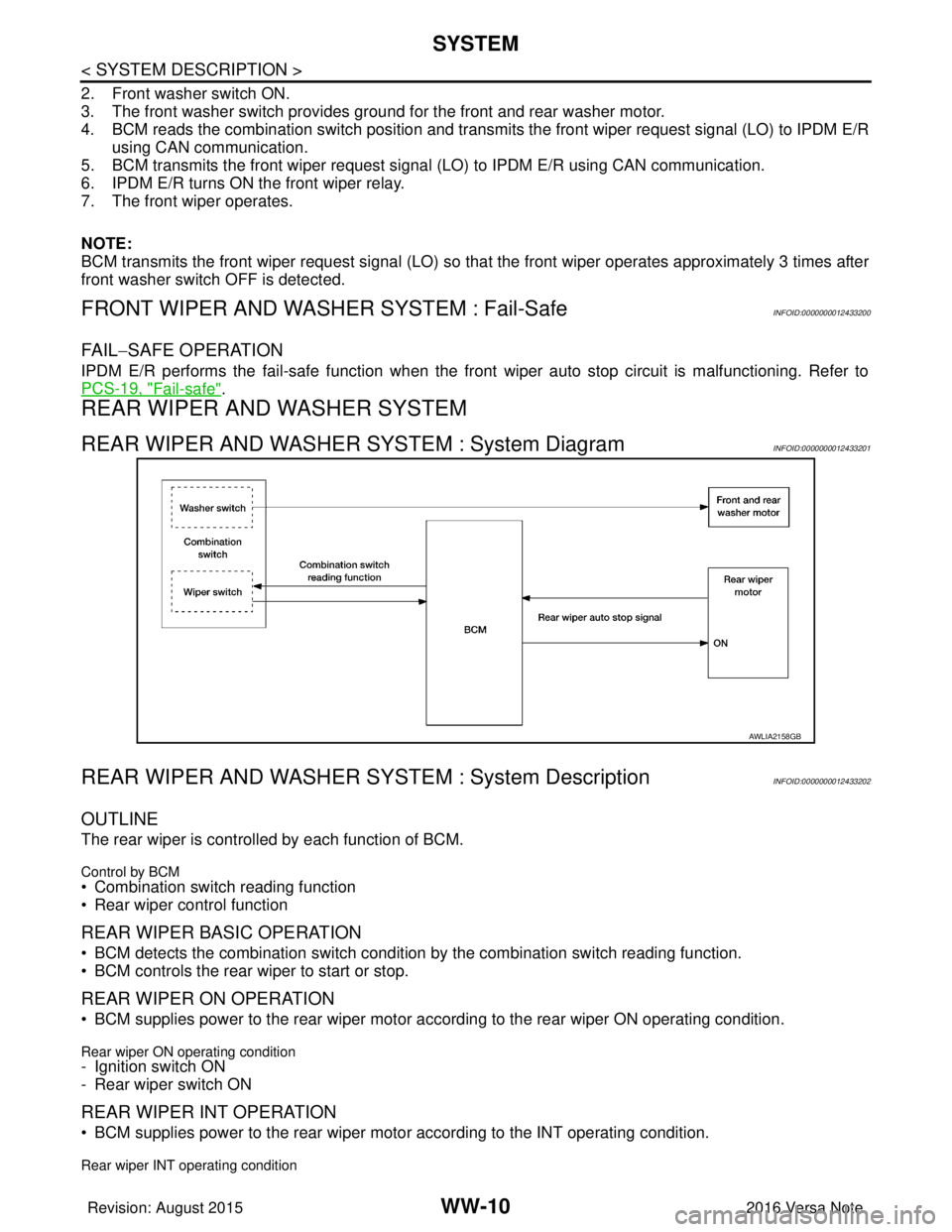

REAR WIPER AND WASHER SYSTEM

REAR WIPER AND WASHER SYSTEM : System DiagramINFOID:0000000012433201

REAR WIPER AND WASHER SY STEM : System DescriptionINFOID:0000000012433202

OUTLINE

The rear wiper is controlled by each function of BCM.

Control by BCM

• Combination switch reading function

• Rear wiper control function

REAR WIPER BASIC OPERATION

• BCM detects the combination switch conditi on by the combination switch reading function.

• BCM controls the rear wiper to start or stop.

REAR WIPER ON OPERATION

• BCM supplies power to the rear wiper motor ac cording to the rear wiper ON operating condition.

Rear wiper ON operating condition- Ignition switch ON

- Rear wiper switch ON

REAR WIPER INT OPERATION

• BCM supplies power to the rear wiper motor according to the INT operating condition.

Rear wiper INT operating condition

AWLIA2158GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3584 of 3641

DIAGNOSIS SYSTEM (IPDM E/R)WW-19

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

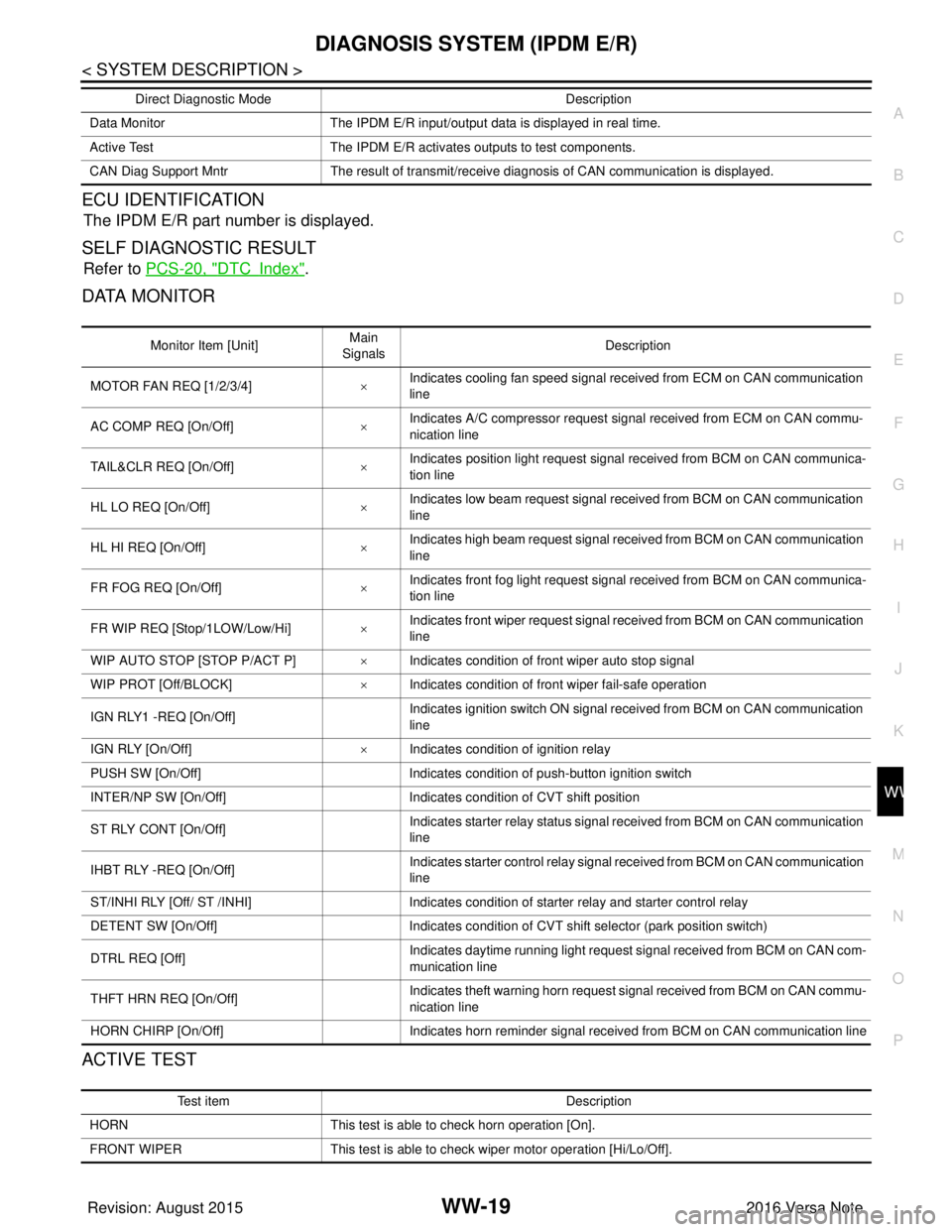

ECU IDENTIFICATION

The IPDM E/R part number is displayed.

SELF DIAGNOSTIC RESULT

Refer to PCS-20, "DTCIndex".

DATA MONITOR

ACTIVE TEST

Data Monitor The IPDM E/R input/output data is displayed in real time.

Active Test The IPDM E/R activates outputs to test components.

CAN Diag Support Mntr The result of transmit/receive diagnosis of CAN communication is displayed.

Direct Diagnostic Mode

Description

Monitor Item [Unit]Main

Signals Description

MOTOR FAN REQ [1/2/3/4] ×Indicates cooling fan speed signal received from ECM on CAN communication

line

AC COMP REQ [On/Off] ×Indicates A/C compressor request signal received from ECM on CAN commu-

nication line

TAIL&CLR REQ [On/Off] ×Indicates position light request signal

received from BCM on CAN communica-

tion line

HL LO REQ [On/Off] ×Indicates low beam request signal received from BCM on CAN communication

line

HL HI REQ [On/Off] ×Indicates high beam request signal received from BCM on CAN communication

line

FR FOG REQ [On/Off] ×Indicates front fog light request signal received from BCM on CAN communica-

tion line

FR WIP REQ [Stop/1LOW/Low/Hi] ×Indicates front wiper request signal received from BCM on CAN communication

line

WIP AUTO STOP [STOP P/ACT P] ×Indicates condition of front wiper auto stop signal

WIP PROT [Off/BLOCK] ×Indicates condition of front wiper fail-safe operation

IGN RLY1 -REQ [On/Off] Indicates ignition switch ON signal received from BCM on CAN communication

line

IGN RLY [On/Off] ×Indicates condition of ignition relay

PUSH SW [On/Off] Indicates condition of push-button ignition switch

INTER/NP SW [On/Off] Indicates condition of CVT shift position

ST RLY CONT [On/Off] Indicates starter relay status signal received from BCM on CAN communication

line

IHBT RLY -REQ [On/Off] Indicates starter control relay signal received from BCM on CAN communication

line

ST/INHI RLY [Off/ ST /INHI] Indicates condition of starter relay and starter control relay

DETENT SW [On/Off] Indicates condition of CVT shift selector (park position switch)

DTRL REQ [Off] Indicates daytime running light request signal received from BCM on CAN com-

munication line

THFT HRN REQ [On/Off] Indicates theft warning horn request signal received from BCM on CAN commu-

nication line

HORN CHIRP [On/Off] Indicates horn reminder signal received from BCM on CAN communication line

Test item Description

HORN This test is able to check horn operation [On].

FRONT WIPER This test is able to check wiper motor operation [Hi/Lo/Off].

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3618 of 3641

FRONT WIPER DOES NOT OPERATEWW-53

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

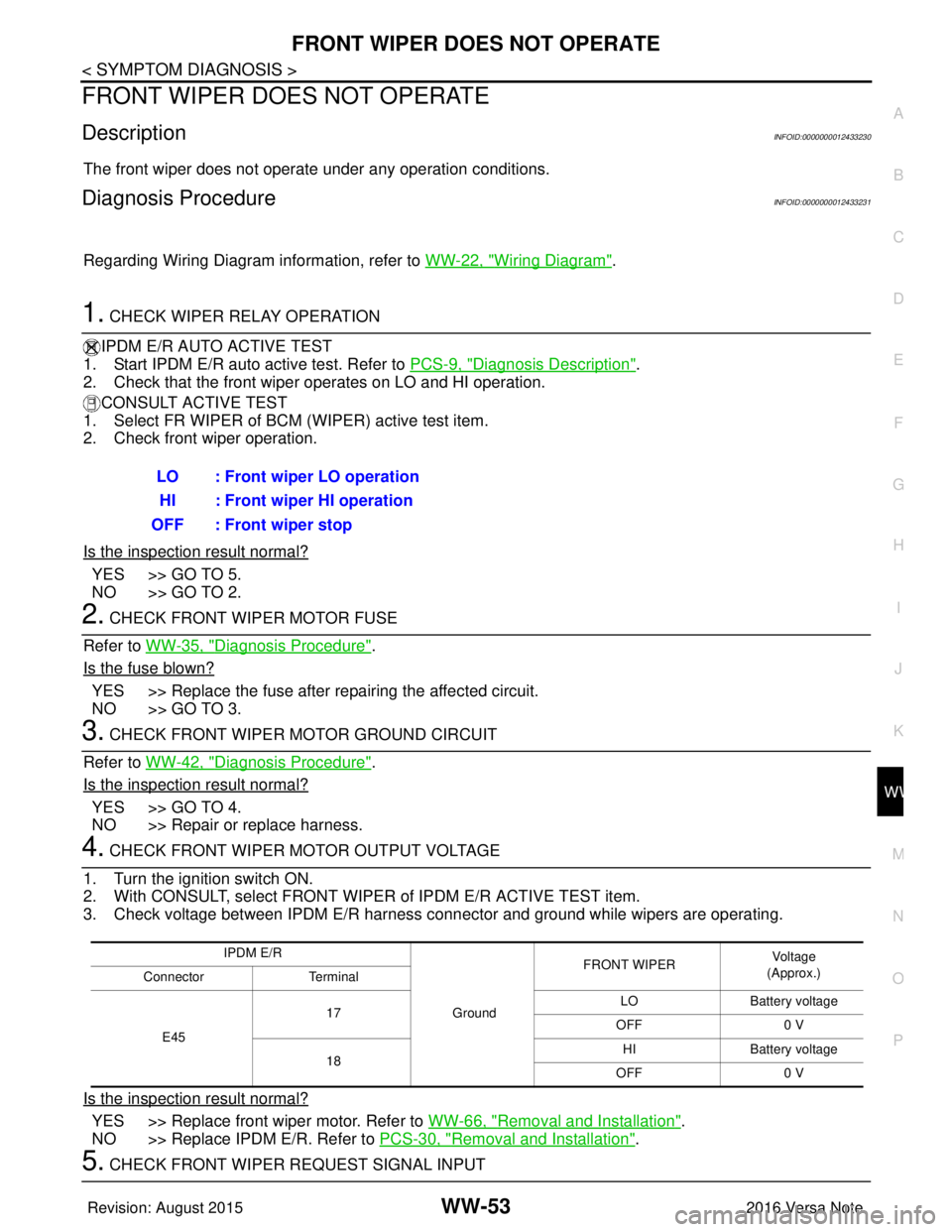

FRONT WIPER DO ES NOT OPERATE

DescriptionINFOID:0000000012433230

The front wiper does not operate under any operation conditions.

Diagnosis ProcedureINFOID:0000000012433231

Regarding Wiring Diagram information, refer to WW-22, "Wiring Diagram".

1. CHECK WIPER RELAY OPERATION

IPDM E/R AUTO ACTIVE TEST

1. Start IPDM E/R auto active test. Refer to PCS-9, "

Diagnosis Description".

2. Check that the front wiper operates on LO and HI operation.

CONSULT ACTIVE TEST

1. Select FR WIPER of BCM (WIPER) active test item.

2. Check front wiper operation.

Is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 2.

2. CHECK FRONT WIPER MOTOR FUSE

Refer to WW-35, "

Diagnosis Procedure".

Is the fuse blown?

YES >> Replace the fuse after repairing the affected circuit.

NO >> GO TO 3.

3. CHECK FRONT WIPER MOTOR GROUND CIRCUIT

Refer to WW-42, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace harness.

4. CHECK FRONT WIPER MOTOR OUTPUT VOLTAGE

1. Turn the ignition switch ON.

2. With CONSULT, select FRONT WIPER of IPDM E/R ACTIVE TEST item.

3. Check voltage between IPDM E/R harness connector and ground while wipers are operating.

Is the inspection result normal?

YES >> Replace front wiper motor. Refer to WW-66, "Removal and Installation".

NO >> Replace IPDM E/R. Refer to PCS-30, "

Removal and Installation".

5. CHECK FRONT WIPER REQUEST SIGNAL INPUTLO : Front wiper LO operation

HI : Front wiper HI operation

OFF : Front wiper stop

IPDM E/R

GroundFRONT WIPER

Vo l ta g e

(Approx.)

Connector Terminal

E45 17

LO

Battery voltage

OFF 0 V

18 HI

Battery voltage

OFF 0 V

Revision: August 2015 2016 Versa Note

cardiagn.com