abs NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 324 of 3641

![NISSAN NOTE 2016 Service User Guide BCS

U1000 CAN COMM CIRCUITBCS-63

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000012432344

R NISSAN NOTE 2016 Service User Guide BCS

U1000 CAN COMM CIRCUITBCS-63

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000012432344

R](/img/5/57363/w960_57363-323.png)

BCS

U1000 CAN COMM CIRCUITBCS-63

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000012432344

Refer to

LAN-25, "CAN COMMUNICATION SYSTEM : System Description".

DTC LogicINFOID:0000000012432345

DTC DETECTION LOGIC

NOTE:

U1000 can be set if a module harness was disconnected and reconnected, perhaps during a repair. Confirm

that there are actual CAN diagnostic symptoms and a present DTC by performing the Self Diagnostic Result

procedure.

Diagnosis ProcedureINFOID:0000000012432346

1. PERFORM SELF DIAGNOSTIC RESULT

1. Turn ignition switch ON and wait for 2 second or more.

2. Perform “Self Diagnostic Result” of “BCM” using CONSULT.

Is

“CAN COMM CIRCUIT” displayed?

YES >> Perform CAN Diagnosis as described in DI AGNOSIS section of CONSULT Operation manual.

NO >> Refer to GI-42, "

Intermittent Incident".

CONSULT Display DTC Detection Condition Possible Cause

CAN COMM CIRCUIT

[U1000] When any listed module cannot communicate

with CAN communication signal continuously for

2 seconds or more with ignition switch ON In CAN communication system, any item (or

items) of the following listed below is malfunc-

tioning.

•Transmission

• Receiving (ECM)

• Receiving (VDC/TCS/ABS)

• Receiving (METER/M&A)

• Receiving (TCM)

• Receiving (IPDM E/R)

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 326 of 3641

![NISSAN NOTE 2016 Service User Guide BCS

U0415 VEHICLE SPEEDBCS-65

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

U0415 VEHICLE SPEED

DTC LogicINFOID:0000000012432349

DTC DETECTION LOGIC

NOTE:

• I NISSAN NOTE 2016 Service User Guide BCS

U0415 VEHICLE SPEEDBCS-65

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

U0415 VEHICLE SPEED

DTC LogicINFOID:0000000012432349

DTC DETECTION LOGIC

NOTE:

• I](/img/5/57363/w960_57363-325.png)

BCS

U0415 VEHICLE SPEEDBCS-65

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

U0415 VEHICLE SPEED

DTC LogicINFOID:0000000012432349

DTC DETECTION LOGIC

NOTE:

• If DTC U0415 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to

BCS-63, "

DTC Logic".

• If DTC U0415 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to BCS-64, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1. DTC CONFIRMATION

1. Erase the DTC.

2. Turn ignition switch OFF.

3. Perform Self Diagnostic Result of BCM with CONSULT, after the ignition switch has been turned ON for 2

seconds or more.

Is any DTC detected?

YES >> Refer to BCS-65, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000012432350

1. ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF DIAGNOSTIC RESULT

Perform “Self Diagnostic Result” of “ABS” with CONSULT. Refer to BRC-31, "

CONSULT Function (ABS)".

Is any DTC detected?

YES >> Perform the trouble diagnosis related to the detected DTC. Refer to BRC-43, "DTC Index".

NO >> GO TO 2.

2. CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) POWER SUPPLY AND GROUND

CIRCUIT

Check ABS actuator and electric unit (control unit) power and ground. Refer to BRC-121, "

Diagnosis Proce-

dure".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness or connectors.

3. COMBINATION METER SE LF DIAGNOSTIC RESULT

Perform “Self Diagnostic Result” of “ME TER M&A” with CONSULT. Refer to MWI-71, "

CONSULT Function

(METER/M&A)".

Is any DTC detected?

YES >> Perform the trouble diagnosis related to the detected DTC. Refer to MWI-77, "DTC Index".

NO >> Refer to GI-42, "

Intermittent Incident".

CONSULT Display DTC Detection Condition Probable Cause

VDC CAN CIR2

[U0415] When the vehicle speed signal received from the

ABS actuator and electric

unit (control unit) re-

mains abnormal for 2 seconds or more. • ABS system

• Combination meter system

• CAN bus harness

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 360 of 3641

![NISSAN NOTE 2016 Service User Guide BCS

DIAGNOSIS SYSTEM (BCM)BCS-99

< SYSTEM DESCRIPTION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

AIR PRESSURE MONITOR

AIR PRESSURE MONITOR : CONSULT Function (BCM - AIR PRESSURE NISSAN NOTE 2016 Service User Guide BCS

DIAGNOSIS SYSTEM (BCM)BCS-99

< SYSTEM DESCRIPTION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

AIR PRESSURE MONITOR

AIR PRESSURE MONITOR : CONSULT Function (BCM - AIR PRESSURE](/img/5/57363/w960_57363-359.png)

BCS

DIAGNOSIS SYSTEM (BCM)BCS-99

< SYSTEM DESCRIPTION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

AIR PRESSURE MONITOR

AIR PRESSURE MONITOR : CONSULT Function (BCM - AIR PRESSURE MONI-

TOR)

INFOID:0000000012432387

NOTE:

The Signal Tech II Tool [– (J-50190)] can be used to perform the following functions. Refer to the Signal Tech

II User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure repor

ted by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

• Test remote keyless entry keyfob relative signal strength

SELF DIAGNOSTIC RESULT

NOTE:

Before performing self diagnostic result, be sure to register the ID, or else the actual malfunction may be differ-

ent from that displayed on CONSULT.

Refer to BCS-115, "

DTCIndex".

DATA MONITOR

ACTIVE TEST

WORK SUPPORT

PANIC ALARM

Monitor Item [Unit] Description

BRAKE SW [On/Off] Indicates condition of stop lamp

switch signal received from ABS actuator and electric unit

(control unit) on CAN communication line.

Monitor Item [Unit] Description

AIR PRESS FL [kPa, kg/cm

2 or Psi] Indicates air pressure of front LH tire.

AIR PRESS FR [kPa, kg/cm

2 or Psi] Indicates air pressure of front RH tire.

AIR PRESS RR [kPa, kg/cm

2 or Psi] Indicates air pressure of rear RH tire.

AIR PRESS RL [kPa, kg/cm

2 or Psi] Indicates air pressure of rear LH tire.

ID REGST FL1 [Done/Yet] Indicates ID registration status of front LH transmitter.

ID REGST FR1 [Done/Yet] Indicates ID registration status of front RH transmitter.

ID REGST RR1 [Done/Yet] Indicates ID registration status of rear RH transmitter.

ID REGST RL1 [Done/Yet] Indicates ID registration status of rear LH transmitter.

WARNING LAMP [Off/On] Indicates condition of low tire pressure warning lamp in combination meter.

BUZZER [Off/On] Indicates condition of buzzer in combination meter.

Test Item Description

HORN This test is able to check horn operation [On].

WARNING LAMP This test is able to check tire pressure warning lamp operation [On/Off].

ID REGIST WARNING This test is able to check ID registration warning chime operation [On/Off].

FLASHER This test is able to check turn signal lamp operation [Off/LH/RH].

Support Item Description

ID READ The registered ID number is displayed.

ID REGIST Refer to WT-22, "

Description".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 388 of 3641

![NISSAN NOTE 2016 Service User Guide BCS

U1000 CAN COMMBCS-127

< DTC/CIRCUIT DIAGNOSIS > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM

DescriptionINFOID:0000000012432401

Refer to

LAN NISSAN NOTE 2016 Service User Guide BCS

U1000 CAN COMMBCS-127

< DTC/CIRCUIT DIAGNOSIS > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM

DescriptionINFOID:0000000012432401

Refer to

LAN](/img/5/57363/w960_57363-387.png)

BCS

U1000 CAN COMMBCS-127

< DTC/CIRCUIT DIAGNOSIS > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM

DescriptionINFOID:0000000012432401

Refer to

LAN-7, "CAN COMMUNICATION SYSTEM : System Description".

DTC LogicINFOID:0000000012432402

DTC DETECTION LOGIC

NOTE:

U1000 can be set if a module harness was disconnected and reconnected, perhaps during a repair. Confirm

that there are actual CAN diagnostic symptoms and a present DTC by performing the Self Diagnostic Result

procedure.

Diagnosis ProcedureINFOID:0000000012432403

1. PERFORM SELF DIAGNOSTIC RESULT

1. Turn ignition switch ON and wait for 2 second or more.

2. Check “Self Diagnostic Result” of “BCM” using CONSULT.

Is

“CAN COMM CIRCUIT” displayed?

YES >> Perform CAN Diagnosis as described in DI AGNOSIS section of CONSULT Operation Manual.

NO >> Refer to GI-42, "

Intermittent Incident".

CONSULT Display DTC Detection Condition Possible Cause

CAN COMM CIRCUIT

[U1000] When any listed module cannot communicate

with CAN communication signal continuously for

2 seconds or more with ignition switch ON In CAN communication system, any item (or

items) of the following listed below is malfunc-

tioning.

•Transmission

• Receiving (ECM)

• Receiving (VDC/TCS/ABS)

• Receiving (METER/M&A)

• Receiving (TCM)

• Receiving (IPDM E/R)

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 403 of 3641

BRM-4

< PRECAUTION >

HANDLING PRECAUTIONS FOR PLASTICS

HANDLING PRECAUTIONS FOR PLASTICS

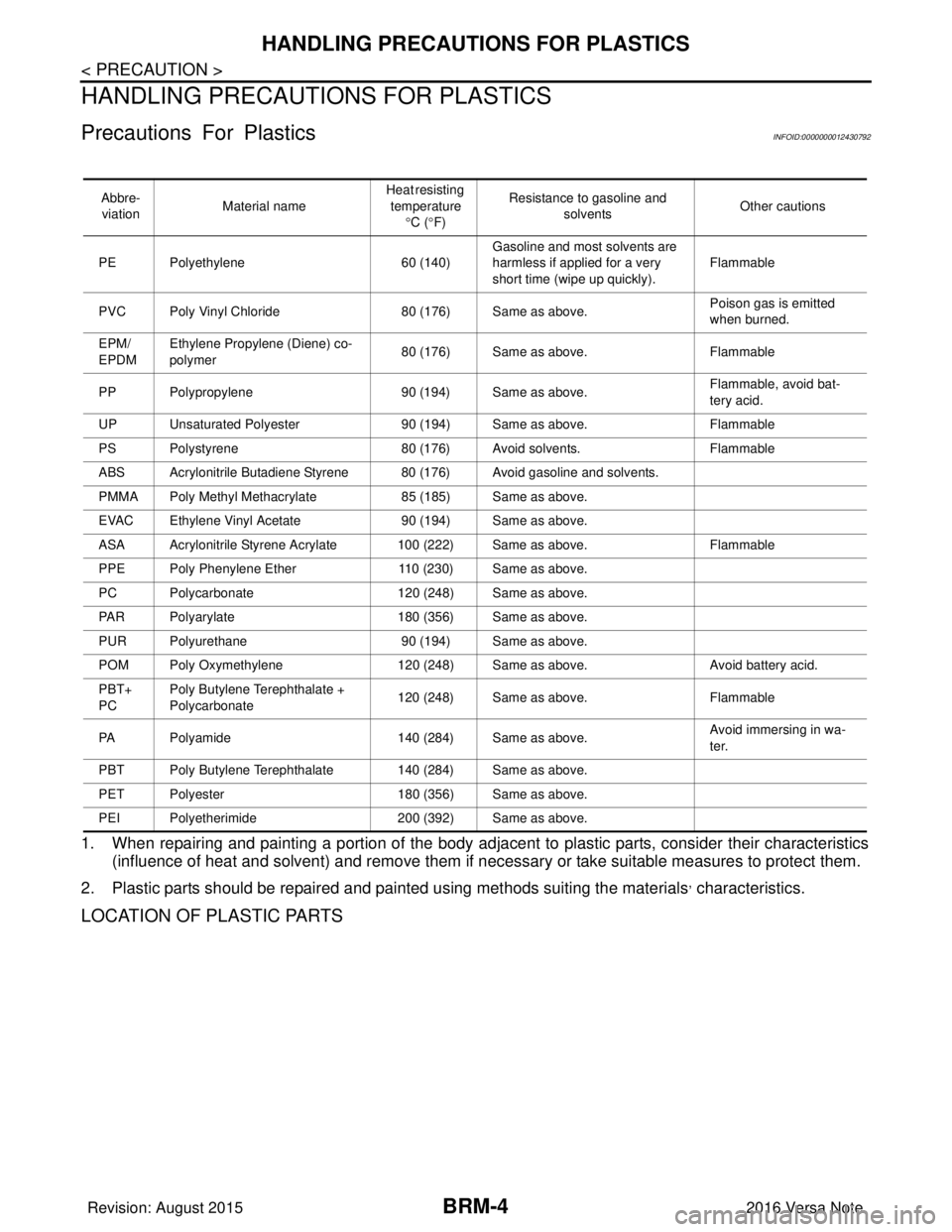

Precautions For PlasticsINFOID:0000000012430792

1. When repairing and painting a portion of the body adjacent to plastic parts, consider their characteristics

(influence of heat and solvent) and remove them if neces sary or take suitable measures to protect them.

2. Plastic parts should be repaired and painted using methods suiting the materials

, characteristics.

LOCATION OF PLASTIC PARTS

Abbre- viation Material name Heat resisting

temperature °C ( °F) Resistance to gasoline and

solvents Other cautions

PE Polyethylene 60 (140)Gasoline and most solvents are

harmless if applied for a very

short time (wipe up quickly). Flammable

PVC Poly Vinyl Chloride 80 (176) Same as above. Poison gas is emitted

when burned.

EPM/

EPDM Ethylene Propylene (Diene) co-

polymer

80 (176) Same as above.

Flammable

PP Polypropylene 90 (194) Same as above. Flammable, avoid bat-

tery acid.

UP Unsaturated Polyester 90 (194) Same as above. Flammable

PS Polystyrene 80 (176) Avoid solvents. Flammable

ABS Acrylonitrile Butadiene Styrene 80 (176) Avoid gasoline and solvents.

PMMA Poly Methyl Methacrylate 85 (185) Same as above.

EVAC Ethylene Vinyl Acetate 90 (194) Same as above.

ASA Acrylonitrile Styrene Acrylate 100 (222) Same as above. Flammable

PPE Poly Phenylene Ether 110 (230) Same as above.

PC Polycarbonate 120 (248) Same as above.

PAR Polyarylate 180 (356) Same as above.

PUR Polyurethane 90 (194) Same as above.

POM Poly Oxymethylene 120 (248) Same as above. Avoid battery acid.

PBT+

PC Poly Butylene Terephthalate +

Polycarbonate

120 (248) Same as above.

Flammable

PA Polyamide 140 (284) Same as above. Avoid immersing in wa-

ter.

PBT Poly Butylene Terephthalate 140 (284) Same as above.

PET Polyester 180 (356) Same as above.

PEI Polyetherimide 200 (392) Same as above.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 404 of 3641

HANDLING PRECAUTIONS FOR PLASTICSBRM-5

< PRECAUTION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

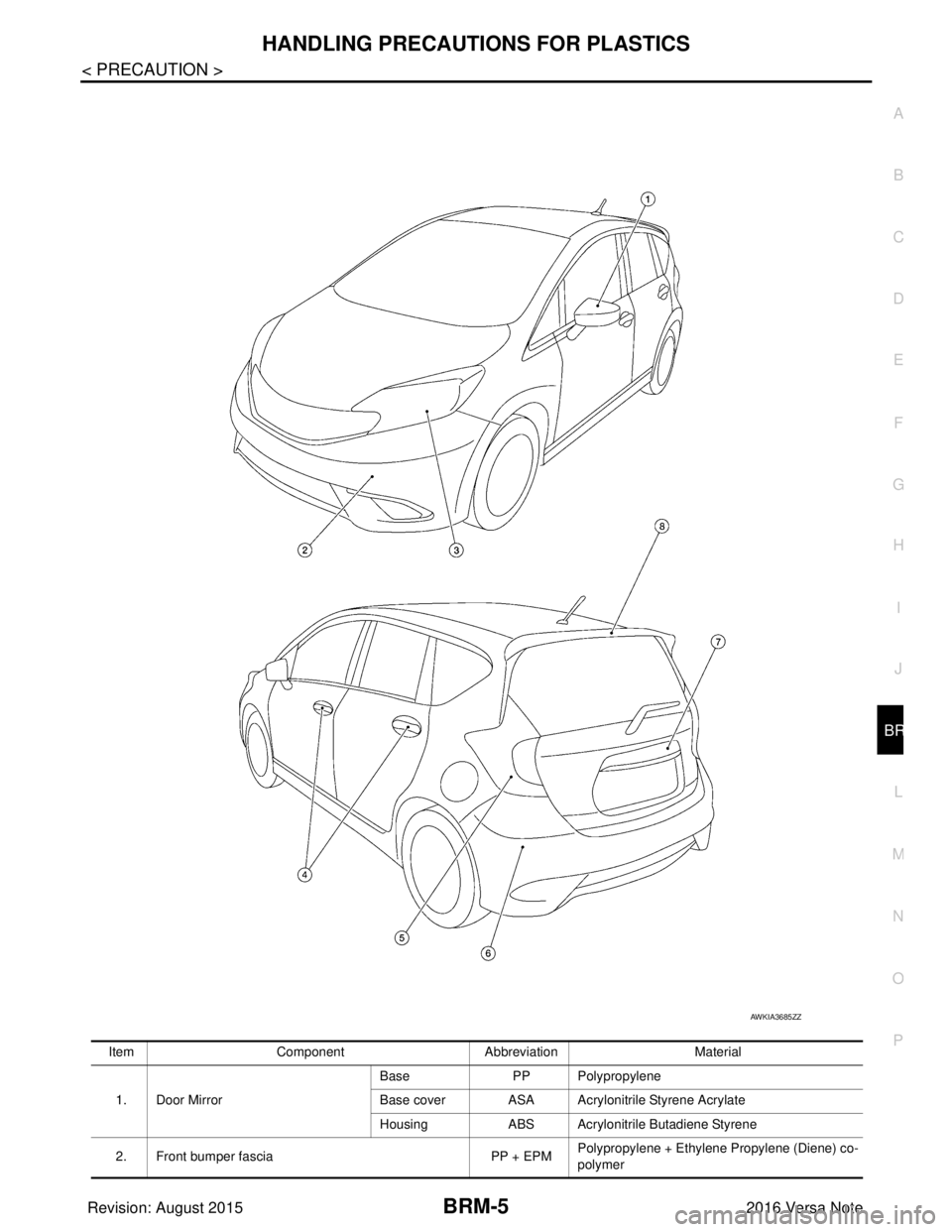

Item Component Abbreviation Material

1. Door Mirror Base

PP Polypropylene

Base cover ASA Acryloni trile Styrene Acrylate

Housing ABS Acrylonitrile Butadiene Styrene

2. Front bumper fascia PP + EPMPolypropylene + Ethylene Propylene (Diene) co-

polymer

AWKIA3685ZZ

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 405 of 3641

BRM-6

< PRECAUTION >

HANDLING PRECAUTIONS FOR PLASTICS

3. Front combination lampLens

PC Polycarbonate

Housing PP Polypropylene

4. Door outside handle Grip

PC + PET Polycarbonate + Polyester

Escutcheon PC + PET Polycarbonate + Polyester

5. Rear combination lamp Lens

PMMA Poly Methyl Methacrylate

Housing PC + ABS Polycarbonate + Acrylonitrile Butadiene Styrene

6. Rear bumper fascia PP + EPMPolypropylene + Ethylene Propylene (Diene) co-

polymer

7. Back door finisher ABS Acronitrile Butadiene Acrylate

8. Rear spoiler ABS Acronitrile Butadiene Acrylate

Item

Component Abbreviation Material

ItemComponent Abbreviation Material

1. Center pillar upper finisher PP Polypropylene

2. Luggage side upper finisher PP Polypropylene

3. Rear kicking plate PP Polypropylene

4. Front kicking plate PP Polypropylene

5. Center console lower PP Polypropylene

6. Glove box assembly PP Polypropylene

7. Steering column covers PP Polypropylene

8. Front pillar finisher PP Polypropylene

AWKIA3211ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 406 of 3641

HANDLING PRECAUTIONS FOR PLASTICSBRM-7

< PRECAUTION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

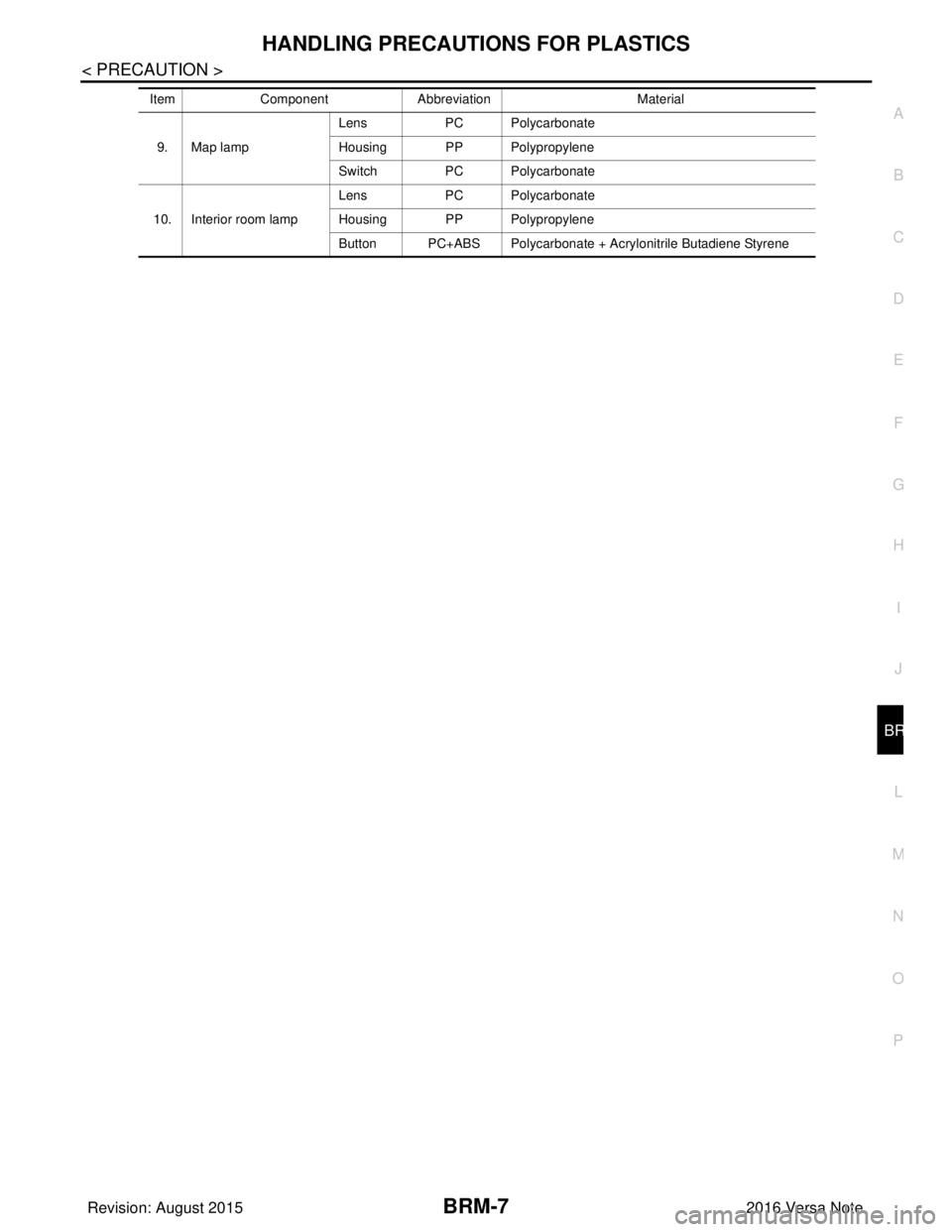

9. Map lamp Lens PC Polycarbonate

Housing PP Polypropylene

Switch

PC Polycarbonate

10. Interior room lamp Lens

PC Polycarbonate

Housing PP Polypropylene

Button PC+ABS Polycarbonate + Acry lonitrile Butadiene Styrene

Item

Component Abbreviation Material

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 415 of 3641

BRM-16

< REMOVAL AND INSTALLATION >

CORROSION PROTECTION

REMOVAL AND INSTALLATION

CORROSION PROTECTION

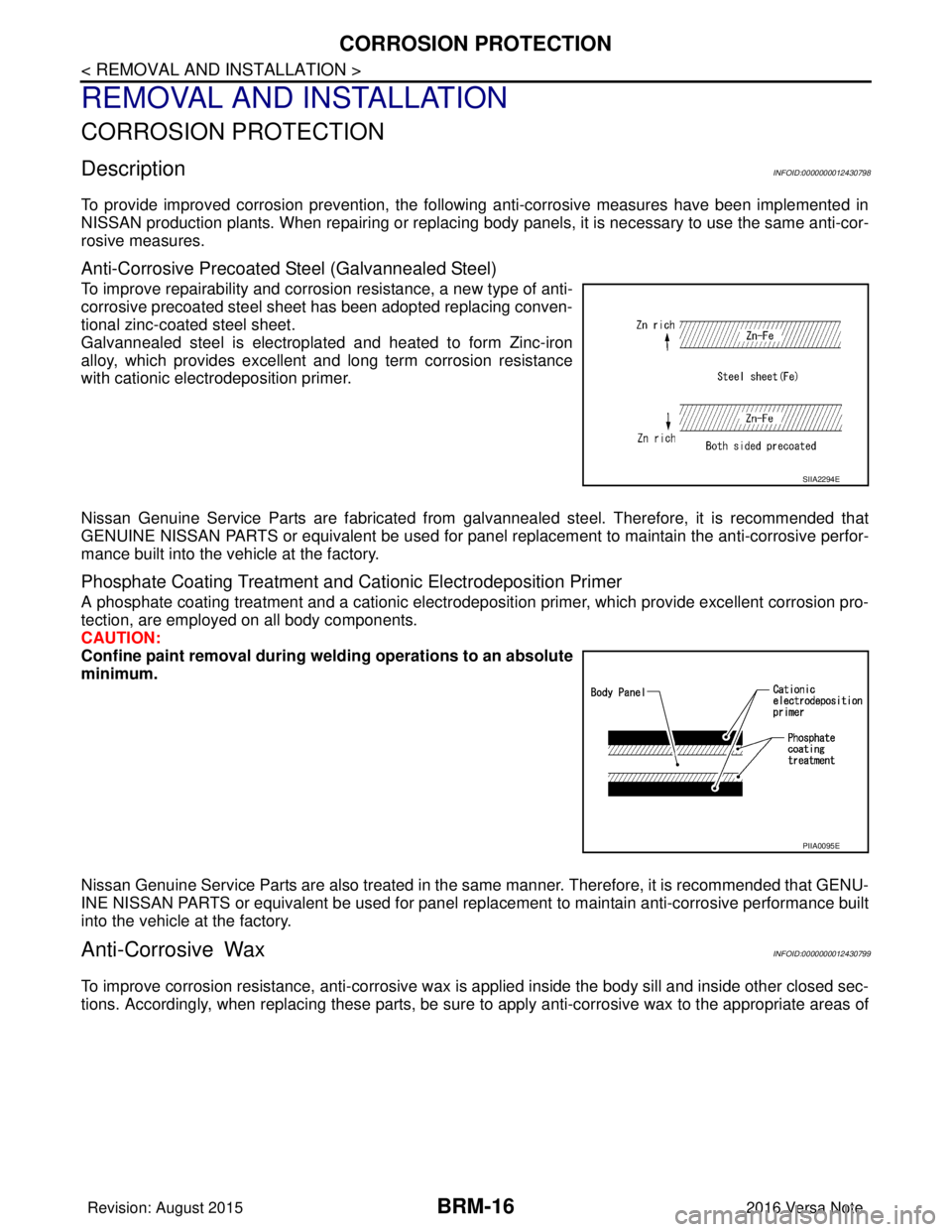

DescriptionINFOID:0000000012430798

To provide improved corrosion prevention, the following anti-corrosive measures have been implemented in

NISSAN production plants. When repairing or replacing body panels, it is necessary to use the same anti-cor-

rosive measures.

Anti-Corrosive Precoated Steel (Galvannealed Steel)

To improve repairability and corrosion resistance, a new type of anti-

corrosive precoated steel sheet has been adopted replacing conven-

tional zinc-coated steel sheet.

Galvannealed steel is electroplated and heated to form Zinc-iron

alloy, which provides excellent and long term corrosion resistance

with cationic electrodeposition primer.

Nissan Genuine Service Parts are fabricated from galvannealed steel. Therefore, it is recommended that

GENUINE NISSAN PARTS or equivalent be used for panel replacement to maintain the anti-corrosive perfor-

mance built into the vehicle at the factory.

Phosphate Coating Treatment and Cationic Electrodeposition Primer

A phosphate coating treatment and a cationic electrodepositi on primer, which provide excellent corrosion pro-

tection, are employed on all body components.

CAUTION:

Confine paint removal during weld ing operations to an absolute

minimum.

Nissan Genuine Service Parts are also treated in the same manner. Therefore, it is recommended that GENU-

INE NISSAN PARTS or equivalent be used for panel replacement to maintain anti-corrosive performance built

into the vehicle at the factory.

Anti-Corrosive WaxINFOID:0000000012430799

To improve corrosion resistance, anti-corrosive wax is applied inside the body sill and inside other closed sec-

tions. Accordingly, when replacing these parts, be sure to apply anti-corrosive wax to the appropriate areas of

SIIA2294E

PIIA0095E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 449 of 3641

BRC-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BRC

A

B

BRC

N

O P

CONTENTS

BRAKE CONTROL SYSTEM

VDC/TCS/ABS

PRECAUTION ....... ........................................

4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution for Brake System ....................................4

Precaution for Brake Control System ........................5

Precaution for Harness Re pair ..................................5

PREPARATION ............................................6

PREPARATION .............................................. .....6

Special Service Tool ........................................... ......6

Commercial Service Tool ..........................................6

SYSTEM DESCRIPTION ..............................7

COMPONENT PARTS ................................... .....7

Component Parts Location .................................. ......7

Component Description .............................................8

ABS Actuator and Electric Unit (Control Unit) ...........8

Wheel Sensor and Sensor Rotor ..............................9

Stop Lamp Switch .....................................................9

Steering Angle Sensor ..............................................9

VDC OFF Switch .....................................................10

Brake Fluid Level Switch .........................................10

Parking Brake Switch ..............................................10

SYSTEM .............................................................11

VDC/TCS/ABS ....................................................... ....11

VDC/TCS/ABS : System Diagram ...........................11

VDC/TCS/ABS : System De scription ......................11

VDC/TCS/ABS : VDC Functi on ...............................22

VDC/TCS/ABS : TCS Function ........... ....................24

VDC/TCS/ABS : ABS Function ........................... ....26

VDC/TCS/ABS : EBD Functi on ...............................27

VDC/TCS/ABS : Fail-safe ......................... ..............28

DIAGNOSIS SYSTEM [ABS ACTUATOR

AND ELECTRIC UNIT (CONTROL UNIT)] .......

31

CONSULT Function (ABS) .................................. ....31

ECU DIAGNOSIS INFORMATION ..............36

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) .............................................

36

Reference Value .................................................. ....36

Fail-safe ...................................................................39

DTC Inspection Priority Chart ..................................42

DTC Index ...............................................................43

WIRING DIAGRAM ......................................44

BRAKE CONTROL SYSTEM ...........................44

Wiring Diagram .................................................... ....44

BASIC INSPECTION ...................................52

DIAGNOSIS AND REPAIR WORK FLOW .......52

Work Flow ............................................................ ....52

Diagnostic Work Sheet ............................................53

INSPECTION AND ADJUSTMENT ..................55

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ....

55

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description .................................

55

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement ......

55

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION ............................................ ....

55

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION : Description .........................

55

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION : Special Repair Require-

ment .........................................................................

55

CALIBRATION OF DECEL G SENSOR ................ ....56

Revision: August 2015 2016 Versa Note

cardiagn.com