fuel filter NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1562 of 3641

![NISSAN NOTE 2016 Service User Guide P219C, P219D, P219E, P219F AIR FUEL RATIO

EC-435

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

10. Allow a 13-17mm (0.52-0.66 in) spacing between spark plug and

grounded metal por NISSAN NOTE 2016 Service User Guide P219C, P219D, P219E, P219F AIR FUEL RATIO

EC-435

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

10. Allow a 13-17mm (0.52-0.66 in) spacing between spark plug and

grounded metal por](/img/5/57363/w960_57363-1561.png)

P219C, P219D, P219E, P219F AIR FUEL RATIO

EC-435

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

10. Allow a 13-17mm (0.52-0.66 in) spacing between spark plug and

grounded metal portion as shown in the figure to fix the ignition

coil with a rope or an equivalent.

11. Crank the engine for approximately 3 seconds to see if sparking occurs between spark plug and the grounded metal portion.

CAUTION:

• The discharge voltage becomes 20 kV or higher. There-fore, always stay away from the spark plug and ignition

coil at least 50 cm (19.7 in) during the inspection.

• Leaving a space of more than 17mm (0.66 in) may damage

the ignition coil.

NOTE:

When the gap is less than 13 mm (0.52 in), a the sp ark might be generated even if the coil is mal-

functioning.

Is the inspection result normal?

YES >> GO TO 8.

NO >> GO TO 10.

8.CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM-13, "

Inspection".

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

9.DETECT MALFUNCTIONING PART

Check fuel hoses and fuel tubes for clogging.

Is the inspection result normal?

YES >> Replace fuel filter and fuel pump assembly. Refer to FL-6, "Exploded View".

NO >> Repair or replace error-detected parts.

10.CHECK FUNCTION OF IGNITION COIL-2

1. Turn ignition switch OFF.

2. Disconnect spark plug and connect a non-malfunctioning spark plug.

3. Crank engine for approximately 3 seconds, and rec heck whether spark is generated between the spark

plug and the grounded metal portion.

Is the inspection result normal?

YES >> GO TO 11.

NO >> Check ignition coil, power transistor and their circuits. Refer to EC-451, "

Component Function

Check".

11 .CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal?

YES >> 1. Repair or clean spark plug. Refer to EM-47,

"Exploded View".

2. GO TO 12.

NO >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-117, "

Spark Plug".

12.CHECK FUNCTION OF IGNITION COIL-3Spark should be generated.

JMBIA0066GB

Spark should be generated.

SEF156I

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1584 of 3641

![NISSAN NOTE 2016 Service User Guide ON BOARD REFUELING VAPOR RECOVERY (ORVR)EC-457

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

Component Function CheckINFOID:00000000124316 NISSAN NOTE 2016 Service User Guide ON BOARD REFUELING VAPOR RECOVERY (ORVR)EC-457

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

Component Function CheckINFOID:00000000124316](/img/5/57363/w960_57363-1583.png)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)EC-457

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

Component Function CheckINFOID:0000000012431660

1.CHECK ORVR FUNCTION

Check whether the following symptoms are present.

• Fuel odor from EVAP canister is strong.

• Cannot refuel/Fuel odor from the fuel filler opening is strong while refueling.

Is any symptom present?

YES >> Go to EC-457, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000012431661

1.INSPECTION START

Check whether the following symptoms are present.

A: Fuel odor from EVAP canister is strong.

B: Cannot refuel/Fuel odor from the fuel filler opening is strong while refueling.

Which symptom is present?

A >> GO TO 2.

B >> GO TO 8.

2.CHECK EVAP CANISTER

1. Remove EVAP canister with EVAP canister vent c ontrol valve and EVAP control system pressure sensor

attached.

2. Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be l ess than 1.6 kg (3.5 lb).

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 4.

3.CHECK IF EVAP CANISTER IS SATURATED WITH WATER

Check if water will drain from EVAP canister.

Does water drain from the EVAP canister?

YES >> GO TO 4.

NO >> GO TO 7.

4.REPLACE EVAP CANISTER

Replace EVAP canister with a new one.

>> GO TO 5.

5.CHECK DRAIN FILTER

Refer to EC-461, "

Component Inspection (Drain filter)".

Is the inspection result normal?

OK >> GO TO 6.

NO >> Replace drain filter.

6.DETECT MALFUNCTIONING PART

PBIB1213E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1585 of 3641

![NISSAN NOTE 2016 Service User Guide EC-458

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

Check the EVAP hose between EVAP canister and

vehicle frame for clogging or poor connection.

>> Repair or replace EVA NISSAN NOTE 2016 Service User Guide EC-458

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

Check the EVAP hose between EVAP canister and

vehicle frame for clogging or poor connection.

>> Repair or replace EVA](/img/5/57363/w960_57363-1584.png)

EC-458

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

Check the EVAP hose between EVAP canister and

vehicle frame for clogging or poor connection.

>> Repair or replace EVAP hose.

7.CHECK REFUELING EVAP VAPOR CUT VALVE

Refer to EC-459, "

Component Inspection (Refueli ng EVAP vapor cut valve)".

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace refueling EVAP vapor cut valve with fuel tank.

8.CHECK EVAP CANISTER

1. Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor attached.

2. Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be l ess than 1.6 kg (3.5 lb).

Is the inspection result normal?

YES >> GO TO 9.

NO >> GO TO 10.

9.CHECK IF EVAP CANISTER IS SATURATED WITH WATER

Check if water will drain from EVAP canister.

Does water drain from the EVAP canister?

YES >> GO TO 10.

NO >> GO TO 13.

10.REPLACE EVAP CANISTER

Replace EVAP canister with a new one.

>> GO TO 11.

11 .CHECK DRAIN FILTER

Refer to EC-461, "

Component Inspection (Drain filter)".

Is the inspection result normal?

OK >> GO TO 12.

NO >> Replace drain filter.

12.DETECT MALFUNCTIONING PART

Check the EVAP hose between EVAP canister and vehicle frame for clogging or poor connection.

>> Repair or replace EVAP hose.

13.CHECK VENT HOSES AND VENT TUBES

Check hoses and tubes between EVAP canister and refueling control valve for clogging, kink, looseness and

improper connection.

Is the inspection result normal?

YES >> GO TO 14.

NO >> Repair or replace hoses and tubes.

14.CHECK RECIRCULATION LINE

PBIB1213E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1588 of 3641

![NISSAN NOTE 2016 Service User Guide ON BOARD REFUELING VAPOR RECOVERY (ORVR)EC-461

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace refueling EVAP va NISSAN NOTE 2016 Service User Guide ON BOARD REFUELING VAPOR RECOVERY (ORVR)EC-461

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace refueling EVAP va](/img/5/57363/w960_57363-1587.png)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)EC-461

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace refueling EVAP vapor cut valve with fuel tank. Refer to

FL-10, "

Removal and Installation".

Component Inspection (Drain filter)INFOID:0000000012431663

1.CHECK DRAIN FILTER

1. Check visually for insect nests in the drain filter air inlet.

2. Check visually for cracks or flaws in the appearance.

3. Check visually for cracks or flaws in the hose.

4. Blow air into port A and check that it flows freely out of port B.

5. Block port B.

6. Blow air into port A and check that there is no leakage.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace drain filter.

1. Filler tube 2. Recirculation line3. EVAP/ORVR line

4. Vacuum/pressure handy pump 5. Fuel tank

JMBIA2315ZZ

PBIB3641E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1595 of 3641

![NISSAN NOTE 2016 Service User Guide EC-468

< SYMPTOM DIAGNOSIS >[HR16DE]

ENGINE CONTROL SYSTEM SYMPTOMS

Engine Cylinder head

55555 55 5EM-80, "Inspection"Cylinder head gasket 4 3

Cylinder block

66666 66 64

EM-102, "

Inspection"

Piston

P NISSAN NOTE 2016 Service User Guide EC-468

< SYMPTOM DIAGNOSIS >[HR16DE]

ENGINE CONTROL SYSTEM SYMPTOMS

Engine Cylinder head

55555 55 5EM-80, "Inspection"Cylinder head gasket 4 3

Cylinder block

66666 66 64

EM-102, "

Inspection"

Piston

P](/img/5/57363/w960_57363-1594.png)

EC-468

< SYMPTOM DIAGNOSIS >[HR16DE]

ENGINE CONTROL SYSTEM SYMPTOMS

Engine Cylinder head

55555 55 5EM-80, "Inspection"Cylinder head gasket 4 3

Cylinder block

66666 66 64

EM-102, "

Inspection"

Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Va l v e

mecha-

nism Timing chain

55555 55 5EM-51, "

Removal and

Installation"

Camshaft

EM-68, "Inspection"

Intake valve timing controlEM-48, "Removal and

Installation"

Exhaust valve timing con-

trolEM-48, "Removal and

Installation"

Intake valve

3EM-68, "Inspection"Exhaust valve

Ex-

haust Exhaust manifold/Tube/

Muffler/Gasket

55555 55 5EX-4, "

Inspection"

EM-31, "Removal and

Installation"Three way catalyst

Lubri-

cation

Oil pan/Oil strainer/Oil

pump/Oil filter/Oil gallery/

Oil cooler 55555 55 5 EM-34, "

Removal and

Installation (Lower Oil

Pan)"

EM-37, "Removal and

Installation (Upper Oil

Pan)"

LU-10, "Removal and

Installation"

LU-11, "Removal and

Installation"

LU-13, "Removal and

Installation"

Oil level (Low)/Filthy oil

LU-7, "Inspection"

SYMPTOM

Reference page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom codeAA AB AC AD AE AF AG AH AJ AK AL AM HA

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1867 of 3641

FL-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION FL

A

FL

N

O P

CONTENTS

FUEL SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

General Precaution ...................................................2

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tools ........................................4

PERIODIC MAINTENANCE ..........................5

FUEL SYSTEM ............................................... .....5

Inspection ............................................................ ......5

Quick Connector .......................................................5

REMOVAL AND INSTALLATION ................6

FUEL LEVEL SENSOR UNIT, FUEL FILTER

AND FUEL PUMP ASSEMBLY ..................... .....

6

Exploded View .................................................... ......6

Removal and Installation ...........................................6

Inspection ............................................................ ......9

FUEL TANK ........................................................10

Exploded View .................................................... ....10

Removal and Installation .........................................10

Inspection ............................................................ ....13

EVAP CANISTER ..............................................14

Exploded View ..................................................... ....14

Removal and Installation .........................................14

Inspection ................................................................15

EVAP CANISTER FILTER ................................16

Exploded View .........................................................16

Removal and Installation .........................................16

EVAP CANISTER VENT CONTROL VALVE ...17

Exploded View .........................................................17

Removal and Installation .........................................17

EVAP CONTROL SYSTEM PRESSURE SEN-

SOR ...................................................................

19

Exploded View .........................................................19

Removal and Installation .........................................19

DISASSEMBLY AND ASSEMBLY ..............20

FUEL LEVEL SENSOR UNIT ...........................20

Exploded View ..................................................... ....20

Disassembly and Assembly .....................................20

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

22

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

22

Fuel Tank ............................................................. ....22

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1872 of 3641

FL-6

< REMOVAL AND INSTALLATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

REMOVAL AND INSTALLATION

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

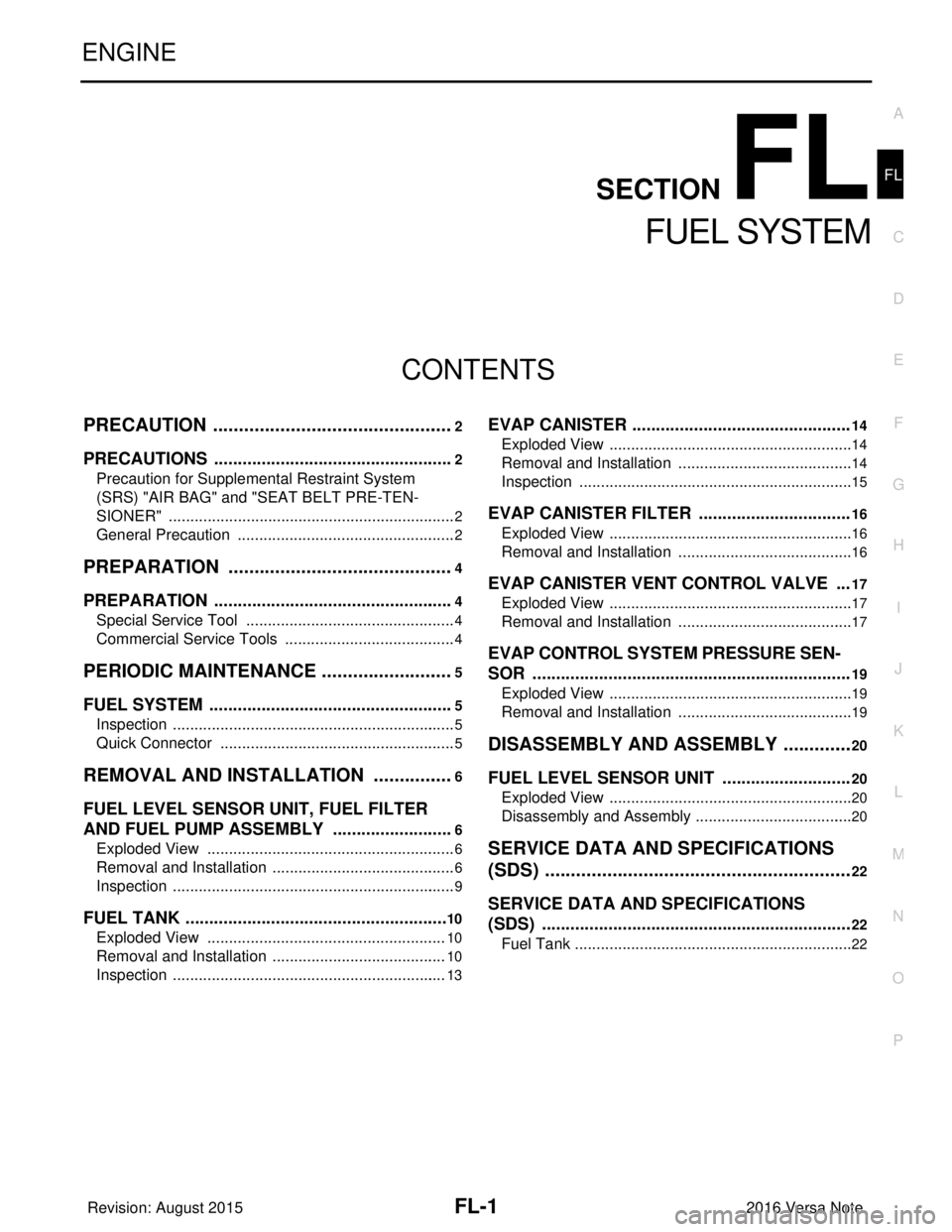

Exploded ViewINFOID:0000000012432109

Removal and InstallationINFOID:0000000012432110

WARNING:

Read “General Precautions” when wo rking on the fuel system. Refer to FL-2, "

General Precaution".

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Release the fuel pressure from the fuel lines. Refer to EC-137, "Work Procedure".

2. Disconnect the battery negative terminal. Refer to PG-70, "

Removal and Installation (Battery)".

3. Open fuel filler lid.

4. Open fuel filler cap and release the pressure inside fuel tank.

5. Remove the rear seat cushion. Refer to SE-26, "

SEAT CUSHION : Removal and Installation".

6. Remove the inspection hole cover. NOTE:

Inspection hole cover is held down by an adhesive.

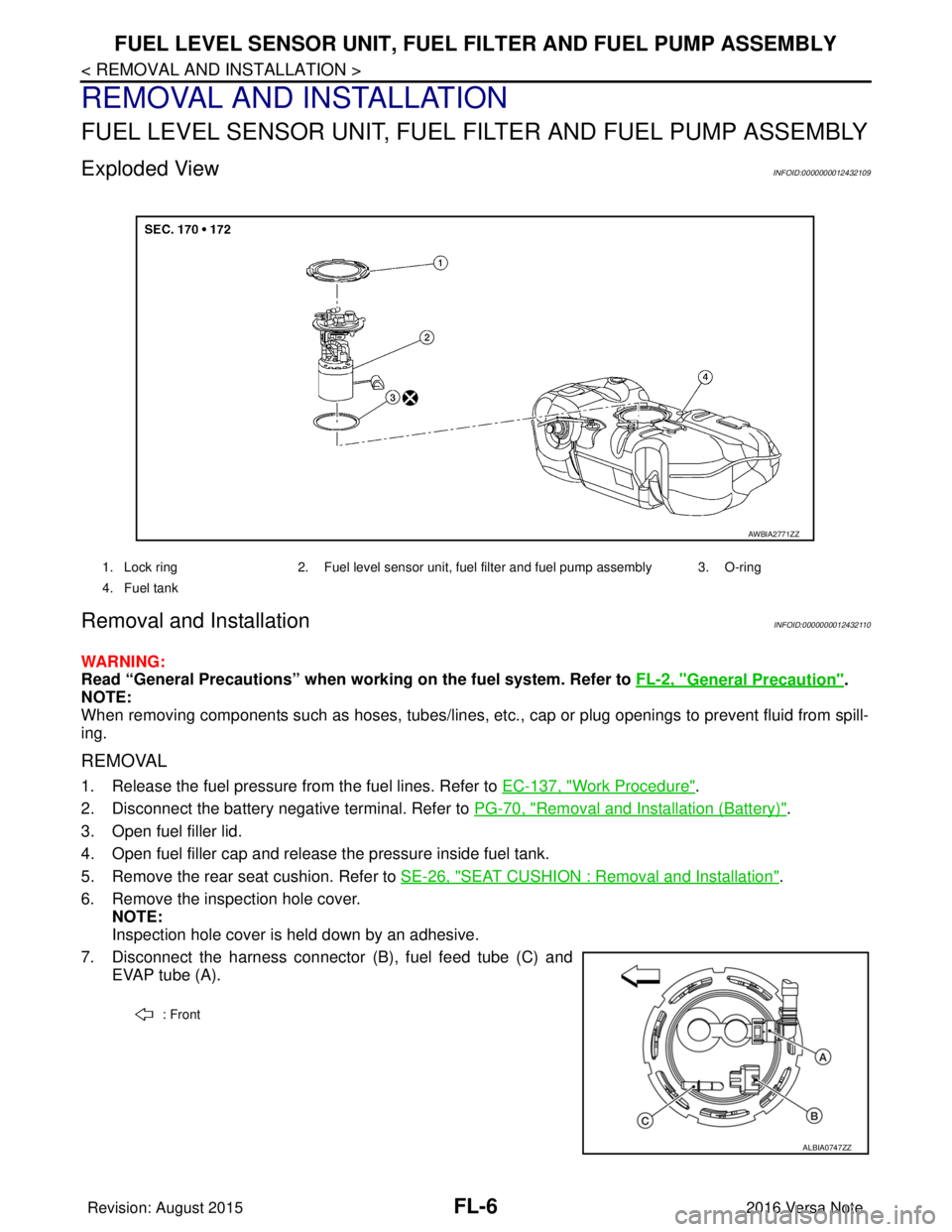

7. Disconnect the harness connector (B), fuel feed tube (C) and EVAP tube (A).

1. Lock ring 2. Fuel level sensor unit, fuel filter and fuel pump assembly 3. O-ring

4. Fuel tank

AWBIA2771ZZ

: Front

ALBIA0747ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1873 of 3641

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLYFL-7

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

Remove the quick connector as follows:

• Hold the sides of the connector, push in tabs (B) and pull (A)

out the tube.

• If the connector and the tube are stuck together, push and pull several times until they start to move. Then disconnect them

by pulling.

CAUTION:

• Quick connector (1) can be disconnected when the tabs (F) are depressed completely. Do not twist it more than

necessary.

• Do not use any tools to disconnected quick connector.

• Keep resin tube (C) away from heat. Be especially careful when welding near the resin tube.

• Prevent acid liquid such as battery electrolyte, etc. from

getting on resin tube.

• Do not bend or twist resin tube during installation and dis- connection.

• Do not remove the remaining retainer (2) on hard tube (or

the equivalent) (A) except when resin tube or retainer is

replaced.

• When resin tube or hard tube (or the equivalent) is

replaced, also replace retainer with new one.

• To keep the connecting portio n clean and to avoid dam-

age and foreign materials, cover them completely with

plastic bags (A) or something similar.

JPBIA0134ZZ

(B) : Connection (cross-section)

(D) : To under floor fuel line

(E) : To fuel tank

(G) : Disconnection

JPBIA0130ZZ

JPBIA0135ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1874 of 3641

FL -8

< REMOVAL AND INSTALLATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

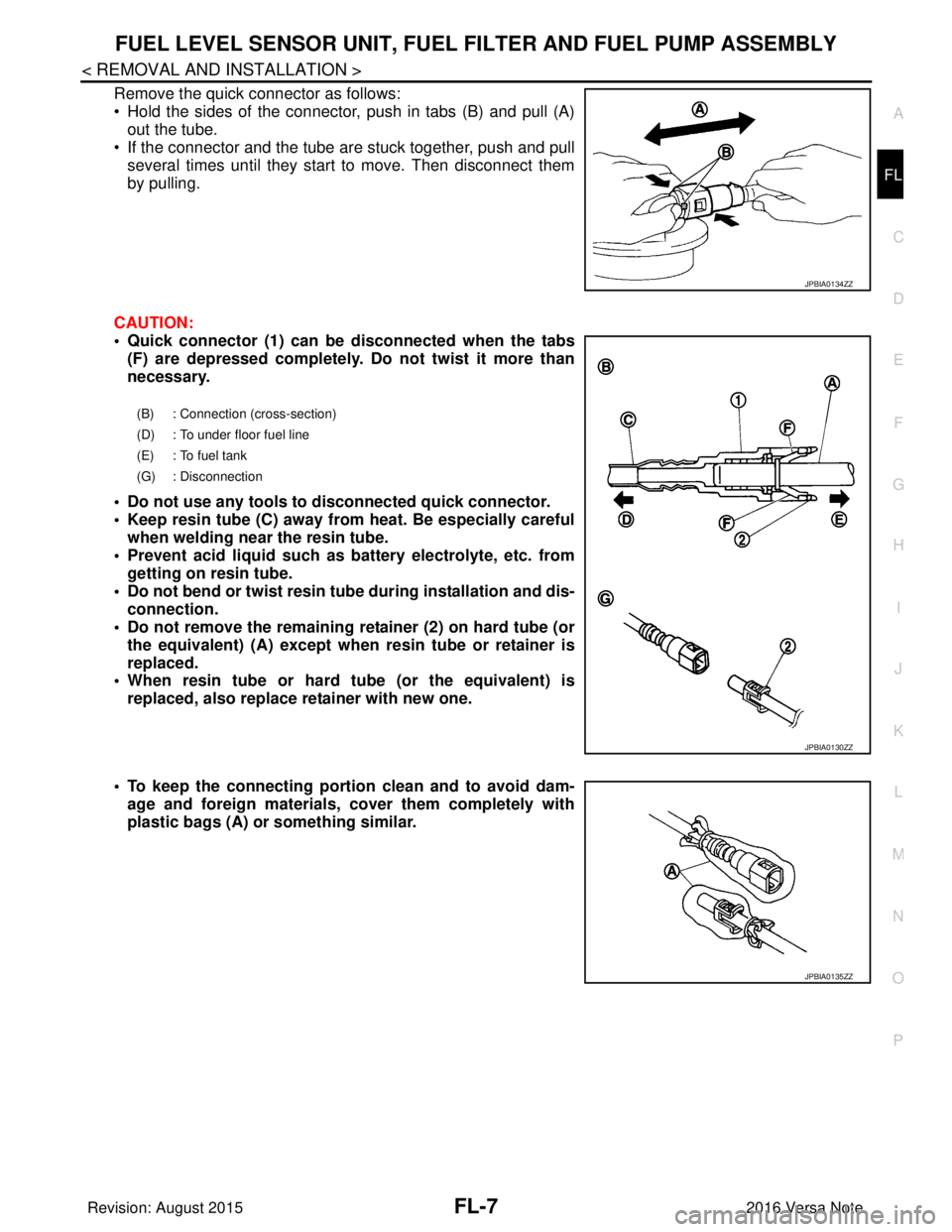

8. Remove lock ring for fuel level sensor unit, fuel filter and fuel

pump assembly using Tool (A) by turning counterclockwise.

9. Remove fuel level sensor unit, fuel filter and fuel pump assembly. CAUTION:

• Do not bend float arm during removal.

• Do not allow contaminants to fa ll inside of the fuel tank.

• Do not cause impacts such by dro pping when handling components.

INSTALLATION

Installation is in the reverse order of removal.

• Install the fuel level sensor, fuel filter, and fuel pump assembly with

the fuel feed tube (C) facing the front of the vehicle as shown. Use

a new O-ring.

CAUTION:

Do not reuse O-ring.

• Connect the quick connector as follows:

- Check the connection for damage or any foreign materials.

- Align the connector with the tube, then insert the connector straight into the tube until a click is heard.

• After the tube is connected, make sure the connection is secure by performing the following checks:

- Pull (A) the tube and the connector to make sure they are securely

connected. Tool number (A) : KV10119900 ( — ) (Shown)

: KV101207S0 ( — )

ALBIA1059ZZ

: Front

(A) : EVAP tube

(B) : Harness connector

ALBIA0747ZZ

JPBIA0140ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1875 of 3641

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLYFL-9

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

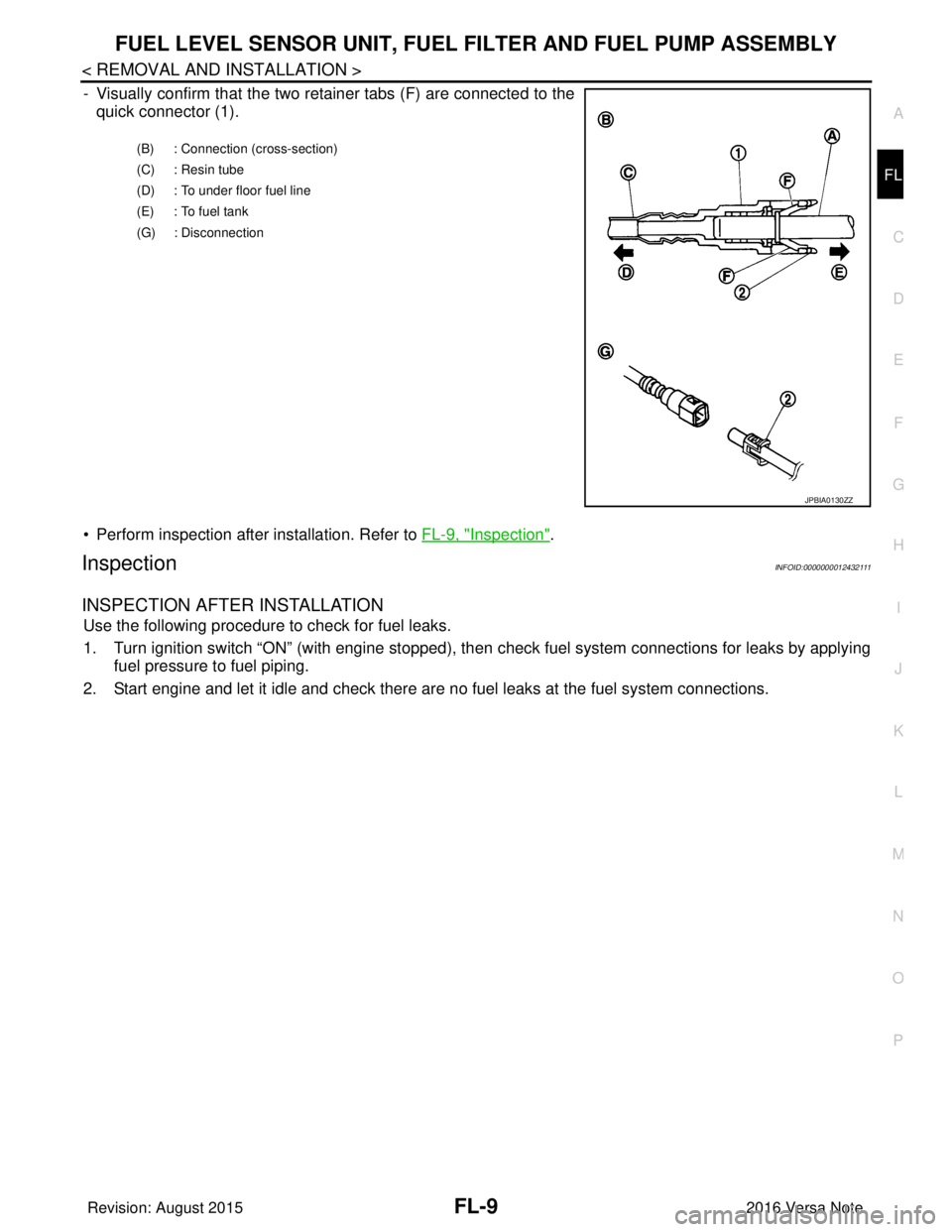

- Visually confirm that the two retainer tabs (F) are connected to the

quick connector (1).

• Perform inspection after installation. Refer to FL-9, "

Inspection".

InspectionINFOID:0000000012432111

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leaks.

1. Turn ignition switch “ON” (with engine stopped), then check fuel system connections for leaks by applying

fuel pressure to fuel piping.

2. Start engine and let it idle and check there are no fuel leaks at the fuel system connections.

(B) : Connection (cross-section)

(C) : Resin tube

(D) : To under floor fuel line

(E) : To fuel tank

(G) : Disconnection

JPBIA0130ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com