maintenance NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 628 of 3641

CL-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432210

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

General PrecautionsINFOID:0000000012432211

WARNING:

After cleaning clutch disc, wipe it with a dust collector. Do not use compressed air.

CAUTION:

• Always use recommended clutch fluid. Refer to MA-11, "

Fluids and Lubricants".

• Do not reuse drained clutch fluid.

• Keep painted surface on the body and other parts free of clutch fluid. If fluid spills, wipe up immedi-

ately and wash the affected area with water.

• Do not use mineral oils, such as gasoline or kerosen e. It will ruin the rubber parts of the hydraulic

system.

• Do not reuse CSC (Concentric Slave Cylinder). CS C slides back to the original position every time

when removing transaxle assembly. At this time, dust on the sliding parts may damage the seal of

CSC and may cause clutch fluid leakage. Refer to CL-17, "

Removal and Installation".

• Do not disassemble clutch master cylinder and CSC.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 631 of 3641

CLUTCH PEDALCL-5

< PERIODIC MAINTENANCE >

CEF

G H

I

J

K L

M A

B

CL

N

O P

PERIODIC MAINTENANCE

CLUTCH PEDAL

Inspection and AdjustmentINFOID:0000000012432215

INSPECTION

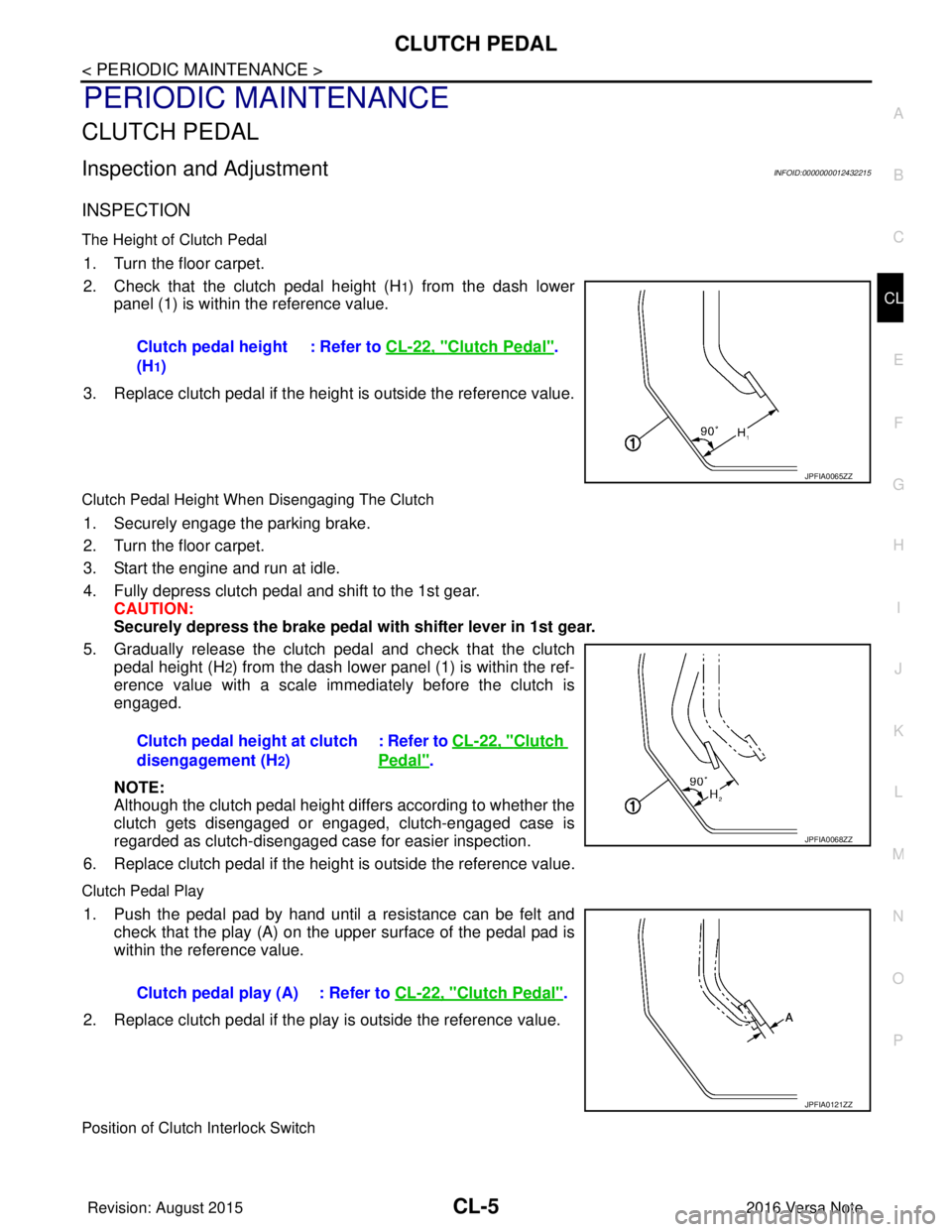

The Height of Clutch Pedal

1. Turn the floor carpet.

2. Check that the clutch pedal height (H

1) from the dash lower

panel (1) is within the reference value.

3. Replace clutch pedal if the height is outside the reference value.

Clutch Pedal Height When Disengaging The Clutch

1. Securely engage the parking brake.

2. Turn the floor carpet.

3. Start the engine and run at idle.

4. Fully depress clutch pedal and shift to the 1st gear. CAUTION:

Securely depress the brake pedal with shifter lever in 1st gear.

5. Gradually release the clutch pedal and check that the clutch pedal height (H

2) from the dash lower panel (1) is within the ref-

erence value with a scale immediately before the clutch is

engaged.

NOTE:

Although the clutch pedal height differs according to whether the

clutch gets disengaged or engaged, clutch-engaged case is

regarded as clutch-disengaged case for easier inspection.

6. Replace clutch pedal if the height is outside the reference value.

Clutch Pedal Play

1. Push the pedal pad by hand until a resistance can be felt and check that the play (A) on the upper surface of the pedal pad is

within the reference value.

2. Replace clutch pedal if the play is outside the reference value.

Position of Clutch Interlock Switch

Clutch pedal height

(H

1) : Refer to

CL-22, "

Clutch Pedal".

JPFIA0065ZZ

Clutch pedal height at clutch

disengagement (H

2) : Refer to CL-22, "

Clutch

Pedal".

JPFIA0068ZZ

Clutch pedal play (A) : Refer to

CL-22, "Clutch Pedal".

JPFIA0121ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 632 of 3641

CL-6

< PERIODIC MAINTENANCE >

CLUTCH PEDAL

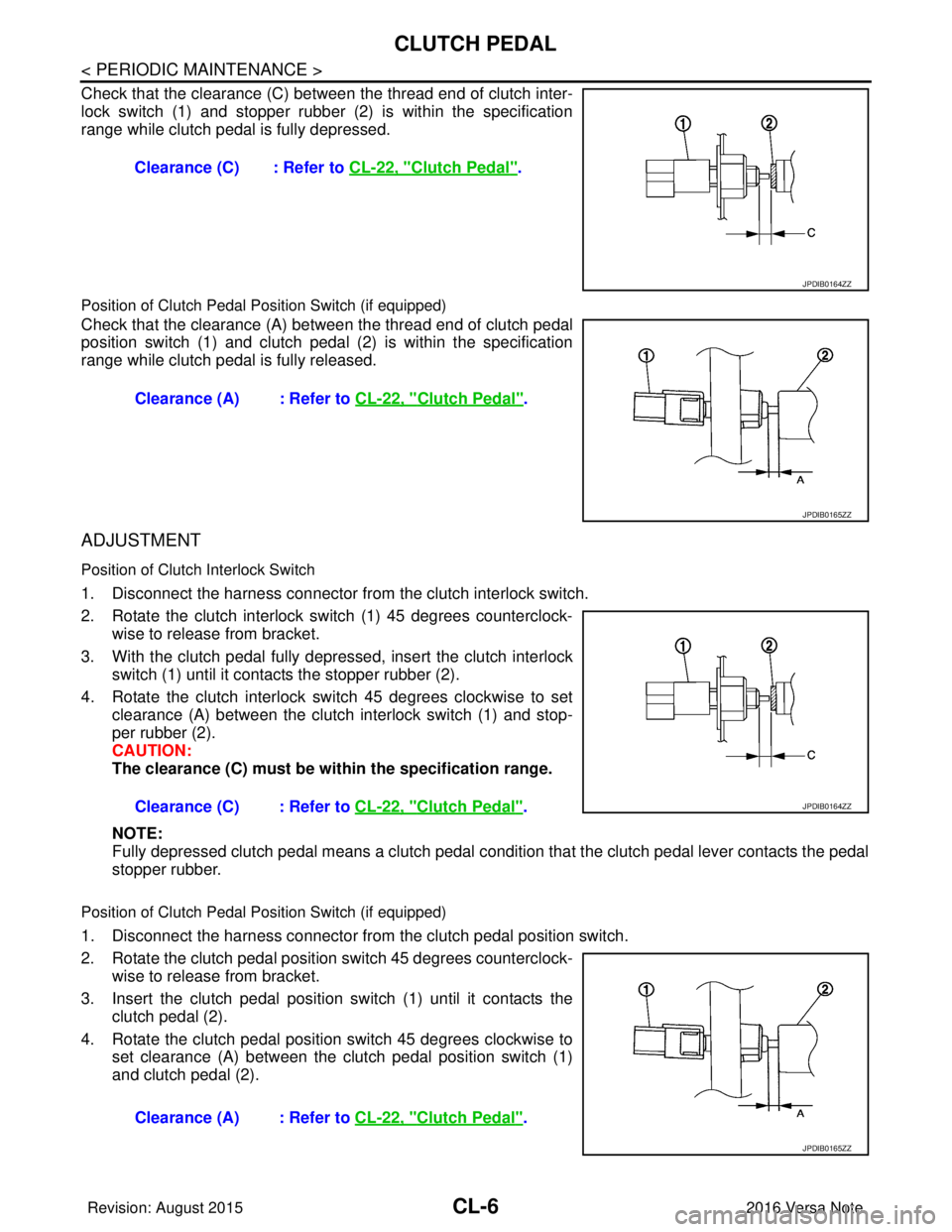

Check that the clearance (C) between the thread end of clutch inter-

lock switch (1) and stopper rubber (2) is within the specification

range while clutch pedal is fully depressed.

Position of Clutch Pedal Position Switch (if equipped)

Check that the clearance (A) between the thread end of clutch pedal

position switch (1) and clutch pedal (2) is within the specification

range while clutch pedal is fully released.

ADJUSTMENT

Position of Clutch Interlock Switch

1. Disconnect the harness connector from the clutch interlock switch.

2. Rotate the clutch interlock switch (1) 45 degrees counterclock- wise to release from bracket.

3. With the clutch pedal fully depressed, insert the clutch interlock switch (1) until it contacts the stopper rubber (2).

4. Rotate the clutch interlock switch 45 degrees clockwise to set clearance (A) between the clutch interlock switch (1) and stop-

per rubber (2).

CAUTION:

The clearance (C) must be wi thin the specification range.

NOTE:

Fully depressed clutch pedal means a clutch pedal condi tion that the clutch pedal lever contacts the pedal

stopper rubber.

Position of Clutch Pedal Position Switch (if equipped)

1. Disconnect the harness connector from the clutch pedal position switch.

2. Rotate the clutch pedal position switch 45 degrees counterclock- wise to release from bracket.

3. Insert the clutch pedal position switch (1) until it contacts the

clutch pedal (2).

4. Rotate the clutch pedal position switch 45 degrees clockwise to set clearance (A) between the clutch pedal position switch (1)

and clutch pedal (2).Clearance (C) : Refer to

CL-22, "

Clutch Pedal".

JPDIB0164ZZ

Clearance (A) : Refer to CL-22, "Clutch Pedal".

JPDIB0165ZZ

Clearance (C) : Refer to CL-22, "Clutch Pedal".JPDIB0164ZZ

Clearance (A) : Refer to CL-22, "Clutch Pedal".

JPDIB0165ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 633 of 3641

CLUTCH FLUIDCL-7

< PERIODIC MAINTENANCE >

CEF

G H

I

J

K L

M A

B

CL

N

O P

CLUTCH FLUID

InspectionINFOID:0000000012432216

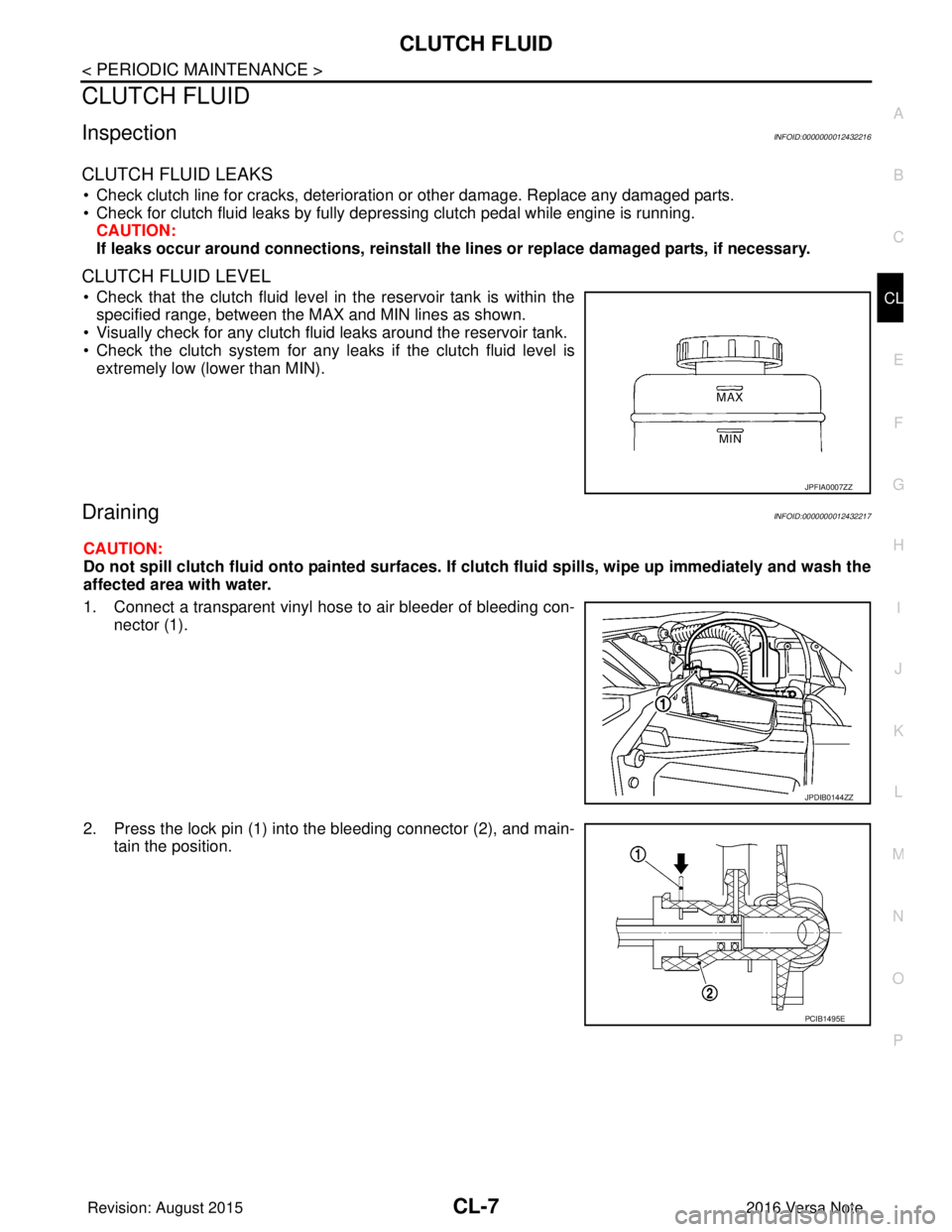

CLUTCH FLUID LEAKS

• Check clutch line for cracks, deterioration or other damage. Replace any damaged parts.

• Check for clutch fluid leaks by fully depressing clutch pedal while engine is running. CAUTION:

If leaks occur around connections, reinstall th e lines or replace damaged parts, if necessary.

CLUTCH FLUID LEVEL

• Check that the clutch fluid level in the reservoir tank is within the

specified range, between the MAX and MIN lines as shown.

• Visually check for any clutch fluid leaks around the reservoir tank.

• Check the clutch system for any leaks if the clutch fluid level is

extremely low (lower than MIN).

DrainingINFOID:0000000012432217

CAUTION:

Do not spill clutch fluid onto painted surfaces. If clutch fluid spills, wipe up immediately and wash the

affected area with water.

1. Connect a transparent vinyl hose to air bleeder of bleeding con-

nector (1).

2. Press the lock pin (1) into the bleeding connector (2), and main- tain the position.

JPFIA0007ZZ

JPDIB0144ZZ

PCIB1495E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 634 of 3641

CL-8

< PERIODIC MAINTENANCE >

CLUTCH FLUID

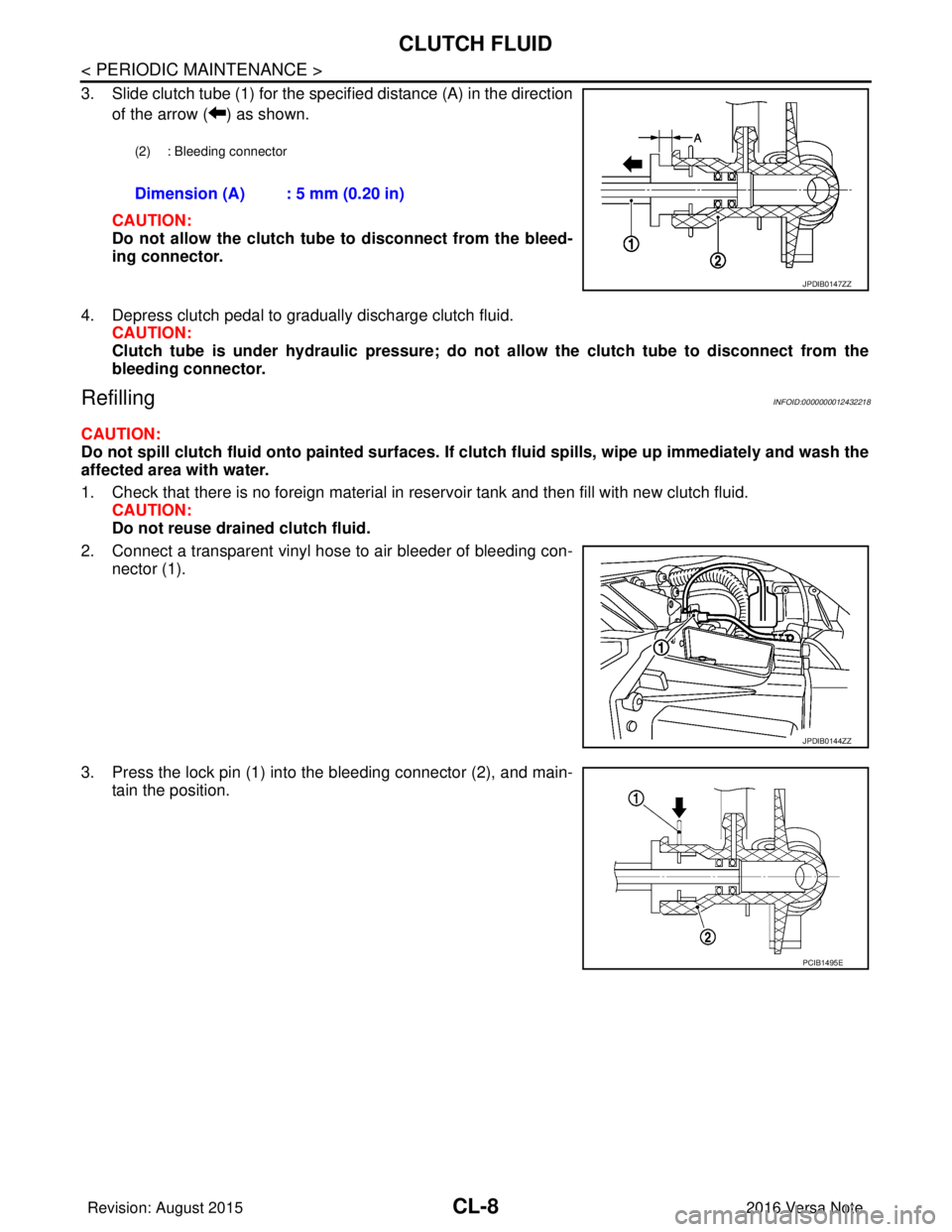

3. Slide clutch tube (1) for the specified distance (A) in the directionof the arrow ( ) as shown.

CAUTION:

Do not allow the clutch tube to disconnect from the bleed-

ing connector.

4. Depress clutch pedal to gradually discharge clutch fluid. CAUTION:

Clutch tube is under hydraulic pressure; do not allow the clutch tube to disconnect from the

bleeding connector.

RefillingINFOID:0000000012432218

CAUTION:

Do not spill clutch fluid onto painted surfaces. If cl utch fluid spills, wipe up immediately and wash the

affected area with water.

1. Check that there is no foreign material in reservoir tank and then fill with new clutch fluid. CAUTION:

Do not reuse drained clutch fluid.

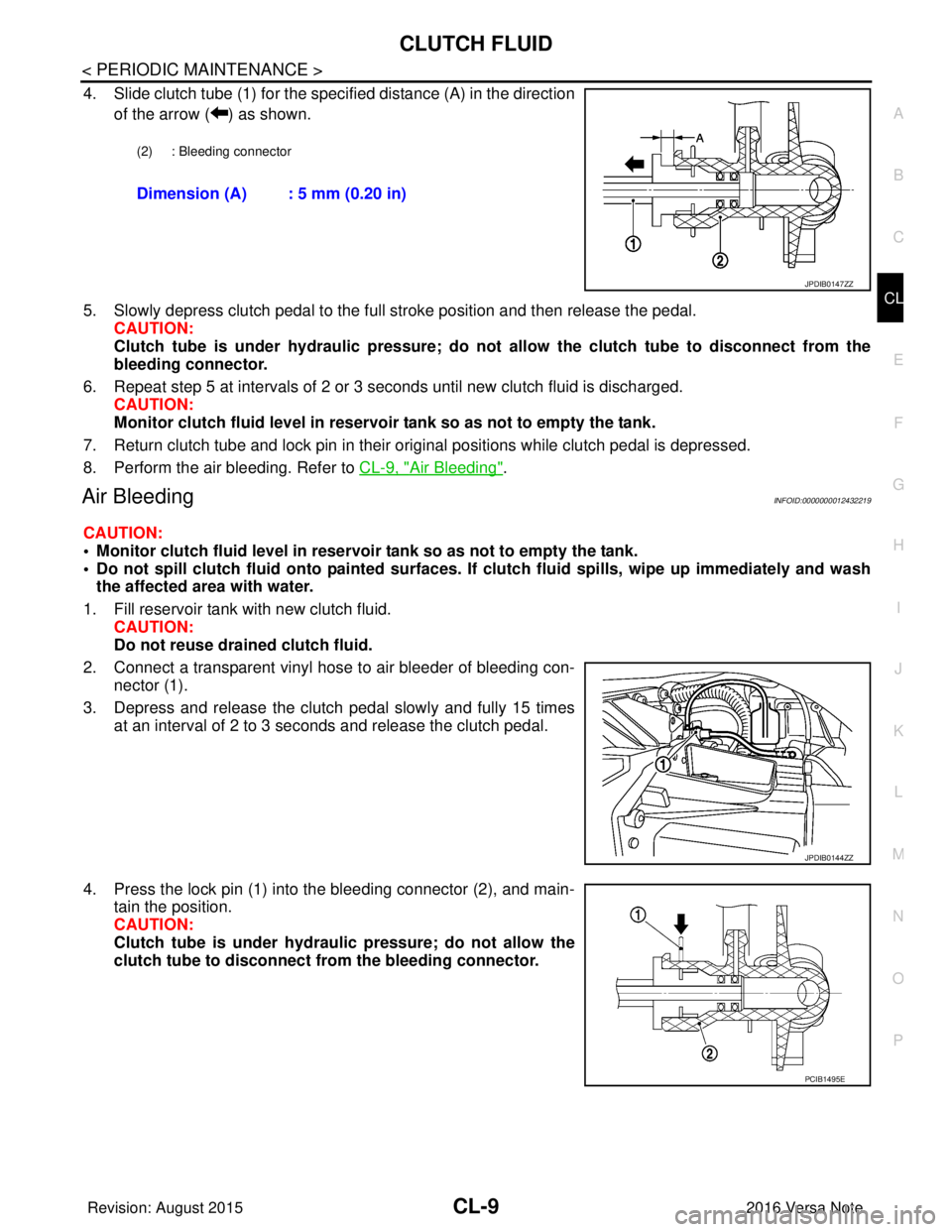

2. Connect a transparent vinyl hose to air bleeder of bleeding con- nector (1).

3. Press the lock pin (1) into the bleeding connector (2), and main- tain the position.

(2) : Bleeding connector

Dimension (A) : 5 mm (0.20 in)

JPDIB0147ZZ

JPDIB0144ZZ

PCIB1495E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 635 of 3641

CLUTCH FLUIDCL-9

< PERIODIC MAINTENANCE >

CEF

G H

I

J

K L

M A

B

CL

N

O P

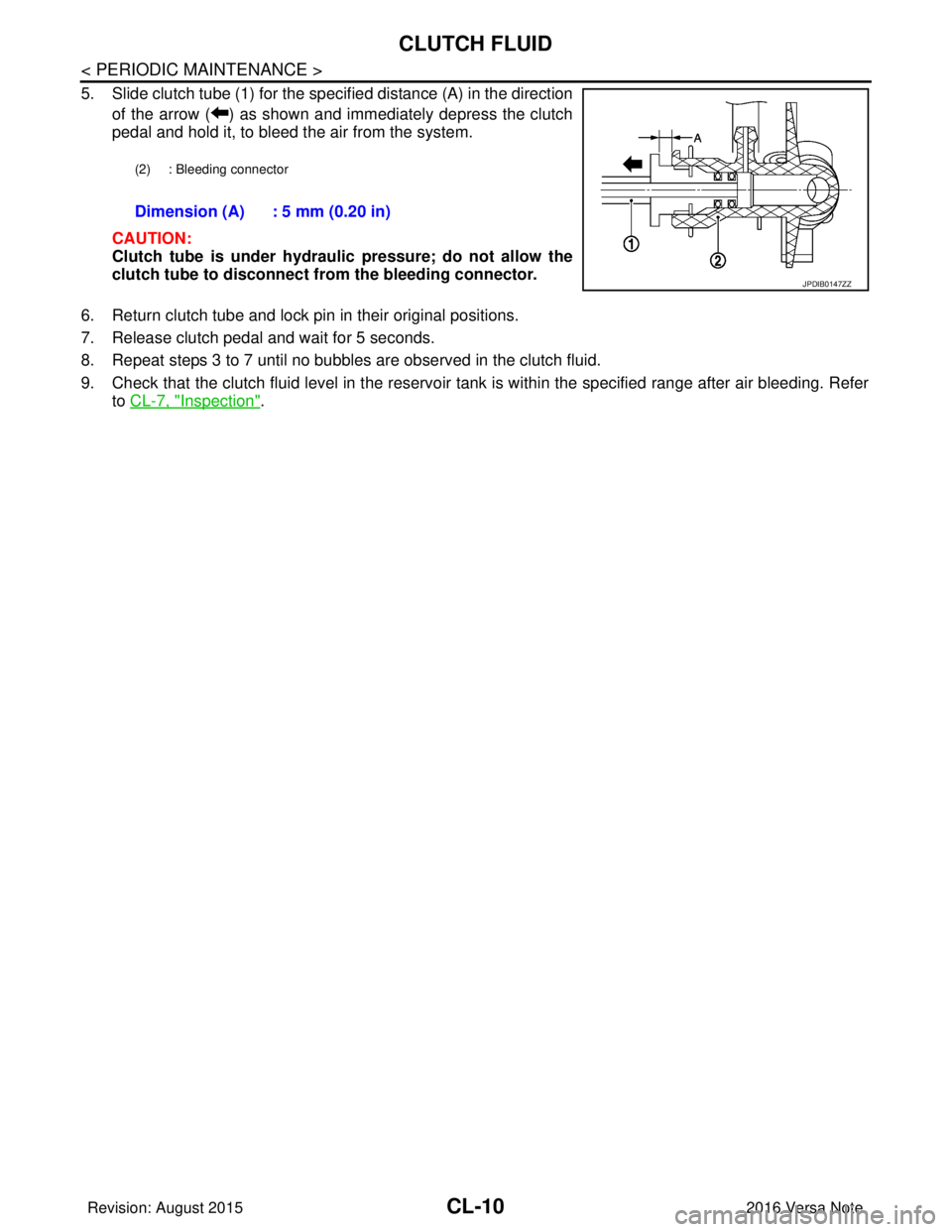

4. Slide clutch tube (1) for the specified distance (A) in the direction of the arrow ( ) as shown.

5. Slowly depress clutch pedal to the full stroke position and then release the pedal. CAUTION:

Clutch tube is under hydraulic pressure; do not allow the clutch tube to disconnect from the

bleeding connector.

6. Repeat step 5 at intervals of 2 or 3 seconds until new clutch fluid is discharged. CAUTION:

Monitor clutch fluid level in reservoir tank so as not to empty the tank.

7. Return clutch tube and lock pin in their original positions while clutch pedal is depressed.

8. Perform the air bleeding. Refer to CL-9, "

Air Bleeding".

Air BleedingINFOID:0000000012432219

CAUTION:

• Monitor clutch fluid level in reservoir tank so as not to empty the tank.

• Do not spill clutch fluid onto painted surfaces. If clutch fluid spil ls, wipe up immediately and wash

the affected area with water.

1. Fill reservoir tank with new clutch fluid. CAUTION:

Do not reuse drained clutch fluid.

2. Connect a transparent vinyl hose to air bleeder of bleeding con- nector (1).

3. Depress and release the clutch pedal slowly and fully 15 times at an interval of 2 to 3 seconds and release the clutch pedal.

4. Press the lock pin (1) into the bleeding connector (2), and main- tain the position.

CAUTION:

Clutch tube is under hydraulic pressure; do not allow the

clutch tube to disconnect from the bleeding connector.

(2) : Bleeding connector

Dimension (A) : 5 mm (0.20 in)

JPDIB0147ZZ

JPDIB0144ZZ

PCIB1495E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 636 of 3641

CL-10

< PERIODIC MAINTENANCE >

CLUTCH FLUID

5. Slide clutch tube (1) for the specified distance (A) in the directionof the arrow ( ) as shown and immediately depress the clutch

pedal and hold it, to bleed the air from the system.

CAUTION:

Clutch tube is under hydraulic pressure; do not allow the

clutch tube to disconnect from the bleeding connector.

6. Return clutch tube and lock pin in their original positions.

7. Release clutch pedal and wait for 5 seconds.

8. Repeat steps 3 to 7 until no bubbles are observed in the clutch fluid.

9. Check that the clutch fluid level in the reservoir tank is within the specified range after air bleeding. Refer to CL-7, "

Inspection".

(2) : Bleeding connector

Dimension (A) : 5 mm (0.20 in)

JPDIB0147ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 650 of 3641

![NISSAN NOTE 2016 Service User Guide CCS-2

< PRECAUTION >[ASCD]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012542559

The Supplemental Rest NISSAN NOTE 2016 Service User Guide CCS-2

< PRECAUTION >[ASCD]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012542559

The Supplemental Rest](/img/5/57363/w960_57363-649.png)

CCS-2

< PRECAUTION >[ASCD]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012542559

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 654 of 3641

PRECAUTIONSDEF-3

< PRECAUTION >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431751

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 698 of 3641

![NISSAN NOTE 2016 Service User Guide PRECAUTIONSDLK-9

< PRECAUTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE NISSAN NOTE 2016 Service User Guide PRECAUTIONSDLK-9

< PRECAUTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE](/img/5/57363/w960_57363-697.png)

PRECAUTIONSDLK-9

< PRECAUTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012429960

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Procedure without Cowl Top CoverINFOID:0000000012429961

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc. to prevent damage to

the windshield.

Precaution for Servicing Doors and LocksINFOID:0000000012429962

WARNING:

Radio waves could adversely affect electric medical equipment. Those who use a pacemaker should

contact the electric medical equipment manufacturer for the possible influences before use,

• After removing and installing the opening/closing parts, be sure to carry out fitting adjustments to check their operation.

• Check the lubrication level, damage, and wear of each part. If necessary, grease or replace it.

• When removing or disassembling each component, be ca reful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component

with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusabl e part, always replace it with a new one.

PIIB3706J

Revision: August 2015 2016 Versa Note

cardiagn.com