maintenance NISSAN NOTE 2016 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1024 of 3641

![NISSAN NOTE 2016 Service Owners Guide SPARK PLUGEM-23

< PERIODIC MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

The ground electrode of the spark plug is positioned in the area of maximum ignitability to improve combustion

eficien NISSAN NOTE 2016 Service Owners Guide SPARK PLUGEM-23

< PERIODIC MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

The ground electrode of the spark plug is positioned in the area of maximum ignitability to improve combustion

eficien](/img/5/57363/w960_57363-1023.png)

SPARK PLUGEM-23

< PERIODIC MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

The ground electrode of the spark plug is positioned in the area of maximum ignitability to improve combustion

eficiency in the cylinder, reduce CO2 (carbon

dioxide) emission and improve fuel economy.

1. Ground electrode of spark plug A. Top view B. Air-fuel mixture flow

C. Poor ignitability region

JPBIA5996GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1134 of 3641

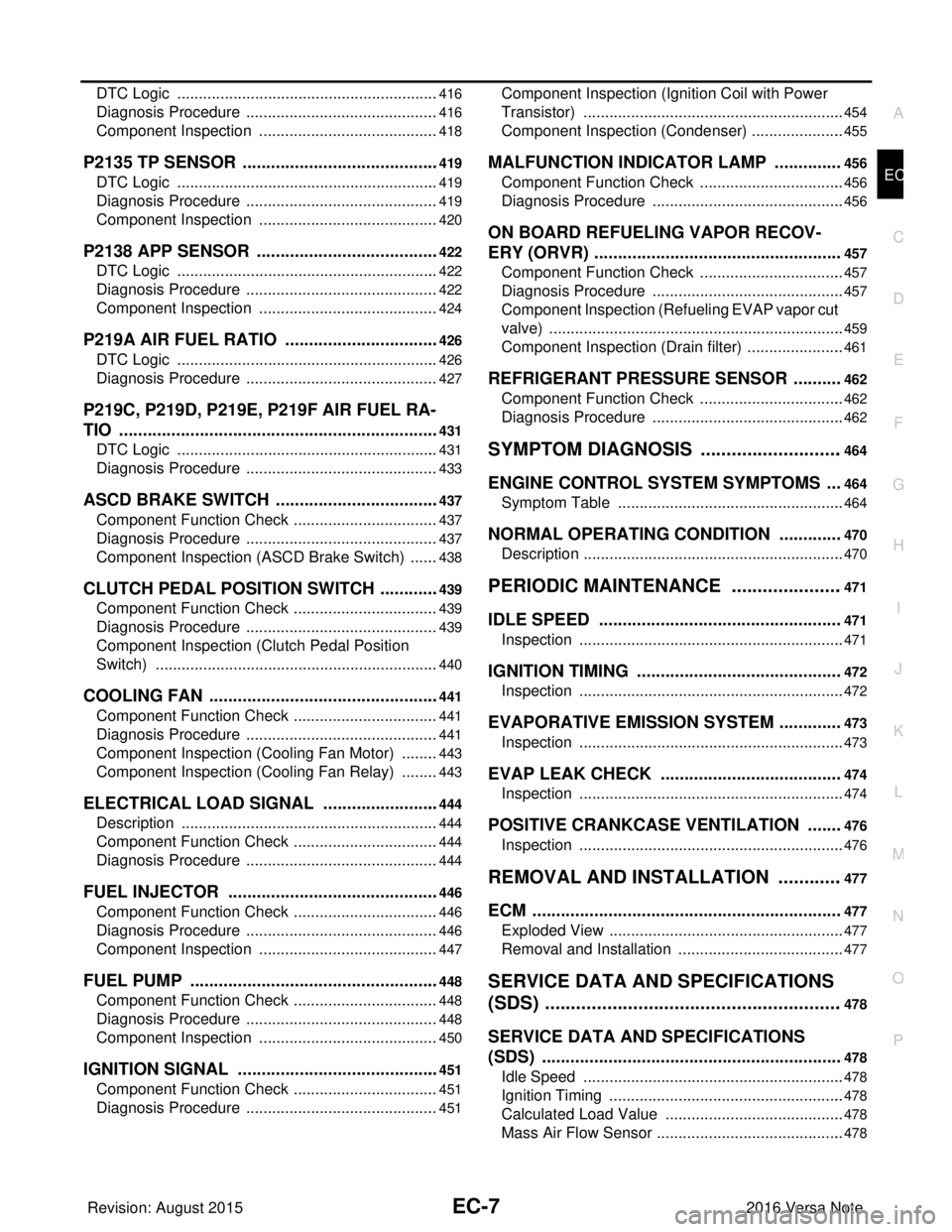

EC-7

C

DE

F

G H

I

J

K L

M

EC A

N

O P

DTC Logic ...........................................................

..

416

Diagnosis Procedure .............................................416

Component Inspection ..........................................418

P2135 TP SENSOR ..........................................419

DTC Logic ........................................................... ..419

Diagnosis Procedure .............................................419

Component Inspection ..........................................420

P2138 APP SENSOR .......................................422

DTC Logic .............................................................422

Diagnosis Procedure .............................................422

Component Inspection ..........................................424

P219A AIR FUEL RATIO .................................426

DTC Logic ........................................................... ..426

Diagnosis Procedure .............................................427

P219C, P219D, P219E, P219F AIR FUEL RA-

TIO ....................................................................

431

DTC Logic ........................................................... ..431

Diagnosis Procedure .............................................433

ASCD BRAKE SWITCH ...................................437

Component Function Check ................................ ..437

Diagnosis Procedure .............................................437

Component Inspection (ASCD Brake Switch) .......438

CLUTCH PEDAL POSITION SWITCH .............439

Component Function Check ................................ ..439

Diagnosis Procedure .............................................439

Component Inspection (Clutch Pedal Position

Switch) ..................................................................

440

COOLING FAN .................................................441

Component Function Check ................................ ..441

Diagnosis Procedure .............................................441

Component Inspection (Cooling Fan Motor) .........443

Component Inspection (Cooling Fan Relay) .........443

ELECTRICAL LOAD SIGNAL .........................444

Description .......................................................... ..444

Component Function Check ..................................444

Diagnosis Procedure .............................................444

FUEL INJECTOR .............................................446

Component Function Check ................................ ..446

Diagnosis Procedure .............................................446

Component Inspection ..........................................447

FUEL PUMP .....................................................448

Component Function Check ................................ ..448

Diagnosis Procedure .............................................448

Component Inspection ..........................................450

IGNITION SIGNAL ...........................................451

Component Function Check ................................ ..451

Diagnosis Procedure .............................................451

Component Inspection (Ignition Coil with Power

Transistor) ........................................................... ..

454

Component Inspection (Condenser) ......................455

MALFUNCTION INDICATOR LAMP ..............456

Component Function Check ..................................456

Diagnosis Procedure .............................................456

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ....................................................

457

Component Function Check ..................................457

Diagnosis Procedure .............................................457

Component Inspection (Refueling EVAP vapor cut

valve) ................................................................... ..

459

Component Inspection (Drain filter) .......................461

REFRIGERANT PRESSURE SENSOR ..........462

Component Function Check ..................................462

Diagnosis Procedure .............................................462

SYMPTOM DIAGNOSIS ............................464

ENGINE CONTROL SYSTEM SYMPTOMS ...464

Symptom Table ................................................... ..464

NORMAL OPERATING CONDITION .............470

Description .............................................................470

PERIODIC MAINTENANCE ......................471

IDLE SPEED .... ...............................................471

Inspection ............................................................ ..471

IGNITION TIMING ...........................................472

Inspection ..............................................................472

EVAPORATIVE EMISSION SYSTEM .............473

Inspection ..............................................................473

EVAP LEAK CHECK ......................................474

Inspection ..............................................................474

POSITIVE CRANKCASE VENTILATION .......476

Inspection ..............................................................476

REMOVAL AND INSTALLATION .............477

ECM .................................................................477

Exploded View ..................................................... ..477

Removal and Installation .......................................477

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... .

478

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

478

Idle Speed ........................................................... ..478

Ignition Timing .......................................................478

Calculated Load Value ..........................................478

Mass Air Flow Sensor ............................................478

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1135 of 3641

![NISSAN NOTE 2016 Service Owners Guide EC-8

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431263

The Supplemental Res NISSAN NOTE 2016 Service Owners Guide EC-8

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431263

The Supplemental Res](/img/5/57363/w960_57363-1134.png)

EC-8

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431263

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

On Board Diagnosti c (OBD) System of Engine and CVTINFOID:0000000012431265

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect the negative battery cable before any repair

or inspection work. The open/short circuit of re lated switches, sensors, solenoid valves, etc. will

cause the MIL to light up.

• Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Certain systems and components, especially those related to OBD, may use a new style slide-lock- ing type harness connector. For descripti on and how to disconnect, refer to PG-9, "

Harness Connec-

tor".

• Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MIL to li ght up due to the short circuit.

• Be sure to connect rubber tubes properly afte r work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfunction of the fuel injection system, etc.

• Be sure to erase the unnecessary malfunction info rmation (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1254 of 3641

![NISSAN NOTE 2016 Service Owners Guide VIN REGISTRATIONEC-127

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

VIN REGISTRATION

DescriptionINFOID:0000000012431352

VIN Registration is an operation to registering VIN in

ECM. It NISSAN NOTE 2016 Service Owners Guide VIN REGISTRATIONEC-127

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

VIN REGISTRATION

DescriptionINFOID:0000000012431352

VIN Registration is an operation to registering VIN in

ECM. It](/img/5/57363/w960_57363-1253.png)

VIN REGISTRATIONEC-127

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

VIN REGISTRATION

DescriptionINFOID:0000000012431352

VIN Registration is an operation to registering VIN in

ECM. It must be performed each time ECM is replaced.

Refer to EC-127, "

Work Procedure".

NOTE:

Accurate VIN which is registered in ECM may be required for Inspection & Maintenance (I/M).

Work ProcedureINFOID:0000000012431353

1.CHECK VIN

Check the VIN of the vehicle and note it. Refer to GI-34, "

Identification Number".

>> GO TO 2.

2.PERFORM VIN REGISTRATION

With CONSULT

1. Turn ignition switch ON and engine stopped.

2. Select “VIN REGISTRATION” in “WORK SUPPORT” mode of “ENGINE” using CONSULT.

3. Follow the instruction of CONSULT display.

>> END

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1260 of 3641

![NISSAN NOTE 2016 Service Owners Guide BASIC INSPECTIONEC-133

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

BASIC INSPECTION

Work ProcedureINFOID:0000000012431362

1.INSPECTION START

1. Check service records for any recent r NISSAN NOTE 2016 Service Owners Guide BASIC INSPECTIONEC-133

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

BASIC INSPECTION

Work ProcedureINFOID:0000000012431362

1.INSPECTION START

1. Check service records for any recent r](/img/5/57363/w960_57363-1259.png)

BASIC INSPECTIONEC-133

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

BASIC INSPECTION

Work ProcedureINFOID:0000000012431362

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related malfunction, or a current need for scheduled maintenance.

2. Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper connections, pinches and cut

- Vacuum hoses for splits, kinks and improper connections

- Hoses and ducts for leaks

- Air cleaner clogging

- Gasket

3. Confirm that electrical or mechanical loads are not applied.

- Headlamp switch is OFF.

- Air conditioner switch is OFF.

- Rear window defogger switch is OFF.

- Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature indicator points to the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no load.

6. Make sure that no DTC is displayed with CONSULT or GST.

Is any DTC detected?

YES >> GO TO 2.

NO >> GO TO 3.

2.REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding Diagnostic Procedure.

>> GO TO 3

3.CHECK TARGET IDLE SPEED

1. Run engine at about 2,000 rpm for about 2 minutes under no load.

SEF983U

SEF976U

SEF977U

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1598 of 3641

![NISSAN NOTE 2016 Service Owners Guide IDLE SPEEDEC-471

< PERIODIC MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PERIODIC MAINTENANCE

IDLE SPEED

InspectionINFOID:0000000012431668

1.CHECK IDLE SPEED

With CONSULT

Check idle speed in NISSAN NOTE 2016 Service Owners Guide IDLE SPEEDEC-471

< PERIODIC MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PERIODIC MAINTENANCE

IDLE SPEED

InspectionINFOID:0000000012431668

1.CHECK IDLE SPEED

With CONSULT

Check idle speed in](/img/5/57363/w960_57363-1597.png)

IDLE SPEEDEC-471

< PERIODIC MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PERIODIC MAINTENANCE

IDLE SPEED

InspectionINFOID:0000000012431668

1.CHECK IDLE SPEED

With CONSULT

Check idle speed in “DATA MONITOR” mode with CONSULT.

Without CONSULT

Check idle speed by installing the pulse type tachometer clamp on the loop wire or on suitable high-tension

wire which installed between No.1 ignition coil and No.1 spark plug.

With GST

Check idle speed with Service $01 of GST.

>> INSPECTION END

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1599 of 3641

![NISSAN NOTE 2016 Service Owners Guide EC-472

< PERIODIC MAINTENANCE >[HR16DE]

IGNITION TIMING

IGNITION TIMING

InspectionINFOID:0000000012431669

1.CHECK IGNITION TIMING

1. Attach timing light (A) to loop wire (1) as shown.

2. Check ignitio NISSAN NOTE 2016 Service Owners Guide EC-472

< PERIODIC MAINTENANCE >[HR16DE]

IGNITION TIMING

IGNITION TIMING

InspectionINFOID:0000000012431669

1.CHECK IGNITION TIMING

1. Attach timing light (A) to loop wire (1) as shown.

2. Check ignitio](/img/5/57363/w960_57363-1598.png)

EC-472

< PERIODIC MAINTENANCE >[HR16DE]

IGNITION TIMING

IGNITION TIMING

InspectionINFOID:0000000012431669

1.CHECK IGNITION TIMING

1. Attach timing light (A) to loop wire (1) as shown.

2. Check ignition timing.

>> INSPECTION END

ALBIA1075ZZ

1 : Timing indicator

MBIB1331E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1600 of 3641

![NISSAN NOTE 2016 Service Owners Guide EVAPORATIVE EMISSION SYSTEMEC-473

< PERIODIC MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

EVAPORATIVE EMISSION SYSTEM

InspectionINFOID:0000000012431670

1.CHECK EVAP CANISTER

1. Block port (B NISSAN NOTE 2016 Service Owners Guide EVAPORATIVE EMISSION SYSTEMEC-473

< PERIODIC MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

EVAPORATIVE EMISSION SYSTEM

InspectionINFOID:0000000012431670

1.CHECK EVAP CANISTER

1. Block port (B](/img/5/57363/w960_57363-1599.png)

EVAPORATIVE EMISSION SYSTEMEC-473

< PERIODIC MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

EVAPORATIVE EMISSION SYSTEM

InspectionINFOID:0000000012431670

1.CHECK EVAP CANISTER

1. Block port (B).

2. Blow air into port (A) and check that it flows freely out of port (C).

3. Release blocked port (B).

4. Apply vacuum pressure to port (B) and check that vacuum pres-

sure exists at the ports (A) and (C).

5. Block port (A) and (B).

6. Apply pressure to port (C) and check that there is no leakage.

>> INSPECTION END

PBIB1212E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1601 of 3641

![NISSAN NOTE 2016 Service Owners Guide EC-474

< PERIODIC MAINTENANCE >[HR16DE]

EVAP LEAK CHECK

EVAP LEAK CHECK

InspectionINFOID:0000000012431671

CAUTION:

• Do not use compressed air

or a high pressure pump.

• Do not exceed 4.12 kPa (0 NISSAN NOTE 2016 Service Owners Guide EC-474

< PERIODIC MAINTENANCE >[HR16DE]

EVAP LEAK CHECK

EVAP LEAK CHECK

InspectionINFOID:0000000012431671

CAUTION:

• Do not use compressed air

or a high pressure pump.

• Do not exceed 4.12 kPa (0](/img/5/57363/w960_57363-1600.png)

EC-474

< PERIODIC MAINTENANCE >[HR16DE]

EVAP LEAK CHECK

EVAP LEAK CHECK

InspectionINFOID:0000000012431671

CAUTION:

• Do not use compressed air

or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm

2, 0.6 psi) of pressure in EVAP system.

NOTE:

• Do not start engine.

• Improper installation of EVAP service port adapter [commercial service tool: (J-41413-OBD)] to the EVAP

service port may cause a leak.

1.EVAP LEAK CHECK

With CONSULT

1. Install EVAP service port adapter [commercial service tool: (J- 41413-OBD)] and pressure pump to EVAP service port.

2. Turn ignition switch ON.

3. Select the “EVAP SYSTEM CLOSE” in “WORK SUPPORT”

mode of “ENGINE” using CONSULT.

4. Touch “START”. A bar graph (Pressure indicating display) will

appear on the screen.

5. Apply positive pressure to the EVAP system until the pressure indicator reaches the middle of the bar graph.

6. Remove EVAP service port adapter [commercial service tool: (J- 41413-OBD)] and hose with pressure pump.

7. Locate the leak using a leak detector [commercial service tool: (J-41416)]. Refer to EC-40, "

EVAPORATIVE EMISSION SYS-

TEM : System Description".

Without CONSULT

1. Install EVAP service port adapter [commercial service tool: (J- 41413-OBD)] and pressure pump to EVAP service port.

2. Apply battery voltage between the terminals of EVAP canister

vent control valve to make a closed EVAP system.

3. To locate the leak, deliver positive pressure to the EVAP system until pressure gauge points reach 1.38 to 2.76 kPa (0.014 to

0.028 kg/cm

2, 0.2 to 0.4 psi).

4. Remove EVAP service port adapter [commercial service tool: (J- 41413-OBD)] and hose with pressure pump.

SEF462UA

SEF200U

SEF462UA

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1602 of 3641

![NISSAN NOTE 2016 Service Owners Guide EVAP LEAK CHECKEC-475

< PERIODIC MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

5. Locate the leak using a leak detector [commercial service tool:

(J-41416)]. Refer to EC-40, "

EVAPORATIVE EM NISSAN NOTE 2016 Service Owners Guide EVAP LEAK CHECKEC-475

< PERIODIC MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

5. Locate the leak using a leak detector [commercial service tool:

(J-41416)]. Refer to EC-40, "

EVAPORATIVE EM](/img/5/57363/w960_57363-1601.png)

EVAP LEAK CHECKEC-475

< PERIODIC MAINTENANCE > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

5. Locate the leak using a leak detector [commercial service tool:

(J-41416)]. Refer to EC-40, "

EVAPORATIVE EMISSION SYS-

TEM : System Description".

>> INSPECTION END

SEF200U

Revision: August 2015 2016 Versa Note

cardiagn.com