warning light NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 580 of 3641

![NISSAN NOTE 2016 Service User Guide BRC-132

< SYMPTOM DIAGNOSIS >[VDC/TCS/ABS]

VDC/TCS/ABS

SYMPTOM DIAGNOSIS

VDC/TCS/ABS

Symptom TableINFOID:0000000012430917

If ABS warning lamp and SLIP indicator

lamp turn ON, perform self diagnostic. NISSAN NOTE 2016 Service User Guide BRC-132

< SYMPTOM DIAGNOSIS >[VDC/TCS/ABS]

VDC/TCS/ABS

SYMPTOM DIAGNOSIS

VDC/TCS/ABS

Symptom TableINFOID:0000000012430917

If ABS warning lamp and SLIP indicator

lamp turn ON, perform self diagnostic.](/img/5/57363/w960_57363-579.png)

BRC-132

< SYMPTOM DIAGNOSIS >[VDC/TCS/ABS]

VDC/TCS/ABS

SYMPTOM DIAGNOSIS

VDC/TCS/ABS

Symptom TableINFOID:0000000012430917

If ABS warning lamp and SLIP indicator

lamp turn ON, perform self diagnostic.

NOTE:

• 1: The ABS does not operate when the speed is 10 km/h (6 MPH) or less.

• 2: Under the following conditions, ABS is activated and vibration is felt when brake pedal is lightly depressed (just place a foot on it).

However, this is normal:

- When shifting gears

- When driving on slippery road

- During cornering at high speed

- When passing over bumps or grooves [approximately 50 mm (1.97 in) or more]

- When pulling away just after starting engine [at approximately 10 km/h (6 MPH) or higher] Symptom

Check itemReference

Excessive ABS function operation fre-

quency Brake force distribution

BRC-133, "

Diag-

nosis Procedure"Looseness of front and rear axle

Wheel sensor and rotor system

Unexpected pedal reaction Brake pedal stroke

BRC-134, "

Diag-

nosis Procedure"Make sure the braking force is sufficient when the ABS is not operating.

The braking distance is long Check stopping distance when the ABS is not operating. BRC-135, "

Diag-

nosis Procedure"

ABS function does not operate (Note 1) ABS actuator and electric

unit (control unit)BRC-136, "Diag-

nosis Procedure"

Pedal vibration or ABS operation sound

occurs (Note 2)Brake pedal

BRC-137, "Diag-

nosis Procedure"ABS actuator and electric unit (control unit)

Vehicle jerks during VDC/TCS/ABS con-

trol ABS actuator and electric unit (control unit)

BRC-138, "

Diag-

nosis Procedure"TCM

ECM

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 587 of 3641

![NISSAN NOTE 2016 Service User Guide NORMAL OPERATING CONDITIONBRC-139

< SYMPTOM DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000012430924

Symptom Result

Slight vibrations a NISSAN NOTE 2016 Service User Guide NORMAL OPERATING CONDITIONBRC-139

< SYMPTOM DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000012430924

Symptom Result

Slight vibrations a](/img/5/57363/w960_57363-586.png)

NORMAL OPERATING CONDITIONBRC-139

< SYMPTOM DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000012430924

Symptom Result

Slight vibrations are felt on the brake pedal and operation noises occur when VDC, TCS or ABS is activated. This is a normal condi-

tion due to the VDC,

TCS or ABS activation.

Stopping distance is longer than that of vehicles without ABS when the vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

The brake pedal moves and generates noises when TCS or VDC is activated due to rapid acceleration or

sharp turn.

The brake pedal vibrates and motor operation noises occur from the engine room after the engine starts and

just after the vehicle starts.

This is normal, and it is

caused by the ABS op-

eration check.

Depending on the road conditions, the driver may experience a sluggish feel in the brake pedal. This is normal, because

TCS places the highest

priority on the optimum

traction (stability).

TCS may activate momentarily if wheel speed changes when driving where road friction coefficient varies,

when downshifting, or when fully depressing accelerator pedal.

The ABS warning lamp and SLIP

indicator lamp may turn ON when the vehicle is subject to strong shaking

or large vibration, such as when the vehicle is rotating on a turntable or located on a ship while the engine

is running. In this case, restart the

engine on a normal

road. If the normal con-

dition is restored, there

is no malfunction. At

that time, erase the self-

diagnostic result memo-

ry.

VDC may not operate normally or th

e ABS warning lamp, and SLIP indicato r lamp may illuminate when driv-

ing on a road that is extremely slanted (e.g., bank in a circuit course).

A malfunction may occur in the yaw rate/side/decel G sensor system when the vehicle turns sharply, such

as during a spin turn, axle turn, or drift driving, while the VDC function is OFF (VDC OFF indicator lamp illu-

minated).

The vehicle speed will not increase even though the accelerator pedal is depressed, when inspecting the

speedometer on a 2-wheel chassis dynamometer. Normal (Deactivate the

VDC/TCS function be-

fore performing an in-

spection on a chassis

dynamometer.)

SLIP indicator lamp may simultaneously turn ON when low tire pressure warning lamp turns ON. This is not a VDC sys-

tem error but results

from characteristic

change of tire.

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 706 of 3641

![NISSAN NOTE 2016 Service User Guide COMPONENT PARTSDLK-17

< SYSTEM DESCRIPTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

INTELLIGENT KEY SYSTEM : Outsi de Key Antenna (Passenger Side)INFOID:0000000012429971

• O NISSAN NOTE 2016 Service User Guide COMPONENT PARTSDLK-17

< SYSTEM DESCRIPTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

INTELLIGENT KEY SYSTEM : Outsi de Key Antenna (Passenger Side)INFOID:0000000012429971

• O](/img/5/57363/w960_57363-705.png)

COMPONENT PARTSDLK-17

< SYSTEM DESCRIPTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

INTELLIGENT KEY SYSTEM : Outsi de Key Antenna (Passenger Side)INFOID:0000000012429971

• Outside key antenna RH detects that Intelligent Key is within the

outside detection area, and then transmits detection status to

BCM. Request signal is transmitted simultaneously to Intelligent

Key.

• Outside key antenna RH is installed in front outside handle RH.

INTELLIGENT KEY SYSTEM : Front Do or Lock Assembly (Driver Side)INFOID:0000000012429972

• Door lock actuator and unlock sensor are Integrated in front door

lock assembly LH.

• Door lock actuator receives lock/unlock signal from BCM, and then

locks/unlocks driver door.

• Only front door lock assembly LH integrates unlock sensor. Unlock sensor transmits lock/unlock status of LH door to BCM.

INTELLIGENT KEY SYSTEM : Remote Keyless Entry ReceiverINFOID:0000000012429973

• Remote keyless entry receiver receives button operation signal

and key ID signal of Intelligent Key, and then transmits them to

BCM.

• Remote keyless entry receiver is installed in the rear of glove box

lid.

INTELLIGENT KEY SYSTEM : Intelligent Key Warning BuzzerINFOID:0000000012429974

• Intelligent Key warning buzzer warns the user, who is outside vehi-cle, of operation confirmation according to Intelligent Key operation

and door request switch operation, or of an inappropriate opera-

tion.

• Intelligent Key warning buzzer is installed in the rear of front bumper and behind LH headlight.

JMKIA8648ZZ

JMKIA8649ZZ

JMKIA8647ZZ

JMKIA8650ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 943 of 3641

![NISSAN NOTE 2016 Service User Guide DLK-254

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

WARNING CHIME FUNCTION

WARNING CHIME FUNCTION

DescriptionINFOID:0000000012430218

Performs operation method guide and warning with buzz NISSAN NOTE 2016 Service User Guide DLK-254

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

WARNING CHIME FUNCTION

WARNING CHIME FUNCTION

DescriptionINFOID:0000000012430218

Performs operation method guide and warning with buzz](/img/5/57363/w960_57363-942.png)

DLK-254

< DTC/CIRCUIT DIAGNOSIS >[WITHOUT INTELLIGENT KEY SYSTEM]

WARNING CHIME FUNCTION

WARNING CHIME FUNCTION

DescriptionINFOID:0000000012430218

Performs operation method guide and warning with buzzer.

Component Function CheckINFOID:0000000012430219

1.CHECK FUNCTION

With CONSULT

1. Check the operation of “BUZZER” in “Active Test”.

2. Touch “IGN KEY WARN ALM”, “SEAT BELT WARN TEST”or “LIGHT WARN ALM”on screen.

Is the inspection result normal?

YES >> Warning buzzer into combination meter is OK.

NO >> Refer to DLK-254, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012430220

1.CHECK METER BUZZER CIRCUIT

Operate the hazard lights by turni ng ON the hazard warning switch.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace combination meter. Refer to MWI-54, "

Removal and Installation" (Type A) or MWI-115,

"Removal and Installation" (Type B).

2.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "

Intermittent Incident".

>> Inspection End.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 944 of 3641

![NISSAN NOTE 2016 Service User Guide HAZARD FUNCTIONDLK-255

< DTC/CIRCUIT DIAGNOSIS > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

HAZARD FUNCTION

DescriptionINFOID:0000000012430221

Perform answer-back for each oper NISSAN NOTE 2016 Service User Guide HAZARD FUNCTIONDLK-255

< DTC/CIRCUIT DIAGNOSIS > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

HAZARD FUNCTION

DescriptionINFOID:0000000012430221

Perform answer-back for each oper](/img/5/57363/w960_57363-943.png)

HAZARD FUNCTIONDLK-255

< DTC/CIRCUIT DIAGNOSIS > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

HAZARD FUNCTION

DescriptionINFOID:0000000012430221

Perform answer-back for each oper ation with number of blinks.

Component Function CheckINFOID:0000000012430222

1.CHECK FUNCTION

Check hazard warning lamp “FLASHER” in “Active Test”.

Is the inspection result normal?

YES >> Hazard warning lamp circuit is OK.

NO >> Refer to DLK-255, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012430223

1.CHECK HAZARD SWITCH CIRCUIT

Operate the hazard lights by turni ng ON the hazard warning switch.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace hazard warning switch circuit. Refer to EXL-108, "

Removal and Installation".

2.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "

Intermittent Incident".

>> Inspection End.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1097 of 3641

![NISSAN NOTE 2016 Service User Guide EM-96

< UNIT DISASSEMBLY AND ASSEMBLY >[HR16DE]

CYLINDER BLOCK

a. Loosen and remove bolts in several steps in reverse of the

numerical order as shown.

NOTE:

When removing or installing signal plate, u NISSAN NOTE 2016 Service User Guide EM-96

< UNIT DISASSEMBLY AND ASSEMBLY >[HR16DE]

CYLINDER BLOCK

a. Loosen and remove bolts in several steps in reverse of the

numerical order as shown.

NOTE:

When removing or installing signal plate, u](/img/5/57363/w960_57363-1096.png)

EM-96

< UNIT DISASSEMBLY AND ASSEMBLY >[HR16DE]

CYLINDER BLOCK

a. Loosen and remove bolts in several steps in reverse of the

numerical order as shown.

NOTE:

When removing or installing signal plate, use socket (size T40).

b. Remove the main bearing cap from the cylinder block while tapping lightly with a plastic hammer.

10. Remove crankshaft (2). CAUTION:

• Do not damage or deform signal plate (1) mounted on

crankshaft.

• When setting crankshaft on a flat floor surface, use a

block of wood to avoid interf erence between signal plate

and the floor surface.

• Do not remove signal plate unless it is necessary to do

so.

NOTE:

When removing or installing signal plate, use socket (size T40).

11. Pull rear oil seal out from rear end of crankshaft.

12. Remove main bearing (upper/lower) and thrust bear ings from cylinder block and main bearing caps.

CAUTION:

Identify original installation positions, and store the bearings without mixing them up.

13. Remove oil jets. CAUTION:

Insert the dowel pin of oil jet into the cylinde r block dowel pin hole to loosen the bolt.

ASSEMBLY

CAUTION:

Do not reuse O-rings.

1. Fully air-blow engine coolant and engine oil passages in cylinder block, cylinder bore and crankcase to

remove any foreign material.

WARNING:

Use goggles to protect your eyes.

2. Install cylinder block plugs. • Apply liquid gasket to the thread of water drain plug (3).

Use Genuine Silicone RTV Seal ant, or equivalent. Refer to

GI-22, "

Recommended Chemical Products and Sealants".

CAUTION:

Do not reuse O-ring.

• Tighten each plug as specified below.

: Engine front

JPBIA4203ZZ

JPBIA4531ZZ

(2) : O-ring : Engine front

AWBIA1607ZZ

Part WasherTightening torque

(1) Yes54.0 N·m (5.5 kg-m, 40 ft-lb)

(3) No9.8 N·m (1.0 kg-m, 87 in-lb)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1135 of 3641

![NISSAN NOTE 2016 Service User Guide EC-8

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431263

The Supplemental Res NISSAN NOTE 2016 Service User Guide EC-8

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431263

The Supplemental Res](/img/5/57363/w960_57363-1134.png)

EC-8

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431263

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

On Board Diagnosti c (OBD) System of Engine and CVTINFOID:0000000012431265

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect the negative battery cable before any repair

or inspection work. The open/short circuit of re lated switches, sensors, solenoid valves, etc. will

cause the MIL to light up.

• Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Certain systems and components, especially those related to OBD, may use a new style slide-lock- ing type harness connector. For descripti on and how to disconnect, refer to PG-9, "

Harness Connec-

tor".

• Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MIL to li ght up due to the short circuit.

• Be sure to connect rubber tubes properly afte r work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfunction of the fuel injection system, etc.

• Be sure to erase the unnecessary malfunction info rmation (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1184 of 3641

![NISSAN NOTE 2016 Service User Guide DIAGNOSIS SYSTEM (ECM)EC-57

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PERMANENT DTC SET TIMING

The setting timing of permanent DTC is stored in ECM

with the lighting of MIL when NISSAN NOTE 2016 Service User Guide DIAGNOSIS SYSTEM (ECM)EC-57

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PERMANENT DTC SET TIMING

The setting timing of permanent DTC is stored in ECM

with the lighting of MIL when](/img/5/57363/w960_57363-1183.png)

DIAGNOSIS SYSTEM (ECM)EC-57

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PERMANENT DTC SET TIMING

The setting timing of permanent DTC is stored in ECM

with the lighting of MIL when a DTC is confirmed.

DIAGNOSIS DESCRIPTION : Malfunction Indicator Lamp (MIL)INFOID:0000000012431339

When emission-related ECU detects a malfunction in the emission

control systems components and/or the powertrain control compo-

nents (which affect vehicle emissions), it turns on/blinks MIL to

inform the driver that a malfunction has been detected.

1. The MIL illuminates when ignition switch is turned ON (engine is

not running).

NOTE:

Check the MIL circuit if MIL does not illuminate. Refer to EC-

456, "Diagnosis Procedure".

2. When the engine is start ed, the MIL should go off.

NOTE:

If MIL continues to illuminate/ blink, perform self-diagnoses and

inspect/repair accordingly because an emission-rela ted ECU has detected a malfunction in the emission

control systems components and/or the powertrain cont rol components (which affect vehicle emissions).

On Board Diagnosis FunctionINFOID:0000000012431340

ON BOARD DIAGNOSIS ITEM

The on board diagnostic system has the following functions.

BULB CHECK MODE

Description

This function allows damage inspection in the MIL bulb (blown, open circuit, etc.).

Operation Procedure

1. Turn ignition switch ON.

2. The MIL on the instrument panel should stay ON.

If it remains OFF, check MIL circuit. Refer to EC-456, "

Diagnosis Procedure".

SRT STATUS MODE

Description

This function allows to read if ECM has completed the self-diagnoses of major emission control systems and

components. For SRT, refer to EC-55, "

DIAGNOSIS DESCRIPTION : System Readiness Test (SRT) Code".

Operation Procedure

1. Turn ignition switch ON and wait 20 seconds.

2. SRT status is indicated as shown blow.

• ECM continues to illuminate MIL if all SRT codes are set.

SAT652J

Diagnostic test mode Function

Bulb check MIL can be checked.

SRT status ECM can read if SRT codes are set.

Malfunction warning If ECM detects a malfunction, it illuminates or blinks MIL to inform the driver that a malfunction

has been detected.

Self-diagnostic results DTCs or 1st trip DTCs stored in ECM can be read.

Accelerator pedal released position

learning ECM can learn the accelerator pedal released position. Refer to

EC-128, "

Description".

Throttle valve closed position learning ECM can learn the throttle valve closed position. Refer to EC-129, "

Description".

Idle air volume learning ECM can learn the idle air volume. Refer to EC-130, "

Description".

Mixture ratio self-learning value clear Mixture ratio self-learning value can be erased. Refer to EC-132, "

Description".

Revision: August 20152016 Versa Note

cardiagn.com

Page 1632 of 3641

![NISSAN NOTE 2016 Service User Guide LU-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432194

The Supplemental Res NISSAN NOTE 2016 Service User Guide LU-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432194

The Supplemental Res](/img/5/57363/w960_57363-1631.png)

LU-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432194

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Liquid GasketINFOID:0000000012432195

REMOVAL OF LIQUID GASKET SEALING

• After removing the bolts and nuts, separate the mating surface and remove the liquid gasket using Tool (A).

• In areas where the cutter is difficult to use, use a plastic hammer to lightly tap (1) the cutter where the liquid gasket is applied. Use a

plastic hammer to slide (2) the cutter by tapping on the side.

CAUTION:

Do not damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using suitable tool (A), remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

• Remove liquid gasket completely from the groove of the liquidgasket application surface, mounting bolts, and bolt holes.

2. Wipe the liquid gasket application surface and the mating sur- face with white gasoline (lighting and heating use) to remove

adhering moisture, grease and foreign materials.Tool number (A) : KV10111100 (J-37228)

AWBIA1249GB

JPBIA0053ZZ

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1653 of 3641

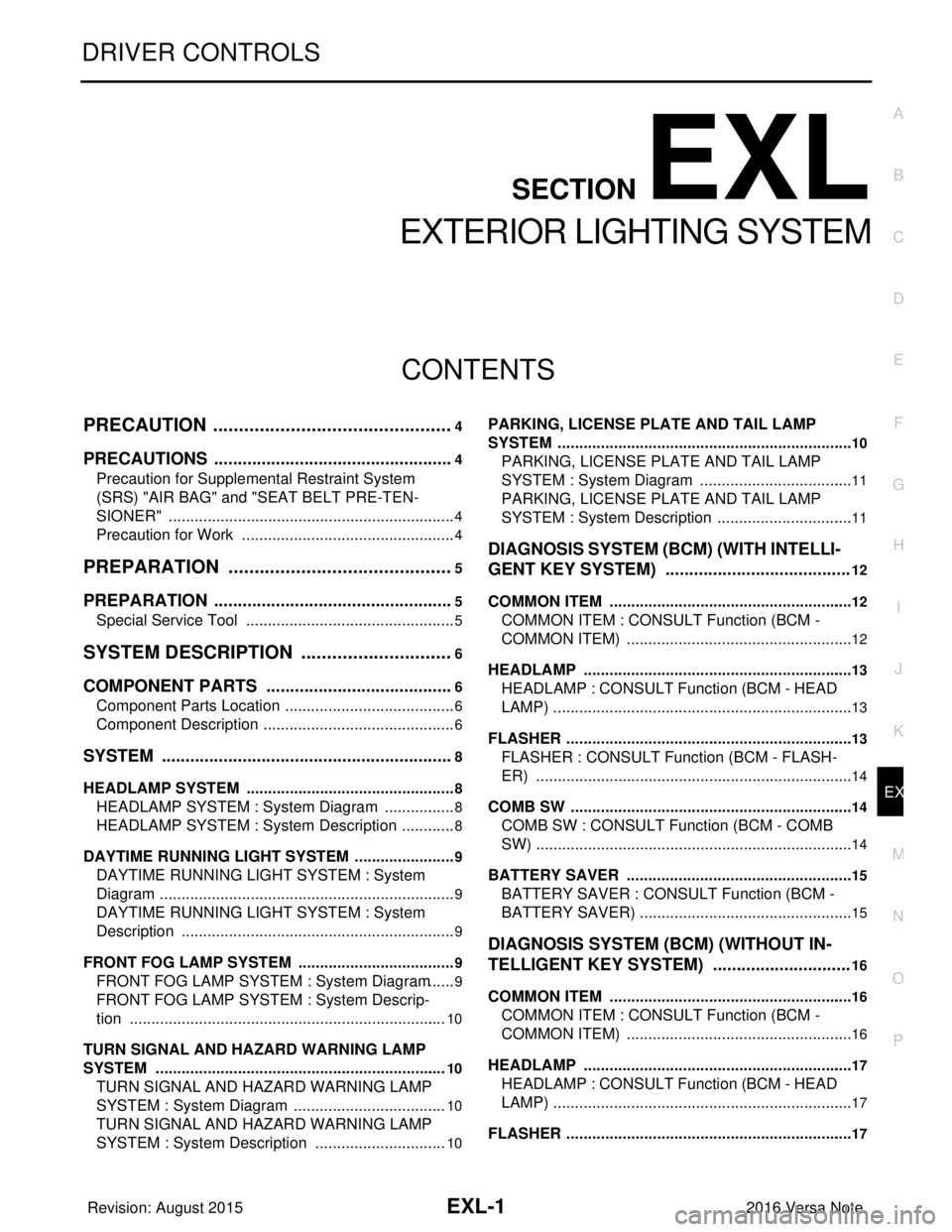

EXL-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION EXL

A

B

EXL

N

O P

CONTENTS

EXTERIOR LIGHTING SYSTEM

PRECAUTION ....... ........................................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution for Work ..................................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Component Description .............................................6

SYSTEM ..............................................................8

HEADLAMP SYSTEM .................................................8

HEADLAMP SYSTEM : Syst em Diagram .................8

HEADLAMP SYSTEM : System Description ....... ......8

DAYTIME RUNNING LIGHT SYSTEM ........................9

DAYTIME RUNNING LIGHT SYSTEM : System

Diagram ............................................................... ......

9

DAYTIME RUNNING LIGHT SYSTEM : System

Description ................................................................

9

FRONT FOG LAMP SYSTEM .....................................9

FRONT FOG LAMP SYSTEM : System Diagram ......9

FRONT FOG LAMP SYSTEM : System Descrip-

tion ..........................................................................

10

TURN SIGNAL AND HAZARD WARNING LAMP

SYSTEM ................................................................ ....

10

TURN SIGNAL AND HAZARD WARNING LAMP

SYSTEM : System Diagram ....................................

10

TURN SIGNAL AND HAZARD WARNING LAMP

SYSTEM : System Description ...............................

10

PARKING, LICENSE PLATE AND TAIL LAMP

SYSTEM .......................................... ...........................

10

PARKING, LICENSE PLATE AND TAIL LAMP

SYSTEM : System Diagram ................................ ....

11

PARKING, LICENSE PLATE AND TAIL LAMP

SYSTEM : System Description ................................

11

DIAGNOSIS SYSTEM (BCM) (WITH INTELLI-

GENT KEY SYSTEM) .......................................

12

COMMON ITEM ..................................................... ....12

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .....................................................

12

HEADLAMP ........................................................... ....13

HEADLAMP : CONSULT Function (BCM - HEAD

LAMP) ......................................................................

13

FLASHER ............................................................... ....13

FLASHER : CONSULT Function (BCM - FLASH-

ER) ..........................................................................

14

COMB SW .............................................................. ....14

COMB SW : CONSULT Function (BCM - COMB

SW) ..........................................................................

14

BATTERY SAVER ................................................. ....15

BATTERY SAVER : CONSULT Function (BCM -

BATTERY SAVER) ..................................................

15

DIAGNOSIS SYSTEM (BCM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) .............................

16

COMMON ITEM ..................................................... ....16

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .....................................................

16

HEADLAMP ........................................................... ....17

HEADLAMP : CONSULT Function (BCM - HEAD

LAMP) ......................................................................

17

FLASHER ............................................................... ....17

Revision: August 2015 2016 Versa Note

cardiagn.com