wheel NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2787 of 3641

WT-44

< PERIODIC MAINTENANCE >

WHEEL

PERIODIC MAINTENANCE

WHEEL

InspectionINFOID:0000000012432465

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheel

runout.

a. Remove tire from wheel and mount wheel on a balancer machine.

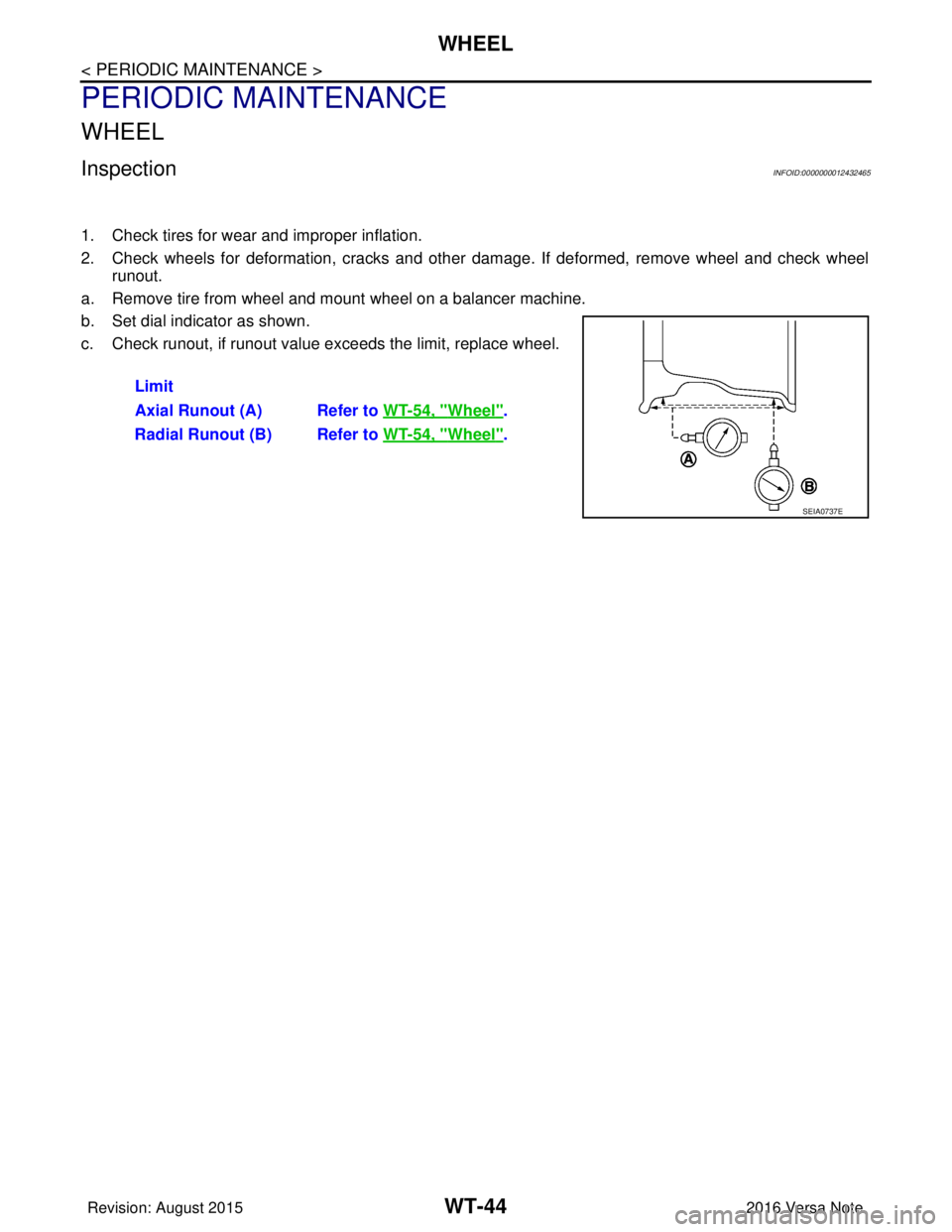

b. Set dial indicator as shown.

c. Check runout, if runout value exceeds the limit, replace wheel.

Limit

Axial Runout (A) Refer to WT-54, "

Wheel".

Radial Runout (B) Refer to WT-54, "

Wheel".

SEIA0737E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2788 of 3641

WHEEL AND TIREWT-45

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

WHEEL AND TIRE

AdjustmentINFOID:0000000012432466

BALANCING WHEELS (ADH ESIVE WEIGHT TYPE)

Preparation Before Adjustment

Remove inner and outer balance weights from the wheel and tire. Using releasing agent, remove double-faced

adhesive tape from the wheel and tire.

CAUTION:

• Be careful not to scratch the wheel and tire during removal.

• After removing double-faced ad hesive tape, wipe clean all traces of releasing agent from the wheel

and tire.

Wheel Balance Adjustment

CAUTION:

• DO NOT use center hole cone-type clamping machin es to hold the wheel during tire removal/installa-

tion or balancing or damage to the wheel paint, cl adding or chrome may result. Use only rim-type or

universal lug-type clamping machines to hold the wheel during servicing.

• If a balancer machine has an adhesive weight mode setting, select the adhesive weight mode setting and

skip Step 2 below. If a balancer machine only has the clip-on (rim flange) weight mode setting, follow Step 2

to calculate the correct size adhesive weight.

1. Set wheel and tire on balancer machine using the center hole as a guide. Start the balancer machine.

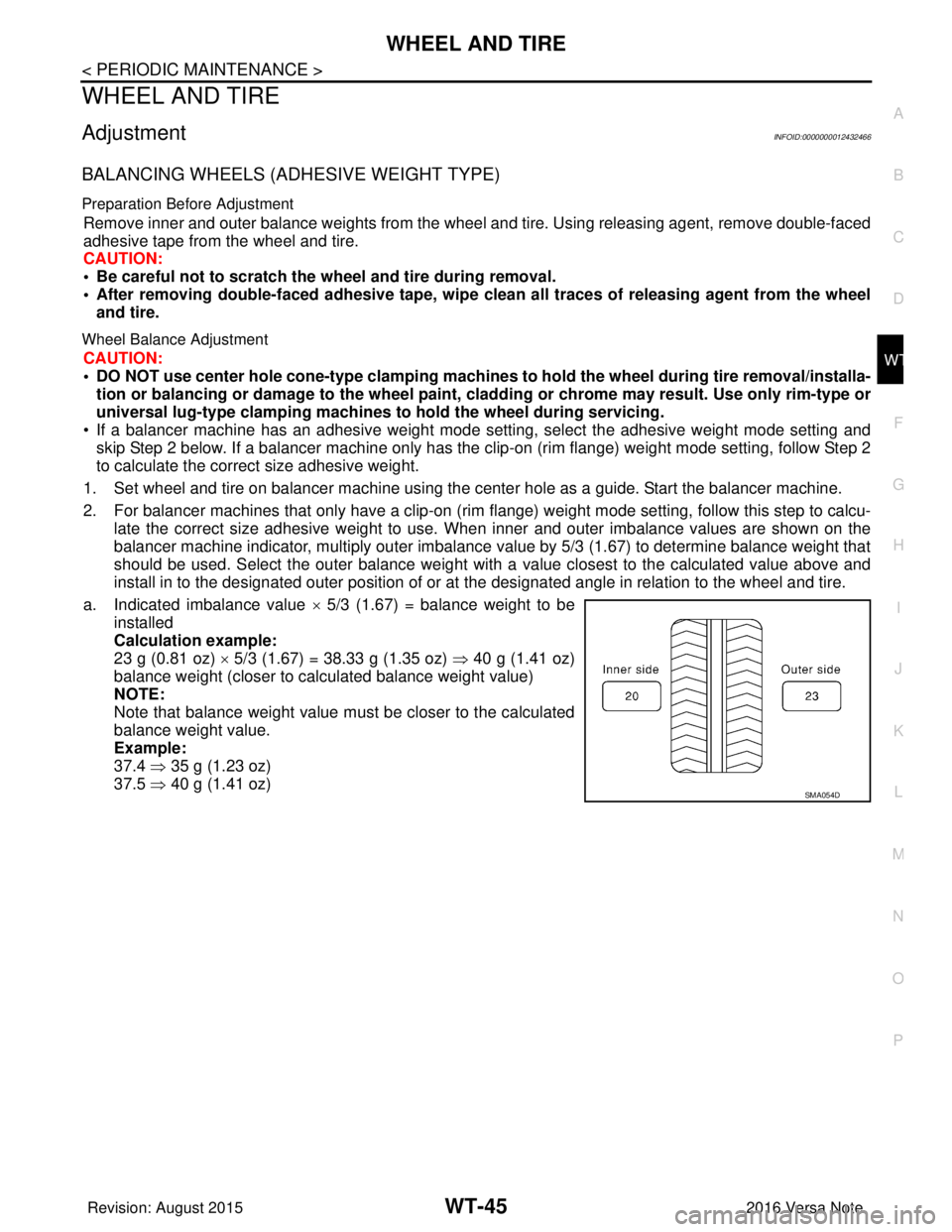

2. For balancer machines that only have a clip-on (rim fl ange) weight mode setting, follow this step to calcu-

late the correct size adhesive weight to use. W hen inner and outer imbalance values are shown on the

balancer machine indicator, multiply outer imbalance value by 5/3 (1.67) to determine balance weight that

should be used. Select the outer balance weight with a value closest to the calculated value above and

install in to the designated outer position of or at the designated angle in relation to the wheel and tire.

a. Indicated imbalance value × 5/3 (1.67) = balance weight to be

installed

Calculation example:

23 g (0.81 oz) × 5/3 (1.67) = 38.33 g (1.35 oz) ⇒ 40 g (1.41 oz)

balance weight (closer to calculated balance weight value)

NOTE:

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

37.4 ⇒ 35 g (1.23 oz)

37.5 ⇒ 40 g (1.41 oz)

SMA054D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2789 of 3641

WT-46

< PERIODIC MAINTENANCE >

WHEEL AND TIRE

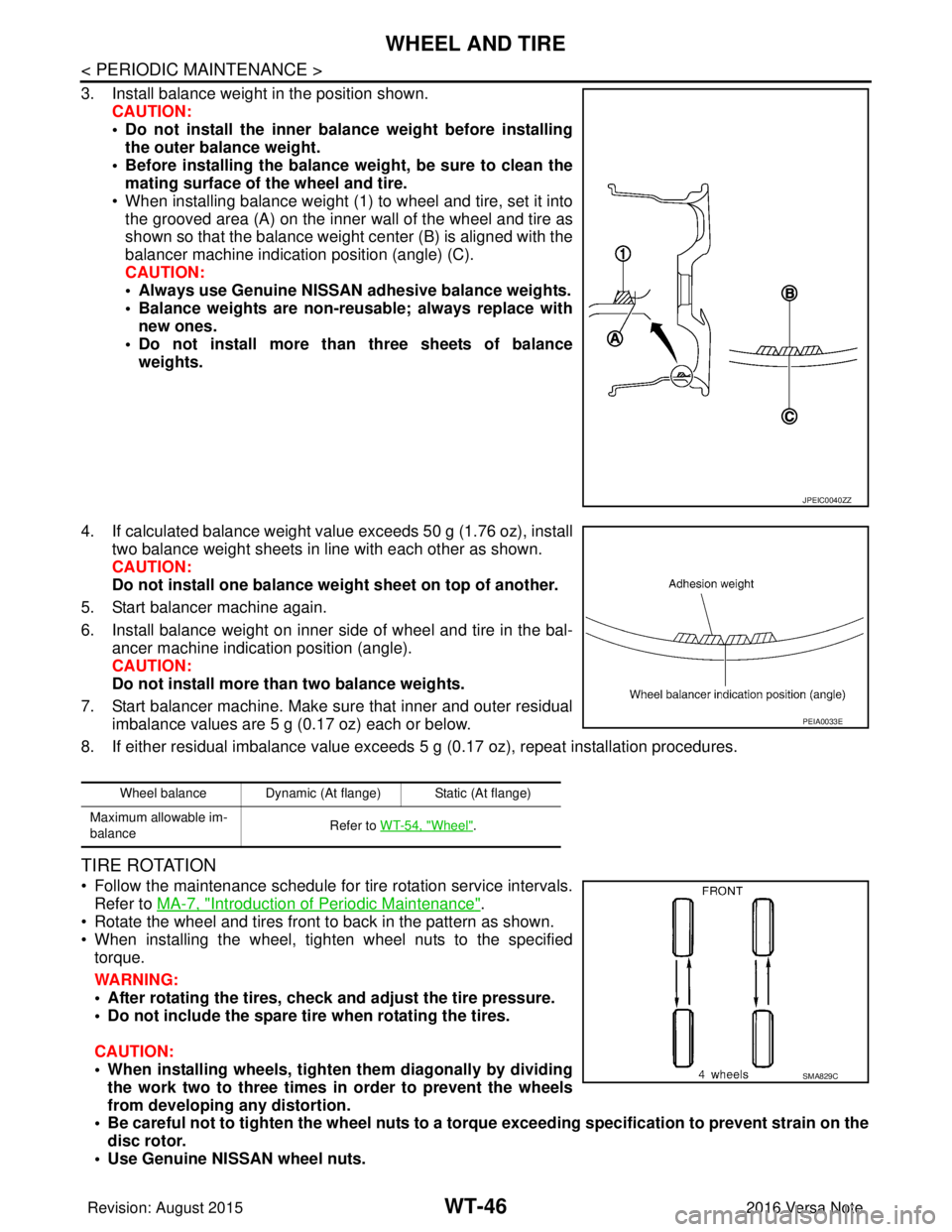

3. Install balance weight in the position shown.CAUTION:

• Do not install the inner bala nce weight before installing

the outer balance weight.

• Before installing the balance weight, be sure to clean the mating surface of the wheel and tire.

• When installing balance weight (1) to wheel and tire, set it into the grooved area (A) on the inner wall of the wheel and tire as

shown so that the balance weight center (B) is aligned with the

balancer machine indication position (angle) (C).

CAUTION:

• Always use Genuine NISSAN adhesive balance weights.

• Balance weights are non-reusable; always replace withnew ones.

• Do not install more than three sheets of balance weights.

4. If calculated balance weight value exceeds 50 g (1.76 oz), install two balance weight sheets in line with each other as shown.

CAUTION:

Do not install one balance weight sheet on top of another.

5. Start balancer machine again.

6. Install balance weight on inner side of wheel and tire in the bal- ancer machine indication position (angle).

CAUTION:

Do not install more than two balance weights.

7. Start balancer machine. Make sure that inner and outer residual imbalance values are 5 g (0.17 oz) each or below.

8. If either residual imbalance value exceeds 5 g (0.17 oz), repeat installation procedures.

TIRE ROTATION

• Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-7, "

Introduction of Periodic Maintenance".

• Rotate the wheel and tires front to back in the pattern as shown.

• When installing the wheel, tighten wheel nuts to the specified torque.

WARNING:

• After rotating the tires, check and adjust the tire pressure.

• Do not include the spare tire when rotating the tires.

CAUTION:

• When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten the wh eel nuts to a torque exceeding speci fication to prevent strain on the

disc rotor.

• Use Genuine NISSAN wheel nuts.

JPEIC0040ZZ

Wheel balance Dynamic (At flange) Static (At flange)

Maximum allowable im-

balance Refer to WT-54, "

Wheel".

PEIA0033E

SMA829C

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2790 of 3641

WHEEL AND TIREWT-47

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

• Perform the ID registration after tire rotation. Refer to WT-22, "Work Procedure".

Wheel nut tightening

torque

:

WT-48, "

Exploded View"

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2791 of 3641

WT-48

< REMOVAL AND INSTALLATION >

WHEEL AND TIRE

REMOVAL AND INSTALLATION

WHEEL AND TIRE

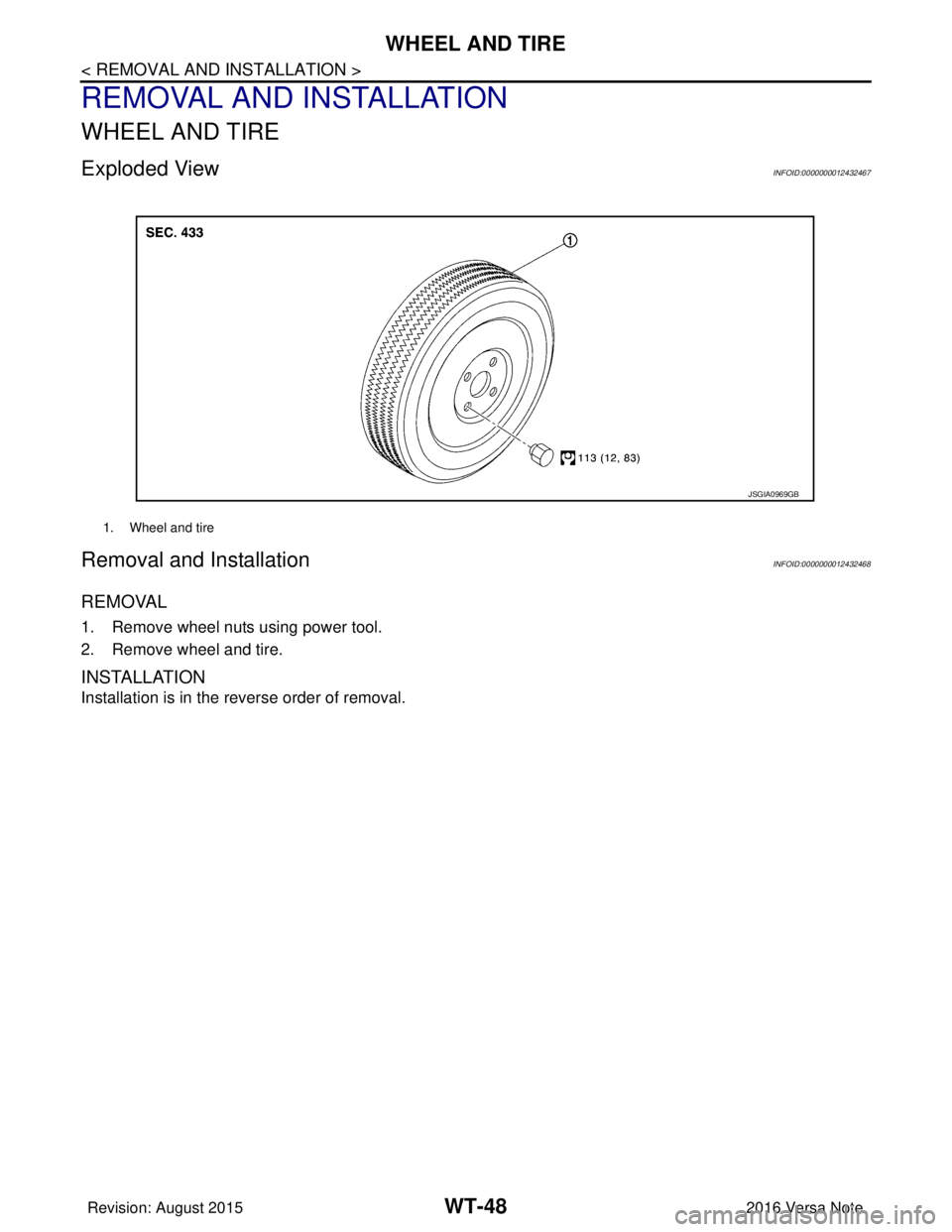

Exploded ViewINFOID:0000000012432467

Removal and InstallationINFOID:0000000012432468

REMOVAL

1. Remove wheel nuts using power tool.

2. Remove wheel and tire.

INSTALLATION

Installation is in the reverse order of removal.

1. Wheel and tire

JSGIA0969GB

Revision: August 20152016 Versa Note

cardiagn.com

Page 2792 of 3641

TRANSMITTERWT-49

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

TRANSMITTER

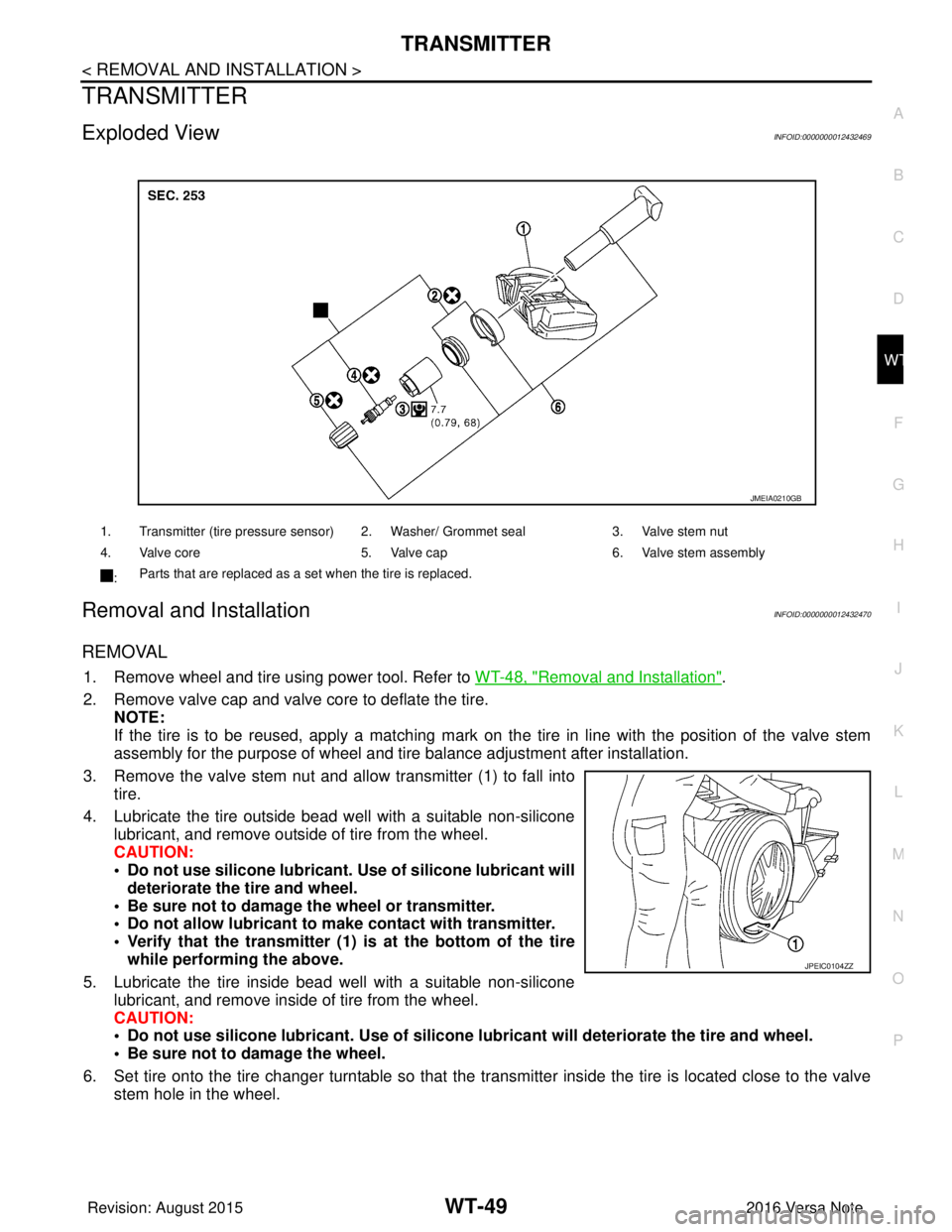

Exploded ViewINFOID:0000000012432469

Removal and InstallationINFOID:0000000012432470

REMOVAL

1. Remove wheel and tire using power tool. Refer to WT-48, "Removal and Installation".

2. Remove valve cap and valve core to deflate the tire. NOTE:

If the tire is to be reused, apply a matching mark on the tire in line with the position of the valve stem

assembly for the purpose of wheel and tire balance adjustment after installation.

3. Remove the valve stem nut and allow transmitter (1) to fall into tire.

4. Lubricate the tire outside bead well with a suitable non-silicone lubricant, and remove outside of tire from the wheel.

CAUTION:

• Do not use silicone lubricant. Use of silicone lubricant will

deteriorate the tire and wheel.

• Be sure not to damage the wheel or transmitter.

• Do not allow lubricant to make contact with transmitter.

• Verify that the transmitter (1) is at the bottom of the tire while performing the above.

5. Lubricate the tire inside bead well with a suitable non-silicone lubricant, and remove inside of tire from the wheel.

CAUTION:

• Do not use silicone lubricant. Use of silicone lubricant will deteriorate the tire and wheel.

• Be sure not to damage the wheel.

6. Set tire onto the tire changer turntable so that the transmitter inside the tire is located close to the valve stem hole in the wheel.

1. Transmitter (tire pressure sensor) 2. Washer/ Grommet seal 3. Valve stem nut

4. Valve core 5. Valve cap6. Valve stem assembly

: Parts that are replaced as a set when the tire is replaced.

JMEIA0210GB

JPEIC0104ZZ

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2793 of 3641

WT-50

< REMOVAL AND INSTALLATION >

TRANSMITTER

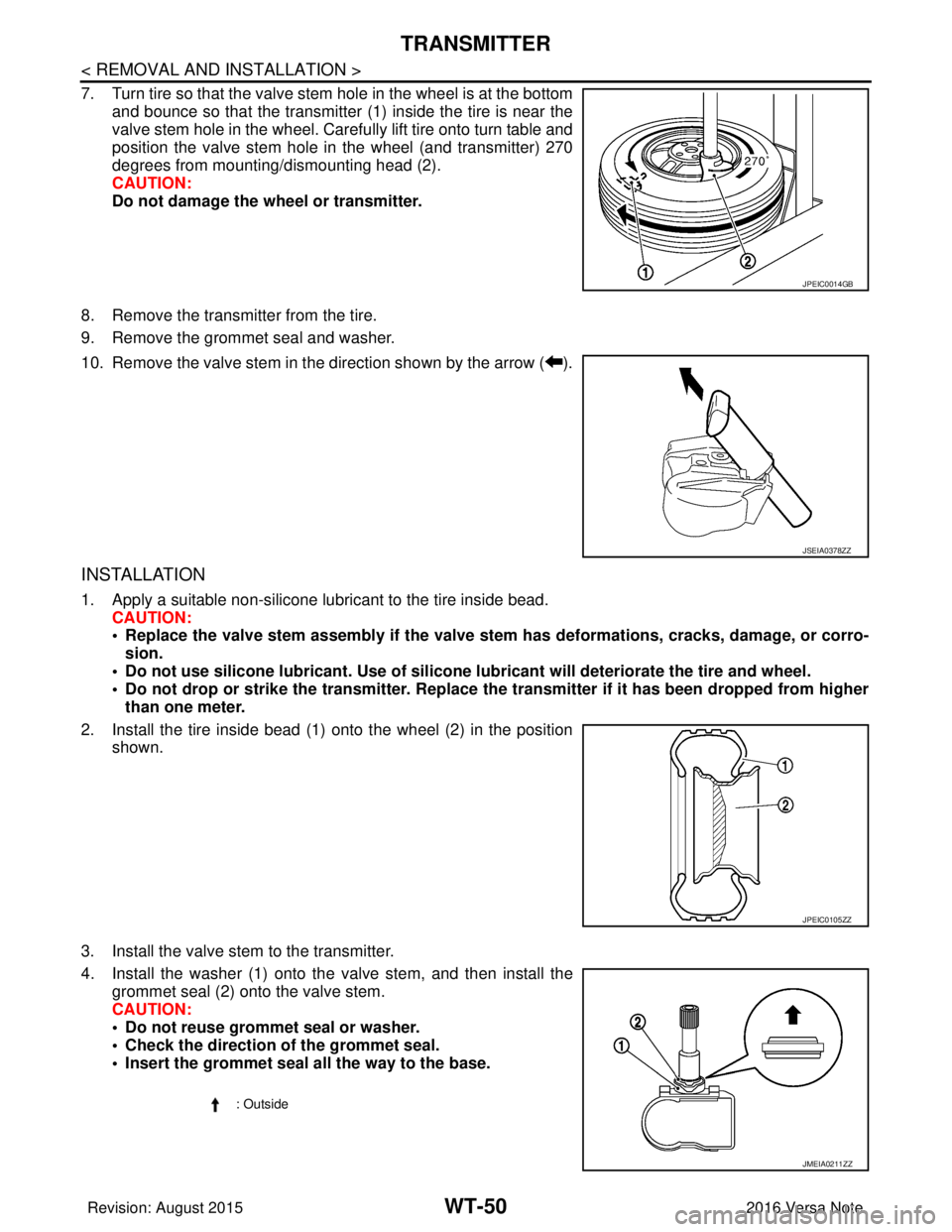

7. Turn tire so that the valve stem hole in the wheel is at the bottom

and bounce so that the transmitter (1) inside the tire is near the

valve stem hole in the wheel. Carefully lift tire onto turn table and

position the valve stem hole in the wheel (and transmitter) 270

degrees from mounting/dismounting head (2).

CAUTION:

Do not damage the wheel or transmitter.

8. Remove the transmitter from the tire.

9. Remove the grommet seal and washer.

10. Remove the valve stem in the direction shown by the arrow ( ).

INSTALLATION

1. Apply a suitable non-silicone lubricant to the tire inside bead. CAUTION:

• Replace the valve stem assembly if the valve stem has deformations, cracks, damage, or corro-

sion.

• Do not use silicone lubricant. Use of silicone lubricant will deteriorate the tire and wheel.

• Do not drop or strike the transmitter. Replace the transmitter if it has been dropped from higher

than one meter.

2. Install the tire inside bead (1) onto the wheel (2) in the position shown.

3. Install the valve stem to the transmitter.

4. Install the washer (1) onto the valve stem, and then install the grommet seal (2) onto the valve stem.

CAUTION:

• Do not reuse grommet seal or washer.

• Check the direction of the grommet seal.

• Insert the grommet seal all the way to the base.

JPEIC0014GB

JSEIA0378ZZ

JPEIC0105ZZ

: Outside

JMEIA0211ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2794 of 3641

TRANSMITTERWT-51

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

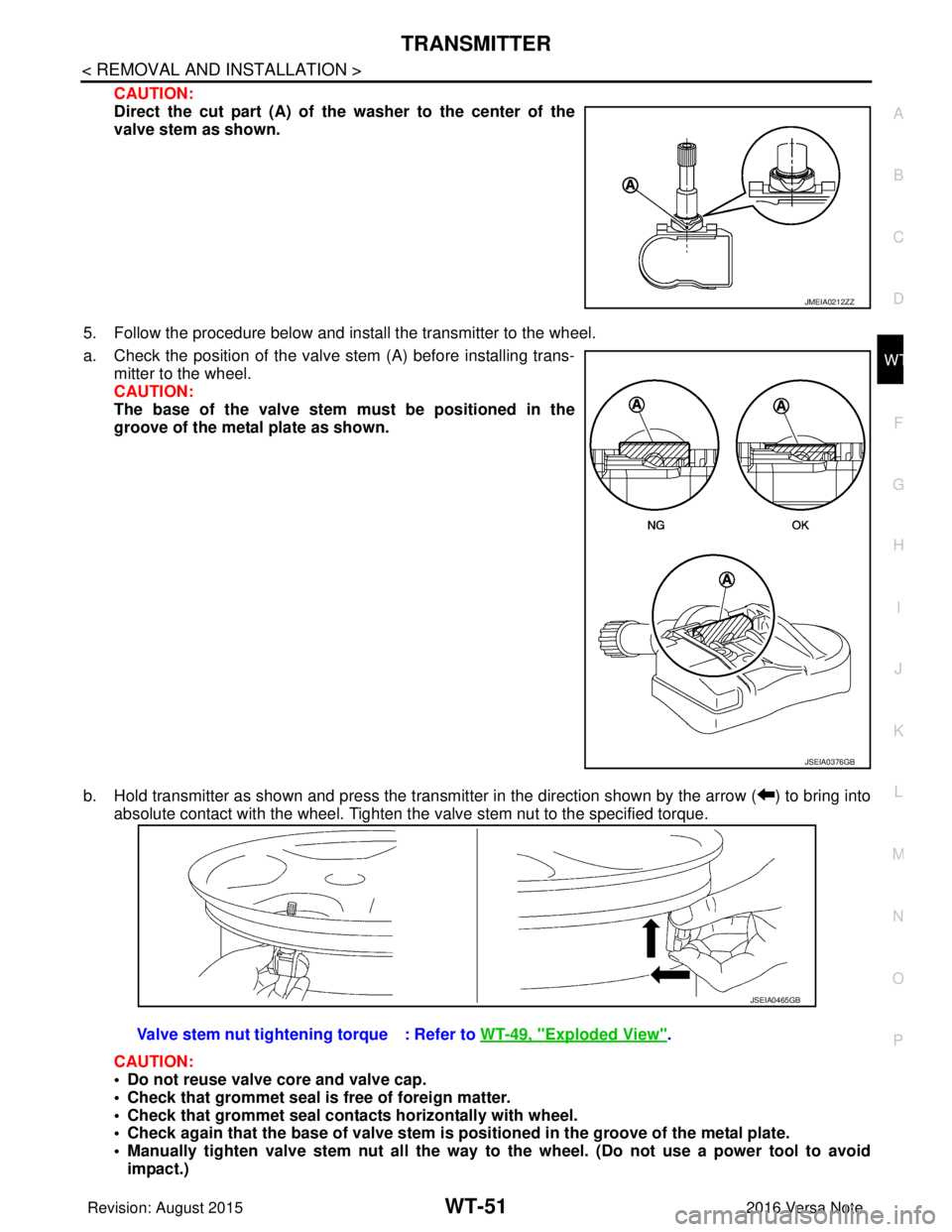

CAUTION:

Direct the cut part (A) of the washer to the center of the

valve stem as shown.

5. Follow the procedure below and install the transmitter to the wheel.

a. Check the position of the valve stem (A) before installing trans-

mitter to the wheel.

CAUTION:

The base of the valve stem mu st be positioned in the

groove of the metal plate as shown.

b. Hold transmitter as shown and press the transmitter in the direction shown by the arrow ( ) to bring into absolute contact with the wheel. Tighten the valve stem nut to the specified torque.

CAUTION:

• Do not reuse valve core and valve cap.

• Check that grommet seal is free of foreign matter.

• Check that grommet seal contacts horizontally with wheel.

• Check again that the base of valve stem is po sitioned in the groove of the metal plate.

• Manually tighten valve stem nut all the way to the wheel. (Do not use a power tool to avoid

impact.)

JMEIA0212ZZ

JSEIA0376GB

Valve stem nut tightening torque : Refer to WT-49, "Exploded View".

JSEIA0465GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2795 of 3641

WT-52

< REMOVAL AND INSTALLATION >

TRANSMITTER

• Do not tighten valve stem nut to more than the specified torque. It may cause grommet seal dam-age.

• Do not tighten valve stem nut to less than th e specified torque. It may cause an air leak.

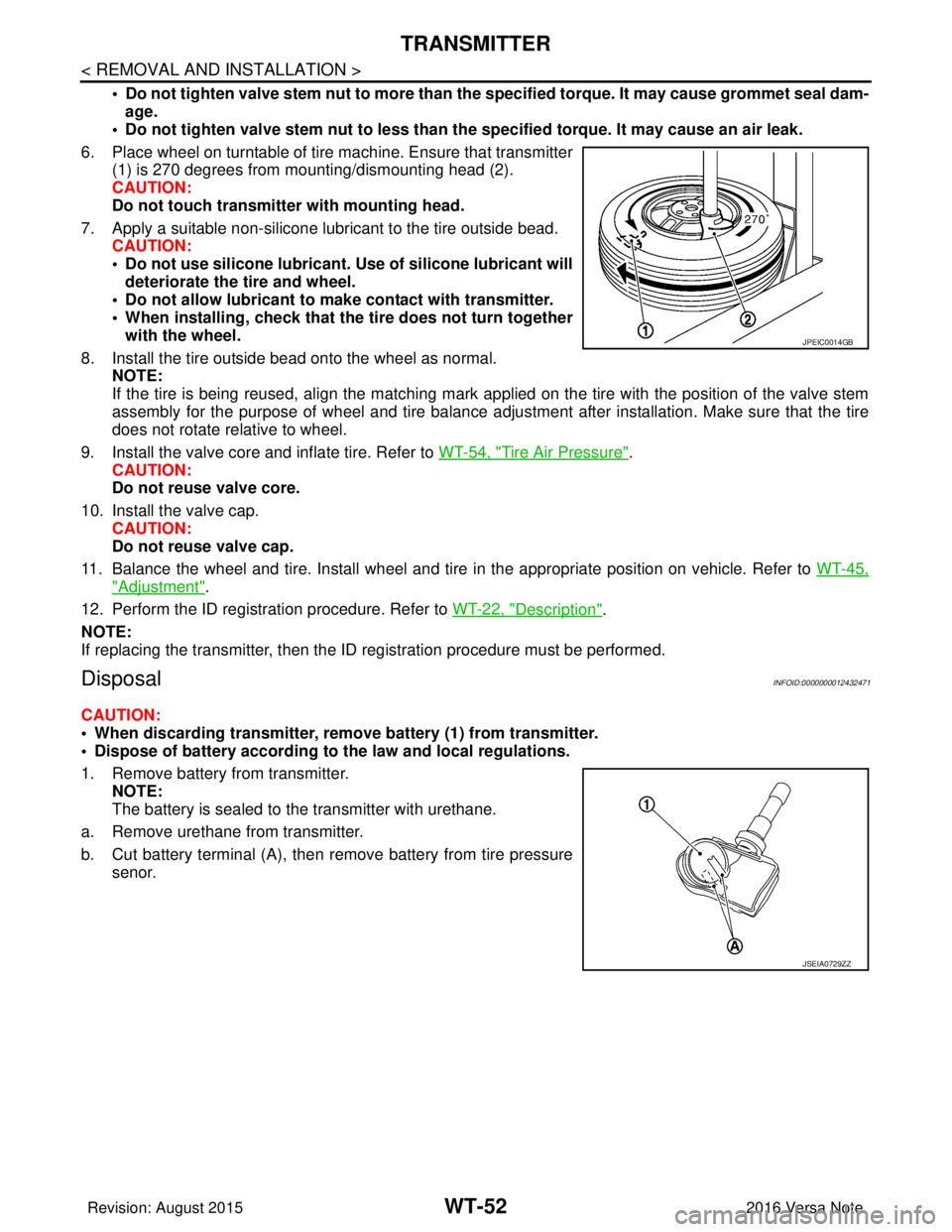

6. Place wheel on turntable of tire machine. Ensure that transmitter (1) is 270 degrees from mounting/dismounting head (2).

CAUTION:

Do not touch transmitter with mounting head.

7. Apply a suitable non-silicone lubricant to the tire outside bead. CAUTION:

• Do not use silicone lubricant. Use of silicone lubricant will

deteriorate the tire and wheel.

• Do not allow lubricant to make contact with transmitter.

• When installing, check that the tire does not turn together with the wheel.

8. Install the tire outside bead onto the wheel as normal. NOTE:

If the tire is being reused, align the matching mark applied on the tire with the position of the valve stem

assembly for the purpose of wheel and tire balance adjus tment after installation. Make sure that the tire

does not rotate relative to wheel.

9. Install the valve core and inflate tire. Refer to WT-54, "

Tire Air Pressure".

CAUTION:

Do not reuse valve core.

10. Install the valve cap. CAUTION:

Do not reuse valve cap.

11. Balance the wheel and tire. Install wheel and tire in the appropriate position on vehicle. Refer to WT-45,

"Adjustment".

12. Perform the ID registration procedure. Refer to WT-22, "

Description".

NOTE:

If replacing the transmitter, then the ID registration procedure must be performed.

DisposalINFOID:0000000012432471

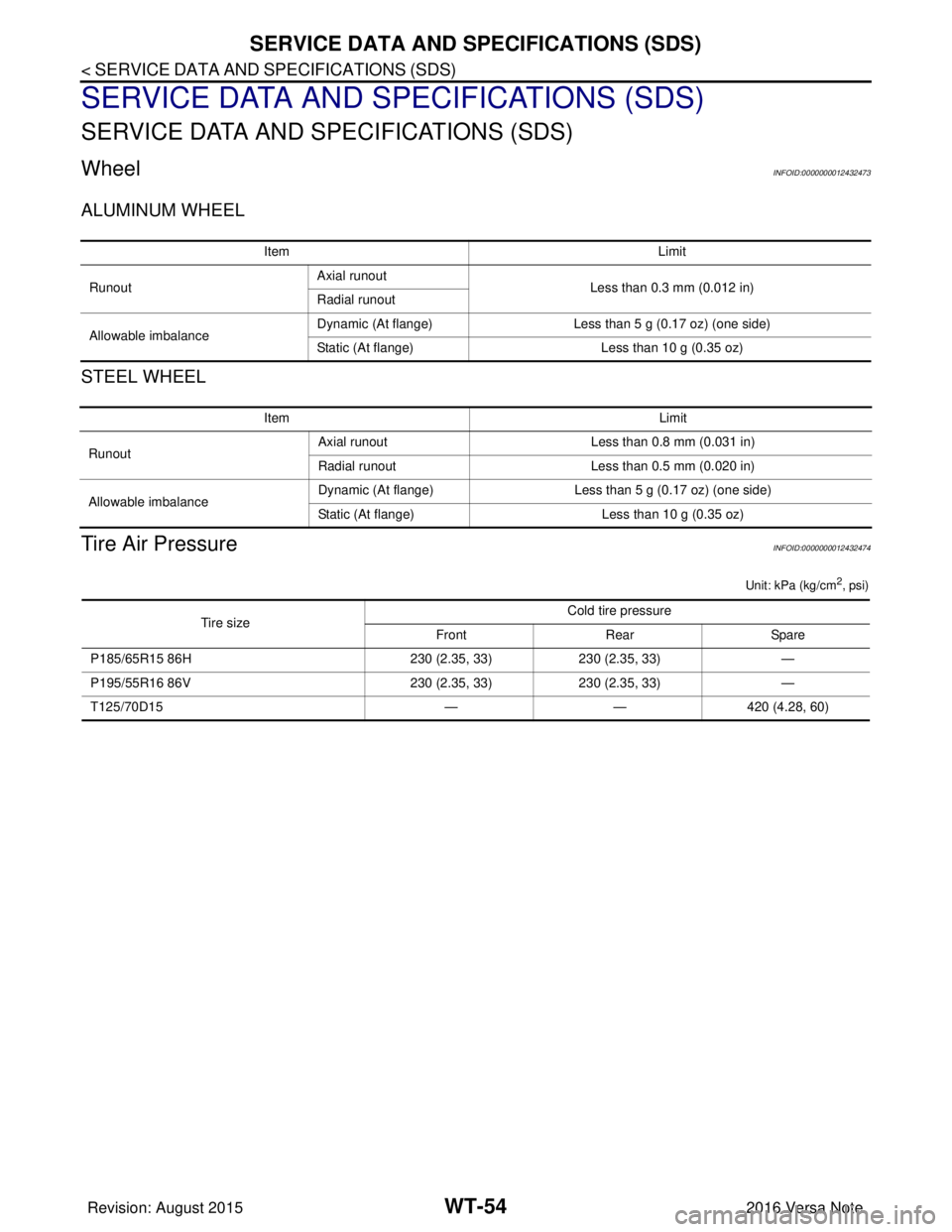

CAUTION:

• When discarding transmitter, remove battery (1) from transmitter.

• Dispose of battery according to the law and local regulations.

1. Remove battery from transmitter. NOTE:

The battery is sealed to the transmitter with urethane.

a. Remove urethane from transmitter.

b. Cut battery terminal (A), then remove battery from tire pressure senor.

JPEIC0014GB

JSEIA0729ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2797 of 3641

WT-54

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

WheelINFOID:0000000012432473

ALUMINUM WHEEL

STEEL WHEEL

Tire Air PressureINFOID:0000000012432474

Unit: kPa (kg/cm2, psi)

ItemLimit

Runout Axial runout

Less than 0.3 mm (0.012 in)

Radial runout

Allowable imbalance Dynamic (At flange)

Less than 5 g (0.17 oz) (one side)

Static (At flange) Less than 10 g (0.35 oz)

Item Limit

Runout Axial runout

Less than 0.8 mm (0.031 in)

Radial runout Less than 0.5 mm (0.020 in)

Allowable imbalance Dynamic (At flange)

Less than 5 g (0.17 oz) (one side)

Static (At flange) Less than 10 g (0.35 oz)

Tire size Cold tire pressure

Front RearSpare

P185/65R15 86H 230 (2.35, 33)230 (2.35, 33) —

P195/55R16 86V 230 (2.35, 33)230 (2.35, 33) —

T125/70D15 ——420 (4.28, 60)

Revision: August 2015 2016 Versa Note

cardiagn.com