warning NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2237 of 3641

![NISSAN NOTE 2016 Service Repair Manual LAN

A-BAG BRANCH LINE CIRCUITLAN-49

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012433363

WARNING:

Always observe the follo NISSAN NOTE 2016 Service Repair Manual LAN

A-BAG BRANCH LINE CIRCUITLAN-49

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012433363

WARNING:

Always observe the follo](/img/5/57363/w960_57363-2236.png)

LAN

A-BAG BRANCH LINE CIRCUITLAN-49

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012433363

WARNING:

Always observe the following items fo

r preventing accidental activation.

• Before servicing, turn ignition sw itch OFF, disconnect battery negative terminal, and wait 3 minutes

or more. (To discharge backup capacitor.)

• Never use unspecified tester or other measuring device.

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the air bag diagnosis sensor unit for damage, bend and loose con-

nection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the main harness.

2.CHECK AIR BAG DIAGNOSIS SENSOR UNIT

Check the air bag diagnosis sensor unit. Refer to SRC-36, "

Work Flow".

Is the inspection result normal?

YES >> Replace the main harness.

NO >> Replace parts whose air bag system has a malfunction.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2250 of 3641

![NISSAN NOTE 2016 Service Repair Manual LAN-62

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 501)]

A-BAG BRANCH LINE CIRCUIT

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785681

WARNING:

Always observe the following items fo

r NISSAN NOTE 2016 Service Repair Manual LAN-62

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 501)]

A-BAG BRANCH LINE CIRCUIT

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785681

WARNING:

Always observe the following items fo

r](/img/5/57363/w960_57363-2249.png)

LAN-62

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 501)]

A-BAG BRANCH LINE CIRCUIT

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785681

WARNING:

Always observe the following items fo

r preventing accidental activation.

• Before servicing, turn ignition sw itch OFF, disconnect battery negative terminal, and wait 3 minutes

or more. (To discharge backup capacitor.)

• Never use unspecified tester or other measuring device.

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the air bag diagnosis sensor unit for damage, bend and loose con-

nection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the main harness.

2.CHECK AIR BAG DIAGNOSIS SENSOR UNIT

Check the air bag diagnosis sensor unit. Refer to SRC-36, "

Work Flow".

Is the inspection result normal?

YES >> Replace the main harness.

NO >> Replace parts whose air bag system has a malfunction.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2264 of 3641

![NISSAN NOTE 2016 Service Repair Manual LAN-76

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 502)]

A-BAG BRANCH LINE CIRCUIT

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785702

WARNING:

Always observe the following items fo

r NISSAN NOTE 2016 Service Repair Manual LAN-76

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 502)]

A-BAG BRANCH LINE CIRCUIT

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785702

WARNING:

Always observe the following items fo

r](/img/5/57363/w960_57363-2263.png)

LAN-76

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 502)]

A-BAG BRANCH LINE CIRCUIT

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785702

WARNING:

Always observe the following items fo

r preventing accidental activation.

• Before servicing, turn ignition sw itch OFF, disconnect battery negative terminal, and wait 3 minutes

or more. (To discharge backup capacitor.)

• Never use unspecified tester or other measuring device.

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the air bag diagnosis sensor unit for damage, bend and loose con-

nection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the main harness.

2.CHECK AIR BAG DIAGNOSIS SENSOR UNIT

Check the air bag diagnosis sensor unit. Refer to SRC-36, "

Work Flow".

Is the inspection result normal?

YES >> Replace the main harness.

NO >> Replace parts whose air bag system has a malfunction.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2278 of 3641

![NISSAN NOTE 2016 Service Repair Manual LAN-90

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 503)]

A-BAG BRANCH LINE CIRCUIT

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785715

WARNING:

Always observe the following items fo

r NISSAN NOTE 2016 Service Repair Manual LAN-90

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 503)]

A-BAG BRANCH LINE CIRCUIT

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785715

WARNING:

Always observe the following items fo

r](/img/5/57363/w960_57363-2277.png)

LAN-90

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 503)]

A-BAG BRANCH LINE CIRCUIT

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785715

WARNING:

Always observe the following items fo

r preventing accidental activation.

• Before servicing, turn ignition sw itch OFF, disconnect battery negative terminal, and wait 3 minutes

or more. (To discharge backup capacitor.)

• Never use unspecified tester or other measuring device.

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the air bag diagnosis sensor unit for damage, bend and loose con-

nection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the main harness.

2.CHECK AIR BAG DIAGNOSIS SENSOR UNIT

Check the air bag diagnosis sensor unit. Refer to SRC-36, "

Work Flow".

Is the inspection result normal?

YES >> Replace the main harness.

NO >> Replace parts whose air bag system has a malfunction.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2293 of 3641

![NISSAN NOTE 2016 Service Repair Manual LAN

A-BAG BRANCH LINE CIRCUITLAN-105

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 504)]

C

D

E

F

G H

I

J

K L

B A

O P

N

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785742

WARNING:

Alway NISSAN NOTE 2016 Service Repair Manual LAN

A-BAG BRANCH LINE CIRCUITLAN-105

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 504)]

C

D

E

F

G H

I

J

K L

B A

O P

N

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785742

WARNING:

Alway](/img/5/57363/w960_57363-2292.png)

LAN

A-BAG BRANCH LINE CIRCUITLAN-105

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 504)]

C

D

E

F

G H

I

J

K L

B A

O P

N

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785742

WARNING:

Always observe the following items fo

r preventing accidental activation.

• Before servicing, turn ignition sw itch OFF, disconnect battery negative terminal, and wait 3 minutes

or more. (To discharge backup capacitor.)

• Never use unspecified tester or other measuring device.

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the air bag diagnosis sensor unit for damage, bend and loose con-

nection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the main harness.

2.CHECK AIR BAG DIAGNOSIS SENSOR UNIT

Check the air bag diagnosis sensor unit. Refer to SRC-36, "

Work Flow".

Is the inspection result normal?

YES >> Replace the main harness.

NO >> Replace parts whose air bag system has a malfunction.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2307 of 3641

![NISSAN NOTE 2016 Service Repair Manual LAN

A-BAG BRANCH LINE CIRCUITLAN-119

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 505)]

C

D

E

F

G H

I

J

K L

B A

O P

N

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785728

WARNING:

Alway NISSAN NOTE 2016 Service Repair Manual LAN

A-BAG BRANCH LINE CIRCUITLAN-119

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 505)]

C

D

E

F

G H

I

J

K L

B A

O P

N

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785728

WARNING:

Alway](/img/5/57363/w960_57363-2306.png)

LAN

A-BAG BRANCH LINE CIRCUITLAN-119

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 505)]

C

D

E

F

G H

I

J

K L

B A

O P

N

A-BAG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785728

WARNING:

Always observe the following items fo

r preventing accidental activation.

• Before servicing, turn ignition sw itch OFF, disconnect battery negative terminal, and wait 3 minutes

or more. (To discharge backup capacitor.)

• Never use unspecified tester or other measuring device.

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the air bag diagnosis sensor unit for damage, bend and loose con-

nection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the main harness.

2.CHECK AIR BAG DIAGNOSIS SENSOR UNIT

Check the air bag diagnosis sensor unit. Refer to SRC-36, "

Work Flow".

Is the inspection result normal?

YES >> Replace the main harness.

NO >> Replace parts whose air bag system has a malfunction.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2318 of 3641

PRECAUTIONSMA-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432240

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2320 of 3641

GENERAL MAINTENANCEMA-5

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

PERIODIC MAINTENANCE

GENERAL MAINTENANCE

Explanation of Gene

ral MaintenanceINFOID:0000000012432243

General maintenance includes those items which shoul d be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operati ng properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the specified pressure.

Check carefully for damage, cuts or excessive wear. WT-54

Wheel nuts

When checking the tires, make sure no nuts are missing, and check for any loose

nuts. Tighten if necessary. WT-48

Tire rotation

Tires should be rotated every 5,000 miles (8,000 km). WT-45

Tire Pressure Monitor-

ing System (TPMS)

transmitter compo-

nentsReplace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age.

WT-53

Wheel alignment and

balanceIf the vehicle should pull to either side while driving on a straight and level road,

or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed. For additional information regarding tires, refer

to "Important Tire Safety Information" (US) or "Tire Safety Information" (Canada)

in the NISSAN Warranty

Information Booklet. WT-44

WT-45

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. GW-12

Windshield wiper

bladesCheck for cracks or wear if they do not wipe properly.

—

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the back

door, trunk lid and back hatch. Also make sure that all latches lock securely. Lu-

bricate if necessary. Make sure that the secondary latch keeps the hood from

opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check lubrica-

tion frequently. MA-40

MA-41

MA-42

MA-42

Lamps

Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and oth-

er lamps are all operating properly and installed securely. Also check headlamp

aim. Clean the headlamps on a regular basis. EXL-98

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly.

—

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak. WW-65

WW-61

WW-71

WW-73

Windshield defroster

Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioning. —

Steering wheel Check that it has the specified play. Check for changes in the steering condition,

such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) ST-5

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2327 of 3641

MA-12

< PERIODIC MAINTENANCE >

RECOMMENDED FLUIDS AND LUBRICANTS

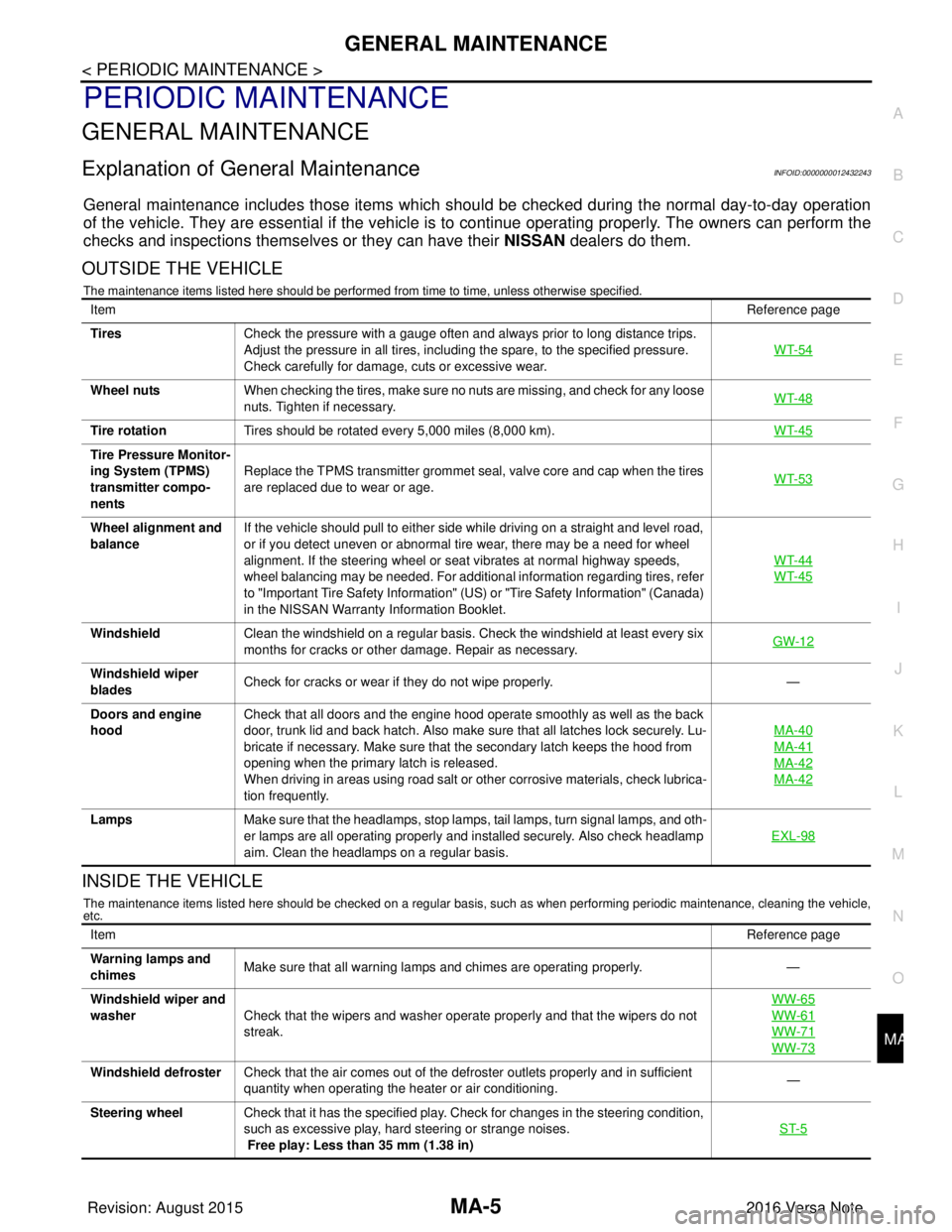

Engine Oil Recommendation

INFOID:0000000012432246

NISSAN recommends the use of an energy conservi ng oil in order to improve fuel economy.

Select only engine oils that meet the American Petroleum Institute (API) certification and International Lubrica-

tion Standardization and Approval Committee (ILSAC) ce rtification and SAE viscosity standard. These oils

have the API certification mark on the front of the container. Oils whic h do not have the specified quality label

should not be used as they could cause engine damage.

Anti-Freeze Coolant Mixture RatioINFOID:0000000012432247

The engine cooling system is filled at the factory with a pre-diluted mixture of 50% Genuine NISSAN Long Life

Antifreeze/Coolant (blue) and 50% water to provide year-round anti-freeze and coolant protection. The anti-

freeze solution contains rust and corrosion inhibitors. Additional engine cooling system additives are not nec-

essary.

WARNING:

• Do not remove the radiator or coolant reservoir cap when the engine is hot. Wait until the engine and radiator cool down. Serious burns could be caused by high pressure fluid escaping from the radia-

tor.

• The radiator is equipped with a pressure type radiator cap. To prevent engine damage, use only a

Genuine NISSAN radiator cap.

CAUTION:

• When adding or replacing coolant, be sure to use only Genuine NISSAN Lo ng Life Antifreeze/Cool-

ant (blue) or equivalent. Genuine NISSAN Long Life Antifreeze/Coolant (blue) is pre-diluted to pro-

vide antifreeze protection to -34 °F (-37 °C). If additional freeze protect ion is needed due to weather

where you operate your vehicle, add Genuine NISSAN long life Antifreeze/Coolant (blue) concentrate

following the directions on the container. If an equivalent coolant other than Genuine NISSAN Long

Life Antifreeze/Coolant (blue) is used, follow the coolant manufact urer’s instructions to maintain

minimum antifreeze protection to -34 °F (-37 °C). The use of other types of coolant solutions other

than Genuine NISSAN Long Life Antifreeze/Coolant (blue) or equivalent may damage the engine

cooling system.

• Mixing any other type of coolant other than Genuine NISSAN Long Life Antifreeze/Coolant (blue),

including Genuine NISSAN Long Life Antifreeze/Coolant (green), or the use of non-distilled water will

reduce the life expectancy of the factory filled coolant.

Air conditioning system refrigerant 0.4 kg0.9 lb 0.9 lb• HFC-134a (R-134a)

• For further details, see “Air condi-

tioner specification label”.

Air conditioning system oil 110 - 130 m3.7 - 4.4 fl oz 3.9 - 4.6 fl oz • A/C System Oil Type R (DH-PR)

• For further details, see “Air condi-

tioner specification label”.

Fluid type

Capacity (Approximate)

Recommended Fluids/Lubricants

Metric US measure Imp measure

1. API certification mark 2. API service symbol

JSPIA0014ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2330 of 3641

ENGINE MAINTENANCEMA-15

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

• When checking immediately after in

stallation, first adjust it to the specified value. Then, after

turning crankshaft two turns or more, readjust to the specified value to avoid variation in deflec-

tion between pulleys.

• When the tension adjustment is performed, the lo ck nut should be in the condition at Step 2. If

the tension adjustment is perfo rmed when the lock nut is loosened more than the temporary

tightening, the idler pulley tilts and the co rrect tension adjustment cannot be performed.

4. Tighten the lock nut to final tightening specification.

ENGINE COOLANT

ENGINE COOLANT : InspectionINFOID:0000000012432252

CHECKING COOLING SYSTEM HOSES

Check hoses for the following:

• Improper attachment

• Leaks

•Cracks

• Damage

• Loose connections

• Chafing

• Deterioration

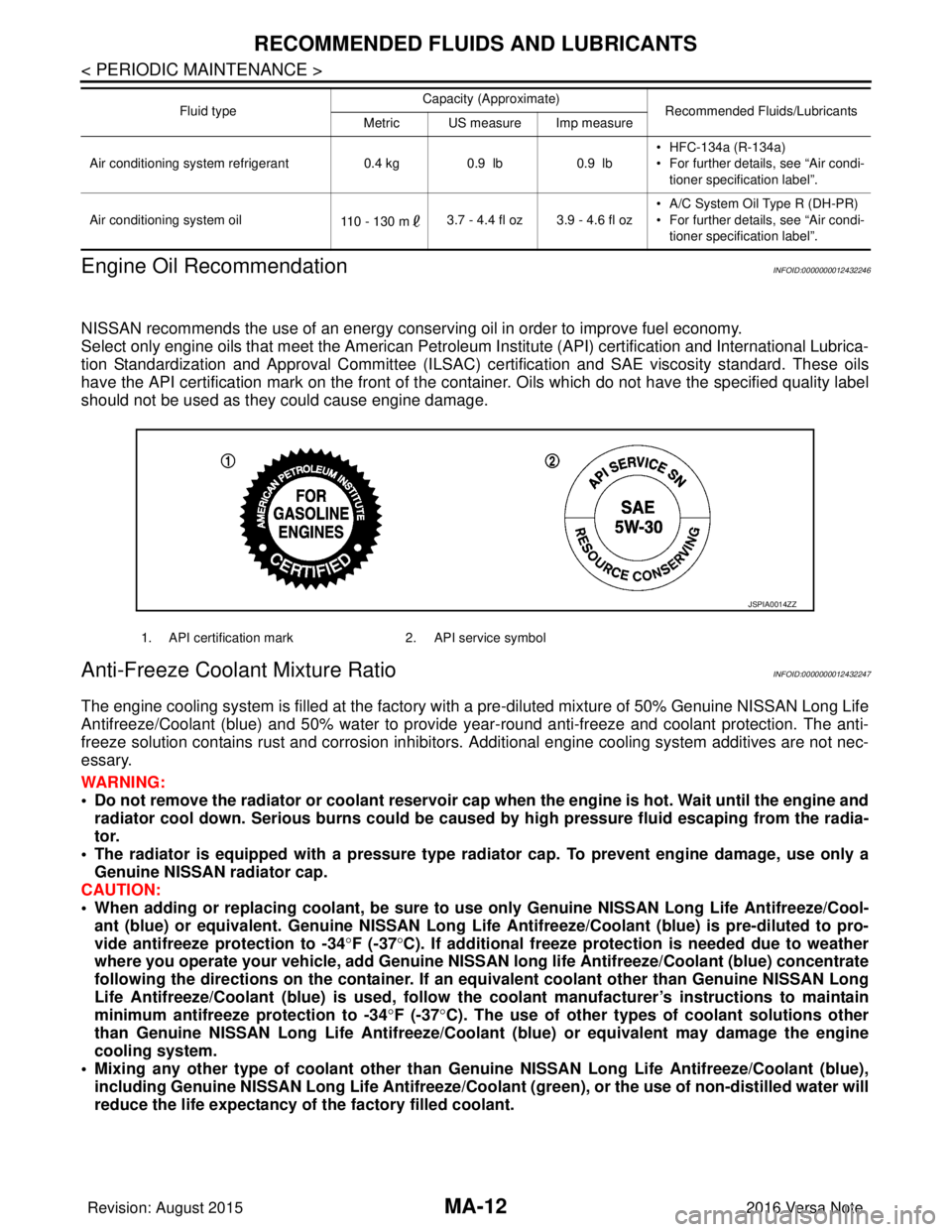

CHECKING RESERVOIR LEVEL

• Check that the reservoir tank engine coolant level is within the MAX (A) to MIN (B) range when the engine is cool.

• Adjust the engine coolant level if necessary. CAUTION:

Refill the engine cooling system with the specified coolant or

equivalent. Refer to MA-11, "

Fluids and Lubricants".

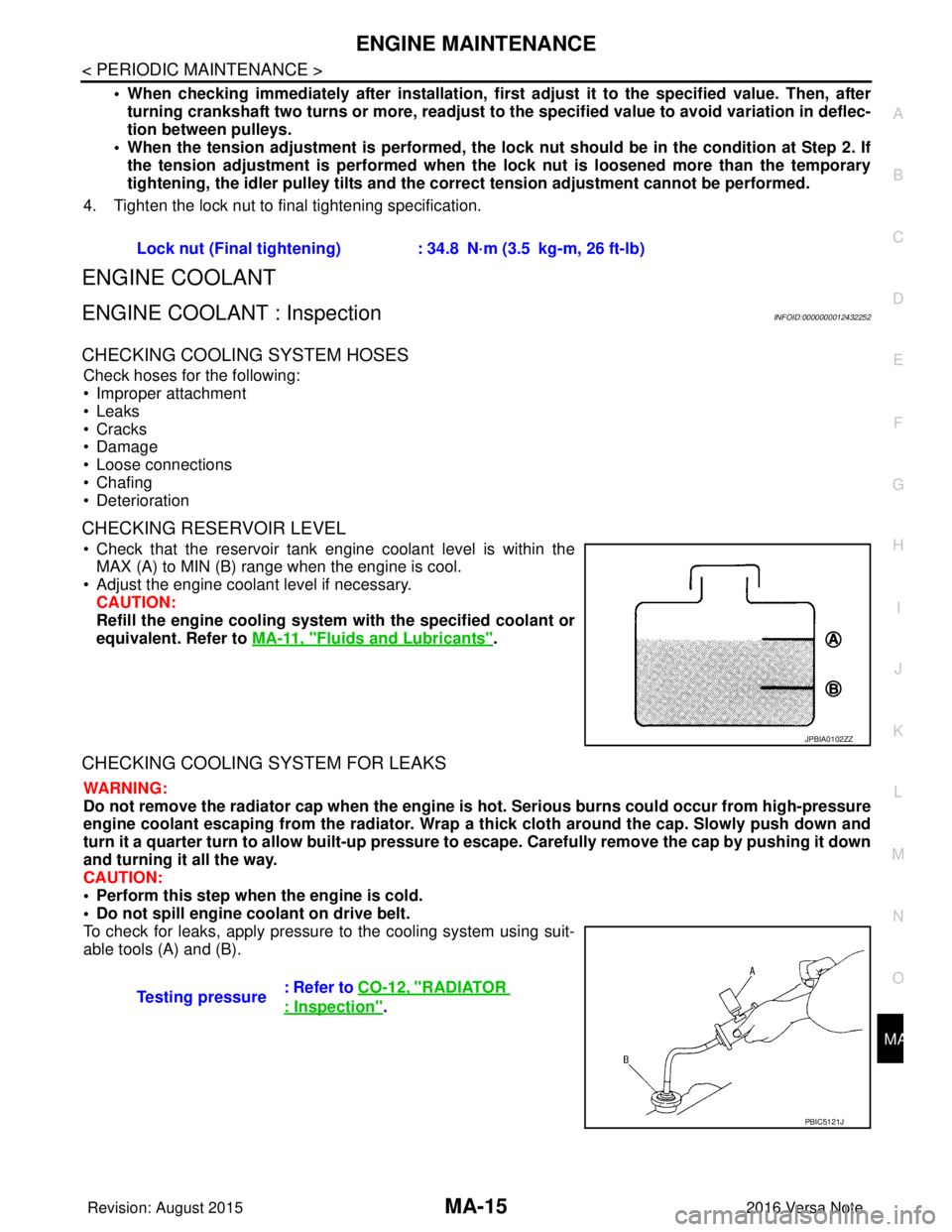

CHECKING COOLING SYSTEM FOR LEAKS

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

CAUTION:

• Perform this step when the engine is cold.

• Do not spill engine coolant on drive belt.

To check for leaks, apply pressure to the cooling system using suit-

able tools (A) and (B). Lock nut (Final tightening) :

34.8 N·m (3.5 kg-m, 26 ft-lb)

JPBIA0102ZZ

Testing pressure: Refer to CO-12, "RADIATOR

: Inspection".

PBIC5121J

Revision: August 2015

2016 Versa Note

cardiagn.com