warning NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2331 of 3641

MA-16

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

ENGINE COOLANT : Draining Engine Coolant

INFOID:0000000012432253

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a th ick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

1. Remove front under cover. Refer to EXT-39, "

FRONT UNDER COVER : Removal and Installation".

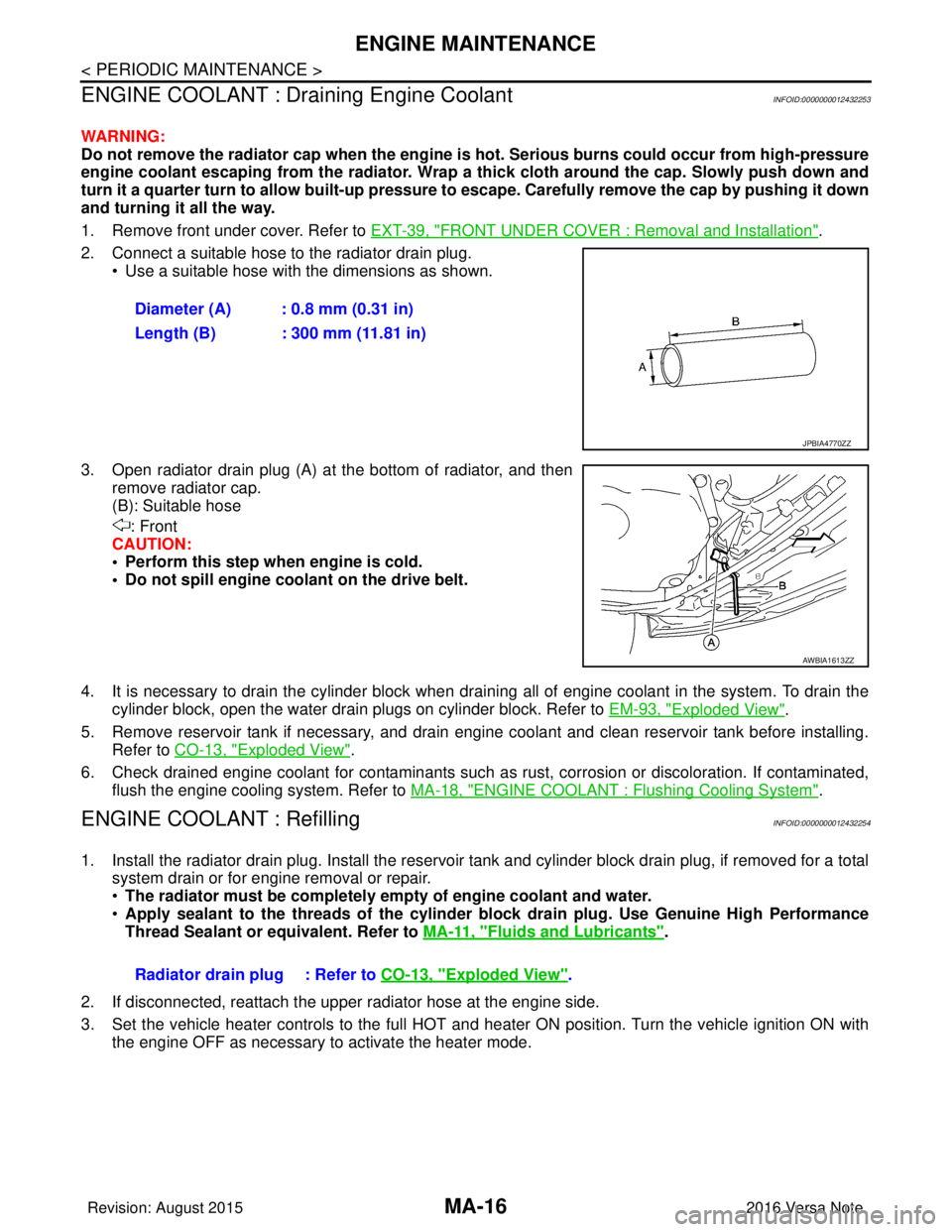

2. Connect a suitable hose to the radiator drain plug. • Use a suitable hose with the dimensions as shown.

3. Open radiator drain plug (A) at the bottom of radiator, and then remove radiator cap.

(B): Suitable hose

: Front

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on the drive belt.

4. It is necessary to drain the cylinder block when drai ning all of engine coolant in the system. To drain the

cylinder block, open the water drain plugs on cylinder block. Refer to EM-93, "

Exploded View".

5. Remove reservoir tank if necessary, and drain engine coolant and clean reservoir tank before installing. Refer to CO-13, "

Exploded View".

6. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system. Refer to MA-18, "

ENGINE COOLANT : Flushing Cooling System".

ENGINE COOLANT : RefillingINFOID:0000000012432254

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be completely empty of engine coolant and water.

• Apply sealant to the threads of the cylinder block drain plug. Use Genuine High Performance

Thread Sealant or equivalent. Refer to MA-11, "

Fluids and Lubricants".

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode. Diameter (A) : 0.8 mm (0.31 in)

Length (B) : 300 mm (11.81 in)

JPBIA4770ZZ

AWBIA1613ZZ

Radiator drain plug : Refer to

CO-13, "Exploded View".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2336 of 3641

ENGINE MAINTENANCEMA-21

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

WARNING:

• Be careful not to burn yoursel

f, as engine oil may be hot.

• When checking engine oil pressure, sh ift selector should be in the "P" (Park) or "N" (Neutral) posi-

tion, and apply parking brake securely.

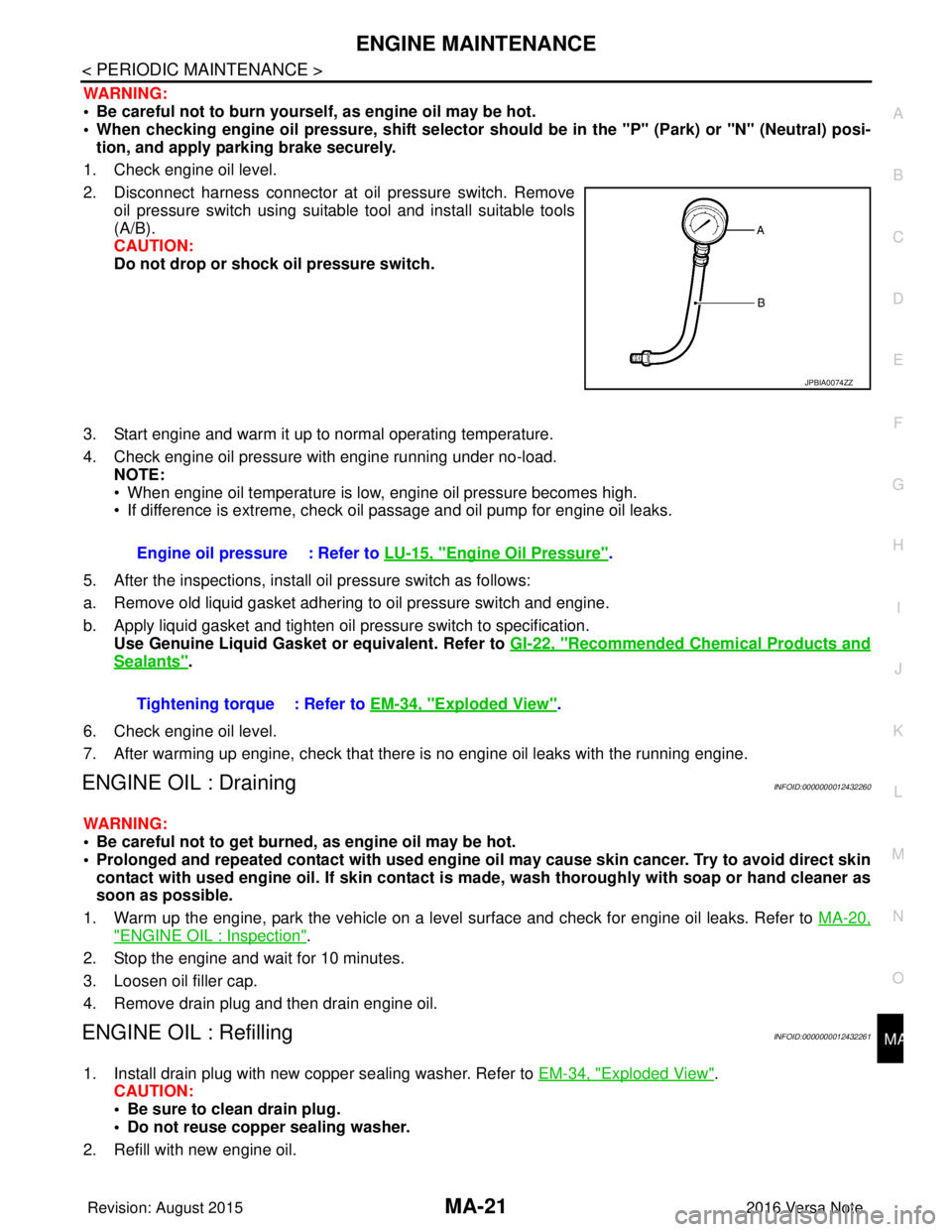

1. Check engine oil level.

2. Disconnect harness connector at oil pressure switch. Remove oil pressure switch using suitable tool and install suitable tools

(A/B).

CAUTION:

Do not drop or shock oil pressure switch.

3. Start engine and warm it up to normal operating temperature.

4. Check engine oil pressure with engine running under no-load. NOTE:

• When engine oil temperature is low, engine oil pressure becomes high.

• If difference is extreme, check oil passage and oil pump for engine oil leaks.

5. After the inspections, install oil pressure switch as follows:

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to specification. Use Genuine Liquid Gasket or equivalent. Refer to GI-22, "

Recommended Chemical Products and

Sealants".

6. Check engine oil level.

7. After warming up engine, check that there is no engine oil leaks with the running engine.

ENGINE OIL : DrainingINFOID:0000000012432260

WARNING:

• Be careful not to get burned, as engine oil may be hot.

• Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thorough ly with soap or hand cleaner as

soon as possible.

1. Warm up the engine, park the vehicle on a level surface and check for engine oil leaks. Refer to MA-20,

"ENGINE OIL : Inspection".

2. Stop the engine and wait for 10 minutes.

3. Loosen oil filler cap.

4. Remove drain plug and then drain engine oil.

ENGINE OIL : RefillingINFOID:0000000012432261

1. Install drain plug with new copper sealing washer. Refer to EM-34, "Exploded View".

CAUTION:

• Be sure to clean drain plug.

• Do not reuse copper sealing washer.

2. Refill with new engine oil.

JPBIA0074ZZ

Engine oil pressure : Refer to LU-15, "Engine Oil Pressure".

Tightening torque : Refer to EM-34, "

Exploded View".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2337 of 3641

MA-22

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

CAUTION:

• The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

• Always use oil level gauge to determine the pr oper amount of engine oil in the engine.

3. Warm up engine and check area around drain plug and oil filter for engine oil leaks. Repair as necessary.

4. Stop engine and wait for 10 minutes.

5. Check the engine oil level. Refer to MA-20, "

ENGINE OIL : Inspection".

OIL FILTER

OIL FILTER : Removal and InstallationINFOID:0000000012432262

REMOVAL

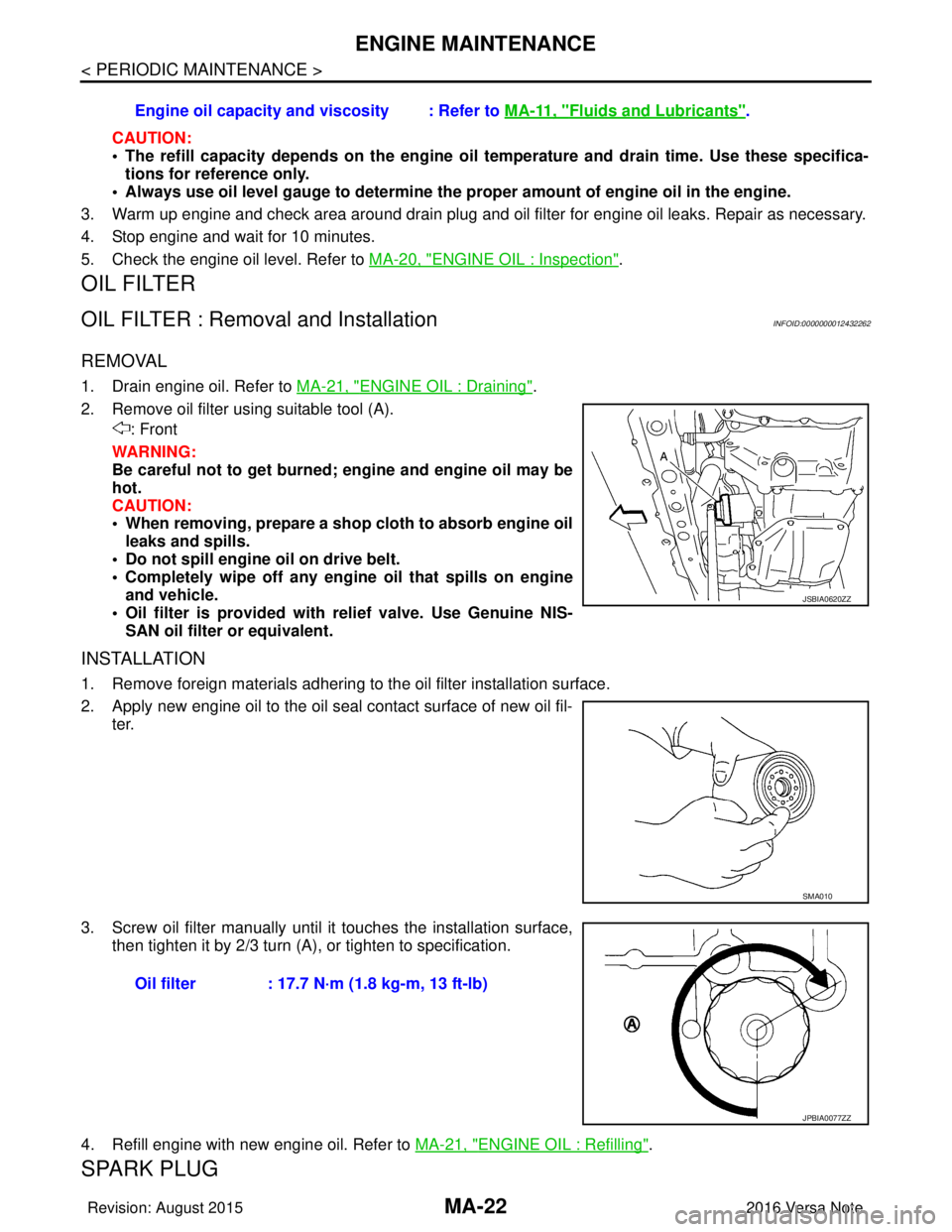

1. Drain engine oil. Refer to MA-21, "ENGINE OIL : Draining".

2. Remove oil filter using suitable tool (A). : Front

WARNING:

Be careful not to get burned; engine and engine oil may be

hot.

CAUTION:

• When removing, prepare a shop cloth to absorb engine oil leaks and spills.

• Do not spill engine oil on drive belt.

• Completely wipe off any engine oil that spills on engine

and vehicle.

• Oil filter is provided with relief valve. Use Genuine NIS- SAN oil filter or equivalent.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal contact surface of new oil fil- ter.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn (A), or tighten to specification.

4. Refill engine with new engine oil. Refer to MA-21, "

ENGINE OIL : Refilling".

SPARK PLUG

Engine oil capacity and viscosity : Refer to MA-11, "Fluids and Lubricants".

JSBIA0620ZZ

SMA010

Oil filter : 17.7 N·m (1.8 kg-m, 13 ft-lb)

JPBIA0077ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2349 of 3641

MA-34

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

TIRE ROTATION

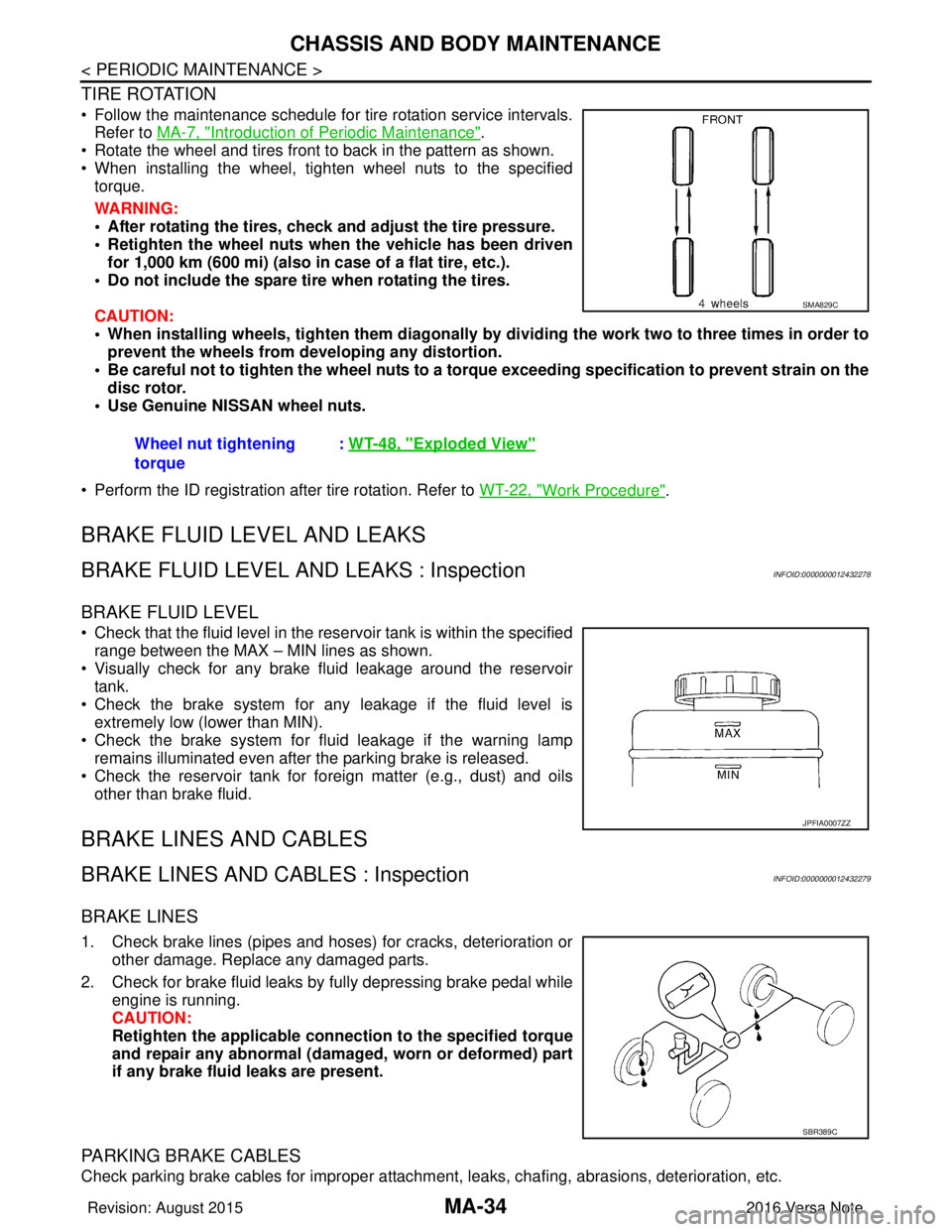

• Follow the maintenance schedule for tire rotation service intervals.Refer to MA-7, "

Introduction of Periodic Maintenance".

• Rotate the wheel and tires front to back in the pattern as shown.

• When installing the wheel, tighten wheel nuts to the specified torque.

WARNING:

• After rotating the tires, check and adjust the tire pressure.

• Retighten the wheel nuts when the vehicle has been driven

for 1,000 km (600 mi) (also in case of a flat tire, etc.).

• Do not include the spare tire when rotating the tires.

CAUTION:

• When installing wheels, ti ghten them diagonally by dividing the work two to three times in order to

prevent the wheels from d eveloping any distortion.

• Be careful not to tighten the wh eel nuts to a torque exceeding speci fication to prevent strain on the

disc rotor.

• Use Genuine NISSAN wheel nuts.

• Perform the ID registration after tire rotation. Refer to WT-22, "

Work Procedure".

BRAKE FLUID LEVEL AND LEAKS

BRAKE FLUID LEVEL AND LEAKS : InspectionINFOID:0000000012432278

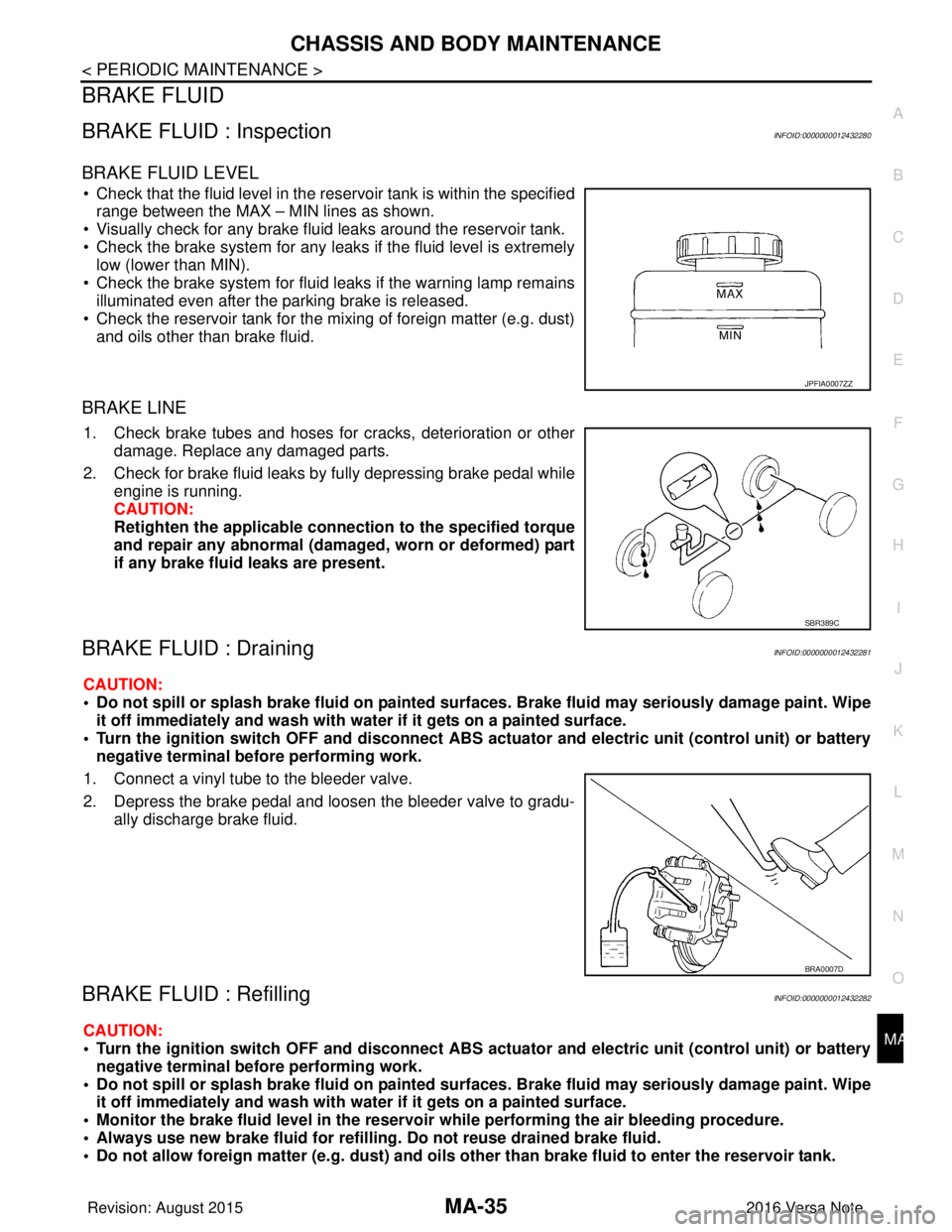

BRAKE FLUID LEVEL

• Check that the fluid level in the reservoir tank is within the specified

range between the MAX – MIN lines as shown.

• Visually check for any brake fluid leakage around the reservoir tank.

• Check the brake system for any leakage if the fluid level is extremely low (lower than MIN).

• Check the brake system for fluid leakage if the warning lamp

remains illuminated even after the parking brake is released.

• Check the reservoir tank for foreign matter (e.g., dust) and oils other than brake fluid.

BRAKE LINES AND CABLES

BRAKE LINES AND CABLES : InspectionINFOID:0000000012432279

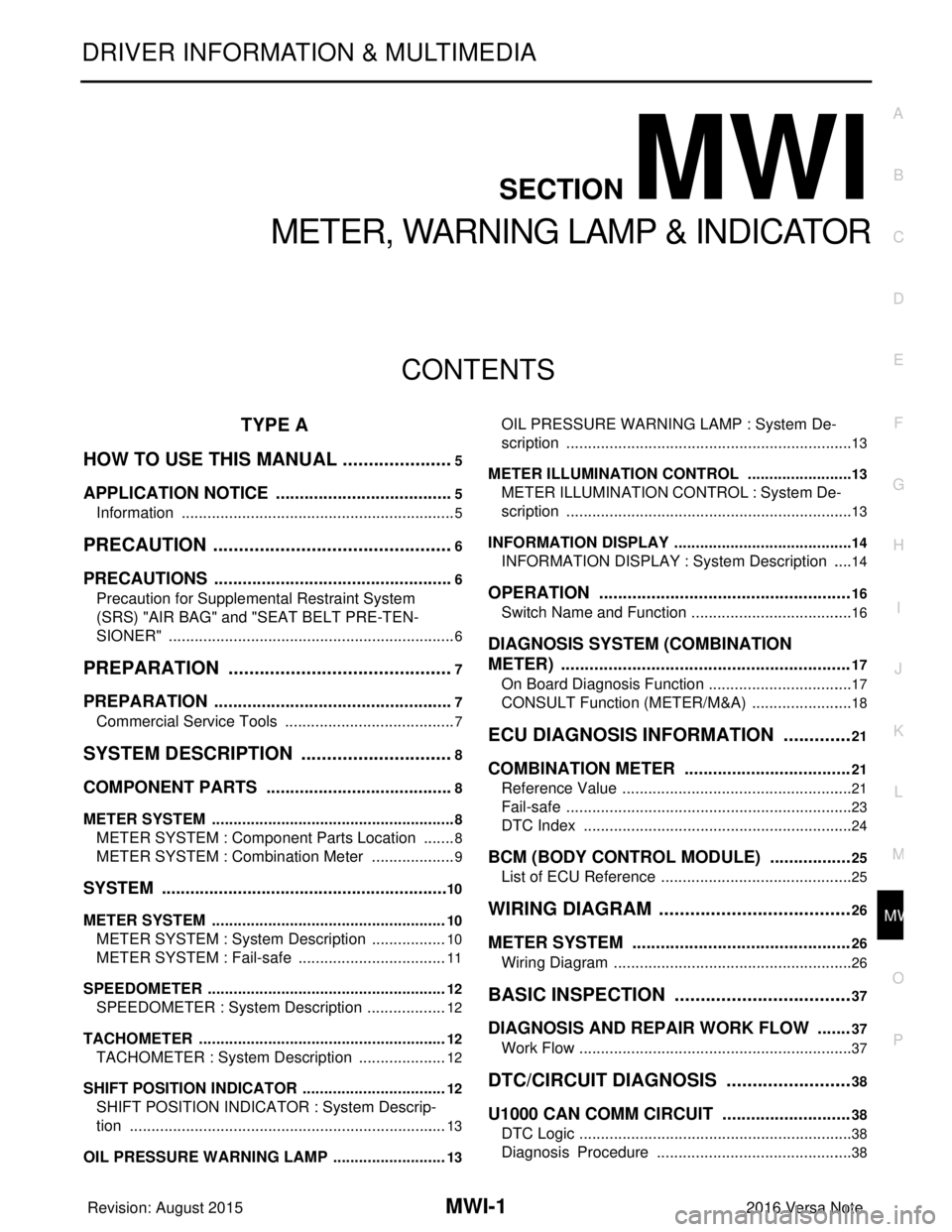

BRAKE LINES

1. Check brake lines (pipes and hoses) for cracks, deterioration or other damage. Replace any damaged parts.

2. Check for brake fluid leaks by fully depressing brake pedal while engine is running.

CAUTION:

Retighten the applicable conn ection to the specified torque

and repair any abnormal (damag ed, worn or deformed) part

if any brake fluid leaks are present.

PARKING BRAKE CABLES

Check parking brake cables for improper attachment , leaks, chafing, abrasions, deterioration, etc.

Wheel nut tightening

torque

:

WT-48, "

Exploded View"

SMA829C

JPFIA0007ZZ

SBR389C

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2350 of 3641

CHASSIS AND BODY MAINTENANCEMA-35

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

BRAKE FLUID

BRAKE FLUID : InspectionINFOID:0000000012432280

BRAKE FLUID LEVEL

• Check that the fluid level in the re

servoir tank is within the specified

range between the MAX – MIN lines as shown.

• Visually check for any brake fluid leaks around the reservoir tank.

• Check the brake system for any leak s if the fluid level is extremely

low (lower than MIN).

• Check the brake system for fluid leaks if the warning lamp remains

illuminated even after the parking brake is released.

• Check the reservoir tank for the mixing of foreign matter (e.g. dust) and oils other than brake fluid.

BRAKE LINE

1. Check brake tubes and hoses for cracks, deterioration or other

damage. Replace any damaged parts.

2. Check for brake fluid leaks by fully depressing brake pedal while engine is running.

CAUTION:

Retighten the applicable conn ection to the specified torque

and repair any abnormal (damag ed, worn or deformed) part

if any brake fluid leaks are present.

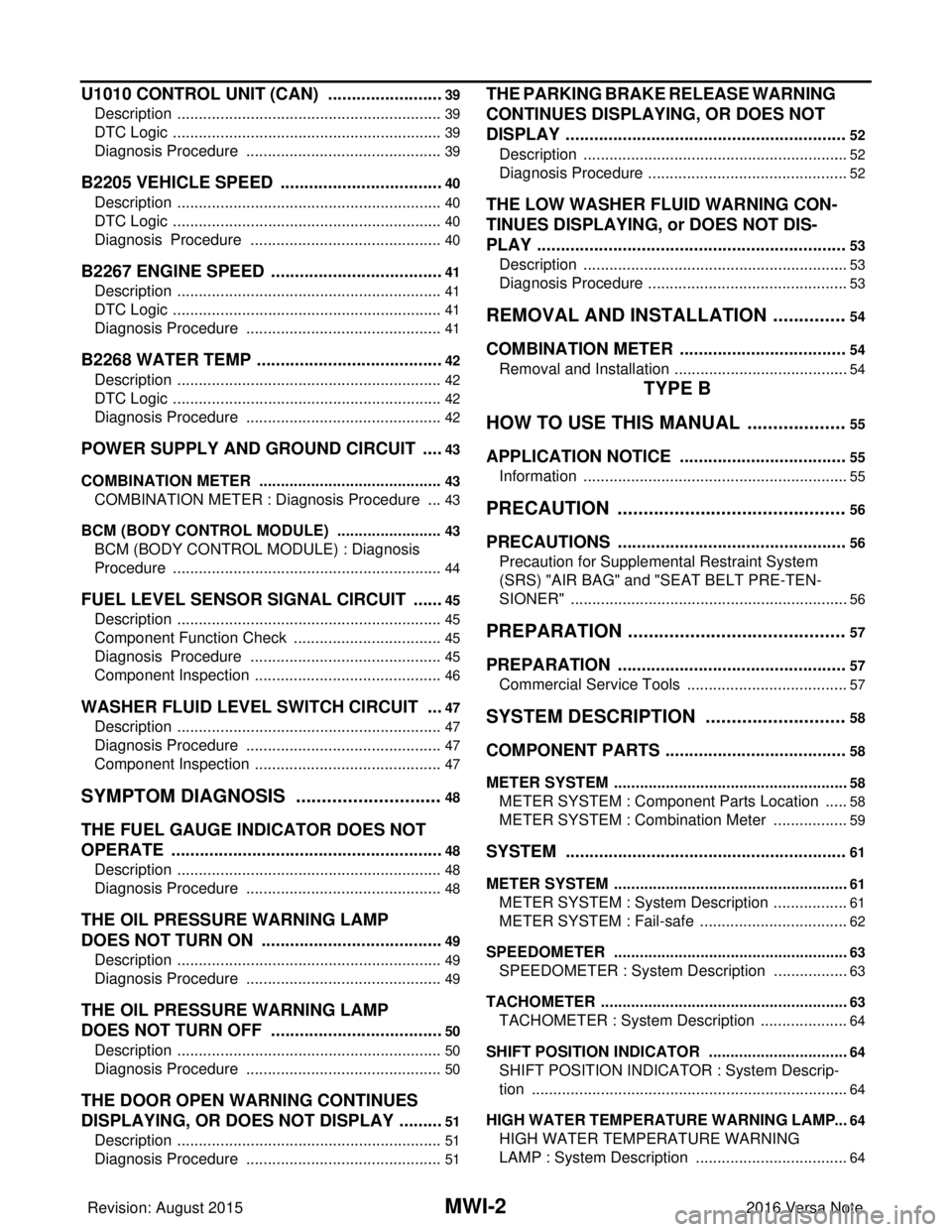

BRAKE FLUID : DrainingINFOID:0000000012432281

CAUTION:

• Do not spill or splash brake fluid on painted su rfaces. Brake fluid may seriously damage paint. Wipe

it off immediately and wash with wa ter if it gets on a painted surface.

• Turn the ignition switch OFF an d disconnect ABS actuator and electric unit (control unit) or battery

negative terminal before performing work.

1. Connect a vinyl tube to the bleeder valve.

2. Depress the brake pedal and loosen the bleeder valve to gradu- ally discharge brake fluid.

BRAKE FLUID : RefillingINFOID:0000000012432282

CAUTION:

• Turn the ignition switch OFF an d disconnect ABS actuator and electric unit (control unit) or battery

negative terminal before performing work.

• Do not spill or splash brake fluid on painted su rfaces. Brake fluid may seriously damage paint. Wipe

it off immediately and wash with wa ter if it gets on a painted surface.

• Monitor the brake fluid level in the reservoir while performing the air bleeding procedure.

• Always use new brake fluid for refillin g. Do not reuse drained brake fluid.

• Do not allow foreign matter (e.g. dust) and oils ot her than brake fluid to enter the reservoir tank.

JPFIA0007ZZ

SBR389C

BRA0007D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2359 of 3641

MWI

MWI-1

DRIVER INFORMATION & MULTIMEDIA

C

DE

F

G H

I

J

K L

M B

SECTION MWI

A

O P

CONTENTS

METER, WARNING LAMP & INDICATOR

TYPE A

HOW TO USE THIS MANU AL ......................

5

APPLICATION NOTICE ................................. .....5

Information .......................................................... ......5

PRECAUTION ...............................................6

PRECAUTIONS .............................................. .....6

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

6

PREPARATION ............................................7

PREPARATION .............................................. .....7

Commercial Service Tools .................................. ......7

SYSTEM DESCRIPTION ..............................8

COMPONENT PARTS ................................... .....8

METER SYSTEM .........................................................8

METER SYSTEM : Compo nent Parts Location ........8

METER SYSTEM : Combinat ion Meter ....................9

SYSTEM ......................................................... ....10

METER SYSTEM .......................................................10

METER SYSTEM : System Description ..................10

METER SYSTEM : Fail-safe ...................................11

SPEEDOMETER ................ ........................................12

SPEEDOMETER : System Description ............... ....12

TACHOMETER ...................................................... ....12

TACHOMETER : System Description .....................12

SHIFT POSITION INDICATOR .............................. ....12

SHIFT POSITION INDICATOR : System Descrip-

tion ...................................................................... ....

13

OIL PRESSURE WARNING LAMP ...........................13

OIL PRESSURE WARNING LAMP : System De-

scription ............................................................... ....

13

METER ILLUMINATION CONTROL ..................... ....13

METER ILLUMINATION CONTROL : System De-

scription ...................................................................

13

INFORMATION DISPLAY ...................................... ....14

INFORMATION DISPLAY : System Description .....14

OPERATION .....................................................16

Switch Name and Function ......................................16

DIAGNOSIS SYSTEM (COMBINATION

METER) .............................................................

17

On Board Diagnosis Function ..................................17

CONSULT Function (METER/M&A) ........................18

ECU DIAGNOSIS INFORMATION ..............21

COMBINATION METER ...................................21

Reference Value .................................................. ....21

Fail-safe ...................................................................23

DTC Index ...............................................................24

BCM (BODY CONTROL MODULE) .................25

List of ECU Reference .............................................25

WIRING DIAGRAM ......................................26

METER SYSTEM ..............................................26

Wiring Diagram .................................................... ....26

BASIC INSPECTION ...................................37

DIAGNOSIS AND REPAIR WORK FLOW .......37

Work Flow ............................................................ ....37

DTC/CIRCUIT DIAGNOSIS .........................38

U1000 CAN COMM CIRCUIT ...........................38

DTC Logic ............................................................ ....38

Diagnosis Procedure ..............................................38

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2360 of 3641

MWI-2

U1010 CONTROL UNIT (CAN) .........................39

Description ........................................................... ...39

DTC Logic ...............................................................39

Diagnosis Procedure ..............................................39

B2205 VEHICLE SPEED ...................................40

Description ........................................................... ...40

DTC Logic ...............................................................40

Diagnosis Procedure .............................................40

B2267 ENGINE SPEED .....................................41

Description ........................................................... ...41

DTC Logic ...............................................................41

Diagnosis Procedure ..............................................41

B2268 WATER TEMP ........................................42

Description ........................................................... ...42

DTC Logic ...............................................................42

Diagnosis Procedure ..............................................42

POWER SUPPLY AND GROUND CIRCUIT .....43

COMBINATION METER ........................................ ...43

COMBINATION METER : Diagnosis Procedure ....43

BCM (BODY CONTROL MODULE) ...................... ...43

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ...............................................................

44

FUEL LEVEL SENSOR SIGNAL CIRCUIT .......45

Description ........................................................... ...45

Component Function Check ...................................45

Diagnosis Procedure .............................................45

Component Inspection ............................................46

WASHER FLUID LEVEL SWITCH CIRCUIT ....47

Description ........................................................... ...47

Diagnosis Procedure ..............................................47

Component Inspection ............................................47

SYMPTOM DIAGNOSIS .............................48

THE FUEL GAUGE INDICATOR DOES NOT

OPERATE ....................................................... ...

48

Description ........................................................... ...48

Diagnosis Procedure ..............................................48

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN ON .......................................

49

Description ..............................................................49

Diagnosis Procedure ..............................................49

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN OFF .....................................

50

Description ........................................................... ...50

Diagnosis Procedure ..............................................50

THE DOOR OPEN WARNING CONTINUES

DISPLAYING, OR DOES NOT DISPLAY ..........

51

Description ........................................................... ...51

Diagnosis Procedure ..............................................51

THE PARKING BRAKE RELEASE WARNING

CONTINUES DISPLAYING, OR DOES NOT

DISPLAY ............................................................

52

Description ........................................................... ...52

Diagnosis Procedure ...............................................52

THE LOW WASHER FLUID WARNING CON-

TINUES DISPLAYING, or DOES NOT DIS-

PLAY ..................................................................

53

Description ........................................................... ...53

Diagnosis Procedure ...............................................53

REMOVAL AND INSTALLATION ..............54

COMBINATION METER ................................. ...54

Removal and Installation .........................................54

TYPE B

HOW TO USE THIS MANU AL ...................

55

APPLICATION NOTICE ................................. ...55

Information ........................................................... ...55

PRECAUTION ............................................56

PRECAUTIONS .............................................. ...56

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ...

56

PREPARATION ..........................................57

PREPARATION .............................................. ...57

Commercial Service Tools ................................... ...57

SYSTEM DESCRIPTION ...........................58

COMPONENT PARTS .................................... ...58

METER SYSTEM .......................................................58

METER SYSTEM : Component Parts Location ... ...58

METER SYSTEM : Combination Meter ..................59

SYSTEM ............................................................61

METER SYSTEM .......................................................61

METER SYSTEM : System Description ............... ...61

METER SYSTEM : Fail-safe ...................................62

SPEEDOMETER .................................................... ...63

SPEEDOMETER : System Description ..................63

TACHOMETER ....................................................... ...63

TACHOMETER : System Description .....................64

SHIFT POSITION INDICATOR .............................. ...64

SHIFT POSITION INDICATOR : System Descrip-

tion ....................................................................... ...

64

HIGH WATER TEMPERATURE WARNING LAMP ...64

HIGH WATER TEMPERATURE WARNING

LAMP : System Description ....................................

64

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2361 of 3641

MWI

MWI-3

C

DE

F

G H

I

J

K L

M B

A

O P

OIL PRESSURE WARNING

LAMP ...........................

65

OIL PRESSURE WARNING LAMP : System De-

scription ............................................................... ....

65

METER ILLUMINATION CONTROL ..................... ....65

METER ILLUMINATION CONTROL : System De-

scription ...................................................................

66

INFORMATION DISPLAY ..................................... ....66

INFORMATION DISPLAY : System Description .....66

OPERATION ................................................... ....68

Switch Name and Function ................................. ....68

DIAGNOSIS SYSTEM (COMBINATION

METER) ..............................................................

69

On Board Diagnosis Function ............................. ....69

CONSULT Function (METER/M&A) .......................71

ECU DIAGNOSIS INFORMATION ..............74

COMBINATION METER ................................. ....74

Reference Value ................................................. ....74

Fail-safe ..................................................................77

DTC Index ...............................................................77

BCM (BODY CONTROL MODULE) ...................78

List of ECU Reference ........................................ ....78

WIRING DIAGRAM ......................................79

METER SYSTEM ............................................ ....79

Wiring Diagram ................................................... ....79

BASIC INSPECTION ...................................92

DIAGNOSIS AND REPAIR WORK FLOW .... ....92

Work Flow ........................................................... ....92

DTC/CIRCUIT DIAGNOSIS .........................93

U1000 CAN COMM CI RCUIT .............................93

DTC Logic ........................................................... ....93

Diagnosis Procedure ..............................................93

U1010 CONTROL UNIT (CAN) ..........................94

Description ..............................................................94

DTC Logic ...............................................................94

Diagnosis Procedure ...............................................94

B2205 VEHICLE SPEED ....................................95

Description ..............................................................95

DTC Logic ...............................................................95

Diagnosis Procedure ..............................................95

B2267 ENGINE SPEED .....................................96

Description .......................................................... ....96

DTC Logic ...............................................................96

Diagnosis Procedure ...............................................96

B2268 WATER TEMP ........................................97

Description .......................................................... ....97

DTC Logic ...............................................................97

Diagnosis Procedure ........................................... ....97

POWER SUPPLY AND GROUND CIRCUIT ....98

COMBINATION METER ........................................ ....98

COMBINATION METER : Diagnosis Procedure .....98

BCM (BODY CONTROL SYSTEM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) .................................. ....

98

BCM (BODY CONTROL SYSTEM) (WITHOUT

INTELLIGENT KEY SYSTEM) : Diagnosis Proce-

dure ..................................................................... ....

98

BCM (BODY CONTROL SYSTEM) (WITH INTEL-

LIGENT KEY SYSTEM) .............................................

99

BCM (BODY CONTROL SYSTEM) (WITH INTEL-

LIGENT KEY SYSTEM) : Diagnosis Procedure .. ....

99

FUEL LEVEL SENSOR SIGNAL CIRCUIT ....101

Description .............................................................101

Component Function Check ..................................101

Diagnosis Procedure ............................................101

Component Inspection ...........................................102

STEERING SWITCH .......................................103

Diagnosis Procedure .............................................103

AMBIENT SENSOR SIGNAL CIRCUIT ..........104

Description .............................................................104

Diagnosis Procedure ............................................104

Component Inspection ...........................................105

WASHER FLUID LEVEL SWITCH CIRCUIT ..106

Description .............................................................106

Diagnosis Procedure .............................................106

Component Inspection ...........................................106

SYMPTOM DIAGNOSIS ............................107

THE FUEL GAUGE INDICATOR DOES NOT

OPERATE .......................................................

107

Description ........................................................... ..107

Diagnosis Procedure .............................................107

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN ON .....................................

108

Description .............................................................108

Diagnosis Procedure .............................................108

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN OFF ...................................

109

Description .............................................................109

Diagnosis Procedure .............................................109

THE DOOR OPEN WARNING CONTINUES

DISPLAYING, OR DOES NOT DISPLAY .......

110

Description .............................................................110

Diagnosis Procedure .............................................110

THE PARKING BRAKE RELEASE WARNING

CONTINUES DISPLAYING, OR DOES NOT

DISPLAY .........................................................

111

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2362 of 3641

MWI-4

Description .............................................................111

Diagnosis Procedure .............................................111

THE STEERING SWITCH (METER CON-

TROL SWITCH) IS INOPERATIVE .................

112

Description ........................................................... ..112

Diagnosis Procedure .............................................112

THE AMBIENT TEMPERATURE DISPLAY IS

INCORRECT ....................................................

113

Description ........................................................... ..113

Diagnosis Procedure .............................................113

THE LOW WASHER FLUID WARNING CON-

TINUES DISPLAYING, or DOES NOT DIS-

PLAY .................................................................

114

Description ........................................................... .114

Diagnosis Procedure .............................................114

REMOVAL AND INSTALLATION .............115

COMBINATION METER ................................. ..115

Removal and Installation .......................................115

AMBIENT SENSOR ..........................................116

Removal and Installation .......................................116

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2364 of 3641

![NISSAN NOTE 2016 Service Repair Manual MWI-6

< PRECAUTION >[TYPE A]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432539

The Supplemental Re NISSAN NOTE 2016 Service Repair Manual MWI-6

< PRECAUTION >[TYPE A]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432539

The Supplemental Re](/img/5/57363/w960_57363-2363.png)

MWI-6

< PRECAUTION >[TYPE A]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432539

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Revision: August 2015 2016 Versa Note

cardiagn.com