charging NISSAN NOTE 2016 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1150 of 3641

![NISSAN NOTE 2016 Service Owners Manual COMPONENT PARTSEC-23

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Exhaust Valve Timing Control Solenoid ValveINFOID:0000000012431286

Exhaust valve timing control solenoi

d valve is NISSAN NOTE 2016 Service Owners Manual COMPONENT PARTSEC-23

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Exhaust Valve Timing Control Solenoid ValveINFOID:0000000012431286

Exhaust valve timing control solenoi

d valve is](/img/5/57363/w960_57363-1149.png)

COMPONENT PARTSEC-23

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Exhaust Valve Timing Control Solenoid ValveINFOID:0000000012431286

Exhaust valve timing control solenoi

d valve is activated by ON/OFF

pulse duty (ratio) signals from the ECM.

The exhaust valve timing control solenoid valve changes the oil

amount and direction of flow through exhaust valve timing control

unit or stops oil flow.

The longer pulse width retards valve angle.

The shorter pulse width advances valve angle.

When ON and OFF pulse widths become equal, the solenoid valve

stops oil pressure flow to fix the exhaust valve angle at the control

position.

Fuel InjectorINFOID:0000000012431287

The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the fuel injector circuit, the coil in the fuel injec-

tor is energized. The energized coil pulls the ball valve back and

allows fuel to flow through the fuel injector into the intake manifold.

The amount of fuel injected depends upon the injection pulse dura-

tion. Pulse duration is the length of time the fuel injector remains

open. The ECM controls the injection pulse duration based on

engine fuel needs.

Fuel PumpINFOID:0000000012431288

*: ECM determines the start signal status by the signals of engine speed and battery voltage.

The ECM activates the fuel pump for a few seconds after the ignition switch is turned ON to improve engine

start ability. If the ECM receives a engine speed signal from the crankshaft position sensor (POS) and cam-

shaft position sensor (PHASE), it knows that the engi ne is rotating, and causes the pump to operate. If the

engine speed signal is not received when the ignition s witch is ON, the engine stalls. The ECM stops pump

operation and prevents battery discharging, thereby improving safety. The EC M does not directly drive the fuel

pump. It controls the ON/OFF fuel pump rela y, which in turn controls the fuel pump.

JSBIA0652ZZ

JSBIA0742ZZ

SensorInput signal to ECMECM functionActuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

Fuel pump controlFuel pump relay

↓

Fuel pump

Battery Battery voltage*

Condition Fuel pump operation

Ignition switch is turned to ON. Operates for 1 second.

Engine running and cranking Operates.

When engine is stopped Stops in 1.5 seconds.

Except as shown above Sto ps .

Revision: August 20152016 Versa Note

cardiagn.com

Page 1152 of 3641

![NISSAN NOTE 2016 Service Owners Manual COMPONENT PARTSEC-25

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

<Reference data>

*: These data are reference values and are measured between ECM terminals.

Intake Valve Timing Con NISSAN NOTE 2016 Service Owners Manual COMPONENT PARTSEC-25

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

<Reference data>

*: These data are reference values and are measured between ECM terminals.

Intake Valve Timing Con](/img/5/57363/w960_57363-1151.png)

COMPONENT PARTSEC-25

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

*: These data are reference values and are measured between ECM terminals.

Intake Valve Timing Control Solenoid ValveINFOID:0000000012431293

Intake valve timing control solenoid valve is activated by ON/OFF

pulse duty (ratio) signals from the ECM.

The intake valve timing control solenoid valve changes the oil

amount and direction of flow through intake valve timing control unit

or stops oil flow.

The longer pulse width advances valve angle.

The shorter pulse width retards valve angle.

When ON and OFF pulse widths become equal, the solenoid valve

stops oil pressure flow to fix the intake valve angle at the control

position.

Knock SensorINFOID:0000000012431294

The knock sensor is attached to t

he cylinder block. It senses engine

knocking using a piezoelectric el ement. A knocking vibration from

the cylinder block is sensed as vibrational pressure. This pressure is

converted into a voltage signal and sent to the ECM.

Battery Current Sensor (With Battery Temperature Sensor)INFOID:0000000012431295

OUTLINE

The power generation voltage variable control enables fuel con-

sumption to be decreased by reducing the engine load which is

caused by the power generation of the generator.

Based on sensor signals, ECM judges whether or not the power

generation voltage variable contro l is performed. When performing

the power generation voltage variable control, ECM calculates the

target power generation voltage based on the sensor signal. And

ECM sends the calculated value as the power generation command

value to IPDM E/R. For the details of the power generation voltage

variable control, refer to CHG-8, "

System Description".

CAUTION:

Never connect the electrical co mponent or the ground wire

directly to the battery terminal. The connection cau ses the malfunction of the power generation volt-

age variable control, and then the battery discharge may occur.

BATTERY CURRENT SENSOR

The battery current sensor is installed to the battery negative cable. The sensor measures the charging/dis-

charging current of the battery.

Intake air temperature [ °C ( °F)] Voltage* (V) Resistance (k Ω)

25 (77) 3.31.800 - 2.200

80 (176) 1.20.283 - 0.359

SEF012P

PBIB1842E

JSBIA0284ZZ

JPBIA3262ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1834 of 3641

FRONT DRIVE SHAFT BOOTFAX-17

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

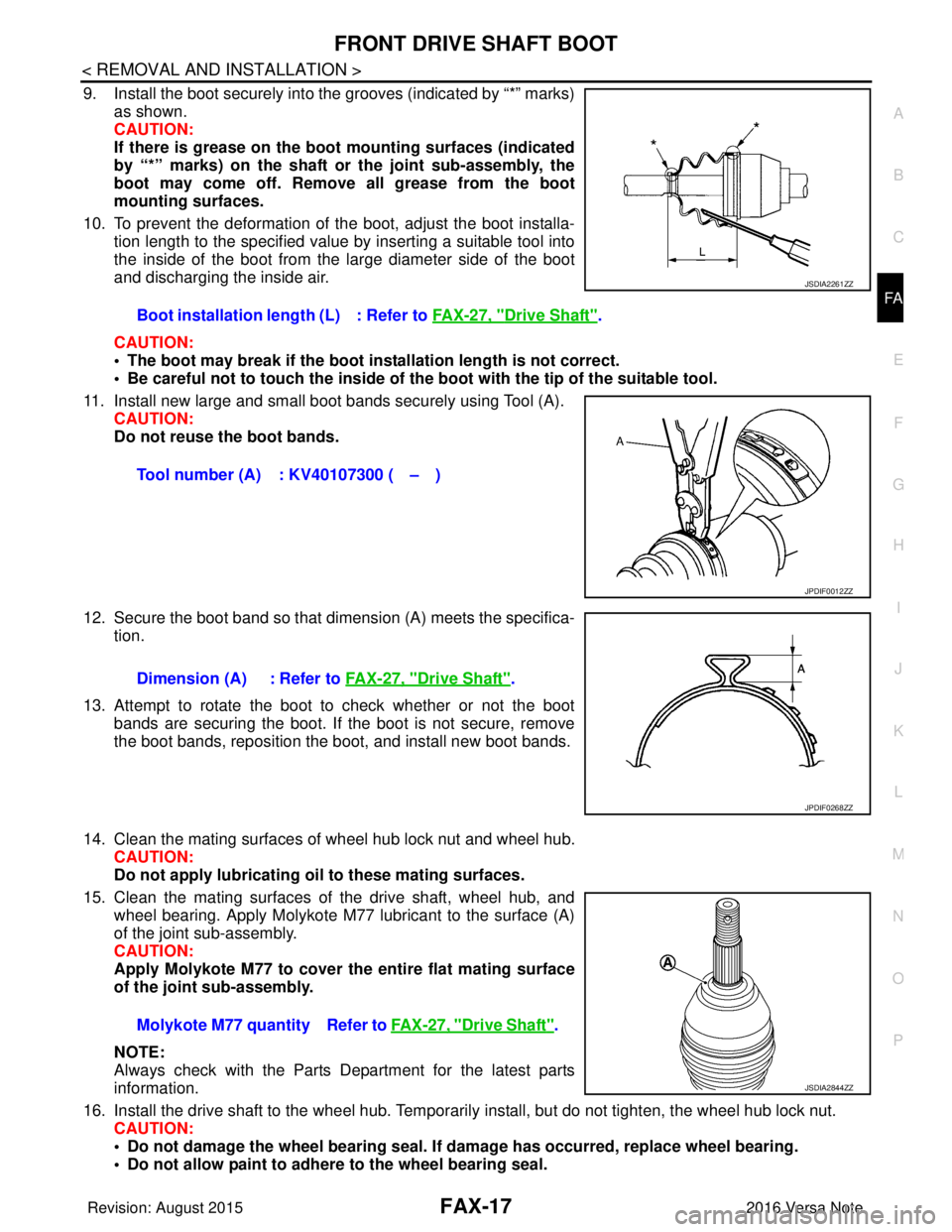

9. Install the boot securely into the grooves (indicated by “*” marks) as shown.

CAUTION:

If there is grease on the bo ot mounting surfaces (indicated

by “*” marks) on the shaft or the joint sub-assembly, the

boot may come off. Remo ve all grease from the boot

mounting surfaces.

10. To prevent the deformation of the boot, adjust the boot installa- tion length to the specified value by inserting a suitable tool into

the inside of the boot from the large diameter side of the boot

and discharging the inside air.

CAUTION:

• The boot may break if the boot in stallation length is not correct.

• Be careful not to touch the inside of the boot with the tip of the suitable tool.

11. Install new large and small boot bands securely using Tool (A). CAUTION:

Do not reuse the boot bands.

12. Secure the boot band so that dimension (A) meets the specifica- tion.

13. Attempt to rotate the boot to check whether or not the boot bands are securing the boot. If the boot is not secure, remove

the boot bands, reposition the boot, and install new boot bands.

14. Clean the mating surfaces of wheel hub lock nut and wheel hub. CAUTION:

Do not apply lubricating oil to these mating surfaces.

15. Clean the mating surfaces of the drive shaft, wheel hub, and wheel bearing. Apply Molykote M77 lubricant to the surface (A)

of the joint sub-assembly.

CAUTION:

Apply Molykote M77 to cover the entire flat mating surface

of the joint sub-assembly.

NOTE:

Always check with the Parts Department for the latest parts

information.

16. Install the drive shaft to the wheel hub. Temporaril y install, but do not tighten, the wheel hub lock nut.

CAUTION:

• Do not damage the wheel bearing seal. If damage has occurred, replace wheel bearing.

• Do not allow paint to adhere to the wheel bearing seal.

Boot installation length (L) : Refer to

FAX-27, "

Drive Shaft".

Tool number (A) : KV40107300 ( – )

JSDIA2261ZZ

JPDIF0012ZZ

Dimension (A) : Refer to FAX-27, "Drive Shaft".

JPDIF0268ZZ

Molykote M77 quantity Refer to FAX-27, "Drive Shaft".

JSDIA2844ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1841 of 3641

FAX-24

< UNIT DISASSEMBLY AND ASSEMBLY >

FRONT DRIVE SHAFT

Always check with the Parts Department for the latest parts information.

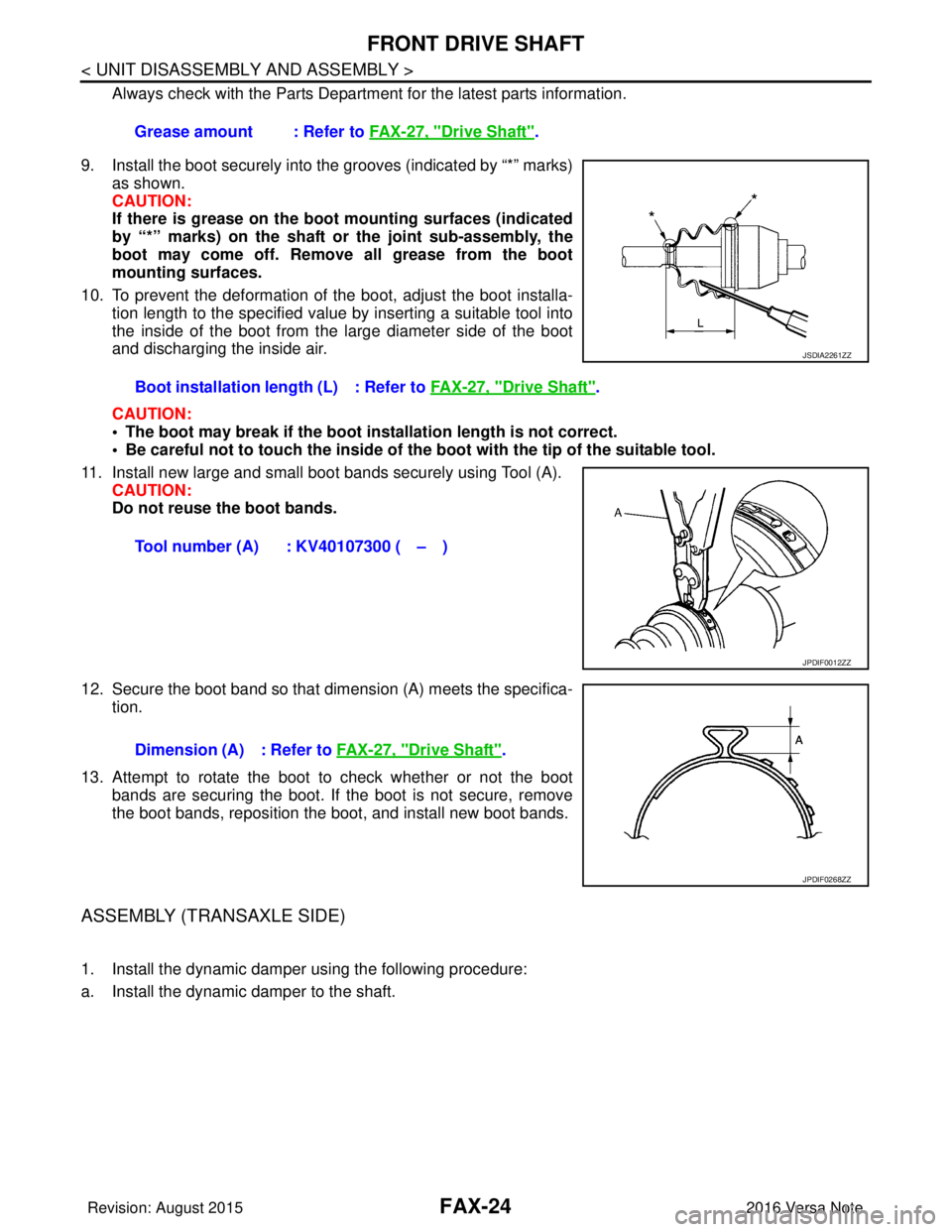

9. Install the boot securely into the grooves (indicated by “*” marks) as shown.

CAUTION:

If there is grease on the boot mounting surfaces (indicated

by “*” marks) on the shaft or the joint sub-assembly, the

boot may come off. Remove all grease from the boot

mounting surfaces.

10. To prevent the deformation of the boot, adjust the boot installa- tion length to the specified value by inserting a suitable tool into

the inside of the boot from the large diameter side of the boot

and discharging the inside air.

CAUTION:

• The boot may break if the boot installation length is not correct.

• Be careful not to touch the inside of the boot with the tip of the suitable tool.

11. Install new large and small boot bands securely using Tool (A). CAUTION:

Do not reuse the boot bands.

12. Secure the boot band so that dimension (A) meets the specifica- tion.

13. Attempt to rotate the boot to check whether or not the boot bands are securing the boot. If the boot is not secure, remove

the boot bands, reposition the boot, and install new boot bands.

ASSEMBLY (TRANSAXLE SIDE)

1. Install the dynamic damper using the following procedure:

a. Install the dynamic damper to the shaft. Grease amount : Refer to

FAX-27, "

Drive Shaft".

Boot installation length (L) : Refer to FAX-27, "

Drive Shaft".

Tool number (A) : KV40107300 ( – )

JSDIA2261ZZ

JPDIF0012ZZ

Dimension (A) : Refer to FAX-27, "Drive Shaft".

JPDIF0268ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1843 of 3641

FAX-26

< UNIT DISASSEMBLY AND ASSEMBLY >

FRONT DRIVE SHAFT

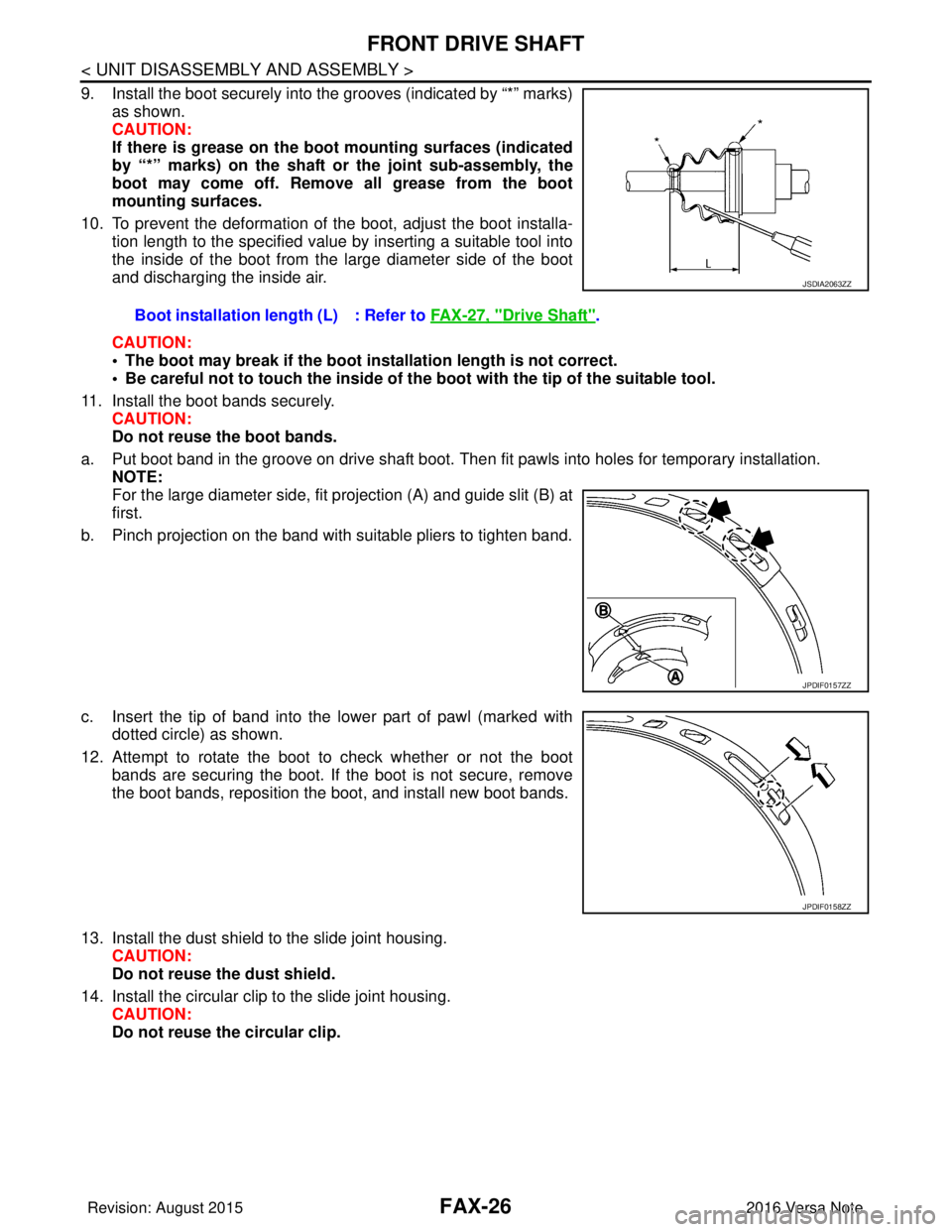

9. Install the boot securely into the grooves (indicated by “*” marks)as shown.

CAUTION:

If there is grease on the boot mounting surfaces (indicated

by “*” marks) on the shaft or the joint sub-assembly, the

boot may come off. Remove all grease from the boot

mounting surfaces.

10. To prevent the deformation of the boot, adjust the boot installa- tion length to the specified value by inserting a suitable tool into

the inside of the boot from the large diameter side of the boot

and discharging the inside air.

CAUTION:

• The boot may break if the boot installation length is not correct.

• Be careful not to touch the inside of the boot with the tip of the suitable tool.

11. Install the boot bands securely. CAUTION:

Do not reuse the boot bands.

a. Put boot band in the groove on drive shaft boot. Then fit pawls into holes for temporary installation. NOTE:

For the large diameter side, fit projection (A) and guide slit (B) at

first.

b. Pinch projection on the band with suitable pliers to tighten band.

c. Insert the tip of band into the lower part of pawl (marked with dotted circle) as shown.

12. Attempt to rotate the boot to check whether or not the boot bands are securing the boot. If the boot is not secure, remove

the boot bands, reposition the boot, and install new boot bands.

13. Install the dust shield to the slide joint housing. CAUTION:

Do not reuse the dust shield.

14. Install the circular clip to the slide joint housing. CAUTION:

Do not reuse the circular clip.Boot installation length (L) : Refer to

FAX-27, "

Drive Shaft".

JSDIA2063ZZ

JPDIF0157ZZ

JPDIF0158ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1972 of 3641

![NISSAN NOTE 2016 Service Owners Manual HAC-4

< PRECAUTION >[MANUAL AIR CONDITIONING]

PRECAUTIONS

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty

area.

• Then dip a cloth int NISSAN NOTE 2016 Service Owners Manual HAC-4

< PRECAUTION >[MANUAL AIR CONDITIONING]

PRECAUTIONS

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty

area.

• Then dip a cloth int](/img/5/57363/w960_57363-1971.png)

HAC-4

< PRECAUTION >[MANUAL AIR CONDITIONING]

PRECAUTIONS

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty

area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Precautions For Refrigerant System ServiceINFOID:0000000012430712

GENERAL REFRIGERANT PRECAUTION

WARNING:

• Do not breathe A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant. Venti-

late work area before resuming service if accidental system discharge occurs. Additional health and

safety information may be obtained fr om refrigerant and oil manufacturers.

• Do not release refrigerant into the air. Use ap proved recovery/recycling recharging equipment to

capture the refrigerant each time an air conditioning system is discharged.

• Wear always eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

• Do not store or heat refrigerant containers above 52 °C (126° F).

• Do not heat a refrigerant container with an open fl ame. Place the bottom of the container in a pail of

warm water if container warming is required.

• Do not intentionally drop, puncture, or incinerate refrigerant containers.

• Keep refrigerant away from open flames. Pois onous gas is produced if refrigerant burns.

• Refrigerant displaces oxygen, therefore be certain to work in well ventilated areas to prevent suffo- cation.

• Do not pressure test or leakage test HFC-134a (R- 134a) service equipment and/or vehicle air condi-

tioning systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a)

have been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause

injury or property damage. Additional health and safety information may be obtained from refriger-

ant manufacturers.

WORKING WITH HFC-134a (R-134a)

CAUTION:

• CFC-12 (R-12) refrigerant and HFC-134a (R-134a) re frigerant are not compatible. These refrigerants

must never be mixed, even in the smallest amount s. Compressor malfunction is likely occur if the

refrigerants are mixed.

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components.

Compressor malfunction is likely to occur if oil other than that specified is used.

• The specified HFC-134a (R-134a) oi l rapidly absorbs moisture from the atmosphere. The following

handling precautions must be observed:

- Cap (seal) immediately the component to minimize the entry of mo isture from the atmosphere when

removing refrigerant components from a vehicle.

- Do not remove the caps (unseal) unti l just before connecting the components when installing refrig-

erant components to a vehicle. Connect all refr igerant loop components as quickly as possible to

minimize the entry of moisture into system.

- Use only the specified oil from a sealed container. Reseal immediately containers of oil. Oil becomes

moisture saturated and should no t be used without proper sealing.

- Do not allow oil (A/C System Oil Type: DH-PR) to come in contact with styrene foam parts. Damage

may result.

REFRIGERANT CONNECTION

A new type refrigerant connection has been introduced to al l refrigerant lines except the following location.

• Expansion valve to evaporator

• Refrigerant pressure sensor to liquid tank

WARNING:

Check that all refrigerant is disch arged into the recycling equipment and the pressure in the system is

less than atmospheric pressure. Then gradually loo sen the discharge side hose fitting and remove it.

CAUTION:

Observe the following when replacing or cleaning refrigerant cycle components.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1973 of 3641

![NISSAN NOTE 2016 Service Owners Manual PRECAUTIONSHAC-5

< PRECAUTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

• When the compressor is removed, store it in th e same way as it is when mounted on the vehicle.

Failure NISSAN NOTE 2016 Service Owners Manual PRECAUTIONSHAC-5

< PRECAUTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

• When the compressor is removed, store it in th e same way as it is when mounted on the vehicle.

Failure](/img/5/57363/w960_57363-1972.png)

PRECAUTIONSHAC-5

< PRECAUTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

• When the compressor is removed, store it in th e same way as it is when mounted on the vehicle.

Failure to do so will cause oil to enter the low-pressure chamber.

• Use always a torque wrench and a b ack-up wrench when connecting tubes.

• Plug immediately all openings to prevent entry of dust and mois ture after disconnecting tubes.

• Connect the pipes at the final stag e of the operation when installing an air conditioner in the vehicle.

Do not remove the seal caps of pipes and other comp onents until just before required for connec-

tion.

• Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

• Remove thoroughly moisture from the refriger ation system before charging the refrigerant.

• Replace always used O-rings.

• Apply oil to the O-rings shown in illustrations wh en connecting tubes. Be careful not to apply oil to

threaded portion.

• O-ring must be closely attached to the groove portion of tube.

• Be careful not to damage O-ring and tube when replacing the O-ring.

• Connect tube until a click can be heard. Then tighten the nut or bolt by hand. Check that the O-ring is

installed to tube correctly.

• Perform leak test and make sure there are no leaks from connections after connecting lines. Discon-

nect that line and replace the O-ring when the refrigerant leak point is found. Then tighten connec-

tions of seal seat to the specified torque.

COMPRESSOR

CAUTION:

• Plug all openings to prevent moisture and foreign matter from entering.

• When the compressor is removed, store it in the same way as it is when mounted on the vehicle.

• Follow “MAINTENANCE OF OIL LEVEL” exactly when replacing or repairing compressor. Refer to HA-22, "

Description".

• Keep friction surfaces between clutch and pulley clean . Wipe them off by using a clean waste cloth

moistened with solvent if the su rfaces are contaminated with oil.

• Turn the compressor shaft by hand more than fi ve turns in both directions after compressor service

operation. This equally distribut es oil inside the compressor. Let the engine idle and operate the

compressor for one hour after the compressor is installed.

• After replacing the compressor magnet clutch, appl y voltage to the new clutch to check for normal

operation.

LEAK DETECTION DYE

CAUTION:

• The A/C system contains a fluorescent leak detect ion dye used for locating refrigerant leaks. An

ultraviolet (UV) lamp is required to il luminate the dye when inspecting for leaks.

• Always wear fluorescence enhancing UV safety goggles to protect eyes and enhance the visibility of

the fluorescent dye. Name : A/C System Oil Type: DH-PR

RHA861F

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1974 of 3641

![NISSAN NOTE 2016 Service Owners Manual HAC-6

< PRECAUTION >[MANUAL AIR CONDITIONING]

PRECAUTIONS

• The fluorescent leak detection dye is not a replacem

ent for an electronic leak detector. The fluores-

cent leak detection dye should be u NISSAN NOTE 2016 Service Owners Manual HAC-6

< PRECAUTION >[MANUAL AIR CONDITIONING]

PRECAUTIONS

• The fluorescent leak detection dye is not a replacem

ent for an electronic leak detector. The fluores-

cent leak detection dye should be u](/img/5/57363/w960_57363-1973.png)

HAC-6

< PRECAUTION >[MANUAL AIR CONDITIONING]

PRECAUTIONS

• The fluorescent leak detection dye is not a replacem

ent for an electronic leak detector. The fluores-

cent leak detection dye should be u sed in conjunction with an electronic leak detector to pin-point

refrigerant leaks.

• Read and follow all manufacture’s operating inst ructions and precautions prior to performing the

work for the purpose of safet y and customer’s satisfaction.

• A compressor shaft seal should not necessarily be repaired becau se of dye seepage. The compres-

sor shaft seal should only be repaired after conf irming the leak with an electronic leak detector.

• Always remove any remaining dye from the leak area after repairs are completed to avoid a misdiag-

nosis during a future service.

• Do not allow dye to come into contact with painted body panels or interior components. Clean imme- diately with the approved dye cl eaner if dye is spilled. Fluorescent dye left on a surface for an

extended period of time cannot be removed.

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bottle [1/4 ounce (7.4 cc)] per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R-12) A/C systems are different. Do not use

HFC-134a (R-134a) leak detection dye in CFC-12 (R-12) A/C system, or CFC-12 (R-12) leak detection

dye in HFC-134a (R-134a) A/C system, or A/C system damage may result.

• The fluorescent properties of the dye remains fo r three or more years unless a compressor malfunc-

tion occurs.

NOTE: Identification

• Vehicles with factory installed fluorescent dye have a green label.

• Vehicles without factory installed fluorescent dye have a blue label.

Service EquipmentINFOID:0000000012430713

RECOVERY/RECYCLING RECHARGING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Do not

introduce any refrigerant other than that specified into the machine.

ELECTRICAL LEAK DETECTOR

Be certain to follow the manufacturer’s instruct ions for tester operation and tester maintenance.

VACUUM PUMP

The oil contained inside the vacuum pump is not compatible with the

specified oil for HFC-134a (R-134a) A/C systems. The vent side of

the vacuum pump is exposed to atmospheric pressure. Vacuum

pump oil may migrate out of the pump into the service hose. This is

possible when the pump is switc hed OFF after evacuation (vacuum-

ing) and hose is connected to it.

To prevent this migration, use a manual valve placed near the hose-

to-pump connection, as per the following.

• Vacuum pumps usually have a manual isolator valve as part of the pump. Close this valve to isolat e the service hose from the pump.

• Use a hose equipped with a manual shut-off valve near the pump

end for pumps without an isolator. Close the valve to isolate the

hose from the pump.

• Disconnect the hose from the pump if the hose has an automatic

shut-off valve. As long as the hose is connected, the valve is open

and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under no vacuum condition. Such valves may restrict the pump’s

ability to pull a deep vacuum and are not recommended.

MANIFOLD GAUGE SET

RHA270DA

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1975 of 3641

![NISSAN NOTE 2016 Service Owners Manual PRECAUTIONSHAC-7

< PRECAUTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threa NISSAN NOTE 2016 Service Owners Manual PRECAUTIONSHAC-7

< PRECAUTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threa](/img/5/57363/w960_57363-1974.png)

PRECAUTIONSHAC-7

< PRECAUTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified oils.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe) . All hoses must be equipped with

positive shut-off devices (either manual or automatic) near the end of

the hoses opposite to the manifold gauge.

SERVICE COUPLERS

Do not attempt to connect HFC-134a (R-134a) service couplers to

the CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers

do not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied oils have been used with the scale. The hose fitting must be 1/

2 ″-16 ACME if the scale controls refrigerant flow electronically.

CHARGING CYLINDER

Using a charging cylinder is not re commended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accura cy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

SHA533D

RHA272D

Shut-off valve rotati on A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2016 of 3641

![NISSAN NOTE 2016 Service Owners Manual HAC-48

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONING]

INSUFFICIENT COOLING

INSUFFICIENT COOLING

DescriptionINFOID:0000000012430750

Symptom

• Insufficient cooling

• No cool air comes out. (Air flow NISSAN NOTE 2016 Service Owners Manual HAC-48

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONING]

INSUFFICIENT COOLING

INSUFFICIENT COOLING

DescriptionINFOID:0000000012430750

Symptom

• Insufficient cooling

• No cool air comes out. (Air flow](/img/5/57363/w960_57363-2015.png)

HAC-48

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONING]

INSUFFICIENT COOLING

INSUFFICIENT COOLING

DescriptionINFOID:0000000012430750

Symptom

• Insufficient cooling

• No cool air comes out. (Air flow volume is normal.)

Diagnosis ProcedureINFOID:0000000012430751

NOTE:

Perform self-diagnosis with CONSULT before performing

symptom diagnosis. If any malfunction result or DTC

is detected, perform the corresponding diagnosis.

1.CHECK MAGNET CLUTCH OPERATION

1. Turn ignition switch ON.

2. Turn fan control dial ON.

3. Press A/C switch.

4. Check that A/C indicator turns ON. Check visually and by sound that compressor operates.

5. Press A/C switch again.

6. Check that A/C indicator turns OFF. Check that compressor stops.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check compressor operation. Refer to HAC-50, "

Diagnosis Procedure".

2.CHECK DRIVE BELT

Check tension of drive belt. Refer to EM-17, "

Inspection".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Adjust or replace drive belt depending on the inspection results.

3.CHECK REFRIGERANT CYCLE PRESSURE

Connect the recovery/recycling recharging equipment to the vehicle and perform the pressure inspection

using gauge. Refer to HA-15, "

Symptom Table".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace parts depending on the inspection results.

4.CHECK AIR LEAKAGE FROM EACH DUCT

Check duct and nozzle, etc. of t he air conditioner system for leakage.

Is the inspection result normal?

YES >> Check air mix door cable installation and air mix door operation.

NO >> Repair or replace parts depending on the inspection results.

Revision: August 2015 2016 Versa Note

cardiagn.com