charging NISSAN NOTE 2016 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2046 of 3641

REFRIGERANTHA-21

< PERIODIC MAINTENANCE >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

2. Operate recovery/recycling/recharging equipment, and evacuate air from A/C system for 25 minutes or more.

CAUTION:

Evacuate air for 15 minutes or more if parts are replaced.

3. Check the airtightness of A/C system for 25 minutes or more. If pressure raises more than the specified

level, charge A/C system with approximately 200g of refrigerant and check that there are no refrigerant

leaks. Refer to HA-18, "

Leak Test".

CAUTION:

Check the airtightness for 15 minutes or more if parts are replaced.

4. If parts other than the compressor are replaced, fill compressor oil according to parts that are replaced.

Refer to HA-22, "

Oil Adjusting Procedure for Components Replacement Except Compressor".

5. Charge the specified amount of refrigerant into A/C system.

6. Check that the A/C system operates normally.

7. Collect the refrigerant from the high-pressure hos e and low-pressure hose of recovery/recycling/recharg-

ing equipment. Disconnect recovery/recycling/recharging equipment.

8. Install A/C service valve caps.

9. Refrigerant charge is complete.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2049 of 3641

HA-24

< PERIODIC MAINTENANCE >

PERFORMANCE TEST

PERFORMANCE TEST

InspectionINFOID:0000000012432006

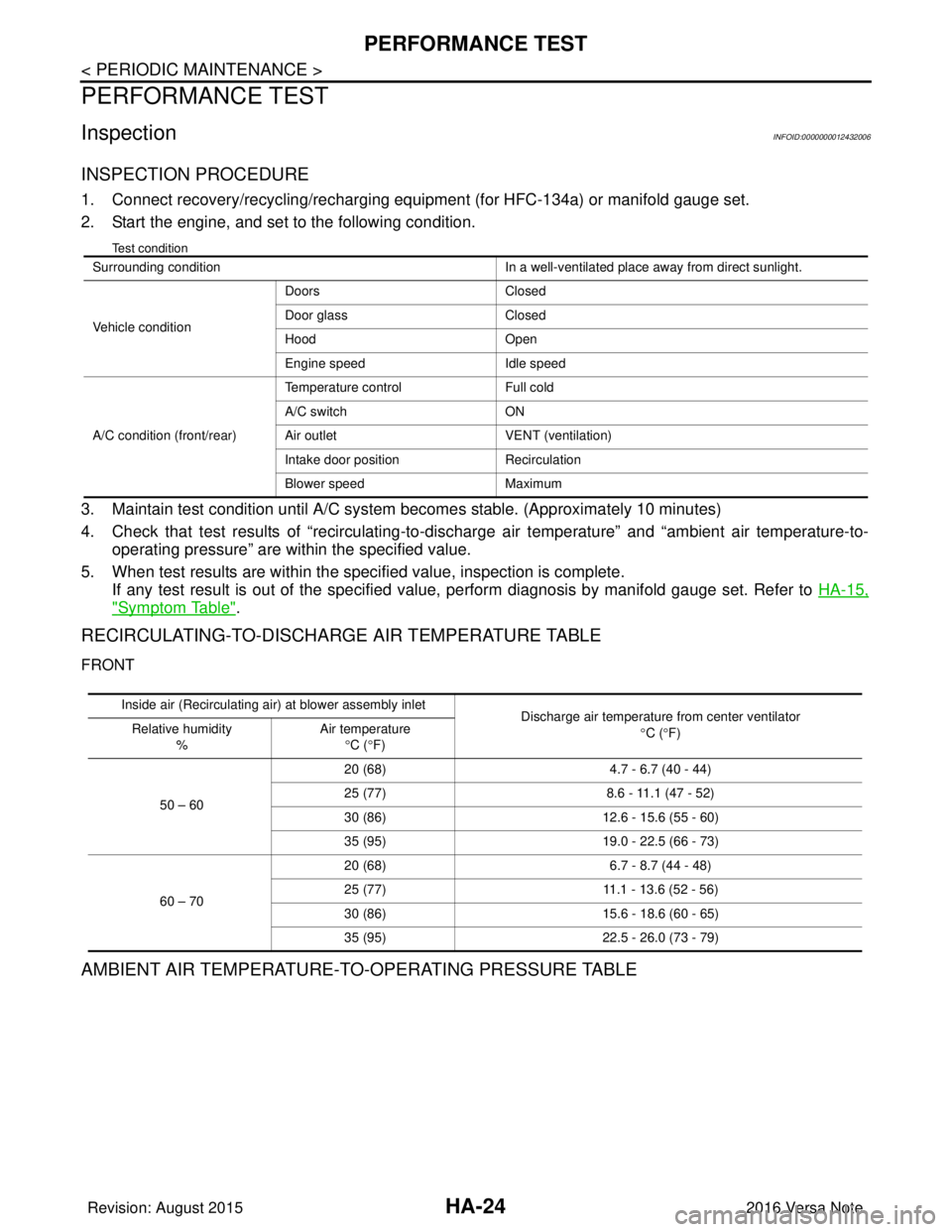

INSPECTION PROCEDURE

1. Connect recovery/recycling/recharging equipment (for HFC-134a) or manifold gauge set.

2. Start the engine, and set to the following condition.

Test condition

3. Maintain test condition until A/C system becomes stable. (Approximately 10 minutes)

4. Check that test results of “recirculating-to-disc harge air temperature” and “ambient air temperature-to-

operating pressure” are within the specified value.

5. When test results are within the spec ified value, inspection is complete.

If any test result is out of the specified val ue, perform diagnosis by manifold gauge set. Refer to HA-15,

"Symptom Table".

RECIRCULATING-TO-DISCHARGE AIR TEMPERATURE TABLE

FRONT

AMBIENT AIR TEMPERATURE-TO-OPERATING PRESSURE TABLE

Surrounding condition In a well-ventilated place away from direct sunlight.

Vehicle condition Doors

Closed

Door glass Closed

Hood Open

Engine speed Idle speed

A/C condition (front/rear) Temperature control

Full cold

A/C switch ON

Air outlet VENT (ventilation)

Intake door position Recirculation

Blower speed Maximum

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature from center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 – 60 20 (68)

4.7 - 6.7 (40 - 44)

25 (77) 8.6 - 11.1 (47 - 52)

30 (86) 12.6 - 15.6 (55 - 60)

35 (95) 19.0 - 22.5 (66 - 73)

60 – 70 20 (68)

6.7 - 8.7 (44 - 48)

25 (77) 11.1 - 13.6 (52 - 56)

30 (86) 15.6 - 18.6 (60 - 65)

35 (95) 22.5 - 26.0 (73 - 79)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2051 of 3641

HA-26

< REMOVAL AND INSTALLATION >

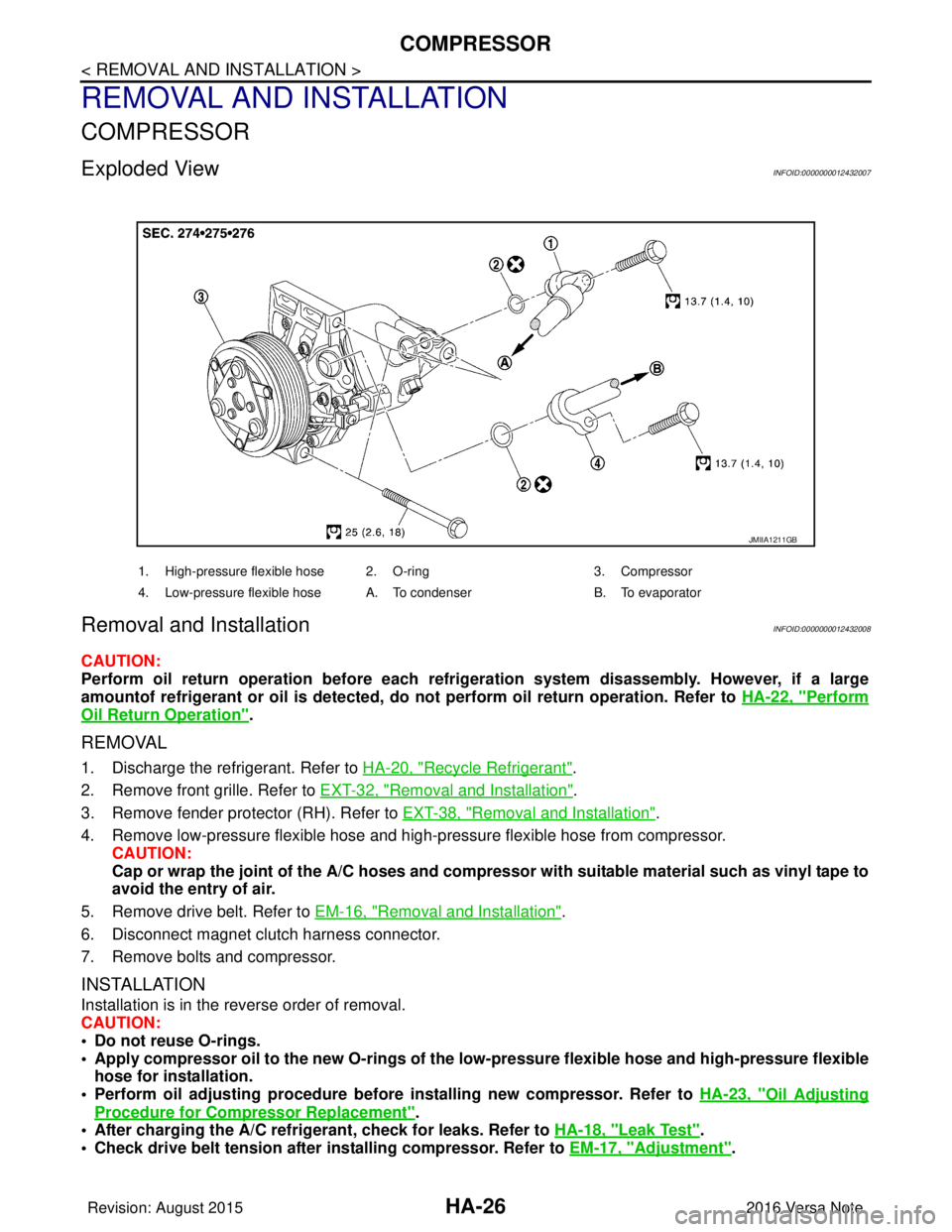

COMPRESSOR

REMOVAL AND INSTALLATION

COMPRESSOR

Exploded ViewINFOID:0000000012432007

Removal and InstallationINFOID:0000000012432008

CAUTION:

Perform oil return operation before each refrigeration system disassembly. However, if a large

amountof refrigerant or oil is detected, do not perform oil return operation. Refer to HA-22, "

Perform

Oil Return Operation".

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "Recycle Refrigerant".

2. Remove front grille. Refer to EXT-32, "

Removal and Installation".

3. Remove fender protector (RH). Refer to EXT-38, "

Removal and Installation".

4. Remove low-pressure flexible hose and high-pressure flexible hose from compressor. CAUTION:

Cap or wrap the joint of the A/C hoses and compr essor with suitable material such as vinyl tape to

avoid the entry of air.

5. Remove drive belt. Refer to EM-16, "

Removal and Installation".

6. Disconnect magnet clutch harness connector.

7. Remove bolts and compressor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply compressor oil to the new O-rings of the low-pressure flexible hose an d high-pressure flexible

hose for installation.

• Perform oil adjusting procedure before installing new compressor. Refer to HA-23, "

Oil Adjusting

Procedure for Compressor Replacement".

• After charging the A/C refrig erant, check for leaks. Refer to HA-18, "

Leak Test".

• Check drive belt tension after installing compressor. Refer to EM-17, "

Adjustment".

JMIIA1211GB

1. High-pressure flexible hose 2. O-ring 3. Compressor

4. Low-pressure flexible hose A. To condenser B. To evaporator

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2054 of 3641

COOLER PIPE AND HOSEHA-29

< REMOVAL AND INSTALLATION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

CAUTION:

Cap or wrap the joint of the A/ C hose and compressor with suitable material such as vinyl tape to

avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply compressor oil to new O-rings of low-pressure flexible hose for installation.

• After charging refrigerant, check for leaks. Refer to HA-18, "

Leak Test".

HIGH-PRESSURE FLEXIBLE HOSE

HIGH-PRESSURE FLEXIBLE HOSE : Removal and InstallationINFOID:0000000012432012

CAUTION:

Perform oil return operation before each refrigeration system disassembly. However, if a large

amountof refrigerant or oil is detected, do not perform oil return operation. Refer to HA-22, "

Perform

Oil Return Operation".

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "Recycle Refrigerant".

2. Remove front grille. Refer to EXT-32, "

Removal and Installation".

3. Remove bolt and high-pressure flexible hose from condenser. CAUTION:

Cap or wrap the joint of the A/C hose and condenser with suitable material such as vinyl tape to

avoid the entry of air.

4. Remove bolt and high-pressure flexible hose from compressor. CAUTION:

Cap or wrap the joint of the A/ C hose and compressor with suitable material such as vinyl tape to

avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply compressor oil to new O-rings of the high-pressure flexible hose for installation.

• After charging refrigerant, check for leaks. Refer to HA-18, "

Leak Test".

HIGH-PRESSURE PIPE

HIGH-PRESSURE PIPE : Removal and InstallationINFOID:0000000012432013

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "Recycle Refrigerant".

2. Remove radiator core support upper. Refer to DLK-144, "

RADIATOR CORE SUPPORT UPPER :

Removal and Installation".

3. Remove low-pressure flexible hose. Refer to HA-28, "

LOW-PRESSURE FLEXIBLE HOSE : Removal and

Installation".

4. Remove high-pressure flexible hose. Refer to HA-29, "

HIGH-PRESSURE FLEXIBLE HOSE : Removal

and Installation".

5. Disconnect high-pressure pipe from expansion valve. CAUTION:

Cap or wrap the joint of the A/C piping and expan sion valve with suitable material such as vinyl

tape to avoid the entry of air.

6. Remove bolt and high-pressure pipe from condenser. CAUTION:

Cap or wrap the joint of the A/C piping and conden ser with suitable material such as vinyl tape to

avoid the entry of air.

7. Release clips and remove high-pressure pipe from vehicle.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2055 of 3641

HA-30

< REMOVAL AND INSTALLATION >

COOLER PIPE AND HOSE

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply compressor oil to new O-rings of the high-pressure pipe for installation.

• After charging refrigerant, check for leaks. Refer to HA-18, "

Leak Test".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2057 of 3641

HA-32

< REMOVAL AND INSTALLATION >

CONDENSER

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply compressor oil to new O-rings of the high-pressure flexible hose and high-pressure pipe forinstallation.

• Perform oil adjusting procedure before installing new condenser. Refer to HA-22, "

Oil Adjusting Pro-

cedure for Components Replacement Except Compressor".

• After charging refrigerant, check for leaks. Refer to HA-18, "

Leak Test".

LIQUID TANK

LIQUID TANK : Removal and Installation of Liquid TankINFOID:0000000012432016

The liquid tank is only serviced as part of the condenser. Refer to HA-31, "CONDENSER : Removal and Instal-

lation".

REFRIGERANT PRESSURE SENSOR

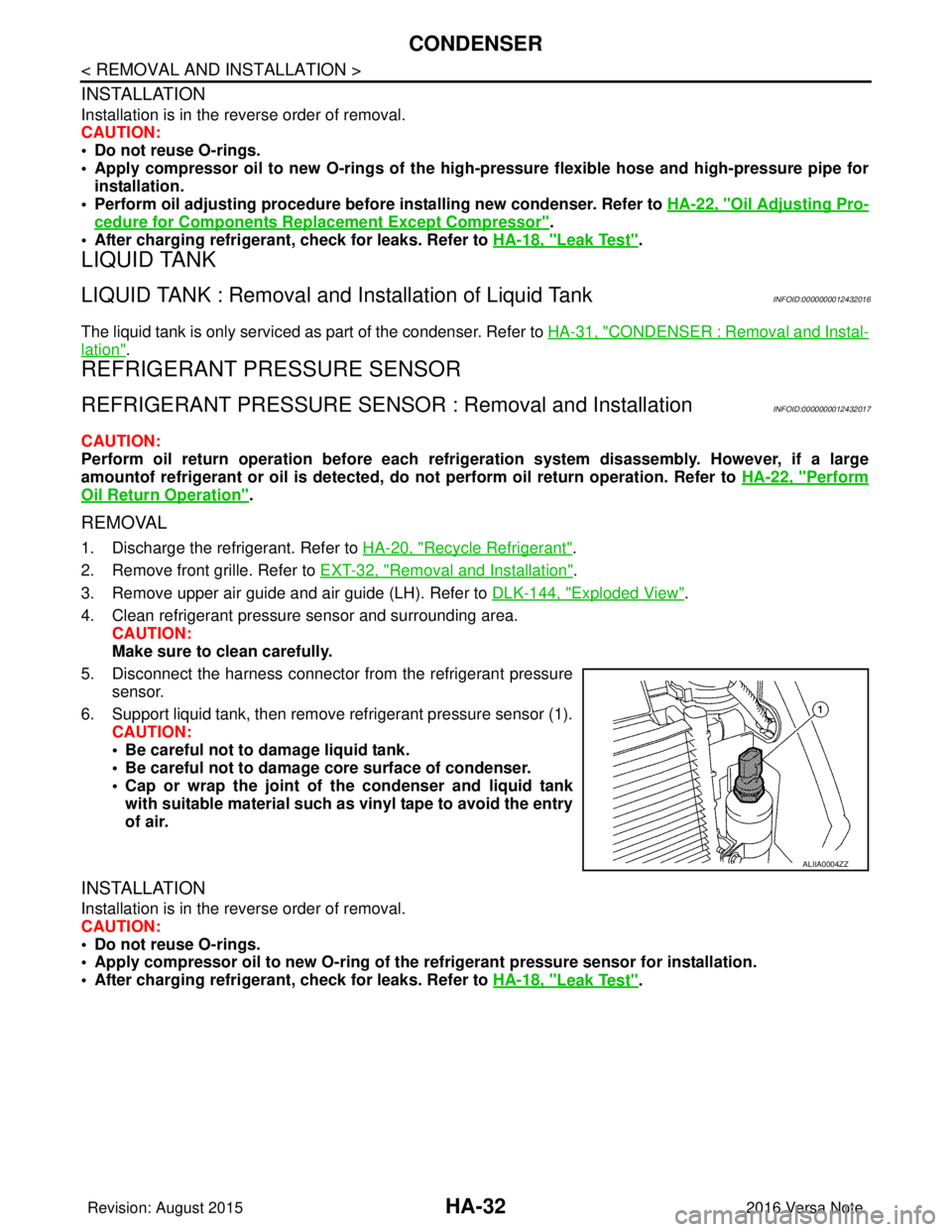

REFRIGERANT PRESSURE SENSOR : Removal and InstallationINFOID:0000000012432017

CAUTION:

Perform oil return operation before each refrigeration system disassembly. However, if a large

amountof refrigerant or oil is detected, do not perform oil return operation. Refer to HA-22, "

Perform

Oil Return Operation".

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "Recycle Refrigerant".

2. Remove front grille. Refer to EXT-32, "

Removal and Installation".

3. Remove upper air guide and air guide (LH). Refer to DLK-144, "

Exploded View".

4. Clean refrigerant pressure sensor and surrounding area. CAUTION:

Make sure to clean carefully.

5. Disconnect the harness connector from the refrigerant pressure sensor.

6. Support liquid tank, then remove refrigerant pressure sensor (1). CAUTION:

• Be careful not to damage liquid tank.

• Be careful not to damage core surface of condenser.

• Cap or wrap the joint of the condenser and liquid tank

with suitable material such as vinyl tape to avoid the entry

of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply compressor oil to new O-ring of the refrigerant pressure sensor for installation.

• After charging refrigerant, check for leaks. Refer to HA-18, "

Leak Test".

ALIIA0004ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2060 of 3641

HEATING AND COOLING UNIT ASSEMBLYHA-35

< REMOVAL AND INSTALLATION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

5. Disconnect heater hoses from heater core.

6. Remove instrument panel assembly. Refer to IP-15, "

Removal and Installation".

7. Disconnect evaporator drain hose from heating and cooling unit assembly.

8. Disconnect harness connectors, grounds, retainers, etc. , and remove bolts required to remove steering

member.

9. Remove steering member and heating and cooling unit assembly.

10. Remove heating and cooling unit assembly from steering member. Refer to HA-33, "

Exploded View".

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply compressor oil to new O-rings of the low-pressure flexible hose and high-pressure pipe for

installation.

• After charging refrigerant, check for leaks. Refer to HA-18, "

Leak Test".

NOTE:

When refilling engine coolant, refer to CO-9, "

Refilling".

HEATER CORE

HEATER CORE : Removal and InstallationINFOID:0000000012432020

REMOVAL

1. Remove the heating and cooling unit assembly. Refer to HA-34, "HEATING AND COOLING UNIT

ASSEMBLY : Removal and Installation".

2. Remove foot duct (LH). Refer to VTL-7, "

FOOT DUCT : Removal and Installation".

3. Remove heater packing.

4. Remove heater pipe flange.

5. Remove heater core.

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

When refilling engine coolant, refer to CO-9, "

Refilling".

EVAPORATOR

EVAPORATOR : Removal and InstallationINFOID:0000000012432021

REMOVAL

1. Remove heating and cooling unit assembly. Refer to HA-34, "HEATING AND COOLING UNIT ASSEM-

BLY : Removal and Installation".

2. Remove foot duct (RH). Refer to VTL-7, "

FOOT DUCT : Removal and Installation".

3. Remove intake case. Refer to HA-33, "

Exploded View".

4. Remove expansion valve. Refer to HA-36, "

EXPANSION VALVE : Removal and Installation".

5. Remove evaporator cover and evaporator assembly.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply compressor oil to ne w O-rings for installation.

• Perform oil adjusting procedure afte r installing new evaporator. Refer to HA-22, "

Oil Adjusting Pro-

cedure for Components Replacement Except Compressor".

• After charging refrigerant, check for leaks. Refer to HA-18, "

Leak Test".

EXPANSION VALVE

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2061 of 3641

HA-36

< REMOVAL AND INSTALLATION >

HEATING AND COOLING UNIT ASSEMBLY

EXPANSION VALVE : Removal and Installation

INFOID:0000000012432022

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "Recycle Refrigerant".

2. Disconnect low-pressure flexible hose from expansion valve. Refer to HA-28, "

LOW-PRESSURE FLEXI-

BLE HOSE : Removal and Installation".

3. Disconnect high-pressure pipe from expansion valve. Refer to HA-29, "

HIGH-PRESSURE PIPE :

Removal and Installation".

4. Remove bolts and expansion valve. CAUTION:

Cap or wrap the joint of the eva porator and expansion valve with su itable material such as vinyl

tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply compressor oil to new O-rings of the low- pressure flexible hose and high-pressure pipe for

installation.

• After charging refrigerant, check for leaks. Refer to HA-18, "

Leak Test".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2062 of 3641

SERVICE DATA AND SPECIFICATIONS (SDS)HA-37

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

F

G H

J

K L

M A

B

HA

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

CompressorINFOID:0000000012432023

OilINFOID:0000000012432024

RefrigerantINFOID:0000000012432025

Model CALSONIC KANSEI CR08b

Ty p e Vane rotary

Displacement Maximum 83 cm

3 (5.1cu in)/rev

Direction of rotation Clockwise (viewed from clutch)

Drive belt Poly V

Disc to pulley clearance Standard0.25 – 0.55 mm (0.010 – 0.022 in)

Name A/C System Oil Type DH-PR

Capacity Total in system

110 - 130 m (3.7 - 4.4 US fl oz, 3.9 - 4.6 Imp fl

oz)

Replacement compressor charging

amount Refer to

HA-23, "

Oil Adjusting Procedure for

Compressor Replacement".

Ty p e HFC-134a (R-134a)

Capacity 0.4 kg (0.9 lb)

Revision: August 20152016 Versa Note

cardiagn.com

Page 2342 of 3641

CHASSIS AND BODY MAINTENANCEMA-27

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

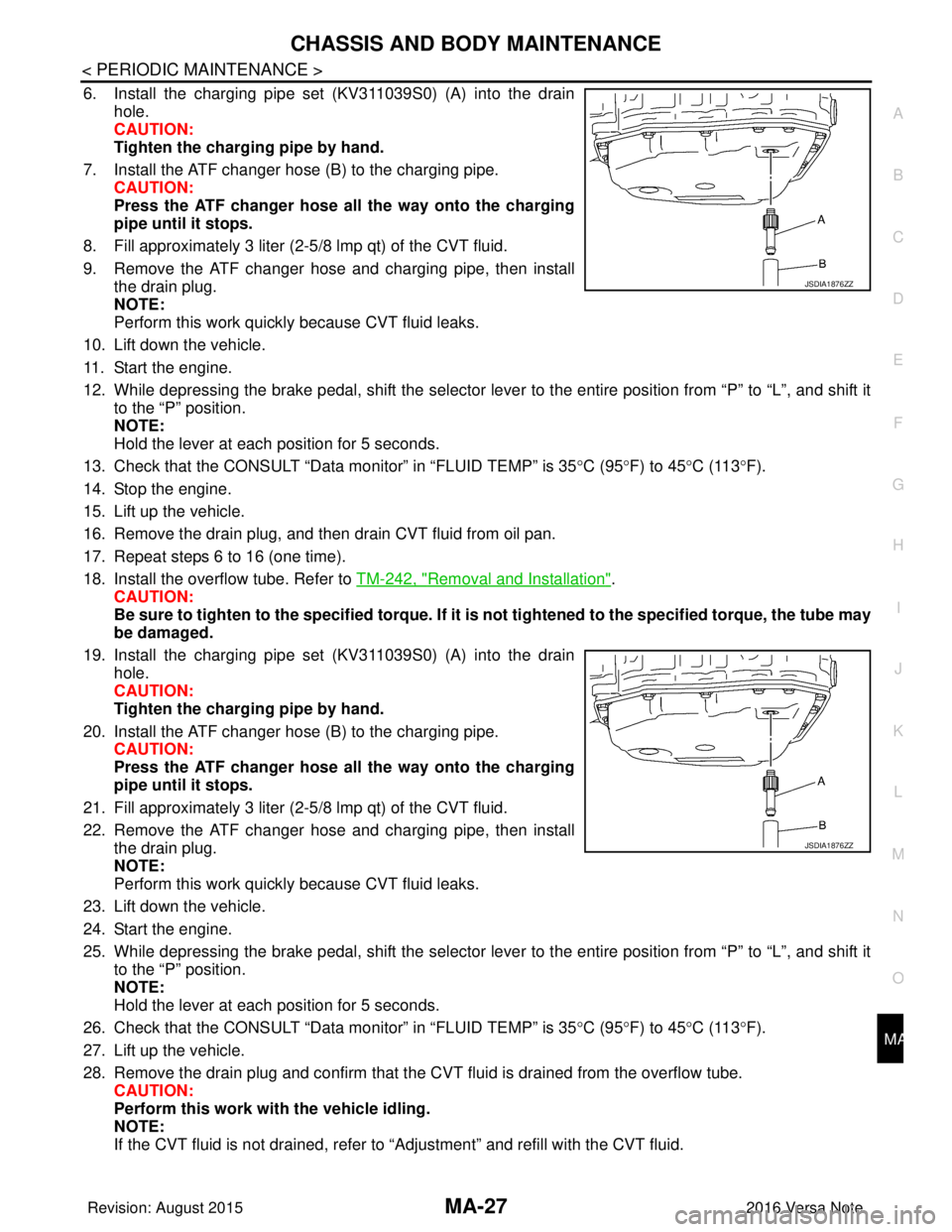

6. Install the charging pipe set (KV311039S0) (A) into the drain

hole.

CAUTION:

Tighten the charging pipe by hand.

7. Install the ATF changer hose (B) to the charging pipe. CAUTION:

Press the ATF changer hose all the way onto the charging

pipe until it stops.

8. Fill approximately 3 liter (2-5 /8 lmp qt) of the CVT fluid.

9. Remove the ATF changer hose and charging pipe, then install the drain plug.

NOTE:

Perform this work quickly because CVT fluid leaks.

10. Lift down the vehicle.

11. Start the engine.

12. While depressing the brake pedal, shift the selector leve r to the entire position from “P” to “L”, and shift it

to the “P” position.

NOTE:

Hold the lever at each position for 5 seconds.

13. Check that the CONSULT “Data monitor” in “FLUID TEMP” is 35°C (95°F) to 45 °C (113 °F).

14. Stop the engine.

15. Lift up the vehicle.

16. Remove the drain plug, and then drain CVT fluid from oil pan.

17. Repeat steps 6 to 16 (one time).

18. Install the overflow tube. Refer to TM-242, "

Removal and Installation".

CAUTION:

Be sure to tighten to the specified torque. If it is not tightened to the specified torque, the tube may

be damaged.

19. Install the charging pipe set (KV311039S0) (A) into the drain hole.

CAUTION:

Tighten the charging pipe by hand.

20. Install the ATF changer hose (B) to the charging pipe. CAUTION:

Press the ATF changer hose all the way onto the charging

pipe until it stops.

21. Fill approximately 3 liter (2-5 /8 lmp qt) of the CVT fluid.

22. Remove the ATF changer hose and charging pipe, then install the drain plug.

NOTE:

Perform this work quickly because CVT fluid leaks.

23. Lift down the vehicle.

24. Start the engine.

25. While depressing the brake pedal, shift the selector leve r to the entire position from “P” to “L”, and shift it

to the “P” position.

NOTE:

Hold the lever at each position for 5 seconds.

26. Check that the CONSULT “Data monitor” in “FLUID TEMP” is 35°C (95°F) to 45 °C (113 °F).

27. Lift up the vehicle.

28. Remove the drain plug and confirm that the CV T fluid is drained from the overflow tube.

CAUTION:

Perform this work with the vehicle idling.

NOTE:

If the CVT fluid is not drained, refer to “Adjustment” and refill with the CVT fluid.

JSDIA1876ZZ

JSDIA1876ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com