low beam NISSAN NOTE 2016 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1731 of 3641

HEADLAMP (LO) CIRCUITEXL-79

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

HEADLAMP (LO) CIRCUIT

DescriptionINFOID:0000000012432807

The IPDM E/R (intelligent power distribution modul e engine room) controls the headlamp low relay based on

inputs from the BCM via the CAN communication li nes. When the headlamp low relay is energized, power

flows through fuses 40 and 41, located in the IPDM E/R.

(Without daytime running light system) power then flow s to the front combination lamp LH and RH low beams.

(With daytime running light system) power then flows to the front combination lamp LH low beam and the day-

time running light relay 2 which becomes energized and t hen power is sent to the front combination lamp RH

low beam.

Component Function CheckINFOID:0000000012432808

1.CHECK HEADLAMP (LO) OPERATION

WITHOUT CONSULT

1. Start IPDM E/R auto active test. Refer to PCS-9, "

Diagnosis Description".

2. Check that the headlamp is turned ON.

CONSULT

1. Select EXTERNAL LAMPS of IP DM E/R active test item.

2. While operating the test items, check that the headlamp is turned ON.

Is the headlamp turned ON?

YES >> Headlamp (LO) is normal.

NO >> Refer to EXL-79, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012432809

Regarding Wiring Diagram information, refer to EXL-25, "Wiring Diagram - For USA" or EXL-31, "Wiring Dia-

gram - For Canada".

1.CHECK HEADLAMP (LO) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not blown:

Is the fuse blown?

YES >> Replace the blown fuse after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK LOW BEAM BULB

Check the applicable low beam bulb to be sure the proper bulb standard is in use and the bulb is not open.

Is the bulb OK?

YES >> GO TO 3.

NO >> Replace the bulb.

3.CHECK HEADLAMP (LO) OUTPUT VOLTAGE

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp connector E25 or E26.

3. Turn the ignition switch ON. LO : Headlamp ON

OFF : Headlamp OFF

Unit

LocationFuse No.Capacity

Headlamp LO (L H) IPDM E/R 4115A

Headlamp LO (RH) IPDM E/R4015A

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1732 of 3641

EXL-80

< DTC/CIRCUIT DIAGNOSIS >

HEADLAMP (LO) CIRCUIT

4. Turn the low beam headlamps ON.

5. With the low beam headlamps ON, check the voltage between the combination lamp connector andground.

Is the inspection result normal?

YES >> GO TO 9.

NO >> GO TO 4 (without daytime running light system). >> GO TO 5 (with daytime running light system).

4.CHECK HEADLAMP (LO) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector E44.

3. Check continuity between the IPDM E/R harness connector E44 and the front combination lamp harness connectors E25 and E26.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-30, "Removal and Installation".

NO >> Repair or replace the harness or connector.

5.CHECK DAYTIME RUNNING LIGHT RELAY 2 TO FR ONT COMBINATION LAMP LH CIRCUIT FOR OPEN

1. Disconnect daytime running light relay 2 connector E38.

2. Check continuity between the daytime running light relay 2 harness connector E38 and the front combina- tion lamp LH harness connector E25.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair or replace the harness or connector.

6.CHECK DAYTIME RUNNING LIGHT RELAY 2 VOLTAGE CIRCUIT

With the low beam headlamps ON, check the voltage bet ween the daytime running light relay 2 connector E38

and ground.

Is the inspection result normal?

YES >> GO TO 7.

NO >> GO TO 8.

7.CHECK DAYTIME RUNNING LIGHT RELAY 2 GROUND CIRCUIT

Check continuity between the daytime running light relay 2 harness connector E38 and ground.

(+) (−)Voltage

Connector Terminal

LH E25 3 Ground Battery voltage

RH E26

Connector TerminalConnector Terminal Continuity

LH E44 14

E25

3Y es

RH 16E26

Connector TerminalConnector Terminal Continuity

E38 3E25 3Yes

(+)

(−)Voltage

Connector Terminal

E38 2

Ground Battery voltage

5

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1743 of 3641

EXTERIOR LIGHTING SYSTEM SYMPTOMSEXL-91

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

SYMPTOM DIAGNOSIS

EXTERIOR LIGHTING SYSTEM SYMPTOMS

Symptom TableINFOID:0000000012432819

CAUTION:

Perform the self-diagnosis with CONSULT before th e symptom diagnosis. Perform the trouble diagno-

sis if any DTC is detected.

Symptom Possible causeInspection item

Headlamp does not

switch to the high beam. One side

•Fuse

• Harness between IPDM E/R

and the front combination lamp

• Front combination lamp

(High beam relay)

• IPDM E/R Headlamp (HI) circuit

Refer to EXL-77

.

Both sides — Symptom diagnosis

"BOTH SIDE HEADLAMPS DO

NOT SWITCH TO HIGH BEAM"

Refer to EXL-93

.

High beam indicator lamp is not turned ON.

(Headlamp switches to the high beam.) • Combination meter

•BCM• Combination meter.

Data monitor "HI-BEAM IND"

• BCM (HEAD LAMP)

Active test "HEADLAMP"

Headlamp does not

switch to the low beam. One side

Front combination lamp (low

beam relay) —

Both sides • Combination switch (lighting

and turn signal switch)

• Harness between the combina- tion switch (lighting and turn sig-

nal switch) and BCM

•BCM Combination switch (lighting and

turn signal switch)

Refer to BCS-72

(with Intelligent

Key system) or BCS-134

(without

Intelligent Key system).

High beam request signal

•BCM

• IPDM E/R IPDM E/R

Data monitor "HL HI REQ"

IPDM E/R —

Headlamp does not turn

ON. One side

•Bulb

• Harness between IPDM E/R

and the front combination lamp

• Front combination lamp

• IPDM E/R Headlamp (LO) circuit

Refer to EXL-79

.

Both sides — Symptom diagnosis

"BOTH SIDE HEADLAMPS (LO)

ARE NOT TURNED ON"

Refer to EXL-94

.

Headlamp does not turn

OFF. When the ignition

switch is turned ON•BCM

• Combination switch (lighting

and turn signal switch) Combination switch (lighting and

turn signal switch)

Refer to BCS-72

(with Intelligent

Key system) or BCS-134

(without

Intelligent Key system).

Daytime light system does not activate. • Either high beam bulb

• Parking brake switch

• Combination switch (lighting

and turn signal switch)

•BCM

• IPDM E/R

• Daytime light relays

• Harness between IPDM E/R

and daytime light relays. Daytime light system description.

Refer to EXL-9

.

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1749 of 3641

HEADLAMP AIMING ADJUSTMENTEXL-97

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

PERIODIC MAINTENANCE

HEADLAMP AIMING ADJUSTMENT

InspectionINFOID:0000000012432828

PREPARATION BEFORE ADJUSTING

Before performing aiming adjustment, check the following:

• Ensure all tires are inflated to correct pressure.

• Place vehicle and screen on level surface.

• Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position).

• Coolant and engine oil filled to correct level, and fuel tank full.

• Remove cargo and/or luggage to maintain an unloaded vehicle condition.

• Confirm spare tire, jack and tools are properly stowed.

• Carefully wipe off any dirt from headlamp lens. CAUTION:

Do not use organic solvent (thinner, gasoline etc.)

• Place a driver or equivalent weight of 68.5 kg (150 lb) on the driver seat.

• By hand, bounce the front and rear of the vehicle to settle the suspension and eliminate any static load.

• Place the front tires in the straight ahead position.

• Confirm headlamp aiming switch is set to "0" (zero) position.

• Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

NOTE:

• For headlamp aiming details, refer to regulations in your area.

• By regulation, no means for horizontal aim adjustment is provided from the factory; only vertical aim is

adjustable.

• Use adjusting screw to perform aiming adjustment.

• Perform headlamp aiming if:

- The vehicle front body has been repaired.

- The front combination lamp has been removed or replaced.

- Any outfitting has been installed.

- The vehicle’s standard load condition has been substantially increased.

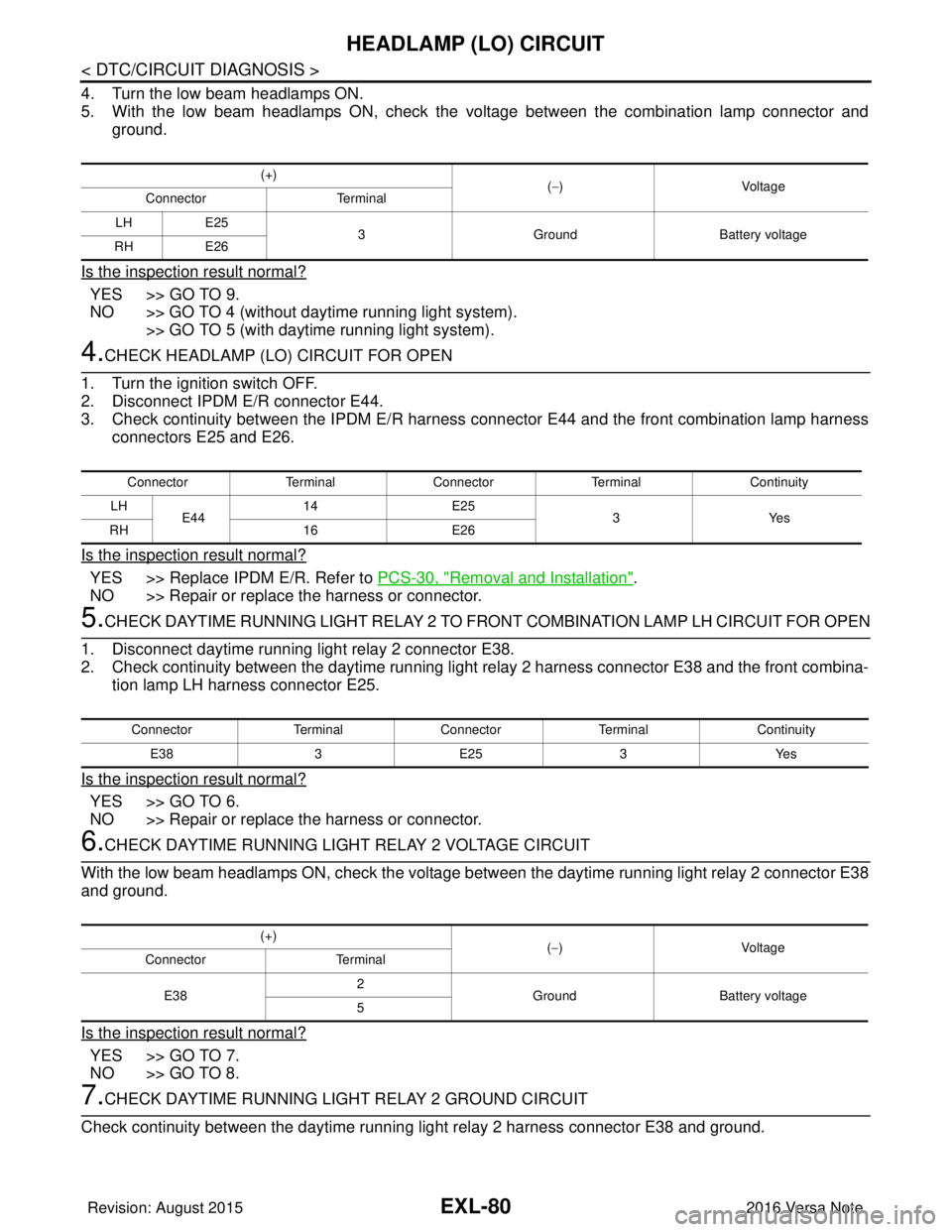

AIMING ADJUSTMENT SCREW

AWLIA2171ZZ

A. Adjusting screw (LH) B. Adjusting screw (RH)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1750 of 3641

EXL-98

< PERIODIC MAINTENANCE >

HEADLAMP AIMING ADJUSTMENT

Aiming Adjustment Procedure

INFOID:0000000012432829

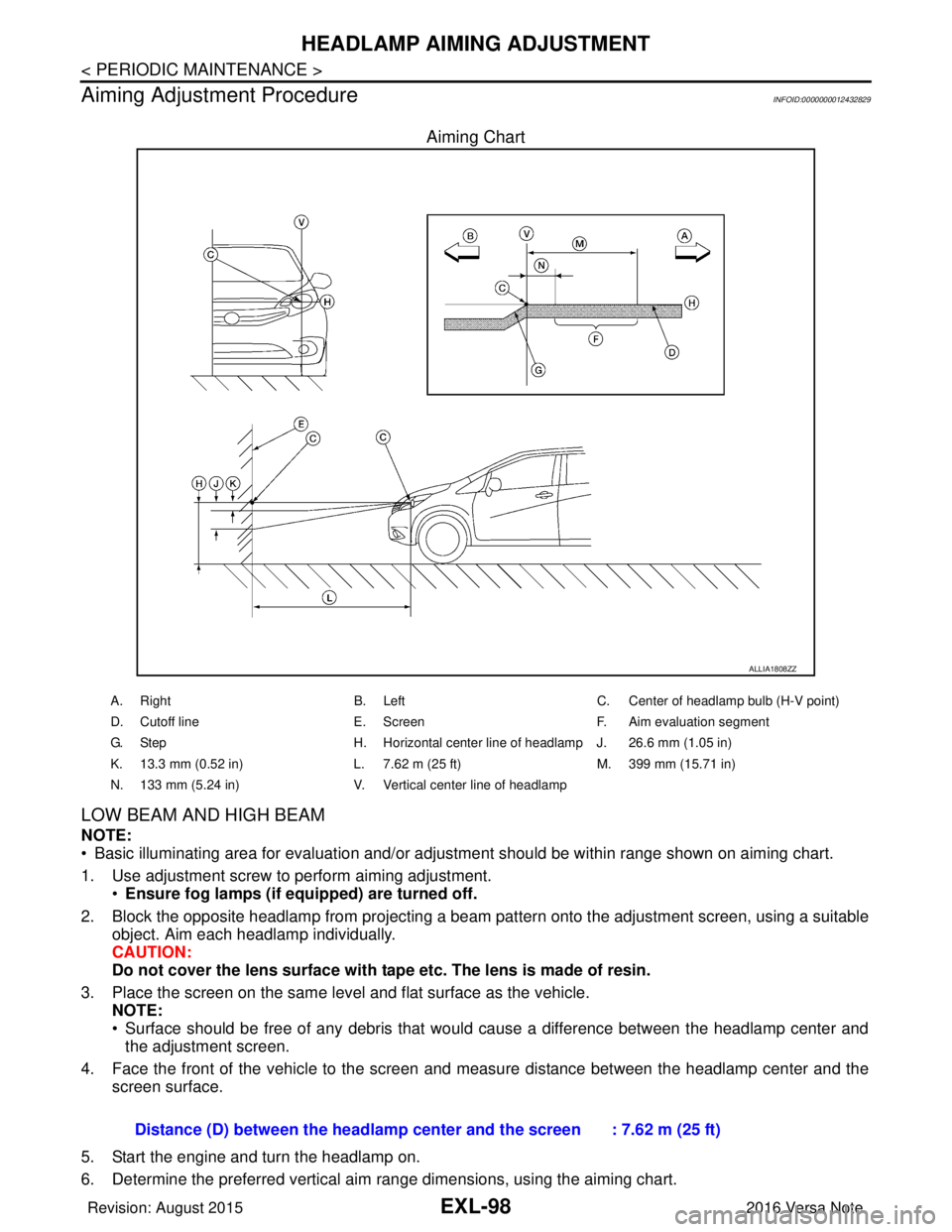

Aiming Chart

LOW BEAM AND HIGH BEAM

NOTE:

• Basic illuminating area for evaluation and/or adjus tment should be within range shown on aiming chart.

1. Use adjustment screw to perform aiming adjustment. •Ensure fog lamps (if eq uipped) are turned off.

2. Block the opposite headlamp from projecting a beam pa ttern onto the adjustment screen, using a suitable

object. Aim each headlamp individually.

CAUTION:

Do not cover the lens surface with tape etc. The lens is made of resin.

3. Place the screen on the same level and flat surface as the vehicle. NOTE:

• Surface should be free of any debris that would cause a difference between the headlamp center and

the adjustment screen.

4. Face the front of the vehicle to the screen and measure distance between the headlamp center and the screen surface.

5. Start the engine and turn the headlamp on.

6. Determine the preferred vertical aim range dimensions, using the aiming chart.

ALLIA1808ZZ

A. Right B. LeftC. Center of headlamp bulb (H-V point)

D. Cutoff line E. ScreenF. Aim evaluation segment

G. Step H. Horizontal center line of headlamp J. 26.6 mm (1.05 in)

K. 13.3 mm (0.52 in) L. 7.62 m (25 ft)M. 399 mm (15.71 in)

N. 133 mm (5.24 in) V. Vertical center line of headlamp

Distance (D) between the headlamp center and the screen : 7.62 m (25 ft)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1751 of 3641

HEADLAMP AIMING ADJUSTMENTEXL-99

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

7. Measure the projected beam within t he aim evaluation segment on the screen.

8. Adjust the beam pattern of each headlamp until the ai m evaluation segment (the area relative to both the

highest and lowest cutoff line height) is positioned within the vertical aim range dimensions shown on the

aiming chart.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1752 of 3641

EXL-100

< PERIODIC MAINTENANCE >

FRONT FOG LAMP AIMING ADJUSTMENT

FRONT FOG LAMP AIMING ADJUSTMENT

InspectionINFOID:0000000012432830

PREPARATION BEFORE ADJUSTING

Before performing aiming adjustment procedure, check the following:

• Ensure all tires are inflated to correct pressure.

• Place vehicle and screen on level surface.

• Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position).

• Coolant and engine oil filled to correct level, and fuel tank full.

• Remove cargo and/or luggage to maintain an unloaded vehicle condition.

• Confirm spare tire, jack and tools are properly stowed.

• Carefully wipe off any dirt from fog lamp lens. CAUTION:

Do not use organic solvent (thinner, gasoline etc.)

• Place a driver or equivalent weight of 68.5 kg (150 lb) on the driver seat.

• By hand, bounce the front and rear of the vehicle to settle the suspension and eliminate any static load.

• Place the front tires in the straight ahead position.

• Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

NOTE:

• For headlamp aiming details, refer to regulations in your area.

• By regulation, no means for horizontal aim adjustment is provided from the factory; only vertical aim is

adjustable.

• Use adjusting screw to perform aiming adjustment.

• Perform headlamp aiming if:

- The vehicle front body has been repaired.

- The front combination lamp has been removed or replaced.

- Any outfitting has been installed.

- The vehicle’s standard load condition has been substantially increased.

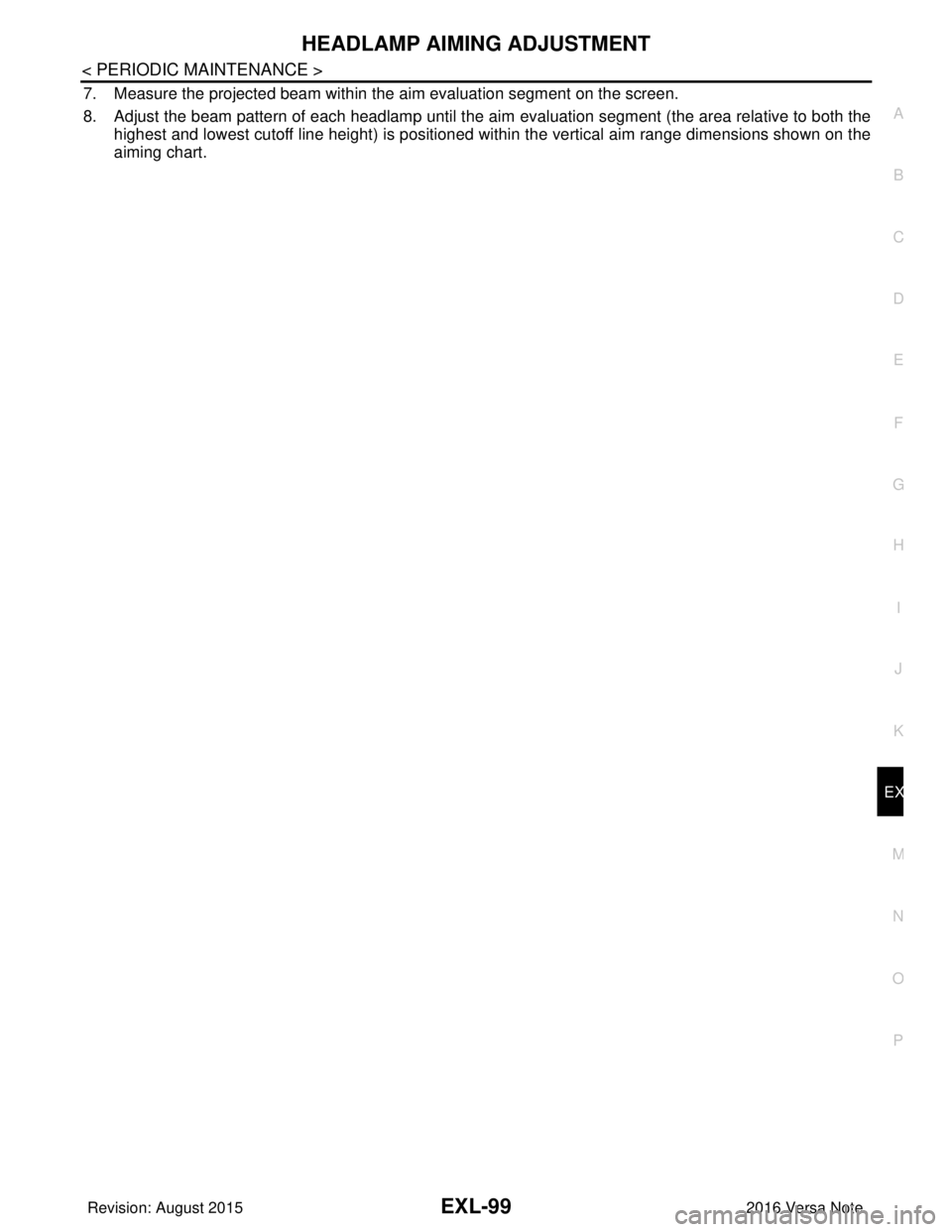

AIMING ADJUSTMENT SCREW

• Turn the aiming adjusting screw using a suitable tool to aim the fog

lamp.

A: UP

B: DOWN

Aiming Adjustment ProcedureINFOID:0000000012432831

1. Screen placement. NOTE:

• Place the screen perpendicular to the level road.

• Position the vehicle facing the screen with 10 m (33 ft) between the front fog lamp center and thescreen.

2. Start the engine. Illuminate the front fog lamp. CAUTION:

Do not cover the lens surface with a tape etc. The lens are made of resin.

JMLIA2040ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2219 of 3641

![NISSAN NOTE 2016 Service Owners Manual LAN

SYSTEMLAN-31

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

Vehicle speed signal (ABS)

TR R R R R

Brake warning lamp signal TR

Detention switch signal TR

Front wiper stop position sign NISSAN NOTE 2016 Service Owners Manual LAN

SYSTEMLAN-31

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

Vehicle speed signal (ABS)

TR R R R R

Brake warning lamp signal TR

Detention switch signal TR

Front wiper stop position sign](/img/5/57363/w960_57363-2218.png)

LAN

SYSTEMLAN-31

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

Vehicle speed signal (ABS)

TR R R R R

Brake warning lamp signal TR

Detention switch signal TR

Front wiper stop position signal TR

High beam status signal RT

Ignition switch ON signal TR

RT

Interlock/PNP switch signal TR

RT

Low beam status signal RT

Push-button ignition switch status signal TR

OD OFF indicator signal RT

RT

Starter control relay signal TR

RT

Starter relay status signal TR

RT

Sleep-ready signal TR

TR

Wake up signal TR

Input shaft revolution signal RT

O/D OFF indicator signal TR

Output shaft revolution signal RT

Shift position signal RT RR

Target gear ratio signal RT

EPS warning lamp signal TR

Overdrive control switch signal RT

Fuel filler cap warning reset signal RT

O/D OFF switch signal RT

Odometer signal TR

Vehicle speed signal (Meter) RR TR

Wake up signal TR

Steering angle sensor signal RR T

A/C ON signal R T

Blower fan ON signal R T

Buzzer output signal RT

Dimmer signal RT

Door switch signal RRT

Engine start operation indicator lamp signal RT

Front wiper request signal RT

High beam request signal RRT

Key warning lamp signal RT

Low beam request signal RRT

Signal name

ECM

ABS

IPDM-E

TCMAV M

EPS

M&A

STRG

BCM

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2430 of 3641

![NISSAN NOTE 2016 Service Owners Manual MWI-72

< SYSTEM DESCRIPTION >[TYPE B]

DIAGNOSIS SYSTEM (COMBINATION METER)

VDC/TCS IND

[ON/OFF]Displays [ON/OFF] condition of VDC OFF indicator lamp.

SLIP IND

[ON/OFF] Displays [ON/OFF] condition of NISSAN NOTE 2016 Service Owners Manual MWI-72

< SYSTEM DESCRIPTION >[TYPE B]

DIAGNOSIS SYSTEM (COMBINATION METER)

VDC/TCS IND

[ON/OFF]Displays [ON/OFF] condition of VDC OFF indicator lamp.

SLIP IND

[ON/OFF] Displays [ON/OFF] condition of](/img/5/57363/w960_57363-2429.png)

MWI-72

< SYSTEM DESCRIPTION >[TYPE B]

DIAGNOSIS SYSTEM (COMBINATION METER)

VDC/TCS IND

[ON/OFF]Displays [ON/OFF] condition of VDC OFF indicator lamp.

SLIP IND

[ON/OFF] Displays [ON/OFF] condition of SLIP indicator lamp.

BRAKE W/L

[On/Off] Displays [ON/OFF] condition of brake warning indicator.

DOOR W/L

[On/Off] Displays [ON/OFF] condition of door warning indicator.

HI-BEAM IND

[On/Off] Displays [ON/OFF] condition of high beam indicator.

TURN IND

[On/Off] Displays [ON/OFF] condition of turn indicator.

LIGHT IND

[On/Off] Displays [ON/OFF] condition of light indicator.

OIL W/L

[On/Off] Displays [ON/OFF] condition of engine oil pressure warning indicator.

MIL

[On/Off] Displays [ON/OFF] condition of malfunction indicator.

CRUISE IND

[Off] Displays [ON/OFF]

condition of CRUISE indicator.

O/D OFF IND

[On/Off] Displays [ON/OFF] condition of O/D OFF indicator.

FUEL W/L

[On/Off] Displays [ON/OFF] condition of

low-fuel warning indicator.

PASS BUCKLE SW

[On/Off] Status of seat belt buckle switch RH.

AIR PRES W/L

[ON/OFF] Displays [ON/OFF] condition of tire pressure warning lamp.

KEY G/Y W/L

[ON/OFF] Displays [ON/OFF] condition of key warning lamp.

EPS W/L

[On/Off] Displays [ON/OFF] condition of EPS indicator.

FUEL CAP W/L

[Off] Displays [ON/OFF] condition of loose fuel cap warning message.

PKB SW

[On/Off] Status of parking brake switch.

BUCKLE SW

[On/Off] Status of seat belt buckle switch (LH).

BRAKE OIL SW

[On/Off] Status of brake fluid level switch.

CHG SIG

[On/Off] Displays [ON/OFF] condition of charge warning indicator.

DISTANCE

[km] or [Mi] Displays distance to empty.

OUTSIDE TEMP

[ ° F] or [ °C] Displays the ambient temperature, which is input from ambient sensor.

FUEL LOW SIG

[ON/OFF] Displays [ON/OFF] condition

of low-fuel warning signal.

BUZZER

[On/Off] X Displays [ON/OFF] condition of buzzer.

Display item [Unit]

MAIN

SIGNALS Description

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2509 of 3641

![NISSAN NOTE 2016 Service Owners Manual PCS-6

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

RELAY CONTROL SYSTEM : Fail-safe

INFOID:0000000012433269

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible, IPDM E/R perform NISSAN NOTE 2016 Service Owners Manual PCS-6

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

RELAY CONTROL SYSTEM : Fail-safe

INFOID:0000000012433269

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible, IPDM E/R perform](/img/5/57363/w960_57363-2508.png)

PCS-6

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

RELAY CONTROL SYSTEM : Fail-safe

INFOID:0000000012433269

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible, IPDM E/R performs fail-safe control. After CAN

communication recovers normally, it also returns to normal control.

If No CAN Communication Is Available With ECM

If No CAN Communication Is Available With BCM

Control relay Input/outputTransmit unit Control part Reference page

• Headlamp low relay

• Headlamp high relay • Low beam request signal

• High beam request signal

BCM (CAN)

• Headlamp LO

• Headlamp HI EXL-8

Tail lamp relay

Position light request signal BCM (CAN) •Parking lamp

• Side marker lamp

• License plate lamp

• Tail lamp

EXL-11

Illuminations

INL-9

• Front wiper relay

• Front wiper high relayFront wiper request signal BCM (CAN)

Front wiper motorWW-8Front wiper stop position sig-

nal Front wiper motor

Starter control relay Starter control relay signal BCM (CAN)

Starter motorSTR-8

(without Intelli-

gent Key)

STR-9

(with Intelligent

Key)

Transmission range switch

signal (CVT models)

Transmission range

switch

Clutch interlock switch signal

(M/T models) Clutch interlock switch

• Cooling fan low relay

• Cooling fan high relay Cooling fan speed request sig-

nal

ECM (CAN)

Cooling fan EC-38

A/C relayA/C compressor request sig-

nal

ECM (CAN)A/C compressor

(Magnet clutch)

HAC-11

Ignition relay-1Ignition switch ON signal BCM (CAN)

Each control unit,

sensor, actuator and

relay (Ignition power

supply) EC-35Vehicle speed signal (Meter)

Combination meter

(CAN)

Push-button ignition switch

signal Push-button ignition

switch

Control part

Fail-safe operation

Cooling fan • The cooling fan relay turn ON when the ignition switch is turned ON (Cooling fan HI operation)

• The cooling fan relay turn OFF when the ignition switch is turned OFF

A/C compressor A/C relay OFF

Generator Outputs the power generation command signal (PWM signal) 0%

Control part Fail-safe operation

Headlamp • Turns ON the headlamp low relay when the ignition switch is turned ON

• Turns OFF the headlamp low relay when the ignition switch is turned OFF

• Headlamp high relay OFF

•Parking lamp

• Side marker lamp

• License plate lamp

• Illumination

• Tail lamp • Turns ON the tail lamp relay when the ignition switch is turned ON

• Turns OFF the tail lamp relay when the ignition switch is turned OFF

Revision: August 2015

2016 Versa Note

cardiagn.com