remove seats NISSAN NOTE 2016 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2665 of 3641

PWC-4

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431791

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for WorkINFOID:0000000012431792

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2741 of 3641

REAR SUSPENSION BEAMRSU-13

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

REAR SUSPENSION BEAM

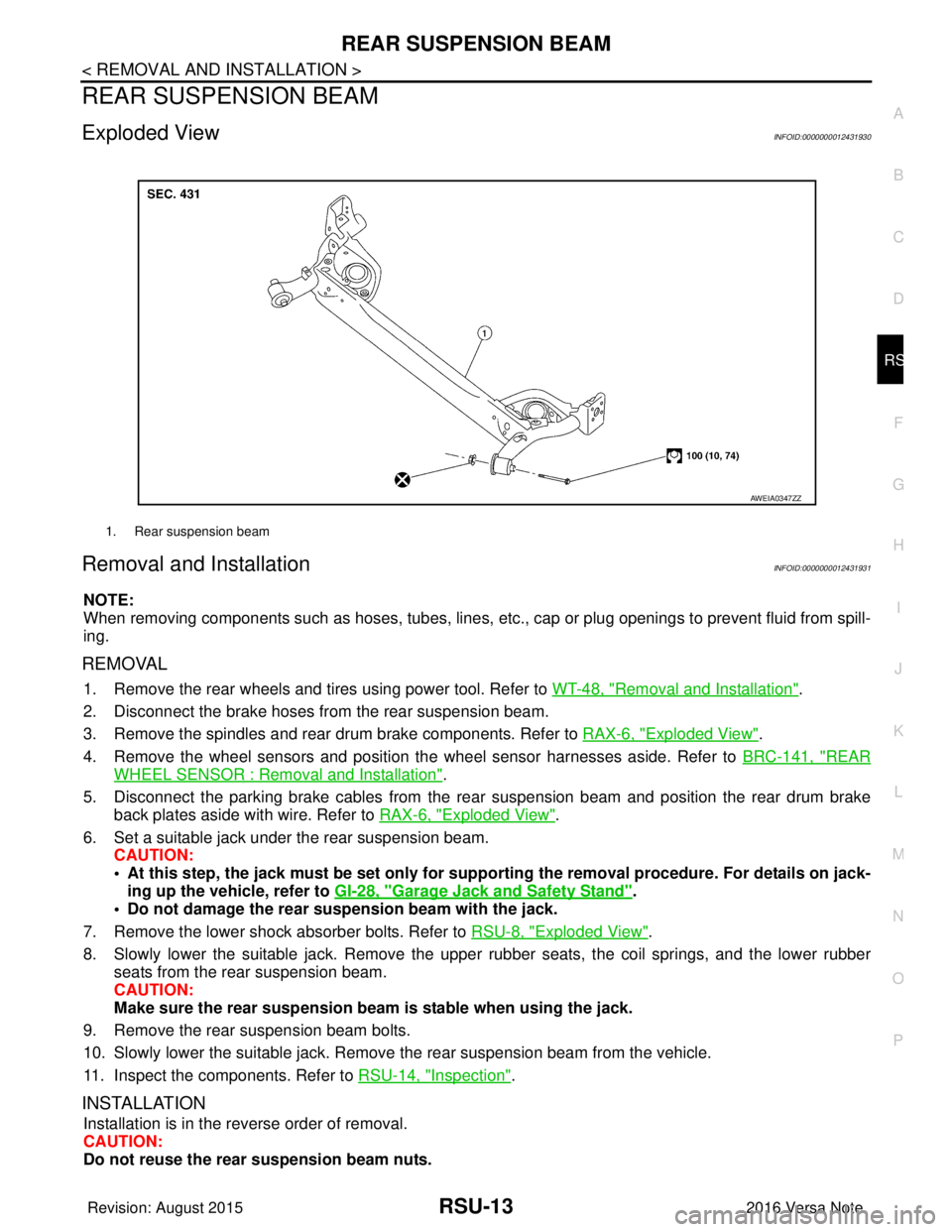

Exploded ViewINFOID:0000000012431930

Removal and InstallationINFOID:0000000012431931

NOTE:

When removing components such as hoses, tubes, lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Remove the rear wheels and tires using power tool. Refer to WT-48, "Removal and Installation".

2. Disconnect the brake hoses from the rear suspension beam.

3. Remove the spindles and rear drum brake components. Refer to RAX-6, "

Exploded View".

4. Remove the wheel sensors and position the wheel sensor harnesses aside. Refer to BRC-141, "

REAR

WHEEL SENSOR : Removal and Installation".

5. Disconnect the parking brake cables from the rear suspension beam and position the rear drum brake

back plates aside with wire. Refer to RAX-6, "

Exploded View".

6. Set a suitable jack under the rear suspension beam. CAUTION:

• At this step, the jack must be set only for suppo rting the removal procedure. For details on jack-

ing up the vehicle, refer to GI-28, "

Garage Jack and Safety Stand".

• Do not damage the rear su spension beam with the jack.

7. Remove the lower shock absorber bolts. Refer to RSU-8, "

Exploded View".

8. Slowly lower the suitable jack. Remove the upper rubber seats, the coil springs, and the lower rubber seats from the rear suspension beam.

CAUTION:

Make sure the rear susp ension beam is stable when using the jack.

9. Remove the rear suspension beam bolts.

10. Slowly lower the suitable jack. Remove the rear suspension beam from the vehicle.

11. Inspect the components. Refer to RSU-14, "

Inspection".

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not reuse the rear suspension beam nuts.

1. Rear suspension beam

AWEIA0347ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2802 of 3641

COMPONENT INSPECTIONSB-5

< BASIC INSPECTION >

C

DE

F

G

I

J

K L

M A

B

SB

N

O P

BASIC INSPECTION

COMPONENT INSPECTION

InspectionINFOID:0000000012430699

AFTER A COLLISION

WARNING:

Inspect all seat belt assemblies in cluding retractors and attaching hardware after any collision.

NISSAN/INFINITI recommends that all seat belt assemblies in use during a collision be replaced

unless the collision was minor and th e belts show no damage and continue to operate properly. Fail-

ure to do so could result in serious personal inju ry in an accident. Seat belt assemblies not in use dur-

ing a collision should also be replaced if either damage or improper operation is noted. Seat belt pre-

tensioners should be replaced even if the seat belts are not in use during a frontal collision in which

the air bags are deployed.

Replace any seat belt assembly (including anchor bolts) if:

• The seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and buckles show no damage and continue to operate properly).

• The seat belt was damaged in an accident (i.e. torn webbing, bent retractor or guide, etc.).

• The seat belt attaching point is damaged in an accident. Inspect the seat belt attaching area for damage or

distortion and repair if necessary before installing a new seat belt assembly.

• Anchor bolts are deformed or worn out.

• The seat belt pre-tensioner should be replaced even if t he seat belts are not in use during the collision in

which the air bags are deployed.

PRELIMINARY CHECKS

1. Check the seat belt warning lamp for proper operation per the following:

a. Turn ignition switch ON. The seat belt warning lamp should illuminate.

b. Fasten driver seat belt. The seat belt warning lamp should turn OFF.

2. If the air bag warning lamp is blinking, perform self-diagnosis with CONSULT and air bag warning lamp. Refer to SRC-14, "

Description".

3. Check that the seat belt retractor, seat belt anchor and buckle bolts are tightened firmly.

4. Check the shoulder seat belt guide and shoulder belt height adjuster for front seats. Check that guide

swivels freely and that webbing lays flat and does not bind in guide. Check that height adjuster operates

properly and holds securely.

5. Check retractor operation:

a. Fully extend the seat belt webbing and check for twists, tears or other damage.

b. Allow the seat belt to retract. Check that webbing retu rns smoothly and completely into the retractor. If the

seat belt does not return smoothly, wipe the inside of the loops with a clean paper cloth. Dirt build-up in the

loops of the upper anchors can cause the seat belts to retract slowly.

c. Fasten the seat belt. Check that seat belt returns smoothly and completely to the retractor. If the webbing does not return smoothly, the cause may be an accu mulation of dust or dirt. Use the “SEAT BELT TAPE

SET” and perform the following steps.

d. Inspect the front seat belt D-ring anchor 1. Pull the seat belt out to a length of 500 mm (19.69 in) or more.

2. Hold the seat belt at the center pillar webbing opening with a clip or other device.

3. Pass a thin wire through the D-ring anchor webbing opening. Hold both ends of the wire and pull it tightly while moving it up and down several times along the webbing opening surface to remove dirt

stuck there.

4. Any dirt that cannot be removed with the wire can be removed by cleaning the opening with a clean

cloth.

5. Apply tape at the point where the webbing contacts the D-ring anchor webbing opening. NOTE:

Apply the tape so that there is no slack or wrinkling.

6. Remove the clip holding the seat belt and check that the webbing returns smoothly.

6. Repeat steps above if necessary to check the other seat belts.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2803 of 3641

SB-6

< BASIC INSPECTION >

COMPONENT INSPECTION

SEAT BELT RETRACTOR ON-VEHICLE CHECK

Emergency Locking Retractors (ELR) and Automatic Locking Retractors (ALR)

NOTE:

All seat belt retractors are Emergency Locking Retractors (ELR) type. In an emergency (sudden stop) the

retractor will lock and prevent the webbing from extendi ng any further. All 3-point type seat belt retractors

except the driver seat belt also have an Automati c Locking Retractors (ALR) mode. The ALR mode (also

called child restraint mode) is used when installing child seats. The ALR mode is activated when the seat belt

is fully extended. When the webbing is then retracted part ially, the ALR mode automatically locks the seat belt

in a specific position so the webbing cannot be extended any further. To cancel the ALR mode, allow the seat

belt to fully wind back into the retractor.

Check the seat belt retractors with the following test(s ) to determine if a retractor assembly is operating prop-

erly.

ELR Function Stationary Check

Grasp the shoulder webbing and pull forward quickly. T he retractor should lock and prevent the belt from

extending further.

ALR Function Stationary Check

1. Pull out the entire length of seat belt from retractor until a click is heard.

2. Retract the webbing partially. A clicking noise shoul d be heard as the webbing retracts, indicating that the

retractor is in the Automatic Locking Retractors (ALR) mode.

3. Grasp the seat belt and try to pull out the retractor. The webbing must lock and not extend any further. If it

does not operate normally, replace the retractor assembly.

4. Allow the entire length of the webbing to re tract to cancel the automatic locking mode.

ELR Function Moving Check

WARNING:

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example, a

large, empty parking lot). Road surface must be p aved and dry. Never perform the following test on

wet or gravel roads or on public streets and highw ays. This could result in an accident and serious

personal injury. The driver and passenger must be prepared to brace themselves in the event that the

retractor does not lock.

1. Fasten driver seat belt. Buckle a passenger into the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h ( 10 mph). Notify any passengers of a pending sudden stop

and the driver and passenger must be prepared to brace themselves in the event that the retractor does

not lock. Apply brakes firmly and make a very hard stop.

During stopping, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock,

perform the retractor off-vehicle check.

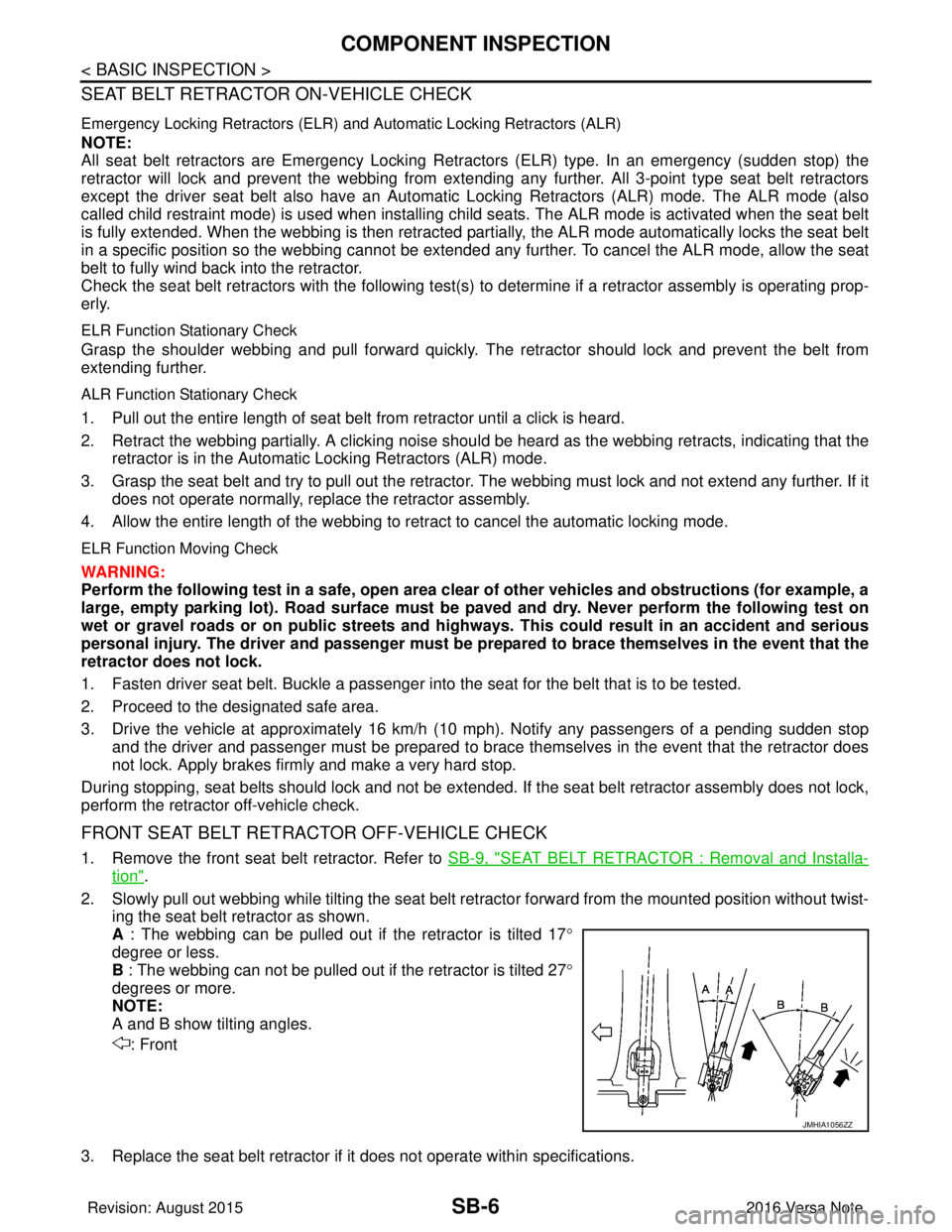

FRONT SEAT BELT RETRACTOR OFF-VEHICLE CHECK

1. Remove the front seat belt retractor. Refer to SB-9, "SEAT BELT RETRACTOR : Removal and Installa-

tion".

2. Slowly pull out webbing while tilting the seat belt re tractor forward from the mounted position without twist-

ing the seat belt retractor as shown.

A : The webbing can be pulled out if the retractor is tilted 17 °

degree or less.

B : The webbing can not be pulled out if the retractor is tilted 27°

degrees or more.

NOTE:

A and B show tilting angles.

: Front

3. Replace the seat belt retractor if it does not operate within specifications.

JMHIA1056ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2815 of 3641

SE-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432026

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for WorkINFOID:0000000012432027

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2840 of 3641

REAR SEATSE-27

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

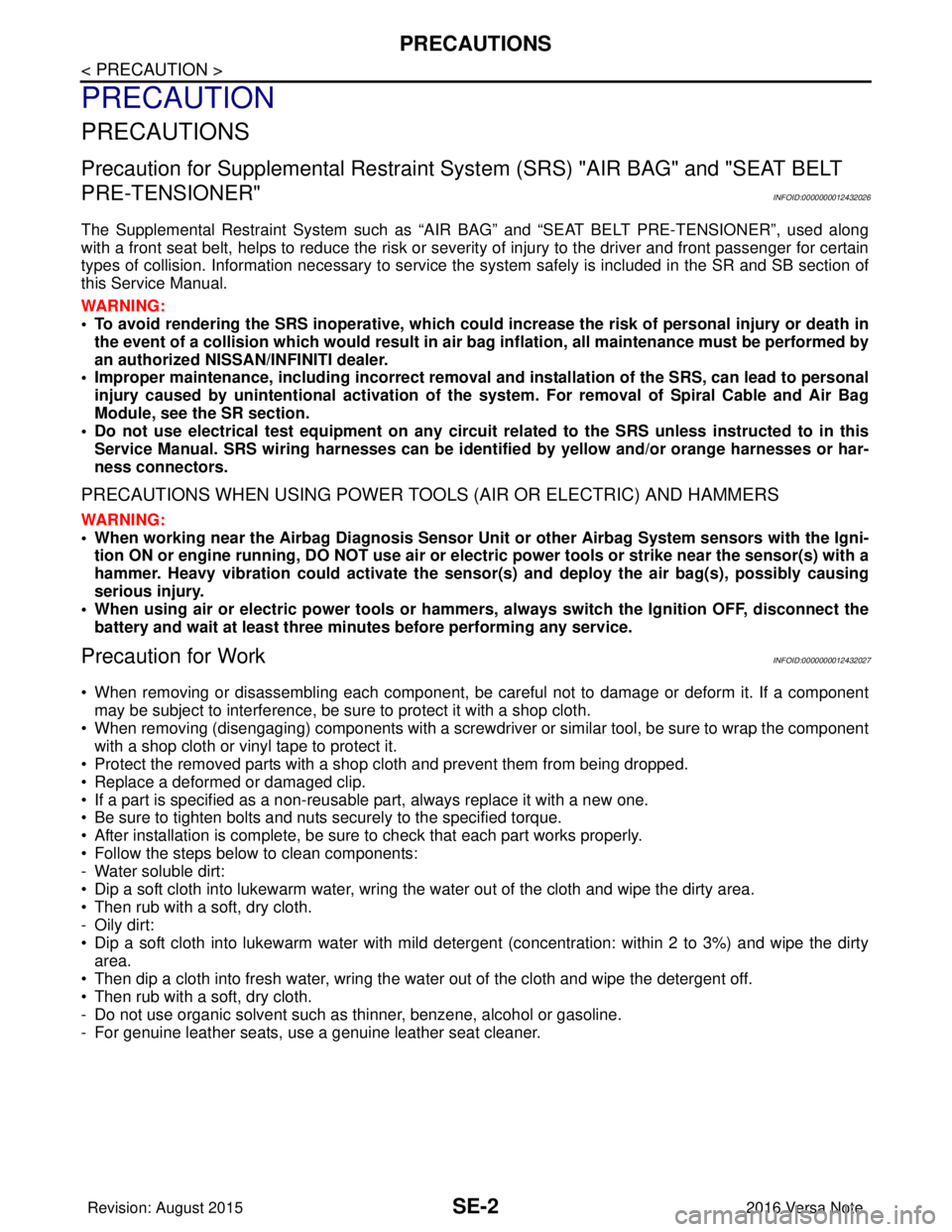

Seatback (RH)

1. Place the seatback (RH) in the folded down position.

2. Release hook fasteners (A).

3. Remove bolts (B) and the seatback (RH) (1).

INSTALLATION

Installation is in the reverse order of removal.

Tighten the seatback assembly bolts to specification. Refer to

SE-23, "

Exploded View".

SEATBACK HINGE

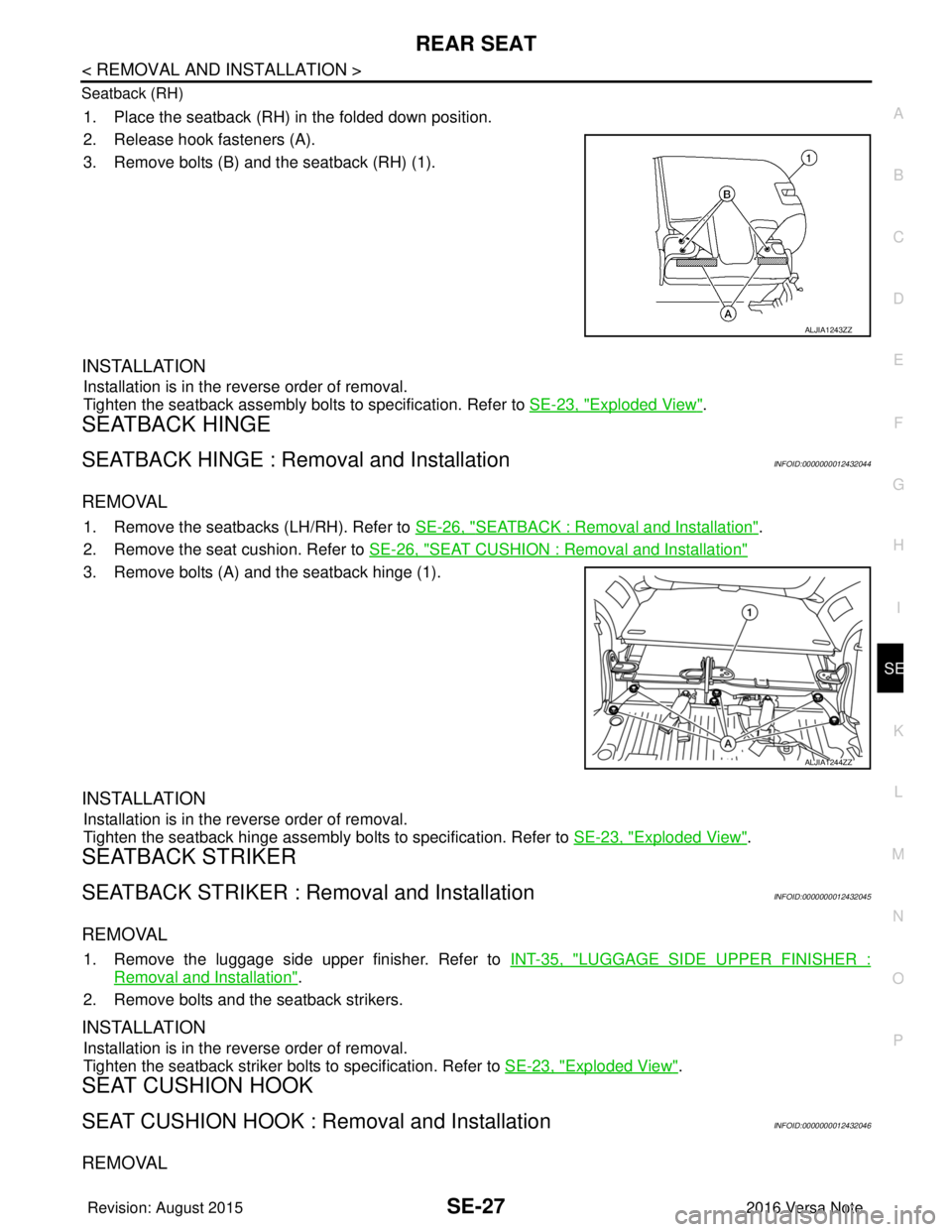

SEATBACK HINGE : Removal and InstallationINFOID:0000000012432044

REMOVAL

1. Remove the seatbacks (LH/RH). Refer to SE-26, "SEATBACK : Removal and Installation".

2. Remove the seat cushion. Refer to SE-26, "

SEAT CUSHION : Removal and Installation"

3. Remove bolts (A) and the seatback hinge (1).

INSTALLATION

Installation is in the reverse order of removal.

Tighten the seatback hinge assembly bolts to specification. Refer to SE-23, "

Exploded View".

SEATBACK STRIKER

SEATBACK STRIKER : Removal and InstallationINFOID:0000000012432045

REMOVAL

1. Remove the luggage side upper finisher. Refer to INT-35, "LUGGAGE SIDE UPPER FINISHER :

Removal and Installation".

2. Remove bolts and the seatback strikers.

INSTALLATION

Installation is in the reverse order of removal.

Tighten the seatback striker bolts to specification. Refer to SE-23, "

Exploded View".

SEAT CUSHION HOOK

SEAT CUSHION HOOK : Removal and InstallationINFOID:0000000012432046

REMOVAL

ALJIA1243ZZ

ALJIA1244ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2846 of 3641

FRONT SEATSE-33

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

ASSEMBLY

Assembly is in the reverse order of disassembly.

Smooth out all wrinkles during assembly.

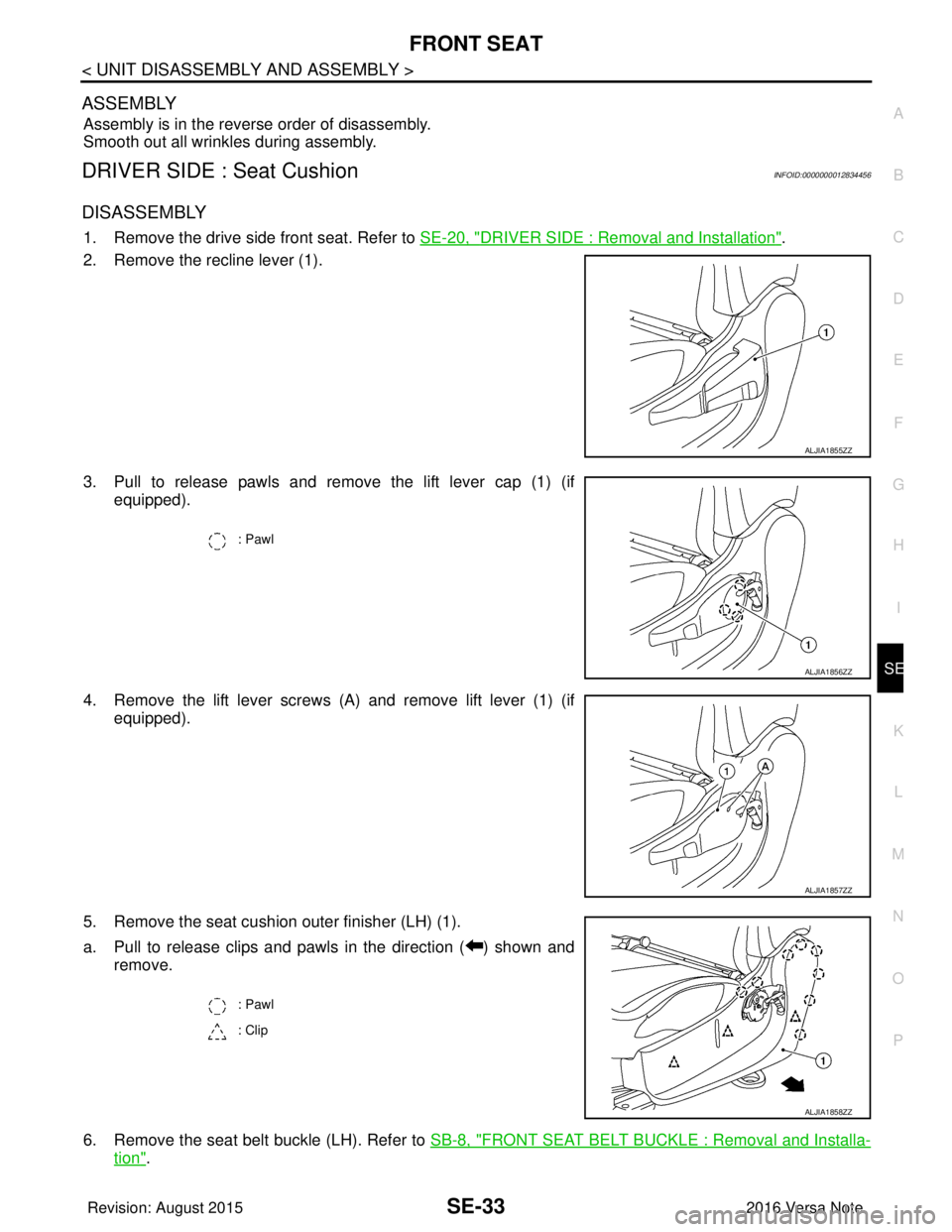

DRIVER SIDE : Seat CushionINFOID:0000000012834456

DISASSEMBLY

1. Remove the drive side front seat. Refer to SE-20, "DRIVER SIDE : Removal and Installation".

2. Remove the recline lever (1).

3. Pull to release pawls and remove the lift lever cap (1) (if equipped).

4. Remove the lift lever screws (A) and remove lift lever (1) (if equipped).

5. Remove the seat cushion outer finisher (LH) (1).

a. Pull to release clips and pawls in the direction ( ) shown and remove.

6. Remove the seat belt buckle (LH). Refer to SB-8, "

FRONT SEAT BELT BUCKLE : Removal and Installa-

tion".

ALJIA1855ZZ

: Pawl

ALJIA1856ZZ

ALJIA1857ZZ

: Pawl

: Clip

ALJIA1858ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2850 of 3641

FRONT SEATSE-37

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

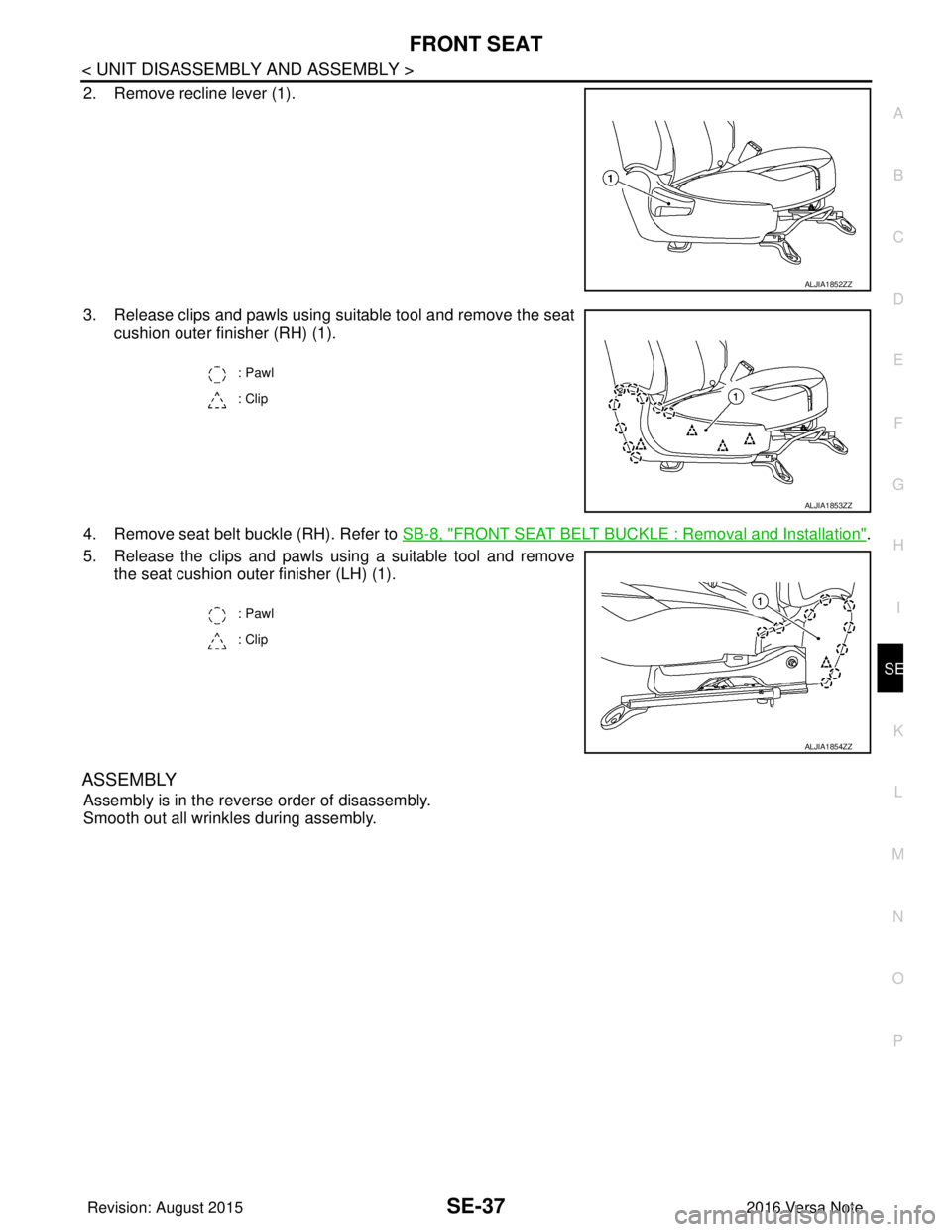

2. Remove recline lever (1).

3. Release clips and pawls using suitable tool and remove the seat cushion outer finisher (RH) (1).

4. Remove seat belt buckle (RH). Refer to SB-8, "

FRONT SEAT BELT BUCKLE : Removal and Installation".

5. Release the clips and pawls using a suitable tool and remove the seat cushion outer finisher (LH) (1).

ASSEMBLY

Assembly is in the reverse order of disassembly.

Smooth out all wrinkles during assembly.

ALJIA1852ZZ

: Pawl

: Clip

ALJIA1853ZZ

: Pawl

: Clip

ALJIA1854ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2854 of 3641

REAR SEATSE-41

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

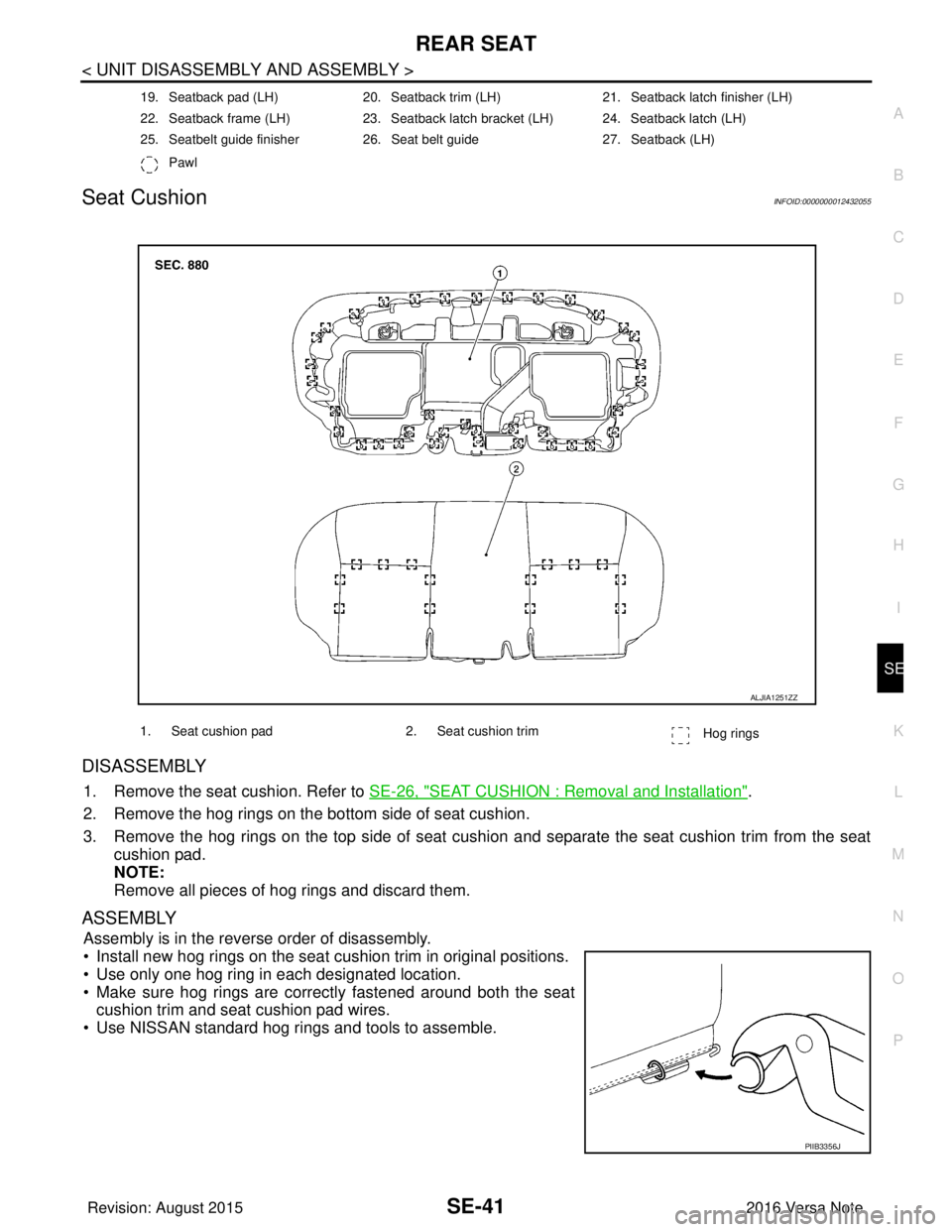

Seat CushionINFOID:0000000012432055

DISASSEMBLY

1. Remove the seat cushion. Refer to SE-26, "SEAT CUSHION : Removal and Installation".

2. Remove the hog rings on the bottom side of seat cushion.

3. Remove the hog rings on the top side of seat cushi on and separate the seat cushion trim from the seat

cushion pad.

NOTE:

Remove all pieces of hog rings and discard them.

ASSEMBLY

Assembly is in the reverse order of disassembly.

• Install new hog rings on the seat cushion trim in original positions.

• Use only one hog ring in each designated location.

• Make sure hog rings are correctly fastened around both the seat cushion trim and seat cushion pad wires.

• Use NISSAN standard hog rings and tools to assemble.

19. Seatback pad (LH) 20. Seatback trim (LH) 21. Seatback latch finisher (LH)

22. Seatback frame (LH) 23. Seatback latch bracket (LH) 24. Seatback latch (LH)

25. Seatbelt guide finisher 26. Seat belt guide 27. Seatback (LH)

Pawl

1. Seat cushion pad 2. Seat cushion trim

Hog rings

ALJIA1251ZZ

PIIB3356J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2856 of 3641

REAR SEATSE-43

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

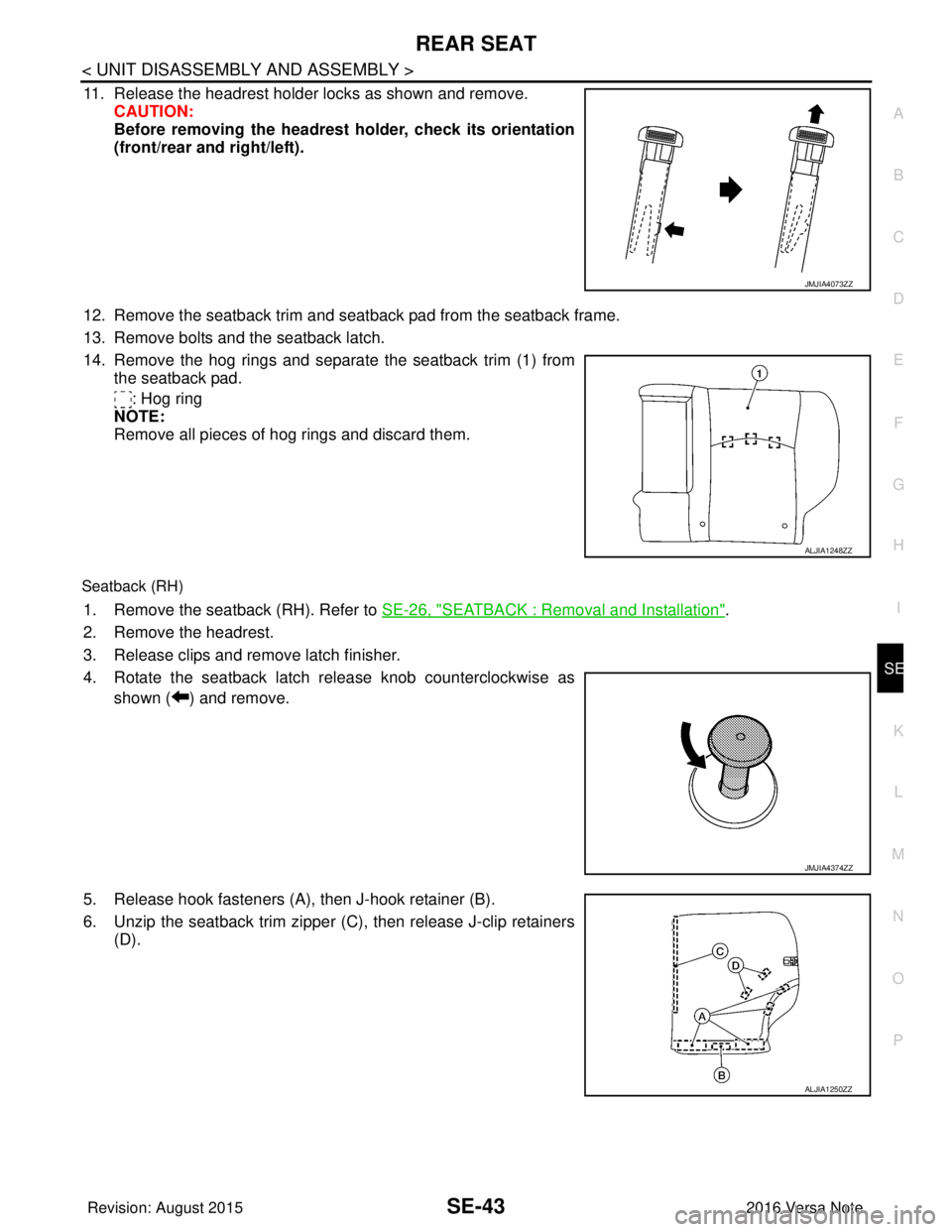

11. Release the headrest holder locks as shown and remove. CAUTION:

Before removing the headrest holder, check its orientation

(front/rear and right/left).

12. Remove the seatback trim and seatback pad from the seatback frame.

13. Remove bolts and the seatback latch.

14. Remove the hog rings and separate the seatback trim (1) from the seatback pad.

: Hog ring

NOTE:

Remove all pieces of hog rings and discard them.

Seatback (RH)

1. Remove the seatback (RH). Refer to SE-26, "SEATBACK : Removal and Installation".

2. Remove the headrest.

3. Release clips and remove latch finisher.

4. Rotate the seatback latch release knob counterclockwise as shown ( ) and remove.

5. Release hook fasteners (A), then J-hook retainer (B).

6. Unzip the seatback trim zipper (C), then release J-clip retainers (D).

JMJIA4073ZZ

ALJIA1248ZZ

JMJIA4374ZZ

ALJIA1250ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com