washer fluid NISSAN NOTE 2016 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2632 of 3641

PG

HARNESSPG-45

< WIRING DIAGRAM >

C

DE

F

G H

I

J

K L

B A

O P

N

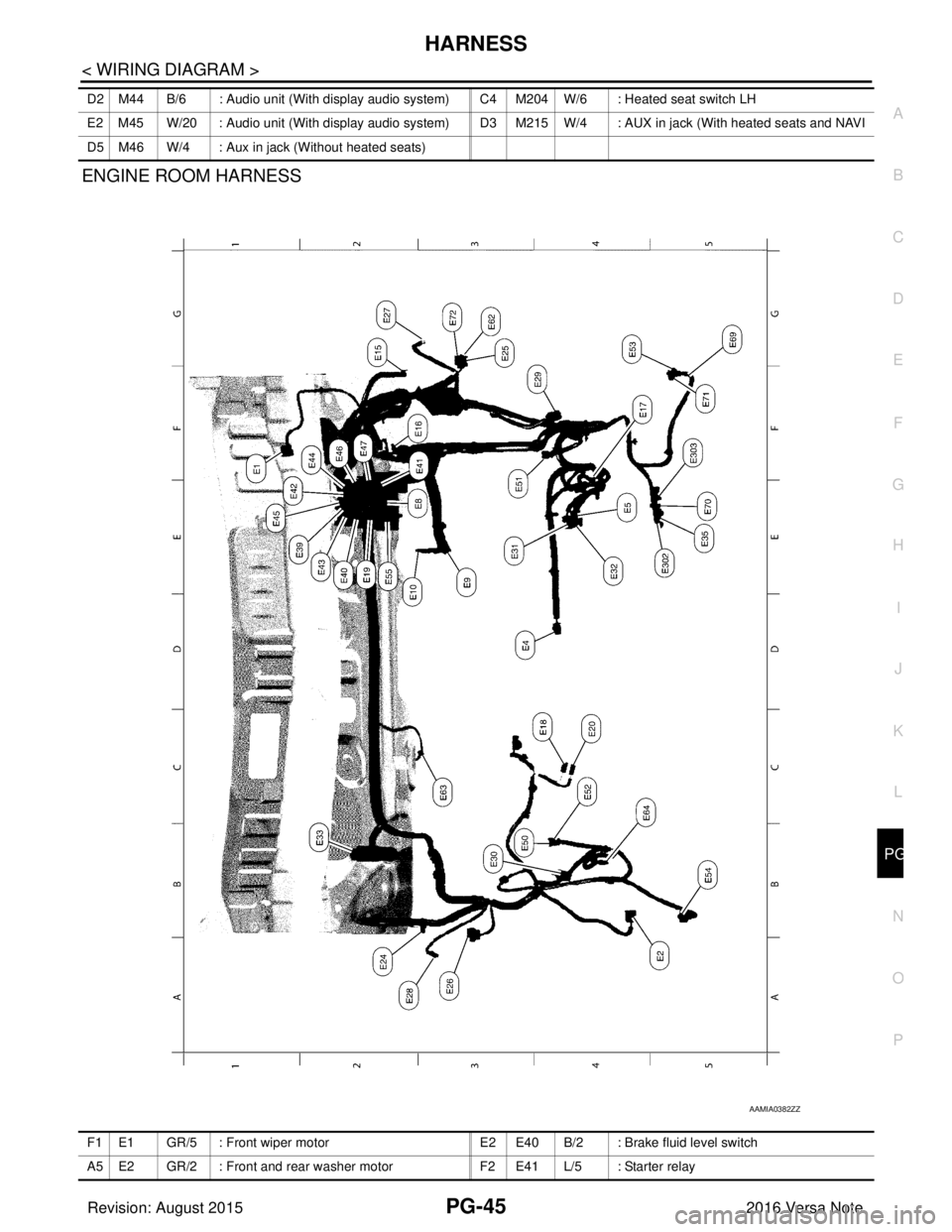

ENGINE ROOM HARNESS

D2 M44 B/6 : Audio unit (With display audio system) C4 M204

W/6 : Heated seat switch LH

E2 M45 W/20 : Audio unit (With display audio system) D3 M215 W/4 : AUX in jack (With heated seats and NAVI

D5 M46 W/4 : Aux in jack (Without heated seats)

AAMIA0382ZZ

F1 E1 GR/5 : Front wiper motor E2 E40 B/2 : Brake fluid level switch

A5 E2 GR/2 : Front and rear washer motor F2 E41 L/5 : Starter relay

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3483 of 3641

![NISSAN NOTE 2016 Service Owners Manual TM-242

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

OIL PAN, CONTROL VALVE

OIL PAN, CONTROL VALVE

Exploded ViewINFOID:0000000012431192

Removal and InstallationINFOID:0000000012431193

REMOVAL

1. Disconne NISSAN NOTE 2016 Service Owners Manual TM-242

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

OIL PAN, CONTROL VALVE

OIL PAN, CONTROL VALVE

Exploded ViewINFOID:0000000012431192

Removal and InstallationINFOID:0000000012431193

REMOVAL

1. Disconne](/img/5/57363/w960_57363-3482.png)

TM-242

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

OIL PAN, CONTROL VALVE

OIL PAN, CONTROL VALVE

Exploded ViewINFOID:0000000012431192

Removal and InstallationINFOID:0000000012431193

REMOVAL

1. Disconnect battery negative terminal.

1. Transaxle assembly

2. O-ring 3. Control valve

4. Manual plate 5. Washer 6. O-ring

7. Strainer 8. Oil pan gasket9. Magnet

10. Oil pan 11. Drain plug gasket 12. Drain plug

13. Overflow tube : Apply petroleum jelly

: Always replace after every disassembly.

: Apply CVT fluid

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

JSDIA6707GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3484 of 3641

![NISSAN NOTE 2016 Service Owners Manual OIL PAN, CONTROL VALVETM-243

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

2. Disconnect the CVT unit harness connector.

3. Remove the drain plug and overflow tube, and t NISSAN NOTE 2016 Service Owners Manual OIL PAN, CONTROL VALVETM-243

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

2. Disconnect the CVT unit harness connector.

3. Remove the drain plug and overflow tube, and t](/img/5/57363/w960_57363-3483.png)

OIL PAN, CONTROL VALVETM-243

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

2. Disconnect the CVT unit harness connector.

3. Remove the drain plug and overflow tube, and then drain the CVT fluid. CAUTION:

Use caution when looking into the drain hole as there is the risk of fluid entering the eye.

4. Remove the drain plug gasket from the drain plug.

5. Remove the oil pan mounting bolts ( ), and then remove the oil pan and oil pan gasket.

6. Remove the magnets from the oil pan.

7. Remove the strainer bolts , and then remove the strainer from the control valve.

8. Remove the nut and washer , and then remove manual plate .

CAUTION:

To remove nut, fix manual plat e with flat-blade screwdriver

(B).

9. Press the CVT unit harness connector into the transaxle case. CAUTION:

Never damage the CVT unit harness connector.

NOTE:

Clean around the CVT unit harness connector to prevent foreign

materials from entering into the transaxle case.

10. Remove the control valve bolts , and then remove the control valve from the transaxle case.

CAUTION:

• Never drop the control valve and manual valve.

:Vehicle front

JSDIA1874ZZ

JSDIA6594ZZ

JSDIA6595ZZ

JSDIA6598ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3485 of 3641

![NISSAN NOTE 2016 Service Owners Manual TM-244

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

OIL PAN, CONTROL VALVE

• To remove bolt of the oil temperature sensor bracket and

the control valve, fix bracket with flat-blade screw-

driver.

11 NISSAN NOTE 2016 Service Owners Manual TM-244

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

OIL PAN, CONTROL VALVE

• To remove bolt of the oil temperature sensor bracket and

the control valve, fix bracket with flat-blade screw-

driver.

11](/img/5/57363/w960_57363-3484.png)

TM-244

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

OIL PAN, CONTROL VALVE

• To remove bolt of the oil temperature sensor bracket and

the control valve, fix bracket with flat-blade screw-

driver.

11. Remove the O-ring to the CVT unit harness connector.

INSTALLATION

1. Install the O-ring to the CVT unit harness connector. CAUTION:

• Never reuse O-ring.

• Apply CVT fluid to the O-ring

• Never pinch the harness , between the control valve and

the CVT unit harness connector bracket .

• Never twist the harness.

• Never slack the harness.

2. Install the control valve, and than tighten control valve bolts to the specitoed torque.

CAUTION:

• Never pinch the harness be tween the control valve and

the transaxle case.

• Never drop the control valve and manual valve.

3. Install the manual plate and washer , and then tighten nut to the specitied torque.

CAUTION:

To tighten nut, fix manual plat e with flat-blade screwdriver.

JSDIA6596ZZ

JSDIA6599ZZ

JSDIA6598ZZ

JSDIA6597ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3567 of 3641

WW-2

FRONT WIPER MOTOR HI CIRCUIT ................38

Component Function Check ................................ ...38

Diagnosis Procedure ..............................................38

FRONT WIPER AUTO STOP SIGNAL CIR-

CUIT ...................................................................

40

Component Function Check ................................ ...40

Diagnosis Procedure ..............................................40

FRONT WIPER MOTOR GROUND CIRCUIT ...42

Diagnosis Procedure ..............................................42

WASHER MOTOR CIRCUIT .............................43

Diagnosis Procedure ........................................... ...43

WASHER SWITCH ............................................44

Description ........................................................... ...44

Component Inspection ............................................44

REAR WIPER MOTOR CIRCUIT ......................46

Component Function Check ................................ ...46

Diagnosis Procedure ..............................................46

REAR WIPER AUTO STOP SIGNAL CIRCUIT

...

48

Component Function Check ................................ ...48

Diagnosis Procedure ..............................................48

SYMPTOM DIAGNOSIS .............................50

WIPER AND WASHER SYSTEM SYMPTOMS

...

50

Symptom Table ................................................... ...50

FRONT WIPER DOES NOT OPERATE ............53

Description ........................................................... ...53

Diagnosis Procedure ..............................................53

NORMAL OPERATING CONDITION ................55

Description ........................................................... ...55

REMOVAL AND INSTALLATION ...............56

WASHER TANK ............................................. ...56

Exploded View ..................................................... ...56

Removal and Installation ........................................56

FRONT WASHER MOTOR ................................58

Exploded View ..................................................... ...58

Removal and Installation ........................................58

WASHER FLUID LEVEL SWITCH ....................59

Removal and Installation ..................................... ...59

FRONT WASHER NOZZLE AND TUBE ...........60

Exploded View ..................................................... ...60

WASHER NOZZLE ................................................. ...60

WASHER NOZZLE : Removal and Installation .......60

WASHER NOZZLE : Adjustment ............................61

WASHER TUBE ..................................................... ...61

WASHER TUBE : Removal and Installation ...........61

WASHER TUBE : Inspection ..................................62

FRONT WIPER ARM .........................................63

Exploded View ..................................................... ...63

Removal and Installation .........................................63

Adjustment ........................................................... ...64

FRONT WIPER BLADE .....................................65

Removal and Installation .........................................65

FRONT WIPER DRIVE ASSEMBLY .............. ...66

Exploded View ..................................................... ...66

Removal and Installation .........................................66

Exploded View ..................................................... ...67

Disassembly and Assembly ....................................67

WIPER AND WASHER SWITCH ......................68

Removal and Installation .........................................68

REAR WIPER ARM ........................................ ...69

Exploded View ..................................................... ...69

Removal and Installation .........................................69

Adjustment ........................................................... ...70

REAR WIPER BLADE .......................................71

Removal and Installation .........................................71

REAR WIPER MOTOR ................................... ...72

Exploded View ..................................................... ...72

Removal and Installation .........................................72

REAR WASHER NOZZLE AND TUBE .......... ...73

Component Parts Location .................................. ...73

WASHER NOZZLE ................................................. ...73

WASHER NOZZLE : Removal and Installation .......73

WASHER NOZZLE : Adjustment ............................73

WASHER TUBE ..................................................... ...74

WASHER TUBE : Removal and Installation ...........74

SERVICE DATA AND SPECIFICATIONS

(SDS) .......... ................................. ...............

76

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

76

Specifications ....................................................... ...76

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3572 of 3641

COMPONENT PARTSWW-7

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

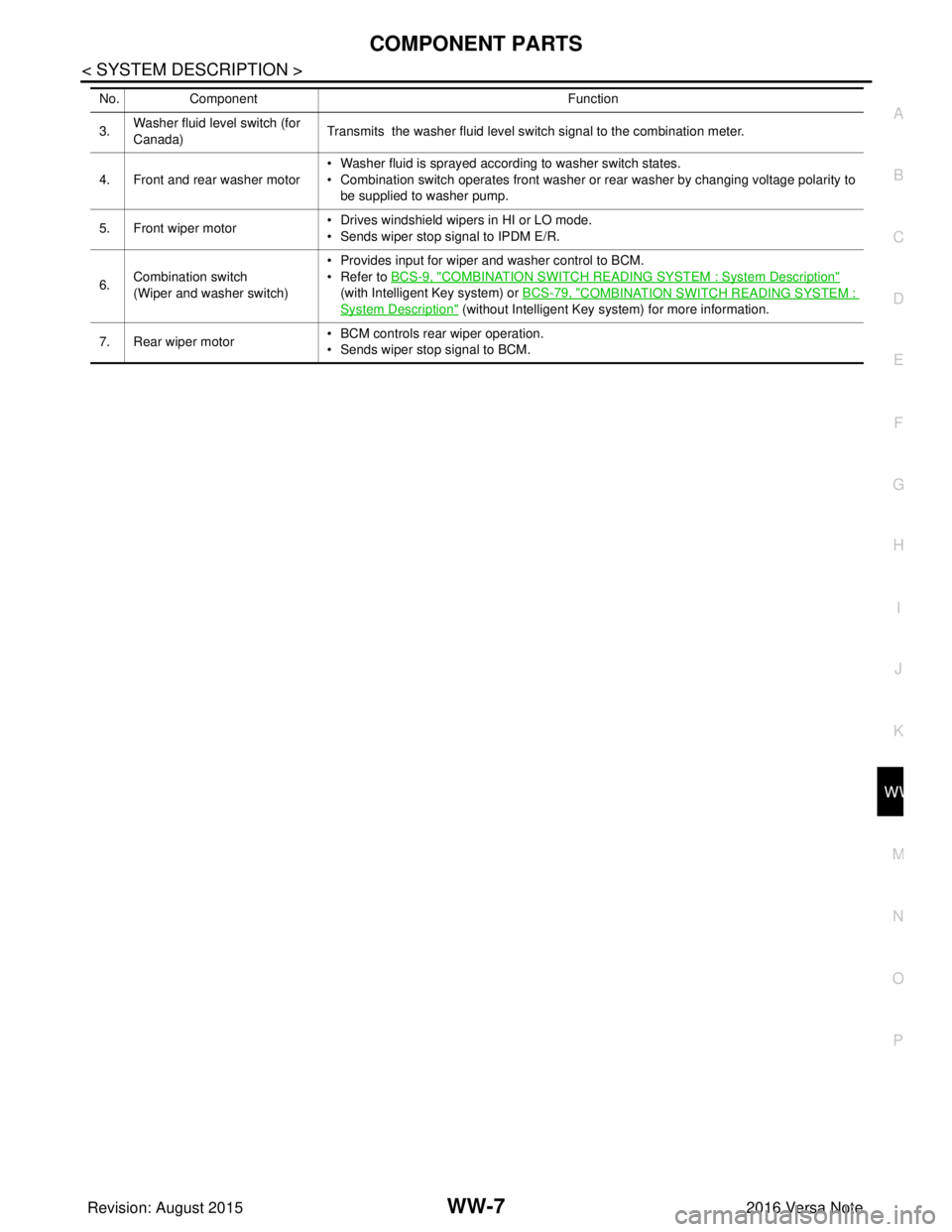

3. Washer fluid level switch (for

Canada) Transmits the washer fluid level switch signal to the combination meter.

4. Front and rear washer motor • Washer fluid is sprayed according to washer switch states.

• Combination switch operates front washer or rear washer by changing voltage polarity to

be supplied to washer pump.

5. Front wiper motor • Drives windshield wipers in HI or LO mode.

• Sends wiper stop signal to IPDM E/R.

6. Combination switch

(Wiper and washer switch) • Provides input for wiper and washer control to BCM.

• Refer to

BCS-9, "

COMBINATION SWITCH READING SYSTEM : System Description"

(with Intelligent Key system) or BCS-79, "

COMBINATION SWITCH READING SYSTEM :

System Description" (without Intelligent Key system) for more information.

7. Rear wiper motor • BCM controls rear wiper operation.

• Sends wiper stop signal to BCM.

No.

Component Function

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3621 of 3641

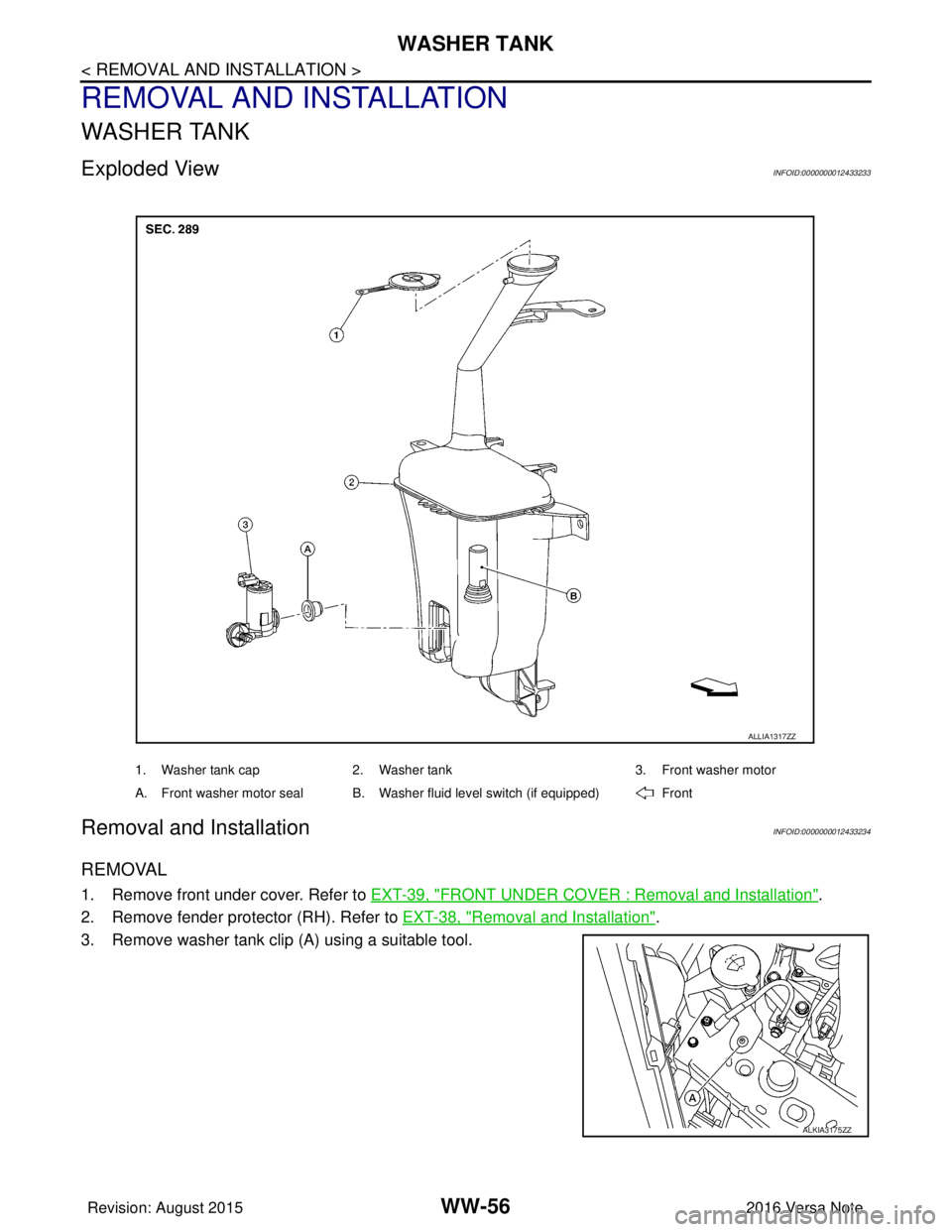

WW-56

< REMOVAL AND INSTALLATION >

WASHER TANK

REMOVAL AND INSTALLATION

WASHER TANK

Exploded ViewINFOID:0000000012433233

Removal and InstallationINFOID:0000000012433234

REMOVAL

1. Remove front under cover. Refer to EXT-39, "FRONT UNDER COVER : Removal and Installation".

2. Remove fender protector (RH). Refer to EXT-38, "

Removal and Installation".

3. Remove washer tank clip (A) using a suitable tool.

1. Washer tank cap 2. Washer tank 3. Front washer motor

A. Front washer motor seal B. Washer fluid level switch (if equipped) Front

ALLIA1317ZZ

ALKIA3175ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3622 of 3641

WASHER TANKWW-57

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

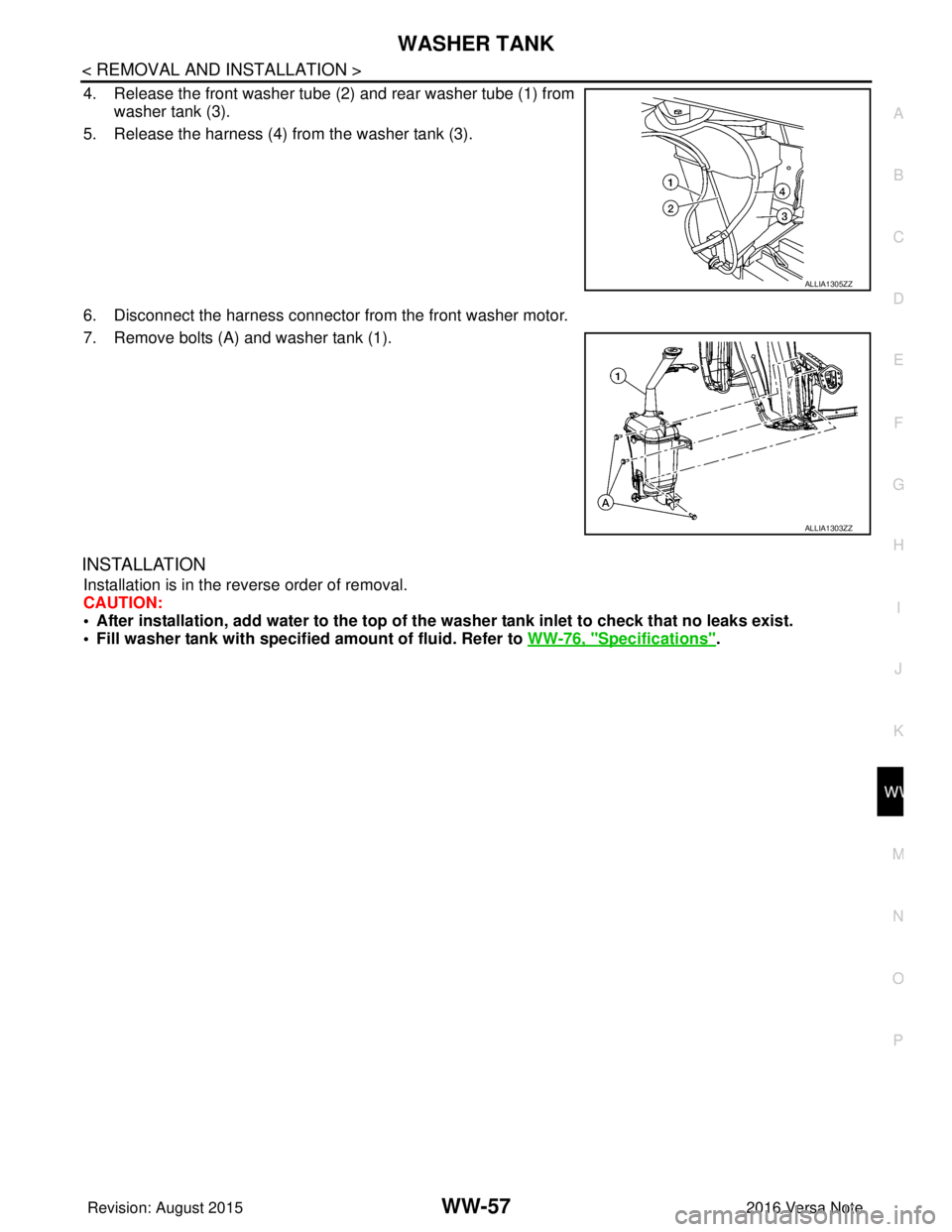

4. Release the front washer tube (2) and rear washer tube (1) from

washer tank (3).

5. Release the harness (4) from the washer tank (3).

6. Disconnect the harness connector from the front washer motor.

7. Remove bolts (A) and washer tank (1).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• After installation, add water to the top of th e washer tank inlet to check that no leaks exist.

• Fill washer tank with specified amount of fluid. Refer to WW-76, "

Specifications".

ALLIA1305ZZ

ALLIA1303ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3623 of 3641

WW-58

< REMOVAL AND INSTALLATION >

FRONT WASHER MOTOR

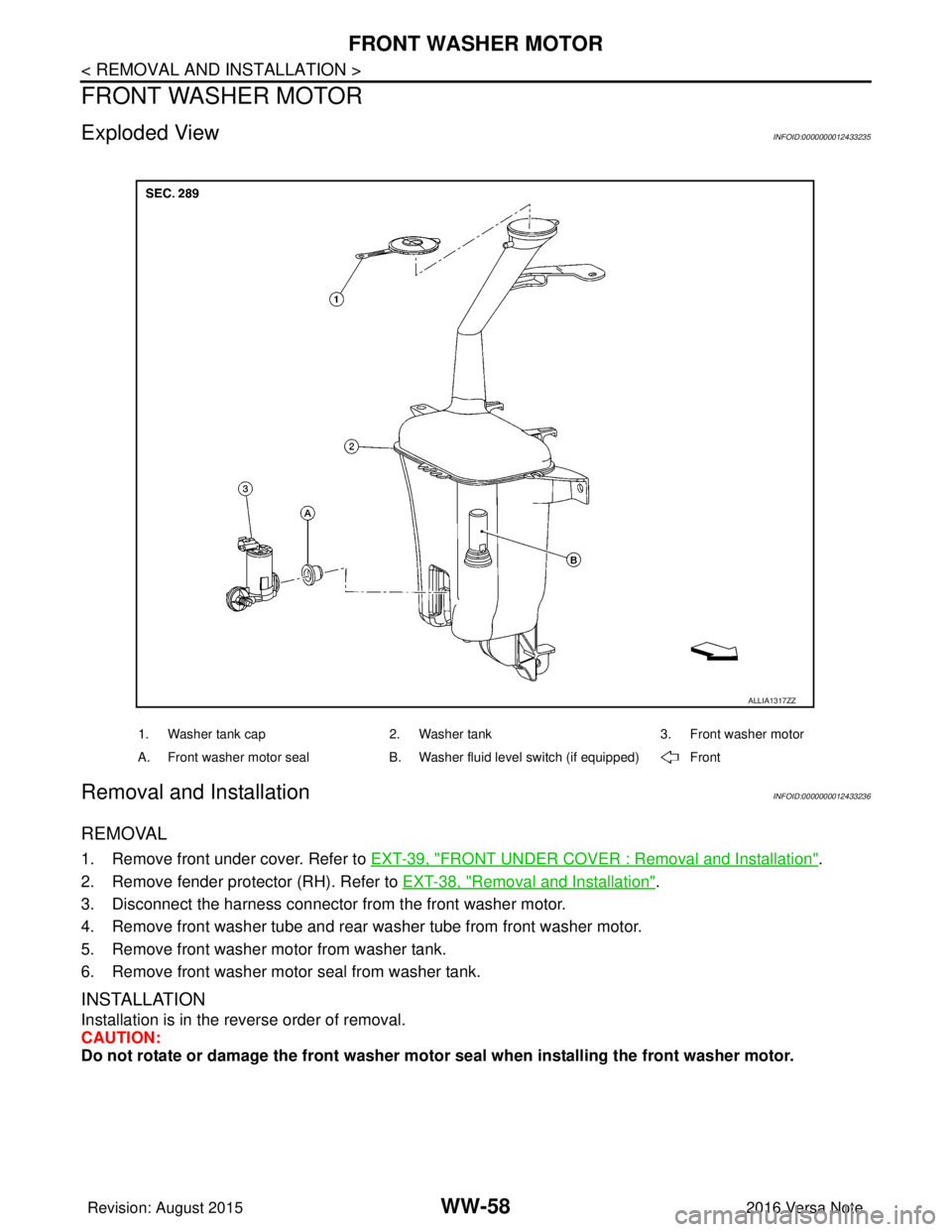

FRONT WASHER MOTOR

Exploded ViewINFOID:0000000012433235

Removal and InstallationINFOID:0000000012433236

REMOVAL

1. Remove front under cover. Refer to EXT-39, "FRONT UNDER COVER : Removal and Installation".

2. Remove fender protector (RH). Refer to EXT-38, "

Removal and Installation".

3. Disconnect the harness connector from the front washer motor.

4. Remove front washer tube and rear wa sher tube from front washer motor.

5. Remove front washer motor from washer tank.

6. Remove front washer motor seal from washer tank.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not rotate or damage the front washer moto r seal when installing the front washer motor.

1. Washer tank cap 2. Washer tank 3. Front washer motor

A. Front washer motor seal B. Washer fluid level switch (if equipped) Front

ALLIA1317ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3624 of 3641

WASHER FLUID LEVEL SWITCHWW-59

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

WASHER FLUID LEVEL SWITCH

Removal and InstallationINFOID:0000000012433237

The washer fluid level switch is serviced as part of the washer tank. Refer to WW-56, "Removal and Installa-

tion".

Revision: August 2015 2016 Versa Note

cardiagn.com