display NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1601 of 3641

![NISSAN NOTE 2016 Service Repair Manual EC-474

< PERIODIC MAINTENANCE >[HR16DE]

EVAP LEAK CHECK

EVAP LEAK CHECK

InspectionINFOID:0000000012431671

CAUTION:

• Do not use compressed air

or a high pressure pump.

• Do not exceed 4.12 kPa (0 NISSAN NOTE 2016 Service Repair Manual EC-474

< PERIODIC MAINTENANCE >[HR16DE]

EVAP LEAK CHECK

EVAP LEAK CHECK

InspectionINFOID:0000000012431671

CAUTION:

• Do not use compressed air

or a high pressure pump.

• Do not exceed 4.12 kPa (0](/img/5/57363/w960_57363-1600.png)

EC-474

< PERIODIC MAINTENANCE >[HR16DE]

EVAP LEAK CHECK

EVAP LEAK CHECK

InspectionINFOID:0000000012431671

CAUTION:

• Do not use compressed air

or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm

2, 0.6 psi) of pressure in EVAP system.

NOTE:

• Do not start engine.

• Improper installation of EVAP service port adapter [commercial service tool: (J-41413-OBD)] to the EVAP

service port may cause a leak.

1.EVAP LEAK CHECK

With CONSULT

1. Install EVAP service port adapter [commercial service tool: (J- 41413-OBD)] and pressure pump to EVAP service port.

2. Turn ignition switch ON.

3. Select the “EVAP SYSTEM CLOSE” in “WORK SUPPORT”

mode of “ENGINE” using CONSULT.

4. Touch “START”. A bar graph (Pressure indicating display) will

appear on the screen.

5. Apply positive pressure to the EVAP system until the pressure indicator reaches the middle of the bar graph.

6. Remove EVAP service port adapter [commercial service tool: (J- 41413-OBD)] and hose with pressure pump.

7. Locate the leak using a leak detector [commercial service tool: (J-41416)]. Refer to EC-40, "

EVAPORATIVE EMISSION SYS-

TEM : System Description".

Without CONSULT

1. Install EVAP service port adapter [commercial service tool: (J- 41413-OBD)] and pressure pump to EVAP service port.

2. Apply battery voltage between the terminals of EVAP canister

vent control valve to make a closed EVAP system.

3. To locate the leak, deliver positive pressure to the EVAP system until pressure gauge points reach 1.38 to 2.76 kPa (0.014 to

0.028 kg/cm

2, 0.2 to 0.4 psi).

4. Remove EVAP service port adapter [commercial service tool: (J- 41413-OBD)] and hose with pressure pump.

SEF462UA

SEF200U

SEF462UA

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1664 of 3641

EXL-12

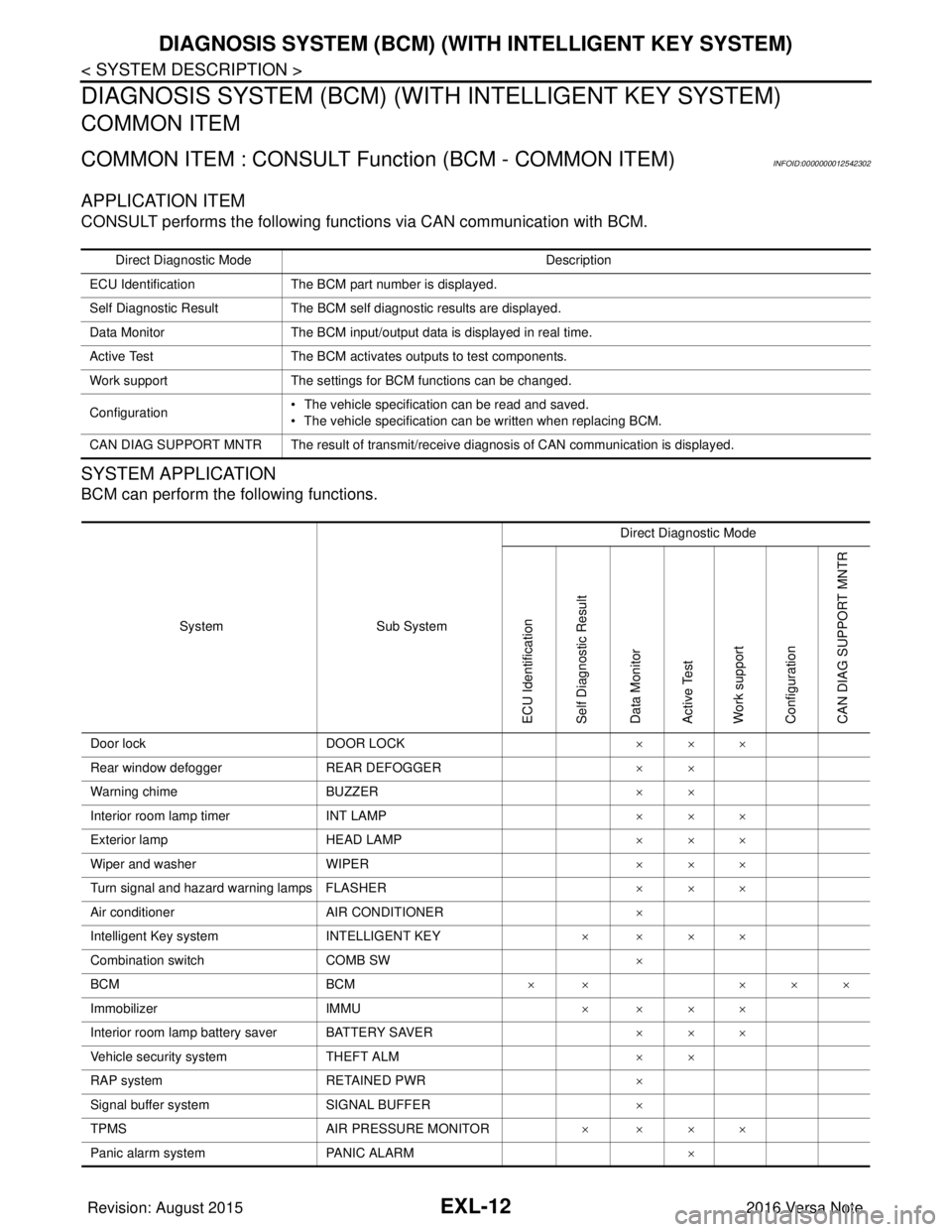

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM)INFOID:0000000012542302

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions.

Direct Diagnostic Mode Description

ECU Identification The BCM part number is displayed.

Self Diagnostic Result The BCM self diagnostic results are displayed.

Data Monitor The BCM input/output data is displayed in real time.

Active Test The BCM activates outputs to test components.

Work support The settings for BCM functions can be changed.

Configuration • The vehicle specification can be read and saved.

• The vehicle specification can be written when replacing BCM.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication is displayed.

System Sub System Direct Diagnostic Mode

ECU Identification

Self Diagnostic Result

Data Monitor

Active Test

Work support

Configuration

CAN DIAG SUPPORT MNTR

Door lock

DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

Air conditioner AIR CONDITIONER ×

Intelligent Key system INTELLIGENT KEY ××××

Combination switch COMB SW ×

BCM BCM× × ×××

Immobilizer IMMU ××××

Interior room lamp battery saver BATTERY SAVER ×××

Vehicle security system THEFT ALM ××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ×

TPMS AIR PRESSURE MONITOR ××××

Panic alarm system PANIC ALARM ×

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1668 of 3641

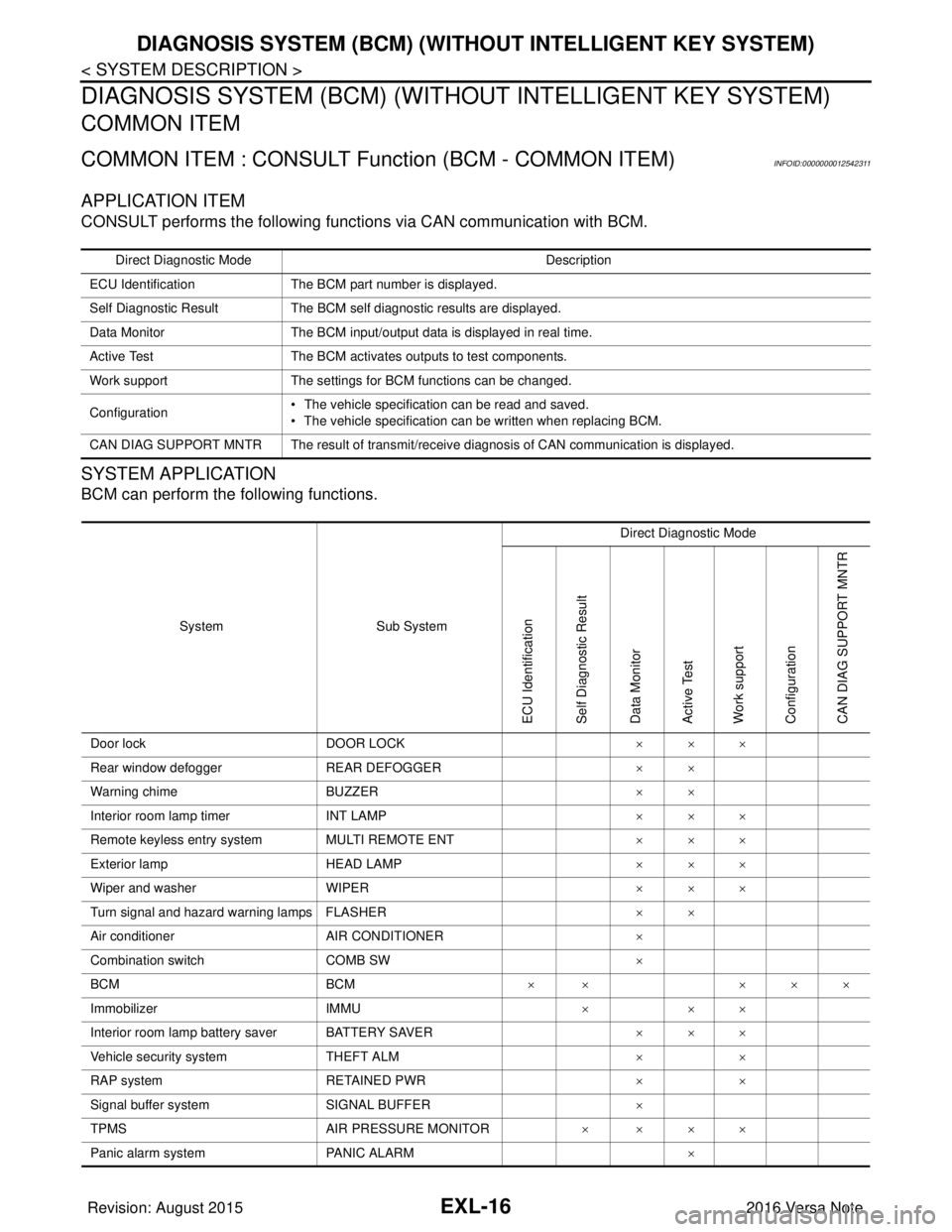

EXL-16

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM) (WITHOUT INTELLIGENT KEY SYSTEM)

DIAGNOSIS SYSTEM (BCM) (WITHOUT INTELLIGENT KEY SYSTEM)

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM)INFOID:0000000012542311

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions.

Direct Diagnostic Mode Description

ECU Identification The BCM part number is displayed.

Self Diagnostic Result The BCM self diagnostic results are displayed.

Data Monitor The BCM input/output data is displayed in real time.

Active Test The BCM activates outputs to test components.

Work support The settings for BCM functions can be changed.

Configuration • The vehicle specification can be read and saved.

• The vehicle specification can be written when replacing BCM.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication is displayed.

System Sub System Direct Diagnostic Mode

ECU Identification

Self Diagnostic Result

Data Monitor

Active Test

Work support

Configuration

CAN DIAG SUPPORT MNTR

Door lock

DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Remote keyless entry system MULTI REMOTE ENT ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ××

Air conditioner AIR CONDITIONER ×

Combination switch COMB SW ×

BCM BCM× × ×××

Immobilizer IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Vehicle security system THEFT ALM ××

RAP system RETAINED PWR ××

Signal buffer system SIGNAL BUFFER ×

TPMS AIR PRESSURE MONITOR ××××

Panic alarm system PANIC ALARM ×

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1673 of 3641

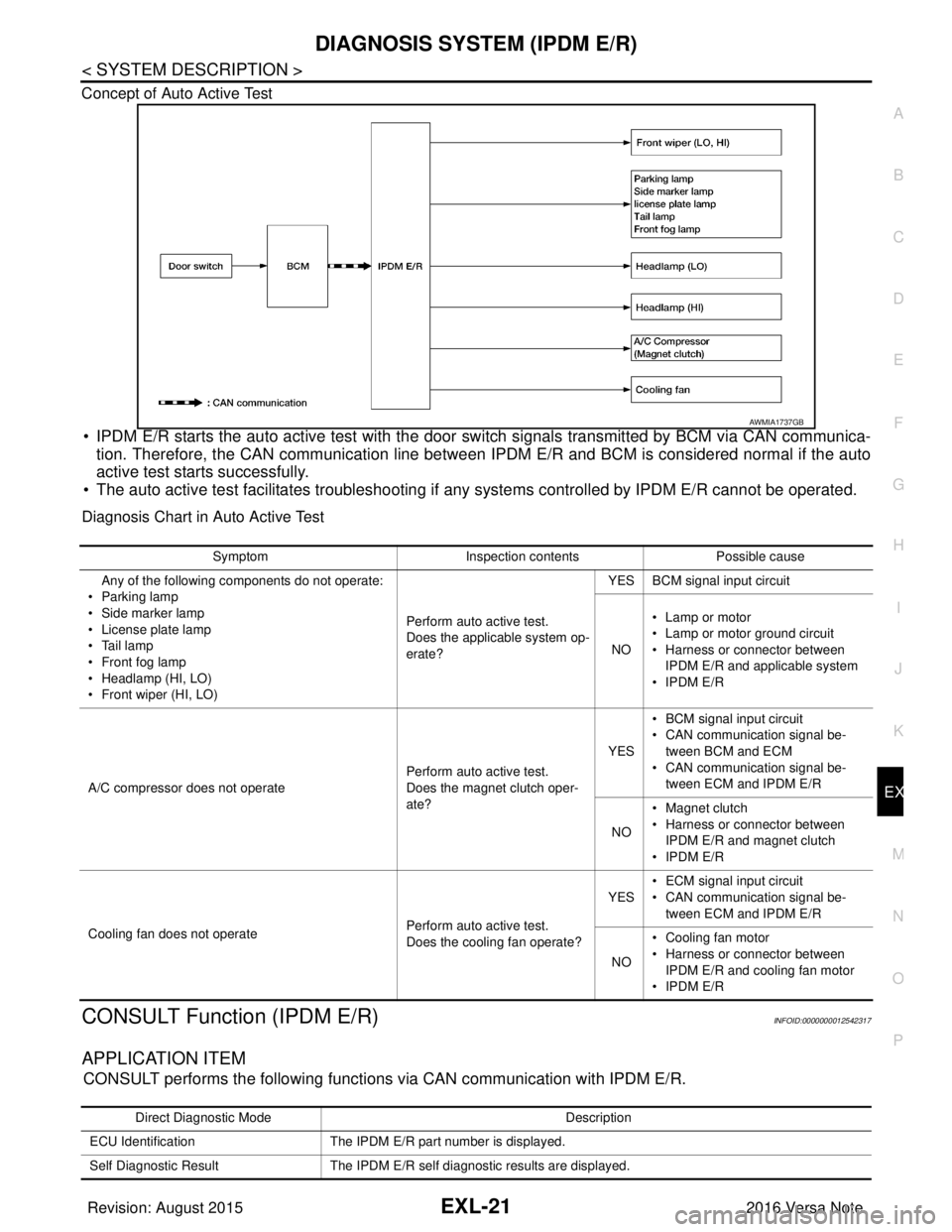

DIAGNOSIS SYSTEM (IPDM E/R)EXL-21

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

Concept of Auto Active Test

• IPDM E/R starts the auto active test with the door

switch signals transmitted by BCM via CAN communica-

tion. Therefore, the CAN communication line between IPDM E/R and BCM is considered normal if the auto

active test starts successfully.

• The auto active test facilitates troubleshooting if any systems controlled by IPDM E/R cannot be operated.

Diagnosis Chart in Auto Active Test

CONSULT Function (IPDM E/R)INFOID:0000000012542317

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with IPDM E/R.

AWMIA1737GB

SymptomInspection contentsPossible cause

Any of the following components do not operate:

•Parking lamp

• Side marker lamp

• License plate lamp

•Tail lamp

•Front fog lamp

• Headlamp (HI, LO)

• Front wiper (HI, LO) Perform auto active test.

Does the applicable system op-

erate?YES BCM signal input circuit

NO • Lamp or motor

• Lamp or motor ground circuit

• Harness or connector between

IPDM E/R and applicable system

•IPDM E/R

A/C compressor does not operate Perform auto active test.

Does the magnet clutch oper-

ate?YES

• BCM signal input circuit

• CAN communication signal be-

tween BCM and ECM

• CAN communication signal be-

tween ECM and IPDM E/R

NO • Magnet clutch

• Harness or connector between

IPDM E/R and magnet clutch

•IPDM E/R

Cooling fan does not operate Perform auto active test.

Does the cooling fan operate?YES

• ECM signal input circuit

• CAN communication signal be-

tween ECM and IPDM E/R

NO • Cooling fan motor

• Harness or connector between

IPDM E/R and cooling fan motor

•IPDM E/R

Direct Diagnostic Mode Description

ECU Identification The IPDM E/R part number is displayed.

Self Diagnostic Result The IPDM E/R self diagnostic results are displayed.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1674 of 3641

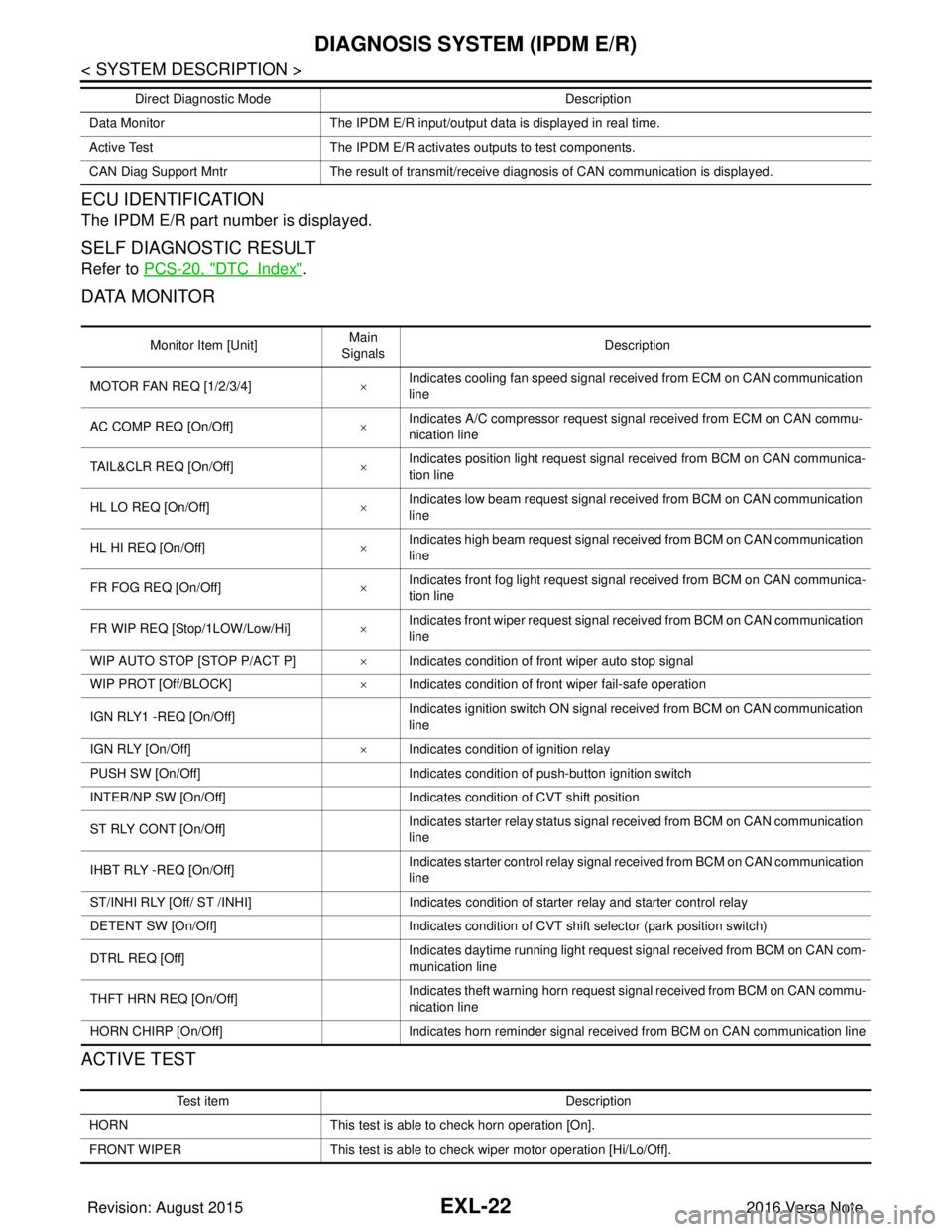

EXL-22

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (IPDM E/R)

ECU IDENTIFICATION

The IPDM E/R part number is displayed.

SELF DIAGNOSTIC RESULT

Refer to PCS-20, "DTCIndex".

DATA MONITOR

ACTIVE TEST

Data Monitor The IPDM E/R input/output data is displayed in real time.

Active Test The IPDM E/R activates outputs to test components.

CAN Diag Support Mntr The result of transmit/receive diagnosis of CAN communication is displayed.

Direct Diagnostic Mode

Description

Monitor Item [Unit]Main

Signals Description

MOTOR FAN REQ [1/2/3/4] ×Indicates cooling fan speed signal received from ECM on CAN communication

line

AC COMP REQ [On/Off] ×Indicates A/C compressor request signal received from ECM on CAN commu-

nication line

TAIL&CLR REQ [On/Off] ×Indicates position light request signal received from BCM on CAN communica-

tion line

HL LO REQ [On/Off] ×Indicates low beam request signal received from BCM on CAN communication

line

HL HI REQ [On/Off] ×Indicates high beam request signal received from BCM on CAN communication

line

FR FOG REQ [On/Off] ×Indicates front fog light request signal received from BCM on CAN communica-

tion line

FR WIP REQ [Stop/1LOW/Low/Hi] ×Indicates front wiper request signal received from BCM on CAN communication

line

WIP AUTO STOP [STOP P/ACT P] ×Indicates condition of front wiper auto stop signal

WIP PROT [Off/BLOCK] ×Indicates condition of front wiper fail-safe operation

IGN RLY1 -REQ [On/Off] Indicates ignition switch ON signal received from BCM on CAN communication

line

IGN RLY [On/Off] ×Indicates condition of ignition relay

PUSH SW [On/Off] Indicates condition of push-button ignition switch

INTER/NP SW [On/Off] Indicates condition of CVT shift position

ST RLY CONT [On/Off] Indicates starter relay status signal received from BCM on CAN communication

line

IHBT RLY -REQ [On/Off] Indicates starter control relay signal received from BCM on CAN communication

line

ST/INHI RLY [Off/ ST /INHI] Indicates condition of starter relay and starter control relay

DETENT SW [On/Off] Indicates condition of CVT shift selector (park position switch)

DTRL REQ [Off] Indicates daytime running light request signal received from BCM on CAN com-

munication line

THFT HRN REQ [On/Off] Indicates theft warning horn request signal received from BCM on CAN commu-

nication line

HORN CHIRP [On/Off] Indicates horn reminder signal received from BCM on CAN communication line

Te s t i t e m D e s c r i p t i o n

HORN This test is able to check horn operation [On].

FRONT WIPER This test is able to check wiper motor operation [Hi/Lo/Off].

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1852 of 3641

WHEEL ALIGNMENTFSU-7

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

WHEEL ALIGNMENT

InspectionINFOID:0000000012430301

PRELIMINARY INSPECTION

WARNING:

Always adjust the wheel alignment with the vehicle on a flat surface.

NOTE:

If the wheel alignment is out of s pecification, inspect and replace any damaged or worn rear suspension parts

before making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, engine coolant, and lubricants are full; the spare tire, jack, hand tools and mats are in

designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to WT-54, "

Wheel".

4. Check the wheel bearing axial end play. Refer to FAX-27, "

Wheel Bearing".

5. Check the shock absorbers for leaks or damage.

6. Check each mount point of the suspension co mponents for any excessive looseness or damage.

7. Check each link, arm, and the suspension member for any damage.

8. Check the vehicle height. Refer to FSU-21, "

Wheelarch Height (Unladen*)".

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is recomm ended for any NISSAN/INFINITI vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be capabl e of accepting any NISSAN/INFINITI vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific a lignment machine for their recommended Service/Cali-

bration Schedule.

ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to FSU-20, "Wheel

Alignment (Unladen*1)".

• When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

- The alignment specifications programmed into your alignment machine that operate these indicators may

not be correct.

- This may result in an ERROR.

• Most camera-type alignment machines are equipped with "Rolling Compensation" method and optional

"Jacking Compensation" method to "compensate" the alignment targets or head units.

"Rolling Compensation" is the preferred method.

- If using the "Rolling Compensation" method, after inst alling the alignment targets or head units, push or pull

on the rear wheel to move the vehicle. Do not push or pull on the vehicle body.

- If using the "Jacking Compensation" method, after inst alling the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn in either direction.

NOTE:

Do not use the "Rolling Compensation" method if you are using sensor-type alignment equipment.

• Follow all instructions for the alignment machine you're using for more information.

CAMBER, CASTER AND KINGPIN INCLINATION ANGLES INSPECTION

• Camber, caster, kingpin inclination angles cannot be adjusted.

• Before inspection, set the front wheels onto a turning radius gauge. Set the rear wheels onto a pad that has

the same height so the vehicle will remain horizontal.

TOTAL TOE-IN INSPECTION

Measure the total toe-in using the following procedure.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1904 of 3641

GI-16

< HOW TO USE THIS MANUAL >

ABBREVIATIONS

I

K

L

M

N

HOCHeated oxidation catalyst

HPCM Hybrid power train control module

ABBREVIATION DESCRIPTION

I/M Inspection and maintenance

IA Intake air

IAC Idle air control

IAT Intake air temperature

IBA Intelligent brake assist

IC Ignition control

ICC Intelligent cruise control

ICM Ignition control module

IPDM E/R Intelligent power distribution module engine room ISC Idle speed control

ISS Input shaft speed

ITS Information technology suite

ABBREVIATION DESCRIPTION

KS Knock sensor

ABBREVIATION DESCRIPTION

LBC Li-ion battery controller

LCD Liquid crystal display

LCU Local control unit

LDP Lane departure prevention

LDW Lane departure warning

LED Light emitting diode

LH Left-hand

LHD Left-hand drive

LIN Local interconnect network

ABBREVIATION DESCRIPTION

M/T Manual transaxle/transmission

MAF Mass airflow

MAP Manifold absolute pressure

MDU Multi display unit

MI Malfunction indicator

MIL Malfunction indicator lamp

MOD Moving object detection

ABBREVIATION DESCRIPTION

NOX Nitrogen oxides

ABBREVIATION

DESCRIPTION

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1938 of 3641

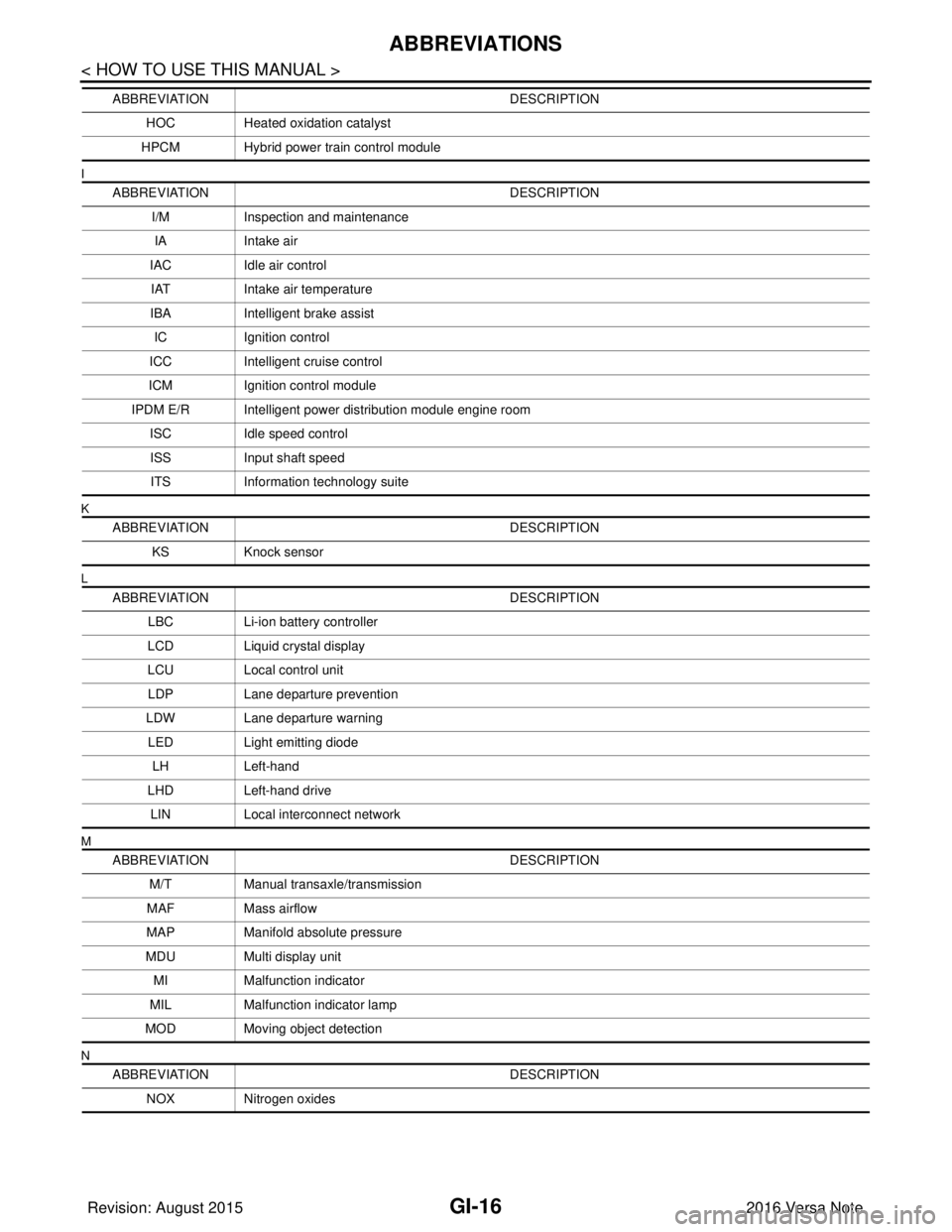

GI-50

< BASIC INSPECTION >

CONSULT/GST CHECKING SYSTEM

CONSULT/GST CHECKING SYSTEM

DescriptionINFOID:0000000012433188

NOTE:

This vehicle is diagnosed using the CONSULT-III plus.

• When CONSULT is connected with a data link connector equippedon the vehicle side, it will communicate with the control unit

equipped in the vehicle and then enable various kinds of diagnos-

tic tests.

• Refer to “CONSULT-III plus Operation Manual” for more informa- tion.

Function and System ApplicationINFOID:0000000012433189

x: Applicable

1: With continuously variable transmission 1 : Hood release handle

2 : Data link connector

ALAIA0095ZZ

Diagnosis (All Systems)

Description

ENGINE

ABS

METER/M&A BCM

AIR BAG

TRANSMISSION

1

EPS/DAST 3 IPDM E/R AV M

MULTI AV

OCCUPANT DETECTION

Self Diagnostic Result The ECU self diagnostic results are displayed. x x x x x x x x x x -

Data Monitor The ECU input/output data is displayed in real

time. xxxxxxxxxx -

Work support The settings for ECU functions can be changed. x x x x - x - - x - x

Active Test The ECU activates outputs to test components. x x - x - - - x - - -

ECU identification The ECU part number is displayed. xxxxxxxxxx -

DTC Work Support The status of system monitoring tests and the

self diagnosis status/results can be confirmed. x----------

Warning History Displays the history of the combination meter

warning lamp indicators.

--x--------

TROUBLE DIAG RECORD Self diagnostic history and trouble diagnosis

records in ECU are displayed. ----x------

CAN Diag This mode displays network diagnostic results of

CAN communication using a diagram. xxxxxxxxxx -

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN

communication is displayed.

xxxxxxxxxx -

Configuration • The vehicle specification can be read and

saved.

• The vehicle specification can be written when

replacing ECU. ---x----xx-

CALIB DATA The calibration values of the ECU are displayed. - - - - - x - - - - -

SRT & P-DTC Confirmation The status of system monitoring tests and the

self diagnosis status/results can be confirmed. x----------

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1975 of 3641

![NISSAN NOTE 2016 Service Repair Manual PRECAUTIONSHAC-7

< PRECAUTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threa NISSAN NOTE 2016 Service Repair Manual PRECAUTIONSHAC-7

< PRECAUTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threa](/img/5/57363/w960_57363-1974.png)

PRECAUTIONSHAC-7

< PRECAUTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified oils.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe) . All hoses must be equipped with

positive shut-off devices (either manual or automatic) near the end of

the hoses opposite to the manifold gauge.

SERVICE COUPLERS

Do not attempt to connect HFC-134a (R-134a) service couplers to

the CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers

do not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied oils have been used with the scale. The hose fitting must be 1/

2 ″-16 ACME if the scale controls refrigerant flow electronically.

CHARGING CYLINDER

Using a charging cylinder is not re commended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accura cy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

SHA533D

RHA272D

Shut-off valve rotati on A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1985 of 3641

![NISSAN NOTE 2016 Service Repair Manual DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

HAC-17

< SYSTEM DESCRIPTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

DIAGNOSIS SYSTEM (BCM) (WIT H INTELLIGENT KEY SYSTEM)

COM NISSAN NOTE 2016 Service Repair Manual DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

HAC-17

< SYSTEM DESCRIPTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

DIAGNOSIS SYSTEM (BCM) (WIT H INTELLIGENT KEY SYSTEM)

COM](/img/5/57363/w960_57363-1984.png)

DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

HAC-17

< SYSTEM DESCRIPTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

DIAGNOSIS SYSTEM (BCM) (WIT H INTELLIGENT KEY SYSTEM)

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM)INFOID:0000000012542299

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions.

Direct Diagnostic Mode Description

ECU Identification The BCM part number is displayed.

Self Diagnostic Result The BCM self diagnostic results are displayed.

Data Monitor The BCM input/output data is displayed in real time.

Active Test The BCM activates outputs to test components.

Work support The settings for BCM functions can be changed.

Configuration • The vehicle specification can be read and saved.

• The vehicle specification can be written when replacing BCM.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication is displayed.

System Sub System Direct Diagnostic Mode

ECU Identification

Self Diagnostic Result

Data Monitor

Active Test

Work support

Configuration

CAN DIAG SUPPORT MNTR

Door lock

DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

Air conditioner AIR CONDITIONER ×

Intelligent Key system INTELLIGENT KEY ××××

Combination switch COMB SW ×

BCM BCM× × ×××

Immobilizer IMMU ××××

Interior room lamp battery saver BATTERY SAVER ×××

Vehicle security system THEFT ALM ××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ×

TPMS AIR PRESSURE MONITOR ××××

Panic alarm system PANIC ALARM ×

Revision: August 2015 2016 Versa Note

cardiagn.com