cvt NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 3500 of 3641

![NISSAN NOTE 2016 Service Repair Manual TRANSMISSION ASSEMBLYTM-259

< UNIT REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

UNIT REMOVAL AND INSTALLATION

TRANSMISSION ASSEMBLY

Exploded ViewINFOID:0000000012431223

Re NISSAN NOTE 2016 Service Repair Manual TRANSMISSION ASSEMBLYTM-259

< UNIT REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

UNIT REMOVAL AND INSTALLATION

TRANSMISSION ASSEMBLY

Exploded ViewINFOID:0000000012431223

Re](/img/5/57363/w960_57363-3499.png)

TRANSMISSION ASSEMBLYTM-259

< UNIT REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

UNIT REMOVAL AND INSTALLATION

TRANSMISSION ASSEMBLY

Exploded ViewINFOID:0000000012431223

Removal and InstallationINFOID:0000000012431224

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

CAUTION:

• Perform these steps after the coolant temperature has cooled sufficiently.

• When replacing the transaxle, perform "ADDI TIONAL SERVICE WHEN REPLACING TRANSAXLE

ASSEMBLY". Refer to TM-127, "

Description".

NOTE:

When removing components such as hoses, tubes/line, etc. , cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Remove the engine and transaxle assembly. Refer to EM-87, "Removal and Installation".

2. Disconnect the harness connectors and harnesses. • For CVT unit harness connector.

• Transmission position switch harness connector

1. Transaxle assembly

A : For the tightening torque, refer to TM-259, "

Removal and Installation".

JSDIA1890ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3501 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-260

< UNIT REMOVAL AND INSTALLATION >[CVT: RE0F11A]

TRANSMISSION ASSEMBLY

• Primary speed sensor harness connector

• Secondary speed sensor harness connector

• Output speed sensor harness con NISSAN NOTE 2016 Service Repair Manual TM-260

< UNIT REMOVAL AND INSTALLATION >[CVT: RE0F11A]

TRANSMISSION ASSEMBLY

• Primary speed sensor harness connector

• Secondary speed sensor harness connector

• Output speed sensor harness con](/img/5/57363/w960_57363-3500.png)

TM-260

< UNIT REMOVAL AND INSTALLATION >[CVT: RE0F11A]

TRANSMISSION ASSEMBLY

• Primary speed sensor harness connector

• Secondary speed sensor harness connector

• Output speed sensor harness connector

• Ground

3. Rotate the crankshaft and remove the nuts that secure the drive plate to the torque converter from the sta- tor motor mount.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from the front of the engine.

4. Remove the bolts (engine to transaxle) that fasten the transaxle assembly and engine assembly.

5. Remove transaxle assembly from engine. CAUTION:

• Secure torque converter to prevent it from dropping.

• Secure transaxle assembly to a suitable jack.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-rings.

• Apply Genuine NISSAN CVT Fluid NS-3 to the O-rings.

• When installing the transaxle assembly onto the engine assembly,

check the engagement of the dowel pins ( ).

• When using suitable tool (A) for alignment, install it to the align- ment stud bolt used to align the torque converter to the drive plate.

JSDIA1839ZZ

Bolt position ABC D

Direction of insertion Transaxle assembly

⇒

Engine assembly Engine assembly

⇒ Transaxle assembly

Q ua ntit y 2213

JSDIA1184ZZ

JPDIA0683ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3502 of 3641

![NISSAN NOTE 2016 Service Repair Manual TRANSMISSION ASSEMBLYTM-261

< UNIT REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

• Rotate the crankshaft so that the alignment hole (A) of drive plate aligns with the pos NISSAN NOTE 2016 Service Repair Manual TRANSMISSION ASSEMBLYTM-261

< UNIT REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

• Rotate the crankshaft so that the alignment hole (A) of drive plate aligns with the pos](/img/5/57363/w960_57363-3501.png)

TRANSMISSION ASSEMBLYTM-261

< UNIT REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

• Rotate the crankshaft so that the alignment hole (A) of drive plate aligns with the position of the torque converter alignment stud bolt.

CAUTION:

• Rotate the crankshaft clockwise (as viewed from the front of

the engine).

• Be careful that torque converter stud bolts are aligned to the

drive plate holes. Otherwise the stud bolts contact the drive

plate.

• Insert the alignment stud bolt of torque converter into the align-

ment hole of the drive plate, ali gning the drive plate holes with the

torque converter stud bolts.

CAUTION:

Be careful not to strike the drive plate with the torque converter stud bolts.

• When installing the torque converter nuts, temporarily tighten the nuts. Then, after installing the engine and transaxle assembly bolts tighten the nuts to the specified torque.

CAUTION:

• Rotate the crankshaft clockwise (as vi ewed from the front of the engine).

• Check the tightening torque for the crankshaft pulley bolts after th e bolts fastening the drive plate

and torque converter have been tightened an d the crankshaft pulley bolts have been secured.

Refer to EM-51, "

Removal and Installation".

• Install the transaxle assembly and engine assembly bolts accord- ing to the following standards.

Inspection and AdjustmentINFOID:0000000012431225

INSPECTION BEFORE INSTALLATION

Check the distance (A) between the converter housing and torque

converter. Tightening torque : 51 N·m (5.2 kg-m, 38 ft-lb)

JPDIA0684ZZ

JSDIA1839ZZ

Bolt position

ABC D

Direction of insertion Transaxle assembly

⇒

Engine assembly Engine assembly

⇒ Transaxle assembly

Q uan tit y 2213

Nominal length [mm (in)] 40 (1.57) 44 (1.73)69 (2.72) 49 (1.93)

Tightening torque

N·m (kg-m, ft-lb) 48.0 (4.9, 35)

(B)

: Scale

(C) : Straightedge

Dimension (A) : TM-265, "Torque Converter"

JSDIA1840ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3503 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-262

< UNIT REMOVAL AND INSTALLATION >[CVT: RE0F11A]

TRANSMISSION ASSEMBLY

INSPECTION AFTER INSTALLATION

Check the following items:

• For CVT position, refer to

TM-232, "

Inspection".

• Before NISSAN NOTE 2016 Service Repair Manual TM-262

< UNIT REMOVAL AND INSTALLATION >[CVT: RE0F11A]

TRANSMISSION ASSEMBLY

INSPECTION AFTER INSTALLATION

Check the following items:

• For CVT position, refer to

TM-232, "

Inspection".

• Before](/img/5/57363/w960_57363-3502.png)

TM-262

< UNIT REMOVAL AND INSTALLATION >[CVT: RE0F11A]

TRANSMISSION ASSEMBLY

INSPECTION AFTER INSTALLATION

Check the following items:

• For CVT position, refer to

TM-232, "

Inspection".

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

• Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

ADJUSTMENT AFTER INSTALLATION

• Adjust the CVT fluid level. TM-229, "Adjustment".

• Perform "ADDITIONAL SERVICE WHEN REPL ACING TRANSAXLE ASSEMBLY". Refer to TM-127,

"Description".

ItemBefore starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakageLeakage

Exhaust gas —Leakage —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3504 of 3641

![NISSAN NOTE 2016 Service Repair Manual TORQUE CONVERTER AND CONVERTER HOUSING OIL SEALTM-263

< UNIT DISASSEMBLY AND ASSEMBLY > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

UNIT DISASSEMBLY AND ASSEMBLY

TORQUE CONVERTER AND CO NVERTER HOU NISSAN NOTE 2016 Service Repair Manual TORQUE CONVERTER AND CONVERTER HOUSING OIL SEALTM-263

< UNIT DISASSEMBLY AND ASSEMBLY > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

UNIT DISASSEMBLY AND ASSEMBLY

TORQUE CONVERTER AND CO NVERTER HOU](/img/5/57363/w960_57363-3503.png)

TORQUE CONVERTER AND CONVERTER HOUSING OIL SEALTM-263

< UNIT DISASSEMBLY AND ASSEMBLY > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

UNIT DISASSEMBLY AND ASSEMBLY

TORQUE CONVERTER AND CO NVERTER HOUSING OIL SEAL

Exploded ViewINFOID:0000000012431226

DisassemblyINFOID:0000000012431227

1. Remove transaxle assembly. Refer to TM-259, "Removal and Installation".

2. Remove torque converter. CAUTION:

Never damage the bushing on the inside of to rque converter sleeve when removing torque con-

verter.

3. Remove converter housing oil seal using an oil seal remover (commercial service tool). CAUTION:

Be careful not to scratch converter housing.

AssemblyINFOID:0000000012431228

Note the followings and install in the reverse order of removal.

CAUTION:

• Never reuse converter housing oil seal.

• Apply CVT fluid to converter housing oil seal.

• Drive converter housing oil seal evenly using a drift (commercial

service tool) so that converter housing oil seal protrudes by the

dimension (A) respectively.

NOTE:

Converter housing oil seal pulling direction is used as the refer-

ence.

1. Torque converter 2. Converter housing oil seal3. Transaxle assembly

: Always replace after every disassembly.

: Genuine NISSAN CVT Fluid NS-3

JPDIA0837ZZ

Dimension (A) : 1.3 ±0.5 mm (0.051 ±0.02 in)

JPDIA0839ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3505 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-264

< UNIT DISASSEMBLY AND ASSEMBLY >[CVT: RE0F11A]

TORQUE CONVERTER AND CONVERTER HOUSING OIL SEAL

• Attach the pawl (A) of the torque converter to the drive sprocket

hole (B) on the transaxle a NISSAN NOTE 2016 Service Repair Manual TM-264

< UNIT DISASSEMBLY AND ASSEMBLY >[CVT: RE0F11A]

TORQUE CONVERTER AND CONVERTER HOUSING OIL SEAL

• Attach the pawl (A) of the torque converter to the drive sprocket

hole (B) on the transaxle a](/img/5/57363/w960_57363-3504.png)

TM-264

< UNIT DISASSEMBLY AND ASSEMBLY >[CVT: RE0F11A]

TORQUE CONVERTER AND CONVERTER HOUSING OIL SEAL

• Attach the pawl (A) of the torque converter to the drive sprocket

hole (B) on the transaxle assembly side.

CAUTION:

• Rotate the torque converter fo r installing torque converter.

• Never damage the bushing inside the torque converter sleeve when installing the converter housing oil seal.

InspectionINFOID:0000000012431229

INSPECTION BEFORE INSTALLATION

After inserting a torque converter to the CVT, check dimension (A)

with in the reference value limit.

SCIA7907J

B: Scale

C : Straightedge

Dimension (A) : Refer to TM-265, "Torque Converter".

JSDIA4115ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3506 of 3641

![NISSAN NOTE 2016 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)TM-265

< SERVICE DATA AND SPECIFICATIONS (SDS) [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATION NISSAN NOTE 2016 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)TM-265

< SERVICE DATA AND SPECIFICATIONS (SDS) [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATION](/img/5/57363/w960_57363-3505.png)

SERVICE DATA AND SPECIFICATIONS (SDS)TM-265

< SERVICE DATA AND SPECIFICATIONS (SDS) [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000012431230

Shift CharacteristicsINFOID:0000000012431231

Unit: rpm

CAUTION:

Lock-up is engaged at the vehicle speed of approximately 10 km/h (11 MPH) to 90 km/h (56 MPH).

Stall SpeedINFOID:0000000012431232

Unit: rpm

Line PressureINFOID:0000000012431233

Unit: MPa (bar, kg/cm2, psi)

Torque ConverterINFOID:0000000012431234

Applied model Engine HR16DE

Axle

2WD

Transaxle model RE0F11A

Stall torque ratio 1.91 : 1

Pulley ratio Forward

2.200 – 0.550

Reverse 2.200

Auxiliary gearbox gear ratio 1GR

1.821

2GR 1.000

Reverse 1.714

Counter gear 0.967

Final drive 3.882

Recommended fluid Refer to MA-11, "

Fluids and Lubricants".

Fluid capacity

Throttle position Shift pattern Engine speed

At 40 km/h (25 MPH) At 60 km/h (37 MPH)

2/8 “D” position (Overdrive control OFF)

1,300 – 3,1001,400 – 3,400

“D” position (Overdrive control ON) 2,200 – 3,1002,700 – 3,500

“L” position 3,000 – 3,8003,500 – 4,300

8/8 “D” position (Overdrive control OFF)

3,600 – 4,4004,300 – 5,100

“D” position (Overdrive control ON) 3,600 – 4,4004,300 – 5,100

“L” position 3,600 – 4,4004,300 – 5,100

Stall speed 2,420 – 2,870

Shift selector positionEngine speed Line pressure

“P” and “N” At idle 0.40 (4, 4.1, 58)

“R” and “D” At idle

0.40 (4, 4.1, 58) – 1.39 (13.9, 14.2, 201.6)

At stall 4.20 (42, 42.8, 609) – 4.70 (47, 47.9, 681.5)

Distance (A) between the converter housing and torque converter 16.2 mm

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3528 of 3641

WCS

DIAGNOSIS SYSTEM (COMBINATION METER)WCS-13

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

DIAGNOSIS SYSTEM (C OMBINATION METER)

TYPE A

TYPE A : On Board Diagnosis FunctionINFOID:0000000012542982

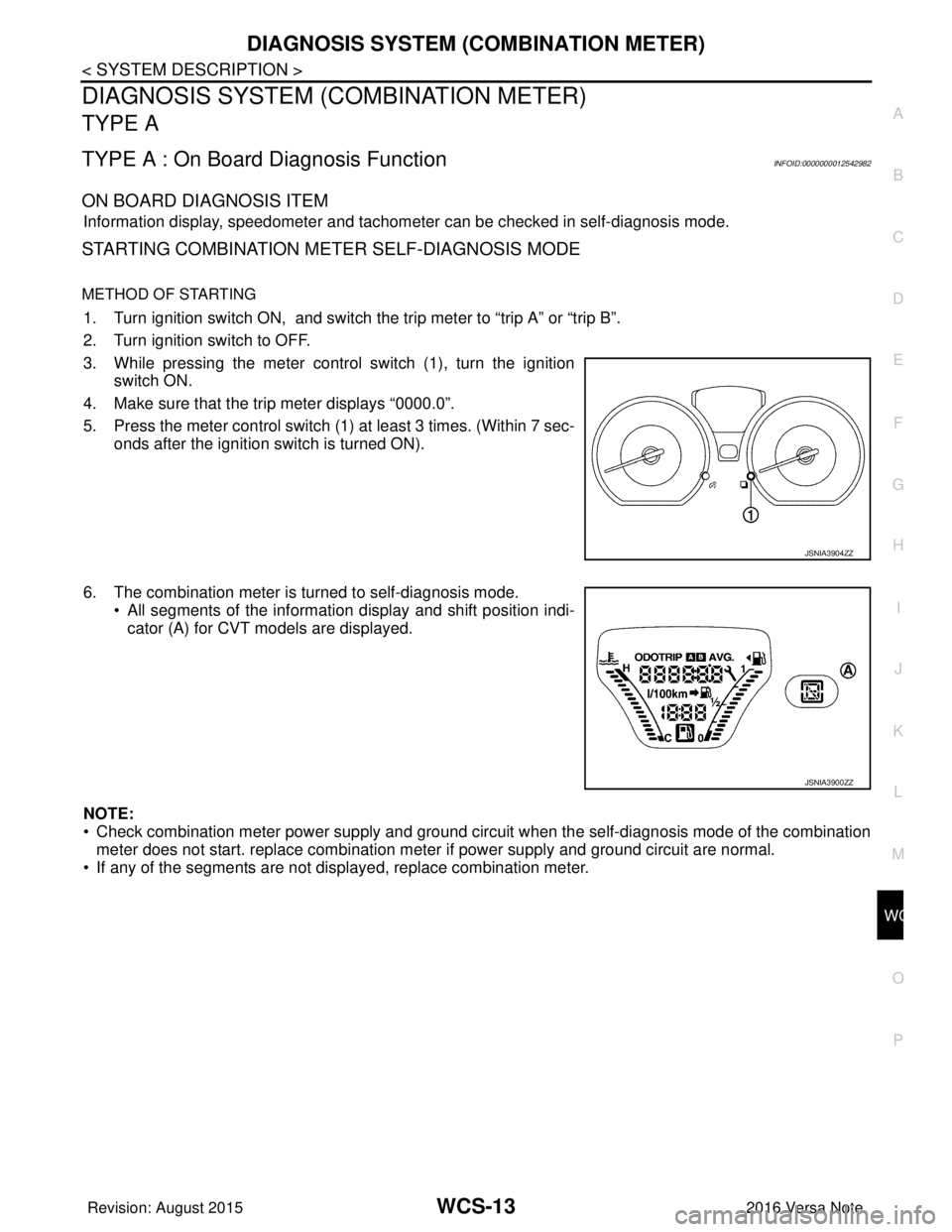

ON BOARD DIAGNOSIS ITEM

Information display, speedometer and tachometer can be checked in self-diagnosis mode.

STARTING COMBINATION ME TER SELF-DIAGNOSIS MODE

METHOD OF STARTING

1. Turn ignition switch ON, and switch the trip meter to “trip A” or “trip B”.

2. Turn ignition switch to OFF.

3. While pressing the meter control switch (1), turn the ignition

switch ON.

4. Make sure that the trip meter displays “0000.0”.

5. Press the meter control switch (1) at least 3 times. (Within 7 sec- onds after the ignition switch is turned ON).

6. The combination meter is turned to self-diagnosis mode. • All segments of the information display and shift position indi-cator (A) for CVT models are displayed.

NOTE:

• Check combination meter power supply and ground circui t when the self-diagnosis mode of the combination

meter does not start. replace combination meter if power supply and ground circuit are normal.

• If any of the segments are not disp layed, replace combination meter.

JSNIA3904ZZ

JSNIA3900ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3584 of 3641

DIAGNOSIS SYSTEM (IPDM E/R)WW-19

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

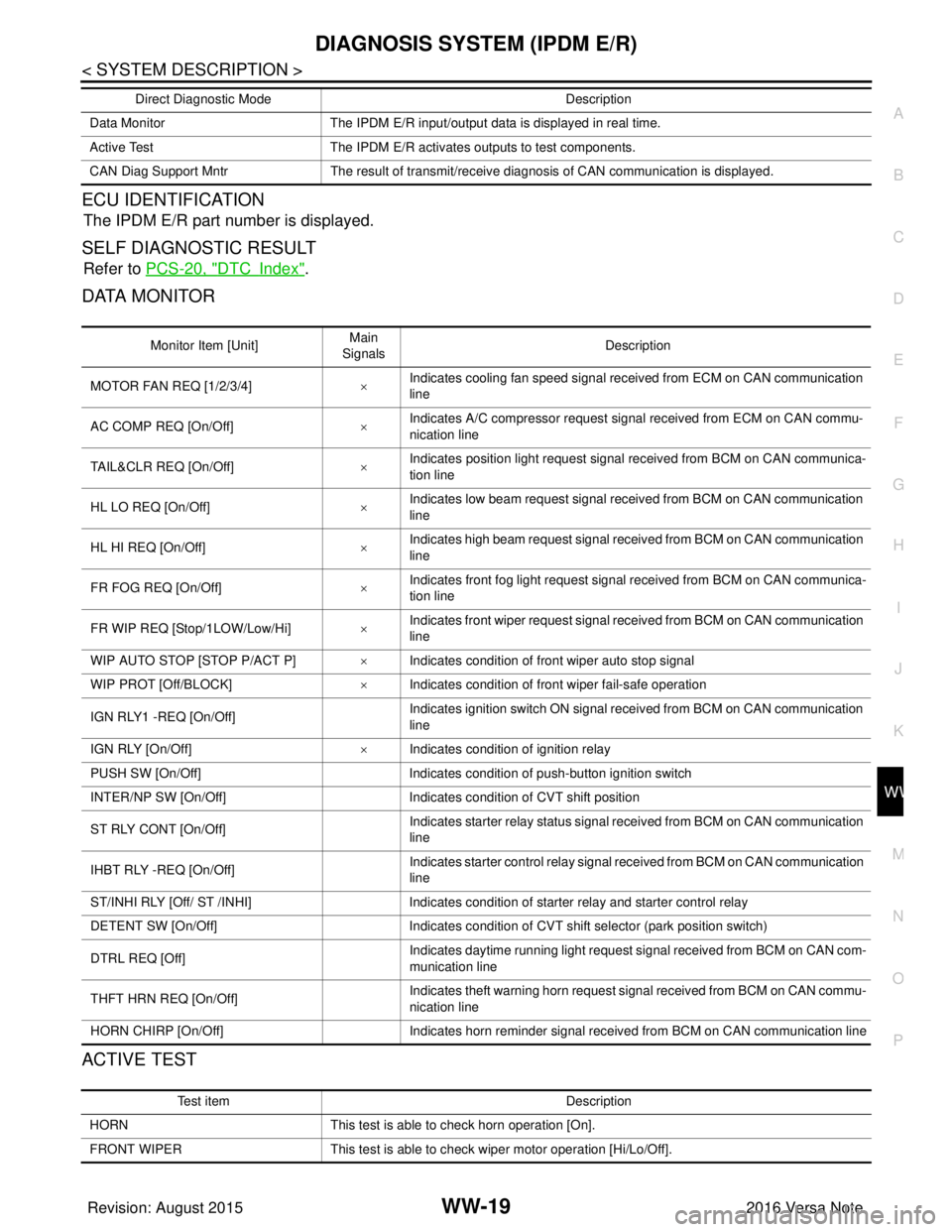

ECU IDENTIFICATION

The IPDM E/R part number is displayed.

SELF DIAGNOSTIC RESULT

Refer to PCS-20, "DTCIndex".

DATA MONITOR

ACTIVE TEST

Data Monitor The IPDM E/R input/output data is displayed in real time.

Active Test The IPDM E/R activates outputs to test components.

CAN Diag Support Mntr The result of transmit/receive diagnosis of CAN communication is displayed.

Direct Diagnostic Mode

Description

Monitor Item [Unit]Main

Signals Description

MOTOR FAN REQ [1/2/3/4] ×Indicates cooling fan speed signal received from ECM on CAN communication

line

AC COMP REQ [On/Off] ×Indicates A/C compressor request signal received from ECM on CAN commu-

nication line

TAIL&CLR REQ [On/Off] ×Indicates position light request signal

received from BCM on CAN communica-

tion line

HL LO REQ [On/Off] ×Indicates low beam request signal received from BCM on CAN communication

line

HL HI REQ [On/Off] ×Indicates high beam request signal received from BCM on CAN communication

line

FR FOG REQ [On/Off] ×Indicates front fog light request signal received from BCM on CAN communica-

tion line

FR WIP REQ [Stop/1LOW/Low/Hi] ×Indicates front wiper request signal received from BCM on CAN communication

line

WIP AUTO STOP [STOP P/ACT P] ×Indicates condition of front wiper auto stop signal

WIP PROT [Off/BLOCK] ×Indicates condition of front wiper fail-safe operation

IGN RLY1 -REQ [On/Off] Indicates ignition switch ON signal received from BCM on CAN communication

line

IGN RLY [On/Off] ×Indicates condition of ignition relay

PUSH SW [On/Off] Indicates condition of push-button ignition switch

INTER/NP SW [On/Off] Indicates condition of CVT shift position

ST RLY CONT [On/Off] Indicates starter relay status signal received from BCM on CAN communication

line

IHBT RLY -REQ [On/Off] Indicates starter control relay signal received from BCM on CAN communication

line

ST/INHI RLY [Off/ ST /INHI] Indicates condition of starter relay and starter control relay

DETENT SW [On/Off] Indicates condition of CVT shift selector (park position switch)

DTRL REQ [Off] Indicates daytime running light request signal received from BCM on CAN com-

munication line

THFT HRN REQ [On/Off] Indicates theft warning horn request signal received from BCM on CAN commu-

nication line

HORN CHIRP [On/Off] Indicates horn reminder signal received from BCM on CAN communication line

Test item Description

HORN This test is able to check horn operation [On].

FRONT WIPER This test is able to check wiper motor operation [Hi/Lo/Off].

Revision: August 2015 2016 Versa Note

cardiagn.com