coolant level NISSAN NOTE 2016 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1752 of 3641

EXL-100

< PERIODIC MAINTENANCE >

FRONT FOG LAMP AIMING ADJUSTMENT

FRONT FOG LAMP AIMING ADJUSTMENT

InspectionINFOID:0000000012432830

PREPARATION BEFORE ADJUSTING

Before performing aiming adjustment procedure, check the following:

• Ensure all tires are inflated to correct pressure.

• Place vehicle and screen on level surface.

• Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position).

• Coolant and engine oil filled to correct level, and fuel tank full.

• Remove cargo and/or luggage to maintain an unloaded vehicle condition.

• Confirm spare tire, jack and tools are properly stowed.

• Carefully wipe off any dirt from fog lamp lens. CAUTION:

Do not use organic solvent (thinner, gasoline etc.)

• Place a driver or equivalent weight of 68.5 kg (150 lb) on the driver seat.

• By hand, bounce the front and rear of the vehicle to settle the suspension and eliminate any static load.

• Place the front tires in the straight ahead position.

• Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

NOTE:

• For headlamp aiming details, refer to regulations in your area.

• By regulation, no means for horizontal aim adjustment is provided from the factory; only vertical aim is

adjustable.

• Use adjusting screw to perform aiming adjustment.

• Perform headlamp aiming if:

- The vehicle front body has been repaired.

- The front combination lamp has been removed or replaced.

- Any outfitting has been installed.

- The vehicle’s standard load condition has been substantially increased.

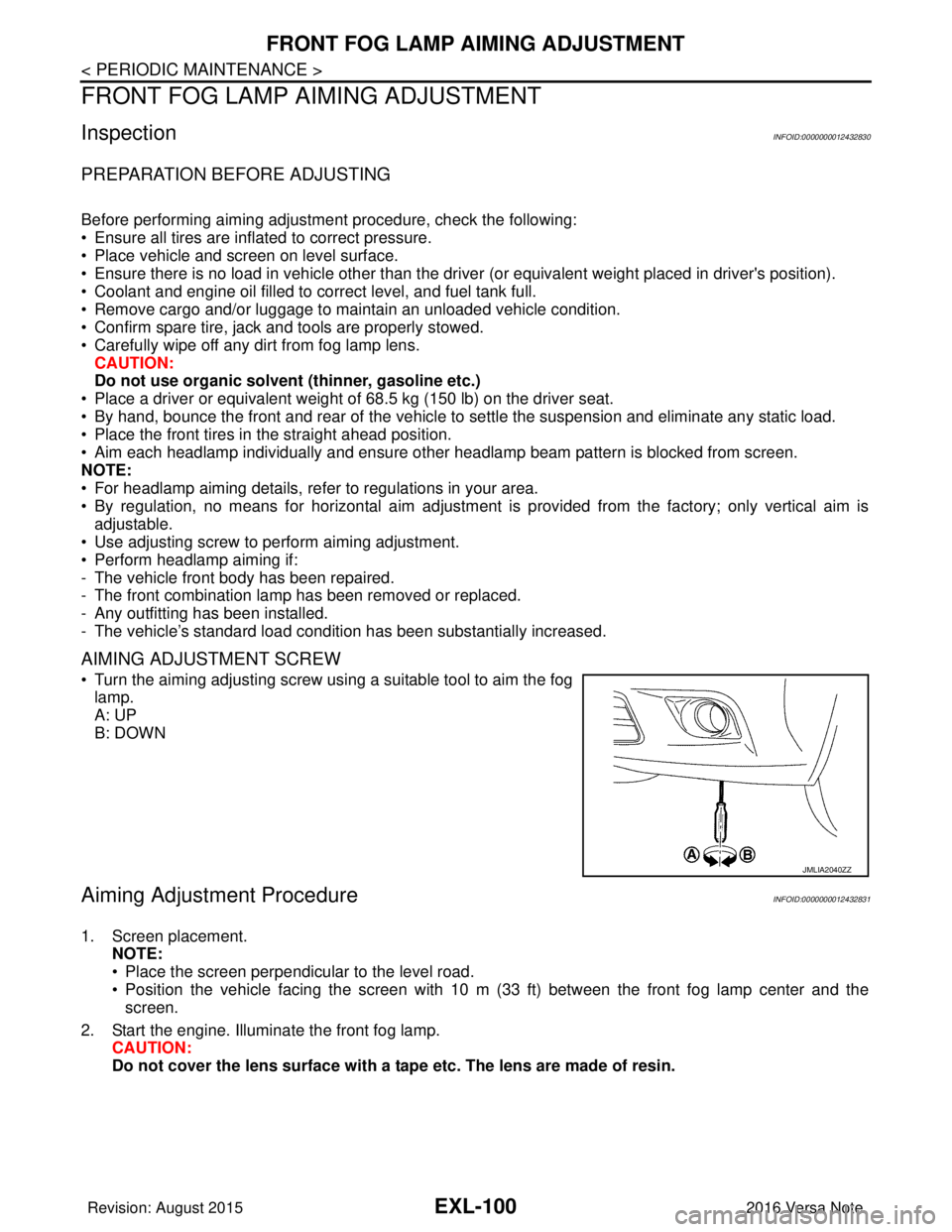

AIMING ADJUSTMENT SCREW

• Turn the aiming adjusting screw using a suitable tool to aim the fog

lamp.

A: UP

B: DOWN

Aiming Adjustment ProcedureINFOID:0000000012432831

1. Screen placement. NOTE:

• Place the screen perpendicular to the level road.

• Position the vehicle facing the screen with 10 m (33 ft) between the front fog lamp center and thescreen.

2. Start the engine. Illuminate the front fog lamp. CAUTION:

Do not cover the lens surface with a tape etc. The lens are made of resin.

JMLIA2040ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1852 of 3641

WHEEL ALIGNMENTFSU-7

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

WHEEL ALIGNMENT

InspectionINFOID:0000000012430301

PRELIMINARY INSPECTION

WARNING:

Always adjust the wheel alignment with the vehicle on a flat surface.

NOTE:

If the wheel alignment is out of s pecification, inspect and replace any damaged or worn rear suspension parts

before making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, engine coolant, and lubricants are full; the spare tire, jack, hand tools and mats are in

designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to WT-54, "

Wheel".

4. Check the wheel bearing axial end play. Refer to FAX-27, "

Wheel Bearing".

5. Check the shock absorbers for leaks or damage.

6. Check each mount point of the suspension co mponents for any excessive looseness or damage.

7. Check each link, arm, and the suspension member for any damage.

8. Check the vehicle height. Refer to FSU-21, "

Wheelarch Height (Unladen*)".

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is recomm ended for any NISSAN/INFINITI vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be capabl e of accepting any NISSAN/INFINITI vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific a lignment machine for their recommended Service/Cali-

bration Schedule.

ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to FSU-20, "Wheel

Alignment (Unladen*1)".

• When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

- The alignment specifications programmed into your alignment machine that operate these indicators may

not be correct.

- This may result in an ERROR.

• Most camera-type alignment machines are equipped with "Rolling Compensation" method and optional

"Jacking Compensation" method to "compensate" the alignment targets or head units.

"Rolling Compensation" is the preferred method.

- If using the "Rolling Compensation" method, after inst alling the alignment targets or head units, push or pull

on the rear wheel to move the vehicle. Do not push or pull on the vehicle body.

- If using the "Jacking Compensation" method, after inst alling the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn in either direction.

NOTE:

Do not use the "Rolling Compensation" method if you are using sensor-type alignment equipment.

• Follow all instructions for the alignment machine you're using for more information.

CAMBER, CASTER AND KINGPIN INCLINATION ANGLES INSPECTION

• Camber, caster, kingpin inclination angles cannot be adjusted.

• Before inspection, set the front wheels onto a turning radius gauge. Set the rear wheels onto a pad that has

the same height so the vehicle will remain horizontal.

TOTAL TOE-IN INSPECTION

Measure the total toe-in using the following procedure.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1903 of 3641

ABBREVIATIONSGI-15

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

E

F

G

H

DLC Data link connector

DTC Diagnostic trouble code

ABBREVIATION DESCRIPTION

E/T Exhaust temperature

EBD Electric brake force distribution

EC Engine control

ECL Engine coolant level

ECM Engine control module

ECT Engine coolant temperature

ECV Electrical control valve

EEPROM Electrically erasable programmable read only memory EFT Engine fuel temperature

EGR Exhaust gas recirculation

EGRT Exhaust gas recirculation temperature EGT Exhaust gas temperature

EOP Engine oil pressure

EP Exhaust pressure

EPR Exhaust pressure regulator

EPS Electronically controlled power steering

ESP Electronic stability program system

EVAP canister Evaporative emission canister EVSE Electric vehicle supply equipment

EXC Exhaust control

ABBREVIATION DESCRIPTION

FC Fan control

FCW Forward collision warning

FIC Fuel injector control

FP Fuel pump

FR Front

FRP Fuel rail pressure

FRT Fuel rail temperature

FTP Fuel tank pressure

FTT Fuel tank temperature

ABBREVIATION DESCRIPTION

GND Ground

GPS Global positioning system

GST Generic scan tool

ABBREVIATION DESCRIPTION

HBMC Hydraulic body-motion control system HDD Hard disk drive

HO2S Heated oxygen sensor

ABBREVIATION

DESCRIPTION

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2017 of 3641

![NISSAN NOTE 2016 Service Owners Guide INSUFFICIENT HEATINGHAC-49

< SYMPTOM DIAGNOSIS > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

INSUFFICIENT HEATING

DescriptionINFOID:0000000012430752

Symptom

• Insufficient heating

� NISSAN NOTE 2016 Service Owners Guide INSUFFICIENT HEATINGHAC-49

< SYMPTOM DIAGNOSIS > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

INSUFFICIENT HEATING

DescriptionINFOID:0000000012430752

Symptom

• Insufficient heating

�](/img/5/57363/w960_57363-2016.png)

INSUFFICIENT HEATINGHAC-49

< SYMPTOM DIAGNOSIS > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

INSUFFICIENT HEATING

DescriptionINFOID:0000000012430752

Symptom

• Insufficient heating

• No warm air comes out. (Air flow volume is normal.)

Diagnosis ProcedureINFOID:0000000012430753

NOTE:

Perform self-diagnosis with CONSULT before performing sy mptom diagnosis. If any malfunction result or DTC

is detected, perform the corresponding diagnosis.

1.CHECK COOLING SYSTEM

1. Check engine coolant level and check for leakage. Refer to CO-8, "

Inspection".

2. Check radiator cap. Refer to CO-12, "

RADIATOR CAP : Inspection".

3. Check water flow sounds of the engine coolant. Refer to CO-9, "

Refilling".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Refill engine coolant and repair or replace the parts depending on the inspection results.

2.CHECK HEATER HOSE

Check installation of heater hose by visually or touching.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace parts depending on the inspection results.

3.CHECK HEATER CORE

1. Check temperature of inlet hose and outlet hose of heater core.

2. Check that inlet side of heater core is hot and the outle t side is slightly lower than/almost equal to the inlet

side.

CAUTION:

Always perform the temperature inspection in a sh ort period of time because the engine coolant

temperature is very hot.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace heater core. Refer to HA-35, "

HEATER CORE : Removal and Installation".

4.CHECK AIR LEAKAGE FROM EACH DUCT

Check duct and nozzle, etc. of air conditioning system for air leakage.

Is the inspection result normal?

YES >> Check air mix door cable inst allation and air mix door operation.

NO >> Repair or replace parts depending on the inspection results.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2321 of 3641

MA-6

< PERIODIC MAINTENANCE >

GENERAL MAINTENANCE

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

SeatsCheck seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restraints move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seatbacks. —

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage. MA-43

Accelerator pedal

Check the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. —

Brakes Check that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to keep

floor mats away from the pedal. BR-9

Clutch pedal

Make sure the pedal operates smoothly and check that it has the proper free play. CL-5

Parking brakeCheck that the lever or pedal has the proper travel and make sure that the vehicle

is held securely on a fairly steep hill when only the parking brake is applied. PB-4

CVT "P" (Park) posi-

tion mechanismOn a fairly steep hill check that the vehicle is held securely with the shift selector

in the "P" (PARK) position without applying any brakes.

—

Item

Reference page

Item Reference page

Windshield washer

fluid Check that there is adequate fluid in the tank.

—

Engine coolant level Check the coolant level when the engine is cold. CO-8

Radiator and hosesCheck the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the radiator hoses have no cracks, deforma-

tion, deterioration or loose connections. CO-12

Brake and clutch fluid

levelsMake sure that the brake and clutch fluid levels are between the “MAX” and “MIN”

lines on the reservoirs. BR-12

CL-7

Battery

Check the fluid level in each cell. It should be between the “MAX” and “MIN” lines.

Vehicles operated in high temperatures or under severe conditions require fre-

quent checks of the battery fluid level. PG-61

Engine drive belts

Make sure that no belt is frayed, worn, cracked or oily. MA-14

Engine oil levelCheck the level on the oil level gauge after parking the vehicle on a level spot and

turning off the engine. MA-20

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate the

trouble and correct it. MA-26

Underbody

The underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these sub-

stances, otherwise rust will form on the floor pan, frame, fuel lines and around the

exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately. —

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2326 of 3641

RECOMMENDED FLUIDS AND LUBRICANTSMA-11

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

RECOMMENDED FLUIDS AND LUBRICANTS

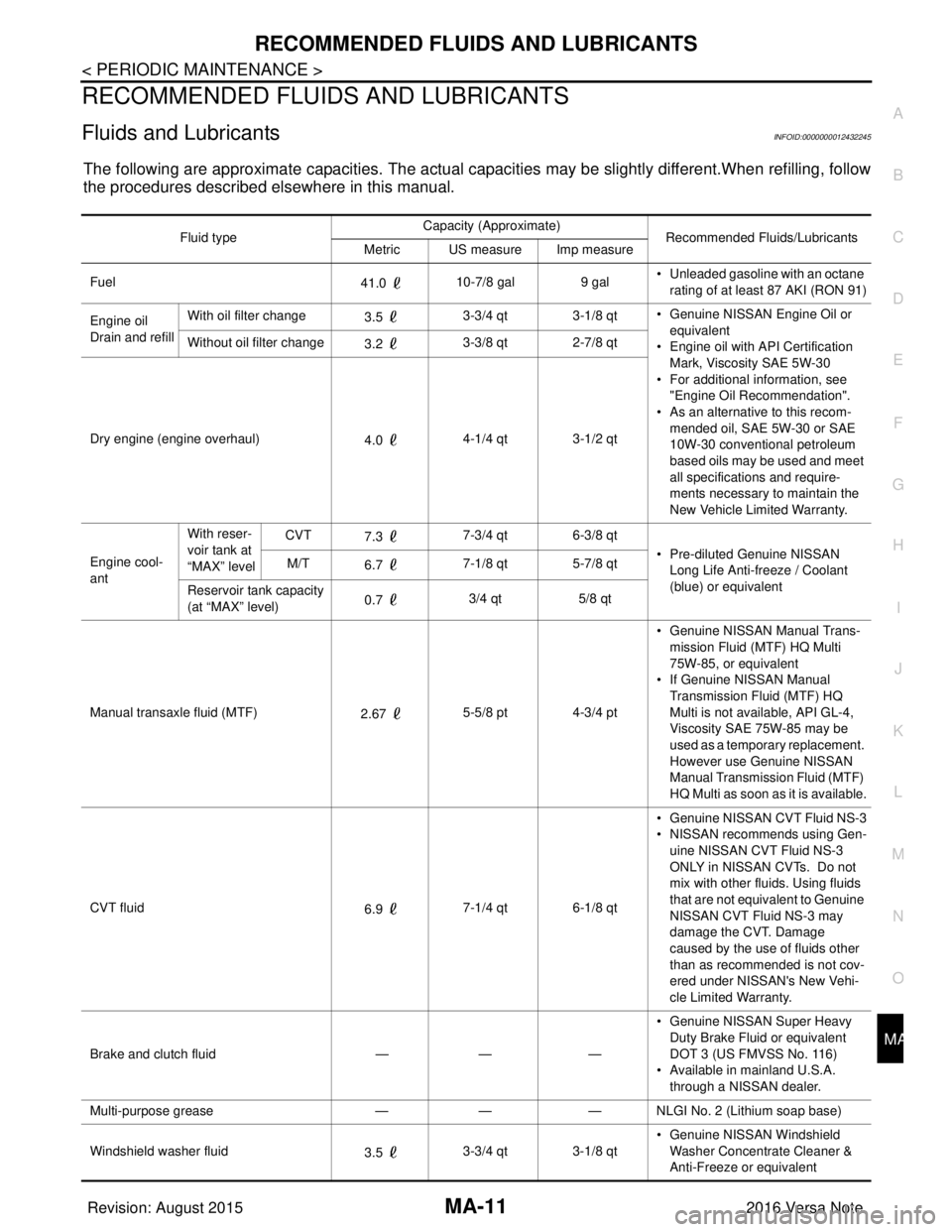

Fluids and LubricantsINFOID:0000000012432245

The following are approximate capacities. The actual capa

cities may be slightly different.When refilling, follow

the procedures described elsewhere in this manual.

Fluid type Capacity (Approximate)

Recommended Fluids/Lubricants

Metric US measure Imp measure

Fuel 41.0 10-7/8 gal

9 gal• Unleaded gasoline with an octane

rating of at least 87 AKI (RON 91)

Engine oil

Drain and refill With oil filter change

3.5 3-3/4 qt 3-1/8 qt

• Genuine NISSAN Engine Oil or

equivalent

• Engine oil with API Certification

Mark, Viscosity SAE 5W-30

• For additional information, see "Engine Oil Recommendation".

• As an alternative to this recom-

mended oil, SAE 5W-30 or SAE

10W-30 conventional petroleum

based oils may be used and meet

all specifications and require-

ments necessary to maintain the

New Vehicle Limited Warranty.

Without oil filter change

3.2 3-3/8 qt 2-7/8 qt

Dry engine (engine overhaul) 4.0 4-1/4 qt 3-1/2 qt

Engine cool-

ant With reser-

voir tank at

“MAX” level

CVT

7.3 7-3/4 qt 6-3/8 qt

• Pre-diluted Genuine NISSAN Long Life Anti-freeze / Coolant

(blue) or equivalent

M/T

6.7 7-1/8 qt 5-7/8 qt

Reservoir tank capacity

(at “MAX” level) 0.7

3/4 qt

5/8 qt

Manual transaxle fluid (MTF) 2.67 5-5/8 pt 4-3/4 pt • Genuine NISSAN

Manual Trans-

mission Fluid (MTF) HQ Multi

75W-85, or equivalent

• If Genuine NISSAN Manual

Transmission Fluid (MTF) HQ

Multi is not available, API GL-4,

Viscosity SAE 75W-85 may be

used as a temporary replacement.

However use Genuine NISSAN

Manual Transmission Fluid (MTF)

HQ Multi as soon as it is available.

CVT fluid 6.9 7-1/4 qt 6-1/8 qt • Genuine NISSAN CVT Fluid NS-3

• NISSAN recommends using Gen-

uine NISSAN CVT Fluid NS-3

ONLY in NISSAN CVTs. Do not

mix with other fluids. Using fluids

that are not equivalent to Genuine

NISSAN CVT Fluid NS-3 may

damage the CVT. Damage

caused by the use of fluids other

than as recommended is not cov-

ered under NISSAN's New Vehi-

cle Limited Warranty.

Brake and clutch fluid —— —• Genuine NISSAN Super Heavy

Duty Brake Fluid or equivalent

DOT 3 (US FMVSS No. 116)

• Available in mainland U.S.A.

through a NISSAN dealer.

Multi-purpose grease —— — NLGI No. 2 (Lithium soap base)

Windshield washer fluid 3.5 3-3/4 qt 3-1/8 qt • Genuine NISSAN Windshield

Washer Concentrate Cleaner &

Anti-Freeze or equivalent

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2330 of 3641

ENGINE MAINTENANCEMA-15

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

• When checking immediately after in

stallation, first adjust it to the specified value. Then, after

turning crankshaft two turns or more, readjust to the specified value to avoid variation in deflec-

tion between pulleys.

• When the tension adjustment is performed, the lo ck nut should be in the condition at Step 2. If

the tension adjustment is perfo rmed when the lock nut is loosened more than the temporary

tightening, the idler pulley tilts and the co rrect tension adjustment cannot be performed.

4. Tighten the lock nut to final tightening specification.

ENGINE COOLANT

ENGINE COOLANT : InspectionINFOID:0000000012432252

CHECKING COOLING SYSTEM HOSES

Check hoses for the following:

• Improper attachment

• Leaks

•Cracks

• Damage

• Loose connections

• Chafing

• Deterioration

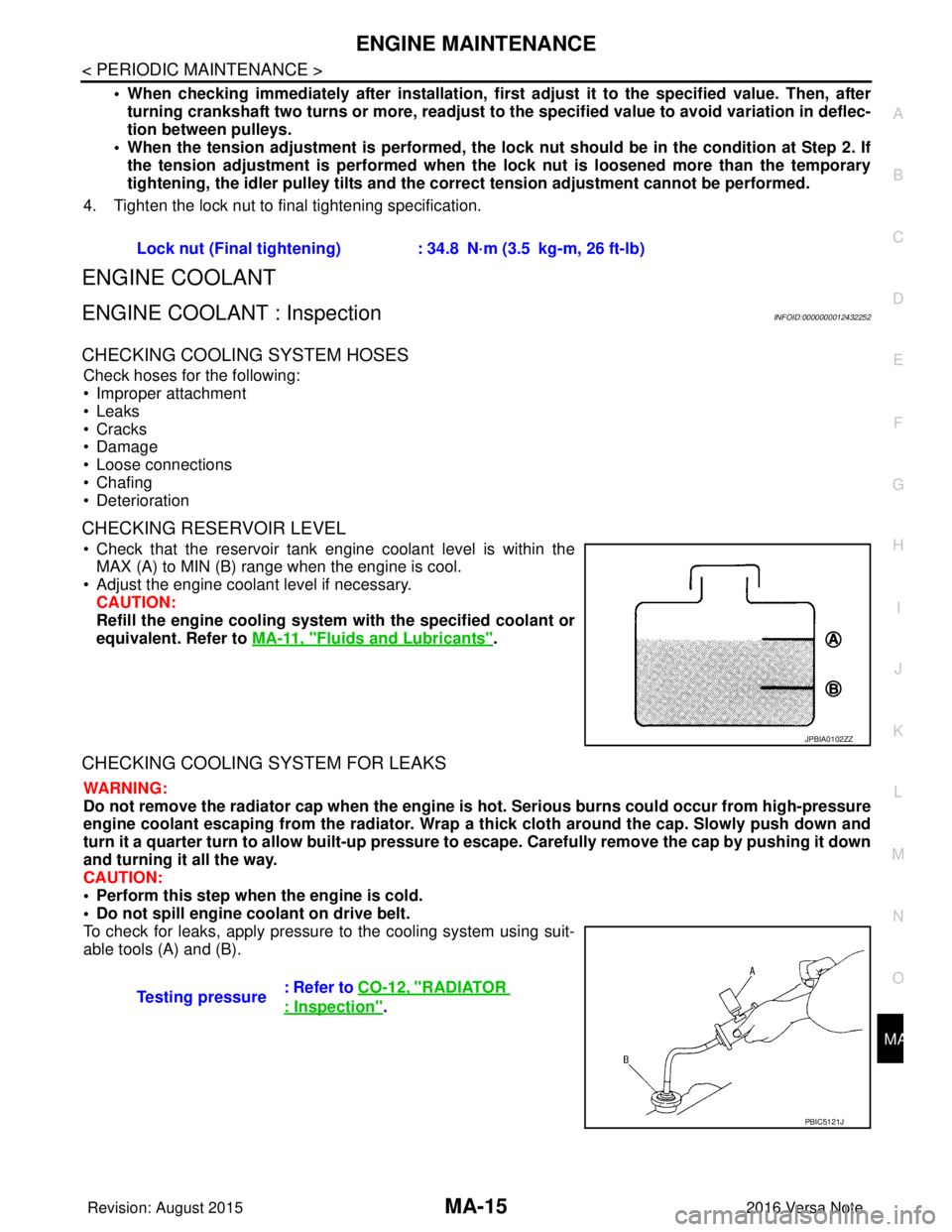

CHECKING RESERVOIR LEVEL

• Check that the reservoir tank engine coolant level is within the MAX (A) to MIN (B) range when the engine is cool.

• Adjust the engine coolant level if necessary. CAUTION:

Refill the engine cooling system with the specified coolant or

equivalent. Refer to MA-11, "

Fluids and Lubricants".

CHECKING COOLING SYSTEM FOR LEAKS

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

CAUTION:

• Perform this step when the engine is cold.

• Do not spill engine coolant on drive belt.

To check for leaks, apply pressure to the cooling system using suit-

able tools (A) and (B). Lock nut (Final tightening) :

34.8 N·m (3.5 kg-m, 26 ft-lb)

JPBIA0102ZZ

Testing pressure: Refer to CO-12, "RADIATOR

: Inspection".

PBIC5121J

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2332 of 3641

ENGINE MAINTENANCEMA-17

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

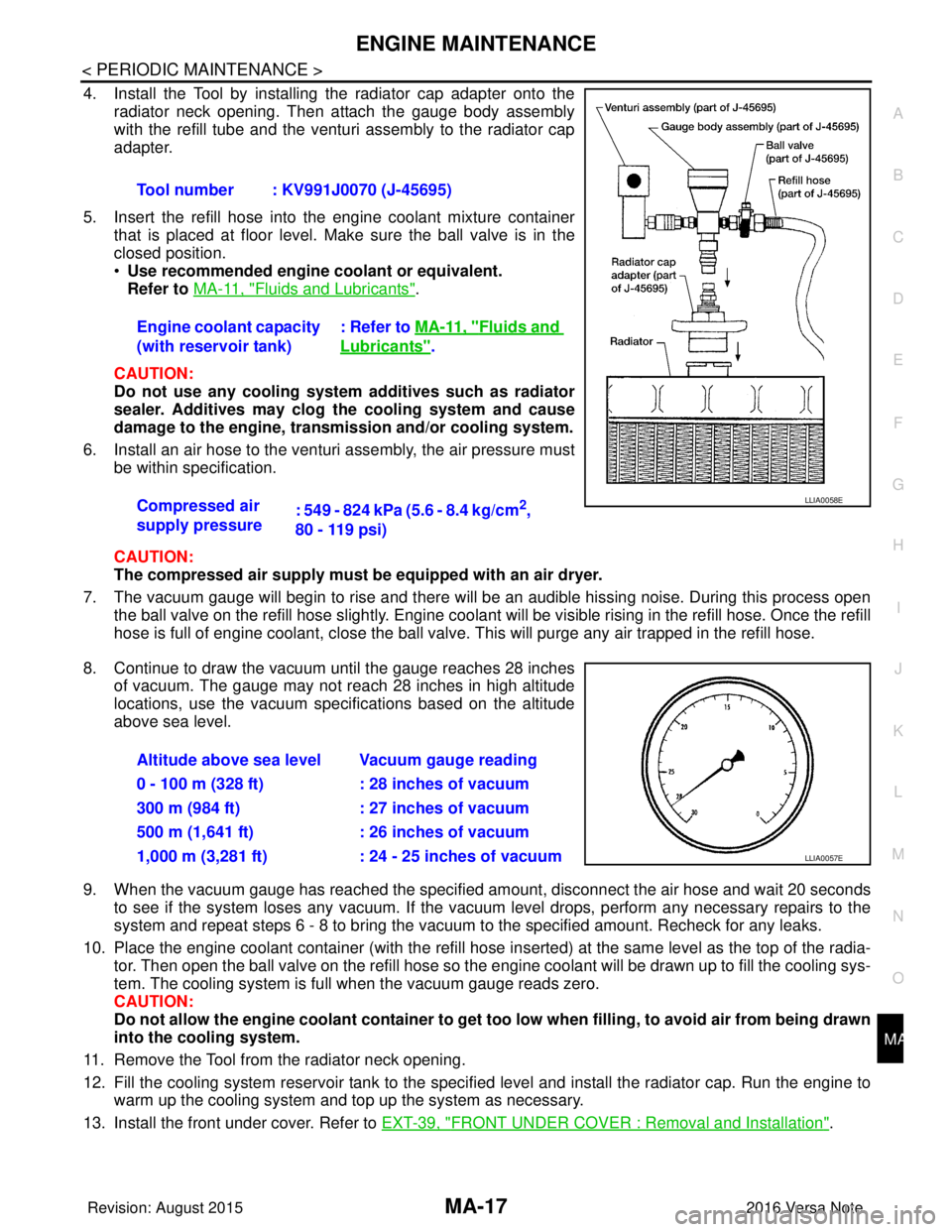

4. Install the Tool by installing the radiator cap adapter onto the

radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the engine coolant mixture container that is placed at floor level. Make sure the ball valve is in the

closed position.

•Use recommended engine coolant or equivalent.

Refer to MA-11, "

Fluids and Lubricants".

CAUTION:

Do not use any cooling system additives such as radiator

sealer. Additives may clog the cooling system and cause

damage to the engine, transmission and/or cooling system.

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Engine coolant will be visible rising in the refill hose. Once the refill

hose is full of engine coolant, close the ball valve. This will purge any air trapped in the refill hose.

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specified amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to br ing the vacuum to the specified amount. Recheck for any leaks.

10. Place the engine coolant container (with the refill hose in serted) at the same level as the top of the radia-

tor. Then open the ball valve on the refill hose so the engine coolant will be drawn up to fill the cooling sys-

tem. The cooling system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the engine coolant co ntainer to get too low when filling, to avoid air from being drawn

into the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specif ied level and install the radiator cap. Run the engine to

warm up the cooling system and top up the system as necessary.

13. Install the front under cover. Refer to EXT-39, "

FRONT UNDER COVER : Removal and Installation".

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank)

: Refer to

MA-11, "

Fluids and

Lubricants".

Compressed air

supply pressure : 549 - 824 kPa (5.6 - 8.4 kg/cm

2,

80 - 119 psi)LLIA0058E

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

LLIA0057E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2335 of 3641

MA-20

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

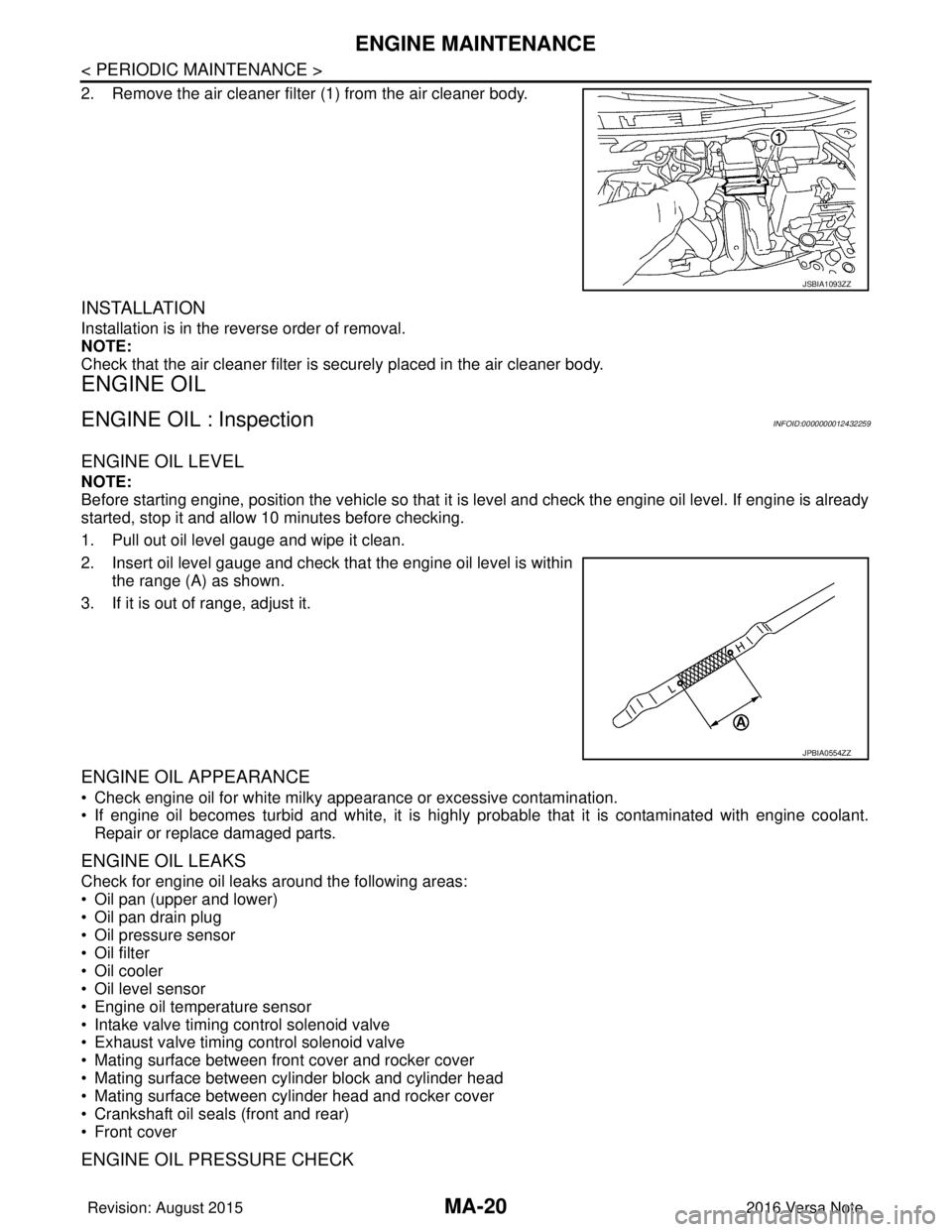

2. Remove the air cleaner filter (1) from the air cleaner body.

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

Check that the air cleaner filter is securely placed in the air cleaner body.

ENGINE OIL

ENGINE OIL : InspectionINFOID:0000000012432259

ENGINE OIL LEVEL

NOTE:

Before starting engine, position the vehicle so that it is level and check the engine oil level. If engine is already

started, stop it and allow 10 minutes before checking.

1. Pull out oil level gauge and wipe it clean.

2. Insert oil level gauge and check that the engine oil level is withinthe range (A) as shown.

3. If it is out of range, adjust it.

ENGINE OIL APPEARANCE

• Check engine oil for white milky appearance or excessive contamination.

• If engine oil becomes turbid and white, it is highl y probable that it is contaminated with engine coolant.

Repair or replace damaged parts.

ENGINE OIL LEAKS

Check for engine oil leaks around the following areas:

• Oil pan (upper and lower)

• Oil pan drain plug

• Oil pressure sensor

• Oil filter

• Oil cooler

• Oil level sensor

• Engine oil temperature sensor

• Intake valve timing control solenoid valve

• Exhaust valve timing control solenoid valve

• Mating surface between front cover and rocker cover

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seals (front and rear)

• Front cover

ENGINE OIL PRESSURE CHECK

JSBIA1093ZZ

JPBIA0554ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2367 of 3641

![NISSAN NOTE 2016 Service Owners Guide MWI

COMPONENT PARTSMWI-9

< SYSTEM DESCRIPTION > [TYPE A]

C

D

E

F

G H

I

J

K L

M B A

O P

METER SYSTEM : Combination MeterINFOID:0000000012432542

The combination meter controls the following items a ccor NISSAN NOTE 2016 Service Owners Guide MWI

COMPONENT PARTSMWI-9

< SYSTEM DESCRIPTION > [TYPE A]

C

D

E

F

G H

I

J

K L

M B A

O P

METER SYSTEM : Combination MeterINFOID:0000000012432542

The combination meter controls the following items a ccor](/img/5/57363/w960_57363-2366.png)

MWI

COMPONENT PARTSMWI-9

< SYSTEM DESCRIPTION > [TYPE A]

C

D

E

F

G H

I

J

K L

M B A

O P

METER SYSTEM : Combination MeterINFOID:0000000012432542

The combination meter controls the following items a ccording to the signals received from each unit via CAN

communication and the signals from switches and sensors:

• Measuring instruments

• Indicator lamps

• Warning lamps

• Meter illumination control

• Information display

ARRANGEMENT OF COMBINATION METER

6. ECM Transmits the following signals to the combination meter via CAN communication:

• Engine speed signal

• Engine coolant temperature signal

• Fuel consumption monitor signal

• Engine oil pressure sensor signal

Refer to EC-14, "

ENGINE CONTROL SYSTEM : ComponentPartsLocation" for de-

tailed installation location.

7. BCM Transmits the following signals to the combination meter via CAN communication:

• Door switch signal

• Buzzer signal

Refer to BCS-137, "

Removal and Installation" for detailed installation location.

8. Combination meter Refer to MWI-9, "

METER SYSTEM : Combination Meter".

9. Fuel level sensor unit and fuel pump

(fuel level sensor) Transmits the fuel level sensor signal to the combination meter.

No.

Component Function

U: USAEU: Except USA

AWNIA3633ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com